#industrialbolier

Explore tagged Tumblr posts

Text

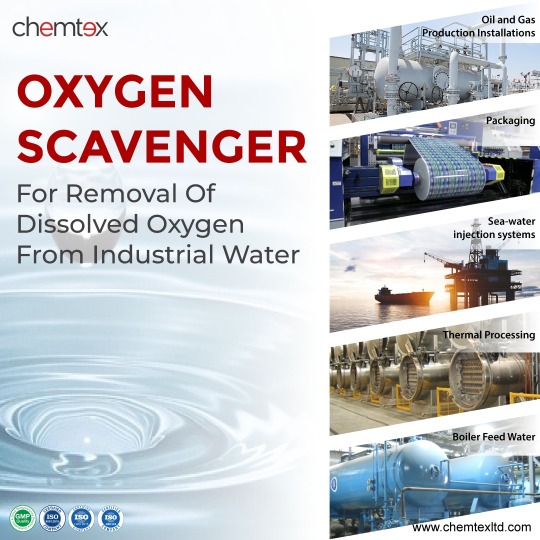

The best oxygen scavenger in boiler corrosion prevention | Chemtex Speciality Limited

Oxygen scavengers for boilers are chemicals or substances that are used to remove or reduce the presence of oxygen in boiler water or boiler feedwater. Steam boilers often operate at high temperatures and pressures, and the presence of oxygen in the boiler feedwater can lead to corrosion of the boiler and associated piping. Oxygen scavengers are added to the feedwater to help protect the boiler from oxygen-related damage, which means it is a chemical treatment for boiler water. By preventing oxygen corrosion, scavenger agents aid in steam boiler maintenance.

Boiler Oxygen Scavengers are highly responsive formulations that promptly engage with free oxygen, rapidly converting it for instant removal from the feed water and industrial boiler water. These formulations also play a crucial role in pH regulation and the reduction of feed water alkalinity. With their precise pH levels, these chemical additives offer several valuable attributes, such as energy conservation, the minimization of oxidative corrosion, and efficient oxygen elimination. This range of formulations finds applications in various industries, including food and beverage, dairy, pharmaceutical, poultry, and sugar.

Additionally, these chemicals function as passivation and rust removers, serving as a comprehensive solution for total corrosion control within internal boiler systems. Mitigating corrosion through oxygen scavenging indirectly reduces the formation of certain scales that might result from corrosion byproducts. Oxygen scavenger corrosion inhibitors are the main driver in boiler water treatment and these corrosion control activities is also part of oxygen stain removal.

Key features

Swiftly eliminates oxygen

Mitigates corrosion linked to oxygen exposure

Highly concentrated formula

Stabilizes pH levels

Promotes energy efficiency

Common types of boiler descaling chemicals used in boilers include:

Sodium Sulfite: Sodium sulfite is a commonly used chemical that reacts with dissolved oxygen to form sodium sulfate. It is effective in corrosion control and removing oxygen in the boiler and associated equipment.

Hydrazine: Hydrazine is another chemical that is used as an oxygen scavenger in boilers. It reacts with oxygen to form water and nitrogen gas. Hydrazine is effective in removing oxygen but should be used with caution due to its toxicity.

Carbohydrazide: Carbohydrazide is a less toxic alternative to hydrazine and is used as an oxygen scavenger in some boiler systems. It functions similarly to hydrazine by reacting with oxygen to produce water and nitrogen.

Catalyzed Sulfite: Catalyzed sulfite blends may be used as an oxygen scavenger in some boiler applications. These products often contain a combination of sodium sulfite, a catalyst, and pH control agents to enhance their effectiveness.

The choice of oxygen scavenger depends on various factors, including the specific requirements of the boiler, water quality, and safety considerations. It's essential to work with a qualified water treatment specialist or chemical supplier to determine the most suitable oxygen scavenger for a specific boiler system and to ensure that the chemical is applied in the correct concentration and according to established procedures. In this case, Chemtex Speciality Limited is dedicatedly involved in formulating a variety of boiler chemicals designed to enhance the overall operational safety of boilers and treat feedwater effectively.

For more information, please visit: https://www.chemtexltd.com/products-and-solutions/water-treatment-chemicals/boiler-water-treatment/boiler-oxygen-scavenger/

#chemtex#chemtexltd#chemicals#manufacturer#oxygenscavenger#corrosion#boiler#scavengeragent#industrialbolier#chemicaltreatment#oxygenstainremoval

0 notes