#PVC Foam Board Sheets Printing

Explore tagged Tumblr posts

Text

Lightweight Materials for Temporary Ceilings: A Comprehensive Guide

Temporary ceilings are a versatile solution for events, exhibitions, renovations, and many other applications where a permanent structure isn't feasible. A key consideration when designing temporary ceilings is the choice of lightweight materials, which make installation easier, reduce costs, and provide flexibility in design. In this blog, we explore some of the best lightweight materials for temporary ceilings and their unique benefits.

1. Fabric

Fabric is one of the most popular materials for temporary ceilings due to its versatility and aesthetic appeal.

Advantages:

Lightweight and easy to handle.

Can be draped, stretched, or layered to create different effects.

Available in a wide range of colors, textures, and transparency levels.

Fire-retardant options are available for safety.

Applications:

Event venues, such as weddings and parties.

Exhibition booths to add a touch of elegance.

Temporary shading in outdoor spaces.

2. PVC Panels

PVC (Polyvinyl Chloride) panels are another excellent choice for temporary ceilings. These panels are both lightweight and durable, making them ideal for short-term use.

Advantages:

Water-resistant and easy to clean.

Quick to install and dismantle.

Available in various designs, including faux wood and metallic finishes.

Applications:

Temporary office spaces or conference rooms.

Outdoor event tents to protect against the elements.

3. Acrylic Sheets

Acrylic sheets are transparent or translucent, making them perfect for designs that require light diffusion.

Advantages:

Lightweight yet sturdy.

Allows natural or artificial light to pass through, creating bright spaces.

Available in clear, frosted, or colored varieties.

Applications:

Backlit ceilings for exhibitions or art installations.

Modern designs for temporary retail spaces.

4. Foam Boards

Foam boards are an affordable and highly customizable option for temporary ceilings.

Advantages:

Extremely lightweight and easy to cut into shapes.

Can be painted or printed on for creative designs.

Provides some soundproofing.

Applications:

Trade shows and promotional events.

Themed parties or photo backdrops.

5. Aluminum Composite Panels (ACP)

ACP is a lightweight yet durable option for more robust temporary ceiling structures.

Advantages:

Strong and weather-resistant.

Sleek and modern appearance.

Easy to install with a framing system.

Applications:

Temporary retail kiosks.

Outdoor events requiring wind resistance.

6. Cardboard

While unconventional, cardboard can be a sustainable and creative option for temporary ceilings.

Advantages:

Eco-friendly and recyclable.

Lightweight and easy to shape.

Can be painted or printed for unique designs.

Applications:

Art installations or pop-up exhibits.

Budget-friendly events with a focus on sustainability.

7. Mesh or Netting

Mesh or netting is ideal for lightweight, breathable ceiling designs.

Advantages:

Extremely lightweight and easy to install.

Allows airflow while creating a semi-covered space.

Can be adorned with lights, flowers, or other decorations.

Applications:

Outdoor events like garden parties.

Concert stages and festival tents.

Tips for Choosing the Right Material

When selecting lightweight materials for temporary ceilings, consider the following:

Purpose: The material should align with the intended use and aesthetic of the space.

Safety: Ensure the materials meet fire safety regulations, especially for indoor use.

Budget: Some materials, like acrylic or ACP, may be more expensive but offer enhanced durability and aesthetics.

Ease of Installation: Lightweight materials reduce labor and installation time.

Reusability: Opt for materials that can be repurposed or recycled to minimise waste.

Conclusion

Lightweight materials for temporary ceilings offer endless possibilities for creativity and functionality. Whether you're hosting an event, designing a pop-up space, or working on a short-term project, choosing the right material is crucial for achieving the desired look and performance. Explore the options mentioned above and let your imagination soar while keeping practicality in mind.

Have you used any of these materials for your temporary ceiling projects? Share your experiences and ideas in the comments below!

0 notes

Text

6 Essential Things To Know Before Purchasing PVC Foam Board

PVC Foam Board is an excellent polymer board used in various applications. It is ideal for all kinds of cabinetry because it is lightweight, waterproof, and strong.

It can be made in various thicknesses and color and is widely used for panels, cabinet doors, construction, and wall sheeting.

Upheld by observation and a deep dive into its application across industries, here’s the list of all the data and basic perspectives to pay special attention to while purchasing a PVC Foam Board in India.

6 Essential Things To Know Before Purchasing PVC Foam Board

When purchasing certain products such as PVC foam sheets or WPC Door Frame, there’s no doubt that JKD Plastics is the best.

Now coming to the article, If PVC is something new to you, you must understand its basics, such as properties, applications, etc.

How are PVC Foam Boards Made?

Petroleum products, resins, and inorganic chemicals manufacture PVC foam boards. After that, these components are combined under controlled conditions and poured into a mould tailored to the intended use. The compound is warmed during this process, permitting it to be shaped or moulded into the ideal form. After that, it is cooled to harden into the desired shape or profile. Depending on the final application, the finished product can be cut, routed, bent, glued, or left in its original state.

Is PVC Foam Boards Water Resistant?

PVC foam boards resist moisture. They also have a particular composition that makes them water-resistant, preventing them from swelling or changing shape when wet. PVC foam boards absorb less than one percent of water, significantly less than wood.

Are they Sturdy Enough?

The molecular structure of PVC foam sheets ensures they remain firm when cooled. Consequently, they are long-lasting and deformation-resistant unless subjected to extreme heat. These foam boards are known to go on for around thirty to forty years without harm, although typical wearing is obvious.

What Are They Mainly Used For?

PVC foam sheets are used in construction and building, advertising and signage, interiors and furnishings, screen printing and graphics, and the refrigeration industry due to their outdoor-friendly properties.

How Can PVC Foam Boards Be Checked For Quality?

PVC foam sheets are quality checked in various ways by various brands. However, the following are some common tests used to evaluate the performance of PVC foam sheets:

Fire Test: PVC foam sheets used in fire tests must have a class A flame spread rating. PVC froth sheets, when in touch with fire, self-quenches.

Moisture Absorption Test: PVC foam sheets are soaked in water. The weight of the PVC foam sheet before it is submerged in water can be compared to that of post-submerging into the water to detect the rate at which it absorbs moisture. PVC should have a water absorption rate of less than 1%.

Strength Test: To see if the foam sheet can withstand direct impact and heavy weight, it is put through a series of strength testing activities.

What is the Price of PVC Foam Boards?

The plastics with the lowest prices are PVC Foam Sheets. It is once in a while more costly than wood; however, when you represent PVCs’ low maintenance qualities, PVC’s long-term cost is much lower than wood.

Why Should You Go For PVC Foam Board in India

Using these boards for your project is optimal due to their durability. This substance is appropriate for use both inside and outside since it resists moisture. PVC foam board can withstand wear and tear over time because it is resistant to scratches, dents, and other forms of damage. Additionally, due to its lightness and strength, PVC foam board is an excellent choice for projects that require flexibility and durability.

PVC foam board is simple to set up. This material can be effortlessly cut and moulded using standard devices, making it simple even for those with minimum Do-It-Yourself experience. Additionally, mounting PVC foam board is simple with various adhesives or screws. PVC foam board is even more cost-effective because you can save time and money on installation costs.

If you wish to own the best PVC foam board or WPC Door Frame, JKD Plastics always delivers the best quality output. After learning about the numerous benefits, it’s normal that you would consider exploring or purchasing a product. Still, you should always go for the best.

Source URL : https://tealfeed.com/6-essential-things-know-purchasing-pvc-b8fcx

#pvc foam board#wpc door frame#wpc manufacturers in india#wpc board#pvc trim board#wpc moulding#wpc doors#pvc foam board exporters in india#wpc chokhat#pvc foam board in india

0 notes

Text

From Vision to Display: A Chronicle of Human Expression Through Printing

Introduction:

Imagine a world, where the ideas were within few minds. And those ideas could only flit from whisper to ear without leaving any lasting trace. Hence, the printing press came into the picture. The printing press puts a transformative impact on each and every aspect of society. Some of the ideas can be mentioned like distribution of pamphlets and treatises, publishing scientific advancements and birth of newspaper. The printing press served as one of the most important tools for cultural, intellectual and social transformations by leaving an incredible mark on the course of history. From the journey of Concept to Canvas, there are certain innovative changes in the material of Melbourne.

The Journey of Concept to Canvas:

Melbourne stands as one of the leading suppliers of panel materials in Australia. The Display Material in Melbourne is one of the finest materials for the printing purpose. They give their expertise and diverse product range to the local market. It provides a wide range of panelling materials like:

PVC Foam Board: Lightweight, versatile, and weather-resistant, ideal for signage, displays, and architectural applications.

Aluminium Composite Panel: Strong, durable, and aesthetically pleasing, perfect for building cladding, signage, and interior design.

PP Corflute Sheet: Affordable, lightweight, and waterproof, suitable for temporary signage, packaging, and point-of-purchase displays.

PS Paper Foam Board: Smooth, printable, and cost-effective, ideal for mounting photos, posters, and artwork.

Cast Acrylic Sheet: Crystal-clear and impact-resistant, excellent for glazing, displays, and fabrication projects.

Aluminium Tread Plate: Slip-resistant and durable, used for flooring, ramps, and walkways.

Paper Honeycomb Board: High-strength, lightweight, and environmentally friendly, perfect for furniture, partitions, and exhibition booths.

Business Card Printing : As a Visual Identity:

Whether your company is large or small, business cards are considered as one of the essential assets for networking and promotional purpose.

By designing professional business cards will improve you to stand out in a busy marketplace.

It will also give you an edge over the competitors.

Business cards not only provides a detailed information about your personality but also shows about your uniqueness among the competitors.

Changing Melbourne’s Landscape: Building and Signage Prints

Building and Signage prints are important part of the City’s landscape. It also changes the ordinary structure into an extraordinary change.

Building and Signage prints of Victoria is one of the bright examples for dynamic display of creativity.

Signage has evolved beyond its functional role to become an art form that communicates brand identity and captures the attention of passersby.

From bold graphics to subtle elegance, the cityscape reflects the diversity of businesses and their stories.

HP Printing Solutions: Evolving Creativity and Technological Innovations:

Wait for what! Decorate your canvas with the creative printing experience of HP Printing Solutions. With the advancement of color printing technology, your imagination can be transformed into a piece of paper colorfully. For further related doubts you can explore the HP Printing Solutions https://hpprintingsolutions.com.au and also our contact +61 425842584.

0 notes

Text

pvc foam sheet board manufacturing machine price

Extrusion lines for Sheet and Board Cheap, resistant and completely recyclable, WPC PVC represents a new frontier in the field of buildings and industry materials, with a variety of applications. PVC WPC Sheet Board and Profiles are used in common applications such as decking, furniture, floor board and kitchens.wpc pvc Wall Ceiling Panel making machine price With EXTRUDERVIP technology, it is possible to obtain profiles composed of natural fiber up to 80%, with features that make them better than wood in terms of reliability, performance and production costs. EXTRUDERVIP also produces systems for the manufacture of WPC (Wood Plastic Composite) granules, which in turn can be transformed in finished product through molding or extrusion. WPC PVC Foam Sheet Application Architecture decoration industry: building template board, outdoors plate, indoors decoration plate, residential house, office, separation of public building, commercial decoration frame, plate used in dust-free room, ceiling plate. Household decoration: bathroom cabinet board, kitchen cabinet, furniture board, home decoration board, various household shelves. Advertisement industry:Screen printing, computer engraving, advertising board, exhibition plate, logo plate. Transport industry: ship, plane, bus, and train, floor covering, core layer, indoors decoration plate. Industrial application: rot proof project in chemical industry, thermal shaped part, plate for refrigeration warehouse, special cool-keeping protection plate. Other applications: construction mold plate, sports apparatus, aquaculture material, seashore wet-proof facility, water-resistant material, arts material and all sorts of light separation plate.

1 note

·

View note

Link

Meghmani is one of the best chemical, dyes, decorative marble UV sheets, PVC marble sheets, flex/banner, wpc sheet, digital printing INK & Packing solutions manufacture & supplier company in India.

#best chemical supplier in india#crop protection chemicals#industrial chemical suppliers#pvc imitation marble sheet#flex / banner#PVC foam boards / sheets#WPC Sheets#digital printing INK#Packing Solutions India

1 note

·

View note

Photo

BHARAT AUTOMOBILES Wholesalers & Dealers In all types of signature material * PVC Foam Boards * PVC Flex Material * Digital Printing Head Inks * Sunpac * Etching Films * All Types Of Acrylic Sheets * Radium & Vinyl * 3M Reflective Tape * All Types Of LED Module Series * Radium Cutting Machine ( plotter ) VISIT STORE- 1029, Fort Road, Opp Majestic Hotel Belagavi-02 KA CALL NOW- +919448860102 +919916891886 WEB- https://www.biztoll.com/ViewBusinessDetails.aspx?CsId=2696 #automobiles #vinyl #acrylic #PVCFoamBoard #bharatautomobile #biztollautomobile #biztollbharatautomobile #bharat #biztoll #automobile #belgaum #belagavi #top #Radium #wholesale #retail (at Fort Road) https://www.instagram.com/p/CK1qNW7Bixr/?igshid=1m1fnpmpn1mbz

#automobiles#vinyl#acrylic#pvcfoamboard#bharatautomobile#biztollautomobile#biztollbharatautomobile#bharat#biztoll#automobile#belgaum#belagavi#top#radium#wholesale#retail

1 note

·

View note

Photo

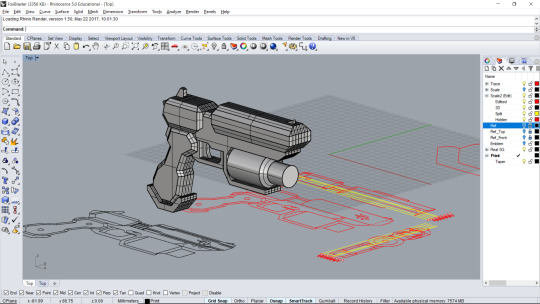

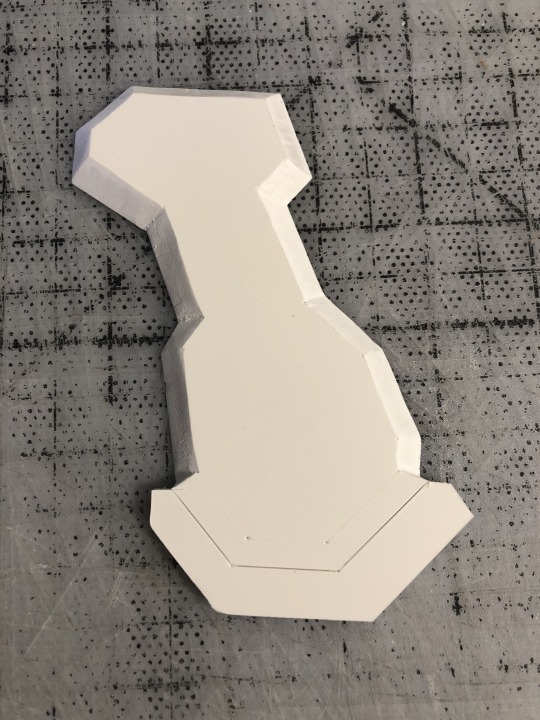

Fox’s Blaster (Super Smash Bros Ultimate)

This is my first finished prop and I am incredibly proud of it. It is not my first prop because I’ve started a few in the past and just never got around to finishing them either for complications, not enough skill, or just boredom; but it is the first prop I’ve completed. I intend to finish all those other, but I just wanted to ride the motivation for this one and it certainly paid off.

For anyone interested in how I made it, please continue reading.

(Tried to edit which messed up my post so most of the pictures are unreadable. Trying to fix, but connection is shoty. Check out someones reblog to see all)

Step 1: References and Drafting

First I needed to get some reference images for the blaster. Thankfully, Smash Bros has a convenient in-game camera mode so I was able to zoom in and take screenshots of the blaster in any frame of gameplay.

I briefly considered making the blaster able to open up like in the second image above, but I had no idea how to do that and figured it’d take too long to figure it out, let alone actually make a prop capable of that. So, I decided on a single piece prop with nothing moving. Better to keep things simple when you’re starting out.

Now I had to draft outlines for it. I use Rhino 3D for all of my drafting, whether 2D or 3D.

I imported my reference images and traced them as best I could. Unfortunately, since there’s no option to turn off perspective in Smash, some dimensions were a bit off, but hardly an issue.

Before I went any further, I needed to make sure I had the right scaling, so I made a mock-up. Since I needed the handle to fit my hand, I made it out of layers of PVC foam board and just used cardboard for the rest of the gun.The sizing was actually perfect by coincidence, but I needed to determine the best thickness. I tried out a few thicknesses for the handle with different numbers of layers and found 5 layers of 6mm foam board was perfect.

Next I made a 3D model to make sure all my dimensions looked right when put together.

Step 2: Materials

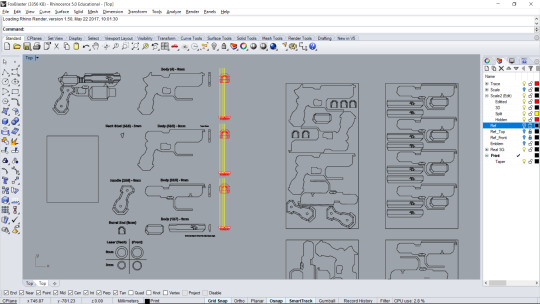

Before I did anything to start making the physical prop, I had to plan out all my materials and cuts. I did some adjustments to my traces so that a length wise cross section would fit into several pieces of equal size. Below, to the left of the yellow lines, are one of each kind of cross section I need. There are 7 total layers. The largest pieces are within layers 2-6, comprising the main body of the blaster and part of the handle, as well as support for the laser-sight barrel. After those are the two outer layers for the handle which will have some beveling, and then layers 1 & 7 include a few smaller pieces to add bulk to the two bulging sections at the top of the gun.

The section to the right of the yellow lines are for planning out how many cuts to fit into each board of material (For some reason I doubled a few layers on the right sheet, not sure why).

Materials (everything in the finished product):

6mm PVC foam board (celtec)

1″ PVC pipe

1.5″ PVC pipe

PVC cement

Spray paint

Acrylic paint

Tools and disposable materials:

X-acto knife

Straight-edge of some kind

Sand paper, both fine and course versions

Blue painter’s tape

Brown paper

PVC pipe cutter (any kind of saw will also work)

Thumbtack (or something with a fine point)

Large piece of cardboard (painting surface; can use whatever you don’t mind being spray painted)

I spent some time debating what I wanted the blaster to be primarily made out of. I had worked with PVC foam board before and I knew it was high quality and would provide a good weight to the prop. I also considered EVA foam which I’d just heard about at the time, or just plain cardboard. PVC foam board was the best choice, though I does take a few passes with an X-acto knife to cute through 6mm, but if you’re patient it’s worth it.

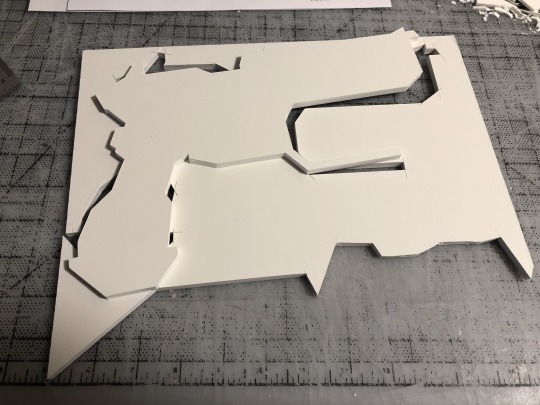

Step 3: Cut and Assemble

Now comes the tedious part.

Since I had digital plans I printed out full-scale outlines of each part. I then taped the sheets down on the PVC boards and used a thumbtack to poke the corners of the outlines and leave small impressions in the board. Then with a straight-edge I used my X-acto to connect the dots and cut out each piece.

Below is layer 5, i.e. the middle most piece of the blaster.

The PVC board is pretty dense, which adds to it’s quality, but like I said I had to run through each line several times before cute when all the way through. Do not rush this part. I may have been a bit too anal about it, but I did not want any mistakes at all.

Some pieces required beveling. I do not have any kind of table saw or other tool made specifically for beveling so I did it all by hand with my X-acto knife. This requires even more patience than the last part. Once you cut too much, you can get it back on and look the same. I recommend listening to some music or have a show play in the background, just be careful with the knife and always cut away from yourself.

Once all the board and pipes where cut I cemented everything together. You can see the other parts which have beveling. Again, takes a long time, especially when it’s circular.

What I found is despite my best efforts, not all the parts where exactly aligned and flush with those next to it. this part was 0.5mm too high here. This one was 1mm too thick there. I spent a lot of time sanding everything down so the edges were all aligned. I didn’t get everything perfecting flush due to my limited tools, but I was happy with it. This actually killed two birds with one stone because I would have needed to sand it down anyway so the paint would hold onto it better.

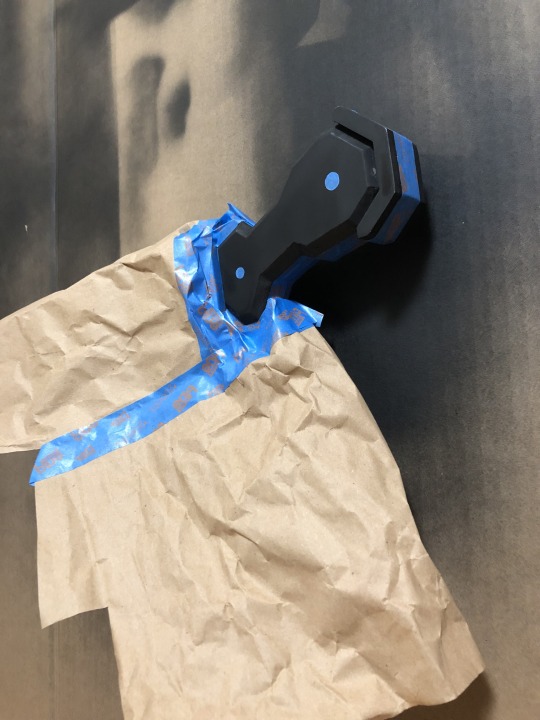

Step 4: Painting

Now for the fun part.

The base of the blaster is black so I can paint the whole thing a black coat, but for the grey on parts like the outer handle I’ll have to tape sections off to protect the black.

As you can see, the only thing I taped off from the black coat was the Star Fox emblem on both sides of the barrel. Since it’s small with lots of curves and made of tape, I had to be delicate with cutting it.

But I think it worked out. Just a little tap residue to wipe off.

The grey was fun because of how I had to weave tape between all the joints and crevices. As you can see, used brown paper and taped that on, rather than cover the whole thing in a layer of tape. Just tape along the edge of the paper and attach.

Lastly, the finer details, i.e. anything orange or blue. I did all these details by hand, again using painter’s tape to make sure my lines were exact. Don’t forget to sand whenever you put on a new layer of paint. I forget to sand for the orange on the picture below the first time and the acrylic ended up peeling off. Sand so the paint can grip onto something rather than a smooth surface.

And voila!

Pretty damn close to Nintendo’s replica (below), don’t you think?

From start to finish, this took me about 2 months in my down time. 1 month drafting and obsessing over how every detail needed to be replicated perfectly, and 1 month of actually building it. I should have paid a little more attention to the spray painting, though. I’ve never spray painted before I had trouble figuring out the right distance to hold the can, and some of the grey paint found it’s way under some edges of the tape, but not a big deal. And maybe some time spent to texture the handle.

Overall, I absolutely love it! It’s got a great weight to it, feels wonderful in my hand. I don’t think I’ll ever cosplay as Fox, but this has been a wonderful use of my down time rather than just web-surfing and video games all the time. I built something with my hands. There’s nothing quite like it.

If you enjoyed this, consider supporting me on Patreon at https://www.patreon.com/erikchamber

#star fox#fox's blaster#smash bros#super smash bros ultimate#ssbu#smash bros ultimate#gotta blast#cosplay#prop#cosplay prop#sci-fi#pvc foam#first cosplay#blaster#nintendo#fox mccloud#spam b

64 notes

·

View notes

Link

Established in 2012, Navratan LLP ( Known as Megasign ) is engaged in manufacturing, supplying and exporting the premium quality flex banners, decorative PVC sheets, PVC laminated tarpaulins, digital printing inks, PVC foam boards, and Warp knitted polyester fabric. Using the most advanced technologies in our state of the art manufacturing facility, our experienced professionals develop the most innovative products completely complying with international quality standards and benchmarks. We use the finest quality raw materials sourced from our reliable vendors, and ensure that all products are dynamically tested on a broad spectrum of quality parameters to ensure flawlessness and top-notch quality.

1 note

·

View note

Text

10 Things You Need to Know About Foamex

Foamex has become quite a popular material in recent times for signage printing, with a lot of brands choosing Foamex printing for their indoor as well as outdoor signage. The versatility and affordability of the material has made it well worth the popularity, so much so that it is one of the most widely used materials today. So let's take a look into the world of Foamex Board and talk about 10 really interesting facts that are sure to interest you and tell you more about this fantastic material that has taken the signage printing world by storm:

Foamex does not refer to the material per se, the material is actually expanded vinyl, and Foamex is the name of the brand. Produced in Switzerland, the company generally supplies the board across the globe and has patented it.

When looking into the creation of Foamex as a material, it was made by compressing PVC foam (don't let the name fool you, it really does not mean that there is any foam in it) to create a board that was durable and also all-weather resistant.

Foamex is rigid in nature and is also hardwearing. Owing to this fact, Foamex is also lightweight, which makes it so perfect for use in outdoor and indoor signage both. While the heavier materials come with the headache of affixing it as well as transporting it, Foamex Board, on the other hand owing to its lightweight nature, does not pose any of these problems.

Since we mentioned earlier that the material is all weather resistant, this means that the changes in temperature or humidity will not end up affecting it. When you compare it to other lighter materials like Correx, that doesn't do so well in outdoor conditions, Foamex, on the other hand, is perfect for both indoor and outdoor usage, so much so that its longevity ranges from somewhere between 3 to 5 years when used outdoors.

Exactly suited for signage printing, a Foamex board can give you vivid results and really bring your designs to life. You can use various kinds of finishes on your signage, which will give it a professional touch and also an air of being expensive. Hence, when you are looking for cost-effective ways to create professional signage that will also last Foamex becomes one of the best options out there.

Signage made out of Foamex is quite easy to mount and one of the best things about them is the fact that they can be affixed to almost any surface, so much so that you could even use double-sided tape or Velcro to mount them with ease and not have to worry about anything.

Foamex is quite easy to customize owing to its lightweight nature, this means that you can mould it to any size as well as design with something as simple as the conventional tools that are used like a jigsaw, drill, etc.

Another great thing about a Foamex Board is the variety of colours that are available in it. Offered in a wide range of colours, it is quite easy to find a sheet in the colour that you are looking for. However, if you are not looking for coloured sheets in particular, the crisp white colour of Foamex is perfect for you to print your designs on it, giving you a vivid payoff.

Apart from using it just for signage, a Foamex board can also be used for personal purposes in your home. You can use them as decorative whenever you want to cover your walls which might have some imperfections in terms of surface texture or even a bad patch that you want to cover.

Another really unique and exciting feature of a Foamex sheet is that you can use a technique which is known as wrapping, which is generally done to the corners of the board. When this technique is applied, you will generally not need a frame to display your board, and it can act as a standalone entity.

With the different kinds of usage and purposes that we told you about, you can understand how Foamex is such a versatile material that can be used for almost any sort of printing needs! So be it thinking about using it for indoor signage or for outdoor signage purposes, it can suit and serve all your needs without any sort of hassles coming your way. Ranging from how easy it is to transport and mount, to the varied options you get in terms of sizes, and colours Foamex printing when well utilised can go a long way in giving you fantastic results that will only help you in creating the right kind of promotional material for your business.

1 note

·

View note

Text

Artist Presentation Research - 50 Artists

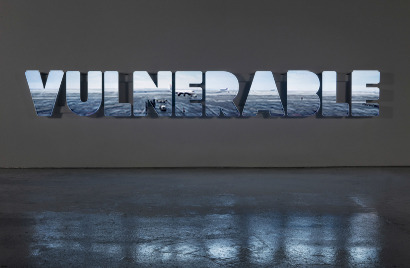

1. Artist name: Doug Aitken

Title of Work: Text Sculptures Series; Vulnerable

Date: 2008

Materials: LED lit lightbox

Dimensions: 28 x 216 1/2 x 7 1/2 inches

(The rest under the cut)

2. Artist name: Richard Artschwager

Title of Work: Piano Grande

Date: 2012

Materials: Laminate on wood

Dimensions: 46 x 79 1/2 x 35 inches

3. Artist name: Matthew Barney

Title of Work: Ancient Evenings: Khaibit Libretto

Date: 2009

Materials: Graphite and ink on paperback copy of Ancient Evenings by Norman Mailer, on carved salt base, in nylon and acrylic vitrine

Dimensions: 15 1/2 x 13 3/4 x 14 3/4 inches

4. Artist name: Joseph Beuys

Title of Work: Amerikanischer Hasenzucke

Date: 1974

Materials: Multiple of offset lithograph with stamp additions and cardboard box, containing sugar packet and cotton wool

Dimensions: 35.4 x 24.7 inches

5. Artist name: Jonathan Borofsky

Title of Work: People Tower

Date: 2008

Materials: Painted steel

Dimensions: 20 meters tall

6. Artist name: Louise Bourgeois

Title of Work: Maman

Date: Late 1990’s

Materials: Steel and marble sculpture from which an edition of six bronzes were subsequently cast

Dimensions: Over 30 feet

7. Artist name: Chris Burden

Title of Work: Metropolis

Date: 2006-2010

Materials: 3 hp DC motor controllers, 1080 custom manufactured die-cast cars, HO-scale train sets with controllers and tracks, steel, aluminum, shielded copper wire, copper sheet, brass, various plastics, assorted woods, manufactured wood products, Legos, Lincoln Logs, Dado Cubes, glass, ceramic/natural stone tiles, acrylics/oil base paints, rubber, and sundry adhesives

Dimensions: 117 x 339 x 230 inches

8. Artist name: Daniel Buren

Title of Work: Colours for a Pergola: situated work

Date: 2014

Materials: Clear acrylic sheets, coloured self-adhesive filters, wood, screws, white paint, self-adhesive black vinyl

Dimensions: 3 x 9 x 3 m / 7.6 x 22.9 x 7.6 cm m

9. Artist name: Janet Cardiff

Title of Work: Dreams - Telephone Series

Date: 2008-2010

Materials: Telephone, iPod

Dimensions: 6 X 8 3/4 X 5 1/2 inches

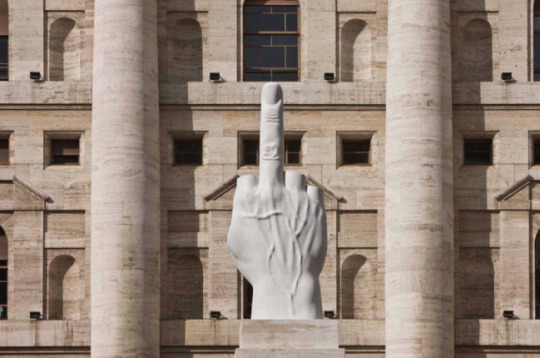

10. Artist name: Maurizio Cattelan

Title of Work: L.O.V.E.

Date: 2010

Materials: White Carrara Marble, roman travertine

Dimensions: 36.1 x 15.5 x 15.5 ft

11. Artist name: Willie Cole

Title of Work: Dasani Beach Bird

Date: 2016

Materials: Recycled bottles and pvc

Dimensions: 6ft

12. Artist name: Jimmie Durham

Title of Work: A Meteoric Fall to Heaven

Date: 2000

Materials: Armchair and stone

Dimensions: 31 1/2 × 19 7/10 × 25 3/5 in

13. Artist name: Tracy Emin

Title of Work: You Loved Me Like a Distant Star

Date: 2015

Materials: Offset lithograph

Dimensions: 19 7/10 × 27 3/5 in

14. Artist name: Dan Flavin

Title of Work: an artificial barrier of blue, red and blue fluorescent light (to Flavin Starbuck Judd)

Date: 1968

Materials: Blue and red fluorescent light

Dimensions: Modular units, each made of two 2-foot (61 cm) vertical fixtures and two 4-foot (122 cm) horizontal fixtures; length variable

15. Artist name: Katharina Fritsch

Title of Work: Frau mit Hund (Woman with Dog)

Date: 2004

Materials: Polyester, iron, wood and paint

Dimensions: 69 x 69 x 42 inches

16. Artist name: Anya Gallaccio

Title of Work: Preserve ‘Beauty'

Date: 1991-2003

Materials: 900 red gerbera 'beauty' pressed behind glass

Dimensions: 86.61 x 43.31 inches

17. Artist name: Gilbert & George

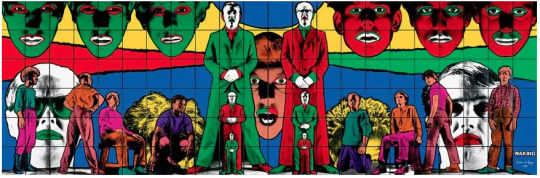

Title of Work: Waking

Date: 1984

Materials: Photo-piece

Dimensions: 11 feet 15/16 inches x 36 feet 3/8 inches

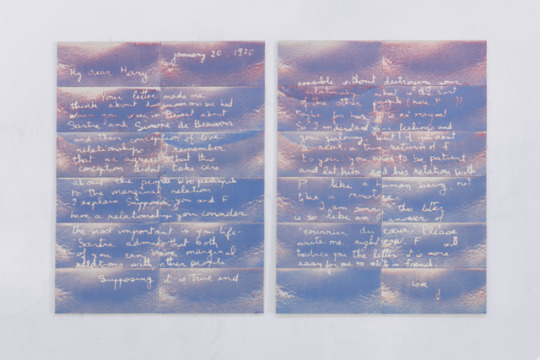

18. Artist name: Felix Gonzales Torres

Title of Work: Untitled

Date: 1992/1993

Materials: Print on paper, endless copies

Dimensions: 8 inches at ideal height x 48 1/4 x 33 1/4 inches

19. Artist name: Douglas Gordon

Title of Work: Exhibit D

Date: 2016

Materials: Carrara marble

Dimensions: 6 11/16 x 4 5/16 x 3 9/16 inches

20. Artist name: Dan Graham

Title of Work: Two 2-Way Mirror Ellipses, One Open, One Closed

Date: 2011-12

Materials: Stainless steel and 2-way mirror

Dimensions: 90 1/2 x 138 x 295 in.

21. Artist name: David Hammons

Title of Work: Pray for America

Date: 1969

Materials: Screenprint and pigment on paper

Dimensions: 60 1/2 × 30 inches

22. Artist name: Mona Hatoum

Title of Work: Grater Divide

Date: 2002

Materials: Patinated mild steel

Dimensions: Overall (overall open - in S shape with 90 degrees angles): 203.2 x 193 x 83.8 cm (80 x 76 x 33 in.) Overall (overall closed/folded): 203.2 x 88.9 x 20.3 cm (80 x 35 x 8 in.)

23. Artist name: Eva Hesse

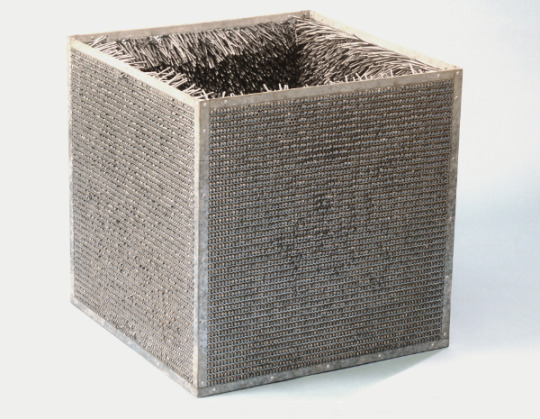

Title of Work: Accession II

Date: 1969

Materials: galvanized steel and vinyl

Dimensions: Overall - 30 3/4 x 30 3/4 x 30 3/4 inches

24. Artist name: Gary Hill

Title of Work: Learning Curve

Date: 1993

Materials: Video (color, silent), projector, plastic, plywood, stainless steel, media player, laserdisc

Dimensions: 35 × 128 × 204 inches

25. Artist name: Damien Hirst

Title of Work: San Souci (Carefree) H4-1

Date: 2018

Materials: Diasec-mounted Giclee print on aluminium panel

Dimensions: 36 11/50 × 49 61/100 in

26. Artist name: Jenny Holzer

Title of Work: All Fall. Text: Truisms

Date: 1977-79

Materials: Sculpture, Array of 5 double-sided LED signs with stainless steel housings: blue & green diodes on front, red & yellow diodes on back

Dimensions: 103.5 x 103.3 x 95.1 inches

27. Artist name: Gary Hume

Title of Work: Untitled 03

Date: 2006

Materials: Linocut print on paper

Dimensions: 555 x 400 mm

28. Artist name: Donald Judd

Title of Work: Untitled

Date: 1963

Materials: Cadmium red light oil on woo with violet acrylic sheet

Dimensions: 20 x 48 5/8 x 47 5/8 inches

29. Artist name: Jesper Just

Title of Work: Intercourses #2

Date: 2014

Materials: Silver Gelantin Print

Dimensions: 29 9/10 × 56 7/10 inches

30. Artist name: Ilya Kabakov

Title of Work: TV

Date: 2005

Materials: Installation, Oil on glass

Dimensions: 16.9 x 15.4 x 11.8 inches

31. Artist name: Nina Katchdorian

Title of Work: Mended Spiderweb #8 (Fish Patch)

Date: 1998

Materials: Cibachrome

Dimensions: 20 x 20 inches

32. Artist name: On Kawara

Title of Work: I Read

Date: 1966-1995

Materials: Clothbound loose-leaf binders with plastic sleeves and inserted printed matter

Dimensions: 11 1/2 × 11 3/4 inches

33. Artist name: Mary Kelly

Title of Work: Beirut

Date: 2017

Materials: Compressed lint

Dimensions: 41 5/8 × 59 3/8 × 2 inches

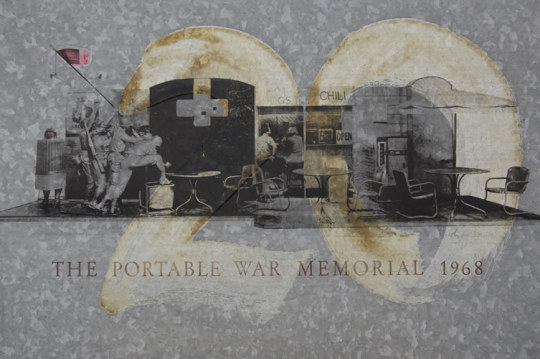

34. Artist name: Ed & Nancy Keinholz

Title of Work: The Portable War Memorial

Date: 1968

Materials: mixed media assemblage

Dimensions: 22 1/4 x 33 1/8 x 3 inches

35. Artist name: Jeff Koons

Title of Work: Bouquet of Tulips

Date: 2016

Materials: polychromed bronze, stainless steel, and aluminum

Dimensions: 409 1/2 (459 with base) x 324 3/4 x 400 3/8 inches

36. Artist name: Joseph Kosuth

Title of Work: Catharsis, Conversion, Traumata

Date: 1986

Materials: neon, transformers

Dimensions: 38 3/16 x 74 inches

37. Artist name: Wolfgang Laib

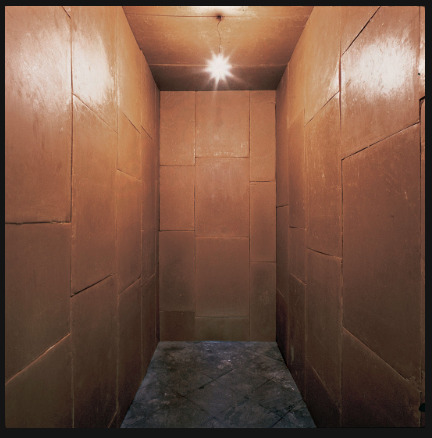

Title of Work: For Another Body

Date: 1988

Materials: Beeswax, brick construction, stucco

Dimensions: 11 ½ × 5 ¼ × 13 feet

38. Artist name: Christian Marclay

Title of Work: Scream (Eye Popping)

Date: 2017

Materials: Woodblock prints

Dimensions: 66.5 x 121.5 cm

39. Artist name: Barry Mcgee

Title of Work: Untitled

Date: 2018

Materials: Paintings, Acrylic and aerosol on canvas, 9 elements

Dimensions: 44 x 38 inches

40. Artist name: Mario Merz

Title of Work: Unreal City, Nineteen Hundred Eighty-Nine

Date: 1989

Materials: Glass, mirror, metal pipes, twigs, latex rubber, clay, polyethylene bags, and clamps

Dimensions: 16 feet 4 7/8 inches x 41 feet 11 15/16 inches x 32 feet 8 inches (5 x 12.8 x 9.9 m) overall

41. Artist name: Annete Messanger

Title of Work: Mes Voeux Cercle - Triangle

Date: 1990

Materials: Installation, Photographs, Framed black and white photographs, strings

Dimensions: Size Notes: Height with strings: 98 7/16 in. (250 cm) Circle: 57 7/8 x 55 1/8 in. (147 x 140 cm)

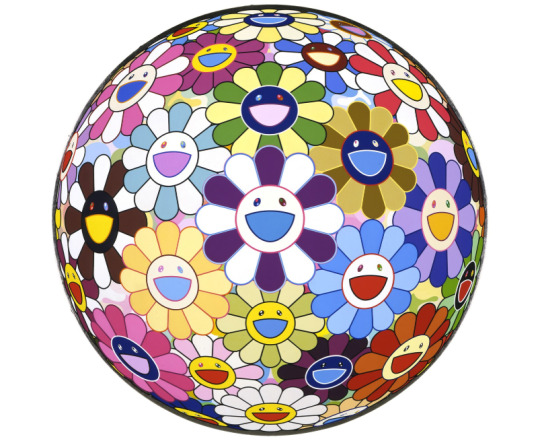

42. Artist name: Takashiki Murakami

Title of Work: Flower Ball (3-D), Kindergarten

Date: 2007

Materials: Acrylics and silver gold leaf on canvas mounted on board

Dimensions: 39 1/2 x 39 1/2 inches

43. Artist name: Bruce Nauman

Title of Work: None Sing Neon Sign

Date: 1970

Materials: Ruby-red and cool-white neon

Dimensions: 13 x 24 1/4 x 1 1/2 inches

44. Artist name: Hermann Nitsch

Title of Work: Schüttbild

Date: 2014

Materials: Paintings, Acryl auf Jute acrylic on jute

Dimensions: 78.7 x 118.1 inches

45. Artist name: Cady Noland

Title of Work: Tower of Terror

Date: 1993–1994

Materials: cast aluminum stockade, bench, link chain, padlocks, key

Dimensions: 65.6 x 158.1 x 50 inches

46. Artist name: Claes Oldenburg

Title of Work: Batcolumn

Date: 1977

Materials: Steel and aluminum painted with polyurethane enamel

Dimensions: 96 ft. 8 in. (29.5 m) high x 9 ft. 9 in. (3 m) diameter, on base 4 ft. (1.2 m) high x 10 ft. (3.1 m) diameter

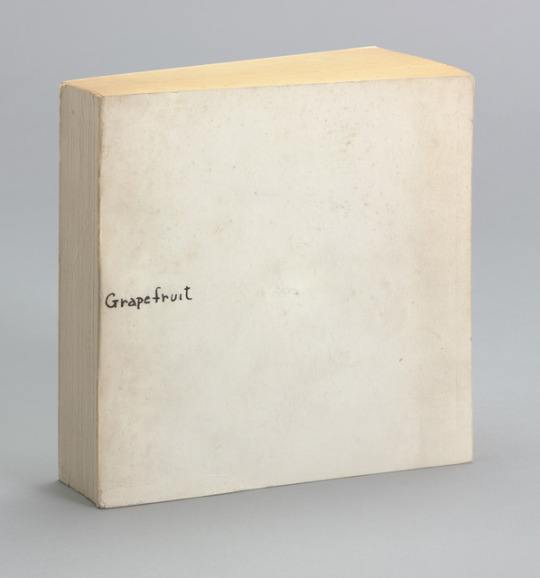

47. Artist name: Yoko Ono

Title of Work: Half-A-Room

Date: 1967

Materials: Various objects cut in half, most painted white. Installation dimensions variable

Dimensions: 5 2/5 × 5 2/5 × 1 3/10 inches

48. Artist name: Julian Opie

Title of Work: Amelia

Date: 2018

Materials: Lenticular acrylic panel comprised of four inkjet prints in colors

Dimensions: 10.6 x 5.9 inches

49. Artist name: Nam June Paik

Title of Work: Technology

Date: 1991

Materials: three-channel video installation with custom-made cabinet; color, silent, continuous loop

Dimensions: 127 x 51 7/8 x 75 5/8 inches

50. Artist name: Judy Pfaff

Title of Work: Neither Here Nor There

Date: 2003

Materials: Mechanical tubing, wood, rigid foam, paint and tape

Dimensions: 153” x 245 1/2” x 209” and 153” x 228 1/2” x 165”

5 notes

·

View notes

Text

Laminate Sheet Price List

Laminates provide a better surface finish for furniture elements and also provide an attractive look for a very less price. Furniture like tabletops, cupboards, surfaces of chairs mostly uses laminates as the finish material. Decorative plastic laminate is a durable flat sheeting material used in home and industrial furnishings. The laminate sheets are made up of three layers the bottom layer of brown paper coated with phenolic resin, the second layer of paper decorated with the desired pattern, and the third layer of clear sheet.

Types of Laminate Sheets

There are various types of Laminate Sheets in India. Some are listed below.

Decorative Laminates

Wood Laminates

High-pressure laminates

Industrial Laminates

Compact Laminates

Post Form Laminates

PVC Foam Board Sheet

Liner Laminate Sheets

Sunmica Laminated Sheet

Exterior Grade Compact Laminate Cladding Sheets

Decorative laminates are the specially designed laminated sheets of brown Kraft papers and decorative printed papers fused together using pressure and heat. These decorative sheets are used to add stylish finishes to furniture items, cabinets, counters, worktops, and other installations and also for wall paneling.

Wood laminates are designed in such a way that they give aesthetics like real wood. wood Laminate sheets is a multi-layer synthetic flooring product fused together with a lamination process.

Laminate sheet price in India

Laminate sheets price

Wooden Texture Laminates, Thickness: 0.7 - 10 mmRs 800/ Piece

Multicolor Designer Laminate SheetRs 1,200/ Sheet

Paper Compact Furniture Sheets, Thickness: 2 to 100 mm 495/ Sheet

Wood Exterior Grade Laminate Sheet, Thickness (millimeter): 6 times 100/ Square Feet

Aluminium Decorative Woodtex Finish LaminatesRs 1,000/ Piece

FunderMax Creek Exterior Grade High-Pressure LaminatesRs 399/ Square Feet

Laminate Sheet Manufacturers In IndiaManufacturerscity

Mahavir HouseNavi Mumbai, Maharashtra, India

Akash T.S. CorporationBhopal, Madhya Pradesh India

Krishna Interial & PlywoodSurat, Gujarat, India

Shiv Trading CompanyBengaluru, Karnataka, India

Chintamani TraderPune, Maharashtra, India

FM-pro, Delhi, India

Lakshmi EnterprisesGhaziabad, Uttar Pradesh, India

The laminate sheets are made up of three layers the bottom layer of brown paper coated with phenolic resin, the second layer of paper decorated with the desired pattern, and the third layer of the clear sheet.

Laminate sheets are made by bonding together two or more layers of materials.

Laminate sheets from plastics are glued to wood to make the surface aesthetic.

These sheets are manufactured by laminating different types of papers with formaldehyde.

1 note

·

View note

Text

6 Essential Things To Know Before Purchasing PVC Foam Board

PVC Foam Board is an excellent polymer board used in various applications. It is ideal for all kinds of cabinetry because it is lightweight, waterproof, and strong.

It can be made in various thicknesses and color and is widely used for panels, cabinet doors, construction, and wall sheeting.

6 Essential Things To Know Before Purchasing PVC Foam Board

When purchasing certain products such as PVC foam sheets or WPC Door Frame, there’s no doubt that JKD Plastics is the best.

Now coming to the article, If PVC is something new to you, you must understand its basics, such as properties, applications, etc.

How are PVC Foam Boards Made?

Petroleum products, resins, and inorganic chemicals manufacture PVC foam boards. After that, these components are combined under controlled conditions and poured into a mould tailored to the intended use. The compound is warmed during this process, permitting it to be shaped or moulded into the ideal form. After that, it is cooled to harden into the desired shape or profile. Depending on the final application, the finished product can be cut, routed, bent, glued, or left in its original state.

Is PVC Foam Boards Water Resistant?

PVC foam boards resist moisture. They also have a particular composition that makes them water-resistant, preventing them from swelling or changing shape when wet. PVC foam boards absorb less than one percent of water, significantly less than wood.

Are they Sturdy Enough?

The molecular structure of PVC foam sheets ensures they remain firm when cooled. Consequently, they are long-lasting and deformation-resistant unless subjected to extreme heat. These foam boards are known to go on for around thirty to forty years without harm, although typical wearing is obvious.

What Are They Mainly Used For?

PVC foam sheets are used in construction and building, advertising and signage, interiors and furnishings, screen printing and graphics, and the refrigeration industry due to their outdoor-friendly properties.

How Can PVC Foam Boards Be Checked For Quality?

PVC foam sheets are quality checked in various ways by various brands. However, the following are some common tests used to evaluate the performance of PVC foam sheets:

Fire Test: PVC foam sheets used in fire tests must have a class A flame spread rating. PVC froth sheets, when in touch with fire, self-quenches.

Moisture Absorption Test: PVC foam sheets are soaked in water. The weight of the PVC foam sheet before it is submerged in water can be compared to that of post-submerging into the water to detect the rate at which it absorbs moisture. PVC should have a water absorption rate of less than 1%.

Strength Test: To see if the foam sheet can withstand direct impact and heavy weight, it is put through a series of strength testing activities.

What is the Price of PVC Foam Boards?

The plastics with the lowest prices are PVC Foam Sheets. It is once in a while more costly than wood; however, when you represent PVCs’ low maintenance qualities, PVC’s long-term cost is much lower than wood.

Why Should You Go For PVC Foam Board in India

Using these boards for your project is optimal due to their durability. This substance is appropriate for use both inside and outside since it resists moisture. PVC foam board can withstand wear and tear over time because it is resistant to scratches, dents, and other forms of damage. Additionally, due to its lightness and strength, PVC foam board is an excellent choice for projects that require flexibility and durability.

PVC foam board is simple to set up. This material can be effortlessly cut and moulded using standard devices, making it simple even for those with minimum Do-It-Yourself experience. Additionally, mounting PVC foam board is simple with various adhesives or screws. PVC foam board is even more cost-effective because you can save time and money on installation costs.

If you wish to own the best PVC foam board or WPC Door Frame, JKD Plastics always delivers the best quality output. After learning about the numerous benefits, it’s normal that you would consider exploring or purchasing a product. Still, you should always go for the best.

Source Link: https://tealfeed.com/6-essential-things-know-purchasing-pvc-b8fcx

0 notes

Text

Expanded PVC foam board is lightweight and rigid

The PVC Foam Sheet, also known as Komatex, is a versatile closed cell foam PVC sheet. It can be used in a variety of applications, and is available in a range of colors and sizes. It's ideal for screen printing, vinyl lettering, and dimensional lettering. It's also a good choice for POP displays, and even for architectural model props.

Expanded PVC foam 4x8 PVC Foam Board board is lightweight and rigid. It can be used for a variety of applications. It is a good substrate for signage and digital printing. It also offers flame resistance, which makes it an attractive choice for outdoor signs and displays. It is resistant to moisture and chemicals and is very easy to cut.

PVC foam board is a popular substrate for trade show displays, advertising and outdoor signage. Its light weight and high strength make it ideal for outdoor use. It can be laminated and printed on both sides. It is resistant to heat, mildew and some inorganic acids. It is an eco-friendly alternative to wood or polycarbonate plastic. It is also available in a variety of colors and densities.

When it comes to outdoor signs, the material must be durable against corrosion. It is also lightweight and easy to transport.

The production of PVC foam boards requires a few laborers. Depending on the quantity of orders, the delivery time will vary.

0 notes

Text

PP, EVA, EVOH, PS and PE Multi-Layer Sheet Co-Extrusion Line

PP, EVA, EVOH, PS and PE multi-layer sheet co-extrusion line To meet market's high request on products, Shanghai JWELL develops advanced technology of five layer symmetrical distribution and seven layer asymmetrical distribution, which makes the sheets having better barrier performance. PP/EVA/EVOH/EVA/PP five or seven multi-layer co-extrusion high barrier fresh keeping sheet has the excellent anti-oxygen and anti-humidity features. It is one of the best barrier packing materials.Mainly used for Jelly packing,meat packing,snack food packing,medicine and cosmetic packing and so on. Main technical specification Model JW100/45/45-1000 JW120/45/30/65-1200 JW150/45/45-1500 Suitable material PP, PE, PET, PS Products Width 800mm 1000mm 1200mm Products thickness 0.5-2mm 0.5-2mm 0.5-2mm Designed speed 15m/min 20m/min 30m/min Capacity 300kg/h 400kg/h 600kg/h Note: The specifications are subject to change without prior notice. T-die(mold) Our T-die (mold)are suitable for the following products: • PET, PP, PA, PVC, PS, PC, PE printing, packaging sheet • PC, PMMA, PS, HIPS, PP, PE, PVDF plate • ABS, PS, HIPS, PMMA sanitary ware board, refrigerator board • PVC hard board, soft board, foam board, aluminum composite board • PP + stone powder, PP + wood powder, PP + hemp fiber sheet • TPO, PE, PVC, EVA waterproofing membrane • CPP, CPE cast film • PP, PP, PVC, PVDF, EVA cast film • PP, PE, EVA paper composite, aluminum composite coating products • PP, LLDPE, PA, EVOH, TPX, EVA Laminating products • PC optical grade sheet, sheet • PET optical grade sheet, sheet • PMMA, GPPS light guide sheet, plate • PMMA, GPPS diffusion sheet • BOPET Biaxially Stretch Film Products • BOPP Biaxially oriented film products • BOPA Biaxially oriented film products • PETG Shrinking film products • PE wet lithium battery two-way stretch diaphragm products • PP dry lithium battery separator products Read the full article

#Barrierpackagingsheetproductionline#Foodpackagingsheetproductionline#Multi-layerco-extrusionpackagingsheetequipment#PAsheetextrusionline#PPSheetExtrusionMachine#Seven-layerbarriersheetequipment

0 notes

Text

I see the light tangled on keyboard

I see the light tangled on keyboard driver#

I see the light tangled on keyboard portable#

I see the light tangled on keyboard android#

In truth, it’s hard to see it as anything but a gaming PC. It’s got water cooling, RGB LED lighting, and an ATX power supply, all of which happen to be mounted inside a flashy computer case complete with a clear window. Posted in Arduino Hacks, Robots Hacks Tagged 3d printed, python, robot arm, robotics, scara, stepper motorĪt first glance, you might think the piece of hardware pictured here is a modern gaming computer. This looks like something that you could reasonably assemble and program over a weekend or two, and then put to work in your ad-hoc PPE factory. We’ve seen some impressive 3D printed robotic arms over the years, but the simplicity of the PyBot is particularly compelling. As the name implies, the PyBot is controlled by Python tools running on the computer, so it should be relatively easy to get this capable arm to do your bidding. But if you wanted to build your own version from the parts bin, you could certainly wire up all the principle components manually. In the base of the arm is a custom control board that combines an Arduino M0, an ESP8266, and a trio of stepper motor drivers. By default it features a simple gripper, but that can easily be changed out for whatever tool or gadget you have in mind. But while that robot was designed to carry an extruder and act as a 3D printer, intends for the PyBot to be more of a general purpose platform. Those who’ve researched similar projects might notice that the design of this arm has clearly been influenced by the Mostly Printed SCARA (MPSCARA). A custom control board keeps the wiring tight. Smooth rods, linear bearings, lead screws, and NEMA 17 motors are all exceptionally cheap these days thanks to the innumerable 3D printer kits that make use of them. One could argue that this is a project made entirely possible by desktop 3D printing as not only are most of the structural components printed, but most of the mechanical elements are common 3D printer parts. The PyBot designed by is an open source robotic arm that should be well within the means of the average hardware hacker. Unless of course, you’re willing to build it yourself. Unfortunately, while the prices for things like 3D printers and oscilloscopes have dropped lower than what many would have believed possible a decade ago, high-performance robotics are still too pricey for the home player. We’ve all seen videos of blisteringly fast SCARA arms working on assembly lines, and more than a few of us have fantasied about having that same kind of technology for the home shop.

I see the light tangled on keyboard portable#

Posted in Raspberry Pi Tagged portable computer, rugged raspberry pi, ruggedized It could also be a nice compartment to keep your RTL-SDR for some mobile radio work.įor those that don’t mind spending name-brand money and have access to a 3D printer, the Raspberry Pi Quick Kit by is another great way to get yourself a rough and tumble Pi without reinventing the wheel. We especially like the large open area that he’s kept around the Raspberry Pi’s ports that allow you to easily hook up to the network or plug in a flash drive.

I see the light tangled on keyboard android#

Rounding out the build, found a cheap Android phone case that included a tiny USB keyboard which plugs right into the Pi and he’s looking to add a BlackBerry trackball to the setup down the line. As for the display, the nine inch LCD is perfectly sized to press fit into the lid. Of course if you have access to the appropriate tools, you could certainly cut the plate out of something stouter. The “carbon fiber” sticker he put on the PVC sheet won’t do much for the structural integrity of the build, but it sure looks nice.

I see the light tangled on keyboard driver#

Most of the effort involves cutting the PVC foam sheet that holds the Raspberry Pi, battery pack, and the driver board for the LCD in the bottom of the $15 USD case managed to track down on AliExpress. Short of just buying one of these rigs pre-built from somebody, it’s hard to imagine it could get much easier than this. You could even do it without soldering anything, if you really wanted to. You don’t need a CNC to cut out any face plates or a 3D printer to create an internal framework for all your components. Inspired by these builds but looking to make it even easier and cheaper to roll your own version, recently took the wraps off of what he calls the Militarish Pi. Especially if you can avoid popping any holes in the side. It’s not hard to see why whether you spring for the Pelican case or get a cheaper alternative, these water-tight cases are far stronger than anything you’re going to 3D print or otherwise cobble together in the home shop. Over the last year we’ve seen a wave of portable computer builds that center around the Raspberry Pi taking up residence inside a commercial heavy-duty storage case.

0 notes

Text

Shika’s Guide To Selling at Conventions #1: Table Set Up

Sooooo, to take my mind off somethings that are bugging me and to give myself a break from drawing; I thought I might offer a bit of insight to those who want to sell at conventions or those who already do but, just might want to read a long ass post about artsy shit. This post in particular will be about your table set up and I’ll probably make another one on what type of things you should sell and where to get your stuff made and or/how to make them yourself, one on what the content of your merch should be, and basic convention etiquette. Coming from someone that has done plenty of research on conventions, is currently getting ready for the 2018 con circuit, and has sold things herself I have quite a bit to talk about.

Strap in kiddies, because I’m going to cover everything I can possibly think of when it comes to table set up.

PART 2: PRODUCTS AND HOW TO MAKE THEM/WHERE TO GET THEM DONE

Now the first thing I want to list is the things that you will need REGARDLESS of your table set up. These are things that everyone needs to have whether they have a grid display, pipe display, etc.

Tablecloth: At most conventions/fairs you’re going to be given a table that is 2′x6′. You can have just a cheap ass plastic tablecloth meant for one time use if you’re just testing the waters but, if you’re going to be selling multiple times a year or if you’re even just going to sell more in the future I recommend that you have something made of cloth. It doesn’t even have to be specifically a tablecloth. Mine is a tapestry that I’m using so whatever fits the table will be fine.

Paper For Keeping Count of Your Inventory: This is important to make sure you’re keeping track of what you have and what you’ve sold.

Pens and Markers

Sign(s) Listing Your Prices For Your Items: It’s annoying to keep having to ask the artist what the price of everything is so make sure everything is marked.

Money Box with Change

Scissors

Container for holding your merch including your prints and everything else

T-Shirt Bags: You can get a box of them at Office Max/Depot, or colored ones on Ebay. Your costumers will thank you for having them trust me.

Pocket Folder

Paracord: This is useful for hanging or tying your banner and so much more.

Invisible Tape

Banner

Card Reader: Not everyone has cash on them these days. I sure as hell don’t so, get one. I recommend Square personally.

Phone Stylus: Get a cheap one at Walmart so people can sign when they buy with a card.

Velcro

And now that, that is out of the way let’s get onto the actual table display. There are tons of ways to set up your table and you can look up pictures as reference but, I will be going over the 5 most common types that I have seen, the pros and cons of each, and the extra items you made need for each particular display. I’ll start at the cheapest and go up.

ABSOLUTELY NOTHING!

Price: $

Eyup, that’s right. You can get by with just having your stuff spread out on your table. This set up is good because it’s cheap and good for first timers and it’s also good if you’re only selling prints and/or maybe a few items. But, at the same time it may be tiresome for customers to have to look down at a table and it may look cluttered and unprofessional as well.

Pros: Cheap, Good for first timers or people on a budget, Good for those with minimal items to sell, Set up is very easy

Cons: Can look cluttered/unprofessional, Can be tiresome for customers to look down.

Extras You May Need: Portfolio/Page Protectors to Display Prints, Binder

PVC PIPING

Price: $

This is probably the one everyone is most familiar with. It’s a simple and cheap and does a great job of displaying many different prints. It’s starting to fade out in recent years as Photography Stands are getting more popular. It’s common for most beginners to use this but, that also may be a con because it can look a bit amateurish with those big white pipes showing. They are readily available at any hardware store and are pretty cheap. Most beginners (especially people in the mid 2000′s) would use clamps to hold the pipes up and tape the hell out of them but, I would recommend a setup like this. No matter how you set it up, the set up its self takes time so you’ll have to go in early to set up.

Pros: Cheap, Readily available, Can be customized to different heights and widths

Cons: Set up may take some time, a bit amateurish and unprofessional, can be a bit wobbly and unstable, Hard to transport to keep track of all of the pieces

Extras You May Need: Plastic Page Sleeves, Binder Clips/Binder Rings

WIRE GRID STORAGE CUBES

Price: $$

This is neck in neck with Photography Stands with the most current popular display method. It’s actually the one I use and its my favorite. It’s very easy to find; You can find it at Walmart, Bed Bath and Beyond, Target, and Kmart (which is where I got mine). You can even order the individual little grids online through certain stores. They come in both black and white. How much you spend will depend on whether you get a 4 cube set or a 6 cube set. I have a 6 cube set that I got at Kmart for $20 and it’s worked perfectly for me. The set up is easy but takes time (longer than the PVC pipes) so you’ll have to go in early to properly set up. My favorite thing with these is how customizable they are. You can do so many different looks with them.

Pros: Fairly inexpensive, Readily available, Customizable, Good for Products like Charms/Jewelry/Bookmarks because they can be hung, Easy to transport

Cons: Can be unstable based on how it’s set up, set up takes time

WIRE GRID PANELS

Price: $$$

This is one of the more rarer ones but, I still think it’s worth mentioning anyways. These work like the Storage Cubes but, on a larger scale. These will have to be placed on the floor unlike the rest and you need to buy more than one, which isn’t a big deal because they’re actually fairly cheap in a pack. They can be bought in different sizes but, because they are so big, heavy, and almost exclusively sold online shipping will probably bite you in the ass. Also set up will most likely be difficult without a helper. Also because of the fact that they are so big will give you plenty of space to display prints. The fact that they’re on the floor will free up you table space and give you more room to show other things.

Pros: Pretty affordable for their size, Very professional looking, Easy to hang things like Charms/Bookmarks/Jewelry from, Plenty of display space, Frees up table space

Cons: Hard to set up without help, Hard to transport, May make your booth space feel crowded with things behind you

Extras You May Need: Zipties

PHOTOGRAPHY STAND

Price: $$$$

This is tied with the Grid Cubes for the most popular option and it’s steadily growing as well. They’ll set you back about $80-$90 but, they have a lot of benefits. They are the easiest to set up. They have the concept of PVC pipes but are far easier to put together, are customizable with the height and width, and are much more sleeker and professional looking. They are perfect for anyone selling alot of prints and like the grid panels they free up table space. And also like the panels they can make the surrounding area feel closed in.

Pros: Very easy setup, Very professional looking, Plenty of Space for prints, Customizable height and width, Frees up table space, Easy Transport

Cons: Very expensive for a quality one, Mostly exclusive to online, Depending on the feet type it can be a tad bit unsturdy, Makes surrounding space feel cluttered

Extras You May Need: Plastic Page Sleeves, Binder Clips/Binder Rings

And those are only the 5 most popular set ups. I’ve seen people use other methods so do you research and pick and choose which one suits you best. And now unto how to display certain popular items. The prints are covered by the stand setup but, this is for the smaller things.

Buttons

Foam Core Board (Can be by it’s self or with a fabric covering like felt)

Jewelry Beading Box

Cork Board

Charms

Foam Core Board

Cork Board

Display Case

Stickers

Bowls (Good for individual stickers)

Foam Core Board (Good for sticker sheets)

Jewelry Beading Box

Jewelry

I would have to list alot but, unless you’re going to have them hanging if you have wire grid panels/storage cubes You’ll need a necklace stand, bracelet stand, ring holder, etc.

These are extras that completely optional but, I thought they would be nice to mention anyhow.

Peg Board With Pegs: These are great for displaying hanging things like Keychains,Charms Etc. They can even be used to display prints if you get them big enough.

Cloth Backdrop for Photography Stand: If you don’t want to put your prints in sleeves and then tape them together, You can attach them to a cloth backdrop.

Gift Card Display, Revolving or Stationary: These are great if you’re like me and you sell 4x6 Mini Prints.

Boxes: I often see these used to elevate certain products and show off certain things. They’re more often than not painted small wooden boxes flipped upside down with the merch placed on top.

Easel Stands: If you’re going to be using Foam Core Boards Or Cork Boards, you’ll need something to prop them up.

Business Cards and Business Card Holder: This may be a weird one to be optional, you’d think it would be up with the essential stuff but, not exactly. I personally prefer to keep businesses cards but, at a Con I went to this year there was alot of people that instead of many business cards they had one little sign with all of their social media (some even had a QR Code) that people would take a picture of.

Brads/Finishing Nails: Again if you’ll be using Foam Core or Cork Board for displays you’ll need something to have your product hang off. I personally prefer brads over finishing nails because they can come in different designs.

Hangers: If you’re selling t-shirts and you’re not going to have them on the table top, you can use hangers to display the t-shirts.

131 notes

·

View notes