#PMSM

Explore tagged Tumblr posts

Text

Puella Magi Madoka Magica: Magia Exedra (2024)

#madoka magica#magia exedra#magia record#oriko magica#tart magica#suzune magica#kazumi magica#puella magi madoka magica#puella magi oriko magica#puella magi tart magica#puella magi kazumi magica#puella magi suzune magica#pmmm#pmkm#pmom#pmtm#pmsm#magireco#gifs#gifset#magical girls#oriko mikuni#suzune amano#iroha tamaki#madoka kaname#kazumi subaru#puella magi

596 notes

·

View notes

Text

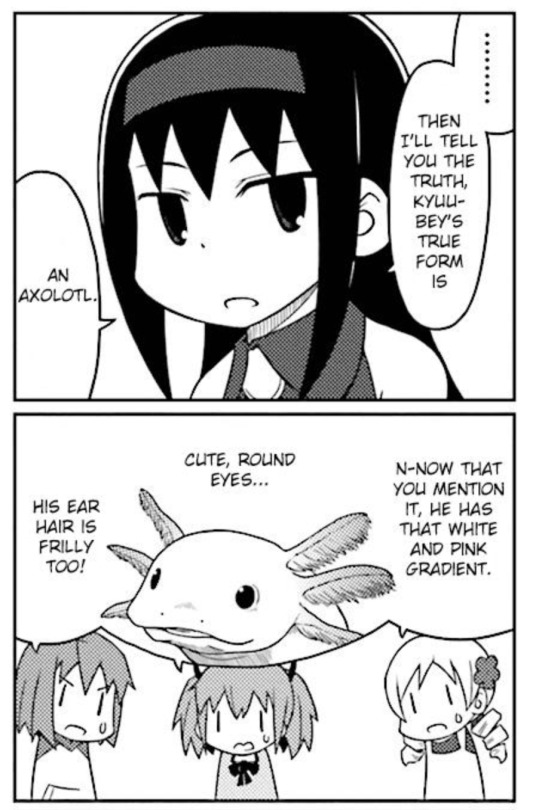

A genie

An angel

A fairy

An axolotl

WTF is Kyubey compilation

#the interpretations are actually pretty fascinating#he grants your wish but it always goes wrong#he has no free will and just serves a greater purpose#he can't lie but he sure as hell can trick#he's cute like an axolotl#kyubey the villain you are ❤#manga#homura tamura#tart magica#suzune magica#veranda of madoka#kyubey#incubator#madoka magica#pmmm#pmtm#pmsm#pmht#my posts#akemi homura#jean tart#liz hawkwood#narumi arisa#miki sayaka#kaname madoka#tomoe mami#puella magi madoka magica#mahou shoujo madoka magica#mssm#queue

59 notes

·

View notes

Text

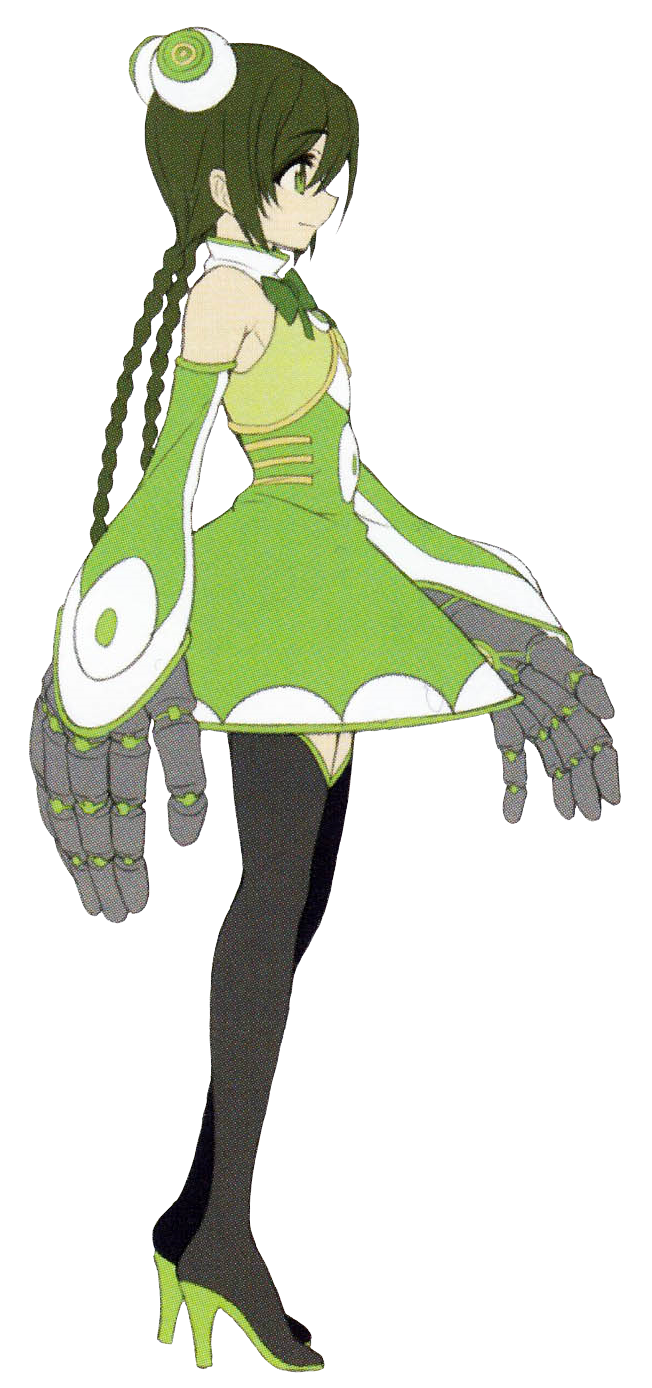

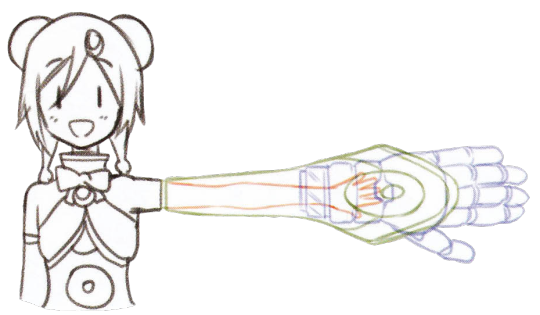

Matsuri Hinata Transparents from the Magia Archive

[ Source ]

Requested by @gorochuva

#Puella Magi Madoka Magica#PMMM#Madoka Magica#Puella Magi Suzune Magica#PMSM#Suzune Magica#Concept Art#Matsuri Hinata#Matsuri#Transparents#PNG#Doppel#Elise

75 notes

·

View notes

Text

Mercedes-Benz EQA 250 Plus: In-Depth Analysis

₹66 Lakh The Mercedes-Benz EQA 250 Plus is a cutting-edge electric SUV that merges sustainability, luxury, and advanced engineering. Below is a detailed breakdown of its features and performance to help understand its appeal and capabilities. Powertrain and Performance Motor Type: The EQA 250 Plus is powered by a Permanent Magnet Synchronous Motor (PMSM). This motor type is known for high…

#540 km range#70.5 kWh battery#ADAS safety#Advanced driver assistance#Burmester Sound System#Compact SUV.#DC Fast Charging#dual-zone climate control#Eco-Friendly Vehicle#Electric SUV#EV Performance#Family EV#front-wheel drive#Luxury EV#luxury features#MBUX infotainment#Mercedes-Benz design#Mercedes-Benz EQA 250 Plus#Panoramic Sunroof#PMSM Motor#Premium interiors#quick charging#regenerative braking#Sustainable Mobility#Urban SUV#zero-emission vehicle

1 note

·

View note

Text

Optimizing Performance & Efficiency by Advanced Techniques in 3-Phase PMSM Motor Control

In the contemporary EV realm, advanced techniques and methodologies aimed at elevating the performance and efficiency of 3-phase PMSM motor controllers, aligning with the evolving landscape of industrial automation.

Sensorless Control

Sensorless control techniques, such as observer-based methods and back-EMF estimation, offer alternatives to traditional sensor-based control, addressing challenges while enhancing reliability and reducing cost.

Advanced Control Algorithms

Exploring sophisticated control algorithms like Model Predictive Control (MPC) and Adaptive Control, which leverage computational intelligence to enhance dynamic response and robustness, ensuring precise motor control in dynamic environments.

Power Factor Correction (PFC)

Power Factor Correction techniques play a vital role in improving the efficiency and power quality of PMSM motor drives. Active and passive PFC methods optimize power utilization, reducing harmonic distortion and enhancing overall system efficiency.

Fault Diagnosis and Protection

Efficient fault diagnosis methods, coupled with fault-tolerant control strategies, safeguard PMSM motor systems against various faults, ensuring uninterrupted operation and prolonging system lifespan in critical industrial applications.

Future Trends and Emerging Technologies

Anticipating the future of PMSM motor control, we delve into emerging trends such as AI integration, digital twin simulations, and advanced semiconductor devices like SiC/GaN, which promise to reshape the landscape of industrial automation with unprecedented efficiency and intelligence.

#PMSM Motor Control#PMSM motor controllers#motor controllers#motor controller EV#EV motor controller#PMSM motor drives

0 notes

Text

HVLS fans in Hyderabad

HVLS fans are becoming increasingly popular in Hyderabad due to their ability to provide efficient cooling solutions. These fans are designed to move large volumes of air at low speeds, creating a comfortable environment without the need for high energy consumption. HVLS fans can be used in a variety of settings, such as commercial buildings, warehouses, factories, and even residential homes. With the help of these fans, businesses in Hyderabad can reduce energy costs while providing a comfortable environment for their customers and employees.

HVLS Fans Manufacturer & Supplier in India | Marley HVLS Fans

2nd floor, 26/9 & 29/9a, Quthbullapur Village,

Industrial Development Area (CIE Expansion)

Gandhi Nagar Quthbullapur Mandal,

Medchal-Malkajgiri District, Telangana – 500 055

+91 7416 874 507

+91 7416 878 070

#Best HVLS Fans Manufacturers in Hyderabad#HVLS Fans Manufacturers in Hyderabad#Best HVLS fans#HVLS fans in Hyderabad#best hvls fans in india#hvls fans in india#hvls pmsm fans in hyderabad#hvls gear fans in india#hvls pmsm fans in india#High Volume Low Speed Fan in Hyderabad#hvls gear fans in hyderabad

1 note

·

View note

Text

阪神のジェットカーと言えばその比類なき高加速力で知られているんだけど、セッティングを見ると何ていうかひっくり返っちゃうんだよね

たとえば5700系、190kwモータを編成で12基吊ってるんだけど、どう考えても4両つなぎの電車にしてはオーバースペックなんですよ。4km/h/sの加速力を出すにしてもこんなパワーは要らない。じゃあ何に使っているかと言えば、空転防止なわけですよ

5700系のギアリングはなんと6.06。5500系よりも2段も浅いギアリングなんです。つまりギアリングが浅くなった分をモータのトルクで補償する。だから起動時の電流は5500系よりも大きくなるからパンタグラフを1個増設して3基にしてるわけ

そんでもってモータをPMSMにしたってことはインバータとの関係は個別制御しかありえない。そうなれば空転管理もより精密になる。だから5700系の走りは5500系よりも数等高級になったわけです。特に雨の日の路面に食いついたような力強い加速はさすが阪神電車と思わせます。とことん走りに対して妥協がないんですよこの電車

ついでに言うとこのセッティングだと定格速度も48~50km/hくらいになるんで、言うなれば定トルク領域終端まで4km/h/sの加速力が維持できてフリーラン領域でも3.0km/h/sくらいの加速力を維持でき、最高認可速度の91km/hまで太いトルクで走れちゃう。

だから最高速度も引っ張っていけば120km/hくらいまではいけちゃうと思うんですよね。昔ジェットが間合いで準急運用に就いていたけど、5700系なら現行の特急運用、問題なくこなせると思いますよ? 5700系は出足で滑らず高加速でトップの伸びもいい。こと走りに関しては日本一贅沢な電車じゃないですかねこれ

西大阪線を走る5500系。慌てて大物で撮影したのでえらいことに

5500系も110kwモータ全軸駆動というぜいたくさですがギアリングは7.07。そしてまだVVVFが発展途上だった���ともあって1C8M制御なんですよ。定格48.1km/hは実に早い脚なんですが雨の日はやっぱり若干やんちゃになる。並列接続とはいえ8モータの面倒を1インバータ、しかも推定式方式で見るわけですから、急激な電圧変動にはどうしても対応できないところはあるんです。せめて1C4Mならねえ…と思うんですが。いやもちろん8モータ直列接続の抵抗制御車5001形なんかと比べりゃあ比較にならない高級な走りをするんですけど

17 notes

·

View notes

Text

Bia Ather: Your Trusted Ather Dealership in Bangalore for Advanced Electric Scooters

Visit BIA Ather Showroom Today!!!

Get in Touch with Us!!!

Book Your Favorite Ather Scooter Today!!!

Why Choose Bia Ather as Your Preferred Ather Dealership in Bangalore?

At Bia Ather, we take pride in being one of the most trusted and authorized Ather dealership in Bangalore, offering the latest and most advanced Ather electric scooters to our valued customers. Our commitment to innovation, sustainability, and excellent customer service makes us the preferred choice for EV enthusiasts in the city. Whether you are looking for the Ather 450X or the Ather 450S, we provide a seamless purchasing experience with comprehensive after-sales support.

Explore the Advanced Ather Electric Scooters at Our Showroom

Ather 450X: The Ultimate Electric Ride

The Ather 450X is a high-performance electric scooter designed for urban commuters seeking speed, efficiency, and advanced technology. It comes with an IP67-rated battery, a powerful 6 kW PMSM motor, and Warp Mode for an exhilarating riding experience. With a range of 146 km on a single charge, it ensures uninterrupted city travel.

Ather 450S: A Smart and Affordable Option

For those looking for an economical yet feature-rich electric scooter, the Ather 450S is an excellent choice. It offers a range of 115 km, a 5.4 kW motor, and a 7-inch DeepView LCD dashboard for enhanced connectivity and ride statistics.

Visit the Bia Ather Showroom in Bangalore

State-of-the-Art Ather Showroom Experience

Our Ather showroom in Bangalore is designed to provide a premium customer experience. From test rides to detailed product demonstrations, our experts are here to guide you through every aspect of the Ather scooters. Whether you're interested in performance, battery life, or smart features, we ensure that you get all the information you need before making your purchase.

Test Ride the Ather Electric Scooters

We encourage our customers to book a free test ride at our showroom to experience the seamless acceleration, superior ride quality, and innovative features of Ather electric scooters firsthand.

Charging Infrastructure and Ather Grid in Bangalore

Bangalore boasts an extensive Ather Grid, a fast-charging network designed to support Ather electric scooters. With strategically placed charging stations across the city, riders can conveniently charge their scooters while on the go. At Bia Ather, we provide complete guidance on Ather Grid locations and the best charging practices to ensure you maximize your scooter’s efficiency.

Join the EV Revolution with Bia Ather

Switching to Ather electric scooters means embracing a sustainable, cost-effective, and technologically advanced mode of transportation. With Bangalore’s rising fuel costs and increasing environmental concerns, electric mobility is the future. At Bia Ather, we are dedicated to helping you make the transition to electric vehicles with ease and confidence.

#ather dealership in bangalore#ather showroom in bangalore#ather showroom in jaya nagar#ather showroom in rajajinagar#ather showroom in jp nagar#best ather showroom in bangalore#Bia Ather#Ather 450#Ather Ritza on road price in Bangalore#Ather Ritza#Ather sales#Ather services

0 notes

Text

How Permanent Magnet Machines Work

Permanent magnet machines (PMMs) are widely used in various industries due to their efficiency, reliability, and compact design. These machines leverage permanent magnets instead of electromagnets or field windings to generate a magnetic field, making them an essential component in modern electrical applications such as electric vehicles, wind turbines, and industrial automation. This article explores the working principles, types, and advantages of permanent magnet machines.

Basic Working Principle of Permanent Magnet Machines

At the core of a permanent magnet machine is a rotor containing permanent magnets that create a constant magnetic field. Unlike traditional electric machines that rely on externally supplied current to generate magnetism, PMMs use naturally occurring magnetization, eliminating the need for additional excitation. The interaction between the permanent magnet field and the stator windings produces torque, which drives the machine.

PMMs operate based on Faraday’s Law of Electromagnetic Induction, where a rotating magnetic field induces an electromotive force (EMF) in the stator windings. This process allows for energy conversion between electrical and mechanical forms, making PMMs highly efficient.

Key Components of Permanent Magnet Machines

Stator: The stationary part of the machine, consisting of laminated iron cores and copper windings. It plays a crucial role in producing the necessary magnetic flux interaction with the rotor.

Rotor: The rotating component embedded with permanent magnets that generate a continuous magnetic field.

Permanent Magnets: Usually made from materials like neodymium, ferrite, or samarium-cobalt, these magnets provide a strong and stable magnetic field without the need for an external power source.

Bearings and Shaft: These components ensure smooth mechanical movement and support the rotor's rotation.

Types of Permanent Magnet Machines

Permanent magnet machines come in different types depending on their construction and operational characteristics:

Permanent Magnet Synchronous Machines (PMSMs)

Operate in synchronism with the supply frequency.

Commonly used in electric vehicles (EVs), industrial motors, and robotics due to their high efficiency and precise control.

2. Permanent Magnet Brushless DC Motors (BLDC)

Use an electronic commutation system instead of mechanical brushes.

Found in applications like household appliances, drones, and medical devices.

3. Permanent Magnet Generators (PMGs)

Convert mechanical energy into electrical energy efficiently.

Used in wind turbines, hydroelectric power plants, and backup power systems.

Advantages of Permanent Magnet Machines

PMMs offer several advantages over traditional electric machines, making them a preferred choice in modern engineering applications:

Higher Efficiency: With no additional excitation losses, PMMs operate at higher efficiencies, reducing energy consumption.

Compact and Lightweight: The elimination of field windings leads to a smaller and lighter design, making them ideal for space-constrained applications.

Improved Reliability: Fewer moving parts and reduced electrical losses increase the machine's lifespan and durability.

Better Power Density: PMMs can generate more power in a smaller footprint, enhancing performance in applications like EVs and renewable energy.

Reduced Maintenance: The absence of brushes (in BLDC motors) and lower heat generation contribute to minimal maintenance requirements.

Challenges in Permanent Magnet Machines

Despite their numerous benefits, PMMs also face some challenges:

High Material Costs: Rare-earth magnets, such as neodymium, can be expensive and subject to price fluctuations.

Thermal Management: Excessive heating can lead to magnet demagnetization, reducing machine performance.

Magnetic Field Control: Managing flux interactions and preventing demagnetization require careful design considerations.

Recycling and Sustainability: Extracting and recycling rare-earth materials pose environmental concerns.

Future Trends in Permanent Magnet Machine Technology

To overcome challenges and improve performance, researchers and manufacturers are developing advanced PMM technologies, including:

Use of non-rare-earth magnets to reduce dependency on expensive materials.

Hybrid PMM designs combining traditional and PM technologies for enhanced performance.

Smart control algorithms to optimize energy efficiency and real-time monitoring.

Integration with IoT and AI to improve predictive maintenance and automation capabilities.

Conclusion

Permanent magnet machines have transformed various industries by offering higher efficiency, compact design, and superior performance compared to conventional electric machines. Their applications range from electric vehicles and wind power generation to industrial automation and consumer electronics. As technological advancements continue, PMMs will become even more powerful, efficient, and environmentally friendly, solidifying their place in the future of electrical engineering.

0 notes

Text

Powering The Future: Understanding EV Motor Technologies by Belrise Industries

Electric vehicles (EVs) are gaining popularity worldwide, and as the demand for these vehicles increases, there is a greater need for efficient and reliable electric motors. When it comes to EV motors, the below three main types are widely used: Permanent Magnet Synchronous Motors (PMSMs), Induction Motors, and Brushless DC Motors.

Each type has its own advantages and disadvantages, making it important for an Automobile company to choose the right motor for their EV vehicles.

EV Motors & Their Types

Let’s start by understanding the basic functionality of these motor types and how they drive the EV industry. Essentially, an electric motor is a device that converts electrical energy into mechanical energy, propelling the vehicle forward. All motors consist of a rotor, a stator, and a set of windings. As electric current flows through the windings, a magnetic field is created. This magnetic field interacts with the magnetic field of the stator, resulting in the rotation of the rotor, which powers the electric vehicle.

Let’s delve into the different types of EV motors:

Ev Motor Types and Their Usages

Permanent Magnet Synchronous Motors (PMSMs):

PMSMs are the most commonly used motors in EVs. They are known for their efficiency, reliability, and long lifespan. PMSMs generate a rotating magnetic field using a permanent magnet, which interacts with the stator coils to produce the electric current that powers the motor. PMSMs strike an optimal balance between efficiency, reliability, and cost-effectiveness. They are also relatively easy to manufacture, contributing to lower overall costs.

Induction Motors:

Induction motors are a more budget-friendly option compared to PMSMs, but they tend to be less efficient and have a shorter lifespan. These motors create a rotating magnetic field through the stator coils, inducing a current in the rotor. The resulting current generates a magnetic field that interacts with the stator field to produce torque. Induction motors are suitable for budget-conscious EV buyers as they offer adequate performance for most driving conditions, though they may not be as efficient as PMSMs.

Brushless DC Motors:

Brushless DC motors are the most efficient type of motor available but also the most expensive. They utilise a DC motor with a controller to generate a rotating magnetic field that interacts with the stator coils, producing the electric current needed to power the motor. These motors are primarily used in high-performance EVs such as Tesla’s Model S Plaid. Despite being more costly, brushless DC motors offer superior efficiency compared to induction motors.

Key Factors in Choosing Motors for EV Segment Vehicles

Now, let’s explore the steps involved in the motor selection process, highlighting the key factors that automobile companies take into account.

The motor selection process involves a series of steps that enable automobile companies to make informed decisions. Let’s examine the factors, which contribute to achieving the desired outcomes for EVs.

Cost Considerations:

Cost is a significant factor in the motor selection process. Automobile companies aim to strike a balance between performance requirements and affordability to ensure their EVs are competitive in the market. Factors such as motor manufacturing costs, economies of scale, and potential long-term savings in maintenance and operating expenses are carefully considered. By selecting a cost-effective motor, automobile companies enhance the overall viability and market competitiveness of their EVs.

Battery Compatibility:

Selecting a motor that is compatible with the EV’s battery system is crucial for seamless integration and efficient power transfer. Factors such as voltage, current, and charging capabilities are taken into account to ensure proper alignment between the motor and battery. Compatibility ensures optimal performance, longevity, and efficient utilization of the battery’s capabilities.

Power Rating:

Determine the power requirements of your application to select a motor that can handle the workload effectively. Consider factors such as load demands, duty cycle, and potential future expansions or changes that may impact power requirements.

Torque Rating:

Assess the torque requirements of your application to ensure the motor can provide sufficient force to move the load. Consider factors such as load characteristics, starting torque requirements, and potential variations in torque during operation.

Efficiency:

Choose a motor with higher efficiency to minimise energy consumption and reduce operating costs. Look for motors that adhere to recognized efficiency standards such as NEMA Premium or IE3.

Performance:

Evaluate various performance factors such as speed, acceleration capabilities, precision control requirements, and noise level. Tailor your motor selection to meet the specific demands of your application effectively.

Warranty and Customer Support:

Opt for a motor from a reputable manufacturer that offers a warranty and good customer support. A longer warranty period provides peace of mind and protects your investment.

By considering these factors, Automobile companies select electric motors, ensuring optimal performance, longevity, and a successful outcome for your motor-driven EV.

The Future of EV Motor Manufacturing

As the demand for EVs continues to rise, the development of more efficient and reliable electric motors becomes paramount. The EV motor manufacturing industry is experiencing rapid growth, with numerous companies striving to develop innovative motor technologies.

Some key trends in EV motor manufacturing include:

Embracing Lighter and Stronger Materials: Enhancing Efficiency and Reducing Vehicle Weight

One of the prominent trends in EV motor manufacturing is the adoption of lighter and stronger materials. By incorporating advanced materials such as high-strength alloys, carbon fibre composites, and lightweight polymers, manufacturers can significantly reduce the overall weight of EV motors. This reduction in weight has a twofold benefit: it enhances the efficiency of the motor and contributes to the overall weight reduction of the vehicle.

Lighter EV motors require less energy to propel the vehicle, resulting in improved energy efficiency and extended driving range. Additionally, reduced vehicle weight translates to lower energy consumption, allowing EVs to maximise their battery capacity and minimise charging frequency. By embracing lighter and stronger materials, manufacturers are pushing the boundaries of efficiency and redefining the possibilities of electric mobility.

Adopting More Efficient Manufacturing Processes: Driving Down Costs and Enhancing Production Efficiency

In the quest for more affordable and accessible EV motors, manufacturers are investing in the development and implementation of more efficient manufacturing processes. Advanced automation technologies, such as robotics and machine learning, are revolutionising the production lines, streamlining operations, and reducing manufacturing costs.

By automating repetitive tasks and optimising production workflows, manufacturers can achieve higher levels of precision, consistency, and productivity. This, in turn, contributes to cost reduction, making EV motors more affordable for consumers. Furthermore, efficient manufacturing processes allow for greater scalability and faster production, enabling manufacturers to meet the growing demand for EV motors in a timely manner.

Developing New Motor Designs: Enhancing Performance and Efficiency

The pursuit of better performance and efficiency is at the core of EV motor development. Manufacturers are continuously exploring new motor designs and configurations to unlock the full potential of electric propulsion. These innovative designs focus on maximising power output, improving torque characteristics, and minimising energy losses during operation.

For instance, some manufacturers are exploring advanced magnet technologies, such as rare-earth magnets and magnetised laminated cores, to enhance the magnetic field strength and overall motor efficiency. Others are integrating advanced control systems and algorithms to optimise motor performance in real-time, allowing for dynamic adjustments based on driving conditions.

Additionally, the development of compact and integrated motor designs is gaining traction. By integrating multiple components and subsystems into a single unit, manufacturers can reduce the size, weight, and complexity of EV motors while maintaining or even enhancing their performance and efficiency.

These developments in motor design hold tremendous potential for the future of electric vehicles. As EV motors become more sophisticated, we can expect increased power, improved acceleration, and enhanced overall driving experience, all while maximising energy efficiency and range.

Conclusion

In conclusion, the evolution of electric vehicle motor technologies is shaped by the adoption of lighter and stronger materials, the implementation of more efficient manufacturing processes, and the development of new motor designs.

These trends not only enhance the efficiency and performance of EV motors but also contribute to the affordability and accessibility of electric vehicles for a wider audience. As the electric revolution accelerates, we can look forward to even more groundbreaking innovations that will propel us towards a cleaner, greener, and more sustainable future of transportation.

0 notes

Text

BTÜ öğrencilerinden yenilikçi mühendislik projeleri

https://pazaryerigundem.com/haber/199902/btu-ogrencilerinden-yenilikci-muhendislik-projeleri/

BTÜ öğrencilerinden yenilikçi mühendislik projeleri

Bursa Teknik Üniversitesinde 13. Geleneksel Genç Mühendisler Sergisi açıldı. Elektrik ve Elektronik Mühendisliği Bölümü öğrencilerinin dönem sonu projelerinin sergilendiği alanı ziyaret eden BTÜ Rektörü Prof. Dr. Naci Çağlar, “Mezun olmadan mühendislik problemlerini çözme başarısı gösteren siz öğrencilerimizi tebrik ediyorum” dedi.

BURSA (İGFA) – BTÜ Mühendislik ve Doğa Bilimleri Fakültesi Elektrik ve Elektronik Mühendisliği Bölümü öğrencilerinin projeleri, Mimar Sinan Yerleşkesi B Blok Fuaye alanında sergilendi.

Elektrik Elektronik Mühendisliği 2’nci ve 3’ncü sınıf öğrencilerinin “Elektromanyetik Alanlar”, “Güç Elektroniği” ve “Elektrik Makinaları” derslerinde verilen proje ödevlerinin sergisine, BTÜ Rektörü Prof. Dr. Naci Çağlar da katıldı.

Öğrencilerin projelerini tek tek inceleyen Rektör Naci Çağlar, “Burada sergilenen projeler öğrencilerimizin, mühendislik biliminin temellerini ne kadar sağlam bir şekilde kavradıklarını ve bu bilgileri pratikte nasıl kullanabildiklerini ortaya koyuyor. Elektrik ve elektronik mühendisliği gibi dinamik ve hızlı gelişen bir alanda, öğrencilerimizin bu projelerle gösterdikleri performans, üniversitemizin mühendislik eğitimindeki güçlü altyapısının bir yansımasıdır” dedi.

BTÜ’de yürütülen eğitim çalışmalarının, sadece teorik bilgilerle sınırlı kalmadığını, aynı zamanda öğrencileri iş hayatına hazırlayan projelerle desteklendiğini ifade eden Rektör Çağlar, “Bu projeler, öğrencilerimizin sadece akademik anlamda değil, aynı zamanda problem çözme, takım çalışması ve yaratıcılık gibi becerilerini de geliştiriyor. Projeler sayesinde öğrencilerimiz mezun olmadan mühendislik problemlerini çözmeye başlıyor ve bunun sonucunda donanımlı bir şekilde mezun oluyor. Bu doğrultuda projelerin hazırlanmasında emeği geçen tüm öğrencilerimize ve onları yönlendiren değerli akademisyenlerimize teşekkür ediyorum” diye konuştu.

Sergilenen projeler hakkında bilgi veren Elektrik Elektronik Mühendisliği Bölümü Öğretim Üyesi Dr. Mehmet Barış Tabakcıoğlu, şu ifadeleri kullandı:

“Bugün sergimizde 3 farklı dersi konu alan projelerimiz yer alıyor. Örneğin öğrencimiz Mustafa Sevinç tarafından hazırlanan “PMSM Motor” projesinde PermanentMagnetSynchronous Motoru (PMSM) tasarlanıp, üzerinde inceleme yapıldı. Proje ile motor teknolojilerinin geliştirilmesine katkı amaçlanıyor. Öğrencimiz Kübra Yiğit’in “Akıllı Garaj” projesinde ise çift güvenlikli ve akıllı garaj sistemi tasarımı amaçlandı. Ayrıca projede HC06 Bluetooth modülü kullanılarak aracın uzaktan kontrolü sağlandı. Aracın önüne koyduğumuz mıknatıs ve garaj kapımızda bulunan RFID sayesinde çift yöntemli giriş sağlandı.”

0 notes

Text

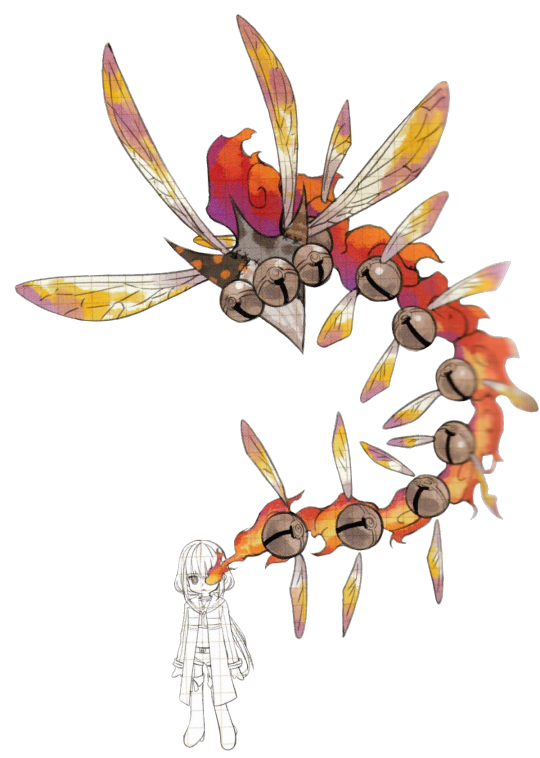

Suzune Amano Transparents from the Magia Archive

[ Source ]

Requested by @gorochuva

#Puella Magi Madoka Magica#Puella Magi Suzune Magica#PMMM#PMSM#Suzune Magica#Madoka Magica#Concept Art#Suzune Amano#Suzune#Transparents#PNG#Doppel#Clothette

48 notes

·

View notes

Text

Tata Punch EV Review: Performance, Safety & Comfort

₹14.99Lakh General Overview Country of Origin: India Model: Punch EV Empowered S LR ACFC Body Type: Compact SUV Colors Available: Pristine White Dual Tone Fearless Red Dual Tone Daytona Grey Dual Tone Seaweed Dual Tone Empowered Oxide Dual Tone The Tata Punch EV Empowered S LR ACFC is a highly customizable SUV with a range of modern, dual-tone exterior color options, appealing to a…

#35 kWh Battery#421 km Range#5-Star NCAP#Apple CarPlay#compact electric SUV#Dual-Tone Design#Electric Compact SUV.#Electric vehicle#Empowered S LR ACFC#Fast charging#HARMAN audio#India EV Market#LED Headlamps#PMSM Motor#regenerative braking#safety features#Tata Motors#Tata Punch EV#Urban SUV#Wireless Android Auto

0 notes

Text

Vehicle Motors Market: Trends, Growth, and Future Opportunities

The Vehicle Motors market is expected to grow from USD 46.39 Billion in 2024 to USD 75.27 Billion by 2030, at a CAGR of 8.40% during the forecast period.

The vehicle motors market has emerged as a pivotal segment of the global automotive industry, fueled by advancements in electrification, stringent emission regulations, and the growing adoption of electric vehicles (EVs). Vehicle motors play a crucial role in converting electrical energy into mechanical energy, ensuring optimal performance and energy efficiency. This market encompasses motors used in various types of vehicles, including electric, hybrid, and conventional internal combustion engine (ICE) vehicles.

Top Key Market Players are

Nidec, Mabuchi, Johnson Electric, Mitsuba, Buhler, Denso, Bosch, ASMO, Brose, Shilin Electric, Remy International, Valeo

For More Insights into the Market, Request a Sample of this Report: https://www.reportprime.com/enquiry/sample-report/19870

Key Market Drivers

Rise of Electric Vehicles (EVs): The accelerating shift toward EVs is one of the primary drivers of the vehicle motors market. Governments worldwide are implementing policies to promote EV adoption, such as subsidies, tax rebates, and infrastructure development. Electric motors, which form the core of EV propulsion systems, are experiencing unprecedented demand. This trend is expected to grow further as automakers expand their EV portfolios to meet sustainability goals.

Stringent Emission Standards: With global efforts to reduce carbon emissions, regulatory bodies are enforcing stricter fuel efficiency and emission norms. This has prompted automakers to adopt advanced motor technologies, such as brushless DC motors and permanent magnet synchronous motors, to enhance vehicle efficiency.

Technological Advancements: Innovations in motor technology, such as high-efficiency motors and lightweight designs, are propelling market growth. Emerging trends, including integrated motor and inverter systems, are reducing the overall weight and complexity of propulsion systems, thereby improving vehicle performance.

Market Segmentation

By Motor Type:

DC Brushed Motors: Common in ICE vehicles for auxiliary applications like power windows and wipers.

Brushless DC Motors (BLDC): Preferred for EVs due to their high efficiency, reliability, and low maintenance.

Induction Motors: Widely used in hybrid vehicles for traction purposes.

Permanent Magnet Synchronous Motors (PMSM): Dominant in high-performance EVs due to their superior efficiency and power density.

By Vehicle Type:

Passenger Cars: The largest market segment, driven by the rapid adoption of EVs and hybrids.

Commercial Vehicles: Growing investments in electric buses and trucks are boosting demand in this segment.

Two-Wheelers: Rising urbanization and e-mobility trends are fueling the use of electric motors in scooters and motorcycles.

By Geography:

North America: Robust EV adoption and government incentives are key growth factors.

Europe: A leader in EV innovation, with stringent emission norms driving market demand.

Asia-Pacific: Rapid industrialization, urbanization, and the dominance of automotive giants like China and Japan make this region a growth hub.

Challenges in the Market

Despite its promising growth, the vehicle motors market faces several challenges. One major obstacle is the high cost associated with advanced motor technologies, which can hinder adoption in cost-sensitive markets. Additionally, the scarcity of raw materials like rare earth metals used in permanent magnet motors poses a supply chain risk. Overcoming these challenges will require a focus on alternative materials, improved recycling technologies, and government policies supporting sustainable practices.

Future Trends and Opportunities

Integration of AI and IoT: The integration of artificial intelligence (AI) and the Internet of Things (IoT) in vehicle motors is revolutionizing their functionality. Smart motors equipped with predictive maintenance capabilities and energy management systems are likely to dominate future markets.

Focus on Sustainability: As sustainability becomes a core focus, the development of recyclable motor components and energy-efficient designs will be pivotal. Research into bio-based materials for motor construction is also gaining traction.

Expansion of EV Infrastructure: The growth of EV charging networks and advancements in battery technology will further enhance the adoption of electric motors.

0 notes

Text

0 notes

Text

Servo Motors in Industrial Automation: Precision, Control, and Efficiency

Servo motors are part of the high-speed industrial automation world, producing precise, controlled, and efficient motion for various applications. Whether it is robotics, conveyor systems, CNC machines, or packaging lines, servo motors make sure that industrial processes are run smoothly with maximum accuracy. In this blog, we will discuss what servo motors are, how they work, their advantages in automation, and why they are indispensable in modern industrial settings.

What is a Servo Motor?

A servo motor is a type of electric motor designed to provide precise control over angular position, speed, and acceleration. Rather than a standard motor, which runs at a fixed speed, a servo motor can vary its speed of rotation and change its position based on input signals. This makes it very useful for applications that need accuracy, such as robotics, automation machines, and CNC machines.

Servo motors consist of a motor (often a DC or AC motor), a feedback device (such as an encoder or resolver), and a controller that processes the feedback signals to adjust motor operations. The feedback mechanism ensures that the motor operates with high accuracy and precision, making it perfect for applications that require consistent and repeatable motion.

Servo motors are integral parts of industrial automation in the modern scene and are essential for obtaining precision in speed, position, and acceleration. A high-quality servo motor ensures exceptional performance; thus, it avails superior accuracy, fast response times, and high efficiency, highly crucial in applications such as robotics, CNC machines, and material handling systems. It enables industries to obtain optimal performance with reduced consumption of energy and minimal downtime by using high-quality servo motors. Advanced materials and sophisticated feedback mechanisms ensure enhanced resilience and reliability, even in challenging environments. Whether it is a matter of precision manufacturing, automated assembly lines, or advanced robotics, high-quality servo motors ensure a high level of operational efficiency, reduced maintenance costs, and consistent, high-precision results.

Types of Servo Motors:

AC Servo Motors: AC servo motors use AC to produce rotary motion, with much higher efficiency and superior speed and torque control. They are thus suited for high power applications.

DC Servo Motors: DC servo motors use direct current and provide accurate speed and position control. They are simpler to control but lack in efficiency at higher powers as opposed to AC motors.

Brushless DC Servo Motors (BLDC): These motors use electronic commutator technology instead of brushes; they are therefore more efficient and longer-lived than DC motors, with less maintenance cost.

Stepper Motors: Stepper motors give exact step-by-step control and thus are known for proper application for positioning without necessarily having a feedback system, usually in low to moderate load applications.

Permanent Magnet Synchronous Motors (PMSM): PMSMs use permanent magnets to create a magnetic field and are noted for their high efficiency, high torque output, and low maintenance, commonly being used in high-performance automation systems.

Applications of Servo Motors in Industrial Automation:

Robotics: In robotics, servo motors are widely applied for accurate positioning, arm movement, and fine control. The motors allow robots to be precise while performing complicated tasks like assembly, material handling, and packaging.

CNC Machines: Computer Numerical Control machines rely on servo motors in performing cutting, milling, or drilling operations. These motors are highly important to accurately move the tool in multiple axes.

Conveyor Systems: Servo motors in automated conveyor systems control the speed and position of conveyor belts. This contributes to the efficiency of handling and packaging materials in industries such as food processing, logistics, and manufacturing.

Packaging Machinery: Servo motors help align and seal packaging materials with high accuracy in packaging machines, improving efficiency and reducing waste.

Injection Molding Machines: The use of servo motors enables precision and efficiency in the control of injection molding, leading to consistently high-quality products with less cycle time.

Servo motors are integral in the industrial automation field, as they have supplied accuracy, speed, and efficiency in a broad range of applications. Efficiency and precision with low energy consumption make servo motors perfect for modern high-performance automation systems. Servo motors enhance the capability of automation systems in all service areas, like robotics, CNC machining, material handling, and reduced downtime, better productivity, and high-quality output. As industries are pushing for more automation and innovation, servo motors will continue to be at the heart of this advancement, changing the future of manufacturing, processing, and assembling.

0 notes