#Pasteurizer Panels Manufacturer

Explore tagged Tumblr posts

Text

CIP Panel Manufacture in India | Electropoint Automation

Experience the excellence of our high-quality Cleaning Place Control Panels as we proudly stand as a leading CIP panel manufacturer in Pune, Maharashtra. Our state-of-the-art manufacturing process ensures that each control panel is meticulously crafted using top-grade components, guaranteeing reliable and efficient performance in cleaning processes. Whether you need to control the cleaning of industrial equipment, tanks, or pipelines, our CIP panels provide seamless automation and monitoring. At Electropoint Automation, customer satisfaction is at the heart of everything we do. We strive to deliver products that exceed expectations and provide you with a competitive edge in your operations.

#CIP Panel Manufacturer#Specially Designed Panel Manufacturer#Specially Designed Panel Supplier#Separator Control Panel Manufacturer#Control Panel Manufacturer#Juice & Beverage plant turnkey automation#Dairy plant turnkey automation#PLC & SCADA Based Automation Manufacturer#Pasteurizer Panels Manufacturer

0 notes

Text

Raw Milk Reception Dock Automation System in Gujarat

Saputo Process Engineering Pvt. Ltd. Is a leading Supplier of Raw Milk Reception Dock Automation System in Gujarat. Our Manufacturing Unit is located in Ahmedabad, Gujarat, India. Saputo Process Engineering Pvt. Ltd. Is a leading Manufacturer, Exporter, and Supplier of Milk Processing Plant, RMRD Equipment, Bulk Milk Cooler, HTST Milk Pasteurization Plant, Paneer and Cheese Processing Systems, and more. Continuous monitoring and automated alerts help maintain the highest quality standards, ensuring that only the best milk is processed. Reducing manual labor and minimizing waste leads to significant cost savings, contributing to the overall profitability of dairy operations. Features: Automated Flow Control: Our system employs advanced sensors and actuators to automate the flow of raw milk from tankers to storage tanks, minimizing human intervention and reducing the risk of contamination. Accurate Measurement: High-precision flow meters accurately gauge the quantity of milk received, ensuring compliance with quality standards and optimizing inventory management. Hygienic Design: Constructed with food-grade materials, our system adheres to stringent hygiene standards. The design includes easy-to-clean surfaces and components, preventing bacterial growth. Real-Time Monitoring: Integrated software allows for real-time monitoring of milk quality parameters, such as temperature and composition. Alerts notify operators of any deviations, ensuring immediate corrective action. User-Friendly Interface: An intuitive control panel simplifies operation, allowing staff to manage the system easily and efficiently. Customizable settings cater to specific operational needs. Remote Access: With IoT integration, operators can monitor and control the system remotely, enhancing flexibility and responsiveness to operational changes. Applications: Dairy Processing Plants Milk Collection Centers Cooperative Dairy Operations Saputo Process Engineering Pvt. Ltd. Is Supplier of Raw Milk Reception Dock Automation System in Gujarat including locations like Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Anand, Gandhinagar, Bharuch, Morbi, Vapi, Valsad, Junagadh, Nadiad, Mehsana, Porbandar, Godhra, Navsari, Surendranagar, Patan, Amreli, Palanpur, Modasa, Dahod, Gandhidham, Bhuj, Ankleshwar, Kalol, Sanand, Halol, Kadi, Khambhat, Jetpur, Kutch, Mundra, Morbi, Rajpipla, Dwarka, Dholka, Gandharpur, Bhachau, Chotila, Dhandhuka, Umargam, Padra, Jhagadia, Kalol, Savli, Palghar, Godhra, Vallabh Vidyanagar, Mandvi, Halvad, Balasinor, Nandesari, Pardi, Karamsad. Please feel free to contact us today for more information, pricing, and availability. View Product: Click Here Read the full article

0 notes

Text

Successful Implementations of Solar Water Heaters in the Industrial Sector

Industries around the world are increasingly turning to solar water heaters to meet their energy needs in a cost-effective and sustainable manner. The benefits of adopting solar water heating technology extend beyond reducing energy bills; they also contribute to environmental stewardship and compliance with regulations. This blog highlights some successful implementations of solar water heaters in the industrial sector, showcasing how different industries have effectively integrated this technology into their operations.

1. Food and Beverage Industry: Brewing with the Sun

A leading brewery in Germany successfully implemented solar water heaters to meet a significant portion of its hot water needs. The brewery installed a solar thermal system with large flat-plate collectors on its rooftop, which pre-heats water used in the brewing process. By integrating solar heating into their operations, the brewery reduced its reliance on natural gas, cut its energy costs by 30%, and decreased its carbon emissions by 25%. This move not only enhanced the brewery's sustainability credentials but also resonated well with eco-conscious consumers.

2. Textile Industry: Solar Solutions for Dyeing Processes

A textile manufacturer in India faced high energy costs associated with heating water for dyeing fabrics. The company decided to invest in a solar water heating system with evacuated tube collectors, which are highly efficient in converting solar energy into heat. The system was designed to provide hot water at temperatures required for the dyeing process. After implementation, the manufacturer saw a reduction in energy costs by 40% and a return on investment (ROI) within three years. The solar system also contributed to a cleaner production process, aligning with the company's environmental goals.

3. Chemical Industry: Reducing Energy Intensity with Solar Heating

In Spain, a chemical processing plant implemented a solar water heating system to reduce the energy intensity of its operations. The plant required large amounts of hot water for various chemical reactions and cleaning processes. By installing a solar thermal system with advanced tracking collectors that follow the sun’s movement, the plant was able to maximize energy capture. The system provided 60% of the plant’s hot water needs, resulting in significant energy savings and a reduction in greenhouse gas emissions by 35%.

4. Dairy Industry: Sustainable Milk Processing

A dairy processing facility in New Zealand incorporated solar water heaters into its milk pasteurization process. The facility installed solar thermal panels on its rooftops, which are used to pre-heat water before it enters the pasteurization units. This approach reduced the facility’s dependency on conventional energy sources, cutting energy costs by 20% and lowering the overall carbon footprint. The use of solar energy in the dairy process also helped the facility gain recognition for its sustainable practices, boosting its market competitiveness.

5. Hospitality Industry: Solar Water Heating for Laundry Services

A large hotel chain in the United States adopted solar water heating systems to support its laundry operations, which required vast amounts of hot water. By installing solar collectors on the rooftops of its hotels, the chain was able to generate sufficient hot water for laundry services, reducing energy consumption by 50%. This implementation not only resulted in substantial cost savings but also positioned the hotel chain as a leader in sustainable hospitality, attracting eco-conscious guests.

6. Pharmaceutical Industry: Green Energy for Sterilization Processes

A pharmaceutical manufacturing plant in Italy needed a reliable and energy-efficient method to generate hot water for sterilization and cleaning. The plant invested in a solar water heating system equipped with high-efficiency evacuated tube collectors. The system was designed to provide hot water at consistent temperatures, critical for maintaining sterilization standards. Post-implementation, the plant reported a 35% reduction in energy costs and enhanced its compliance with environmental regulations, all while maintaining the quality and safety of its products.

These case studies demonstrate the versatility and effectiveness of solar water heaters across various industries. By leveraging solar energy, companies can significantly reduce their energy costs, enhance sustainability, and improve their bottom line. Whether in food and beverage, textiles, chemicals, dairy, hospitality, or pharmaceuticals, solar water heating systems offer a proven solution for industrial applications.

Are you ready to explore the benefits of solar water heaters for your industrial operations? Contact us today to learn how we can help you implement a solar thermal system tailored to your industry’s needs, ensuring cost savings and sustainability for the future. For more info contact Solar Water Heater Supplier in UAE or call us at +971 4 2522966.

0 notes

Text

Study maps main genes involved in immune response to infection by dengue virus

- By Maria Fernanda Ziegler , Agência FAPESP -

By comparing data for the immune response to natural infection by dengue virus to data for activation of the immune system by dengue vaccines, researchers at the University of São Paulo (USP) have identified molecular markers that could be used in the development of novel vaccines and treatments for dengue.

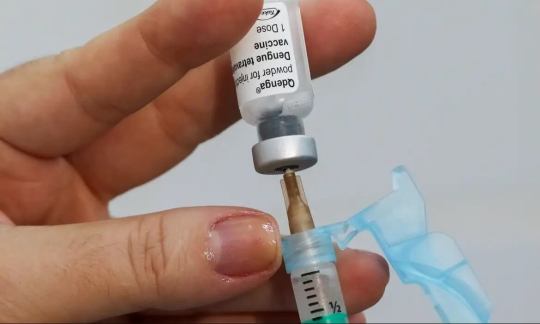

They also reiterated the efficacy of two vaccines already available on the market: Q-Denga, manufactured by Takeda Pharma (Japan) and now being distributed by the national health service in Brazil (Sistema Único de Saúde, SUS); and Dengvaxia, produced by Sanofi-Pasteur (France). Both are live attenuated virus vaccines.

“We analyzed the data systemically and found various similarities between the immune response elicited by vaccines and the immune response to natural infection. Of course, vaccines induce an immune response without the damage done by the virus. We were also able to characterize several pathways [that involve signaling between defense cells]. The interferon pathway [mediated by this antiviral protein produced by leukocytes – white blood cells – and fibroblasts] proved to be crucial, with several important genes that can be considered novel biomarkers of the disease,” Otávio Cabral-Marques, a professor of molecular medicine at the University of São Paulo’s Medical School (FM-USP) and principal investigator for the study, told Agência FAPESP.

The study was supported by FAPESP via two projects (18/18886-9 and 20/01688-0) and reported in an article published in the journal Frontiers in Immunology. It is the first to identify immune signatures of dengue by systems vaccinology, an approach that explores the complex interactions underlying vaccine-induced immunity in humans.

The researchers analyzed 955 transcriptome samples from patients with natural dengue infection and participants in clinical trials of dengue vaccines (the transcriptome is the complete set of RNA molecules in the organism). They obtained the data from a public database.

They found 237 differentially expressed genes common to both the patient samples and trial participant samples. “Based on 20 of these shared genes, we were able to create a panel to distinguish disease severity, especially in the late acute stage. We also used machine learning techniques to classify ten predictors [immune signatures] of disease severity in cases of natural infection. These are crucial to the immune response to the virus,” said Desirée Rodrigues Plaça, first author of the article and a PhD candidate at USP with a scholarship from FAPESP.

Dengue is caused by four viral serotypes (DENV-1 through DENV-4) and, when symptomatic, progresses through three clinical stages: febrile (initial acute), critical (late acute) and recovery.

Interferon pathway

“There are many differences, but we also found many similarities between the immune responses induced by vaccines and natural infection. By funneling the dataset, we identified 20 genes that are common to both processes and similarly expressed. They are responsible for enriching the immune system’s protective pathways, especially the type I and type II interferon pathways,” Plaça said.

Interferons are cytokines whose main role is to inhibit viral replication. They trigger a chain reaction that affects several molecules. According to the article, the interferon antiviral pathways are not only responsible for early (front-line) defense, but their complex biological functions also set the stage for development of robust and lasting adaptive immunity.

“The interferon pathways are very important to activate the adaptive response, which consists of T cells and B cells [types of white blood cells called lymphocytes] and provides permanent protection [as do vaccines]. It’s extremely important therefore to know which genes associated with the interferon pathways are key drivers of the adaptive response that affords the best protection,” Placa said.

Genes

With the information they obtained in the study, the researchers were able to develop therapeutic strategies to inhibit, activate or induce expression of genes involved in the immune response, opening up possibilities for the investigation of targeted therapies for dengue fever.

They identified the main genes (such as OAS2, ISG15, AIM2, OAS1, SIGLEC1, IFI6, IFI44L, IFIH1 and IFI44) involved in orchestrating various aspects of the adaptive immune response. OAS2 and OAS1 have antiviral functions, while ISG15 restricts virus replication, for example. AIM2 activates the inflammasome, a multiprotein complex of the innate immune system that when activated produces molecules that tell the system to send reinforcements to the infection site, initiating pro-inflammatory responses crucial for effective antiviral defense.

SIGLEC1 participates in immune cell interactions, facilitating antigen presentation and adaptive immune recognition. IFI6, IFI44L and IFI44, all of which are interferon-inducible, are implicated in modulation of apoptosis (programmed cell death) and antiviral defense. IFIH1 is a crucial sensor in shaping adaptive responses to RNA viruses such as dengue. IFIT5 and HERC5 “are known for their roles in interferon-mediated inhibition of viral replication”, the authors note.

“The many relevant genes involved in this complex process underscore the intricacy of the link between the initial antiviral pathways and subsequent adaptive immune processes. It’s as if the beginning and end of a story were joined up,” Cabral-Marques said.

The article “Immunological signatures unveiled by integrative systems vaccinology characterization of dengue vaccination trials and natural infection” is at: www.frontiersin.org/journals/immunology/articles/10.3389/fimmu.2024.1282754/full.

This text was originally published by FAPESP Agency according to Creative Commons license CC-BY-NC-ND. Read the original here.

--

Header image: The study identified similarities between the immune response to natural infection and the immune response elicited by the vaccines Q-Denga and Dengvaxia. Credit: Fabio Rodrigues-Pozzebom/Agência Brasil.

Read Also

Butantan Institute’s dengue vaccine protects 79.6% of those vaccinated, study shows

#dengue#virus#genomics#brazil#immunology#vaccine#vaccination#public health#health#infectious diseases

0 notes

Text

Batch Milk Pasteurizer Manufacturer and Suppliers in India

At Indian Trade Bird, we provide the best prices on batch milk pasteurizer. Batch milk pasteurizers such as cream separators, milk boilers, mini dairy plants, milk pasteurization plants, powder plants, milk dairies pumps, milk homogenizers, milk chilling plants, curd-making machines, ghee plants, milk centrifuges, can scrubbers, milk scrub brushes, evaporated milk plants, drip savers, skid-mounted process modules, curd separators, soya curd machines, and many more are produced by us in great quantities. The milk is pasteurized in a batch pasteurizer when dairy products are being produced. The batch pasteurizer is made out of an electrical stirring machine with an overhead stirrer, motor reductor, and stainless steel control panel mounted above a triple-walled, insulated stainless steel vat. Because of their durable construction and low maintenance requirements, our clients greatly value our excellent quality products. It is applied to achieve a higher bulk density. Because of their best efficiency, usefulness, and longevity, our machines are in high demand on the market.

0 notes

Text

youtube

SM BIOTECH (Mushroom Machinery Manufacturing) is the No.1 supplier and manufacturer of all kinds of Mushroom Farming Machinery equipment’s and provides complete Mushroom Project Consultancy services which include our visit to their farm, project report formation which is prepared by our CA, Site Mapping, complete Farm Layout prepared by our Civil Engineer, Insulated Puff Panel rooms construction, Composting Unit Formation and installation of latest technology based fully and semiautomatic machinery under the supervision repudiated scientist and consultant. We also deal in all type of shed constructions work which includes the formation of Pre-Fabricated shed which are used for multipurpose. The shed work is completed under the guidance of our highly experienced & expert team.

We work intending to provide customized solutions to our customers as per there Project requirement as we are the manufacturer of a wide range of Mushroom Farming Machinery. Our Machinery is fully Automatic, Computerized as well as semiautomatic based on customer need.

If you have an inquiry regarding Price & Capacity and How it works; Please call us or email:

Phone: +91-8171599292 Email: [email protected]

Visit our website: https://www.mushroommachines.com/

Our Product List: - Mushroom Farming Consultancy & Project Report - Phase 1 Composting Bunker & Blowers - Phase 2 Pasteurization Tunnel & Blowers - Tunnel AHU - Pasteurization Tunnel Doors - Spawning & Bag Filling Machine - Bunker Filler Machine - Compost Turner - Straw Pasteurization Machine - Bag Filling Machine - PUF Panel Mushroom Growing Rooms - PUF Panel Cold Rooms - Mushroom Racks - Environment Control System- Air Handling Unit & Cold Room Unit - Water Spray Machine - APFC & Distribution Panel - Steam Generator - Laminar Air Flow

1 note

·

View note

Text

Mini Dairy Plant Tanzania

Dairy N Pack is a leading manufacturer and supplier of mini dairy plant equipment machines Tanzania. If you're in the market for the best dairy plant equipment machines, Dairy N Pack is the right place for you. With its state-of-the-art manufacturing facilities and experienced team of professionals, Dairy N Pack offers top-quality equipment that is sure to meet your needs.

Dairy N Pack offers a wide range of mini dairy plant equipment machines, including milk pasteurizers, homogenizers, milk storage tanks, milk processing equipment, and more. Each machine is made using the latest technology and highest-quality materials, ensuring durability and longevity. Whether you're starting a new dairy business or looking to upgrade your existing equipment, Dairy N Pack has the perfect solution for you.

One of the most popular machines from Dairy N Pack is the milk pasteurizer. The milk pasteurizer is used to heat milk to a specific temperature for a set period of time, killing any harmful bacteria present in the milk. The pasteurizer is available in a range of sizes and capacities to meet the needs of both small and large-scale dairy operations. It is also easy to operate, maintain and clean.

Another popular machine from Dairy N Pack is the homogenizer. The homogenizer is used to process milk and other dairy products to create a smooth and consistent texture. Dairy N Pack's homogenizers are designed to be efficient, reliable and easy to operate. They are also available in different sizes and capacities to meet your specific needs.

Dairy N Pack also offers milk storage tanks in various capacities to suit your needs. These tanks are made using high-quality materials and are designed to ensure that the milk remains fresh and safe for consumption. The milk storage tanks come with an easy-to-use control panel and are easy to clean and maintain.

Apart from the above equipment, Dairy N Pack also offers a range of milk processing equipment such as milk separators, cream separators, butter churns, and more. These machines are designed to help you process milk and other dairy products quickly and efficiently.

In addition to manufacturing and supplying top-quality dairy equipment, Dairy N Pack also offers excellent customer service. The company has a team of knowledgeable professionals who are always ready to assist you with any questions or concerns you may have. They also offer after-sales support to ensure that your equipment continues to function optimally for years to come.

Dairy N Pack's commitment to quality and customer satisfaction has earned it a reputation as one of the leading mini dairy plant equipment machine manufacturers in the industry. Whether you're in the market for milk pasteurizers, homogenizers, milk storage tanks, or any other dairy equipment, Dairy N Pack has the expertise and experience to meet your needs.

In conclusion, if you're looking for the best mini dairy plant equipment machines, Dairy N Pack is the right place for you. With its state-of-the-art manufacturing facilities, high-quality materials, and experienced team of professionals, Dairy N Pack offers top-quality equipment that is sure to meet your needs. Contact them today to learn more about their products and services.

0 notes

Text

best electric pressure cooker

New Post has been published on https://bestreviewstar.com/best-electric-pressure-cooker-reviews

best electric pressure cooker

BEST Electric Pressure Cooker Full REVIEW and Compression chart

If you are looking for an easy and fast way to prepare delicious and healthy meals, a electric pressure cooker is a must! Whether you’re looking to feed the masses or make a quality private meal, this guide will guide you through everything you need to know to select the best electric pressure cooker to meet your needs. Take a look at our comparison of programmable pots to help you find the best brand and model suitable for your kitchen. In addition to the pressure cooker, Sous Vide Mahcine is a modern slow cooker.

Currently there are usually two types of pressure cookers – electric pressure cookers and stovetop pressure cookers. The electric pressure cookers offer many options and ease of use while cooking models are robust, reliable and offer users advanced some additional options. There may be a place for both of you in your kitchen depending on the applications that interest you most.

Electric Pressure Cooker

Stovetop Pressure Cooker

The following products are all solid options. We have based these reviews on careful research, product comparison and user reviews, all to provide a complete guide to buy the model that best suits your needs. The pressure cookers on this list have met or exceeded the standards of an easy-to-use, durable, safe, multifunctional, low-consumption and environmentally friendly product that is expected from quality pressure cookers. The first models are programmable pots, while those that appear at the end of the list represent some models of solid stoves.

Electric Pressure Cooker Compression Chart in 2019

Name

Capacity

Certified

Rating

Price

01. Ninja OP401 Foodi 8-Quart Pressure, Steamer, Air Fryer All-in- All-in-One Multi-Cooker

7.57 litters

PTFE / PFOA free + 14 Safety

★★★★★ 5/5 Latest Discount

02. Instant Pot DUO Plus 60, 6 Qt 9-in-1 Multi- Use Programmable Pressure Cooker

5.67 litters

UI + 10 Safety

★★★★★ 5/5 Latest Discount

03. Mealthy MultiPot 9-in-1 Programmable Pressure Cooker

5.67 litters

Intertek 5004102

★★★★★ 4.7/5 Latest Discount

04. Instant Pot DUO60 6 Qt 7-in-1 Multi-Use Programmable Pressure Cooker

5.67 litters

UL/ULC + 10 Safety

★★★★★ 5/5 Latest Discount

05. COSORI CP018-PC 8Qt 8-in-1 Electric Pressure Cooker

7.57 litters

ETL, CETL, FCC & FDA + 9 Sefty

★★★★★ 4.4/5 Latest Discount

06. Power Pressure Cooker XL 6 Quart – Silver

5.67 litters

PFOA free + FDA aproved

★★★★★ 4.4/5 Latest Discount

07. Instant Pot Ultra 6 Qt 10-in-1 Multi- Use Programmable Pressure Cooker

5.67 litters

UL, ULC + 11 Safety

★★★★★ 4.9/5 Latest Discount

08. Instant Pot IP-LUX60 v2 6-in-1 Programmable Pressure Cooker

5.67 litters

UL and ULC + 10 Safety

★★★★★ 4.9/5 Latest Discount

09. Elite Platinum EPC-1013 Maxi-Matic 10 Quart Electric Pressure Cooker

9.46 litters

Nill

★★★★★ 4.7/5 Latest Discount

10. Fagor LUX – Multipurpose kitchen

5.67 litters

Nill

★★★★★ 4.6/5 Latest Discount

The 10 BEST Electric Pressure Cooker Reviews in 2019

# 01

Ninja OP401 Foodi 8-Quart Pressure All-in-One Multi-Cooker

Ninja pot is the best electric pressure cooker that is solved the cooking problem. It allows you to cook up to a maximum of 7.57 liters. This is Food Op 401 Big Time Glitter Multicooker. The largest pressure cooker model has 1700 watts of cooking power that you can use to cook, steam, slow cook, suit bake, roast, boil dehydrate, and so on.

Compared to other pressure cookers you can cook it 70% faster. You can easily cook a 7-pound chicken in the Ninja Pot. We have to use a lot of oil to make traditional dishes. As a result, we suffer from various diseases – eg gastric, fat growth, and etc.

You can cook 75% less fat than any traditional frying methods with Ninja Pressure Cooker. **Versus deep-fried hand-cut French fries (It is proven). Enjoy healthier foods. This will keep you and your family healthy. Ninja pressure cooker is 2 sizes- 7.57 liters ceramic-coated pot, 4.73 liters ceramic-coated cook and crisp basket. It has a PTFE/PFOA-free stainless steel reversible rack.

Before cooking a meal, you have to think about its safety. Because cooked food can be overcooking, the smell can be wasted and so on. So there are 14 safety features to keep food safe. This will not ruin your diet and the food will be 100% delicious.

It can be cooked in the refrigerated meat for just 20 minutes. About 75% less time than other pressure cookers. It will save both time and money.

Buy It on Amazon

# 02

Instant Pot DUO Plus 60, 6 Qt 9-in-1 Multi- Use Programmable Pressure Cooker

If you are looking for the best electric pressure cooker , Instant Pot IP-DUO Plus 60 9-in-1 Programmable Pressure Cooker is our FIRST OPTION in terms of features, price and quality. The IP-DUO Plus60 9 in 1 instant cooker is the newest in the Duo series and one of the best-selling pots in the pressure cooker industry. Instant Pot is the most loved American’s Number 1 Brand for pressure cooker.

This new instant pot comes with advanced microprocessor technology that incorporates all the great features that previously made the Duo, one of the best sellers on the market, and now it has been equipped with new and improved features that support the latest conscious lifestyle of health.

If you are one of those people who would like everything to work at the press of a button, a fully programmable pressure cooker like this from the Duo series is an option. This pot is designed to cook food up to 2-6 times faster , and is known to save up to 70% energy.

The following products are all solid options. We have based these reviews on careful research, product comparison and user reviews, all to provide a complete guide to buy the model that best suits your needs. The pressure cookers on this list have met or exceeded the standards of an easy-to-use, durable, safe, multifunctional, low-consumption and environmentally friendly product that is expected from quality pressure cookers. The first models are programmable pots, while those that appear at the end of the list represent some models of solid stoves.

Highlights

A full range of functions with the 9-in-1 multifunction pot– allows you to cook any dish with ease – for example, meat, chicken, potatoes, yams, fish, vegetables, pork, soup, stew, desserts, beans, grains and many others products.

Easy to use control panel with 14 built-in intelligent programs.

UL and ULC certification with 10 proven safety mechanisms … and MUCH MORE.

Unlike its predecessors, the Duo Plus 9 in 1 has three new programs that include Cake, Egg and Sterilize. As the name implies, the Cake program has been designed to cook moist and soft cakes, while the Egg program ideally helps you prepare eggs in minutes.

The sterilization program is designed to help you pasteurize milk, sterilize jars, bottles and utensils. All these features are included in the Instant Pot IP-DUO Plus60 9 in 1 to offer you a full instant boat.

Note: The instant pot also comes with a free pressure cooker recipe book . The link above provides information on how to download and access the recipe book. It is a great resource of electric pressure cooker complete with cooking schedules,

Buy It on Amazon

# 03

Mealthy MultiPot 9-in-1 Programmable Pressure Cooker

The Mealthy MultiPot 9 in 1 is one of the best electric pressure cookers in its price range. With this pressure cooker, you can perform various tasks, including making cakes, slow cooking, steaming, cooking rice, heating pre-cooked meals, making yogurt, pasteurization and stir fry.

You receive a stainless steel basket to help you separate the dishes you are cooking simultaneously, as well as a 6-quart stainless steel pot, which is ideal for a medium family. This model is easy to use thanks to the 14 easy-to-use programs that help you cook a variety of meals for your family.

Among the best features of this program is its mobile application. After purchasing this programmable pot , you are asked to register by registering on the Mealthy website. You will be allowed to download the Mealthy mobile phone application that has a large list of easy-to-cook recipes made by hand for this device. There are also step-by-step videos to show how these recipes are prepared. In addition to this, you will also receive a 1 year warranty on your device after registering.

This pressure cooker comes with plenty of additional accessories, including silicone gloves, an extra silicone gasket, a steam basket, a steam rack, a ladle, a paddle of rice and a measuring cup.

However, there are some complaints that this product is easily scratched.

Notable features

It has an intuitive programming interface

Its 6-quart stainless steel container makes it ideal for a family of 2 to 6 members.

It comes with exceptional instruction guides

It is a 9-in-1 appliance with 14 easy-to-use cooking programs

In general, it is one of the best electric pressure cookers on the market thanks to its many unique features that include a mobile application and a quick start guide, as well as many advantages such as the steam basket, the rice paddle and the additional gasket .

Buy It on Amazon

# 04

Instant Pot DUO60 7-in-1 Multi-Use Programmable Pressure Cooker

From the same manufacturers on our #2 list, but at a better price, the Instant Pot DUO60 is a great option when it comes to selecting a quality programmable pot . The lowest price comes at the sacrifice of some of the new clicks and whistles of the aforementioned product. However, this pressure cooker is still of great value!

Made of stainless steel, the Instant Pot DUO60 offers you a quick and easy way to cook healthy meals. Simply load the ingredients in the pot, cover it and start cooking. The DUO60 cooker is cooked under high pressure and reduces traditional cooking time by up to 70% without sacrificing important water-soluble vitamins and minerals in the process.

In terms of safety, the product has passed the strict UL and ULC certification that seeks to guarantee the user’s peace of mind when cooking with equipment such as a pressure cooker. The non-stick and non-stick stainless steel pot, the sealing ring and the anti-lock shield can be washed in the dishwasher , as well as the shelf, the rice paddle, the soup spoon and the accompanying measuring cup. Not to mention that all this comes with a very practical recipe book for you to cook in a short time. Instant Pot is the American’s Number 1 Brand for pressure cooker.

The Instant Cooker Cooker is designed to do everything. All its great features and elegant appearance combine to turn it not only into a pressure cooker, but also into a rice cooker, a slow cooker, a steamer and a heater capable of sauteing and browning as well. Obtaining an almost perfect rating of more than 9500+ consumers , we feel very comfortable recommending this product to anyone looking for the best pressure cooker in the market. Built to last, this pressure cooker has replaced many outdated models due to its better efficiency, engineering design and performance. This 1000 watt pressure cooker is protected by the manufacturer’s 1 year warranty. You will never have to worry about the quality or performance of this device.

Buy It on Amazon

# 05

COSORI CP018-PC 8Qt 8-in-1 Electric Pressure Cooker

COSORI CP018-PC Electric Pressure Cooker is the better pressure cooker than the other brands. It has extra silicone seal, taller steaming trivet with Handel, and an extra glass lid for slow cooking and covering. It is adjusted 17 smart programs. You can make bbq chicken, muffins, lasagna, pork ribs, egg bites, cheese and mac, even yogurt!

COSORI CP018 is the new cooking appliance with a large LED display and a new interface for easily cooking setting and pressure levels. It is totally automatic machine and included the latest technology. If your cooking is done the machine will shut down automatically and a notification is issued for the warning.

The COSORI CP018 is designed to solve all pitfalls by making improvements to other pressure cookers. It has 9 standard protection mechanisms to give you casual protection and peace of mind. The COSORI CP018 is also ETL, FCC, and FDA certified for better safety.

The advanced steam technology use in COSORI CP018-PC Electric Pressure Cooker for seals. As a result, it can cook up to 70% faster and save time and money. It is a fully user-friendly cooker emits which can not out steam when cooking. Since no steam can be released, more nutrients and vitamins are locked. It has 3-ply bottom stainless steel inner pot, rack with handle and glass lid are dishwasher safe.

The COSORI CP018 is 2 years warranty with 30 days unconditional free return and 24 hours customer service for your help.

Buy It on Amazon

# 06

Power Pressure Cooker XL 6 Quart – Silver

The pressure cooker TV PPC Power Pressure Cooke is a perfect device for those who wish to cook their favorite dishes easily. Complete with an extra large size, multiple functions and, of course, 70% faster cooking compared to traditional kitchen utensils. This pressure cooker allows you to cook delicious and healthy meals daily without sacrificing your precious time.

Its flavor infusion technology is a special feature that is rarely found apart from this pressure cooker designed to maintain all the aroma, flavor and flavor of your dishes. Not only will the taste of the food cooked in this pressure cooker leave you impressed, but the aroma with which you fill your home is definitely an additional advantage.

The pressure cooker from PPC Power Pressure Cooker , which makes it ideal for canning vegetables, fruits and other foods. Keep Warm automatic mode preserves food for a long time, and its stainless steel liningensures that heat never escapes from food.

It is very easy to care for and maintain the condition of this pressure cooker – simply clean the stainless steel housing and observe how it is easily cleaned. All these features make the price of this robust and high quality pressure cooker only $ 80!

Buy It on Amazon

# 07

Instant Pot Ultra 10-in-1 Multi- Use Pressure Cooker

The Instant Pot Ultra 6 Qt 10-In-1 Pressure Cooker is a great choice for those looking for the latest and best features from the leading manufacturer of pressure cookers. This model offers all the main features of our #2 pressure cooker and more, all at a reasonable price if you consider the variety of features you are getting. Instant Pot is the American’s Number #1 Brand for pressure cooker.

It uses an embedded microprocessor which is the latest 3rd generation technology. This microprocessor monitors the temperature and pressure, keeps time and adjusts heating intensity and duration.

Instant Pot Ultra’s components are made of food-grade 304 stainless steel. For safe handling, it includes new steam release reset button. Complimented by UL with 11 safety features to enhance mental calmness and quality.

It has included more new feature-altitude adjustment, cooking indicator for sterilizing, cake and egg programs. The ultra button has included for custom programming. Other general programs are connected.

Notable features

Innovative latest generation sphere for program selection and cooking modes

Custom programming with additional functions

Third generation technology with improved processor and added monitoring functions

Buy It on Amazon

# 08

Instant Pot IP-LUX60 v2 6-in-1 Programmable Pressure Cooker

The Instant Pot LUX60 V3 6-in-1 is the most economical Instant Pot model that offers great performance at a very affordable price – without compromising efficiency and effectiveness. The Instant Pot Lux V3 adds some new features to the offer that include a pastry program, an egg program and the third generation microprocessor that, among other things, provides some additional cooking time options. American Number #1 Brand is Instant Pot

If we compare the names of Instant Pot, DUO60 and LUX60 , we may have already been inclined to think that there is not much difference between the two devices. In fact, they are quite similar in terms of design, controls, characteristics and cooking capacity. In light of all the similarities, there is a small minor difference that causes the price difference.

The DUO60 display increases by 30% compared to the LUX60 , especially in terms of functionality (using 14 built-in smart programs compared to 10 of the LUX60), the pressure sensor is improved (the DUO60 doubles compared to the LUX60) and the DUO has some more recent safety features.

Much of what makes the LUX60 the best pressure cooker can also be attributed to the DUO60. However, if the DUO60 or DUOPlus 60 is too expensive for your budget, then the LUX60 is a perfect alternative. It is powerful, multifunctional (Multifunctional kitchen 6 in 1 with 10 built-in intelligent programs) and comes at a very reasonable price. If you are looking for money, look no further than buying the Instant Pot IP-LUX60.

Buy It on Amazon

# 09

Elite Platinum Electric Pressure Cooker

Elite Platinum Electric Pressure Cooker is the best electric pressure cooker that many users say it. It is easy to use. It is a built-in stainless steel lid and non-stick interior pot qt. You can make any large batches of soups, stews, etc.

An elite pressure cooker is a great tool for your kitchen. 8lbs for frozen beef cooked in just 90 minutes. it is automatically shut down when the cook ends. So, no need to look repeatedly to close the oven. It has a removable pot that is easy to clean.

Elite has 8 multi functions that allow you to easily and safely cook food. Each meal has a separate safe function. Keeps you healthier than any microwave by reheating food. It has a very convenient browsing function. If you want to cook it by delaying it for 24 hours, the next time you specify the setting It will be cooked in time. Also, the cooking time can be set from 0 to 90 minutes. An automatic switch-off will alert you when the cooking is finished.

Elit is the pressure cooker so there is no need to buy a stove or electric cooker. It is easy to celean.

When cooked, it is automatically closed so it is automatically safe.

Buy It on Amazon

# 10

Fagor LUX – Multipurpose kitchen

Like other programmable pots, the Fagor 670041880 LUX Multipurpose Pot can reduce your cooking time by up to 70% compared to conventional cooking processes. This pot allows some flexibility in your cooking process due to your selection of high or low pressure depending on the recipe and amount of food you want to cook.

In addition to the pressure setting, it also includes numerous different cooking modes to address the task in question: Slow cooking, Rice cooking, Pressure cooking (high or low), Yogurt, Steaming, Slow cooking, Golden, Heating.

Notable features

Automatic pressure release option.

4-digit LED display

Delayed cooking for up to 6 hours.

Removable ceramic container.

Automatic mode to keep food warm

It includes a recipe book and an electronic recipe book (more than 75 recipes).

Although there are many competitive products on the market, Fagor America has a reputation for pristine products that you won’t find with other brands. This model is no exception and competes well with the other frontline brands.

Buy It on Amazon

The Benefits of Electric Pressure Cooker

With a pressure cooker, the cooking time for meals is reduced by half so you can enjoy before eating your dishes and also spend less time cooking and cleaning. A pressure cooker not only cooks food quickly, but also preserves more nutrients and vitamins in foods that are normally lost in alternative cooking methods.

The magic and efficiency of programmable express pots revolve around the simple concept that, under pressure, the boiling point of any liquid is always greater. Once the pot is sealed, the pressure in the device begins to increase. The internal pressure raises the boiling point of water from 211 degrees to 250 degrees. The increase in pressure creates steam and, consequently, hot steam heats food in the pressure cooker, which makes the cooking process much faster and more efficient. In addition, pressure cookers tend to consume less energy than traditional methods. Below you will find a list of other benefits that you can get by choosing to use a pressure cooker.

Save time:

With a normal stove, you can cook a couple of pounds of beef by boiling it for 3-4 hours, in addition to stirring occasionally. If you use one of the best pressure cookers, that time is reduced by 70%, which means you save 2 to 3 hours! Imagine what you could do with 2-3 extra hours! You could spend time with your family, prepare other dishes or just relax while waiting for your guests to arrive.

Save money:

Because the pressure cooker can cook in much less time, you save tons on electricity and energy bills.

Your safety:

Modern pressure cookers are now quite safe to use. They are designed to allow excess pressure (if any) to be ventilated at any time. They have handles to keep cool, and some of the models will automatically switch to heat setting when your meal is complete, so it will remain hot until you are ready to serve without retaining excess heat.

The taste of food:

A pressure cooker helps you maintain the nutritional value of food. In terms of the physical attractiveness of the food, the food maintains its texture and color, the meats retain their flavor and all other ingredients are cooked until they reach their ideal consistency.

Save space:

Multifunctional pressure cookers today double as rice cookers and slow cookers, which means you can even reduce the number of appliances and save valuable closet space. (Find the best rice cooker and the best slow cooker for the money right now!

The Type of Electric Pressure Coooker

In addition to seeing the general benefits of having a pressure cooker in your home, you have to decide on what type of pot. To help you decide, we have compiled a detailed comparison of the pressure cookers on the stove and the electric pressure cookers. When deciding which one is best for your home, this guide will tell you the exact characteristics that you want your pressure cooker to have. With this table you can also see the advantages and disadvantages of the two types of pressure cookers.

There are two types of pressure cookers: second generation and electric. There are still some variations of first generation pressure cookers, or “old style”, on the market today, but they have generally fallen in popularity, since they usually only had a heavy pressure setting.

The most popular pressure cooker models today are the second generation and the electric pressure cooker models. In addition to their extensive safety features, these models have also added the advantage of having more than two pressure settings. This allows you to modify the pressure inside the pot to control how food will be cooked. This characteristic, combined with the heating element of the pot, produces great flexibility in the exact way of preparing food.

Difference Between Table and Electric Pressure Cooker

Table Pressure Cooker

Eelectric Pressure Cooker

You can have two or more pressure settings that you can modify

There are many different types of pressure cookers for stoves, depending on the material with which they are made (from alumina or stainless steel).

There are many different types of pressure cookers for stoves, depending on the material with which they are made (from alumina or stainless steel).

It only releases steam when it opens, but you can use the rotary knob to reduce steam beforehand.

Cheaper, and can also be used as a normal pot

It can have two or more pressure settings

Stainless steel

It has its own heat source, so there is no need for a stove

The electric heat source is responsible for regulating the operating pressure.

It has a spring loaded valve to release steam

Insulated exterior to reduce the possibility of burn accidents

How to choose the best one between an electric pressure cooker and a tablet cooker?

Stove pressure cooker pros and cons

Before the invention of the electric pressure cooker, the kitchen version was the only one on the market. Its design has been modified over the years to meet the needs of many different users. Many still argue that this is the best pressure cooker, but in the spirit of objectivity, here are some pros and cons to weigh.

PROS

It usually takes approximately 11 minutes for sufficient pressure to build up, which is faster than the 14 minutes of the electric pressure cooker.

You can use the quick release method with cold water to release the pressure, which takes about 30 seconds. In addition, it can be opened using the normal release method, which takes about 2 minutes, or the natural release method, which takes about 10 minutes.

From a safety point of view, it has a lid locking system that is activated when the pot is under pressure and an additional discharge valve that releases pressure in case it accumulates in excess.

It can be used and stored as a normal pot.

CONS

This model usually does not have an integrated timer or programming functions.

Aluminum pressure cookers are not very durable, but stainless steel models are very durable.

Electric pressure cooker pros and cons

With the best electric pressure cooker, you have the ability to program and adjust multiple settings depending on your needs. For the electric pressure cooker, you can change the temperature and pressure levels with one click. There are also small screens that will give you the current temperature as well as the pressure levels in your pot.

Electric pressure cookers are very convenient and are often frequented by people who depend on canned or processed foods. Although it is relatively new in the world of kitchen appliances, the electric pressure cooker is making waves quickly, partly due to its ability to have food ready in minutes. Here is a brief summary of the pros and cons of electric pressure cookers based on several reviews of electric pressure cookers we have analyzed.

>>>Most Important Cooking Accessories: best kitchen knife set under 200$

PROS

Everything is controlled: Both temperature and pressure can be controlled by electric pressure cookers. This avoids the hassle of having to try to control the flame manually, in addition to being limited to the pressure control capabilities of manual pressure cookers.

Many models have many pressure settings to make cooking easier. Examples of these labels are “meat,” “high pressure,” “low pressure,” and even “rice.”

The heat regulation is fully automated. Simply select the pressure and cooking time, and you’re ready to start cooking!

These models have integrated timers to control the cooking time. Gone are the days when you had to watch your pot for fear of burning!

Some models even allow you to delay the start of cooking up to 11 hours! This allows you to choose the desired settings before leaving, and then your meal will be ready by the time you get home.

This is possibly the best feature of electric pressure cooker available.

The digitization of these units has allowed a more precise control of heat and pressure, which means that if the pressure rises excessively, the pressure diffuses safely to eliminate the risk. In addition, it has its own integrated electric battery as a heat source.

CONS

It does not have the feature of quick release of cold water to release pressure in the pot.

It is slightly larger than the pressure cookers on the stove.

Usually some newer models can be used as ordinary electric pots. But generally, electric pressure cookers cannot be used unless you are cooking under pressure.

The electric pressure cooker is a modern wonder. With so many automated functions, it can often seem that meals are being cooked alone. If you prefer to save space at the counter or in the warehouse to support your other activities, such as finding the best panini press, then an electric pressure cooker is the ideal choice.

How to choose the best electric pressure cooker?

Pressure cooker made of aluminum or stainless steel?

Pots made of stainless steel can better withstand corrosion, scratches and deformations. This means that it retains its pristine appearance and function for much longer. Stainless steel does not react negatively to food products and is more durable. A stainless steel kitchen has an elegant and elegant appearance and is more expensive than aluminum.

Aluminum pots, on the other hand, are often cheaper and better conductive than stainless steel. However, aluminum is also a softer metal and therefore prone to dents and scratches that could spoil its appearance. In addition, aluminum can react negatively with certain acidic foods.

Basically, the choice between the two metals is reduced to two important factors: price and durability. Models made of aluminum are very affordable, better heat conductors, but they often come at the expense of design and quality. While stainless steel kitchens are expensive, they are often more durable and today they are accompanied by an aluminum bottom for better heat absorption. If your budget is quite limited, you will do well with an aluminum kitchen, but if quality and durability are a priority, having a stainless steel kitchen will be a better long-term option.

>>>Most Important Cooking Accessories: best container

The features to consider in the search for the best electric pressure cooker

Security

Safety features are especially important when it comes to electric pressure cookers. This is because the pressure cookers operate under the principle of accumulated pressure and, in the worst case, an intense amount of steam and pressure could, in theory, cause a destructive explosion in the kitchen. You will do well to obtain a device that comes with pressure gauges, secure lid closures, and effective release valves.

Regulators

There are three types of regulators to choose from:

Weighted Valve Pressure Regulators

Modified Weighted Valve Pressure Regulators

Spring valve Pressure regulator

Regardless of the regulator you use, look for one with a maximum of 15 pounds per square inch. This is considered standard, and all recipes are designed for this amount of pressure. Anything lower will delay cooking time.

The pressure regulator of the weighted valve is also called “jiggle top”. It has a modest price and is used on the top of the ventilation pipe where excess steam escapes. It is necessary to remove it for cleaning, and always make sure it is not locked before each use. The pressure is regulated by a rolling movement exhibited by the regulator. When he starts rocking, that means he is cooking, and he must rock with a gentle rhythm, letting him know that everything is fine. Check immediately if this stops and becomes silent.

The Modified Weighted Valve Pressure Regulators are connected to the pressure cooker and release steam in small bursts to reach and maintain 15 pounds of pressure per square inch (PSI). Its price is modest, although slightly more expensive than the weighted valve. Be careful with this device, since it is not always easy to know when the pressure is being released, and it should also be borne in mind that cooking with lower temperatures usually means an easier release of pressure.

Spring valve pressure regulators use a one inch valve to indicate the pressure in the pot. They are more expensive, and most allow you to choose between 10 or 15 PSI. It doesn’t make noise, so you’ll have to watch it closely to see if the pressure is releasing or not. The upper temperature of the stove is used to adjust the pressure level, and sometimes less liquids are needed with this version.

Choose a brand

Several manufacturers manufacture pressure cookers. Choose someone who has been in business for many years and has a good financial history. This is especially important because, if you ever need replacement parts, you will want a company that is still in business, and the pressure cooker parts cannot be mixed between manufacturers.

Only buy pressure cookers from reputable retailers. Check if they sell the spare parts, which will mean less headache if you ever need to buy any. Choose a pressure cooker that is approved by UL, Underwriters Laboratories or another qualified testing organization. This lets you know that it meets an established standard of quality and safety.

Latch interlocking mechanisms

Always buy a pressure cooker with a lid interlocking system. It is an essential safety feature that will automatically lock the cover while the internal pressure is high, and it is unlocked once the pressure drops safely. Nor will it allow pressure to build up until the cover is in place correctly. This is a safe solution for many of the uncertainties and risks that many fear when it comes to using a pressure cooker.

Some pressure cookers also have a visual pressure gauge for added safety. It lets you know if the internal pressure is high. When cooking with pressure, you can never have too many safety features. Look for models that offer a secondary pressure relief mechanism that relieves pressure if the vent tube is blocked.

Mangoes

Mangoes, even if they seem a small consideration, should also be inspected for their durability, as it is likely that, at some point, you will have to carry a pot full of food. The handles should be safe and comfortable to grip. Practice holding the pressure cooker before buying it to make sure it fits well in your hands, and also keep in mind that they should be relatively heat resistant, as they will be in contact with intense heat while the pressure cooker is in use.

Pressure relief

There are two types of pressure release methods used in recipes, often noted by the following phrases:

“Cold kitchen at once”

“Natural pressure drop”

Always follow the recipe to know which one to use. To cool a pot at once, place the pressure cooker in a cold water pot or under the cold water tap to quickly release the pressure. A pressure cooker with a quick-release pressure knob can be removed from the fire and then use this feature to quickly release the pressure, which is noted by a vapor spray that is released.

If a recipe requires a natural pressure drop, remove the pressure cooker from the heat source and allow it to cool on its own.

Kitchen Baskets and Racks

Racks and baskets allow you to separate different types of food inside the pressure cooker. This often produces optimal results, since separate foods can be cooked without allowing them to influence each other.

Interior materials

The inner and outer material of the pressure cooker is usually the same. However, some models have nonstick interiors that can sometimes be beneficial in terms of cleanliness; However, according to many pressure cooker reviews, this feature is not very important since non-stick materials are not kept well under intense pressure.

Base materials

For easy cleaning, no burns and perfect heat conduction, buy a pressure cooker with a trimetallic or bimetallic base. Bimetallic and trimetallic bases are found in several models, and usually include an aluminum layer that minimizes burning and cooks evenly by allowing heat to be distributed evenly throughout the pot.

Compatible cooking plates

Some pressure cookers cannot be used in ceramic cookers, so it is better to check compatibility when looking for a pressure cooker. However, most pressure cookers are compatible with all cooking plates. This consideration is not necessary if you are looking for an electric pressure cooker, since these models have their own heat source.

Latest Discount

Here are the details of the best electronics pressure cooker. Hopefully, you can easily purchase the pressure cooker you need. If this post helps to buy the best electric profession cooker for you then my collection will be fostering. This site also features, Best Sous Vide Machine Review, Best Vacuum Sealer Review, Best Sous Vide Container Review, Best Sous Vide Rack Review.

#best electric pressure cooker#electric pressure cooker#electric pressure cooker review#electric pressure cooker reviews

2 notes

·

View notes

Text

Double Cone Mixer In Pharmaceutical Industry: The Magic Behind It

A double cone mixer is one of the several innovative techniques developed in recent years to lessen the burden on the pharmaceutical industry. The double cone mixer technique has been widely adopted by a majority of industries due to its ability to deliver high density, low air content, and high viscosity products.

Double Cone Mixer can be used in the pharmaceutical industries for mixing or blending dry materials. The dry material is fed into the top part and rotates on the lower cone with high speed due to which it gets blended properly. It helps in relieving pressure build-up and prevents any adverse effects that might result from using a single shaft mixer.

The cone mixer is a very important piece of equipment in the pharmaceutical and chemical industries today. These are used for mixing, dissolving, homogenizing, disintegrating, and pasteurizing the chemicals and solutions.

In the pharmaceutical manufacturing industry, the double cone mixer is often called a “magical machine”. It really is magic, but behind it, there’s a lot of science and engineering.

The Double Cone Mixer is also called a Double Cone Blender because the two mixing cones are arranged vertically.

This mixer is equipped with two mixing cones connected at the top by a drive shaft. The mixer is operated via a central control panel that allows choosing different speeds, different time intervals, and different temperatures. The two cones move around at extremely high speeds. This creates an environment where all ingredients can be thoroughly mixed together without any clumping or separation.

Conclusion:

A double cone mixer is a kind of machine that can be used in the pharmaceutical industry to mix two or more ingredients. A double cone blender machine not only helps to mix the materials but also kneads and creates blends. This reduces the consumption of energy and saves time as compared to any other equipment available in the market today.

When you are in the market to purchase a double cone mixer, you need to look for one that is efficient and will suit your needs. There are several different models on the market today, but they all serve the same purpose.

0 notes

Text

Organic Milk Market Growth, Trends, Absolute Opportunity and Value Chain 2021-2031

Fact.MR analyse the Organic Milk market by considering mentioned factors collected through extensive primary research from key opinion leaders (KOL) and demand-side participants at regional/country level, such as shrimp industry participants, retail and channel partners, end users etc. These estimates are further validated with supply-side participants such as C-level executives of key market participants, product managers, distributors as well as our in-house expert panel. The participants for primary research interviews are selected through a stratified sampling method, and the numbers are inferred for one illustrative country, followed by benchmarking.

The Market survey of Organic Milk offers a comprehensive analysis of diverse features, including production capacities analysis of Organic Milk, demand, product developments, revenue generation, and Size of Organic Milk Market across the globe.

Click Here To get a Sample Report (Including Full TOC, Table & Figures):-https://www.factmr.com/connectus/sample?flag=S&rep_id=1981

Segmentation

The organic milk market is segmented on the basis of product type (skimmed milk, whole milk and partly skimmed milk), source (cow, buffalo and other sources), packaging type (pouches, cans, bottles, tetra packs and bulk packs), pasteurization type (high temperature short time method, ultra-pasteurization and vat pasteurization), distribution channel (HoReCa, specialty stores, modern trade, convenience stores, e-retailers and other), flavor type (non-flavored and flavored) and region (North America, Latin America, Europe, CIS & Russia, Japan, Asia Pacific excluding Japan and Middle East and Africa).

Deduced data points by adopting the mentioned approach is triangulated from the overall market. In order to build the hypothesis, Fact.MR examines the key market segments in representative countries. Fact.MR then map the penetration of products in each country from a predefined set of the sample of such product manufacturers/suppliers. During the process, FACT.MR conducts a detailed value chain analysis through which products are procured and offered in the Organic Milk market. All these numbers are statistically analyzed to arrive at the Organic Milk market estimates.

Key stakeholders in Market including industry players, policymakers, and investors in various countries have been continuously realigning their strategies and approaches to implement them in order to tap into new opportunities.

Need More information about Report Methodology? Click here:-https://www.factmr.com/connectus/sample?flag=RM&rep_id=1981

Some Notable Offerings by Fact.MR Report on Organic Milk market:

We will provide you an analysis of the extent to which this Organic Milk market research report acquires commercial characteristics along with examples or instances of information that helps you to understand it better.

We will also help to identify customary/ standard terms and conditions, as offers, worthiness, warranty, and others.

Also, this report will help you to identify any trends to forecast growth rates.

The analyzed report will forecast the general tendency for supply and demand.

Some of the Organic Milk Market insights and estimations that make this study unique in approach and effective in guiding stakeholders in understanding the growth dynamics. The study provides:

Details regarding latest innovations and development in Organic Milk and how it is gaining customer traction during the forecast period.

Analysis about the customer demand of the products and how it is likely to evolve in coming years.

Latest regulations enforced by government bodies and local agencies and their impact on Demand of Organic Milk Market .

Insights about adoption of new technologies and its influence on the Organic Milk market Size.

Overview of the impact of COVID-19 on Organic Milk Market and economic disruptions caused by the pandemic.

Evaluates post-pandemic impact on the Sales of Organic Milk Market during the forecast period.

To get all-in insights on the regional landscape of the Organic Milk Market, buy now:-https://www.factmr.com/checkout/1981

After reading the Market insights of Organic Milk Report, readers can:

Understand the drivers, restraints, opportunities and trends affecting the Sales of market.

Analyze key regions holding significant share of total Organic Milk market revenue.

Study the growth outlook of Organic Milk market scenario, including production, consumption, history and forecast.

Learn consumption pattern and impact of each end use & supply side analysis of Organic Milk market.

Investigate the recent R&D projects performed by each market player & competitive analysis of Organic Milk Market Players.

How Fact.MR Assists in Making Strategic Moves For Organic Milk Market Manufacturer?

The data provided in the Organic Milk market report offers comprehensive analysis of important industry trends. Industry players can use this data to strategize their potential business moves and gain remarkable revenues in the upcoming period.

The report covers the price trend analysis and value chain analysis along with analysis of diverse offering by market players. The main motive of this report is to assist enterprises to make data-driven decisions and strategize their business moves.

Watch Trending Video on High Purity Quartz Sand Industry Survey Report by Fact.MR – https://www.youtube.com/watch?v=ItwHQrt-vmY

About Fact.MR:

Market research and consulting agency with a difference! That’s why 80% of Fortune 1,000 companies trust us for making their most critical decisions. While our experienced consultants employ the latest technologies to extract hard-to-find insights, we believe our USP is the trust clients have on our expertise. Spanning a wide range – from automotive & industry 4.0 to healthcare & retail, our coverage is expansive, but we ensure even the most niche categories are analyzed. Our sales offices in United States and Dublin, Ireland. Headquarter based in Dubai, UAE. Reach out to us with your goals, and we’ll be an able research partner.

Contact: US Sales Office : 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583 E-Mail: [email protected]

Corporate Headquarter: Unit No: AU-01-H Gold Tower (AU), Plot No: JLT-PH1-I3A, Jumeirah Lakes Towers, Dubai, United Arab Emirates

0 notes

Text

Turnkey Automation Services In Maharashtra | Electropoint Automation

Electropoint Automation is a trusted provider of turnkey automation services in various process industries. We specialize in offering turnkey automation solutions for pharma plants in Pune, Maharashtra. With our expertise and experience, we ensure seamless integration of automation systems to enhance productivity, efficiency, and compliance in pharmaceutical manufacturing processes. Contact Electropoint Automation today to explore our comprehensive turnkey automation services for your pharma plant needs.

#turnkey automation services#Pasteurizer Panels Manufacturer#dairy plant turnkey automation service in Pune#dairy plant turnkey automation service in Maharashtra#MCC & PCC Panels Supplier#CIP Panel Manufacturer#PLC & SCADA Based Automation Manufacturer#Paneer Press Panels#Paneer Press Machines#Juice & Beverage plant turnkey automation#Dairy plant turnkey automation

0 notes

Text

Dairy Automation and Control Systems in Gujarat

Saputo Process Engineering Pvt. Ltd. Provides Dairy Automation and Control Systems in Gujarat. Our Manufacturing Unit is located in Ahmedabad, Gujarat, India. Saputo Process Engineering Pvt. Ltd. Is a leading Manufacturer, Exporter, and Supplier of Milk Processing Plant, RMRD Equipment, Bulk Milk Cooler, HTST Milk Pasteurization Plant, Paneer and Cheese Processing Systems, and more. We ensure that every step of the dairy process meets stringent quality standards. Our solutions help in maintaining product consistency and minimizing wastage. Our automation solutions provide real-time data analytics, enabling you to make informed decisions. Monitor key metrics such as temperature, humidity, and product quality from anywhere, at any time. Our intuitive control panels and software make it easy for your team to operate and manage the automation systems, reducing training time and increasing efficiency. Features of Our Dairy Automation Systems: Milking Automation: Automated milking systems that enhance milking efficiency and animal comfort. Pasteurization Control: Precise control systems for pasteurization processes that ensure safety and compliance with health standards. Packaging Solutions: Automated packaging lines that improve speed and reduce errors in the packaging process. Inventory Management: Smart inventory tracking systems to manage raw materials and finished products effectively. Maintenance Alerts: Predictive maintenance features that help reduce downtime and prolong the lifespan of your equipment. Applications: Milk Production Cheese Manufacturing Yogurt Production Butter Processing Dairy Packaging Saputo Process Engineering Pvt. Ltd. Provides Dairy Automation and Control Systems in Gujarat including locations like Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Mehsana, Porbandar, Vapi, Bharuch, Palanpur, Bhuj, Valsad, Gondal, Veraval, Godhra, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For further details, please feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

UHT MILK PLANT IN MAURITANIA

Mauritania, a country in Northwest Africa, whose economy is still largely based on the agro and livestock sector reclaimed a massive portion of economic independence for its people through the installation of a UHT milk plant.

Ultra-Heat-Treatment or UHT, is a process wherein milk is heated at 135-150 degrees Celsius for only two seconds in order to kill any prevalent bacteria in the milk and increase its longevity and shelf life.

The Challenge: The aim of the Mauritania government was to reduce its dependence on imported UHT Milk. To successfully achieve which; a dynamic supply-demand chain for deliverables, with a main production unit had to be set up. The design, supply and construction of this essential service was entrusted to Jaguar Overseas Limited- JOL

The Outline

A modern, state of the art, fully equipped UHT milk plant at the provincial capital of Nema. With an addition of three milk collection centers on turnkey basis. The objective was to bring down the cost of UHT milk through local treatment, whilst ensuring optimum utilization of locally procured fresh (or raw) milk.

JOL’s Scope

With their work cut out for them, Jaguar Overseas endeavored to complete this project in record time, so as to enable Mauritania to reap its benefits as soon as possible. On top of Jaguar Overseas’s to-do list was:

To create a contemporary central processing unit, wherein manufacturing and packaging of Pasteurized Milk, Curdled milk, Yoghurt, butter and the all important UHT milk, would take place. This plant had to include:

● Power substation

● Transformer

● DG sets

● LT panels

● Refrigeration Plant

● Boiler

● Effluent Treatment Plants (ETP)

● Staff Quarters

To ensure that the plant delivered meets the highest standards that met client’s expectations and JOL’s promise; the main plant and machinery for the UHT sterilizer and the aseptic packing machinery were bought in from Europe. Whereas the remaining machinery and pre-engineering building structures were hauled in from India. The fully functional and highly productive, world class project saw fulfilment and handover in February 2017, and since then has been run and managed under the control of the Mauritania Government.

The Challenges Overcome:

To traverse a path that hasn’t been mapped is perhaps the most difficult of all tasks. For the Mauritania UHT Milk Plant Project that meant not only creating the infrastructure, but also educating the people on it, in tandem. The other technical challenges Jaguar Overseas faced included:

1. Management of Logistics- the plant was constructed 1200kms from the capital of Nouakchott, in Nema, which at the time did not possess any credible infrastructure.

2. The collection centers were located in regions with barely any construction power or even drinking water.

3. The low rainfall accompanied by perineal high atmospheric temperatures, that impeded upon everyday labor productivity.

Despite these hurdles, the UHT Plant saw successful construction and implementation amongst the local population; true to JOL’s word.

In Conclusion

The able team, spearheaded by; Mr. Manas Agarwal were able to surpass the expectation of all the elated stakeholders along with the Federal and Provincial Governments. However JOL’s true victory is conveyed by the following:

● The rural masses are now empowered with the know how and the proper infrastructure to sell their milk, with reduced dependency on imports.

● Enhanced employment opportunities in both technical and non-technical aspects have benefited every strata of the economy by increasing direct and indirect employment.

Today, the local population is claiming ownership and management of the project, verifying its success and validating all of Jaguar Overseas Limited’s earnest efforts.

0 notes

Text

Rooftop Solar Benefits and Solar Financing

Solar sector is extremely dynamic in India right now as India is the fifth biggest power generator on the planet. Exploring the rooftop solar market is crucial for India to meet its massive energy needs. Solar parks need land, and the land is scarce in a densely populated country like India. Rooftops, on the other hand, hold huge potential. Companies that want to make the transition into an eco-friendly energy option can consider investing in a rooftop solar panel setup. Taking the green approach could bring about a wide variety of advantages for businesses.

Why go solar?

Save money for other business expenses:

Sunlight is a clean as well as cost-effective source of energy unlike coal-based sources. You can utilize rooftop solar panels to reduce your energy expenses. The money saved can be hence reinvested for business expansion or purchase/update machinery.

Save on maintenance expenses:

Besides the reduced energy costs, you can expect lower maintenance. This is due to the lack of moving parts, which are prone to wear and tear, and consequently, high repair or replacement cost. The only maintenance factor for rooftop solar panels is keeping the panels free from dirt as it may obstruct the absorption of sunlight, and subsequently, the generation of electricity.

Relatively faster payoff:

It doesn’t typically take a long time to see your commercial rooftop solar investment pay off (approximately 5-6 years). It has a faster value realization.

Reduce dependence on costly power sources:

If you are a rural consumer or situated at a remote location, solar is the most economical solution to complete your electricity needs. By using rooftop solar power, you can not only stabilize your existing electricity supply but also reduce your dependence on more expensive sources of power like diesel generators and inverters.

Flexibility of utilization:

When many people think of solar power possibilities, they consider interior lighting as the only application. Besides that, solar energy, when converted into heat energy, can be utilized for – hot water usage for bathing and washing, boilers, Pasteurization, condensation and cleaning in milk dairies, drying and tanning in leather process industries, degreasing and phosphating in metal finishing industry, resin emulsification in polymer industry, drying in food, wood, livestock etc., all of which could boost a company’s cost efficiency.

However, the upfront cost of a rooftop solar power system can be sizeable, especially depending on your specific needs. Financing and service have to become an integral part of the solar solution offerings. SMEs can opt for financing solutions to cover up the purchase and installation costs.

For MSMEs, installing a rooftop solar power unit can be a trouble for multiple reasons. Due to credit ratings limit, it is difficult for small entrepreneurs to raise funds from banks. Even though lending institutions like banks have got rooftop specific credit lines and are providing loans at concessional rates and both private sector and nationalized banks have been very forthcoming in providing loans for financing rooftop solar projects, higher interest rates are another challenge for SMEs. Some lending institutions also need collateral even for small loan amounts, which can be a crisis for some SMEs. It is crucial to select a solar financing choice that suits your establishment.

Electronica Finance Ltd. offers a rooftop solar power loan at attractive interest rates to not only manufacturing companies, but also to educational institutions, hospitals, service industries etc. to encourage the use of solar energy. It is the only NBFC which offers a rooftop solar power loan. The loan covers around 75% value of system or installation. For loan amount up to Rs.15 lakhs, it can be availed collateral-free. Interest rates are flexible and based on the customer’s profile. EFL rooftop solar panel loans can be availed within 7 working days and require minimal documentation.