#Oxygen scavenger Manufacturer in India

Explore tagged Tumblr posts

Text

Oilfield chemicals manufacturer in India | imperialchem

Imperial Oilfield Chemicals Pvt. Ltd. is a premier turbine cleaner manufacturer in India, providing effective solutions for maintaining optimal turbine performance. As a leading oilfield chemicals manufacturer and exporter in India, we specialize in high-quality products tailored to the energy sector. Recognized as the best oilfield chemicals company in Gujarat, we are committed to delivering innovative and reliable solutions.

Trust Imperial Oilfield Chemicals for all your oilfield chemical needs, crafted with expertise and precision.

#Oxygen scavenger manufacturer in India#Oxygen scavenger Chemical in Vadodara#Corrosion inhibitor in Vadodara#Corrosion inhibitors manufacturer in India#Foamer manufacturer in India#Foamer exporter in Gujarat#Turbine cleaner manufacturer in India#India#Gujarat#Vadodara

3 notes

·

View notes

Text

A Deep Dive into the Industrial Water Treatment Chemicals Market: Insights and Analysis

The global industrial water treatment chemicals market size is expected to reach USD 21.23 billion by 2030, registering a CAGR of 4.9% during the forecast period, according to Grand View Research, Inc. The growth is majorly driven by growing demand for freshwater and favorable regulatory support for water treatment.

High requirement for drinkable water across the world has surged demand for the chemicals that are utilized in cleaning. The environment is seriously endangered by company waste. Due to accelerating urbanization, a rising economy, and expanding industrial activity, freshwater is witnessing high demand.

The U.S. Environmental Protection Agency (EPA) establishes national standards to ensure that consumption by humans is safe while considering the country's available technology and associated costs. The Safe Drinking Water Act and its amendments set up the fundamental framework for safeguarding the solution used by public systems in the U.S. This law specifies the requirements for guaranteeing the security of the nation's municipal drinking supplies. Systems that regularly serve 25 or more people per day or that have at least 15 service connections are considered public drinking sources.

In response to COVID-19, the governments of the affected economies have resorted to lockdowns and social distancing that have impacted the global supply chains. Several manufacturing activities were suspended which in turn, to resulted in the decline in sales of oil & gas and other industrial products. Moreover, due to the supply disruption, the price of raw materials increased significantly which in turn, was followed by an increase in the cost of treatment chemicals.

Gather more insights about the market drivers, restrains and growth of the Industrial Water Treatment Chemicals Market

Industrial Water Treatment Chemicals Market Report Highlights

• Effluent water treatment application is expected to witness the fastest growth rate of 5.1% on account of stringent wastewater disposal limitations imposed by the major international as well as regional regulatory bodies

• Raw treatment is also estimated to witness a notable growth rate. Due to the presence of suspended particles and heavy metals, the demand for pretreated industrial water is anticipated to increase especially in key countries such as the U.S., China, India, the UK, Germany, and Brazil

• During the forecasted years, it is anticipated that the presence of manufacturing facilities in the chemical, pharmaceutical, food & beverage, and automotive sectors in the U.S. and Canada would play a significant role in driving up demand for treatment services, thus triggering demand in the North America region

• Key players in the market are engaged in R&D activities coupled with mergers & acquisitions to gain a higher share of the market. For instance, Ecolab purchased Purolite a purification and separation life science solution provider in October 2021

Industrial Water Treatment Chemicals Market Segmentation

Grand View Research has segmented the global industrial water treatment chemicals market report based on the application and region:

Industrial Water Treatment Chemicals Application Outlook (Revenue, USD Million; Volume, Kilotons; 2018 - 2030)

• Raw Water Treatment

o Deoiling Polyelectrolytes (DOPE)

o Organic Coagulants

o Flocculants

o Filtration Aids

o Dewatering Aids

o Others

• Water Desalination

o Biocides

o Cleaning Agents

o Carbonates

o Sulfates

o Metal Oxides

o Silica

o Chelating Agents incl. NaOH

o Biofilms

o Others

o Antiscalants

o Flocculants

o Defoaming Agents

o Others

• Cooling & Boilers

o Sludge Controllers

o Antifoams

o Antiscalants

o Oxygen Scavengers

o Others

• Effluent Water Treatment

o Deoiling Polyelectrolytes (DOPE)

o Organic Coagulants

o Flocculants

o Filtration Aids

o Dewatering Aids

o Others

• Others

Industrial Water Treatment Chemicals Regional Outlook (Revenue, USD Million; Volume, Kilotons; 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

o Spain

o Belgium

o Sweden

o Austria

o Finland

o Poland

o Turkey

• Asia Pacific

o China

o Japan

o South Korea

o India

o Singapore

o Indonesia

o Thailand

o Vietnam

o Australia

o New Zealand

o CIS

o Indonesia

o Rest of Asia Pacific

• Latin America

o Brazil

o Argentina

o Chile

• Middle East & Africa

o South Africa

Order a free sample PDF of the Industrial Water Treatment Chemicals Market Intelligence Study, published by Grand View Research.

#Industrial Water Treatment Chemicals Market#Industrial Water Treatment Chemicals Market Size#Industrial Water Treatment Chemicals Market Share#Industrial Water Treatment Chemicals Market Analysis#Industrial Water Treatment Chemicals Market Growth

0 notes

Text

Industrial Waste Water Treatment Chemicals Market — Forecast(2025–2031)

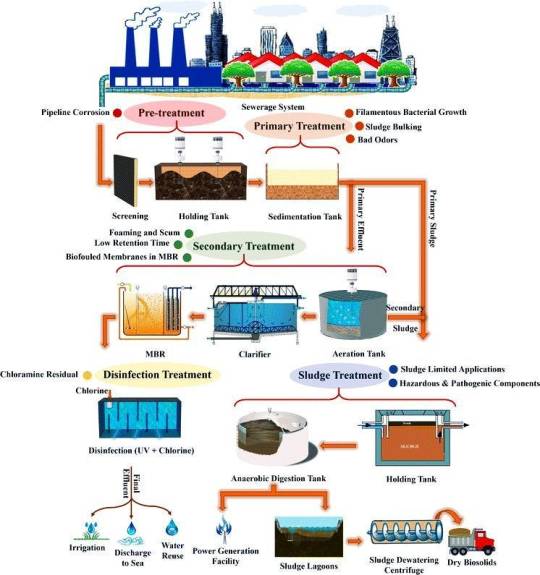

Industrial Waste Water Treatment Overview

Industrial Waste Water Treatment Chemicals Market size is forecast to reach $8.5 billion by 2025, after growing at a CAGR of 4.58% during 2020–2025.

Request Sample :

Report Coverage

The report: “Industrial Waste Water Treatment Chemicals Market — Forecast (2020–2025)”, by IndustryARC, covers an in-depth analysis of the following segments of the Industrial Waste Water Treatment Chemicals industry.

By Type of Chemicals — Scale Inhibitors, Corrosion Inhibitors, Defoamer, Biocides, Organic Polymers, Oxygen Scavengers, Coagulants, Others.

By Geography — North America, South America, Europe, APAC, RoW.

Key Takeaways

Asia-Pacific dominates the Industrial Waste Water Treatment Chemicals market owing to larger water demand due to larger population.

Increasing water pollution and scarcity of water are major factors driving the waste water treatment services market.

Due to the covid 19 pandemic, the residential usage of water has increased due to which the Industrial waste water treatment chemicals market is growing.

One notable challenge for Industrial waste water treatment chemicals is that, it is considerably costly to set up.

Inquiry Before Buying :

Type of Chemicals — Segment Analysis

Organic Polymers segment holds the largest share in the Industrial Waste Water Treatment Chemicals market. Organic polymers consist of polyacrylamide, polyaluminium chloride among others. Organic polymers are used to purify low quality water either for drinking or industrial purposes. These are used in industrial waste water treatment process to inhibit the growth of harmful organisms and also to kill the existing ones. The efficiency of the industrial waste water treatment chemicals depends on dosage rate and duration of the additive’s presence in water. Industrial waste water treatment facilities are growing at a faster pace due to excess generation of wastewater from industrial sector. The soda ash industry is a part of the chemical industry, which is responsible for the production of sodium carbonate, calcium chloride, absorbent masses, evaporated wet salt, food salt, pickling salt or salt tablets. During manufacturing of those products, strongly alkaline wastewater is generated. Owing to this the Industrial Waste Water Treatment Chemicals market is growing.

Geography — Segment Analysis

APAC has dominated the Industrial Waste Water Treatment Chemicals market with a share of more than xx%, owing to high demand from the end-user industries, such as power, steel, and food & beverage. Countries such as India, China, Japan are the epicentre for the Industrial Waste Water Treatment Chemicals market, as these countries consist of large number of industries. The wastewaters from large-scale industries such as oil refineries, petrochemical plants, chemical plants, and natural gas processing plants commonly contain gross amounts of oil and suspended solids. Those industries use a device known as an API oil-water separator which is designed to separate the oil and suspended solids from their wastewater effluents.

Schedule A Call :

Industrial Waste Water Treatment Chemicals Market Drivers

Implementation of Stringent Government regulations

Implementation of Stringent Governments’ regulations and efforts to reuse water and wastewater treatment in industries, will further aid the market growth of Industrial Waste Water Treatment Chemicals market. The removal of impurities from wastewater, or sewage, before they reach aquifers or natural bodies of water such as rivers, lakes, estuaries, and oceans. Since pure water is not found in nature (i.e., outside chemical laboratories), any distinction between clean water and polluted water depends on the type and concentration of impurities found in the water as well as on its intended use.

Increasing demand for clean water

As demand for water increases across the globe, the availability of fresh water in many regions is likely to decrease because of climate change, as warns by latest edition of the United Nations’ World Water Development Report (WWDR4). It predicts that these pressures will exacerbate economic disparities between certain countries, as well as between sectors or regions within countries. So, the demand for fresh and clean water are increasing due to which the Industrial waste water treatment chemicals market will grow.

Industrial Waste Water Treatment Chemicals Market Challenges

Costly setting up of Equipment.

In manufacturing, setup cost is the cost incurred to get equipment ready to process a different batch of goods. Hence, setup cost is regarded as a batch-level cost in activity-based costing. Setup cost is considered to be a non-value-added cost that should be minimized. One notable hurdle of cooling water treatment chemicals market is that, it is considerably costly to set up. So, small industries are financially not that much strong to setup these equipments. So, they look to escape the installing of these equipments. Whereas Antifoams are chemical agents designed to control the wasteful formation of foam during industrial processes.

Buy Now :

Impact of COVID-19

The rapid spread of coronavirus has had a major impact on global markets as, major economies of the world are completely lockdown due to this pandemic. Because of this major lockdown, suddenly all the consumer market has started to show zero interest towards purchasing equipments regarding the IWTC. One of the major difficulties, market is facing are the shutdown of all kinds of International transportation. Global crisis for all sectors including manufacturing sector have slower down the demand of goods’ production and exports of effect pigments market.

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Industrial Waste Water Treatment Chemicals market. In 2019, the market of Industrial Waste Water Treatment Chemicals has been consolidated by the top five players accounting for xx% of the share. Major players in the Industrial Waste Water Treatment Chemicals Market are Akzo Nobel N.V., Angus Chemical Company, BASF SE, BWA Water Additives UK Ltd., Kemira OYJ, The Lubrizol Corporation, Tiarco Chemical, Shandong Taihe Water Treatment Co., Ltd, Kurita Water Industries Ltd, among others.

Acquisitions/Technology Launches

In April 2020, AkzoNobel has completed the acquisition of 100% of the shares of Mauvilac Industries Limited, a leading paints and coatings company in Mauritius.

For more information about Industrial Waste Water Treatment Chemicals Market click here

#WasteWaterTreatment#IndustrialChemicals#WaterManagement#Sustainability#EnvironmentalProtection#CleanWaterSolutions

0 notes

Text

Industrial Waste Water Treatment Chemicals Market — Forecast(2024–2030)

Overview

With rise in the growing consumption for industrial waste water treatment chemicals is increasing due to increase in population, rapid urbanization and fresh water shortage, due to this the Industrial Waste Water Treatment Chemicals market is expected to grow in the forecast period. Growing governments implementation towards industrial waste water treatment will further enhance the overall market demand for Industrial Waste Water Treatment Chemicals during the forecast period.

Report Coverage

The report: “Industrial Waste Water Treatment Chemicals Market — Forecast (2020–2025)”, by IndustryARC, covers an in-depth analysis of the following segments of the Industrial Waste Water Treatment Chemicals industry.

By Type of Chemicals — Scale Inhibitors, Corrosion Inhibitors, Defoamer, Biocides, Organic Polymers, Oxygen Scavengers, Coagulants, Others.

By Geography — North America, South America, Europe, APAC, RoW.

Key Takeaways

Asia-Pacific dominates the Industrial Waste Water Treatment Chemicals market owing to larger water demand due to larger population.

Increasing water pollution and scarcity of water are major factors driving the waste water treatment services market.

Due to the covid 19 pandemic, the residential usage of water has increased due to which the Industrial waste water treatment chemicals market is growing.

One notable challenge for Industrial waste water treatment chemicals is that, it is considerably costly to set up.

Request Sample

Type of Chemicals — Segment Analysis

Organic Polymers segment holds the largest share in the Industrial Waste Water Treatment Chemicals market. Organic polymers consist of polyacrylamide, polyaluminium chloride among others. Organic polymers are used to purify low quality water either for drinking or industrial purposes. These are used in industrial waste water treatment process to inhibit the growth of harmful organisms and also to kill the existing ones. The efficiency of the industrial waste water treatment chemicals depends on dosage rate and duration of the additive’s presence in water. Industrial waste water treatment facilities are growing at a faster pace due to excess generation of wastewater from industrial sector. The soda ash industry is a part of the chemical industry, which is responsible for the production of sodium carbonate, calcium chloride, absorbent masses, evaporated wet salt, food salt, pickling salt or salt tablets. During manufacturing of those products, strongly alkaline wastewater is generated. Owing to this the Industrial Waste Water Treatment Chemicals market is growing.

Geography — Segment Analysis

APAC has dominated the Industrial Waste Water Treatment Chemicals market with a share of more than xx%, owing to high demand from the end-user industries, such as power, steel, and food & beverage. Countries such as India, China, Japan are the epicentre for the Industrial Waste Water Treatment Chemicals market, as these countries consist of large number of industries. The wastewaters from large-scale industries such as oil refineries, petrochemical plants, chemical plants, and natural gas processing plants commonly contain gross amounts of oil and suspended solids. Those industries use a device known as an API oil-water separator which is designed to separate the oil and suspended solids from their wastewater effluents.

Industrial Waste Water Treatment Chemicals Market Drivers

Implementation of Stringent Government regulations

Implementation of Stringent Governments’ regulations and efforts to reuse water and wastewater treatment in industries, will further aid the market growth of Industrial Waste Water Treatment Chemicals market. The removal of impurities from wastewater, or sewage, before they reach aquifers or natural bodies of water such as rivers, lakes, estuaries, and oceans. Since pure water is not found in nature (i.e., outside chemical laboratories), any distinction between clean water and polluted water depends on the type and concentration of impurities found in the water as well as on its intended use.

Increasing demand for clean water

As demand for water increases across the globe, the availability of fresh water in many regions is likely to decrease because of climate change, as warns by latest edition of the United Nations’ World Water Development Report (WWDR4). It predicts that these pressures will exacerbate economic disparities between certain countries, as well as between sectors or regions within countries. So, the demand for fresh and clean water are increasing due to which the Industrial waste water treatment chemicals market will grow.

Industrial Waste Water Treatment Chemicals Market Challenges

Costly setting up of Equipment.

In manufacturing, setup cost is the cost incurred to get equipment ready to process a different batch of goods. Hence, setup cost is regarded as a batch-level cost in activity-based costing. Setup cost is considered to be a non-value-added cost that should be minimized. One notable hurdle of cooling water treatment chemicals market is that, it is considerably costly to set up. So, small industries are financially not that much strong to setup these equipments. So, they look to escape the installing of these equipments. Whereas Antifoams are chemical agents designed to control the wasteful formation of foam during industrial processes.

Inquiry Before Buying

Impact of COVID-19

The rapid spread of coronavirus has had a major impact on global markets as, major economies of the world are completely lockdown due to this pandemic. Because of this major lockdown, suddenly all the consumer market has started to show zero interest towards purchasing equipments regarding the IWTC. One of the major difficulties, market is facing are the shutdown of all kinds of International transportation. Global crisis for all sectors including manufacturing sector have slower down the demand of goods’ production and exports of effect pigments market.

Buy Now

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Industrial Waste Water Treatment Chemicals market. In 2019, the market of Industrial Waste Water Treatment Chemicals has been consolidated by the top five players accounting for xx% of the share. Major players in the Industrial Waste Water Treatment Chemicals Market are Akzo Nobel N.V., Angus Chemical Company, BASF SE, BWA Water Additives UK Ltd., Kemira OYJ, The Lubrizol Corporation, Tiarco Chemical, Shandong Taihe Water Treatment Co., Ltd, Kurita Water Industries Ltd, among others.

0 notes

Text

Oxygen Scavenger Market Industry Outlook: Forecasting Market Trends and Growth for the Coming Years

Oxygen Scavenger Market Landscape Including Strategic, Unique Insights By 2032

The 2024 Oxygen Scavenger Market Report offers a comprehensive overview of the Oxygen Scavenger Market industry, summarizing key findings on market size, growth projections, and major trends. It includes segmentation by region, by type, by product with targeted analysis for strategic guidance. The report also evaluates industry dynamics, highlighting growth drivers, challenges, and opportunities. Key stakeholders will benefit from the SWOT and PESTLE analyses, which provide insights into competitive strengths, vulnerabilities, opportunities, and threats across regions and industry segments.

According to Straits Research, the global Oxygen Scavenger Market market size was valued at USD 1.99 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 3.15 Billion by 2031, growing at a CAGR of 5.2% during the forecast period (2023–2031).

New Features in the 2024 Report:

Expanded Industry Overview: A more detailed and comprehensive examination of the industry.

In-Depth Company Profiles: Enhanced profiles offering extensive information on key market players.

Customized Reports and Analyst Assistance: Tailored reports and direct access to analyst support available on request.

Oxygen Scavenger MarketInsights: Analysis of the latest market developments and upcoming growth opportunities.

Regional and Country-Specific Reports: Personalized reports focused on specific regions and countries to meet your unique requirements.

Detailed Table of Content of Oxygen Scavenger Market report: @https://straitsresearch.com/report/oxygen-scavenger-market/toc

Report Structure

Market Overview: As per Straits Research, the global Oxygen Scavenger Marketsize was valued at AAA in 111. It is projected to reach from BBB in 222 to CCC by 333, growing at a CAGR of XYZ% during the forecast period (222–333).

Economic Impact: Analysis of the economic effects on the industry.

Production and Opportunities: Examination of production processes, business opportunities, and potential.

Trends and Technologies: Overview of emerging trends, new technologies, and key industry players.

Cost and Market Analysis: Insights into manufacturing costs, marketing strategies, regional market shares, and market segmentation by type and application.

Request a free request sample (Full Report Starting from USD 995) :https://straitsresearch.com/report/oxygen-scavenger-market/request-sample

Regional Analysis for Oxygen Scavenger Market:

North America: The leading region in the Oxygen Scavenger Market, driven by technological advancements, high consumer adoption rates, and favorable regulatory conditions. The United States and Canada are the main contributors to the region's robust growth.

Europe: Experiencing steady growth in the Oxygen Scavenger Market, supported by stringent regulations, a strong focus on sustainability, and increased R&D investments. Key countries driving this growth include Germany, France, the United Kingdom, and Italy.

Asia-Pacific: The fastest-growing regional market, with significant growth due to rapid industrialization, urbanization, and a rising middle class. China, India, Japan, and South Korea are pivotal markets fueling this expansion.

Latin America, Middle East, and Africa: Emerging as growth regions for the Oxygen Scavenger Market, with increasing demand driven by economic development and improved infrastructure. Key countries include Brazil and Mexico in Latin America, Saudi Arabia, the UAE, and South Africa in the Middle East and Africa.

Top Key Players of Oxygen Scavenger Market :

Mitsubishi Gas Chemical Company Inc.

BASF SE

Ecolab Inc.

Clariant International Ltd.

Kemira OYJ

Arkema Group

Baker Hughes Incorporated

Innospec

Sealed Air Corporation

SUEZ Water Technologies & Solutions

and more....

Oxygen Scavenger Market Segmentations:

By Form

Schets/Canisters/Bottle Caps & Labels

OS films & PET bottles

Liquid Form

Powder Form

By Type

Metallic

Non-Metallic

By Composition

Organic

Inorganic

By End-Use Industry

Food & Beverage

Pharmaceutical

Chemicals

Power

Oil & Gas

Pulp & Paper

Others

Get Detail Market Segmentation @ https://straitsresearch.com/report/oxygen-scavenger-market/segmentation

Unit Economics considered by C-suite professionals:

Cost of Goods Sold (COGS): Includes material, labor, and overhead costs in manufacturing.

R&D Costs: Investment in innovation and compliance with regulations.

Engineering and Design Costs: Resources for design, prototyping, and meeting technical standards.

Production Costs: Specialized manufacturing and quality control expenses.

Supply Chain Costs: Managing procurement and logistics for specialized components.

Testing and Quality Assurance: Costs for ensuring product safety and reliability.

SG&A Costs: Marketing, sales, and administrative expenses.

Revenue per Unit: Income from contracts, services, and licensing.

Gross Margin: Revenue minus COGS, showing unit profitability.

Break-even Analysis: Units or contracts needed to cover total costs.

Customer Acquisition Cost (CAC): Costs to secure new contracts.

Lifetime Value (LTV): Total revenue from a customer over time.

Capital Expenditure (CapEx): Investments in facilities and technology.

Economies of Scale: Cost reductions in larger production runs.

Profit Margin: Final profit after all expenses.

FAQs answerd in Oxygen Scavenger Market Research Report

What recent brand-building initiatives have key players undertaken to enhance customer value in the Oxygen Scavenger Market?

Which companies have broadened their focus by engaging in long-term societal initiatives?

Which firms have successfully navigated the challenges of the pandemic, and what strategies have they adopted to remain resilient?

What are the global trends in the Oxygen Scavenger Market, and will demand increase or decrease in the coming years?

Where will strategic developments lead the industry in the mid to long term?

How significant is the growth opportunity for the Oxygen Scavenger Market, and how will increasing adoption in mining affect the market's growth rate?

What recent industry trends can be leveraged to create additional revenue streams?

Scope

Impact of COVID-19: This section analyzes both the immediate and long-term effects of COVID-19 on the industry, offering insights into the current situation and future implications.

Industry Chain Analysis: Explores how the pandemic has disrupted the industry chain, with a focus on changes in marketing channels and supply chain dynamics.

Impact of the Middle East Crisis: Assesses the impact of the ongoing Middle East crisis on the market, examining its influence on industry stability, supply chains, and market trends.

This Report is available for purchase on @https://straitsresearch.com/buy-now/oxygen-scavenger-market

About Us:

Straits Research is a leading research and intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & research reports.

Contact Us: email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: +1 646 905 0080 (U.S.) +91 8087085354 (India) +44 203 695 0070 (U.K.)

#Oxygen Scavenger Market#Oxygen Scavenger Market Share#Oxygen Scavenger Market Size#Oxygen Scavenger Market Research#Oxygen Scavenger Industry#What is Oxygen Scavenger?

0 notes

Text

Medical gas pipeline systems (MGPS) are critical components in modern healthcare facilities, ensuring the safe and efficient delivery of medical gases such as oxygen, nitrous oxide, and medical air. These systems are designed to provide a continuous supply of gases directly to various points of use throughout hospitals, significantly enhancing patient care and operational efficiency. This article explores the landscape of MGPS suppliers, their offerings, and the importance of safety and compliance in their operations.

Overview of Medical Gas Pipeline Systems

MGPS are complex networks that transport medical gases from a central supply source to various outlets in a healthcare facility. These systems typically include components such as gas storage tanks, pressure regulators, valves, alarms, and distribution piping. The design and installation of MGPS must adhere to stringent safety standards to prevent contamination, ensure reliability, and maintain patient safety.

Key Components of MGPS

1. Main Gas Stations: These stations manage the high-pressure distribution of medical gases and often include automatic switch-over systems to ensure continuous supply.

2. Medical Compressed Air Stations: These facilities produce and supply medical air on-site, which is essential for various clinical applications.

3. Medical Vacuum Stations: Designed for suctioning secretions, these stations are crucial in surgical and intensive care settings.

4. Anaesthetic Gas Scavenging Systems: These systems safely vent unused anesthetic gases from operating rooms to prevent environmental contamination.

5. Cryogenic Tanks: Used for storing liquefied gases, cryogenic tanks are vital for hospitals with high gas consumption needs.

6. Distribution Piping: Typically made from copper due to its antibacterial properties, the piping must comply with international standards to ensure safety and reliability.

7. Monitoring Alarms: These alarms alert staff to any issues with gas supply or pressure levels, enhancing safety protocols within the facility.

Importance of Safety and Compliance

The safety of MGPS is paramount; failures can lead to dire consequences for patients. Historical data indicates that improper installation or maintenance has resulted in fatalities due to crossed pipelines or defective connectors. Therefore, suppliers must ensure that their systems meet established standards such as ISO 7396-1 and NFPA 99.

Regulatory Standards

Compliance with regulatory standards is critical for MGPS suppliers. In many regions, including Europe and North America, regulations dictate the design, installation, and maintenance of these systems. For instance:

- ISO 7396-1: This standard outline the requirements for piped medical gas systems.

- NFPA 99: This code provides guidelines for health care facilities regarding the safe use of medical gas systems.

- HTM 02-01: In the UK, this document details operational management for medical gas pipeline systems.

These standards help mitigate risks associated with gas supply interruptions and contamination.

Major Suppliers in the Market

Several companies dominate the MGPS supplier landscape:

1. Air Liquide Healthcare: Known for its comprehensive range of products and services related to medical gases, Air Liquide ensures compliance with international standards while providing robust support services including installation and maintenance.

2. Helix India: With over two decades of experience, Helix specializes in providing cost-effective solutions for medical gas distribution. Their focus on quality materials and after-sales service sets them apart in the industry.

3. Johnson Medical: This company emphasizes operational management through detailed guidelines that ensure safe and reliable MGPS installations.

4. Local Suppliers: Many regions also have local suppliers who offer tailored solutions based on specific healthcare facility needs while adhering to national regulations.

Conclusion

The role of medical gas pipeline system suppliers is crucial in ensuring patient safety and operational efficiency within healthcare facilities. As technology advances and regulatory requirements evolve, these suppliers must continue to innovate while maintaining compliance with established safety standards. By prioritizing quality materials, skilled installation practices, and ongoing maintenance support, MGPS suppliers contribute significantly to enhancing healthcare delivery worldwide.

In summary, a well-designed MGPS not only supports clinical operations but also plays a vital role in safeguarding patient health—a responsibility that suppliers must take seriously as they navigate an increasingly complex healthcare environment.

0 notes

Text

Understanding the Competitive Landscape of the Aluminum Deoxidizer Market

The aluminum deoxidizer market is estimated to be valued at US$ 3.13 Bn in 2023 and is expected to exhibit a CAGR of 5.7% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview: Aluminum deoxidizers are chemicals added during aluminum smelting and refining to remove dissolved oxygen from molten aluminum. Common types of aluminum deoxidizers include calcium, strontium, barium and rare earths. They act as scavengers for dissolved oxygen in molten aluminum and protect the aluminum from re-oxidation. This helps improve the quality and properties of final aluminum products. Aluminum deoxidizers play a key role in enhancing heat resistance, strength and toughness in final aluminum products.

Market key trends: One of the key drivers of the aluminum deoxidizer market is the growing aluminum production across the globe. Aluminum finds wide usage in various end-use industries like construction, transportation, packaging and consumer goods due to its light weight and corrosion resistance properties. According to International Aluminum Institute, global primary aluminum production increased from 64 million tons in 2016 to 67 million tons in 2021. This rising aluminum production is driving significant demand for aluminum deoxidizers to remove dissolved oxygen from molten aluminum during smelting and refining processes. Additionally, stringent quality and purity standards in aluminum production are also boosting adoption of specialized aluminum deoxidizers to enhance quality of final aluminum products. Leading aluminum deoxidizer manufacturers are actively engaging in new product development through advanced technology and R&D to cater to the evolving requirements of aluminum industry.

Porter's Analysis

Threat of new entrants: New entrants face high capital requirements to build production facilities.

Bargaining power of buyers: Buyers have moderate bargaining power due to availability of substitutes.

Bargaining power of suppliers: Suppliers have moderate bargaining power due to availability of substitutes.

Threat of new substitutes: Substitutes like hydrazine may pose threat.

Competitive rivalry: Intense competition among existing players.

SWOT Analysis

Strengths: Large untapped market potential. Wide range of end-use industries.

Weaknesses: Fluctuations in raw material prices. Environmental concerns related to aluminum production.

Opportunities: Rising construction activities in developing nations. Increasing automobile production.

Threats: Stringent regulations regarding emissions. Growing adoption of aluminum substitutes.

Key Takeaways

The global aluminum deoxidizer market size was valued at US$ 3.13 Bn in 2023 and is expected to reach US$ 4.21 Bn by 2030, growing at a CAGR of 5.7% during the forecast period. Growth of the market can be attributed to rising consumption in the construction industry. Regional analysis - Asia Pacific dominated the global market in 2023 and is expected to continue its dominance over the forecast period. This can be attributed to presence of developing economies like China and India with massive construction projects underway. Key players - Key players operating in the aluminum deoxidizer market are Almatis GmbH, AluChem, Inc., Motim Electrocorundum Ltd., READE Advanced Materials, Zibo Honghe Chemical Co., Ltd., Henan HengXin Industrial & Mineral Products Co., Ltd., Prince Minerals LLC, HAIHUI Group Co., Ltd., Gongyi City Meiqi Industry & Trade Co., Ltd., Xinzheng Chengxin Carbon Co., Ltd.,Henan Junsheng Refractories Limited, Luoyang Zhongsen Refractory Co., Limited, Jiaozuo BeiYuan Chemical Co., Ltd., Gongyi City Xianke Water Supply Material Co., Ltd., Zibo Jiuchen Industry & Trade Co., Ltd.

0 notes

Text

Antioxidant Additive Masterbatches: Extending the Lifespan of Plastics

Plastics have become an integral part of modern society, finding applications in various industries from packaging and automotive to electronics and construction. However, the durability and longevity of plastic materials can be compromised by various external factors, leading to degradation, brittleness, and color fading. One effective solution to enhance the lifespan of plastics and maintain their structural integrity is using antioxidant additive color masterbatches.

Understanding Antioxidant Additive Masterbatches

Antioxidant additive masterbatches are specialized formulations that are added to plastic resins during the manufacturing process. These color masterbatches are designed to protect plastics from the harmful effects of oxidation, which is a chemical reaction triggered by exposure to oxygen and other environmental factors such as heat, light, and pollutants. Oxidation can form free radicals, leading to the degradation and weakening of the plastic material.

By incorporating antioxidant additive masterbatches, plastic manufacturers can significantly extend the lifespan of their products and ensure that they retain their mechanical properties and aesthetic appeal over time. These masterbatches act as a shield, inhibiting the formation of free radicals and slowing down the oxidation process.

Benefits of Antioxidant Additive Masterbatches

Enhanced Durability: Plastics treated with antioxidant additive masterbatches are more resistant to environmental stressors, making them less prone to cracking, chipping, and brittleness. This is especially important for applications where plastics are exposed to harsh conditions, such as outdoor furniture and automotive components.

Color Stability: UV radiation from sunlight can cause color fading and degradation of plastics. Antioxidant additives help preserve the vibrant colors of plastic products, maintaining their visual appeal and marketability.

Extended Service Life: Products made from plastics with antioxidant protection are likely to have a longer service life, reducing the need for replacements and contributing to sustainability efforts.

Reduced Maintenance Costs: Industries that rely on plastic components can benefit from reduced maintenance and replacement costs, ultimately leading to cost savings in the long run.

The Science Behind Antioxidant Additives

Antioxidant additive masterbatches function through a complex chemical process that involves neutralizing or scavenging free radicals before they can cause damage to the plastic matrix. These color masterbatches typically contain various antioxidants, such as hindered phenols, phosphites, and thioesters, which work synergistically to provide comprehensive protection.

Hindered phenols are particularly effective antioxidants that interrupt the oxidation chain reaction by donating hydrogen atoms to stabilize the free radicals. Phosphites and thioesters serve as secondary antioxidants, regenerating the primary antioxidants and enhancing their longevity.

Choosing the Right Antioxidant Additive Masterbatch

Selecting the appropriate antioxidant additive masterbatch depends on factors such as the type of plastic resin, intended application, and environmental conditions. Collaborating with a reputable color masterbatch manufacturer in India is crucial to ensure optimal results.

Kandui Industries: Pioneering Excellence in Masterbatches

Regarding reliable and high-quality color masterbatch solutions in India, Kandui Industries stands out as a leading player in the industry. With a strong commitment to innovation and customer satisfaction, Kandui Industries has earned a reputation for delivering tailor-made masterbatch solutions that cater to the unique needs of its clients.

Driven by a team of experienced professionals and backed by state-of-the-art technology, Kandui Industries offers various masterbatch products, including antioxidant additive masterbatches. Their formulations are designed to enhance the performance and longevity of plastic materials, making them the ideal partner for industries seeking to maximize the lifespan of their products.

Conclusion

In conclusion, the use of antioxidant additive masterbatches is a strategic approach to extend the lifespan of plastics and ensure their durability in the face of environmental challenges. These masterbatches play a pivotal role in inhibiting oxidation and preserving plastic products' structural and aesthetic integrity. For businesses in India seeking top-notch masterbatch solutions, Kandui Industries emerges as the premier choice, with its unwavering commitment to excellence and innovation in the field of color masterbatch technology. With Kandui Industries as a partner, industries can confidently navigate the realm of plastics, bolstering their products' performance and longevity.

0 notes

Text

Chemicals used In Boiler, Cooling Tower, RO Plant & ETP

Boilers, Cooling Towers, Reverse Osmosis Plants, and Effluent Treatment plants are essential for various industries to optimize the essential system. These systems require chemicals to enhance operational efficiency, optimize membrane life expectancy and reduce maintenance costs.

This blog helps you to understand the key chemicals for each system and their significance in maintaining their performance.

Chemicals for Boiler

Boilers generate steam to generate power for industries. The capacity of boiler that are installed depends upon the type of industries. The main issue with them is that they are prone to scaling, corrosion, fouling, and many more that can lead to reducing the capacity of steam production, reason being the quality of water used. To avoid such adverse instances, chemical treatment of water is required.

Oxygen Scavengers: These chemicals help to remove dissolved oxygen from the boiler water, preventing corrosion and reducing the alkalinity of the feed water.

Antiscalants: To inhibit formation of scales due to the precipitation of minerals, which would otherwise impact the heat transfer efficiency.

pH Boosters - These chemicals are used to control and impart optimum pH levels of boiler water to minimize scaling and corrosion.

Chemicals for Cooling Tower

The continuous circulation of water in cooling towers lead to various issues, such as slime formation, algal bloom, corrosion, scale deposition, and others which can be addressed by following chemicals.

Biocides: These chemicals prevent biofilm formation by controlling the growth of harmful bacteria, algae, and fungi.

Scale and Corrosion Inhibitors - These formulation helps to prevent the formation of scale and corrosion system, ensure heat transfer efficiency, extends equipment life, and minimizes maintenance cost.

Dispersants – These chemicals prevent the accumulation of suspended particles and sludge formation, improving overall system performance.

Chemicals for RO Plant

RO membrane filtration system is the most widely used potable water treatment process for the removal of impurities such as salts, minerals, and other contaminants. RO membranes are designed with a dense, thin, and semi-permeable layer that allows water molecules to pass through while rejecting dissolved solids and other contaminants. But continuous subjection of contaminated water in membranes results in membrane fouling, scaling, and other complexities, calling for chemical treatment.

RO Antiscalants, available in high/low/neutral pH formulations to prevent the formation of scales such as carbonates/sulfates/silicates of Ca/Mg/Ba/Sr over membrane surfaces

RO Membrane Cleaners, to remove dirt, dust, iron deposits, and silicates from membrane surfaces

Biocide, to remove biofilms, slimes, algae, and foul smell.

Chemicals for ETP

Effluent Treatment Plants are utilized to treat wastewater generated by industrial processes.

Coagulants and Flocculants – These chemicals are crucial in the removal of suspended solids and contaminants from wastewater by promoting their aggregation for easier separation.

pH Adjusting Agents – pH adjustment is crucial for the efficiency of various treatment processes. These chemicals are used to adjust the pH of the feedwater to meet the requirement.

Chemtex Speciality Limited plays a vital role in this industry by giving efforts in research and development which leads to an excellent formulation for the water treatment industry. It is one of India’s leading chemical manufacturers offering a wide range of water treatment chemicals with varied applications

Visit Us: https://www.chemtexltd.com/products-and-solutions/water-treatment-chemicals/

0 notes

Text

Shakti Chemicals - Manufacturer and Exporter of Oil Drilling, Food Grade & Commercial Chemicals

Shakti Chemicals is a company based in Vadodara, Gujarat, India that specializes in the manufacturing and exporting of various chemical products such as:

Ammonium Bisulphite 70% Solution

Ammonium Bisulphite Catalyst

Potassium Hydroxide Solution

Potassium Sulphite (K2SO3)

Potassium Bisulphite (KHSO3)

Ammonium Bisulphite 70% Solution is a clear, colorless liquid that is commonly used in the food industry as a preservative and antioxidant. It can also be used in the production of various chemicals, such as sodium metabisulphite and ammonium thiosulfate.

Potassium Hydroxide Solution is a strong alkali that is commonly used in the production of various chemicals such as detergents, fertilizers, and pharmaceuticals. It is also used in the production of biodiesel.

Potassium Sulphite (K2SO3) and Potassium Bisulphite (KHSO3) are both used as preservatives in the food industry to prevent the growth of bacteria and other microorganisms. They are also used in the production of photographic chemicals, dyes, and pharmaceuticals.

Shakti Chemicals also specializes in the production of Oxygen Scavenger chemicals. Oxygen Scavengers are used in various industries to prevent corrosion and extend the shelf life of products by reducing the amount of oxygen present in a given environment.

Shakti Chemicals offers a range of Oxygen Scavenger products designed to meet the specific needs of different industries. Their products are used in industries such as oil and gas, food and beverage, pharmaceuticals, and water treatment.

The company is committed to providing high-quality products that meet or exceed industry standards. They use advanced manufacturing processes and rigorous quality control measures to ensure that their products are of the highest quality.

Shakti Chemicals also offers excellent customer service and technical support. They work closely with their clients to understand their needs and provide customized solutions to meet their specific requirements. The company has a strong reputation for reliability, quality, and innovation, and is widely recognized as a leader in the Oxygen Scavenger industry.

Overall, Shakti Chemicals specialize in the production of a range of chemical products that have a variety of uses in different industries. To get best quote or more details to buy our chemical products call Mr. Rahul Madan Shimpi (+91-9825043369) or mail us at [email protected].

0 notes

Text

Oxygen scavenger Chemical in Vadodara | imperialchem

Imperial Oilfield Chemicals Pvt. Ltd. is a trusted name in the industry, renowned as a leading oxygen scavenger manufacturer in India. Based in Vadodara, we provide high-performance oxygen scavenger chemicals in Vadodara to ensure superior protection against corrosion. As the best chemical company in Vadodara, we take pride in being one of the best oilfield chemicals suppliers, delivering innovative solutions tailored to the energy sector.

Choose us for unmatched quality and reliability!

#Oxygen scavenger manufacturer in India#Oxygen scavenger Chemical in Vadodara#Best chemical company in Vadodara#Best oilfield chemicals suppliers#Best oilfield chemicals company in India#Oilfield chemical exporter#India#CIS Countries

5 notes

·

View notes

Text

0 notes

Link

#oxygen scavenger#oxygen scavenger chemical#oxygen scavenger oil and gas#Oxygen Scavenger Manufacturers In India#Oxygen Scavenger Manufacturers & Suppliers in India#Oxygen Scavenger at Best Price in India

0 notes

Text

Active And Intelligent Packaging Market 2022, Scope, Emerging Trends, Drivers, Growth Strategy and Forecast to 2030

Over recent years, the packaging industry has expanded at an unprecedented rate. This is partly attributed to the increased consumption of packaged food worldwide. Packaging has become an important part of product marketing strategy. The focus is moving beyond making the packaging attractive, companies are now adding novel functional qualities to their packaging solutions in order to gain consumer trust and create a distinct brand image. Moreover, changing lifestyle and rising level of health awareness among consumers to an extent has influenced the packaging industry. Brands are paying greater attention towards identifying and understanding consumer expectations and preference. Packaging can play an important role in luring a time-bound consumer. Factors as such are creating growth opportunities for active and intelligent packaging solutions.

In 2021, The global Active and Intelligent Packaging Market is projected to reach USD 51,239.39 million by 2030, expressing a CAGR of 9.03% throughout the forecast period.

Recent trend shows that increase in packaging companies focusing on expanding the shelf life and packaged food products being exported. Traditional packaging products failed to meet requirements of food products like meat and frozen foods. These constraints have given rise to new technologies which provide longevity and freshness to the food products.

The growing role of government and other agencies to safeguard consumers on a global platform. Government agencies are accountable for setting food safety standards, conducting inspections, ensuring that standards are met, and maintaining strong enforcement. The Food Safety Modernization Act (FSMA) enables the Food and Drug Administration (FDA) to better protect public health by strengthening the food safety system.

Segmentation:

The global report, with details of the active and intelligent packaging market, is banking on a proper segmentation to get to the core. This segmentation includes technology and application as a part of the report. The assessment has its focuses on providing insights and bolstering market growth by assisting in forming strategies.

By technology, the report discussing the active and intelligent packaging market reveals segments like oxygen scavenger, shelf life sensing, temperature indicators, moisture absorbers, and others.

By application, the global report on the active packaging of the meat market includes a discussion on food & beverage, personal care, healthcare, and others. The demand to know the exact state of food is boosting the food and beverage segment.

Key Players

Some of the key players in the global Active and Intelligent Packaging Market include Amcor Limited (Australia), Ampacet Corporation (U.S.), Ball Corporation (U.S.), Bemis Company, Inc. (U.S.), Constar International Inc.(U.S.), Crown Holdings Incorporated (U.S.), W.R. Grace and Company (U.S.), Graham Packaging Company Inc.(U.S.), Klockner Pentaplast (Subsidiary Of Blackstone Group) (U.S.), Landec Corporation (U.K.), Mitsubishi Gas Chemical Company (Japan), and Rexam plc. (U.K.)

Access the Full Report Of the Active and Intelligent Packaging Market With TOC @ https://www.marketresearchfuture.com/reports/active-and-intelligent-packaging-market-5550

Regional Analysis

The global market is segmented on the basis of geography: Asia Pacific, North America, Europe, and the Middle East & Africa. Regions such as North America and Europe are dominating the active packaging of the meat market due to stringent legislation regarding food and beverage packaging and technological advances in the field of active packaging. Asia Pacific is expected to experience the fastest growth during the forecasted period due to the economic growth of China and India. The increasing demand for fresh and quality packaged food, consumer convenience, and manufacturers' concern for the longer shelf life of the food products are providing an opportunity to the Asia Pacific region to grow further.

Over recent years, the packaging industry has expanded at an unprecedented rate. This is partly attributed to the increased consumption of packaged food worldwide. Packaging has become an important part of product marketing strategy. The focus is moving beyond making the packaging attractive, companies are now adding novel functional qualities to their packaging solutions in order to gain consumer trust and create a distinct brand image. Moreover, changing lifestyle and rising level of health awareness among consumers to an extent has influenced the packaging industry. Brands are paying greater attention towards identifying and understanding consumer expectations and preference. Packaging can play an important role in luring a time-bound consumer. Factors as such are creating growth opportunities for active and intelligent packaging solutions.

Contact us:

Market Research Future (part of Wantstats Research and Media Private Limited),

99 Hudson Street, 5Th Floor,

New York, New York 10013

United States of America

+1 628 258 0071

Email: [email protected]

#Active & Intelligent Packaging Market Size#Active & Intelligent Packaging Market Share#Active & Intelligent Packaging Market Type#Active & Intelligent Packaging Market Application

0 notes

Text

Medical & Pharmaceutical Gases & Equipment Market - Forecast, 2022-2027

Medical & Pharmaceutical Gases & Equipment Market size is estimated to reach $25.4 billion by 2027, growing at a CAGR of 6.2% during the forecast period 2022-2027. Medical and pharmaceutical gases can be delineated as fluids or specialized gases that are taken into account for performing several medical procedures, research, and manufacturing activities in the biopharmaceutical industry. Furthermore, gases equipment is the hardware or assemblies used to storm the gases and supply them when needed. Equipment such as cylinders, valve with integrated pressure regulators, vacuum insulated evaporators, and flow meters are considered in handling the storage and delivery of gases. Besides, storing and maintaining a constant supply few devices such as anaesthetic gas scavenging systems work as scavengers by removing the mixture of gases out of storage facilities and operating rooms in order to keep medical staff exempt from their exposure. Generally, oxygen, helium, argon, nitrogen, and compressed air are used as medical gases when performing therapeutic treatments and anesthetic procedures. Furthermore, gas equipment is the hardware or assemblies used to store the gases and supply them when needed. The medical & pharmaceutical gases & equipment market outlook is exceptionally enchanting ascribing to their colossal demand. Augmenting chronic ailments such as cardiovascular hitches, road tragedies, and mounting research and development spending are factors set to drive the growth of the Medical & Pharmaceutical Gases & Equipment Market for the period 2022-2027.

Report Coverage

The ort: “Medical & Pharmaceutical Gases & Equipment Market Forecast (2022-2027)”, by Industry ARC, covers an in-depth analysis of the following segments of the Medical & Pharmaceutical Gases & Equipment Market.

By Composition: Concentrate/Pure gases (Nitrogen, Helium, Carbon dioxide, Oxygen, and others), Dilute/Mixture gases (Blood gas mixtures, Sterilant gas mixtures, lung diffusion mixtures, and others). By Application: Therapeutics, Anesthetic, and Research. By Equipment Type: Masks, Manifolds, Air compressors, Cylinders, Hose assemblies, Flowmeters, and Others. By End User: Hospitals, Clinics, Cancer treatment centers, ASCs, Biotech Industries, and Others. By Geography: North America (U.S., Canada, and Mexico), Europe (Germany, UK, France, Italy, Spain, Russia, and Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Australia & New Zealand, and Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and Rest of South America) and Rest of World (the Middle East and Africa).

Key Takeaways

Geographically, the North America Medical & Pharmaceutical Gases & Equipment Market accounted for the highest revenue share in 2021. However, Asia-pacific is poised to dominate the market over the period 2022-2027.

Enlarging the elderly population, a frantic upsurge in the prevalence of cardiovascular complications CVDs is said to be a preeminent driver driving the growth of the Medical & Pharmaceutical Gases & Equipment Market. whereas, health problems associated with medical gases are said to reduce the market growth.

Detailed analysis of the Strength, Weaknesses, and Opportunities of the prominent players operating in the market will be provided in the Medical & Pharmaceutical Gases & Equipment Market report.

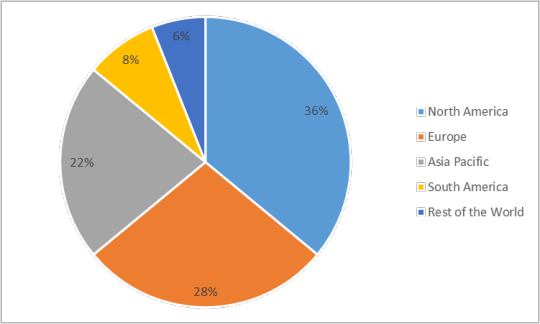

Medical & Pharmaceutical Gases & Equipment Market Share, By Geography (%) in 2021

For More Details on This Report - Request for Sample

Medical & Pharmaceutical Gases & Equipment Market Segment Analysis-By Composition

The Medical & Pharmaceutical Gases & Equipment Market based on the composition type can be further segmented into concentrate/Pure gases (Nitrogen, Helium, Carbon dioxide, Oxygen, and others), dilute/mixture gases (Blood gas mixtures, Sterilant gas mixtures, lung diffusion mixtures, and others). The concentrate gases segment held the largest share in 2021. The growth is owing to humongous demand as chronic obstructive pulmonary diseases are coming to the foreground like never before. COPD maladies like emphysema and chronic bronchitis are so severe that they inflict irreparable damage to the lungs which can’t be cured. Therefore, patients suffering from such conditions required constant medical care and treatment. On another hand, cases associated with cardiac arrest and trauma have heightened the use of medical oxygen. It can’t be proclaimed that only the pure gases segment will witness growth aspects over the undermentioned time frame because both of these gases’ usage go hand-in-hand. Mixture gases play a significant role in the maintenance of devices that distributes anesthetic gases. Moreover, they are also taken into consideration during lung diagnosis. Therefore, the concentrated along with dilute segment is estimated to be the fastest-growing segment with a CAGR of 7.8% over the forecast period 2022-2027.

Medical & Pharmaceutical Gases & Equipment Market Segment Analysis-By End User

The Medical & Pharmaceutical Gases & Equipment Market based on end-user can be further segmented into hospitals, clinics, cancer treatment centers, ASCs, biotech Industries, and others. The hospital segment held the largest share in 2021. The growth is owing to broadening hospitalization trends as chronic illnesses are on the loose and roaming around the globe. Moreover, the COVID-19 has played a significant role in upsurging hospitalization. Many COVID patients witness lower levels of oxygen in the blood which drives the tissues and organs of the body to starve. This condition obligates constant access to oxygen. Therefore, to meet the shooting up demand hospitals are supposed to be in a fit state all the time to meet the requirements. In today’s world hospitals have a far-reaching presence throughout the countries whether it’s a city or pastoral area it doesn’t matter. That is why they have become the first and foremost point of contact for people who want to undergo some sort of treatment. Moreover, the hospital segment is estimated to be the fastest-growing segment with a CAGR of 7.3% over the forecast period 2022-2027. This growth is owing to the enlightening infrastructure of hospitals with heightened government spending post-COVID-19.

Medical & Pharmaceutical Gases & Equipment Market Segment Analysis-By Geography

The Medical & Pharmaceutical Gases & Equipment Market based on Geography can be further segmented into North America, Europe, Asia-Pacific, South America, and the Rest of the World. North America held the largest share with 36% of the overall market in 2021. The growth in this segment is owing to the factors such as the heavy pervasiveness of asthma. The US dominates when it comes to bronchial asthma due to widespread obesity. According to the American Lung Association, being overweight can narrow the lungs by encircling pressure and set breathing difficulties in motion. More than 40% of adults in the US are obese. Similarly, gun violence leads to thousands of injuries every year, and the immense spread of cancer cases especially breast and lung cancer are quite high which is also driving the growth in the respective segment. However, Asia-pacific is expected to be the fastest-growing segment over the forecast period 2022-2027. This growth is owing to the soaring elderly population which is shooting up the incidences of heart attack and cancer. Besides cancer and heart attack the worst air quality is another big factor behind amplified hospitalization. India and China are home top cities with the worst particulate matter (PM2.5) concentration which impairs the lungs of residents more than 30 times the WHO satisfactory levels. According to a report published in 2021, Asia is the epicenter of the most polluted cities worldwide. Out of the most 100 polluted cities all around the globe, 46 lie in India, and 42 are situated in China. Considering the aforementioned factors, the number of people afflicted with chronic obstructive pulmonary disease (COPD) is rising.

Medical & Pharmaceutical Gases & Equipment Market Drivers

Shooting up chronic illnesses is Anticipated to Boost Product Demand.

Jumping incidences of chronic illnesses is a major factor behind the growth of the medical & pharmaceutical gases and equipment market. According to the report, chronic maladies like heart attack and cancer are the biggest reason for increased mortality rates all over the globe. More than 600,000 people die from heart attacks in the US. Moreover, around 17-18 million lose their lives due to coronary heart diseases worldwide. Now as a major faction of the total world population is turning old these numbers are anticipated to witness a spike before long. It is estimated that are going to be 1-2 billion old people on this planet before long. All these factors are contributing their fair share to the growth of the aforementioned market.

Augmenting obesity and hospitalization ascribing to COVID-19 are Expected to Boost Product Demand.

COVID-19 is the prime reason behind the increased hospitalization in the last two years. Studies have found a direct link between COVID-19 and respiratory distress syndrome (ARDS) as the lungs are the most overwhelmed organ of the body. On another hand, the prevalence of chronic obstructive pulmonary disease (COPD) has become so common that every year India record more than 10 million cases. Likewise, the U.S. has recorded 16 million cases in 2021. Moreover, the budding trend of obesity due to poor intake and reduced activity is another reason driving the growth of the respective market.

Medical & Pharmaceutical Gases & Equipment Market Challenges

Health complications associated with medical gases are Anticipated to Hamper Market Growth.

Although incidences of serious health hitches associated with medical gases occur once in blue moon but still in many cases inhalation of gases like carbon dioxide and nitrous oxide can erupt many severe health complications which can be factor incongruent with the growth of medical & pharmaceutical gases & equipment market. CO2 exposure sets health hitches like tingling, asphyxia, uneven heartbeat, convulsion, and nuisances in motion. According to National Center for Biotechnology Information, the incidence of birth asphyxia in most developed countries accounts for less than 0.1% of newborn deaths. But, in developing countries, it ranged from 4.6/1000 to 7–26/1000 live births. More than 25.0% of the world's newborn deaths have occurred in Africa. Of those, birth asphyxia accounts for 24.0%. Moreover, excess nitrous oxide may give rise to nerve damage, coma, seizures, and loss of life in some cases.

Medical & Pharmaceutical Gases & Equipment Industry Outlook:

Product launches, mergers and acquisitions, joint ventures, and geographical expansions are key strategies adopted by players in the Medical & Pharmaceutical Gases & Equipment Market. Key companies in this market are-

Linde Group

BeaconMeadaes LLC

Air Liquide

BPR Medical

INOX Air products

Praxair

Gulf Cryo

Messer group

Taiyo Nippon Sanso

Atlas Copco

Recent Developments

On April 19, 2022, FDA approved GE Healthcare software that automates anesthesia and reduces greenhouse gas emissions during surgery. The software is cleared for use with GE Healthcare’s Aisys CS2 anesthesia delivery system.

On May 11, 2021, Sweden-based company “Atlas Copco” which develops and manufactures air compressors announced that it has successfully acquired North Carolina, United States-based company “Compressed air system Inc.” the financials of this deal were kept hidden but the acquisition is supposed to extend several advantages to Atlas Copco to enhance its overall reach to its customers.

On April 3, 2019, German industrial gas supplier “Messer Group” and British equity and investment company “CVC Capital partners” concluded an acquisition deal with “Linde.” Under the deal, Messer acquired many gases businesses which are located in America from Linde. The total value of this transaction was around $3.3 billion.

#Medical & Pharmaceutical Gases & Equipment Market share#Medical & Pharmaceutical Gases & Equipment Market size#Medical & Pharmaceutical Gases & Equipment Market forecast

0 notes

Text

Diethyl Ether Market - Forecast (2021-2026)

Diethyl Ether Market size is forecast to reach the market size of $12.5 billion by 2025, after growing at a CAGR of 7.4% during 2020-2025. One of the major factor driving the market is the growing demand for Industrial and laboratory solvents. However, formation of explosive peroxides is expected to hinder the growth of diethyl ether industry.

Dimethyl ether has multiple fuel properties which make it attractive for diesel engine use. It has a very high number of cetane which is an indicator of the ignitivity of the fuel in compression-ignition engines. Diethyl ether is a highly volatile organic solvent with a high flammability. DEE can form organic peroxides when stored for a long time which can be blocked by adding butylated hydroxytoluene (BHT) as a stabiliser. BHT scavenges the free radicals necessary for the formation of peroxides.

Download Report Sample @ https://www.industryarc.com/pdfdownload.php?id=502883

Report Coverage

The report: “Diethyl Ether Market – Forecast (2020-2025)”, by IndustryARC, covers an in-depth analysis of the following segments of the Diethyl Ether Industry.

Key Takeaways

Automotive industry dominated the market in 2018 and is expected to grow during the forecast period.

Manufacturing multi-walled carbon nanotubes, using diethyl ether is likely to act as an opportunity in the future.

North America dominated the market across the globe with the largest consumption from the United States.

By End-Use Industry - Segment Analysis

Due to its various applications in the sector, the growing demand from the automotive industry is expected to drive the ethyl ether market. The key automobile uses are its use as an octane or lubricating oil that increases the vehicle's fuel efficiency. It is used as a charging fluid for diesel or gasoline engines in conjunction with petroleum. Growing demand from Asia Pacific countries is contributing significantly to the growth of the automotive industry due to rising disposable income and changing lifestyle. Due to ever-increasing crude oil prices, automobile fuel efficiency is the target of government and car manufacturers.

Inquiry Before Buying @ https://www.industryarc.com/reports/request-quote?id=502883

Geography - Segment Analysis

North America was the largest producer of ethyl ether, as well as the largest consumer with the market share of 43% in 2019. Ethyl ether's key uses are its use in automobile starting fluid and smokeless gun powder, although modest growth is expected. Growing demand from applications for laboratory and industrial solvents is expected to drive this region's ethyl ether industry. In terms of production, North America was led by Asia Pacific due to high demand from India and China. Due to market saturation and rising competition, Japan is expected to show low growth. With demand from major applications such as chemical synthesis and military applications, the ethyl ether market in Europe is expected to show moderate growth.

Drivers – Diethyl Ether Market

Increasing Demand from the Automotive Industry.

Diethyl ether is used as an enhancer of octane and oxygen in petrol and as a blend of lubricating oils in the automotive sector. The other usage involves the use of diethyl ether as a liquid beginning fuel additive. Because of its low cetane amount and high energy capacity, the CI engine's cold-starting efficiency is increased by mixing the fuel with diethyl ether. Diethyl ether is a highly flammable material, providing a rapid boost to the engine by rising the piston pressure to nearly triple. For countries with cold climates, the diethyl ether additive may be of greater interest in the starting fluid as it tends to cold-start the engine at sub-zero temperatures. The development of the automotive industry worldwide, especially in Asia-Pacific and the Middle East, driven by growing expenditure by giant companies such as, Volvo, Daimler, and Volkswagen in the production of commercial vehicles, is likely to drive diethyl ether demand in the coming years.

Schedule a Call @ https://connect.industryarc.com/lite/schedule-a-call-with-our-sales-expert

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Diethyl Ether market. In 2019, the market of Diethyl Ether has been consolidated by the top five players accounting for xx% of the market share. Diethyl Ether top 10 companies are BASF SE, Industrial Solvents & Chemicals Pvt. Ltd (ISCPL), INEOS, LyondellBasell Industries Holdings BV, Merck KGaA, Sasol, Standard Reagents Pvt. Ltd, and TKM Pharma Pvt. Ltd, among others.

For more Chemical and Materials related reports, please

click here

0 notes