#OxygenScavenger

Explore tagged Tumblr posts

Text

Each food preservation method has its unique strengths and applications. Oxygen absorbers shine in long-term dry food storage, while vacuum sealing, freezing, and dehydrating serve different purposes. For optimal results, consider combining these techniques to create a robust food storage strategy that meets all your needs.

0 notes

Text

Oxygen Scavenger - Effective Solutions for Extending Product Shelf Life

Protect your products from degradation caused by oxygen with the powerful Oxygen Scavenger offered by Cilicant. Safeguarding against spoilage and maintaining product freshness, our Oxygen Scavenger is the ultimate solution. Discover how our innovative technology can help you extend the shelf life and enhance the quality of your goods.

0 notes

Text

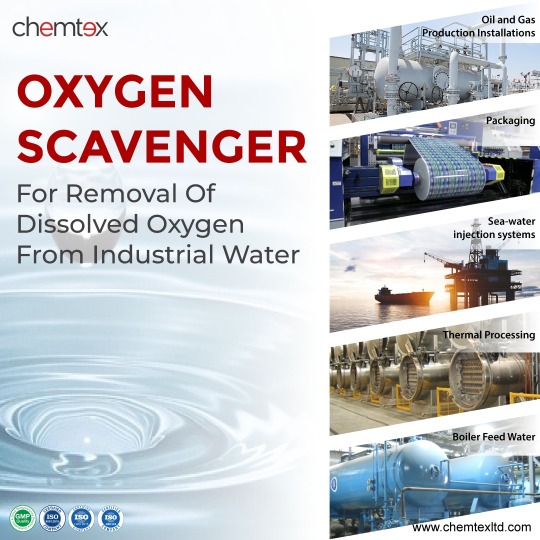

The best oxygen scavenger in boiler corrosion prevention | Chemtex Speciality Limited

Oxygen scavengers for boilers are chemicals or substances that are used to remove or reduce the presence of oxygen in boiler water or boiler feedwater. Steam boilers often operate at high temperatures and pressures, and the presence of oxygen in the boiler feedwater can lead to corrosion of the boiler and associated piping. Oxygen scavengers are added to the feedwater to help protect the boiler from oxygen-related damage, which means it is a chemical treatment for boiler water. By preventing oxygen corrosion, scavenger agents aid in steam boiler maintenance.

Boiler Oxygen Scavengers are highly responsive formulations that promptly engage with free oxygen, rapidly converting it for instant removal from the feed water and industrial boiler water. These formulations also play a crucial role in pH regulation and the reduction of feed water alkalinity. With their precise pH levels, these chemical additives offer several valuable attributes, such as energy conservation, the minimization of oxidative corrosion, and efficient oxygen elimination. This range of formulations finds applications in various industries, including food and beverage, dairy, pharmaceutical, poultry, and sugar.

Additionally, these chemicals function as passivation and rust removers, serving as a comprehensive solution for total corrosion control within internal boiler systems. Mitigating corrosion through oxygen scavenging indirectly reduces the formation of certain scales that might result from corrosion byproducts. Oxygen scavenger corrosion inhibitors are the main driver in boiler water treatment and these corrosion control activities is also part of oxygen stain removal.

Key features

Swiftly eliminates oxygen

Mitigates corrosion linked to oxygen exposure

Highly concentrated formula

Stabilizes pH levels

Promotes energy efficiency

Common types of boiler descaling chemicals used in boilers include:

Sodium Sulfite: Sodium sulfite is a commonly used chemical that reacts with dissolved oxygen to form sodium sulfate. It is effective in corrosion control and removing oxygen in the boiler and associated equipment.

Hydrazine: Hydrazine is another chemical that is used as an oxygen scavenger in boilers. It reacts with oxygen to form water and nitrogen gas. Hydrazine is effective in removing oxygen but should be used with caution due to its toxicity.

Carbohydrazide: Carbohydrazide is a less toxic alternative to hydrazine and is used as an oxygen scavenger in some boiler systems. It functions similarly to hydrazine by reacting with oxygen to produce water and nitrogen.

Catalyzed Sulfite: Catalyzed sulfite blends may be used as an oxygen scavenger in some boiler applications. These products often contain a combination of sodium sulfite, a catalyst, and pH control agents to enhance their effectiveness.

The choice of oxygen scavenger depends on various factors, including the specific requirements of the boiler, water quality, and safety considerations. It's essential to work with a qualified water treatment specialist or chemical supplier to determine the most suitable oxygen scavenger for a specific boiler system and to ensure that the chemical is applied in the correct concentration and according to established procedures. In this case, Chemtex Speciality Limited is dedicatedly involved in formulating a variety of boiler chemicals designed to enhance the overall operational safety of boilers and treat feedwater effectively.

For more information, please visit: https://www.chemtexltd.com/products-and-solutions/water-treatment-chemicals/boiler-water-treatment/boiler-oxygen-scavenger/

#chemtex#chemtexltd#chemicals#manufacturer#oxygenscavenger#corrosion#boiler#scavengeragent#industrialbolier#chemicaltreatment#oxygenstainremoval

0 notes

Text

Oxygen Scavengers: Best O2 Defenders for Pharmaceuticals, Nutraceuticals and More

Oxygen scavengers are the best choice for healthcare industries looking to lower the oxygen levels in their primary packaging container's headspace. They effectively prevent oxidation in tablets, capsules, soft gel capsules and more, maintaining the products' quality and stabilizing various pharmaceuticals, nutraceuticals, medical devices, injectables, and more.

0 notes

Text

"Oxygen Offense: Oxygen Scavenger Market Dynamics (2024-2033)"

The oxygen scavenger market is poised for substantial growth from 2024 to 2033, driven by the increasing need for extending shelf life and preserving quality in packaged food, pharmaceuticals, and beverages.

Market research indicates a rising demand for oxygen scavengers due to their ability to prevent oxidation and spoilage, thereby enhancing product freshness and safety. With consumers becoming more conscious about food quality and safety, manufacturers are increasingly incorporating oxygen scavengers into packaging materials to maintain product integrity and extend shelf life. Additionally, the growing popularity of convenience foods and ready-to-eat meals is driving demand for oxygen scavengers to prevent microbial growth and maintain product freshness during storage and transportation. As regulatory standards on food safety and packaging materials tighten, the demand for oxygen scavengers is expected to further escalate, shaping the future of food preservation and packaging technologies. This decade will witness continued innovation and advancements in oxygen scavenger formulations, ensuring the quality and safety of packaged goods in the global market. #OxygenScavenger #FoodPackaging #Pharmaceuticals #Beverages #FoodSafety #ShelfLife #PackagedFoods #Preservation #ConsumerDemand #ConvenienceFoods #PackagingTechnologies #RegulatoryStandards #MarketTrends #Innovation #QualityAssurance #MarketForecast

0 notes

Photo

Industrial Cleaning Chemicals Manufacturers in Chennai #watertreatment #watertreatmentchemicals #oxygenscavenger #boilerchemicals #reverseosmosissystems #roantiscalant #corrosioninhibitor #membranecleaners #biocides #descalingchemicals #descalingservices #coolingtowerservices #wastewatertreatment #stp #etp #scaleinhibitor #coolingtowermanufacturers #revamping #reconstruction #chennai (at Chennai, India) https://www.instagram.com/p/B9LdwckFCNS/?igshid=esemcv7gej1u

#watertreatment#watertreatmentchemicals#oxygenscavenger#boilerchemicals#reverseosmosissystems#roantiscalant#corrosioninhibitor#membranecleaners#biocides#descalingchemicals#descalingservices#coolingtowerservices#wastewatertreatment#stp#etp#scaleinhibitor#coolingtowermanufacturers#revamping#reconstruction#chennai

0 notes

Photo

supplying Carbohydrazide,also called carbonyl dihydrazine.CAS No.497-18-7.

Can be used as boiler oxygen scavenger.

#oxygenscavenger #carbohydrazide #bimuss #bimusschemical

0 notes

Link

via Twitter https://twitter.com/vajrakayat

0 notes

Link

If you have boiler treatment chemicals requirement please contact us at 7416079566 or email us at [email protected]

0 notes

Text

Oxygen absorbers for dehydrated food do not harm the fruits and vegetables and don't lead to toxication. A major benefit is that it eliminates the use of vacuum packaging and nitrogen flushing, as our OxySorb removes 99.9% oxygen from the product and keeps them fresh for a longer period. They are not reusable, however, can be partially used. It is important to store the rest of the content of the sachet in an air-tight container for future usage.

0 notes

Text

the oxygen absorbing packets for protein powder and oxygen absorbers for baby food products act as a barrier and protect your product from being rancid. It also helps to keep the nutrient-rich powder, i.e., the nutrients don't get volatile and stay there for extended periods. With this, the texture of protein powder remains well. There's no chance of being lumps of powder due to moisture and humidity at times, which is a bonus point for you.

#protein powder#foodsafety#foodpackaging#nutrition#healthy#shelflife#oxygenscavenger#oxygenabsorber#food#food texture#humidity#mold

0 notes

Text

Feb, 2024

Insects And Bug Solution for Retail Or Super-marts Flour Packaging With Oxygen Absorbers

Insect and bug infestation in flour packaging is a nightmare not only for retailers but also for consumers who buy and consume them on a regular basis. The presence of these insects and microorganisms inside flour packaging can raise serious food safety concerns, lead to effectiveness damage the product quality, and make it unfit for consumption.

The food industry is also highly regulated and thus it is of prime importance that the consumable product be in its best form, and texture, free from pesticides, chemicals, and other damage causing bacteria and insects/bugs. Thus, it is important to use an insect and bug solution for retail or supermarket flour packaging that is non-toxic, inert, safe to use with food products, and follows all the necessary regulations and compliances such as USFDA and ISO.

You can use Oxygen absorber packets when storing, packaging, and transporting flour packaging either in supermarts or during long transits during shipping and handling. Oxygen absorbers are small packets designed to protect and preserve food products from insects and spoilage caused by high levels of oxygen. They work by absorbing and maintaining high oxygen levels in the packaging.

This helps to maintain the quality of the food, the freshness, the texture, and the aroma for a longer time. Oxygen-absorbing small packets are eco-friendly and cost-effective as they are available in different package sizes to fit your requirements. You can use oxygen absorbers to keep your retail or supermarkets flour packaging insect-free and high quality.

How Oxygen Absorbers work in packaging and storing flour?

Many sensitive food products such as flour packaging are highly susceptible to even minute changes in weather, humidity levels, moisture content present in the surrounding air, etc. Thus it is essential to maintain optimum levels of these environmental factors while storing flour packaging for longer durations in retail or supermarkets. The product's texture, freshness, potency, quality, and shelf life are all impacted by changes in the environment. Due to the possibility of mold and fungus development, this makes the product prone to deterioration and unfit for human consumption.

Oxygen absorber packets work by removing any excess oxygen from the sealed environment or surrounding air within food packaging, creating an optimum storage environment by decreasing and reducing oxygen from packaging, which helps preserve the quality of the product during long-term storage on the shelves of supermarkets and retail stores.

This nitrogen environment helps maintain the quality of the food which here in this case is powdered flour, during long-term shelf storage. Oxygen absorption is especially important for maintaining the quality and prolonging the shelf life of food products such as flour and other food as if not used the flour can lose its texture, efficiency, and freshness and turn clumpy and soggy. The removal of oxygen prevents the presence and growth of microorganisms, slows down the oxidation of fats in the food, prevents spoilage, and rancidity of the food, and preserves its freshness, flavor, and texture for longer on the shelves and storage.

Oxygen absorbers help prevent insect damage and maintain the nutritional value of stored food products by maintaining optimal oxygen levels. Oxygen absorbers are also sustainable and environmentally friendly packaging solutions as they use eco-friendly materials that are safe to use with food and other sensitive products. and available in various sizes to suit different packaging needs.

5 tips for incorporating Oxygen absorbers in retail flour packaging.

Choosing the right absorber packet size

Choose the right size oxygen absorber based on the size of your packaging. For instance, if your packages are irregularly shaped, you can consider using several smaller oxygen absorbers to achieve even oxygen absorption from excess oxygen in the surrounding air. There are many varieties and sizes available so you can choose according to your specific requirements and needs. Choosing the correct required quantity can lead to better maintenance of retail or supermart flour packaging.

Place the oxygen absorber packets efficiently.

Oxygen absorbers should be placed strategically within the retail packaging. You can place them close to the product’s packaging to ensure uniform distribution and optimal oxygen absorption, which is essential for keeping the flour fresh and maintaining its high quality throughout the shelf life. When stored in retail or supermarkets, flour packaging that uses oxygen absorbers can be stored at optimum conditions and for longer durations without damage like pests, insects, and bugs that may occur due to humid conditions.

Use compliant and compatible oxygen absorber solutions

When it comes to packaging sensitive edible items and products such as flours and powders, it is very important to make sure that the oxygen absorber you are using to protect the packaging and the product from excess oxygen and moisture damage is safe to use with food products. They should be packaged in food-grade materials and they also should be USFDA and ISO compliant to be used with edibles and keep them bug-free throughout their shelf life.

Airtight seal for flour packaging

When storing flour packaging on shelves of retail and supermarkets, make sure that the flour packaging is airtight and has a good seal on the packaging. This will ensure that no excess oxygen, air, or moisture can enter the packaging and help maintain or enhance the shelf life of the product. Oxygen absorbers prevent the growth of harmful bacteria, keeping your products safe and building confidence in their quality.

Choose eco-friendly and sustainable options

When choosing the right oxygen absorber packets, you should always go for affordable options that are made with eco-friendly materials and packaging making them sustainable and durable options to safeguard your flour packaging during long shelf life and storage. This will also help reduce the overall carbon footprint and help save a lot of wastage and unwanted dump disposal in landfills.

Oxygen absorbers in retail and supermarket flour packaging help preserve product quality, extend shelf life, and reduce food waste. They prevent insect infestation, microbial growth, and excess oxygen, preserving color, texture, aroma, and nutritional value.

Their eco-friendly nature and cost-saving benefits make them an indispensable tool for retailers and supermarkets. Integrating oxygen absorbers into retail packaging is highly recommended to ensure high-quality, fresh products and minimize spoilage and waste.

We are the leading manufacturers of premium quality Oxygen absorbers that can maintain and enhance the shelf life of various food products and other sensitive items effectively. We source sustainable and affordable moisture and oxygen-absorbing insects and bug solution for retail or supermarts flour packaging.

#oxysorb#food#foodpackaging#supermarts#insects and bug solution#flour packaging#wheat flour#whole wheat flour#food manufacturing#foodsafety#moisture#oxygen absorbers#oxygenscavenger

0 notes

Text

Protect and Save Food Products During Delayed Shipping With OxySorb

In the wake of recent events such as the Truck Drivers’ protest the Red Sea crisis and global trade, the transportation of food products through cargo and other mediums in general has undergone delay, damage, or spoilage due to unforeseen conditions.

In such situations, food products are susceptible to changing environmental conditions, like moisture, oxygen, organisms, humidity, heat, dust, etc. One of the factors that poses a serious risk to the quality of the food products shipped in cargo is the presence of oxygen. Excess amounts of oxygen can cause the food products to lose their texture, freshness, and potency.

Oxygen absorbers can safeguard, protect and preserve the quality of food products from spoilage due to these detrimental factors of excess oxygen present in cargo settings.

How Oxysorb can help prevent damage to food products during shipping?

High oxygen absorption capabilities: An oxygen absorber is a packet filled with iron powder. When exposed to oxygen, it oxidizes and absorbs it. This process prolongs the shelf life of dried foods and grains, while also protecting them from mold and other harmful organisms.

Protect a wide range of products: They are suitable for a variety of food products and provide a wide range of oxygen and humidity protection, such as dry fruits, sweets, dried flowers, nuts, seeds, coffee, tea, dry seafood packaging, spices, herbs & seasonings, flour, pulses, grains, poultry, dairy, dry pasta, candies & confectioneries, and organic food products.

Preserve product quality effectively: Oxysorb can help preserve food quality, freshness, texture, and aroma for longer periods of time due to effectively maintaining optimum levels of oxygen inside the packaging and cargo settings.

Sustainable and eco-friendly packaging solution: Oxysorb packets are made keeping in mind the sustainability factor and with natural and eco-friendly materials. They can effectively absorb up to 98% of oxygen from the food product packaging, keeping its entire nutritive value and maintaining proper storage conditions or delays like during the Truck drivers' protest and the Red Sea crisis.

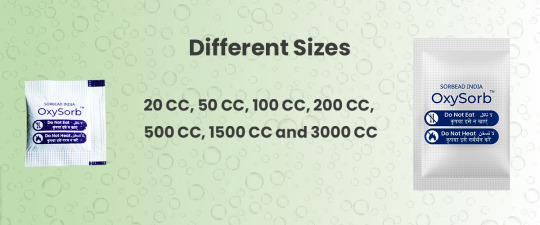

Available in various sizes: Oxysorb packets are available in various sizes making them suitable for use in small or large scale applications efficiently. You can choose from 20cc Oxygen Absorber to 3000cc Oxygen Absorber packets as per your needs.

USFDA-approved and compliant: Since Oxysorb is used along with food products, it is compliant with numerous stringent regulations and compliances and is USFDA-approved so you can rest assured that the product is non-toxic inert in nature, and safe for use.

Affordable and preservative-free option: When you use Oxysorb for protecting food products from spoilage, you are saving a lot of money, and using a preservative-free packaging solution that can help enhance and maintain the shelf life of your food products during shipping and unexpected delays like during the Truck drivers' protest and the Red Sea crisis.

Oxysorb, oxygen absorber has helped save and protect numerous cargo and shipping container contents of food products from the detrimental factors of excess oxygen and moisture levels during the Truck drivers' protest and the Red Sea crisis, and helped save goods worth $100,000,000.

#oxygenabsorbers#foodsafety#oxygenscavenger#SupplyChain#TruckDriver#logistics#transport#transportation#supplychain#logisticscompany#delivery#logisticsmanagement#business#Driver#strike#trafficjam#NewLaw#Drivers#Strike#India#hrtc#latestNews#truckdriver#truckers#HitAndRunCase#Transporter#roadsafetyreform#truckdriverprotest#HitandRunLaw#import

0 notes

Text

oxygen Absorbs in your peanuts, which will expand the Peanut's life span. It also provides the atmosphere where mold development can be stopped & preventing rancidity .This method of storage is highly preferred to import and export. It requires a lot of time to reach the destination.It even expands the shelf-life of your food to 3× times!

0 notes

Text

Oxygen Absorbers Use For Food Storage

oxygen absorber is primarily designed to prolong the food's shelf-life and prevent changes in the food's colour, taste and odour. It even prevents the packed food from becoming rancid and the growth of aerobic microorganisms such as fungi. An oxygen absorber comprises powered irons, which work to eliminate oxygen within a confined environment. Therefore, an oxygen absorber absorbs the excess oxygen and effectively reduces the aerobic environment to 0% oxygen.

0 notes

Text

Oxygen Absorbers Use As Life Extender For Food Storage

oxygen absorber- "OxySorb" for food storage, preserves the freshness, flavour and structure by eliminating oxygen from the packed products. Our OxySorb absorbs 98% of oxygen from the product keeping its entire nutritive value intake, and it can be used in vacuum-sealed and manual-sealed packaging.

#foodpackaging#oxygenscavenger#oxysorb#oxygenabsorber#different sizes#20ccoxygenabsorbers#50cc#100ccoxysorb#300ccoxyegnabsorber#500cc oxygen absorbers

0 notes