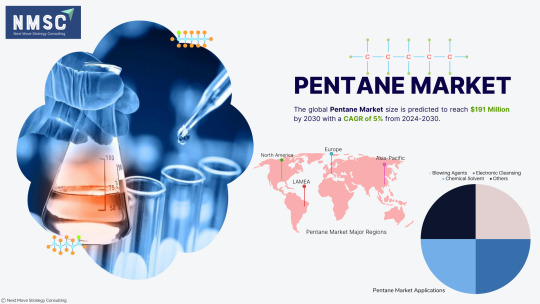

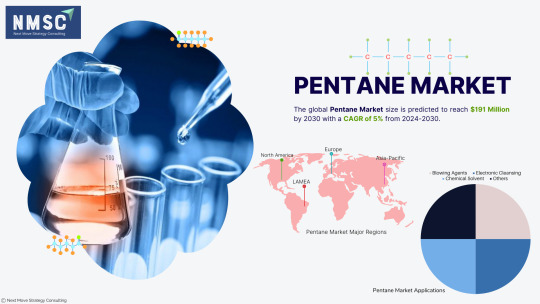

#Pentane Market

Explore tagged Tumblr posts

Text

Unveiling the Dynamics of the Pentane Market: Innovations and Efficiency Enhancements

In the complex tapestry of the global chemical industry, pentane market holds a modest yet pivotal role, especially in sectors demanding high-purity solvents and efficient blowing agents. Characterized by its low boiling point, pentane is a hydrocarbon of significant interest across various industries, from pharmaceuticals to refrigeration and foam manufacturing.

The ongoing innovations, particularly in pentane blends, are not just enhancing efficiency but also promising a shift towards more sustainable practices. This article delves into the pentane market, spotlighting the evolution and impact of these innovations.

Download FREE Sample: https://www.nextmsc.com/pentane-market/request-sample

The Pentane Market: An Overview

Pentane, a component of natural gas and crude oil, is primarily segregated into three types: n-pentane, isopentane, and neopentane, each with distinct properties and applications. The global market for pentane is on an upward trajectory, driven by its widespread use in blowing agents for foam production, solvent applications in the pharmaceutical industry, and as a specialty fuel. Moreover, the surge in demand for pentanes in the electronics industry for cleaning and as a refrigerant blend component further amplifies its market growth.

However, the market's expansion is not without challenges. Environmental regulations and the quest for sustainability are pushing for innovations that reduce emissions and enhance energy efficiency. This backdrop sets the stage for the advent of advanced pentane blends, aimed at meeting the dual objectives of performance enhancement and environmental compliance.

Innovations in Pentane Blends for Improved Efficiency

The quest for efficiency and sustainability is leading to significant innovations in pentane formulations. These novel blends are tailored to enhance performance in refrigeration, foam manufacturing, and as solvents, among other applications.

Refrigeration

In the refrigeration sector, pentane blends are being optimized to replace hydrofluorocarbons (HFCs), which are known for their high global warming potential (GWP). The new blends, characterized by lower GWP and excellent thermodynamic properties, promise not only environmental benefits but also operational efficiencies. For instance, the use of isopentane and n-pentane mixtures offers an optimal balance between low GWP and high energy efficiency, making them ideal for use in commercial refrigeration systems.

Foam Manufacturing

The foam manufacturing industry, particularly producers of polyurethane and polystyrene foams, is witnessing a shift towards pentane blends that offer superior blowing efficiency and lower environmental impact. These innovative blends are engineered to optimize foam expansion and insulation properties while minimizing the emission of volatile organic compounds (VOCs). The result is high-performance foams that meet stringent environmental standards, used in everything from insulation panels to packaging materials.

Pharmaceutical Solvent Applications

Pentanes are invaluable in the pharmaceutical industry, serving as solvents in drug formulation and extraction processes. The innovation in pentane blends here focuses on enhancing solvent efficiency and ensuring the purity of pharmaceutical products. By adjusting the proportion of isomers in these blends, manufacturers can achieve solvents with tailored evaporation rates, non-reactivity, and minimal residue, critical factors in the production of high-quality pharmaceuticals.

Inquire Before Buying: https://www.nextmsc.com/pentane-market/inquire-before-buying

The Market Implications of Pentane Innovations

The continuous evolution in pentane blends is reshaping the market dynamics. On one hand, these innovations align with the growing regulatory and consumer demand for greener and more efficient products. On the other, they present challenges, including the need for industry players to adapt to new technologies and formulations, and potentially higher costs associated with the transition to more sustainable alternatives.

However, the long-term market outlook for pentane remains positive. The ongoing research and development efforts promise not only to expand pentane's application range but also to solidify its role in the transition towards a more sustainable and efficient global economy. Key market players are increasingly investing in these innovations, recognizing the strategic importance of pentane in maintaining competitiveness and achieving environmental goals.

Conclusion The pentane market is at a pivotal juncture, driven by innovations that promise to redefine its role across industries. The development of new pentane blends for improved efficiency and reduced environmental impact reflects a broader trend toward sustainability in the chemical sector.

As these innovations continue to unfold, they not only promise to meet the immediate needs of industries but also to pave the way for new applications and market growth opportunities. The journey of pentane, from a simple hydrocarbon to a key player in energy efficiency and sustainability, is a testament to the transformative power of innovation in meeting the challenges of the modern world.

#pentane market#chemical solvents#chemical innovations#materials and chemicals industry#global market#market research

0 notes

Text

GALTx eNews: Keep Your Hounds Safe From Xylitol

Xylitol is a natural sugar alcohol found in some plants. It has become ubiquitous in consumer products ranging from sugarless gum to “healthy” peanut butters, cooling clothing to cosmetics, toothpaste to melatonin. It’s literally everywhere now and it is extremely toxic to dogs. A dog doesn’t need to ingest a lot for it to be lethal and vets can only offer supportive care.

Click here to see a guide of hundreds of products that are known to contain Xylitol. Even this extensive list is not comprehensive and you really need to be checking the labels of everything you purchase that will be within reach of your dog. Be sure to look under “other ingredients,” “inactive ingredients,” or “supplemental facts” as it might be listed under any of these headings. Unfortunately, marketers have come up with a number of clever things to call Xylitol, making it hard to spot. These other names for the same lethal thing include:

wood sugar

birch sugar

sugar alcohol

birch sap

birch bark extract

sucre de bouleau

European code E967 or just 967

Meso-Xylitol

Xlitol

Xylite

Xylo-pentane-1,2,3,4,5-pentol

Sugar Alcohols

XyloSweet

Lite&Sweet

Xyla

Global Sweet

In addition to keeping your house safe from Xylitol, be careful to prevent your dogs from eating any food that someone has dropped when you are out on a walk. If you can’t check the label, you can’t be sure it is safe. If you see discarded food like power bars or gum that might pose a risk, please pick it up to keep the next dog safe too. Thank you!

2/15/24

#Xylitol#Other Names For Xylitol#Toxic to dogs#Hound Safety#greyhounds#dogblr#snootblr#dogs#greyhound#greyblr#sighthounds#galtx enews#pets#greyhound adoption#Warning for Dogs

6 notes

·

View notes

Text

The Pentane Market is expected to reach US$ 173.60 million by 2030, thanks to growth in the industrial uses segment. The report analyzes Pentane market dynamics by region and applications.

0 notes

Text

Pentan Cultural Overview: Daily Life and Food

Pentan daily life revolves around ensuring the tribe has the necessities needed for survival. The main camp of the tribe is a central hub, but the herds will spread out around it for quite a distance in every direction. At any given time, there must be people out watching these herds. The horses largely take care of themselves, but a herder must at least keep an eye on their location and watch out for any dangers that the herd's stallion is unable to deal with, such as wolf packs or earthshakers, and other herds require significantly more care.

Pentan herders most often keep sheep and goats as their main non-horse herd animals, followed in descending order by yaks, cows, and camels. Individual herds for these animals are generally larger than individual horse herds, and require more care to avoid danger. Herders rely more on their dogs to help with these, and more herders are needed to keep watch over them at any given time. It is not uncommon for a tribe to keep multiple kinds of herd, outside of Pure Horse tribes, who do not keep non-horses at all. Typically, males are slaughtered for food first unless they are prized specimens for breeding, while females are kept for their milk. Herders will rotate in shifts, spending a day or two with the herds and then returning to camp for several days to do other work when the next group of herders arrives.

All Pentans spend some time tending the herds, even warriors, but it is the followers of herding gods such as Oria, Galana, Dostal and Eyritha who lead the herders. When not herding, Pentans spend their days pursuing the other tasks they specialize in. Hunters head out to seek prey and scout the lands the tribe has settled in, while herding specialists work to store, cook and prepare food or wool. Crafters make things the tribe will need or repair goods. The cults the tribe maintains will also spend time performing vital rituals to keep up the tribe's magical blessings and honor the gods. Solving immediate problems, performing maintenance and repairs, performing vital religious rites, or preparing food always take precedence over practice and training. This takes up the majority of time for each member of the tribe.

When the tribe's immediate needs are being met, time is spent practicing and training or preparing for upcoming festivals. Warriors will drill together or practice their combat skills, everyone practices archery, crafters will work on personal projects to improve their skills, and similar. This time can also be used to pursue personal interests, and Riders often head out on exploration trips during this 'free' time, with permission from the khan and their family's Grandparent. In theory, this time could be spent on anything, but there is a strong social expectation of pursuing excellence in skill, especially skills which have competitive festivals. Success in archery, racing and wrestling are especially prestigious, as is skill in weaving.

Traders, judges and hunters pursue somewhat different activities than most of the tribe, as do other priests. Priests spend more time on ritual activities overall, and often serve as overseers for other work. Judges spend most of their time mediating disputes within the tribe, consulting with people on the Law of Yu-Kargzant, and overseeing the work of the criminals belonging to the East Sting Wind cult. Traders work closely with the crafters, and many traders also work as crafters. Traders will often spend a decent chunk of each season attending the markets of friendly tribes and moving small caravans of goods and herds for trade, spending relatively little time at home.

Hunters, likewise, often spend little time at home, and may not even be expected to tend to the herds. Manurl cultists, especially, are not expected to do so. However, to earn this right, they are expected to provide food for the tribe each season, bringing in enough meat to feed a certain number of people. This number varies based on local traditions and interpretations of the Law, which demands an equivalent amount of work to that which is being given up. The Law's guidelines are vague, laying down merely that the duty of a tribe's members is to work for the good of all, and that failure to do so is a minor crime. Punishments for neglecting one's tribal duty vary in severity based on the severity of the offense, ranging from punitive fines and being given unpleasant labor to being beaten or assigned to the East Sting Wind cult for a time.

There are generally two large meals in the day, one at midday and one after sunset, as well a smaller morning meal. Snacks are typically meat buns, small amounts of dried meat, berries, and airag (a very weakly alcoholic fermented mare's milk). The midday and sunset meals are generally held in large family gatherings in the yurt of a family elder, while the morning meal is typically small and eaten in one's own yurt. Salty milk tea is commonly served at meals, and it is considered rude to speak at a meal before being given a drink or food.

Day to day meals are usually simple grilled, dried or stewed meat, sometimes mixed with barley noodles. Spices are rare other than salt, which is common, and vegetables are rare outside of the vegetarian meals eaten by the Erissa cult, who rely heavily on dried berries, fruits and bread. Wild garlic and onion feature heavily in cooking, as well, and it is common for herders to gather berries, fruits and edible herbs, fungi and tubers while watching over the herds.

Barley is the most common grain used in Pentan cooking, followed by rice, both typically traded or stolen from Half-Man villages along the rivers or in the lands of Pelanda and Kralorela. Airag and milk are both common drinks alongside tea; water is more typically reserved for the herds. Fish may be eaten as well, depending on if the tribe is traveling along a river. Cheese and yogurt are both frequently eaten for special occasions, but take enough time to make that they are not seen every day, though dried curd may be. Bread is also saved for special occasions, requiring more grain than meat buns or noodles; typically, it is various kinds of flatbread and almost always served with meat. The best cuts of meat are saved for guests and elders, though what is considered 'best' varies by tribal tradition. Nothing is wasted; anything which is edible from a slaughtered beast is going to be eaten.

Festivals will have much greater food variety, with cooks dipping into the expensive imported spices, dried fruits and berries for sweetening, and more complex cooking techniques. Cheese and yogurt are festival staples, as is clarified butter, the purest food and favored gift of the gods. Sacrifices, especially during festivals, are typically only partially burned, with the remaining food being distributed for eating. A particular dish of hunting festivals is known as boodhog, in which the slain prey is cut open and filled with heated stones, grilling the beast within its own skin.

Winter meals are often sparser, especially as supplies run low. Dried meats and dried curds feature more heavily, and preserving enough food with salt and drying before winter is a very important part of each year.

#pent#pentan cultural overview#secret history of the horse sun#glorantha#gloranthaposting#rpg#questworlds#heroquest

0 notes

Text

Expanded Polystyrene - Latest Trends and Future Growth Study by 2033

Expanded polystyrene (EPS) is a rigid, lightweight, closed-cell foam. It is used in a variety of applications, including packaging, insulation, and construction.

Key Trends

There are several key trends in Expanded Polystyrene (EPS) technology. One is the development of more environmentally friendly production processes. For example, some manufacturers are using recycled EPS in their products, and others are using more energy-efficient production methods.

Another trend is the development of new uses for EPS. For example, EPS is being used more and more in the construction industry as an insulation material. It is also being used in the packaging of electronic products and in the production of lightweight composite materials.

Finally, there is an increasing focus on the recycling of EPS. As EPS is a lightweight and easily recyclable material, it has the potential to be recycled multiple times. This would reduce the number of waste EPS that ends up in landfill sites.

Key Drivers

The key drivers of the expanded polystyrene market are its low cost, easy availability, and wide range of applications. Expanded polystyrene is a lightweight, rigid, and thermally-insulating material made from petroleum-based styrene monomer. It is used in a variety of applications, including packaging, insulation, and construction. The material is produced by expanding styrene monomer with a blowing agent, typically pentane.

The global expanded polystyrene market is driven by the growing demand from the packaging industry. Expanded polystyrene is widely used in the packaging of food, electronics, and other consumer goods. The material is lightweight and has excellent cushioning properties, making it ideal for packaging applications. The growing demand from the construction industry is another key driver of the expanded polystyrene market. The material is used in a variety of construction applications, including insulation, soundproofing, and structural support.

The expanded polystyrene market is restrained by the volatile prices of raw materials. The prices of styrene monomer and pentane, the two key raw materials used in the production of expanded polystyrene, are highly volatile. This volatility affects the cost of expanded polystyrene and, ultimately, the demand for the material.

Unlock Growth Potential in Your Industry – Get Your Sample Report Now@https://www.globalinsightservices.com/reports/expanded-polystyrene-market/?utm_source=PranaliP-organic

0 notes

Text

0 notes

Text

Exploring Expanded Polystyrene: Applications, Manufacturing Techniques, and Major Market Players!

Welcome to the world of Expanded Polystyrene (EPS), a polymer with boundless versatility across industries. In construction, EPS reigns supreme for its remarkable insulation properties, resistance to pests and bacteria, and minimal water absorption. It serves as a key player in building elements, from insulated panels for facades to flotation material for marinas.

In food packaging, EPS proves its adaptability by being molded into trays for fruits and vegetables, ensuring freshness with its non-nutritive composition that deters microbial Join us as we explore the range of applications of EPS, from enhancing construction efficiency to preserving the freshness of our daily produce and safeguarding fragile goods along their journey. We will also throw light on the manufacturing process used for the production of EPS.

Introduction

Expanded Polystyrene (EPS) is a white foam plastic material, consisting of solid beads of Polystyrene, primarily used in packaging and construction. It is a closed-cell, rigid foam produced from styrene, which forms the cellular structure, and pentane, serving as a blowing agent. Comprising 98% air, EPS is highly recyclable and exceptionally lightweight. Its notable attributes include low thermal conductivity, minimal moisture absorption, and superior cushioning properties. With physical properties stable within a service temperature range of up to 167°F/75°C, EPS exhibits chemical resistance comparable to Polystyrene. EPS remains a versatile and widely utilized material across various industries, offering solutions for insulation, protection, and structural support. Also, Expanded Polystyrene, identified by plastic resin code 6, is entirely recyclable.

Here's a breakdown of the key features that make EPS so valuable in the world of polymers:

Energy Efficiency: Building on the high R-Value, EPS products translate to significant energy savings. By keeping your desired temperature (hot or cold) contained within a space, you can rely less on heating or cooling systems, leading to lower energy bills.

Constant Thermal Resistance: Unlike some insulation materials, EPS maintains its insulating properties consistently over time.

Strength: Don't be fooled by its lightweight nature! EPS is surprisingly strong and can withstand significant compression and impact. This makes it suitable for various applications where structural integrity is important.

Recyclability: EPS can be recycled multiple times throughout its life cycle, and its manufacturing process does not generate any leftover solid waste.

No Bacterial Growth or Decay: EPS is resistant to mold, mildew, and bacteria growth. This makes it ideal for applications where hygiene is a concern, especially in food packaging and construction materials.

Dimensional Stability: EPS maintains its shape and size over time, ensuring consistent performance and long-lasting functionality.

Chemical Inertness: EPS doesn't react with most chemicals, making it a safe and reliable material for use in various settings.

Low Cost: Compared to many other insulation materials, EPS offers excellent value for money. This affordability makes it an attractive option for a wide range of applications.

Manufacturing Process

Here's a breakdown of the key points involved in the manufacturing of EPS:

Expanded Polystyrene (EPS) foam is derived from expandable polystyrene (EPS) beads, a rigid cellular plastic containing an expansion agent sourced from oil. The EPS manufacturing process is closely linked to the process described previously, which traced the journey from oil extraction to the creation of expandable polystyrene. Now, let's delve into the transformation process leading to the production of EPS foam parts. The raw material, obtained through a chemical process, undergoes a series of physical transformations in three stages.

Firstly, in the pre-expansion stage, the raw material (beads) is heated in specialized machines known as pre-expanders using steam at temperatures around 215°F. This causes the material's density to decrease from approximately 40 lbs/cu ft to typically between 1 to 2 lbs/cu ft. During pre-expansion, the solid beads transform into cellular plastic beads with small closed cells that trap air inside.

In the second stage, intermediate maturing and stabilization, the recently expanded particles cool down, forming a vacuum within. This vacuum is compensated for by air diffusion, enhancing the beads' mechanical elasticity and expanding capacity. This stage occurs during the material's intermediate maturing in aerated silos or mesh bags, where the beads are simultaneously dried.

Finally, in the third stage, expansion and final molding, the stabilized pre-expanded beads are transported to molds where they are exposed to steam once again, causing them to fuse together. This process yields large blocks through "block molding" (later cut into desired shapes like boards, panels, cylinders, etc.) or directly produces products in their final finished form through "shape molding."

Here is the production process used by INEOS, one of the leading producers of EPS on a global scale. INEOS Technologies provides cutting-edge expandable polystyrene (EPS) technology, offering a combination of competitive variable costs, low investment expenses, and a diverse range of high-quality products widely accepted globally. The demonstrated operational reliability of the process presents a significant competitive edge over other expandable polystyrene producers for upcoming projects.

In the production phase, a reactor is employed to catalyze the polymerization of styrene by introducing a specific blend containing blowing agents, water, initiators, suspending agents, and various additives. This complex mixture undergoes controlled temperature-time conditions with continuous stirring to ensure the dispersion of the monomer and the formation of Polystyrene beads. The entire process is managed by a Distributed Control System (DCS) following an automated sequence.

After polymerization, the resulting Polystyrene beads and water are transferred to a slurry tank, where the subsequent steps become fully continuous. This involves centrifugation to remove a significant portion of the suspension water, followed by conveying the beads to a pneumatic flash dryer to eliminate surface moisture. The dried beads undergo screening, resulting in the extraction of two specific product cuts out of a potential four. The effectiveness of this separation is enhanced by the presence of mineral suspension.

The precise segmentation achieved through this process allows for tailored targeting of product cuts to meet market demands. Typically, finer to medium cuts serve the packaging market, while medium to larger cuts are directed towards insulation applications.

Source: INEOS Technologies

Main Applications of Expanded Polystyrene

Food Packaging

EPS can undergo extrusion using standard equipment to create a continuous sheet, which can then be shaped through vacuum forming and pressure forming processes to manufacture items like fruit trays. Devoid of any nutritional value, EPS effectively inhibits the growth of fungi, bacteria, and other microorganisms. Its thermal insulation properties play a pivotal role in preserving the freshness of food and preventing condensation across the distribution chain. Widely employed in food packaging, EPS serves as a protective medium for seafood, fruits, and vegetables. Furthermore, it is utilized in the production of food service containers such as drink cups, food trays, and clamshell containers, offering versatility and practicality in various culinary settings.

Construction:

EPS finds extensive application in various structural components of buildings, including walls, roofs, and floors, where its compressive strength can be customized to suit specific construction systems such as beam and block setups, underfloor heating installations, and beneath concrete floor slabs. Additionally, it is utilized for void filling purposes and, when densified, serves as a suitable base material for road or rail embankments, particularly in scenarios where traditional fill materials prove excessively heavy. Notably, in urban areas, EPS offers the advantage of alleviating congestion and traffic by facilitating the efficient delivery of large quantities of product compared to conventional hardcore materials.

Industrial Packaging

EPS ensures the comprehensive safeguarding of industrial products during transportation and handling, thanks to its remarkable shock absorption capabilities. This rigid yet lightweight foam can be molded into various shapes to effectively protect and insulate sensitive items, ranging from delicate medical equipment and electronic components to toys and horticultural products during storage and transit. Additionally, EPS finds utility in crafting disposable foam coolers and packing peanuts for shipping purposes. In packaging applications, the selection of appropriate cushioning levels depends on the packaging density to ensure optimal protection.

Market Outlook:

The Expanded Polystyrene (EPS) market is experiencing momentum from various factors, notably its diverse applications spanning construction, packaging, and insulation, leveraging its lightweight nature and excellent insulation capabilities. Particularly, the escalating demand for sustainable and energy-efficient construction materials propels EPS utilization in the building sector. In packaging, EPS's ability to provide protective cushioning proves advantageous, alongside its cost-effectiveness, recyclability, and ease of shaping, all contributing to its extensive acceptance. As environmental consciousness grows, the recyclability and sustainability aspects of EPS products emerge as pivotal drivers, resonating with worldwide initiatives toward eco-conscious solutions.

Expanded Polystyrene Main Players

Significant companies in the Global Expanded Polystyrene market are BASF SE, Atlas Roofing Corp., Alpek S.A.B. de C.V., Kaneka Corp., SIBUR Holding PJSC, BEWI, SUNPOR, Synthos, TotalEnergies, Flint Hills Resources, NOVA Chemicals Corporate, StyroChem, Ravago Manufacturing, UNIPOL, Versalis S.p.A., SABIC, Sundolitt Ltd, and Others.

Conclusion:

Expanded Polystyrene (EPS) is quietly revolutionizing the packaging industry with its impressive versatility. This lightweight champion is a favorite for its protective qualities, safeguarding products in sectors like industrial, food & beverage, and electronics with its exceptional shock-resistance. Not only does EPS shield products from bumps, but its chemical-resistant nature and ability to inhibit bacterial growth ensure items stay safe from harmful interactions and unwanted microbes. Furthermore, EPS goes beyond protection - its insulating properties make it a cost-effective choice for cold storage, refrigerators, and construction applications, promoting temperature control and long-lasting durability. The future of EPS seems particularly promising, with the rapid urbanization driving demand for efficient packaging solutions in construction and consumer goods. As sustainability remains a top concern, ongoing advancements in EPS recyclability promise an even brighter future for this versatile and adaptable material.

0 notes

Text

High Purity Solvents Market Analysis, Key Stakeholders, Regional Outlook, End-User Applicants by 2030

Global high purity solvents market generated revenue of US$ 36,542.0 million in 2021 and is estimated to reach valuation of US$ 64,003.7 million by 2030 at a CAGR of 6.5% during the forecast period, 2022–2030. By volume, the market is expected to reach 59,621.7 000’ MT in 2030 thus, growing with a CAGR of 5.2%.

Astute Analytica recently published a highly anticipated market report, providing invaluable insights into the Global High Purity Solvents Market. This comprehensive report offers a detailed analysis of key drivers, restraints, regional trends, segmentation, and valuation, enabling businesses to make informed decisions for sustainable growth.

A Request of this Sample PDF File@- https://www.astuteanalytica.com/request-sample/high-purity-solvents-market

Key Highlights of the Report:

Comprehensive Analysis: The report presents a holistic view of the High Purity Solvents Market, analyzing various factors such as market size, trends, and growth opportunities. This analysis helps businesses identify emerging market trends and make strategic decisions to drive growth.

Key Drivers and Restraints: The market report provides an in-depth analysis of the key drivers and restraints shaping the market. By understanding these factors, businesses can capitalize on growth opportunities and mitigate potential risks.

Valuation and Forecast: The report includes a thorough valuation of the market, providing businesses with a clear understanding of the market's current and future potential. This information assists in making well-informed investment decisions and strategic planning.

Regional Analysis: The report offers a detailed regional analysis, highlighting key market trends and opportunities across different geographic regions. This invaluable insight enables businesses to identify untapped markets and tailor their strategies accordingly.

Companies Profile

The report identifies and analyzes the key players in the High Purity Solvents Market. By understanding the competitive landscape, businesses can benchmark their performance and develop effective strategies to stay ahead.

Akzo Nobel N.V.

American International Chemical LLC

Apchem Pvt. Ltd.

Asahi Kasei Corporation

BASF SE

CABB Group GmbH

Central Drug House

Chemtronics

DAWN SCIENTIFIC INC

Dow

Evonik Industries AG

Exxon Mobil Corporation

FINAR

High Purity Laboratory Chemicals Pvt. Ltd.

Merck KGaA

Mitsubishi Chemical Corporation

Mountain Air

Spectrum Chemical Manufacturing Corp.

Thermo Fisher Scientific Inc.

Other Prominent Players

For Purchase Enquiry: https://www.astuteanalytica.com/industry-report/high-purity-solvents-market

Segmentation Overview:

The High Purity Solvents Market report provides a comprehensive segmentation overview, allowing businesses to identify and target specific customer segments. This segmentation analysis helps businesses customize their offerings and enhance their market presence.

By Type

Acetone

Ethanol

Heptane

Hexane

Isopropyl Alcohol

Methanol

Pentane

By Grade

HPLC Solvents

HPLC Isocratic Solvents

HPLC Gradient Solvents

HPLC Plus Solvents

LC-MS Solvents

UHPLC-MS Solvents

By Category

Polar Solvent

Non-polar Solvent

By Packaging

Amber bottles

Aluminum bottles

Recyclers

Borosilicate bottles

By End User

Laboratories

Culturing Cells and Tissues in Petri Dishes

Liquid Chromatography Analysis

Gas Chromatography Analysis

Molecular Biology Experiments

ICP-MS

Plastics & Adhesives

Sealants

Textiles

Pharmaceuticals

Food & Beverages

Chemicals

Cosmetics & Personal Care

Agriculture

Paints & Coatings

Soaps & Detergents

Electronics

Others

By Distribution Channel

Online

Offline

Direct

Distributor

By Region

North America

The U.S.

Canada

Mexico

Europe

Western Europe

The UK

Germany

France

Italy

Spain

Rest of Western Europe

Eastern Europe

Poland

Russia

Rest of Eastern Europe

Asia Pacific

China

India

Japan

Australia & New Zealand

South Korea

ASEAN

Rest of Asia Pacific

Middle East & Africa (MEA)

Saudi Arabia

South Africa

UAE

Rest of MEA

South America

Argentina

Brazil

Rest of South America

The company has partnered with industry-leading experts, utilizing cutting-edge research methodologies and data analysis techniques to provide a reliable and accurate market report. With a focus on delivering actionable insights, this report is an indispensable tool for businesses looking to navigate the complexities of the High Purity Solvents Market and unlock new growth opportunities.

Download Sample PDF Report@- https://www.astuteanalytica.com/request-sample/high-purity-solvents-market

About Astute Analytica:

Astute Analytica is a global analytics and advisory company that has built a solid reputation in a short period, thanks to the tangible outcomes we have delivered to our clients. We pride ourselves in generating unparalleled, in-depth, and uncannily accurate estimates and projections for our very demanding clients spread across different verticals. We have a long list of satisfied and repeat clients from a wide spectrum including technology, healthcare, chemicals, semiconductors, FMCG, and many more. These happy customers come to us from all across the globe.

They are able to make well-calibrated decisions and leverage highly lucrative opportunities while surmounting the fierce challenges all because we analyse for them the complex business environment, segment-wise existing and emerging possibilities, technology formations, growth estimates, and even the strategic choices available. In short, a complete package. All this is possible because we have a highly qualified, competent, and experienced team of professionals comprising business analysts, economists, consultants, and technology experts. In our list of priorities, you-our patron-come at the top. You can be sure of the best cost-effective, value-added package from us, should you decide to engage with us.

Get in touch with us

Phone number: +18884296757

Email: [email protected]

Visit our website: https://www.astuteanalytica.com/

LinkedIn | Twitter | YouTube | Facebook | Pinterest

0 notes

Text

The Pentane market is heating up with robust growth projections and dynamic trends!

𝑮𝒆𝒕 𝒂 𝑭𝑹𝑬𝑬 𝒔𝒂𝒎𝒑𝒍𝒆: https://www.nextmsc.com/pentane-market/request-sample

Discover the latest insights into this booming sector, including market drivers, key players, and future prospects.

Stay ahead of the curve with our comprehensive analysis.

#pentane#markettrends#industryinsights#materials and chemicals#businessinsights#industryanalysis#health

0 notes

Text

0 notes

Text

Regional Outlook of the Blowing Agents Market

Blowing Agents: An Essential Component in Foam Manufacturing Foam insulation plays a vital role in our daily lives from cushioning to thermal and acoustic insulation. However, what most people don't realize is the crucial role that blowing agents play behind the scenes in manufacturing various foam products. In this article, we delve deeper into blowing agents, their types and importance in the foam industry. What are Blowing Agents? Blowing agents refer to gases or liquids added to foam formulations that produce gas bubbles when reacted with other components during the foaming process. These gas bubbles create the cellular structure within polymer foams, resulting in the lightweight, insulating properties we see in finished foam products. Without blowing agents, it would not be possible to manufacture foams as we know them today. Types of Blowing Agents There are different types of blowing agents used depending on the type of foam being produced and their respective applications. Some of the major blowing agent types include: - Hydrochlorofluorocarbons (HCFCs): HCFCs such as HCFC-141b were widely used previously but are being phased out due to their ozone depletion potential. - Hydrofluorocarbons (HFCs): HFCs like HFC-134a and HFC-245fa are currently popular blowing agents with no ozone depletion. However, they have high global warming potentials. - Hydrocarbons: Hydrocarbons like pentane are attractive natural blowing agent alternatives with low environmental impact. Care needs to be taken to avoid flame risks. - Carbon dioxide: CO2 has gained popularity lately as a natural blowing agent for polyurethane foam with no ozone depletion and low global warming potential. However, higher pressures are required for use. - Water: Water is used as a blowing agent for discontinuous panel foams and insulating concrete forms where it reacts to produce carbon dioxide gas bubbles. Importance of Blowing Agents Without blowing agents, it would simply not be possible to manufacture the lightweight, insulating foams we rely on in construction, automotive, appliance and packaging applications: - Cellular structure: Blowing agents react to form millions of stable gas bubbles dispersed uniformly within the viscous foam reactants or polymer mass. This cellular structure gives foams their distinctive properties. - Volume expansion: The gas bubbles expand the viscous reactants mixture several-fold, resulting in volume expansion and the formation of a solid foam structure after reactant reactions are complete. - Weight reduction: The gas-filled voids within the solid foam structure make foams much lighter than comparable solid block materials. This weight savings is vital across industries. - Thermal insulation: Gas pockets retard heat flow through foams, making them excellent thermal insulators. This protects buildings, keeps food fresh and improves appliance/vehicle efficiency. - Sound dampening: The cellular structure dampens sound transmission through foams, making them useful as acoustic barriers and insulation. So in essence, without the essential gas-producing function of blowing agents, foams would simply fail to form their characteristic lightweight, insulating cellular structure throughout the manufacturing process. Conclusion In summary, blowing agents play an invisible yet indispensable role behind the scenes in manufacturing the lightweight foams and insulators all around us. Continuous research aims to deliver newer blowing agent options that allow foam production with lower environmental footprints. Their importance underscores the need for solutions that sustainably enable the crucial job of producing high-performance foams into the future.

0 notes

Text

0 notes

Text

0 notes