#Organic Fertilizer Compost Turning Machine

Explore tagged Tumblr posts

Text

In the production equipment of organic fertilizer and biological organic fertilizer, Compost Turning Machine is the first essential equipment. So, what is the important role of Compost Turning Machine in the production of organic fertilizer? What are the benefits of using Windrow Compost Turning Machine for the production and fermentation of organic fertilizer?

Tipping machine sorting

Stacking machines are divided into two types: the type of stacking machine that can walk on the ground and the trough type stacking machine that works on the fermentation tank.

Application and benefits of ground type pile tilter

The raw materials for the production of organic fertilizer are more extensive, and the more common ones are chicken manure, pig manure, cow manure, sheep manure and other livestock and poultry manure. Such raw materials need to undergo biological fermentation, and then let it reach the standard of harmless treatment, so as to further produce into commercial organic fertilizer.

The specific operation of the pile turning machine:

Determine the fermentation site, the ground fermentation site needs to be open, the site needs to be smooth, so that it can be convenient for large-scale fermentation production.

Under normal circumstances, the water content of raw materials is large, and a certain proportion of dry materials need to be added for water adjustment, such as straw powder, mushroom residue, etc. Take the sheep manure as an example, pile the sheep manure on the ground, sprinkle the fermentation agent for sheep manure compost on the surface of the raw material, according to the size of the water, add the appropriate amount of dry material/auxiliary materials, the general ratio of raw materials: auxiliary materials are 3:1, the width and height of the pile are determined according to the respective pile model number.

Taking the Wheel Type Windrow Compost Turning Machine as an example, the width and length are determined according to the length of the field. Then the pile turning machine itself walks on top of the material pile, evenly turning, stirring and crushing the raw materials, so that the sheep manure and dry materials and bacteria are fully stirred and evenly, the pile turning machine has the crushing function, even if the sheep manure or dry materials and accessories are large, under the action of the pile turning machine, the large materials can be crushed and decomposed to facilitate full fermentation.

After turning the pile, a new flat material pile is formed, and the new pile body is fluffy and loose, creating a favorable aerobic state for material fermentation, which is very conducive to the production and fermentation of organic fertilizer. In this state, the overturned reactor can rise to the fermentation high temperature within 24 hours, and the reactor can maintain the high temperature for 2-3 days, and then the reactor can be turned. This state has basically become fat in 7 days. At high temperatures, bacteria, grass seeds, and eggs in sheep dung will be killed, and large molecular proteins will be broken down into small molecular proteins that are conducive to crop absorption. In the process of biological fermentation, it can effectively prevent the production of harmful and odorous gases such as hydrogen sulfide, amine gas and indole in feces, and completely remove the odor in feces.

With the high temperature, turning the pile, the moisture in the raw material will gradually decrease, and the general fermentation cycle is 12-15 days. Can continue the next step of deep processing, screening, crushing, granulation, etc. As long as the early fermentation work is done well, the quality of organic fertilizer will be better, and the late deep processing will be easier to carry out, such as granulation, there will be no problems such as not easy to form balls.

In summary, it can be seen that the role played by the turnover machine in the production and application of organic fertilizer is very critical, and it is crucial to choose the right high-quality and inexpensive Organic Fertilizer Compost Turning Machine.

Stack turning machine compared with other products

Some customers want to save costs, with a forklift instead, in fact, the role of the forklift is far less than a special organic fertilizer turning equipment, and the cost will not be reduced.

Fermented organic fertilizer semi-finished products are brown, dark brown, no odor, there will be a little ammonia smell.

Such organic fertilizer applied to the field, do not worry about will produce soil-borne diseases, will not burn the roots, organic fertilizer in nitrogen, phosphorus and potassium and other nutrients are rich and comprehensive, more easily absorbed by crops, long-term application, will completely improve the soil dry crack, the situation of compaction, so that the soil water retention performance is enhanced, so that crop increase and income, quality is further improved!

#Organic Fertilizer Compost Turning Machine#Wheel Type Windrow Compost Turning Machine#Windrow Compost Turning Machine

0 notes

Text

The daily maintenance method of Organic Fertilizer equipment is particularly important, because once we do not operate at will according to precautions, even a small failure may cause big problems in production and use, and ultimately affect production.

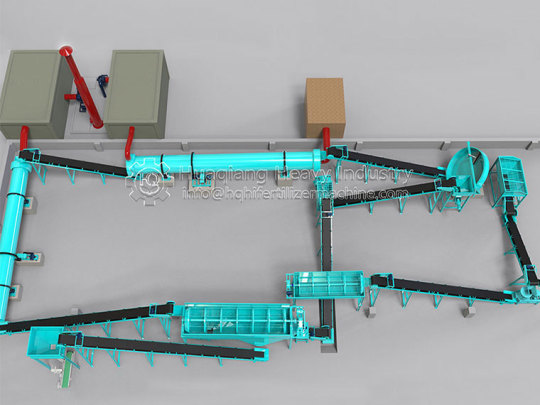

First of all, let’s understand the Organic Fertilizer equipment process

It is mainly divided into the following two parts: Organic Fertilizer Compost Turning Machine, Compost Crusher, Rotary Screening Machine, And the Organic Fertilizer Granulator, Disc Granulator, Rotary Drum Granulator, Fertilizer Granules Compaction Machine, Rotary Dryer Machine, Rotary Cooler Machine, grading screen, Powder/Granules Fertilizer Packing Machine, and Belt Conveyor in the middle link.

Secondly, since we want to understand the daily maintenance methods of Organic Fertilizer fermentation equipment – ground Compost Turning Machine, let me briefly introduce the following two commonly used Compost Turning Machine types:

One, Wheel Type Windrow Compost Turning Machine is a special machine used to produce Organic Fertilizer and turn over viscous materials such as animal manure, sludge, distiller’s lees and furfural using strip compost fermentation process. The power is diesel engine. The stacking width of the material is 2 meters, the stacking height is about 0.8 meters, and the maximum processing capacity is 380m³/h. This machine can not only turn and gather the material evenly, but also effectively loosen the clumps in the fertilizer base after fermentation. It is an indispensable machine for harmless treatment of livestock and poultry manure and fertilizer making operations. Two, the use of Windrow Compost Turning Machine is very common, and it is a special machine for turning, crushing, oxygen supply and stacking of materials. This machine is mainly composed of four parts: turning auger power part, walking power part, hydraulic lifting part, control part.

The ground-type Compost Turning Machine produced by Zhengzhou Huaqiang Heavy Industry is designed according to the principle of aerobic fermentation, so that the fermentation bacteria have the space to give full play to their functions. Its machinery and equipment has the obvious advantages of less investment, low energy consumption, fast fertilizer production, and large output, saving a lot of civil construction and human and material resources.

Finally, let Xiaobian focus on the maintenance and maintenance of Compost Turning Machine

1.Com Maintenance and maintenance of post Turning Machine Daily maintenance:

The Compost Turning Machine should be maintained once a week when it is not often operated, and the Compost Turning Machine should be maintained once a day when it is often operated. Its maintenance content:

(1) Half maintenance inspection (after 10 hours of work), check whether the connection bolts, nuts and oil drain plugs are loose.

(2) Check all parts of the latch, cotter pin for defects, and timely replacement (cotter pin shall not be replaced with other things).

(3) Check whether the tilting knife is defective and whether the fastening bolts are loose, and if necessary, fill, tighten or replace the new knife.

(4) Check whether the electrical joints are tight, whether the insulation of the wire is good, and repair or replace it in time if necessary.

(5) Check whether the fastening screws of diesel engine, gearbox, bearing seat and other components are loose.

(6) Clean the bonded attachments on the Compost Turning Machine.

(7) Check the surplus of the fuel tank and water tank.

(8) Wheel Type Windrow Compost Turning Machine Should also pay attention to whether the tire pressure is normal.

2.Compost Turning Machine maintenance and maintenance Compost Turning Machine regular maintenance

(1) After working for a season, replace the gear oil of the reducer, check the bearings of all parts, apply new butter after disassembling and cleaning, and install it. If the wear is serious, it should be replaced.

(2) Remove the dust cover on the equipment, check and tighten the bolts on each transmission rod. Prevent the bolts on the transmission rod from loosening, resulting in the parts not being driven in place and causing the parts to wear and scrap.

(3) Remove the cab seat and cover plate under the seat and check to tighten the bolts on the drive shaft. Prevent the shaft body from being inclined and broken due to the loosening of the bolts on the drive shaft seat.

(4) Antifreeze should be added to the water tank when used in winter. If no antifreeze is added, warm water should be added to the water tank, body and cooler before operation, and the water in the water tank, body and cooler should be discharged after operation to prevent freezing.

(5) Check whether the electrical appliance is working normally, whether the circuit insulation performance is good, and replace the connected wire if necessary.

(6) It is necessary to regularly check the tension of the drive belt, adjust the tension if necessary, and check whether the belt is broken, worn or has other signs of aging, and replace the belt if necessary. Check the belt path and make sure there is no obstruction between the other parts of the engine and the belt. After replacing the belt, the new belt should be re-adjusted after two or three weeks of use to eliminate slack.

(7) When Compost Turning Machine is operated for a long time, the exposed parts should be coated with oil to prevent rust, and should be covered when placed outdoors.

3.Compost Turning Machine maintenance and maintenance of important components of compost Turning Machine

(1) Diesel engine maintenance and maintenance please follow the diesel engine manufacturer’s operating instructions for maintenance and maintenance.

(2) The maintenance of the car air conditioner (if equipped) see the operation and maintenance manual of the air conditioner.

(3) Compost Turning Machine battery maintenance:

Make the battery firmly fixed.

Terminals and connecting parts should be kept clean and firm.

If Compost Turning Machine starts frequently for a short time, the battery may not be supplemented by the electric energy on the generator. Please check the battery memory power frequently and charge the battery in time to prevent the battery from being scrapped due to power loss.

If the vehicle is not used for a long time, the battery wiring should be separated.

When separating the battery, the negative wiring of the battery must be removed first and installed last.

#Compost Turning Machine#Organic Fertilizer Compost Turning Machine#Wheel Type Windrow Compost Turning Machine#Windrow Compost Turning Machine

0 notes

Text

Factors affecting the price of fermentation compost turning machine

The price of fermentation compost turning machine is affected by a variety of factors, mainly including the following aspects:

1. Technological progress: With the advancement of agricultural machinery technology, the tilting machine has realized automation and intelligence, equipped with advanced control systems and sensors, which can accurately control the tilting depth and frequency, while reducing energy consumption. The more advanced the technology of organic fertilizer equipment, the price may be relatively high, but it will help improve production efficiency and reduce operating costs in the long run.

2. Equipment size and capacity: The size and capacity of the flipping machine is an important factor affecting the price. Large overturning machines usually have higher production capacity and stronger material handling capacity, so the price is relatively high.

3. Market competition: The degree of market competition will also affect the price of the flipping machine. In a competitive market, producers may lower prices to attract customers, while in a less competitive market, prices may be relatively high.

4. Supply and demand relationship: the market supply and demand relationship will also affect the price of the flipping machine. If demand is strong and supply is limited, prices may rise; Conversely, if the market is oversupplied, prices may fall.

5. After-sales service and maintenance costs: Different brands of flipping machines may differ in terms of after-sales service and maintenance costs, which will also affect the overall cost of ownership of the equipment.

To sum up, the price of the fermentation machine is affected by a variety of factors, and investors should consider these factors comprehensively when purchasing to ensure the selection of cost-effective equipment.

0 notes

Text

Detailed points for composting of organic fertilizer equipment

In the organic fertilizer production line, the efficient operation of the fermentation compost turning machine is very important for the whole production process. Here are some key steps and points to ensure proper operation and maintenance of the compost tiller:

1. Equipment inspection: Before operation, check whether the various parts of the pile tilter are intact, whether the fasteners are fastened, and whether there are foreign objects that may affect the operation.

2. Lubrication system: Ensure that the lubrication system of the pile tilter works normally, and add lubricating oil regularly to reduce friction and wear between components.

3. Operation training: the operator should receive professional training and be familiar with the operation process and safety procedures of the pile turning machine.

4. Uniform feeding: to ensure that the material evenly into the pile turning machine, to avoid uneven equipment load caused by uneven feeding.

5. Adjust parameters: According to the characteristics of the material and the requirements of the pile, timely adjust the operation parameters of the pile tilter, such as speed and Angle.

6. Monitoring operation: During the operation of the equipment, the temperature, vibration and noise of the equipment are monitored to ensure the smooth operation of the organic fertilizer equipment.

7. Cleaning and maintenance: Regularly clean the tipping machine, especially the material contact part, to prevent material accumulation and corrosion.

8. Troubleshooting: For abnormal sound or vibration in operation, it should be stopped immediately for inspection and maintenance if necessary.

9. Record maintenance: Establish maintenance records of the heap tilter, record the time, content and result of each maintenance, and facilitate the tracking of equipment status.

By following these steps, you can ensure the effective operation of the compost tiller, improve production efficiency, and at the same time ensure the safety of the operator.

#organic fertilizer equipment#organic fertilizer production line#fermentation compost turning machine

0 notes

Text

How to debug the fermentation compost turning machine correctly

The correct adjustment of the fermentation compost turning machine is very important to ensure the efficient operation of the organic fertilizer production line. Here are some basic steps and considerations:

1. Equipment inspection: Before starting, a thorough equipment inspection should be carried out to ensure that all components are intact, the connections are tight, the power cables and plugs are normal, and the filter is clean and properly installed.

2. Lubrication: According to the recommendations of equipment manufacturers, bearings, gears and other parts that need lubrication are lubricated to reduce friction and wear.

3. Operation training: Operators should receive appropriate training to understand the correct operation methods and safety procedures of organic fertilizer equipment.

4. Preparation before starting the equipment: Before starting the equipment, ensure that the working environment is safe and free of obstacles, and operate according to the instructions.

5. Trial run: Before the formal production, carry out no-load test run to check whether the steering of the equipment is correct and whether the gear noise is uniform.

6. Feeding operation: the fully mixed materials are transported to the front of the fermentation tank by forklift, and piled into a certain thickness.

7. Flipping operation: Before starting, idling for half a minute to see and listen to whether the equipment is running abnormally; This parameter can be used only when no exceptions exist.

8. Monitoring operation: During the operation of the equipment, the temperature, vibration and noise of the equipment are monitored to discover and solve problems in time.

9. Maintenance records: Establish maintenance and maintenance records of the equipment, record the time, content and result of each maintenance, and facilitate the tracking of equipment status.

10. Safe operation: comply with all safe operation procedures to ensure the safety of operators.

By following these steps, you can ensure the effective operation of the fermentation tiller, improve production efficiency, and at the same time ensure the safety of the operator.

#organic fertilizer equipment#organic fertilizer production line#fermentation compost turning machine

0 notes

Text

The natural advantages and broad prospects of fermentation compost turning machine

The fermentation compost turning machine has a natural advantage in the organic fertilizer production line and has a positive impact on agricultural development. Here are its main advantages and implications:

1. Improve production efficiency: Through mechanized operation, the stacking machine significantly improves the fermentation efficiency of organic fertilizer and shorens the production cycle.

2. Improve product quality: The turnover machine can evenly turn the material to ensure the uniformity of the material during the fermentation process, thereby improving the quality and consistency of the organic fertilizer.

3. Resource recycling: The turnover machine can convert agricultural waste into organic fertilizer, realizing the resource utilization of agricultural waste and reducing environmental pollution.

4. Improve crop quality: Organic fertilizers can provide the comprehensive nutrition needed by crops, helping to improve crop quality and yield.

5. Environmental design: The design of the stacking machine takes into account environmental factors, such as reducing dust and noise, which helps to improve the working environment and protect the environment.

6. Technological progress: With the development of technology, the level of automation and intelligence of the stacking machine continues to improve, improving production efficiency and product quality.

7. Policy support: Many countries and regions provide policy support and financial subsidies to encourage the use of organic fertilizers, which helps to reduce the production cost of organic fertilizers and improve their market competitiveness.

8. Market demand: With the increasing demand of consumers for healthy food and environmentally friendly products, the market potential of organic fertilizers is huge, helping to promote the sustainable development of agriculture.

Through the above advantages, the fermentation stacking machine not only improves the efficiency and quality of agricultural production, but also helps to achieve sustainable development of agriculture and environmental protection.

#organic fertilizer equipment#organic fertilizer production line#fermentation compost turning machine

0 notes

Text

In modern agriculture, large-scale composting production has become an important means to improve soil fertility and promote sustainable agricultural development. In this green revolution, the compost turning machine has become an indispensable equipment in the compost fermentation process with its unique advantages. So, why do we use a flip machine for large-scale composting? Let's unravel the mystery of it.

First, the Turning Machine, especially the Windrow Compost Turning Machine, ensures an even distribution of oxygen during the composting process through its powerful turning capacity. In large-scale composting production, the volume of the material pile is huge, and if the lack of effective turning, the internal anaerobic environment is easy to form, affecting the microbial activity and reducing the fermentation efficiency.

The use of flipping machine not only solves this problem, but also promotes the uniform propagation of microorganisms, accelerates the decomposition and transformation of organic matter, and lays a solid foundation for the production of high-quality organic fertilizer. Naturally, this is closely related to the Organic Fertilizer Production Line, because high-quality compost is a prerequisite for subsequent granulation, screening and other processes.

Secondly, the turning machine also helps to regulate the humidity and temperature of the compost. In the early stage of compost fermentation, the material humidity is high and the temperature rises rapidly. Regular operation of the tilting machine can effectively reduce the temperature of the pile, prevent excessive evaporation of water, and maintain a suitable fermentation environment. With the deepening of the fermentation process, the tilting machine can also mix the partially decomposed material in the outer layer with the insufficiently fermented material inside to further improve the uniformity of fermentation. This process, echoing the working principle of the Disc Granulator or Rotary Drum Granulator in the Fertilizer Granulating Production Line, both emphasize the importance of material uniformity to the quality of the finished product.

Moreover, the use of the turning machine has greatly improved the efficiency and automation level of composting production. Compared with the traditional manual turning method, the turning machine not only saves the labor cost, but also reduces the influence of human factors on the quality of compost. Especially when dealing with a large amount of organic waste, such as urban sludge, agricultural straw, etc., the application of the rollover machine is indispensable. It not only speeds up the conversion of waste to Fertilizer, but also provides a reliable guarantee for the production of Organic-Inorganic Fertilizer Compound Fertilizer.

Finally, it is worth noting that the selection and operation of the rollover machine also need to be adjusted according to the characteristics of the compost raw materials, production scale and expected objectives. Whether it is a bar type, wheel type or large wheel disk overturning machine, it has its applicable scenes and advantages. The correct selection and rational use of turning machine will bring greater economic and ecological benefits for large-scale composting production.

In summary, the use of large-scale composting machine is not only an inevitable choice to improve fermentation efficiency and ensure fertilizer quality, but also an important measure to promote the green transformation of agriculture and achieve sustainable development. In the future development of agriculture, the turning machine will continue to play its irreplaceable role, leading the composting production to a more efficient and environmentally friendly new chapter.

#Windrow Compost Turning Machine#Organic Fertilizer Production Line#Disc Granulator#Rotary Drum Granulator

0 notes

Text

The fermentation process of organic fertilizer is the key link to produce high quality organic fertilizer. Judging whether the fermentation is normal can not only ensure the quality of the fertilizer, but also improve the production efficiency. The following are some methods and key factors to determine whether the fermentation of organic fertilizer equipment is normal.

1. Temperature change

Temperature is the most direct and sensitive index to judge whether the fermentation of organic fertilizer is normal. In the Organic Fertilizer Production Line, the fermentation process is usually divided into three stages: early, middle and late. The temperature in the early stage should rise rapidly but not too fast, the temperature in the middle stage should be maintained at 50~60℃, and the temperature in the later stage should gradually decrease. If the temperature fluctuates abnormally during fermentation, it may mean that the fermentation is not normal.

2. Smell changes

Smell is also an important indicator to judge whether the fermentation of organic fertilizer is normal. Normal fermentation of organic fertilizer will gradually lose the original odor, and instead emit a scent similar to soil. If there is still a strong odor of ammonia or hydrogen sulfide during the fermentation process, it indicates that the fermentation is incomplete or anaerobic fermentation has occurred.

3. Color change

During the fermentation process, the color of the organic fertilizer will gradually change from light to dark. Fully fermented organic fertilizers usually appear dark brown or black. If the color change is not obvious, it may be a sign of insufficient fermentation.

4. pH value

pH value is another important indicator to judge whether organic fertilizer fermentation is normal. During the fermentation process, the pH value will go through a process of first falling and then rising, and eventually stabilize at about 7. If the pH value is too high or too low, it may affect the activity of microorganisms, resulting in abnormal fermentation.

5. Microbial activity

Microbial activity is the core index to judge whether organic fertilizer fermentation is normal. By measuring the number and types of microorganisms in the compost, you can get an idea of how fermentation is progressing. In normal fermentation of organic fertilizer, microbial activity should be maintained at a high level, and beneficial microorganisms dominate.

6. Use a compost tumbler

Compost Turning Machine plays a key role in the fermentation process of organic fertilizer. By turning the pile regularly, the uniformity and ventilation of the compost can be ensured and the occurrence of anaerobic fermentation can be prevented. Windrow Compost Turning Machine and and Wheel Type Windrow Compost Turning Machine is a common device choice.

7. Degree of automation of equipment

Modern organic Fertilizer Production lines are often equipped with highly automated equipment, such as the NPK Fertilizer Production Line, which monitors the temperature, humidity and gas composition of the fermentation process in real time to ensure that the fermentation process is stable and efficient.

In summary, to determine whether the fermentation of organic fertilizer equipment is normal, multiple factors such as temperature, odor, color, pH value, and microbial activity need to be comprehensively considered. Through scientific methods and advanced equipment, the fermentation quality of organic fertilizer can be effectively improved to ensure the production of efficient and environmentally friendly organic fertilizer.

#Organic Fertilizer Production Line#Windrow Compost Turning Machine#Wheel Type Windrow Compost Turning Machine#NPK Fertilizer Production Line

0 notes

Text

New Zealand, an island country located in the southern hemisphere, with its unique natural environment and advanced agricultural technology, has become an important producer and exporter of global dairy products. In New Zealand, the dairy industry is not only an important pillar of the economy, but also part of the national image. Today, we explore how the New Zealand dairy industry is harnessing leading technology to maintain its leading position in the global market by ensuring quality through efficient feed granulation.

1. Innovative application of Organic Fertilizer Production Line

New Zealand dairy farmers know that good feed is the foundation for producing high quality milk. Therefore, they use the Organic Fertilizer Production Line to improve the quality and yield of pasture. Through this production line, organic waste from the farm can be converted into efficient organic fertilizers that improve the soil structure and increase the nutrient content of pasture, thereby providing better quality food for cows.

2. NPK Fertilizer Production Line precision nutrition

In addition to organic fertilisers, NPK Fertilizer Production Line is widely used on New Zealand dairy farms. This production line can accurately adjust the ratio of nitrogen, phosphorus and potassium according to the growth needs of different grasses to ensure that the grasses get balanced nutrition. This precise nutrient supply not only improves the yield and quality of forage, but also helps to improve the nutritional content of milk, meeting the needs of consumers for healthy food.

3. Efficient transformation of Fertilizer Granules Series

4. the application of Windrow Compost Turning Machine in feed fermentation

New Zealand dairy farmers also make use of the Windrow Compost Turning Machine to process feed. This equipment can evenly turn the material during the feed fermentation process to ensure the oxygen supply and temperature control during the fermentation process, thus accelerating the decomposition and conversion of organic matter. The fermented feed not only has high nutritional value, but also can enhance the immunity of dairy cows and improve the quality and safety of dairy products.

Conclusion

The success of the New Zealand dairy industry is due to its continuous pursuit and application of scientific and technological innovation. Through the use of advanced equipment such as the Organic Fertilizer Production Line, NPK Fertilizer Production Line, fertilizer pelletizer series and compost turners, New Zealand dairy farmers are able to provide their cows with customized and efficient feed. To ensure the quality and safety of dairy products. This innovative approach not only brings economic benefits to the New Zealand dairy industry, but also provides valuable experience for the sustainable development of the global dairy industry.

#Organic Fertilizer Production Line#NPK Fertilizer Production Line#Fertilizer Granules Compaction Machine#Windrow Compost Turning Machine

0 notes

Text

How to properly clean the fermentation compost turning machine in the organic fertilizer equipment

1. Stop unloading: Before cleaning, first stop the operation of the fermentation compost turning machine and unload the materials on the equipment.

2. Cleaning residue: Use shovels, brushes and other tools to clean up the material residues inside the fermentation pile turning machine, especially the parts that are easy to store materials such as fermentation tanks and pile turning gears.

3. Wash with water: Use high pressure water gun or water pipe to wash the fermentation pile turning machine comprehensively to ensure that the inside and outside surfaces of the equipment are clean. Note that the washing should be carried out from the top down to avoid damage to organic fertilizer equipment caused by water impact.

4. Clean the turning gear: remove the turning gear and clean it with diesel or special cleaning agent to remove stubborn stains on the gear. In the cleaning process, be careful not to let the gear be strongly impacted to avoid damage.

5. Clean the gearbox: Open the gearbox and clean up the oil and impurities inside. Use diesel or special cleaning agent for cleaning to ensure that the inside of the reducer is clean. At the same time, check whether the lubricating oil is sufficient, if there is insufficient need to add in time.

6. Clean the electrical equipment: Wipe the electrical equipment of the fermentation pile turning machine with a wet cloth to ensure that the surface of the electrical equipment is clean. Do not flush electrical equipment directly with water to avoid short circuit.

7. Drying: After cleaning, the fermentation pile turning machine is dried to avoid corrosion of the equipment in a humid environment.

8. Check and maintenance: During the cleaning process, check the various parts of the equipment. If the parts are found to be damaged or severely worn, replace or repair them in time.

0 notes

Text

Ways to practice eco-friendly living in your home

1. Reduce energy consumption:

- Install energy-efficient appliances and LED light bulbs.

- Turn off lights and unplug electronics when not in use.

- Use natural light as much as possible.

- Set your thermostat to a lower temperature in winter and higher in summer.

- Insulate your home properly to reduce heating and cooling needs.

2. Save water:

- Fix any leaks in faucets and toilets promptly.

- Install low-flow showerheads and faucets.

- Collect rainwater for watering plants.

- Only run the dishwasher and washing machine with full loads.

- Use a broom instead of a hose to clean outdoor spaces.

3. Practice waste reduction:

- Recycle paper, plastic, glass, and metal.

- Compost kitchen scraps and yard waste.

- Opt for reusable products instead of disposable ones (e.g., cloth napkins, rechargeable batteries).

- Avoid single-use plastics, such as plastic bags and water bottles.

- Use a reusable shopping bag.

4. Use eco-friendly cleaning products:

- Choose natural, non-toxic cleaning products or make your own using ingredients like vinegar, baking soda, and lemon juice.

- Avoid products containing harmful chemicals that can harm the environment and your health.

5. Grow your own food:

- Plant a garden to grow vegetables, fruits, and herbs.

- Use organic and natural fertilizers instead of synthetic ones.

- Compost food scraps to enrich the soil.

6. Opt for sustainable materials:

- Choose furniture made from sustainable materials like bamboo or reclaimed wood.

- Use eco-friendly flooring options like bamboo, cork, or reclaimed hardwood.

- Select paint and other finishes that have low or no volatile organic compounds (VOCs).

7. Reduce plastic waste in the kitchen:

- Use glass or stainless-steel containers for food storage instead of plastic.

- Replace plastic wrap with beeswax wraps or reusable silicone covers.

- Use refillable water bottles and avoid buying bottled water.

8. Conserve energy in the kitchen:

- Use energy-efficient appliances.

- Cook with lids on pots and pans to retain heat and reduce cooking time.

- Opt for smaller appliances like toaster ovens instead of full-sized ovens when possible.

9. Encourage sustainable transportation:

- Use public transportation, walk, or bike whenever possible.

- Carpool or arrange a car-sharing service with neighbors or colleagues.

- Transition to an electric or hybrid vehicle if feasible.

10. Educate and involve your family:

- Teach your family about the importance of eco-friendly practices and involve them in the decision-making process.

- Encourage everyone to adopt sustainable habits and lead by example.

- Discuss environmental issues and brainstorm new ideas for greener living.

#home improvement#work from home#make money from home#homebrew#ecology#ecofriendly#sustainability#home design#home#acne treatment#homedesign#homemade#home decor#home business#home & lifestyle#homestuck#welcome home#homens de sunga#homeinterior#homestyle#cozyplaces#cozy glow#cozyhome#cozy cozy#cozy living#cozyvibes#cozy autumn#cozy fall#cozy mystery#cozycore

88 notes

·

View notes

Text

In modern agricultural production, organic fertilizers are favored for their environmental protection and soil improvement properties. However, the quality and safety of raw materials in organic fertilizer production lines are directly related to the effect of fertilizers and the safety of agricultural products. Here are some key steps to take to ensure the quality and safety of Organic Fertilizer Production Line materials:

Raw material selection and pretreatment: First of all, the raw materials of organic fertilizer need to be strictly selected and pretreatment. Livestock manure, crop straw and other raw materials should be crushed before fermentation to increase the surface area and promote the decomposition of microorganisms. For example, the use of Cage Crusher can effectively crush materials such as urea, thereby improving fermentation efficiency.

Fermentation process control: the fermentation link in the organic fertilizer production line is crucial. Turning raw materials through a Compost turning Machine, such as the Windrow Compost Turning Machine, ensures that the fermentation process is uniform and adequate, helping to kill pathogens and weed seeds while releasing heat and promoting the breakdown of organic matter.

Mixing uniformity: The use of Double Shafts Paddles Mixer can ensure that the NPK Fertilizer and other additives in the organic fertilizer are evenly mixed to avoid the difference in fertilizer effect caused by uneven mixing.

Granulation quality: The granulation link in the organic fertilizer production line is equally important. Through the fertilizer Granulator series, such as the Flat-Die Pellet Machine or Rotary Drum Granulator, uniform fertilizer particles can be formed to improve the efficiency and effectiveness of fertilizer application.

Screening and dust removal: After granulation, use fertilizer screening Machine (such as Rotary Screening Machine) to screen fertilizer particles, remove unqualified particles, and ensure the uniformity of the finished product. At the same time, it is equipped with efficient dust removal equipment to reduce dust emissions in the production process and protect the environment and workers' health.

Drying and cooling: organic fertilizer particles need to be dried and cooled before packaging. The use of Rotary Dryer Machine and Rotary Cooler Machine can effectively remove the moisture in the particles, extend the shelf life of the fertilizer, and reduce the risk of mildew caused by excessive moisture.

Quality testing: In the whole process of Organic Fertilizer Production Line, the quality of raw materials and finished products are regularly tested to ensure that they meet national and industry standards. This includes the detection of organic matter content, nutrient composition, heavy metal content and other indicators to ensure the safety and effectiveness of organic fertilizers.

Through the above measures, we can effectively ensure the quality and safety of raw materials in the organic fertilizer production line, produce efficient and environmentally friendly organic fertilizer products, and promote the sustainable development of agriculture.

#Organic Fertilizer Production Line#Cage Crusher#Windrow Compost Turning Machine#Double Shafts Paddles Mixer#Rotary Screening Machine

0 notes

Text

Organic fertilizer is an indispensable part of agricultural production, and every link of its production process is crucial. The correct use of organic fertilizer fermentation equipment can not only improve the quality and efficiency of fertilizers, but also ensure the safety and environmental protection of the production process. Here are a few key points to pay attention to when using organic fertilizer fermentation equipment:

Use of Uniform Feeder: In the production process of organic fertilizer, uniform feeding is an important link to ensure the quality of fermentation. By using a uniform feeder, the material can be ensured to enter the fermentation equipment continuously and evenly, avoiding the problem of incomplete or excessive fermentation caused by uneven feeding.

Selection and use of fertilizer mixer: mixer plays a role in the production of organic fertilizer. Horizontal Ribbon Mixer and Double Shafts Paddles Mixer are two common types of mixers that ensure an even mix of ingredients and improve fermentation efficiency. When using, pay attention to the mixing speed and time to avoid destroying the microbial activity in organic fertilizer.

Application of fertilizer Screening Machine: Organic fertilizer will produce materials of different particle sizes during fermentation. The Rotary Screening Machine or Vibration Screening Machine can effectively separate the fertilizer particles that meet the standard and improve the uniformity and quality of the final product.

Maintenance of Organic Fertilizer Production Line: Organic Fertilizer Production Line includes multiple links, such as raw material treatment, fermentation, drying, screening and packaging. Regular maintenance and inspection of all aspects of the equipment, such as Fertilizer Granules Compaction Machine, Flat-Die Pellet Machine, Rotary Drum Granulator, etc., can ensure the continuous and stable operation of the production line. Reduce the risk of failure.

Operation of Compost Turning Machine: compost turning machine, such as Windrow Compost Turning Machine, is the key equipment to improve the efficiency of compost fermentation. Proper operation can ensure the air permeability and temperature control inside the compost, promote the activity of microorganisms, and accelerate the decomposition of organic matter.

The rational use of fertilizer crusher: In the production process of organic fertilizer, the crushing of materials is an important step to improve the fermentation efficiency. Equipment such as Cage Crusher can crush large pieces of material into a suitable size for fermentation, but the crushing size should be adjusted to avoid excessive fine materials affecting the fermentation effect.

Environmental control: During the use of organic fertilizer fermentation equipment, the temperature, humidity and pH value of the fermentation environment need to be strictly controlled to ensure the activity of microorganisms and fermentation efficiency. At the same time, it is also necessary to pay attention to ventilation and stacking to avoid the accumulation of harmful gases.

Safe operation: When operating organic fertilizer fermentation equipment, the relevant safety procedures must be followed to ensure the safety of the operator. This includes properly wearing protective equipment, following instructions in the operating manual, and conducting regular safety training.

Through the strict implementation of these precautions, you can ensure the efficient, safe and environmentally friendly operation of organic fertilizer fermentation equipment, so as to produce high-quality organic fertilizer to meet the needs of modern agriculture.

0 notes

Text

Wheel type windrow compost turning machine has played a great role in the development of agriculture

Wheel type windrow compost turning machine plays an important role in the development of agriculture, and its credit is mainly reflected in the following aspects:

1. Improve composting efficiency: By turning compost materials, the push machine increases the contact between materials and air, thereby improving the aerobic metabolism rate in the composting process, shortening the composting cycle, and improving the composting efficiency.

2. Improve the quality of compost: the turning machine can evenly turn the compost material, making the water and temperature distribution in the material more uniform, which helps to improve the quality of compost products.

3. Reduce environmental pollution: Through effective turning and ventilation, the odor and harmful gas emissions generated during the composting process are reduced, and the impact on the surrounding environment is reduced.

4. Resource utilization: The push machine helps to convert agricultural waste into organic fertilizer, which realizes the resource utilization of agricultural waste and promotes the sustainable development of agriculture.

5. Improve agricultural economic efficiency: The use of organic fertilizers produced by the rollover can improve crop yield and quality, thereby improving the economic efficiency of agriculture.

6. Policy support: With the state's attention to the utilization of agricultural waste resources, the push machine as an important agricultural machinery has been supported and promoted on the policy.

7. Advances in technology: the technology progress of organic fertilizer equipment, such as automatic control, such as highly efficient drive, make the equipment more efficient, energy saving and environmental protection.

Article 8. Above all, wheeled stamping compost turns pushing role in agricultural development to be reckoned with, it not only improves the efficiency and quality of agricultural production, also contribute to environmental protection and sustainable utilization of resources.

0 notes

Text

The important role of windrow compost turning machine in the agricultural field

The important role of crawler dumper in the agricultural field is mainly reflected in the following aspects:

1. Improve production efficiency: The windrow compost turning machine, through automated operation, speeds up the stacking and mixing process of agricultural waste, improves the preparation efficiency of organic fertilizer, and thus improves the overall efficiency of agricultural production.

2. Resource recycling: The organic fertilizer equipment can effectively transform agricultural waste such as livestock manure and crop straw into organic fertilizer, realizing the resource utilization of agricultural waste and promoting the sustainable development of agriculture.

3. Reduce environmental pollution: By converting agricultural waste into organic fertilizer, the pollution of these wastes to the environment is reduced, and the use of fertilizers is also reduced, reducing the negative impact of agricultural production on the environment.

4. Improve crop quality: The use of organic fertilizers helps to improve the quality and nutritional value of crops, produce healthier and safer food, and meet the market demand for high-quality agricultural products.

5. Strong adaptability: The crawler design enables the tiller to operate flexibly in a variety of complex farmland environments, such as wetlands, slopes, etc., expanding the scope of application of the equipment.

6. Promote technological progress: With the development of science and technology, crawler tipping machine is also constantly carrying out technological innovation and upgrading, such as more efficient tipping mechanism, more environmentally friendly material use, etc., to promote the continuous progress of agricultural technology.

Through the above role, the caterpillar stacking machine not only improves the efficiency and quality of agricultural production, but also helps to realize the resource utilization of agricultural waste and environmental protection, which is of great significance for the sustainable development of agriculture.

0 notes

Text

What are the positive effects of using a wheel type compost turning machine on the soil

The positive effects of using wheel type windrow compost turning machine on soil are mainly reflected in the following aspects:

1. Improve soil fertility: Organic fertilizer treated by organic fertilizer equipment can increase the content of organic matter in the soil, thereby improving soil fertility and providing continuous nutrient supply for crops.

2. Improve soil structure: Organic fertilizer helps to improve the physical structure of the soil, increase the porosity and permeability of the soil, and is conducive to the growth of crop roots and water retention.

3. Promote microbial activity: Microorganisms in organic fertilizers can promote the propagation and activity of beneficial microorganisms in the soil, which contribute to the circulation of nutrients in the soil and the suppression of crop diseases.

4. Improve crop yield and quality: Organic fertilizer can provide comprehensive nutrition needed for crop growth, help to increase crop yield and improve the quality of agricultural products.

5. Enhance soil water retention capacity: Organic fertilizers can improve soil water retention capacity, reduce water evaporation, and improve soil resistance to drought.

6. Reduce soil erosion: Organic fertilizers help to enhance soil erosion resistance, reduce soil erosion, and protect soil resources.

7. To promote the ecological balance, the use of organic fertilizers help maintain and restore the balance of soil ecosystem, promote the sustainable development of the agricultural ecosystem.

In summary, the application of wheeled composting machine in agricultural production not only improves the quality of soil and crop yield, but also helps to achieve sustainable development of agriculture and environmental protection.

0 notes