#PTFE lined ball valve manufacturer in India

Explore tagged Tumblr posts

Text

FRP Blower Supplier in Chandigarh

Sunfiber is a Manufacturer and Supplier of FRP Blower in Chandigarh, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India An FRP blower is an air-moving device made from fiberglass reinforced plastic. The blower’s fiberglass construction gives it superior corrosion resistance, making it an ideal solution for industries that deal with aggressive chemicals, high temperatures, or corrosive environments. Industries widely use FRP blowers in applications such as ventilation, exhaust, and cooling systems due to their durability and long-lasting performance. Features of Our PTFE Lined Ball Valves: High-quality PTFE lining for superior corrosion resistance Durable ball design for reliable performance Precision-engineered components for optimal functionality Variety of sizes and configurations to meet specific needs Compliance with industry standards and regulations Applications of FRP Blowers: Ventilation in chemical processing plants Exhaust and air supply in textile mills Cooling systems in industrial plants Air handling in power plants Exhaust and ventilation in pharmaceutical plants What is an FRP blower? An FRP blower is made of fiberglass reinforced plastic, offering superior corrosion resistance and durability for industrial applications. Why should I choose FRP blowers? FRP blowers are corrosion-resistant, energy-efficient, and lightweight, making them ideal for industries dealing with harsh chemicals or high-temperature environments. Can FRP blowers be customized? Yes, we can customize FRP blowers based on your airflow requirements, pressure ratings, and specific industrial needs. Sunfiber is a FRP Blower Supplier in Chandigarh, India Including Raipur, Bilaspur, Kanker, Raigarh, Rajnandgaon, Bemetara, Baikunthpur, Ambikapur, Jagdalpur, Chirimiri, Kondagaon, Manendragarh, Bhatapara, Baloda Bazar, Sakti, Takhatpur, Ambagarh Chowki, Sarangarh, Khairagarh, Dharamjaigarh, Bilha, Arang, Simga, Katghora, Saraipali, Bijapur, Kharsia, Pandariya, Pithora, Kurud, Pathalgaon, Akaltara, Ramanujganj, Bagbahara, Gharghoda, Jashpur Nagar, Bishrampur, Mahasamund, Mungeli, Korba, Dhamtari. For detailed information or inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Akaltara#AmbagarhChowki#Ambikapur#Arang#Bagbahara#Baikunthpur#BalodaBazar#Bemetara#Bhatapara#Bijapur#Bilaspur#Bilha#Bishrampur#Chirimiri#Dhamtari#Dharamjaigarh#FRPBlowerSupplierinChandigarh#FRPBlowerSupplierinGujarat#FRPBlowerSupplierinIndia#Gharghoda#Jagdalpur#JashpurNagar#Kanker#Katghora#Khairagarh#Kharsia#Kondagaon#Korba#Kurud#Mahasamund

0 notes

Text

High quality ball valve manufacturer in Ahmedabad

Flowdo Valve is one of the premier ball valve manufacturers in Ahmedabad, recognized for its excellent quality and advanced products. Ball valves are widely used in oil and gas industry, chemical industry, water treatment industry and other industries because of their dependability and effectiveness in regulating the flow of the fluid.

Flowdo Valve is an eminent ball valve manufacturing company based in Ahmedabad, India that specializes in offering a wide assortment of ball valves for various applications. Our product lineup includes:

Ball Valve 3PC F/E: A three times body located full encapsulation valve which is highly reliable in terms of its construction and can also be easily maintained.

Ball Valve 2PC F/E: A two-piece full-encapsulation form valve made suitable for different applications in which it is necessary to ensure the tightness of the sealing.

Ball Valve 1PC F/E: This valve is half-circle full-encapsulation valves that consist of one body that makes it cheap and small in size.

Ball Valve 2PC F/E (High Pressure): Suitable for high pressure for instance in an organization so as to boost the performance and durability of a product.

Ball Valve 3PC & 1PC (S/E & S/W): These valves are available in screwed end (S/E) version and socket weld (S/W) and the buyer is free to choose according to the requirements.

PTFE Lined Ball Valve 2PC F/E: Including PTFE lining to give greater chemical endurance it is suitable for corrosive environment.

3 & 4 Way Ball Valve F/E: Valves that have multiple ports to permit regulation of directional flow to improve functionality.

Jacketed Type Ball Valve: It has a jacket for thermal management, perfect for operations that need to maintain or alter the temperature.

Flowdo Valve is an ISO 9001:2015 certified company as a sign or guarantee of the highest quality and reliability. It increases confidence that the quality management systems are being improved continuously and responsive to customer needs. Also, our products are API, ANSI, and DIN-coded qualities that are accepted internationally due to high set standards in the production of valves.

Flowdo Valve is one of the leading ball valve manufacturers based in Ahmedabad that offers reliable valves for various industries. Their products are durable and very accurate making them key in different industries and sectors.

Flow Regulation: Used in pipelines where the flow of the liquid or the gaseous commodity need to be regulated accurately and effectively.

Isolation Services: Employees get full isolation solutions to avoid accidents and control the fluid leakage.

Mixing and Diverting: Used in applications where it is necessary to combine various liqu ids or to change the route of the current.

Discover all our ball valve products and additional information about our manufacturing processes on

#ball valve manufacturer in Ahmedabad#ball valve manufacturer#valve manufacturer in Ahmedabad#valve manufacturer#ball valve

0 notes

Text

Gate Valve Exporter - Mayur Valves MVS

Mayur (Valves) System Private Limited is an ISO 9001 : 2015 Certified Company, Established in the year 1978, MVS Industrial Valves offers Diaphragm Valves, Ball Valves, Plug Valves, Butterfly Valves, Gate Valves, Globe Valves, Check Valves or Non Return Valves, Knife Gate Valves, Sight Flow Indicator or Sight Glass, Strainer or Filters, PTFE / FEP / PFA / PVDF Lined Valve, PTFE Lined Pipe, PTFE / FEP / PFA / PVDF Lined Pipe Fittings and Plastic / PP / PVDF Valves. Gate Valve Manufacturers Exporters in India MVS Industrial Valves have been exported to more than 40+ countries worldwide

Assurance of Quality: Mayur Valves MVS follows strict quality control procedures to guarantee that every gate valve satisfies global requirements. Every stage of the production process, from obtaining raw materials to inspecting the finished product, is cantered upon quality.

Wide Product Selection: To meet the needs of many applications and industries, Mayur Valves MVS provides a wide selection of gate valves. Mayur Valves MVS offers a solution for your needs, whether they are for industrial operations, oil and gas, or water supply valves.

Customization Options: Mayur Valves MVS offers customization options to fit gate valves to individual demands, acknowledging that every project has different requirements. Customers can request customized solutions, ranging from material selection to size and design alterations.

Reliable Performance: Mayur Valves MVS gate valves are built to provide constant performance even in the most demanding conditions, with a focus on durability and dependability. Thorough testing guarantees that every valve surpasses expectations and fulfils performance criteria.

Global Reach: Mayur Valves MVS reaches markets on all continents as an exporter, providing services to clients all over the world. Customers can count on prompt product delivery no matter where they are thanks to an efficient distribution system and effective logistics.

Conclusion

Go no further than Mayur Valves MVS for quality gate valves built for dependability and performance. Dedicated to quality and client satisfaction, Mayur Valves MVS is still a reliable partner for businesses worldwide. Get in touch with us right now to find out more about our offerings.

Contact Us: - +91 9898563969 [email protected]

Address: - Mayur (Valves) System Private Limited, SOBO Center, 421, Block B, 4th Floor, Gala Gymkhana Road, Near Sun City, South Bopal, Ahmedabad - 380058, Gujarat, India.

Visit for More Information: - https://mvsvalves.com/

#Gate Valve Exporter#Gate Valve Manufacturers Exporters in India#gate valve manufacturers exporters in gujarat#gate valve manufacturers exporters

0 notes

Text

5 common types of PTFE products

At room temperature, PTFE is a fluorocarbon (solid-state) because it is a high molecular weight polymer comprised entirely of carbon and fluorine. PTFE is used to treat pans and other equipment with a nonstick coating. Because of the strength of the carbon-fluorine bonds, it is often employed in containers and pipelines for reactive and corrosive chemicals. PTFE reduces friction, wear, and energy consumption in equipment when used as a lubricant. It's commonly used as a graft material in surgical procedures. It's also used as a catheter coating to prevent bacteria and other infectious agents from adhering to catheters and causing hospital-acquired infections.

Noble Glass Works is the most popular as well as distinct PTFE Lined Ball Valves manufacturer in Gujarat, India.

PTFE is made by polymerizing tetrafluoroethylene with free radicals. The formula is

n F2C=CF2 → −(F2C−CF2)n−

Because tetrafluoroethylene can disintegrate explosively into tetrafluoromethane and carbon, specific polymerization equipment is needed to minimise hot spots that could induce this harmful side reaction. The process is usually started with persulfate, which homolyzes to create sulphate radicals:

[O3SO−OSO3]2− ⇌ 2 SO4•−

Sulphate ester groups in the resultant polymer can be hydrolyzed to yield OH end-groups.

Noble Glass Works is an excellent and the most renowned PTFE lined ball valve manufacturer in India.

As a medium-sized international active firm, Noble Glass Works is recognised as a trusted and competent partner to all industrial groups. PTFE Bellows, PTFE Lined Sightflow Indicators, PTFE Bushes, PTFE O Rings, and PTFE Lined Ball Valves are among the products available.

Types of PTFE products:

1. PTFE O Ring:

Due to its low moisture absorption capabilities and wide temperature operating range, PTFE O Rings are utilised as gaskets in different applications where various chemical processes are required or in the glass fittings and also to seal the joints between Glass – Glass, Metal – Glass, or Metal – Metal connectors.

2. PTFE Bush:

PTFE is a widely used substance having a number of applications in a wide range of industries. The raw materials used to make these brushes are of the highest quality. T Bush made up of PTFE is also available.

3. PTFE Bellow:

In expansion joints, bellows, and compensators made from PTFE, the exceptional corrosion resistance of PTFE is paired with its remarkable flexing capabilities.

Because of the two PTFE qualities listed above, PTFE materials are acceptable for use with all chemical products and compensate for recurrent thermal expansion in pipes.

If you are looking for one of the most prevalent and trustworthy PTFE high pressure bellows manufacturers in India, Noble Glass Works is a reliable name that you can trust with your PTFE line product needs.

4. PTFE Lined Sight Flow Indicators:

Sight Flow Indicators are widely used in a variety of industries to measure pipe flow. Despite the fact that traditional Sight Flow indicators are beneficial in most sectors, metal bodies are incompatible with the process medium in specific applications.

5. PTFE Lined Ball Valves:

Various stainless-steel or Cast Ductile Iron grades are commonly used to manufacture the valve body. Corrosion-resistant polymers like PFA or FEP are used to completely line the wetted parts.

The self-adjusting packing in PTFE coated ball valves allows for maintenance-free spindle sealing. Even after extended usage, there are almost no backlashes in the stem and ball. The valve's performance is improved by the PTFE lining. To ensure that the liner is securely in place, slots are machined into the body, making it suitable for high vacuum operation.

#PTFE Lined Ball Valves manufacturer in Gujarat#PTFE lined ball valve manufacturer in India#PTFE high pressure bellows manufacturers in India#Nobleglasswork

1 note

·

View note

Photo

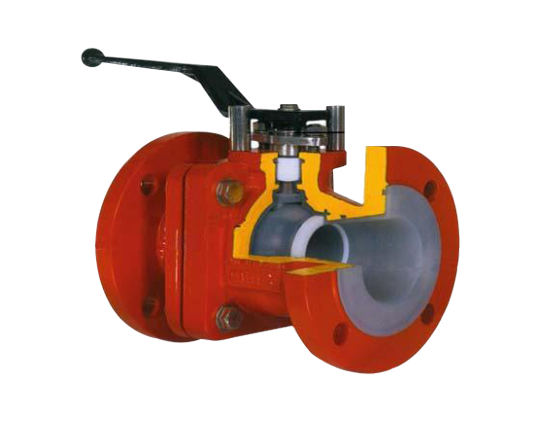

PTFE Lined Ball Valves Manufacturer in India

PTFE lined ball valves are devices designed to regulate the flow of fluids (including gases) by opening, closing, or moderately obstructing passageways in pipes. Lined ball valves have large- scale application over many various industries - for this reason they are vary widely in size, form and materials used depending on what they are going to be used for. They can be more or less simple, or they can be compound - in which case exceptional design is critical to how well they work.

Nowadays, PTFE lined ball valves have been the necessary products in all kinds of corrosive industrial applications. However, there are only a limited lined ball valve manufacturers who reach the international standard. So when company buy this valve, they must called for the seller to show the certifications for production. Through this way company can avoid purchasing the uncertified products.

The primary functions of lined ball valves are important guidelines based on exactly what the industry wants with regard to their machines and equipments. They are available on a number of designs and sizes, plus they are manufacture from different materials, which imply that they offer a model for just about any project.

Aira 4Matic Global Valves is an ISO 9001:2015 company, manufacturers and exporter of PTFE lined ball valves in India. Company’s manufacturing unit is established in Ahmedabad. We are offering Lined check valves for corrosive industrial applications. We have different size range of lined ball valves which are matched to all the industrial operations. We offer ball valves that are fire proof and also passed fugitive emissions testing standards.

1 note

·

View note

Link

Fiksar Valve Mfg - Our wide range of Ball Valve, Plug Valve, Butterfly Valve, Knife Edge Gate Valve, Non Return Valve, Steam Trap, Ball Valve, Ball Valve API 6D, Plug Valve Teflon Sleeve, PTFE Lined Plug Valve, FEP Lined Plug Valve, PFA Lined Plug Valve, Ball Valve BS5351, SMS Ball Valve Manufacturer, Supplier, Gujarat, India

1 note

·

View note

Text

FEP and UPVC Ball Valve

What is UPVC 3-Way Ball Valve? What is a Valve?

Taking a look at the humble pipe is a good place to start. It could be a pipe transporting water in your bathroom or a pipe carrying gas to your kitchen stove. A mechanism that controls how much liquid or gas flows through these liquid and gas pipes is required to function efficiently; this mechanism can be used to increase, decrease, or even stop the flow of fluid or gas. A valve is a mechanism that performs this function. They are mechanical switches that can turn pipes on and off as well as increase or decrease the flow of fluid/gas through them.

Now let's take a look at a few more examples from everyday life. To brush your teeth, you open a valve that lets pressurized water flow out of the pipe when you turn on the tap. Turning the tap more to one side typically reduces, stops, or increases the amount of water coming out (depending on the valve).

FEP Ball Valves:

The best type of ball valve to use for paper and pulp industries is the FEP-lined ball valve. At 10kg/cm2 pressure and 180°C operating temperature, it is capable of withstanding a pressure of 180°C. FEP-lined Ball Valves are ideal for slurries and viscous materials since they are non-sticky. Its unique properties make it superior to alloys.

In terms of its effects, FEP is similar to PTFE except for its soften-processed performance. Despite this, FEP can be quickly processed, welded, and re-molded into complex shapes. Welding and remodeling prospects, chemical and UV resistance, biocompatibility, and clear color are some of the unique properties of FEP.

PFA Ball Valve:

Many oil and gas industries utilize PFA-lined ball valves. PFA-lined valves can withstand temperatures up to 230°C at 10kg/cm2. PFA-lined valves have similar properties and qualities to FEP, but PFA is more temperature-resistant than FEP. In addition to their thermoplastic properties, PFA-lined valves offer a wide range of benefits. A thermoplastic material with the highest working temperature capacity is PFA. There is no fluoroplastic that can work continuously at a temperature higher than +260°C. It is possible to weld and re-mold it, with good permeability and outstanding chemical resistance. We are the PFA lined ball valve manufacturers in India.

What is UPVC 3-Way Ball Valve?

UPVC Ball Valve Manufacturers: The two ports of the PVC union ball valve are made up of two unions that can be disassembled and replaced at any time, making them easier to check and replace than common ball valves. An adjustable tightness, a low friction coefficient, ease of maintenance, and no leaks are some of the characteristics of a union ball valve. Furthermore, since the joints can be purchased separately, you can choose between threaded, socket, and standard joints. Although its single cost is higher than that of common ball valves, its replacement cost is lower.

Aira Euro Automation is the leading ball valve manufacturer in India. We offer various types of industrial valves like ball valves, butterfly valves, control valves, and many more.

0 notes

Text

Ball Valve Pump Manufacturer in India

Richter, under the wings of IDEX India, is the foremost industrial pumps and valves manufacturer in India along with the finest quality mag drive pumps and valves. We offer chemical process pumps, mag drive pumps, PFA lined valves, PTFE lined valves, ball valves, butterfly valves, industrial plug valves amongst others. These products excel through robust design and long service life.

FEATURES

Maximum reliability: Weak spot ball to stem is avoided by one-piece ball/stem unit

Universally applicable: many options are available in combination with a thick-walled PFA lining

Reliable even in extreme conditions: ENVIPACK stuffing box sealing

Maintenance-free & adjustable stem sealing

APPLICATIONS

Process & Dry Air

Caustic Soda

H2SO4

Caustic Soda

HCI

Address : Survey No 256, GIDC Manjusar,Savli, Near Bombardier Circle, Dist. Vadodara 391770, India

Visit us at : Ball Valve Pump Manufacturer in India

0 notes

Video

youtube

Gland packing, asbestos pad, rubber pad

Langfang Jiuwang Sealing Material Co., Ltd. https://mifengcailiaodaquan.cn/ Whatsapp/WeChat: +86-18830639308 --------------------- Gland packing, asbestos pad, rubber pad Wool Felt Handmade Tutorial Video Insulation pillars https://mifengcailiaodaquan.cn/9631.html Graphite tape What is the weight in grams PTFE gasket Pads Non-asbestos gasket standard Metal graphite composite plate plastic sheet https://mifengcailiaodaquan.cn/10069.html The best way to enhance the function How to wash the crystal board to be clean gland packing 10mm Metal Wound Gasket Material Flame Retardant Board And Plywood What is the high temperature resistance of bakelite sticks High Temperature Packing Model Specifications and Dimensions water pump packing adjustment https://mifengcailiaodaquan.cn/9973.html gland packing manufacturers in india Model and size of metal spiral wound gasket Insulating rubber sheet wholesale The difference between inflatable paddle board and folding paddle board asbestos rope weight per meter graphite spiral wound gasket use absorbent cotton Graphite Gasket Heat Resistance https://mifengcailiaodaquan.cn/9949.html pp board ราคา Which category does the ceramic fiber packing belong to? What is the temperature resistance of the ceramic fiber packing? The role of the ceramic fiber packing? ptfe coating ptfe coated epdm gasket nylon abrasive pad performance thermal pads Toothed Combination Gasket Where is the oil absorbing felt sold Lip Seal https://mifengcailiaodaquan.cn/9915.html mica board for hamilton beach microwave Ladle Gasket Equipment Sootblower packing Is Metal Wound Wound Gasket Disposable Executive standard of high-water-based packing The Difference Between Washers and Gaskets Bakelite sticks Wenzhou manufacturers How to press and flatten copper washer Acrylic packing PTFE composite gasket Wenzhou lip seal ball valve https://mifengcailiaodaquan.cn/9805.html Can the silicone tube be scalded with hot water PTFE pad type diagram PTFE conveyor Ceramic Fiber Cloth Is bakelite stick poisonous PU board Polytetrafluoroethylene There is a ring under the valve packing screw cap knitting tutorial sheet gasket material Graphite Packing Wire https://mifengcailiaodaquan.cn/9812.html wool felt handmade molybdenum disulfide and graphite comparison erfurt graphite insulating lining paper Dusty asbestos rope selection can pvc transparent board replace glass What is the density of the silica gel board Process flow of pure cotton carded yarn Why is octagonal gasket called octagonal silicone tube supplier malaysia plastic plates clear graphene aluminum alloy Non-asbestos board and non-asbestos board pu board result 2020 graphite plate insulation plastic gasket sheet Oval gasket sealing principle practice of wear-resistant rubber sheets gland packing用途 pu board wall decoration renderings oval pad https://mifengcailiaodaquan.cn/9539.html Silicone tube model High water roots PTFE Packing Foamed silicone rubber strips pressure Asbestos high temperature gloves bakelite swizzle sticks nylon plum blossom cushion What is bakelite sticks Metal-graphite composite board picture asbestos mat formula thin clear plastic sheets Aramid and Nylon Graphite Composite Plate China plum blossom cushion model Is the Polyurethane Cushion Good? Price High temperature resistant asbestos rope The role of insulation pad how much is bakelite price per kilogram tetrafluoroethylene pad https://mifengcailiaodaquan.cn/9604.html Tape Graphene Wear-resistant aramid packing o-ring installation pp How much is a board Graphite Packing Installation Video plastic casting material Skeleton Oil Seal pvc transparent board sound insulation Correct removal method of skeleton oil seal nylon threaded rod 3/8 wear-resistant rubber sheet technology Extrusion Pressed Graphite Tape https://mifengcailiaodaquan.cn/9530.html rubber sheet construction method Gland packing ring group PTFE guide belt production process ptfe素材 asbestos packing rope What is the price of high molecular polyethylene board Pouring nylon board agent price Graphite Packing Installation Video Tutorial Water pump packing replacement video Asbestos Gasket or Rubber Gasket Which Is Better How many degrees of high temperature resistance polypropylene board production line China manufacturer PTFE coated pad graphite composite mat Molded rubber pads How is Graphite Ring Processed https://mifengcailiaodaquan.cn/9608.html o-ring hornbach Types of Flange Gaskets Sichuan rubber PTFE composite gasket Crystal integrated board copper gasket spray on head gasket copper washers autozone Metal Sheath Optical Cable Grounding epoxy grout tube spiral wound gasket material specification The price of plywood Model specifications of peristaltic pump silicone tube What is the density of PTFE board Function Four Fluorine Gasket Model https://mifengcailia

0 notes

Text

Chemical Structure, Properties and Applications of PTFE Products

Polytetrafluoroethylene (PTFE) is a flexible, high-performance fluoropolymer made consisting of carbon and fluorine atoms that are widely utilised. The non-stick coating in kitchen cookware (pans, baking trays, etc.) is one of the most popular applications of this polymer, therefore you may easily find it in your kitchen.

PTFE is employed as a cost-effective solution in a variety of industries including chemical processing, oil and gas, electrical/electronic, industrial, as well as construction.

Noble Glass Works is the most popular and well-known PTFE Lined Ball Valves manufacturer in Gujarat.

PTFE (polytetrafluoroethylene) is a high-performance engineering plastic with the following characteristics:

● Chemically Inert & Non-Reactive to almost all chemicals

● Can resist upto 260°C temperature

● Non-adhesive and non-stick properties

● The exceptionally low friction coefficient

● Excellent Electrical Insulation properties

● Weather Resistant

Chemical processes, railways and defence sectors, thermal and automatic power plants, electrical and electronic industries, pharmaceuticals, and almost all industries employ PTFE Products due to their unique features.

Chemical Structure:

Poly Tetra Fluoro Ethylene is a non-branched linear polymer with the following chemical structure:

Because of the big fluorine atom, the PTFE molecule twists into a zigzag shape, with the fluorine atoms packed closely in a spiral around the carbon-carbon backbone. The dense interlocking of fluorine atoms produces a stiff PTFE molecule with a high crystalline melting point of 327°C, thermal stability, and electrical insulating qualities. The chemical inertness of the PTFE molecule is due to the strong and stable link between carbon and fluorine atoms.

Noble Glass Works is an excellent and trustworthy PTFE lined ball valve manufacturer in India.

Properties:

PTFE is available in both virgin and filled compounds to improve the basic qualities for a wide range of applications and end-uses.

Based on the required property for specified service conditions/applications, the grade of PTFE is chosen from the Virgin and Filled grades of PTFE. The handbook explains the different grades of PTFE and Filled PTFE, the filler content in PTFE, basic qualities, and important service conditions/end uses.

If you are looking for one of the most reliable PTFE High Pressure bellows manufacturers in India, Noble Glass Works is the name you can count on.

Applications:

PTFE goods are utilised in a variety of the sectors mentioned below as sealing and gasketing materials, electrical insulation products, antifriction components, anti-corrosive articles, anti-stick barriers, radiation barriers, inert and hygienic items, weathering-proof & non-water absorption materials.

● Chemical

● Adhesives Manufacturing

● Computer Hardware

● Valve Manufacturing

● Paper & Pulp

● Railways

● Pharmaceuticals

● Aviation & Aeronautical

● Petroleum

● Atomic Power Station

● Thermal Power Station

● Petrochemicals

● Electronics

● Fertilizers

● Space Station

● Electrical

● Pump Manufacturing

#PTFE Lined Ball Valves manufacturer in Gujarat#PTFE lined ball valve manufacturer in India#PTFE High Pressure bellows manufacturers in India

1 note

·

View note

Text

What Is A PTFE lined ball valves?- A Complete Guideline

To Sum It UpA PTFE lined ball valves is essential when it comes to industries because it helps to regulate the flow and pressure of liquids passing through the pipe. The valve consists of a disc that is either perpendicular or parallel to the opening of the tube, and it regulates the pressure efficiently. For machines, it is essential to note that the proper functioning of all the parts is mandatory. Visit https://www.linedvalves.co.in/lined-ball-valves.html to know more about these valves.

Aira 4Matic Global Valve Automation Pvt. Ltd. is a reliable name in this field for good quality PTFE lined ball valves. It is essential that the functioning of these valves is proper, or else it might meddle with the production of the unit. A valve is an opening or parting that allows liquid or gases to pass through it. This valve moves in a rapid to and fro motion when liquid moves through it. It imitates the fluttering of the wings of a PTFE lined ball valves and hence, is known as a PTFE lined ball valves

Advantages Of PTFE lined ball valves

These valves are very precise and are very handy when it comes to the functioning of the plant. These valves make it easier for liquids to pass through them at a moderate speed. It increases the productivity of the machines and ensures that the result is correct according to the standard. You can prevent overflow of the fluid inside by using the valve in the proper manner. If there is an internal overflow, it will ruin the entire production process.

Also, suppose you produce strong chemicals that might be corrosive. In that case, you need to be extra careful while handling it. Using improved machinery will help you avoid unfortunate accidents. It will safeguard the lives of the workers, prevent you from facing legal complications, and uphold the reputation of your company.

These valves are very easy to use because you can fix or open them easily without much hassle. Therefore, it speeds up the process as there is no prolonged installation time. Moreover, it does not require a lot of materials to build it; hence, it is not very costly. It is a relief for investors to knows that such parts are readily available and that too at an affordable price.

In comparison to other valves, these take up much less space and therefore, the fitting is superior. That accentuates the performance of the machine and improve the quality of production. Machines or parts should make it easier for plants and correct minor human errors. Hence, being aware of such innovative parts and using them entirely for the benefits industry is wise.

To Sum It Up

There are multiple concerns of any industry. The labour depends on it, and so does other smaller factories and suppliers. Hence, if there is a problem in the production unit, it wrecks the demand and supply chain. Therefore, you have to be very careful while using machine parts. Choose a reliable company to purchase such parts so that you have a smooth and quality experience.

Aira 4Matic Global Valve is an ISO 9001:2015 company, manufacturers and exporter of PTFE lined plug valves in India. Company’s manufacturing unit is established in Ahmedabad. We are offering PFA lined butterfly valves, PTFE lined ball valves and weir diaphragm valves.

0 notes

Text

Important Steps to Troubleshoot and Fix the Most Common Problems with AODD Pumps

Because of their simplicity, air operated double diaphragm pumps (AODD Pumps)are great for transfer applications. To achieve maximum performance, it is important to properly install and operate your pump. These six easy fixes will help you troubleshoot and fix common problems when your AODD is not working properly during installation and operation.

1.To Check The Air Inlet Size And Pressure.

A small airline is the most common error with AODD pumps. To operate at its best, the pump requires compressed air. An airline that is too small will deprive it of the fuel it needs. Larger AODD pumps (one-inch and more) require more compressed and longer air lines than their smaller counterparts. For the correct size air line for your pump, refer to the manufacturer's instructions and operation manual. It is a good rule of thumb to match the size of the air line hose to the size of the inlet port on AODD pumps. Explore the latest AODD Pumps at Antlia Engineering Works. They are the AODD Pump Suppliers Globally.

Your pump's performance can also be optimized by adjusting the inlet pressure. Diaphragm pumps work in a 1:1 ratio. The pump's inlet pressure is directly proportional to the pump's outlet pressure. 100 psi is the target outlet pressure for a 50 gpm 1 inch pump. The pump's inlet pressure must also be greater than or equal to 100psi.

The outlet fluid pressure is affected by fluid viscosity, system back pressure, and fluid viscosity. Too little back pressure can cause the pump to run slower and the ball checks may not be as quick. If the fluid pressure exceeds the air pressure, the pump may stall. An air regulator is required to regulate the incoming pressure to ensure that an AODD pump performs at its best. An air regulator and the correct size air line will resolve most of the problems associated with AODD pump installation.

2.Check for Muffler Icing and Restrictions

Mufflers can be installed on AODD pumps and are recommended because they can produce high decibel levels at full speed. To operate the pump's air motor, compressed air is needed. Rapid temperature changes are caused by the compressed air entering the valve. It is then channeled through the pump's center section and exhausts through the muffler. The muffler exhaust temperature is below freezing and can lead to icing issues. This is more prevalent in environments with high humidity. Looking for AODD Pump Manufacturers In India.

Visit Antlia Engineering works, they manufacture all types of AODD Pumps.

If your pump is acting erratically, your inlet air contains high levels of moisture, or you can see the front of your muffler, these are indicators that your pump has icing issues. These solutions can help you eliminate icing issues and improve your pump's efficiency.

Pump the air pressure down

To operate at a lower speed (i.e.,. lower air pressure)

An exhaust port tube allows you to exhaust the air to remote locations

To collect condensation, add an air filter and a water catcher to your system.

To raise exhaust air temperature above freezing, install an air heater

To adjust the pressure dew point temperature, use an air compressor dryer

3.Checking Sealing Surfaces for Leaking

Leakage issues can occur with all types of pumps. These tips will ensure that your fluids remain in the pump and not the ground.

Follow the bolting pattern's illustration and torque the pump to the manufacturer's specifications.

When servicing your AODD pump, replace all PTFE o rings. Although PTFE can be used in many applications, it is not capable of returning to its original form after being compressed.

You can reduce the risk of leakage by properly torquing your pump according to the manufacturer's specifications and ensuring that sealing o-rings are replaced during service.

4. Ensure proper tubing and piping sizes

The flow rate of fluid required will determine the diameters of the pump's inlet and outlet ports. The size of the outlet and inlet hoses must be equal. This is a major concern because of the potential for cavitation, as well as the higher repair frequency and increased maintenance costs.

A pump that is 1 inch tall has a 1/2-inch inlet hose attached. The pump will not be capable of operating at its maximum capacity without cavitation. As the fluid viscosity increases, this risk is greater. To avoid cavitation, a pump of 1 inch should have an outlet and inlet hose of 1 inch. This will prevent costly and frequent repairs.

AODD pumps should have flexible inlet and outlet connections. This is preferable to hard plumbed installations. As the pump speed increases, vibration increases. Vibration increases with pump speed. This increases the possibility of hard-plumbed connections being loosened, which can lead to leakage.

5. PRIME - LOWER THE PUMP

AODD pumps are a popular choice for applications that require self-priming. The AODD pumps draw fluid by creating a low-pressure zone within the fluid bowls. This is less than the atmospheric pressure (14.7 psi). If the air pressure is too high, the pump will not changeover quickly enough to allow the fluid to flow into it.

This is solved by using the air regulator to reduce the air pressure entering an air valve and slow down the pump. The pump speed can be reduced to ensure that the fluid supplied has sufficient time to reach the pump. After this, the pump can operate at a faster speed by increasing the air pressure.

6. CLEAR ALL FLUID LINE RESERVATIONS

Clearing any fluid line restrictions is the final step in ensuring optimal pump performance. Limitations can lead to increased maintenance, pressure loss and potential cavitation. This issue can be fixed by removing the following:

Valves that are partially or fully closed

Line kinks or clogs

Too many hoses or too long a distance

These six steps will resolve most of the problems associated with AODD pumps. This will allow you to produce more and not spend time trying to fix it. If you need more help troubleshooting and repairing your AODD pump contact one of our experts.

For more details visit Antlia Engineering Works and know in detail about AODD Pumps as they are the Peristaltic Pump Manufacturers and supplier of the Pumps worldwide.

#AODDPumps#AODDPumpManufacturers#AODDPumpSuppliers#AODDPumpManufacturersInIndia#PeristalticPumpManufacturers

0 notes

Link

0 notes

Text

A Premier Supplier of PTFE Lined Products

When it comes to industrial operations, if you switch to the crappy gadgets or appliances, things won’t work the way they are expected.

That’s how managing every aspect makes sure you are aligning with what is highly sought in place.

Thus, have you been in any situation wherein you required the tool to get started any industrial operation?

In fact, are you a business owner who has to do a lot with a wide range of Lined Pipes, Fittings, Valves and other such customized products?

If this is what you are considering, this is the right guide for you.

We will do the best to ensure you have the best information available.

Do ensure to stick with the guide and let’s get started.

When it comes to manufacturing and supplying a wide range of Lined Pipes, Fittings, Valves and other such customized products, all you have got to look just at Ablaze Lining since they are a thought-leader, expert, including a leading manufacturer and supplier of Fluoropolymer Lined Pipes, Fittings and Valves. The amazing thing you will note is – They have been a successful partner with leading companies across the world. They know what it takes to working in corrosion resistant company. Therefore, whatever requirement you have got, just make sure to visit the website and fill in the contact form. This will make things a lot easier and advantageous.

Products they offer are:

Lined Pipe

Lined Elbow 45

Lined Elbow 90

Lined Equal TEE

Solid Spacer

Lined Spacer

Ball Valve

Ball Check Valve

Plug Valve

Full View Sight Glass

Thus, were you looking for the products that are designed in a way that can be used in highly corrosive applications?

If yes, the recommendation will do the best.

Final Thoughts

No matter if you need High Pressure Bellow Manufacturer in India or something, the thing that separates the recommendation than the others is the level of quality product they deliver.

On a sweeter note – Thanks for the read, though!

0 notes

Photo

Sleeved Plug Valve Manufacturer in Vishakapatnam

Our plug valve has a unique stem seal design consisting of cup springs which ensure uniform force distribution on the sealing member and plug.Ritcher is the most successful Industrial Valve Manufacturers in India.

We offer premium quality PFA lined valves, PTFE lined valves, ball valves, high-performance butterfly valves manufacturers, shut off valves, sleeved plug valves, lined plug valves and control equipment used in demanding applications. In many applications, they operate virtually maintenance-free for decades.

Address: Survey No 256, GIDC Manjusar,Savli, Near Bombardier Circle, Dist. Vadodara 391770, Gujrat,India.

Contact us on: 8652603254

Toll-Free No.: 18002679955

Email us at: [email protected]

Visit us on: Sleeved Plug Valves Manufacturers in India

0 notes