#PLC course Thane

Explore tagged Tumblr posts

Text

A Leading PLC Training Institute in Thane

Presently industries are being replaced by Automation and robotics. All procedure and work are automated by machines and robotics process computerization. Each industrial sector like manufacturing, process enterprises, chemical, food & beverages, Oil Gas , Transport, machine devices everywhere Industrial automation is used.

PLC Training is organized by Taact Campus. Taact Campus is a leading Industrial automation training institute in Mumbai. We offer major technical course at affordable price. The Best PLC SCADA training institute in Thane offers the best technical IT training for the regarding course. We provide basic and advanced level PLC SCADA Training in Thane with proper practically knowledge. At Taact Campus, PLC SCADA Training is offered by industry experts having 25+ years of experience.

Taact Campus has well prepared hardware lab for PLC training in Thane. Our trainers organize job oriented PLC training. Taact Campus is one of the well-equipped PLC SCADA training center in Thane. We provide training on a real-time industrial project which helps to student in a better understanding. Taact Campus & our trainers also help to student to get placement in top MNCs by preparation at different strategies. We have designed PLC SCADA course syllabus as per industrial requirements to achieve their professional goals.

In addition to this, we have updated syllabus as per industry requirements and well-structured lab through which aspirants learn the skills for Introduction to PLC SCADA, PLC SCADA Architecture, Programming, .dat and .dml files, Database components, Translate components, PLC training on real time projects along with placement. PLC Training Thane is provided by us as per latest industry trends. We provide PLC SCADA Course in Thane ensuring the optimum level of knowledge and efficiency to overcome any critical technical issue. Since the day of our commencement, it has been our aim to help the students to get placement in reputed companies.

Facilitated with high tech infrastructure and modern lab facilities and the options of opting for multiple courses at Thane location, Taact campus is the best PLC-SCADA Training Institute in Thane. We have trained thousands of aspirants automation at affordable fee also provides course content notes to each candidate. PLC-SCADA Course in Thane is provided by us using ultra-modern infrastructure for performing well-practices and real-time activities. Moreover, our well-trained and highly experienced counselors will help you till placement. We warmly welcome our student’s feedback that helps us to make our training as better as possible.

Furthermore, Taact Campus is leading PLC SCADA training center in Thane with well-structured lab facilities. More than 5000+ candidates are trained by Taact campus in PLC SCADA training in Thane at very affordable fees.

In addition, Taact institute have multi facilitate class rooms with projectors. So that, candidates can better understand the topic in the easier way. Strong associations with top companies have been availing training services of Taact, few of them are, Mahindra & Mahindra group, SAIL, General Motors Ltd, Volksvagen Ltd, Jindal Steel & Power Ltd Tata Motors Ltd, Electrotherm, Times of india, LIoyd Steel Ltd., Thysenkrupp Steel Ltd Indian Railways etc. Taact Campus is one of the Best PLC training center in Thane with 100% placement support. We closely monitor the growth of students individually in our training and assist them to increase their performance and level of knowledge.

Key Features of PLC Training are:

· Live Project Based Training.

· Job oriented syllabus.

· Course Notes with rich contents from basic concepts to practical guidelines.\

· Course syllabus is approved by Hiring Professionals of our client.

· Certification Based Training is designed by Certified Professionals as per requirement of industries.

· Interview calls till placement.

Call Now: +91 8976293301

Visit: http://www.taact.co.in/plc-scada-automation-training-thane.php

#PLC training Thane#PLC scada training Thane#SCADA training Thane#PLC course Thane#PLC automation training Thane

0 notes

Photo

Learn what is timer in PLC and its types. There are 3 types of timer in PLC - On delay, Off delay and Retentive On/Off timer.

To know more, visit : https://www.gotosage.in/

#industrial automation training in mumbai#plc training in mumbai#best plc scada training institute in mumbai#best industrial automation training institute in india#plc scada training in mumbai#plc scada course in thane#plc programming courses in mumbai#allen bradley plc training courses in mumbai#automation courses in mumbai#plc classes in thane

0 notes

Text

THE BEST ‘INDUSTRIAL AUTOMATION’ TRAINING CENTER

As Bill Gates once said, “Automation applied to an inefficient operation, will magnify the inefficiency”

This sums up an important message of how the process of “Industrial Automation” is not a silver bullet and does not fix up broken processes. Automation only does as you tell it, if you command it to complete a broken or faulty process, it will.

Industrial Automation is an interesting and vast ocean to dive in, but it's really important to have your training done in the right way.

To run operations efficiently in automation without any faulty process, advanced training with a high level of expertise is required. The latest trends in industrial automation include rise in use of analytics, growing use of PLCs, PACs, and increased cloud-based supervisory control and data acquisition (SCADA) systems. These trends will influence the industrial automation control market, according to a report.

A well updated training center like “Just engineering” thrives to provide advanced knowledge about industrial automation right from the basis of automation to complex automation concepts. It also has a flexible syllabus when it comes to keeping up with the trends included in plc/scada.

Just Engineering the best plc/scada training center in Thane, India offers certified courses with experience on live projects and opportunities to work internationally.

Enroll yourself to acquire certified courses of your choice at Just Engineering.

#plc#plc/scada#industrialautomation#plcclassespune#bestplcclassespune#automationtrainingcenterinpune

1 note

·

View note

Text

Plc training

In our Thane Training Institute / Center we offer following Courses. PLC Training Mechanical courses. Training for Mechanical Engineers. PLC SCADA Training

0 notes

Text

Advantages of PLC SCADA Automation | PLC SCADA Certification Course | Livewire Ambernath

Industrial automation is the way forward in the 21st century. Industrial automation as the name suggests is the use of automated instruments such as robots and computers for managing different machines and handling process. PLC and SCADA are one of the leading devices used in industrial automation. And anyone willing to start a career in it should be willing to undergo PLC SCADA course at premium institutes like Livewire Ambernath.

The first thought of the people was that only the overall productivity of industries will increase as machines have the capability to work around the clock. Now, as time has passed, the perception of the industry has changed. Automation now manages to increase the flexibility and quality in the process of manufacturing. According to a recent survey, previously the installation of pistons was done by humans and had an error rate of 1-1.5% but with the use of an automated machine, the error rate was reduced to 0.00001%.

Industrial automation can be broken down into two segments namely, Programmable Logic Controller (PLC) and Distributed Control Systems (DCS).

PLC: It tracks the state of input devices and controls the state of output devices depending on some programming instructions.

DCS: The number of controllers based on a different level is connected by communication networks which can be monitored and controlled.

SCADA or Supervisory Control and Data Acquisition devices are also an integral part of the automation framework in industries. They are automation control systems that monitor every site of the plant. This centralized system provides the user with remote control of any given machine in the plant.

Advantages of Industrial Automation

Industries all over the world took notice of automation practices. Automation plays a major role in deciding the growth of a company and has many advantages:

Less Production time: Having an automated machine on your side definitely speeds up the production time.

Reduction in Error: Every human is bound to commit errors at some point. But with the introduction of machines, the error rate goes down drastically, thereby increasing efficiency. The overall quality also increases.

Fewer Employees: With the major works done by machines, the need for human employees is less. The initial investment would be on the higher side in case of automation. But in the long run, it will prove beneficial.

Safe: Humans have the natural tendency to make mistakes and in industries, it might lead to accidents. In the case of machines, the probability of accidents occurring will be at a minimum.

High Production: An automated equipment can work for 24 hours and hence greater productivity is expected with more efficiency. Repetition can be a headache for humans, but not for machines.

High Flexibility: Unlike humans, machines don’t need proper training before the beginning of a new process. With industrial automation, a change in code is all it needs.

And with the onset of new technologies like the Internet of Things, AI, Big data, it is almost a guarantee that industrial automation will play a major role in the future too. As of now it has become a differentiating factor in terms of growth and will continue to do so. There will always be a demand for trained professionals in industrial automation training.

PLC SCADA Course by Livewire Ambernath, Thane

The PLC SCADA certification course by Livewire Ambernath will surely help you in your journey towards a successful career. Livewire Ambernath provides specializations in PLC, SCADA, HMI and VFD. A candidate can choose the right technology for him to make a mark in, and begin a career. The PLC SCADA course from Livewire Ambernath includes both theoretical knowledge as well as practical knowledge, as evident from the need to finish a live project by the end of the coursework.

To understand the basics of PLC and SCADA, you can refer to this article written by Livewire Karur. The article by Livewire Trivandrum regarding the future scope of industrial automation will put to rest any reservations you might have had about taking this course. If you have gone through these articles, I am sure you will be more than willing to join our PLC SCADA certification course at Livewire Ambernath as soon as possible.

#plcscadatrainingambernath#plcscadacourseinambernath#industrialautomationcourseinambernath#advantagesautomation

0 notes

Link

Take a look at the advantages of PLC SCADA automation. This article has been written by Livewire Ambernath.

#plcscadatraininginambernath#plcscadacoursesinambernath#industrialautomationcoursesinambernath#plcscadaambernath

0 notes

Link

India's Top Training Center Wohlstand India - offer PLC,SCADA, DCS & financial, management training, DeltaV, Yokogawa training, computer and hardware networking, online training classes, online training courses, jobs near me, job alert, oil and gas training, fire fighting training, gas piping training, industrial automation training, plc scada training, electrical training, embedded training in Mumbai, electronics and embedded training, IOT training courses.

#PLC#SCADA#DCS#financial tranining#management training#DeltaV#Yokogawa training#computer and hardware networking#online training classes in Thane#online training courses in Thane#jobs near me#job alert#oil and gas training#fire fighting training#gas piping training#industrial automation training#plc scada training#electrical training in Thane#embedded training in mumbai#electronics and embedded training in Thane#IOT training in Thane#Wohlstand India

0 notes

Link

Nettech India’s PLC (Programmable Logic controller) training imparts the skills for implementing machinery and hardware related automation to rule the modern industrial automation process. Participants gain the understanding of PLC architecture, applications, instructions, programming, interfacing and troubleshooting. The learning curve encompasses ladder logic for establishing mathematical and logical concepts. The methods of controlling industrial electronic circuits namely relays and sensor interfacing is also covered. The training program provides insight and practical exposure on the leading brands of PLCs.

0 notes

Text

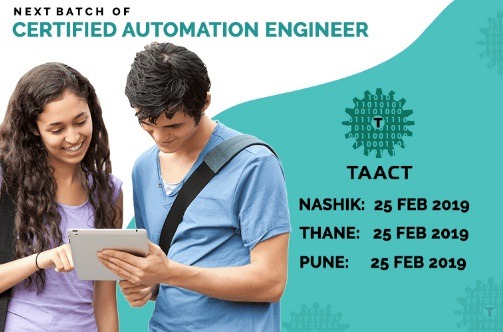

Best Institute for Industrial Automation Training Thane

Teknocrat’s Academy of Automation and Control Technology (TAACT) is India’s leading training institute with its enormous enthusiasm and 15 years of existence in Industrial Automation. Taact have faculties with 16+ years of industrial experience. Taact has trained 1500+ engineering students in industrial automation technology. TAACT has also trained 4000+ working professionals from industries like Mahindra & Mahindra, Times of India, Delhi Metro, Jindal group, Volkswagen, General Motors, Sterlite group, SAIL, Suzlon, Indian Railways, TATA motors and many more. Taact is experts in industrial automation technologies like PLC, SCADA, SENSORS, HYDRAULICS, PNEUMATIC, ROBOTICS and related technologies. We offers skills from basic to advance automation programming of PLC, SCADA, HMI (Siemens WinCC Flexible), Hydraulics & Pneumatics.

Our Industrial Automation training welcomes students with technical background and give them direction by providing 100% placement assistance in different automation sectors. Hands on training, industry experienced trainer are features of this automation training program. Join our training program and become a certified automation engineer for opening the doors of career and job opportunities.

We Offered Following Industry Oriented Courses : PLC Training Thane, PLC Scada Training Thane, SCADA Training Thane, PLC Course Thane, PLC Automation Training Thane

Programmable Logic Controller (PLC) is used in various automation sectors because of its functional features as easy programming and great controlling ability. Benefiting from our wide industrial experience in PLC programming, we have training programs for students as well as industry experts. The friendly and appropriate surrounding is given to students for building up their skills. We have well structured advanced lab, experienced faculties, who endeavour to render best practices in this competitive industrial automation. Supervisory control and data acquisition (SCADA) is a system of software and hardware elements used for analyzing real-time data. Scada systems are crucial for many industries, used to analyze and control the machinery in the industrial processes like manufacturing, production, development and fabrication. The industries processes include gas and oil distribution stations, electrical power generation and distribution plants, water transportations etc. Thus our PLC SCADA training Thane institute will creates the job opportunities.

who can join Certified Automation Engineer ( CAE) - PLC SCADA Training Thane

· Engineering or diploma Students(Electical,Electronics,Mechanical,Instrumentation)

· B.Sc. / M.Sc./ Instrumentation Students

· Working company professional

· Company sponsored training programs

· Job Aspirants.

Benefits of joining our Scada PLC Automation Training Thane

· Earn Valuable Professional Certificate.

· Learn From Experts.

· Well equipped Lab’s with latest industrial kits and components.

· Guaranteed Career Growth.

· Industry Experienced & Dedicated Faculties.

· Hands On Experienced working with industry Live project.

· 100 % placement Assistance.

For More Details About Contact Us: Address: In Vidya Prasarak Mandal's Polytechnic College Building No. 1, 'Jnanadweepa' Ground floor, College Campus, Chendani Bunder Road, Thane West, Maharashtra 400601 Call Now: +91 8976293301 Visit:

http://www.taact.co.in/plc-scada-automation-training-thane.php

#PLC training Thane#PLC scada training Thane#SCADA training Thane#PLC course Thane#PLC automation training Mumbai

0 notes

Text

What is a Contactor?

A contactor is an electrical device that is used to turn on and off an electrical circuit. It is regarded as a unique sort of relay. The main difference between a contractor and a relay is that the contractor is utilized in applications that require a larger current carrying capacity, whilst the relay is used in situations that require a lower current carrying capacity. Contactors are small and easy to install in the field. These electrical devices usually have many contacts. When the contactor coil is powered, these contactors are generally open and give operating power to the load. For the most part, contactors are used to regulate electric motors.

Contactors come in a variety of shapes and sizes. Each type has its own set of characteristics, capabilities, and uses. Contactors can handle currents ranging from a few amperes to thousands of amperes, as well as voltages ranging from 24 VDC to thousands of volts. Moreover, these electrical devices come in a multitude of sizes, – from small hand-held devices to all those measuring a meter or yard on one side (approximately).

The contactor is most commonly used in high-current load applications. Contactors are well-known for their capacity to manage currents of more than 5000 amperes and high power of more than 100 kW. When a large motor current is interrupted, it produces arcs. These arcs can be decreased and controlled with a contractor.

Contactor Components-

The contactor is made up of three essential components:

1. Coil or Electromagnet: This is the most essential part of the contactor. The coil or electromagnet of the contactor offers the required driving force to close the contacts. An enclosure protects the coil or electromagnet and its contacts.

2. Enclosure: Contactors, like any other device, have an enclosure that provides insulation and protection against personnel touching the contacts. Polycarbonate, polyester, Nylon 6, Bakelite, thermosetting polymers, and other materials are used to construct the protective enclosure. In most instances, an additional enclosure is built to the open-frame contactor to protect it from severe weather, explosion threats, dust, and oil.

3. Contacts: This is another vital part of this electrical device. The contacts are currently performing the contactor's carrying role. In a contactor, there are mainly three types of contacts: contact springs, auxiliary contacts, and power contacts. Each type of contact has a certain function to perform.

Different Types of Contactor Devices-

1. Knife Blade Switch- In the late 1800s, the knife blade switch was introduced. It was most likely the very first contactor used to control (start or stop) electric motors. The switch was made out of a metal strip that slid across a contact. This switch had a lever that could be used to pull the switch down or up. The knife blade switch had to be lowered into the closed position by standing next to it back then. However, there was an issue with this way of switching. Because it was difficult to manually open and close the switch fast enough to avoid arcing, the contacts wore out quickly. As a result, the soft copper switches began to rust, increasing susceptibility to moisture and filth. The size of the motors became larger over time, requiring the use of larger currents to operate them. As a result, operating such high current carrying switches could be dangerous, posing a major safety concern. Despite the number of technical advances, the knife blade switch was never fully developed due to the challenges and risks of dangerous operation as well as the contacts' short life.

2. Manual Contactor- Engineers created a new contactor device after the knife blade switch became potentially unsafe to use. This contactor device included several functions that the knife blade switch lacked. This device was described as a manual controller.

These characteristics included:

Operation is risk-free.

A unit that is not visible and is appropriately enclosed

Smaller in size

Contacts with single breaks have been replaced by contacts with double breaks.

3. Magnetic Contactor- The magnetic contactor is operated electromechanically and does not require human interaction. This is one of the most advanced contactor designs available, and it can be remotely operated. As a result, it reduces the dangers of running it manually and placing operational staff in danger. The magnetic contactor only requires a small amount of control current to open or close the circuit. In industrial control applications, this is the most common type of contactor.

How Does the Contactor Work?

The electromagnet is activated by the current that flows through the contactor. The contactor core moves the armature due to the magnetic field produced by the excited electromagnet. The circuit between the fixed contacts and the movable contacts is completed by a normally closed (NC) contact. This allows current to flow from the contacts to the load. The coil de-energizes and closes the circuit when the current is released. Contactor contacts are recognized for their quick opening and closing action.

To know more, visit: https://www.gotosage.in/

#industrial automation training in mumbai#plc training in mumbai#best plc scada training institute in mumbai#best industrial automation training institute in india#plc scada training in mumbai#plc scada course in thane#plc programming courses in mumbai#allen bradley plc training courses in mumbai#automation courses in mumbai#plc classes in thane#scada classes in thane#best plc courses thane#automation training in thane#scada courses in thane

0 notes

Photo

Learn what is a contactor and its components. There are 3 essential components of contactors- Coil or Electromagnet, Enclosure and Contacts.

#industrial automation training in mumbai#plc training in mumbai#best plc scada training institute in mumbai#best industrial automation training institute in india#plc scada training in mumbai#plc scada course in thane#plc programming courses in mumbai#allen bradley plc training courses in mumbai#automation courses in mumbai

0 notes

Text

What is Direct Online Starter?

This info graphic explain what is DOL and its principle. The DOL starter is a kind of motor starter that connects the electric engine straightway to the line voltage. It's the simplest and cheapest approach to start an induction motor.

#top plc classes in thane#top scada classes in thane#top industrial automation courses in thane#types of courses for automation in thane#industrial automation courses in thane#plc courses in thane#scada courses in india#best plc scada training institute in india#best industrial automation training institute in india#best plc training institute in india

0 notes

Photo

This infographic explains what is Star-Delta Starter and its three different types. Star/Delta Starter comes under the PLC program. Manual Star Delta Starter, Semi-Automatic Star Delta Starter and Fully Automatic Star Delta Starter, these three types are explained in an above image.

#plc scada training#plc training in mumbai#scada training in mumbai#PLC/SCADA courses in thane#Best Automation training in Thane PLC SCADA Automation Training in Thane Industrial Automation Training Institute in Thane Automation Traini#scada courses in mumbai#best industrial automation training in thane

0 notes

Photo

Student gives the feedback after complete training. Present and Past student feedback on testimonials. Saga automation Provide training and experience. More information visit: http://www.gotosage.in/

#PLC SCADA Courses in Thane#Automation training institutes in Thane#PLC SCADA Automation Training in Thane#PLC training in Thane

1 note

·

View note

Link

Our Industrial Automation training welcomes students with technical background and give them direction by providing 100% placement assistance in different automation sectors. For More Details About Contact Us: Call Now: +91 8976293301 Visit: http://www.taact.co.in/plc-scada-automation-training-thane.php

0 notes

Link

Teknocrat’s Academy of Automation and Control Technology #TAACT is India’s leading training institute with its enormous enthusiasm and 15 years of existence in Industrial Automation. For More Details About Contact Us: Call Now: +91 8976293301 Visit: http://www.taact.co.in/plc-scada-automation-training-thane.php

0 notes