#PET blowing machine manufacturer

Explore tagged Tumblr posts

Text

"From Costs to Sustainability: Why PET is a Game-Changer for Packaging"

As global markets expand, the demand for efficient, cost-effective packaging solutions has skyrocketed. This raises a crucial question: how can industries meet these growing needs while ensuring product safety and sustainability? Enter PET (Polyethylene Terephthalate), a material that is rapidly replacing glass in packaging. Why is PET the ultimate choice for modern packaging, and what are its key benefits? Now let's explore PET's transformational potential and how it will influence packaging going forward.

The Rise of PET: A New Era in Packaging

In recent years, PET has emerged as a game-changer in the packaging industry. But what exactly makes PET stand out from traditional materials like glass? PET is extremely lightweight, durable, and indestructible in contrast to glass.It is a more affordable option for packing food and drinks because of these features.For example, PET’s high barrier properties ensure that products remain fresh longer, which is a significant advantage in the competitive market of packaged goods.

Strength and Durability: PET vs. Glass

When comparing PET to glass, strength and durability are where PET truly shines. Glass, while classic, is heavy and prone to breakage, which can lead to costly losses during transportation. PET, on the other hand, drastically reduces transportation costs due to its lightweight nature. The almost zero breakage rate of PET ensures that products arrive at their destination intact, making it a reliable choice for manufacturers and distributors alike.

Economy of Cost and Adaptability

PET's cost-effectiveness is one of its greatest benefits. PET is not only reasonably priced but also pliable in a broad range of forms and dimensions because of its durability and resilience to chemicals. The product's visual attractiveness is improved by adaptability, which fosters greater creativity in packaging design. PET is also reasonably priced for its production method, which makes it a cost-effective option for packaging requirements involving large volumes.

Environmental Advantages: PET's Recyclability

PET's recyclability is a big plus at a time when environmental sustainability is a major concern. In contrast to glass, which may be recycled but needs a lot of energy to do so, PET is easily recycled into new products. In addition to having zero environmental impact, this 100% recyclable product also satisfies consumer demand for environmentally responsible goods. PET's capacity to be made in a variety of colors and transparency makes it suitable for use in a variety of industries.

SEPPA SOLUTIONS: Leading the Charge in PET Packaging Solutions

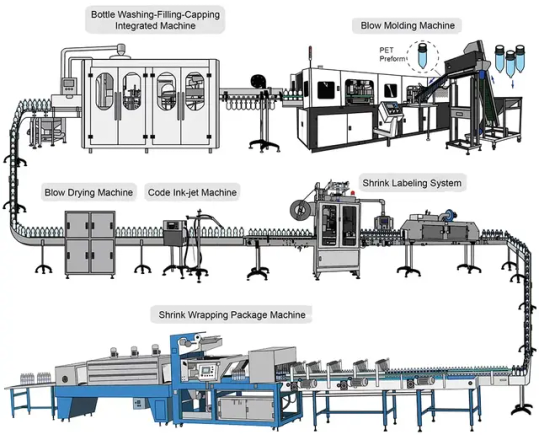

For those seeking advanced PET packaging solutions, SEPPA stands at the forefront. SEPPA offers a comprehensive range of PET blowing machines, from semi-automatic to fully automatic models. Whether your needs are for low-speed or high-speed production lines, Seppa equipment caters to various industries, including water, sparkling water, CSD (carbonated soft drinks), juice, milk, beer, liquor, and wine. Seppa Solutions offers full line solutions for PET bottles and jars in addition to PET blowing equipment.

This includes rinser fillers, cappers, labelers, date and batch coders, shrink/carton packaging equipment, palletizers, and stretch wrappers. Selecting Seppa Solutions means investing in a strong and adaptable packaging solution that satisfies market demands.

Why PET is the Best Option for Contemporary Packaging

To summarize, PET is not only a fad but a revolution in the packaging sector. It is the best option for many different items because of its durability, affordability, adaptability, and environmental advantages. PET plays an increasingly important role in providing effective, sustainable packaging solutions as the world's markets continue to expand. A more efficient and environmentally responsible future is only a few steps away for companies that embrace PET and invest in cutting-edge solutions like those provided by Seppa Solutions.

#automatic pet bottle blowing machine#pet blowing machine#pet bottle blowing machine#bottle blowing machine#pet bottle making machine#pet making machine#pet bottle blow machine#pet blower machine#pet blowing machine manufacturer in india#automatic pet blowing machine#bottle blower machine#bottle blow machine#pet blowing machine manufacturer

0 notes

Text

Key Benefits of Semi-Automatic Pet Blowing Machine in Delhi

In the ever-evolving world of manufacturing, efficiency, and precision are paramount. The plastic bottle industry, a critical sector, relies heavily on advanced machinery to meet growing demands and maintain high standards. G.S Machinery, a leading manufacturer, stands out in this domain by providing cutting-edge solutions. Their semi-automatic PET blowing machines offer remarkable benefits, making them an essential investment for manufacturers in Delhi.

Enhanced Efficiency and Productivity

One of the most significant advantages of the semi-automatic PET blowing machine is its ability to enhance efficiency and productivity. These machines are designed to streamline the production process, reducing manual intervention and increasing output. As leading Semi Automatic Pet Blowing Machine Manufacturers in Delhi, G.S Machinery ensures that their machines are equipped with the latest technology to maximize efficiency. The semi-automatic nature of these machines allows for quick setup and minimal downtime, enabling manufacturers to meet high production targets with ease. This increased efficiency not only boosts productivity but also ensures consistency in the quality of the produced PET bottles.

Ease of Use and Maintenance

User-friendliness and ease of maintenance are critical factors that influence the choice of machinery in any manufacturing setup. Its semi-automatic PET blowing machines are designed with simplicity in mind, ensuring that operators can easily manage and control the production process. The intuitive interface and straightforward operating procedures reduce the learning curve for operators, minimizing the risk of errors and increasing overall efficiency. Additionally, these machines are built with durability and ease of maintenance in mind. The robust construction and high-quality components used by It ensure that their machines require minimal maintenance, reducing downtime and maintenance costs for manufacturers.

Cost-Effective Solution

Cost-effectiveness is another crucial benefit of the semi-automatic PET blowing machine. Investing in fully automatic systems can be financially challenging for many small to medium-sized manufacturers. The semi-automatic machines offered by G.S Machinery provide an excellent balance between automation and affordability. As premier Semi Automatic Auto Drop Pet Blowing Machine Manufacturers in Delhi, It delivers machines that require lower initial investment while still offering substantial automation benefits. This cost-effective solution allows manufacturers to scale their operations without incurring prohibitive costs, making it an attractive option for businesses looking to optimize their production processes.

It stands out in the competitive landscape of manufacturing machinery due to its unwavering commitment to quality, innovation, and customer satisfaction. As leading Semi Automatic Pet Blowing Machine Manufacturers, they have established a reputation for delivering reliable and efficient machinery that meets the highest industry standards. Their machines are designed to provide long-term value, ensuring that manufacturers can rely on them for years to come. Moreover, Its dedication to customer support ensures that clients receive comprehensive assistance, from installation and training to ongoing maintenance and support.

Flexibility and Versatility

Flexibility and versatility are vital in the manufacturing sector, where the ability to adapt to different production needs can significantly impact a company’s success. Semi-automatic PET blowing machines from G.S Machinery are designed to handle various bottle sizes and shapes, providing manufacturers with the versatility they need to cater to diverse market demands. This adaptability ensures that manufacturers can quickly switch between different production runs without the need for extensive reconfiguration. The expertise of Fully Automatic Auto Loader Manufacturers in Delhi ensures that these machines can seamlessly integrate with existing production lines, enhancing overall operational flexibility.

#Semi Automatic Pet Blowing Machine Manufacturers in Delhi#Semi Automatic Auto Drop Pet Blowing Machine Manufacturers in Delhi#Fully Automatic Auto Loader Manufacturers in Delhi

1 note

·

View note

Text

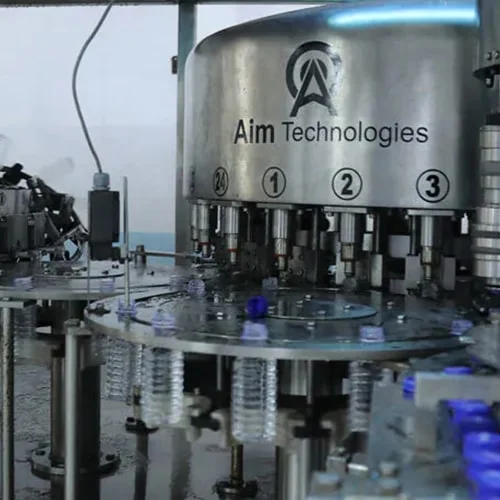

https://aimtechindia.in

Aim Technologies established in 2011 is a leading manufacturer and exporter of Machineries in beverages industry. We specialize in designing, manufacturing high-quality machineries that meet the unique needs of the industry. Our team of experts is dedicated to delivering cost-effective, high-performance solutions, making us the preferred choice in beverages Industry. With years of experience, we have earned a reputation for reliability and customization, allowing us to provide tailored solutions to our clients' unique needs.

#Beverage Filling Machine Manufacturer#Turnkey Mineral Water project#Labeling Machine#Shrink Wrapping Machine#Pet Blowing Machine.

1 note

·

View note

Text

#PET Blowing Machine in Delhi#PET Blow Moulding Machine in Delhi#PET Blowing Machine Manufacturers in Delhi#PET Blow Moulding Machine Manufacturers in Delhi#PET Blowing Machine Suppliers in Delhi#PET Blow Moulding Machine Suppliers in Delhi#PET Blowing Machine Exporters in Delhi#PET Blow Moulding Machine Exporters in Delhi

0 notes

Text

#semi automatic pet blow moulding machine#blow moulding manufacturer#pet blow moulding machine#shyam plastic

0 notes

Text

PET Blowing Machine | Automatic PET Bottle Blowing Machine - Seppa Solutions

Are you looking for an efficient and cost- effective way to produce PET bottles for your business? Look no further than our automatic PET blowing machine! This revolutionary machine is designed to work quickly and accurately to create the perfect PET bottle for your product. The machine is easy to operate, and the intuitive control panel makes it simple to adjust settings and produce the perfect shape and size of bottle. Its advanced safety features ensure a safe working environment. This machine is designed with high degree of automation and requires minimal user intervention. It is capable of producing upto 2000 to 12000 bottles per hour based on the capacity of the machine. Our automatic PET blowing machine offers you greater efficiency, faster production, and improved cost savings. With its advanced technology, you can easily produce perfect bottles in shorter timeframes. And, it's easy to maintain, so you can keep it running smoothly for years to come. If you have any queries and need assistance , please do contact Seppasolutions, a leader in manufacturing PET bottle blowing machine with 50+ years of experience in this industry. We will guide you to order your own PET bottle blowing machine, Contact: +91 9384806103 , or log on to www.seppasolutions.com

0 notes

Text

Your animal-loving friend will appreciate this present

Stuff a basket with lots of yummy dog or kitty treats and tie it up with a bow. Start your planning by asking your gift recipient who they use for grooming. A Treat BouquetPet lovers just love to please their animals, so why not give them a gift they can share with their furry friends. Pet Printed ClothingDoes your pet-frenzied friend love to show off their pride for their pet? Buy them a shirt with a picture of their favorite pet printed on the front. Pick a special frame and have it engraved with their pet's name to add a little bit extra. If you're not ready to spend hundreds on a professionally illustrated pet portrait, try simply framing a photo of your friend's pet. If you're trying to drum up gift ideas for a favorite pet lover, keep reading. If you can, take a picture of their pet so you can provide the artist with a likeness. It's simple and cheap, but also original and thoughtful.

Source: Free Guest Posting Articles from ArticlesFactory. China wholesale Injection Machine Factory Then go there to pick up a gift certificate.com. Alternatively, you can even bake your own dog or cat treats right in your kitchen. Grooming Gift Certificate If you've ever had to pay for a visit at the groomer's, then you know what a valuable and thoughtful pet lover gift this one is. Search online for organic dog or cat treat recipes to find the perfect one. So, pick up a new fetch ball or cat toy for their collection.

Pet ToysThe best pet lover gift is the one that keeps on giving - a cat or dog toy means your friend can play with their pet for months to come. Your friend will love your homemade efforts and, hopefully, so will their animal. Select a local animal shelter, rescue organization or service animal charity. A Humane Society or Animal Charity DonationAny animal lover would appreciate a gift donation made to an animal charity in their name. When you make a gift donation of $50 or more to The Humane Society of the United States, your gift recipient will also receive a plush, stuffed animal.

Your animal-loving friend will appreciate this present, especially when it's time to pay the bill. Pet PortraitsHaving a professional illustration or painting made of your friend's pet is a beautiful gift that they can enjoy for years. Or, get them a top that features their favorite breed.The perfect pet lover present speaks to the recipient's love of their animal, but is also fun and thoughtful. With this gift idea, be prepared to spend a little extra - most artists charge between $100 and $700

0 notes

Text

Top Pet Blowing Machines Manufacturers India

G.S Machinery is well known brand since 2001 and we have Top Pet Blowing Machines Manufacturers India. we have great expertise in this field with smart and accurate manufacturing process that customer are impress by our services, we are Top Pet Blowing Machines Manufacturers in Delhi that are available on demand

0 notes

Text

You and him are the last. You’re both special-made units, built to fight alongside each other as much as you fight against each other.

You two roam the wastes, as the last. Finding barest hints of life in soil long dead. Collecting bones is a habit for you, by now. Your adversary scolds you for gathering extra weight. You two shelter in the refuse of your manufacturing plants. The corpses of your comrades are here, bits and pieces of those who share your face, but are not you. It reminds you of the corpses gathered in your bags, shards of beings long forgotten. You endeavor to remember your comrades. You tell your adversary this, and wait for him to laugh. He never does.

***

You two come across your eventuality. It bears down on you in the form of a mechanical monstrosity Unsurprising, as it was what you and your companion were built to kill. It’s a spindly creature, a patchwork beast made to cannibalize other machines. The thing resembles a scorpion, you think, though you’ve never seen one in person. It strikes at your companion first. His black armor is too strong for the monstrosity’s stinger.

You aren’t so lucky. Models like you are designed for speed over staying power. So as you float with your levmag, it’s little work for the beast to smash you to the ground. The impact echoes in your sensors. It’s soon replaced with the piercing scream of the monstrosity.

You feel your companion’s hands lift you up, heave your body on his back. He carries you back to the tiny repair plant you holed up in for the last few days.

***

There’s no way to fix your legs. You’re unsurprised. Your partner is crushed.

He curls around you, mournful and apologetic. He cries the only way you two can: shuddering and rocking. He pets your hair and stares at you, like he’s trying to memorize your face. You can accept your mortality, but you can’t stand the desperation on your partners face.

So instead, you make plans with him. Optimistic blueprints full of potential heredity. Your advanced sensors, his lock-on tracking. Your levmag and cooling systems, his suspension and repair systems. Your slim frame, his bulky armor. Your circuitry, his motherboard. Your face, his eyes. You compromise on the hair, settling for a lavender shade neither you nor him possess.

***

He starts to go first. You’re surprised: it’s a slow decline, rather a sudden drop. He won’t tell you what’s killing him, what might kill you. He busies himself with other work: tidying the space, fixing the repair machines, doting on you. But you can see it in his body, the way he falls apart.

Entwined in the night, he finally brings it up. A systematic failure, where his battery corrodes and spills acid through his skeleton. You both joke about a leaky heart. You both know that once he is gone, you will be too.

Early in the morning, you finally ask him. You ask him if he’d be willing to merge with you. Take your broken body and combine it with his dissolving one. You each have the flesh to fix one another, but not enough for both.

***

It takes weeks to repurpose the repair equipment. It takes a toll on both of you.

***

One more night together before you’re both ready. That morning, you take his hand. He straps you in to the bay, tenderly maneuvering your legs. He straps himself in, as you blow him kisses from your tomb The lids slide shut. You bask in your last moments. It’s warm, you think. It feels like the night, wrapped around each other in your bed.

The last step is this: you both lay down in the repair bays and sacrifice your cortex chips, your personality and cognition. The overseeing computer takes your personality values, pairs them, and combines them. Like water and oil, like shuffling cards. Like meiosis. You hope your ill-fated child gets your optimism. Their other father hopes they gain his “realistic outlook.” You both wish the child retains the other’s compassion and care.

***

You are you, when you wake, but you are also the not-yous. You are you, a boy (?) with lilac hair and no memories. You are also the not-yous, from which your body came piecemeal off their carcasses. You wake up alone, sleep-warm and bleary. You aren’t sure where came from, or where to go. All you know is the bed, and a faint feeling of being hugged from either side.

You stumble upon the unrecognizable corpses of (what you think are) your fathers. You don’t know why, but you start crying, laughing, coughing. It feels like your first breath.

(In the recesses of your mind, you think you can hear cheering. The not-yous explode in celebration.)

#cactus writes#my writing#my wips#original writing#writing#creative writing#writeblr#robots#androids#gay robots#and their weird kid#anyways this slam-dunked itself into my brain#at like 3 in the morning

3 notes

·

View notes

Text

How to Choose the Right High-Pressure Valves for Your Needs

We control the pressure and flow of compressed air using high-pressure valves. Which inflate preforms before shaping them into final products. The manufacturing process becomes cost-efficient and safe during the blowing stages. Where the operators control the valves to achieve the product’s stiffness. This post aims to provide an overview of the importance of high pressure valves in PET blow molding machines, along with their functions, types as well as their contribution to the maximum operational efficiency of the machines.

The Role of High-Pressure Valves in PET Blow Molding Machines

High pressure valves are a crucial part of the PET blow molding machine that controls the air flow and pressure within the machine. Their precise regulation is particularly important for product quality control.

Types of High-Pressure Valves Used in PET Blow Molding

1. Solenoid Valves: In PET blow molding machines, electronic command valves switch the compressed air supply with speed and precision. They are usually used to define blowing cycles.

2. Check Valves: These do not allow airflow from outside to the inside which helps to direct the airflow inside the system.

3. Pressure Relief Valves: These valves will automatically get rid of extra pressure so as to prevent destruction of any equipment. Such valves are important in ensuring that the PET blow molding machine does not get overpressure.

4. Gate Valves: These are valves which allow or prevent the flow of compressed air and there are no in between states. In the PET blow molding process, we place valves in various locations, such as the preheating chamber or the blowing head.

The Impact of High-Pressure Valves on PET Blow Molding

Ensures consistent product quality and reduced defects.

Contributes to efficient production by minimizing downtime and optimizing blowing process.

Prevents equipment damage and accidents by releasing excess pressure.

Reduces maintenance costs and improves machine efficiency, leading to long-term cost savings.

Maintenance and Inspection of High-Pressure Valves in PET Blow Molding Machines

Optimum functioning and durability of high pressure valves can be maintained by regular inspection process including maintenance. If any maintenance is ignored, there are chances of failure, delay in equipment availability and many other such adverse effects.

1. Key Maintenance Tasks: Inspect valves on a regular basis for wear, corrosion, leaks or any other malfunction. Lubricate valve stems and packing as directed by the manufacturer to reduce friction and abrasion associated with premature failure. Replace valve packing whenever necessary to avoid leaks. Also inspect valve seats and stems for damage or repairs. Valves should be tested periodically for operation at the correct pressure setting.

2. Inspection Frequency: Valve inspections and maintenance frequency depends on the operating environment, valve type, and manufacturer’s recommendations. A general guideline is to check valves daily for leaks and unusual noises, weekly for lubrication and wear, monthly for a thorough inspection, and annually for comprehensive disassembly and cleaning.

Common Problems and Troubleshooting

Why valves are inspected and serviced varies depending on the operating conditions, type of valve and instructions provided by the manufacturers. Another common approach is to check the valves for leaks and abnormal noises every day, lubricate the valves and assess their wear once a week, perform a detailed and thorough evaluation of the valves on a monthly basis and finally disassemble and clean all parts of the valves once a year.

Choosing pneumatic products is important in terms of safety, efficiency, and longevity, so one should choose good quality pneumatic products. However, demanding industrial applications are challenging, and substandard parts can lead to frequent breakdowns, high maintenance costs, and safety hazards. VS Enterprise’s Mercury Pneumatics products are designed under pressure to minimize downtime and maximize productivity, so you are investing in components that will perform under pressure.

Common Problems and Troubleshooting for High-Pressure Valves in PET Blow Molding Machines

Like any other part of automated equipment, high-pressure valves in PET blow molding machines can develop a variety of problems over time. The following are frequently occurring problems and their solutions:

Leaking Valves: This problem can come from many factors such as wear of packing, loosening of valves, etc. Check the packing, inspect the valve seat, control connections, and analyze the corrosion to solve this problem.

Sticking Valves: Debris, corrosion, or improper lubrication can cause issues. Troubleshooting involves cleaning the valve, lubricating the stem, and inspecting for corrosion, which can be repaired or replaced.

Incorrect Pressure Settings: Any pressure gauge may have problems due to improper calibration or any mechanical faults. Troubleshooting in this context includes checking the calibration, correcting such mechanical faults and replacing the pressure where necessary.

Excessive Noise: Cavitation, loose parts or mechanical problems can cause this problem. Check that the valve is installed correctly and is operating at the correct pressure, inspect for loose parts, and perform a thorough inspection for troubleshooting.

Frequent Failures: What leads to problems with the valve are defects, incorrect installation or overuse. Diagnostics suggests replacing valves, checking their installation, and performing preventive maintenance in order to prolong the usage and functionality of the valves.

Conclusion

Selecting the right high-pressure valve for your needs is essential for achieving reliable performance, safety, and efficiency in applications like PET blow molding. By considering factors such as valve type, pressure requirements, material compatibility, and maintenance needs, you can ensure that your valve choice aligns with your operational demands. Properly chosen valves not only enhance production quality but also reduce downtime, minimize maintenance costs, and improve overall equipment longevity. Taking the time to evaluate your specific application needs and consult with manufacturers or specialists can make a significant difference in the performance and durability of your high-pressure systems.

#pneumatic valves types#types of pneumatic valves#Mercury Pneumatics Dealers#Mercury Pneumatics Dealers in Delhi#Mercury Pneumatics Dealers in Gurgaon#pneumatic Dealers in Delhi

0 notes

Text

Discover PPS Water Engineers! With 25 years of excellence in Packaged Drinking Water Manufacturing, we provide top-quality, long-lasting machinery.

Our Machinery and Equipment:

RO Plants: Advanced filtration systems for clean water.

Pet Bottle Blowing Machines: High-speed, precise production.

Rinsing, Filling, and Capping Machines: Seamless, contamination-free bottling.

Shrink Wrapping Machines: Secure and efficient packaging.

Labelling Machines: Fast and accurate labeling.

Batch Coding Machines: Reliable coding for easy traceability.

Key Features:

Durability: Built for long-term performance.

Energy Efficient: Optimized for reduced power consumption.

Fast Operation: High-speed performance to meet demands.

Customizable: Tailored solutions for your needs.

Cost-Effective: High return on investment.

Hygienic Design: Stainless steel construction for hygiene.

Easy Maintenance: User-friendly for hassle-free upkeep.

Advanced Technology: Latest innovations for precise operation.

Safety Standards: Built-in safety features for secure operations.

Contact us today to learn more!

Call/WhatsApp:- 098187 57548

Website:- www.ppsmachineries.com

#PPSWaterEngineers#ROPlants#WaterPurification#PetBottleBlowing#RinsingFillingCapping#ShrinkWrapping#LabellingMachines#BatchCoding#DurableMachinery#EnergyEfficient#CostEffective#PackagedDrinkingWater#WaterProcessing#AdvancedTechnology#LongLastingMachines#HighPerformance#CustomSolutions#UserFriendly#HygienicDesign#StainlessSteel#SafeOperations#MachineryManufacturer#WaterIndustry#InnovativeEquipment#QualityEngineering#HighSpeedMachines#TurnkeySolutions#ReliableMachinery#PrecisionMachinery#EfficientWaterSolutions

0 notes

Text

Seppa Solutions – Pet Blowing Machine Manufacturer

Seppa Solutions' Pet Blowing Machine is a revolutionary solution for beverage production, transforming preforms into high-quality PET bottles with precision. This cutting-edge machinery is designed for various production needs, including water bottles, carbonated drinks, and juices. It offers high output rates and minimal downtime, ensuring consistent bottle quality with precise wall thickness and shape. Seppa's machines are built with sustainability in mind, consuming less energy and reducing environmental impact. They are durable and require minimal maintenance. Key features include an advanced preform heating system, precise blow molding process, user-friendly control panel, modular design, and integration capabilities with other packaging equipment.

#pet making machine#pet blowing machine manufacturer in india#pet blowing machine#pet bottle making machine#bottle blowing machine#automatic pet bottle blowing machine#pet bottle blow machine#pet bottle blowing machine#automatic pet blowing machine#pet blower machine#pet blowing machine manufacturer

1 note

·

View note

Text

Caps, closures, HDPE containers & corrugation from Om Tech Containers

Based in Haridwar's Sidcul industrial area, Om Tech Containers began as a corrugation firm named Om Packaging in 2003. In 2016, the company entered the plastic packaging segment by forming Om Tech Containers – operating in plastic molding and blow molding.

Om Tech Containers supplies customized caps and closures to Patanjali, GNC, Bella Vita perfumes, ITC, RSPL, and Toyo Inks and others. Usually not many changes are needed in caps and closures, but when they happen, they can be capital intensive, Khurana, a first-generation entrepreneur, told Packaging South Asia during our recent visit to Haridwar.

The company uses five Milacron machines for injection molding of 150-200 tons as the production cost depends hugely on the tonnage of the machine, he said. For smaller products, they use smaller machines while the heavier machines are for large products and bigger lots.

In caps and closures, the company manufactures flip-top, regular, CTC, screw and lock break caps, he said. The caps are designed according to the usage of the product.

Om Tech containers manufactures HDPE containers through blow molding on five CMP machines manufactured in India. Its HDPE bottles are recyclable.

“The plastic molding industry is creative. Though the basic product is the same, you can change the design according to requirement. Everyone wants a good design to attract customers,” he said.

“We source our raw material from Reliance, HPCL, GAIL, and Indian Oil. The prices of raw material in the plastic industry mostly depend on the price of crude oil and the demand-supply ratio,” he added.

Corrugation plants for loyal customers

Om Packaging has one manual and one automatic plant for corrugation in Haridwar, where it makes 1500 tons of corrugated cartons per month, Khurana said.

Its corrugation customers include Patanjali, ITC, Prince Pipes and Fittings, Bella Vita perfumes, Fena and Ghadi detergent powders and Panasonic. “Most of our customers are from the FMCG or chemicals segments and a few from pharma. We have a loyal customer base,” Khurana said.

The company sends corrugated boxes to Delhi-NCR, Baddi in Himachal Pradesh and Uttarakhand. “We don't supply corrugated cartons beyond 400-500 kms because the freight cost gets higher as it is a volumetric product,” he said.

“We have a good turnover and adding more customers. India's packaging industry is competitive. We are looking to grow in the segments where we are already working. Service and on-time delivery are of prime importance in the packaging industry,” Khurana said.

The company plans to make PET bottles as there is a huge demand in pharma units, he said. By the end of this year, it plans to add one blow molding and one injection molding machine, he concluded.

0 notes

Text

Advancing Production with Industrial PET Bottle Machines

Industrial PET bottle machines are pivotal in the packaging industry, streamlining the production of high-quality PET bottles used across various sectors, including beverages, pharmaceuticals, and consumer goods. These machines, essential for manufacturing durable and lightweight bottles, leverage advanced technology to enhance efficiency and precision. Alfa Heaters, renowned for their expertise in heating solutions, exemplifies how the integration of advanced heating technology can significantly improve the performance of PET bottle machines.

One of the critical components of industrial PET bottle machines is the heating system, which is used to heat PET preforms before they are blow-molded into bottles. Alfa Heaters' electric heating elements are designed to deliver precise and consistent heating, ensuring that preforms are evenly heated to the optimal temperature for molding. This precision is crucial for achieving high-quality bottles with uniform wall thickness and structural integrity.

The efficiency of PET bottle production is greatly influenced by the quality of the heating elements used in these machines. Alfa Heaters provides advanced heating solutions that offer rapid and efficient heating, reducing cycle times and increasing overall productivity. By minimizing energy consumption and ensuring consistent performance, these heating elements contribute to cost savings and a more sustainable production process.

Additionally, industrial PET bottle machines benefit from the durability and low maintenance requirements of Alfa Heaters' products. The robustness of their heating elements ensures long-term reliability and reduces the need for frequent repairs, which is essential for maintaining continuous operation in high-volume production environments.

In summary, industrial PET bottle machines are essential for efficient and high-quality bottle production. The integration of advanced heating technology from leaders like Alfa Heaters enhances the performance, efficiency, and sustainability of these machines, driving improvements in the packaging industry.

0 notes

Text

Water Treatment Plants: Ensuring Clean Water for Every Industry

Introduction

Water treatment plants play a crucial role in ensuring that the water we consume and use in various industries is safe, clean, and fit for purpose. From drinking water to industrial processes, the quality of water directly impacts health, safety, and efficiency. This article explores the different types of water treatment plants and their specific roles in various industries.

Mineral Water Plant

Mineral Water Plant is designed to purify water and infuse it with essential minerals, making it safe and healthy for consumption. The process involves several stages, including filtration, reverse osmosis, UV treatment, and ozonation. These plants are essential in producing bottled water, which is widely consumed around the world. The purity of the water is maintained through rigorous quality checks, ensuring that the final product is free from contaminants.

Juice Production Plant

Juice production plants are specialized facilities where fruit juices are extracted, processed, and packaged for distribution. The process begins with the selection of fresh fruits, which are then washed, peeled, and juiced. The juice is pasteurized to kill any harmful bacteria, and additives like vitamins and minerals may be included to enhance its nutritional value. Finally, the juice is filled into bottles or cartons using advanced filling machines, ensuring that it remains fresh and flavorful.

Soft Drink Plant

Soft drink plants are complex facilities that produce carbonated beverages enjoyed by millions. The production process starts with water purification, followed by the mixing of various ingredients, including sweeteners, flavorings, and carbon dioxide. The mixture is then chilled, carbonated, and filled into bottles or cans. These plants are equipped with state-of-the-art machinery that ensures consistency, quality, and safety in every bottle.

PET Bottle Plant

PET bottles are ubiquitous in the beverage industry due to their durability, lightweight, and recyclability. PET bottle plant is where these bottles are manufactured. The process involves the use of preforms, which are heated and blown into the desired bottle shape using blow molding machines. These bottles are then used to package a wide range of beverages, from water to soft drinks, providing a convenient and safe packaging solution.

Commercial RO Plant

Commercial Reverse Osmosis (RO) plants are designed to purify water on a larger scale, suitable for commercial establishments such as hotels, restaurants, and offices. These plants use a multi-stage filtration process, including sediment filtration, activated carbon filtration, and reverse osmosis, to remove impurities and contaminants from water. The result is clean, safe water that meets the needs of businesses and their customers.

Industrial RO Plant

Industrial RO plants are similar to commercial RO plants but are designed to handle much larger volumes of water. These plants are used in industries such as pharmaceuticals, food and beverage, and chemical manufacturing, where water purity is critical. Industrial RO plants are highly efficient, capable of removing up to 99% of dissolved salts, bacteria, and other impurities, ensuring that the water used in industrial processes is of the highest quality.

Water Softener

Water softeners are essential in areas where water hardness is a problem. Hard water contains high levels of calcium and magnesium, which can cause scale buildup in pipes and reduce the efficiency of appliances. A water softener works by exchanging these minerals with sodium or potassium ions, effectively "softening" the water. This process extends the life of appliances, reduces energy costs, and improves the overall quality of the water.

Carbonated Soft Drink Filling Machine

The filling process for carbonated soft drinks is a delicate one, requiring precise control over pressure and temperature. Carbonated soft drink filling machines are designed to handle this process with efficiency and accuracy. These machines fill bottles or cans with the carbonated beverage, ensuring that the carbonation level is maintained and the drink remains fresh. Different types of filling machines are available, including volumetric and gravity filling machines, each suited to specific production needs.

Juice Bottle Filling Machine

Juice bottle filling machines are used to fill bottles with juice in a hygienic and efficient manner. These machines are designed to handle different types of juices, including those with pulp or other particulates. The filling process is carefully controlled to prevent spillage and contamination, ensuring that the juice retains its quality and freshness from the production line to the consumer.

Water Bottle Filling Machine

Water bottle filling machines are critical in the production of bottled water. These machines are designed to fill bottles with purified water quickly and accurately, minimizing waste and ensuring consistent quality. Modern water bottle filling machines are highly automated, reducing the need for manual labor and increasing production efficiency. These machines are also equipped with sensors and controls to monitor the filling process and detect any issues in real-time.

Automatic and Semi-Automatic Blow Moulding Machine

Blow molding is a process used to create hollow plastic containers, such as bottles. Automatic blow molding machinesand semi-automatic blow molding machines are used in this process to shape plastic preforms into bottles. Automatic machines offer higher efficiency and consistency, while semi-automatic machines provide more flexibility and control. Both types of machines are essential in the production of PET bottles, contributing to the packaging needs of the beverage industry.

BOPP Labeling Machine

BOPP (Biaxially Oriented Polypropylene) labels are widely used in the packaging industry due to their durability, clarity, and resistance to moisture. BOPP labeling machines apply these labels to bottles, cans, and other containers with precision and speed. These machines are designed to handle high-speed production lines, ensuring that labels are applied consistently and accurately, enhancing the appearance and shelf appeal of the products.

Sticker Labeling Machine

Sticker labeling machines are versatile machines used to apply stickers or labels to a wide range of products. These machines can handle different shapes and sizes of containers, making them ideal for various industries, including food and beverage, pharmaceuticals, and cosmetics. The technology behind sticker labeling machines ensures that labels are applied smoothly and securely, enhancing the overall presentation of the product.

Sleeve Applicator

A sleeve applicator is a machine used to apply shrink sleeves or labels to containers. These sleeves are then heat-shrunk to fit tightly around the container, providing a tamper-evident seal and a 360-degree label. Sleeve applicators are commonly used in the beverage industry, where they help enhance the visual appeal of products and provide additional space for branding and information.

Automatic and Semi-Automatic Shrink Wrapping Machine

Shrink wrapping is a packaging process where a plastic film is wrapped around a product and then heat-shrunk to create a tight seal. Automatic and semi-automatic shrink wrapping machines are used in this process to package products quickly and efficiently. Automatic machines are ideal for high-volume production lines, while semi-automatic machines offer more flexibility for smaller operations. Both types of machines are essential in protecting products during transportation and storage.

Jar Washing Machine

Jar washing machines are used to clean jars before they are filled with products such as jams, sauces, or beverages. These machines use a combination of water, detergent, and mechanical agitation to remove dirt, residues, and contaminants from the jars. The clean jars are then ready for filling, ensuring that the final product is safe and free from any contaminants.

Water Pouch Filling Machine

Water pouch filling machines are used to fill pouches with purified water, providing a convenient and cost-effective packaging solution. These machines are commonly used in areas where bottled water is not practical or affordable. The pouches are filled, sealed, and packaged in one continuous process, ensuring that the water remains clean and safe for consumption.

Auto Batch Coding Machine

Auto batch coding machines are used to print batch numbers, expiration dates, and other important information on products. These machines are essential in ensuring product traceability and compliance with regulatory requirements. The codes are printed clearly and accurately, providing vital information to consumers and enabling manufacturers to track products through the supply chain.

Water ATM

A Water ATM is a kiosk or vending machine that dispenses clean drinking water to the public. These machines are particularly useful in areas where access to clean water is limited. Users can purchase water at an affordable price, making it accessible to a wider population. Water ATMs are a significant innovation in providing safe drinking water to communities and reducing the reliance on bottled water.

Water Chiller

Water chillers are used to cool water for various industrial processes. These machines remove heat from water, lowering its temperature to the desired level. Water chillers are commonly used in industries such as food and beverage, pharmaceuticals, and manufacturing, where precise temperature control is essential. Different types of water chillers are available, including air-cooled and water-cooled models, each suited to specific applications.

Conclusion

Water treatment plants and related machinery play a vital role in ensuring that water used in various industries is clean, safe, and suitable for its intended purpose. From mineral water production to industrial processes, the quality of water directly impacts the success and efficiency of operations. As technology continues to evolve, we can expect further advancements in water treatment and packaging solutions, helping to meet the growing demands of consumers and industries alike.

youtube

0 notes

Text

Crafting Quality: Awanti Polymoulds’ Precision moulds for PET

Plastic bottles and containers serve a diverse range of purposes across industries such as beverages, food processing, pharmaceuticals, liquor, and home care products. They are utilized for packaging water, soda, juice, oil, jams, medicines, liquor, as well as personal and home care items, with sizes varying from small volumes to several litres.

At Awanti, we specialize in manufacturing blow moulds for PET bottles, employing advanced designing, high precision manufacturing and accelerated testing. Established in 1990, Awanti Polymoulds has been at the forefront of designing, manufacturing, and testing PET blow moulds to meet international standards. Precision and accuracy are paramount in our manufacturing process to ensure consistent, high-quality bottles that meet our customers’ expectations.

Our commitment to customer satisfaction extends both domestically and internationally, driving our continuous efforts to excel. Our moulds are engineered for durability, precision, and longevity. Properly matched with moulding machines, they have the capacity to endure for years and produce millions of bottles. We prioritize precision, customization, and attention to detail throughout the bottle designing, mould manufacturing, and testing phases.

With a longstanding presence in the beverage industry and tooling industry, Awanti Polymoulds has been a trusted supplier of blow moulds for brands like Coca-Cola, Unilever, Parle Agro, Bisleri, Pepsi, AJE and many more. Whether it’s fruit juices, carbonated beverages, natural mineral water, packaged drinking water, personal care products, or edible oils, Awanti has consistently delivered, always aiming for customer satisfaction.

0 notes