#Optical Transparent Ceramic Materials Market

Explore tagged Tumblr posts

Text

Optical Transparent Ceramic Materials Market Trends, Growth and Regional Outlook and Forecast 2030

This report describes the global market size of Optical Transparent Ceramic Materials from 2018 to 2021 and its CAGR from 2018 to 2021, and also forecasts its market size to the end of 2030 and its expected to grow with a CAGR of 12.4% from 2023 to 2030.

0 notes

Text

0 notes

Text

Unlocking Industrial Potential with Premium Quartz Granules

The excellent physical and chemical characteristics of quartz granules make them an essential part of many industrial applications. The natural quartz used to make these granules is known for its hardness, durability, and ability to withstand heat and chemicals. Quartz granules are used as a basic raw material in a variety of sectors, including construction, paint, electronics, glassmaking, and ceramics, demonstrating its significance and adaptability.

Comprehending the features, uses, and quality requirements of Supplier of Quartz Granules is crucial if you're looking for a trustworthy source. Reliable quartz granules contribute to cost-effectiveness, durability, and efficiency in industrial processes by guaranteeing the intended performance.

Describe the Quartz Granules.

Granules of quartz are quartz particles that have been graded and treated into different sizes. These granules are extracted from naturally existing quartz deposits and then refined to guarantee uniformity and purity. They are usually divided into different sizes based on the use, such as coarse, medium, and fine granules.

The main component of quartz, silicon dioxide (SiO₂), is what gives it its special qualities. Quartz is an excellent material for industrial usage because of its remarkable durability and abrasion resistance, as evidenced by its Mohs hardness of 7. Its performance in high-temperature environments is further improved by its low coefficient of thermal expansion and high melting point.

Utilizing Quartz Granules

Glass Production

Granules of quartz are a key component used in the making of glass. The creation of transparent and long-lasting glass for windows, bottles, and optical instruments is guaranteed by their high silica content and chemical purity.

Ceramics Sector

Quartz grains serve as a flux in the production of ceramics, assisting in the regulation of the melting point and enhancing the durability and polish of finished goods. They are also utilized in the manufacturing of porcelain, sanitary ware, and tiles.

coatings and paints

Paints and coatings are enhanced with quartz granules because of their superior binding qualities and resilience to weathering and abrasion. Because they improve the coatings' quality and longevity, they can be used both indoors and outdoors.

Electronics Quartz is an important material in the electronics industry because of its piezoelectric qualities. The production of semiconductors, oscillators, and other electronic components uses quartz granules.

Construction Supplies

Quartz grains are utilized in the manufacturing of ornamental aggregates, concrete, and engineered stone. Their strength and beauty make them the perfect material for architectural facades, floors, and countertops.

Properties of Superior Quartz Granules

Authenticity: Because premium quartz granules contain more than 99% silica, they are suitable for a range of industrial procedures.

In applications such as glass and ceramics, uniform particle size and distribution are crucial for obtaining consistent outcomes.

Thermal Stability: When used in applications such as refractory materials, quartz granules should be stable at high temperatures.

Chemical Resistance: The ability of quartz to withstand acids and chemicals guarantees that it will function well in harsh conditions.

Why Opt for a Trustworthy Provider?

To guarantee constant supply and high-quality products, choosing a reliable provider of quartz granules is essential. Reputable suppliers offer tailored solutions and are aware of the unique needs of various industries. Their capacity to deliver quartz grains in large quantities while keeping consistent quality and strict adherence to quality control procedures are essential.

Known for supplying quartz, Pratibha Refractory Minerals

In the market for high-quality quartz granules, Pratibha Refractory Minerals is a reliable source. The company is renowned for its dedication to quality, producing quartz granules that satisfy the most exacting industry standards. Prioritizing client pleasure, Pratibha Refractory Minerals guarantees prompt delivery, affordable prices, and reliable product quality, which makes it a popular option for businesses all over the world.

Final Thoughts

The unparalleled durability, chemical resistance, and thermal stability of quartz granules make them an essential resource for a wide range of industries. Their importance in contemporary industrial processes is highlighted by their applications, which range from electronics to glass making.

0 notes

Text

The Rising Demand for Quartz Grains: India's Role in Global Supply

India, with its vast geological diversity, is a hub for minerals essential to various industries. Among these, quartz grains play a pivotal role due to their versatile applications across sectors such as glassmaking, ceramics, electronics, and construction. As demand for high-quality quartz grains manufacturers continues to rise, the manufacturers in India have stepped up to cater to both domestic and international markets with precision and consistency.

What Are Quartz Grains?

Quartz grains are small particles derived from quartz, a naturally occurring mineral known for its hardness, chemical inertness, and transparency. These grains are primarily composed of silicon dioxide (SiO2), making them one of the most abundant minerals found on earth. The purity and particle size of quartz grains determine their use across various industries.

High-purity quartz grains are valued for their non-reactive nature and are commonly used in the production of glass, ceramics, and electronics. They are also employed in industries requiring specific mechanical or thermal properties, such as foundry work, paints, and coatings.

Applications of Quartz Grains

The versatility of quartz grains makes them indispensable in a wide range of industries. Some of the primary applications include:

Glass Manufacturing: Quartz grains are a key raw material in the production of various types of glass, including flat glass, container glass, and fiberglass. Their high melting point and clarity make them an ideal component for glassmaking.

Ceramics: In the ceramics industry, quartz grains are used to enhance the strength, durability, and thermal properties of ceramic products. They are used in tiles, sanitary ware, and tableware manufacturing.

Electronics: Quartz is widely used in the electronics industry for producing silicon wafers, which form the foundation of most electronic devices. Quartz grains are also utilized in the production of semiconductors, photovoltaic cells, and optical devices.

Construction: The construction industry employs quartz grains in various applications such as flooring, paints, and as a filler material in adhesives. Their hardness and resistance to weathering make them suitable for construction purposes.

Foundry Work: Quartz grains are commonly used in foundries for molding sand, which is crucial in metal casting processes. They help create smooth and precise molds, contributing to the quality of the cast products.

India: A Leading Producer of Quartz Grains

India has emerged as a global leader in the production and export of quartz grains due to its rich deposits of high-quality quartz. The country's mineral-rich regions, such as Rajasthan, Andhra Pradesh, and Gujarat, have become the epicenters for quartz mining and processing.

Indian quartz grain manufacturers are known for their expertise in mining, processing, and delivering high-quality quartz products. With state-of-the-art technology and strict quality control measures, these manufacturers cater to industries not only within India but also across Europe, the United States, and Asia.

Factors Driving the Growth of Quartz Grain Manufacturers in India

Several factors contribute to the growth of quartz grain manufacturing in India:

Abundant Resources: India is blessed with significant quartz deposits, especially in Rajasthan, which is known as the mineral capital of India. This abundant supply allows manufacturers to meet the increasing global demand.

Advanced Processing Technology: Indian manufacturers have embraced advanced mining and processing techniques that enable them to produce quartz grains with high purity levels. These technologies include sophisticated crushing, screening, and washing methods that ensure the consistency and quality of the final product.

Export Opportunities: Indian quartz grain manufacturers have expanded their reach to global markets, with growing exports to countries like the USA, China, and European nations. The competitive pricing and adherence to international standards have further cemented India’s position as a preferred supplier.

Diverse Applications: The increasing demand for quartz grains in industries such as electronics, glass, ceramics, and construction has propelled the need for high-quality products. Manufacturers in India have been quick to adapt to these requirements, further fueling their growth.

The Future of Quartz Grains in India

The future looks bright for quartz grains manufacturers in India as industries continue to evolve and require more specialized raw materials. The growing demand from sectors like electronics, renewable energy (solar panels), and high-tech industries is expected to boost the production and innovation within the quartz industry.

Manufacturers are also investing in research and development to explore new applications and improve the efficiency of quartz grain production. As sustainability becomes a priority, Indian manufacturers are working towards more eco-friendly mining and processing methods, reducing the environmental impact of quartz production.

Conclusion

India has firmly established itself as a leading player in the global quartz grain market. With a rich supply of high-quality quartz, cutting-edge processing techniques, and a strong focus on meeting international standards, Indian manufacturers are well-positioned to cater to the growing demand across industries. Companies like Sudarshan Group exemplify the commitment to quality and innovation, ensuring that India remains at the forefront of the global quartz industry. As quartz continues to be an integral material for numerous applications, India's role as a reliable and efficient supplier of quartz grains is set to grow even stronger in the years to come.

0 notes

Text

Unlocking the Potential of Quartz Powder in Manufacturing

Quartz powder, a finely ground form of crystalline silica, is an essential industrial material used in various sectors such as glass manufacturing, electronics, ceramics, construction, and more. It is highly valued for its physical and chemical properties, including durability, high melting point, low electrical conductivity, and resistance to wear. Industries across the globe are reliant on high-quality Quartz Powder Manufacturers to create products ranging from everyday household items to advanced technological components.

When it comes to sourcing premium-grade quartz powder, Sudarshan Group has established itself as a leading manufacturer and supplier in the market. With decades of experience and a commitment to innovation, Sudarshan Group has become a name synonymous with quality and reliability in the mineral industry. In this article, we will explore the importance of quartz powder, its applications, and why Sudarshan Group stands out among quartz powder manufacturers.

What is Quartz Powder?

Quartz powder is derived from natural quartz, a mineral composed primarily of silicon dioxide (SiO2). It is abundant in the Earth’s crust and occurs in a variety of forms, including large crystals, sand, and finely ground powder. Quartz has exceptional hardness, chemical stability, and optical properties, making it ideal for use in multiple industrial applications.

The process of creating quartz powder typically involves mining quartz deposits, crushing the raw material, and then grinding it to the desired particle size. High-purity quartz powder, which has fewer impurities such as iron and other trace minerals, is often used in specialized applications, especially in electronics and high-tech industries.

Applications of Quartz Powder

Glass Manufacturing: One of the most well-known applications of quartz powder is in the glass industry. Quartz is a key ingredient in the production of glass, contributing to the material’s strength, transparency, and resistance to high temperatures. The silica content in quartz powder acts as a flux, lowering the melting point of the raw materials used in glassmaking. This allows for the production of various types of glass, including soda-lime glass, borosilicate glass, and specialty glass used in laboratory equipment and optics.

Ceramics: In the ceramics industry, quartz powder is used as a filler material to enhance the mechanical strength of the final product. It helps improve the thermal shock resistance and overall durability of ceramic items, making them suitable for use in high-temperature environments. The fine particle size of quartz powder also ensures a smooth surface finish for ceramics, contributing to their aesthetic appeal.

Construction: Quartz powder is widely used in the construction industry, particularly in the production of concrete and mortar. The addition of quartz powder improves the strength, durability, and weather resistance of these materials, making them ideal for building structures that need to withstand harsh environmental conditions. In addition, quartz is used in engineered stone products, such as countertops and flooring, which combine beauty with practicality.

Electronics: High-purity quartz powder plays a critical role in the electronics industry. It is used in the production of semiconductors, integrated circuits, and solar cells due to its excellent electrical insulation properties. Quartz also has piezoelectric properties, meaning it can generate an electrical charge when subjected to mechanical stress. This makes it an essential component in devices like oscillators, sensors, and watches.

Paints and Coatings: In the paints and coatings industry, quartz powder is used as a filler material to improve the durability, gloss, and resistance of paints. It helps create coatings that are resistant to chemicals, heat, and wear, making them suitable for use in harsh environments. Quartz powder also enhances the adhesion of paint to surfaces, ensuring a long-lasting finish.

Foundry and Refractory Applications: Quartz powder is used in foundries to create molds for casting metals. Its high melting point and resistance to thermal expansion make it ideal for producing molds that can withstand extreme temperatures. In refractory applications, quartz powder is used to create heat-resistant materials that are essential for lining furnaces, kilns, and other high-temperature processing equipment.

Leading the Way in Quartz Powder Manufacturing

As one of the foremost quartz powder manufacturers, Sudarshan Group has a proven track record of providing high-quality quartz products to clients across various industries. Established with a mission to supply premium-grade minerals, Sudarshan has become a trusted name in the field of industrial minerals, especially quartz powder.

Commitment to Quality

Sudarshan Group prides itself on delivering quartz powder that meets the highest standards of purity and consistency. The company uses state-of-the-art technology in its mining and processing operations to ensure that the final product is free from impurities and has the desired particle size distribution. This commitment to quality is what sets it apart from other manufacturers.

The company also adheres to strict quality control measures throughout the production process, ensuring that every batch of quartz powder meets the specifications required by its clients. Whether it’s for glass manufacturing, electronics, or construction, Sudarshan quartz powder is designed to meet the demanding requirements of various industries.

Conclusion

Quartz powder is a versatile and essential material in a wide range of industries, from glass manufacturing to electronics and construction. As demand for high-quality quartz products continues to grow, manufacturers like Sudarshan Group play a crucial role in meeting this need. With a commitment to quality, sustainability, and customer satisfaction, it has earned its reputation as a leading quartz powder manufacturer. Whether you’re in the market for quartz powder for industrial or technological applications, it is a trusted partner that can deliver the products and support you need.

0 notes

Text

Global Top 14 Companies Accounted for 67% of total Transparent Conductive Films (TCF) market

Transparent conducting films (TCFs) are optically transparent and electrically conductive in thin layers. They are an important component of a number of electronic devices including flat panel displays, OLEDs and Thin-film photovoltaics etc. While indium tin oxide (ITO) is the most widely used, alternatives including other transparent conductive oxides (TCOs), conductive polymers, metal grids, and carbon nanotube (CNT), graphene and nanowire thin films all show promise in some applications. Transparent conductive oxides (TCO) have high optical transmission at visible wavelengths and electrical conductivity close to that of metals. TCO’s ranges are from simple binary compounds to exotic ternary and quaternary compounds. Examples of TCO’s are indium tin oxide (ITO), zinc oxide (ZnO), tin oxide, aluminum doped zinc oxide (AZO), indium oxide and cadmium oxide.

According to the new market research report “Global Transparent Conductive Films (TCF) Market Report 2023-2029”, published by QYResearch, the global Transparent Conductive Films (TCF) market size is projected to reach USD 0.67 billion by 2029, at a CAGR of 2.7% during the forecast period.

Figure. Global Transparent Conductive Films (TCF) Market Size (US$ Million), 2018-2029

Figure. Global Transparent Conductive Films (TCF) Top 14 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Transparent Conductive Films (TCF) include Nitto Denko, Jiangsu Rijiu Optoelectronics, OIKE, LG Chem, O-film, SVG Tech, Cambrios, TDK, Ushine, SEKISUI, etc. In 2022, the global top 10 players had a share approximately 67.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Exploring Quartz Powder: 5 Common Applications

Quartz powder, a versatile mineral substance, finds a myriad of applications across industries worldwide. As a renowned Quartz Powder exporter in India, the country contributes significantly to the global supply chain of this valuable material. In this article, we delve into the multifaceted uses and applications of Quartz Powder, shedding light on its various industrial and daily uses.

Quartz Powder, derived from quartz stones, undergoes meticulous processing to attain its fine powdered form. This finely ground substance serves as a crucial raw material in several industries due to its exceptional properties and versatile nature.

Understanding Quartz Powder

Quartz Powder, primarily composed of silica, exhibits remarkable hardness, transparency, and chemical stability. These inherent characteristics make it an indispensable ingredient in diverse industrial processes. From construction to electronics, Quartz Powder plays a pivotal role in enhancing product quality and performance.

Common Applications

Construction Industry

In the construction sector, Quartz Powder serves as a key ingredient in manufacturing concrete, mortar, and various construction materials. Its high silica content enhances the strength and durability of concrete structures, making them more resilient to harsh environmental conditions. Additionally, Quartz Powder is utilized in the production of ceramic tiles, paints, and coatings, imparting superior finish and resistance properties.

Electronics Manufacturing

Quartz Powder finds extensive usage in the electronics industry, particularly in the fabrication of semiconductors and electronic components. Its exceptional thermal and electrical properties make it an ideal material for manufacturing high-performance electronics. From integrated circuits to quartz crystal oscillators, Quartz Powder contributes to the seamless functioning of electronic devices.

Glassmaking Industry

The glassmaking industry extensively relies on Quartz Powder as a primary raw material for producing glass products of various shapes and sizes. Its high purity and low thermal expansion coefficient make it an ideal material for manufacturing glassware, optical lenses, and laboratory equipment. As a leading Quartz Powder exporter in India, the country caters to the global demand for high-quality quartz-based glass products.

Foundry Industry

In the foundry industry, Quartz Powder serves as a crucial additive in the production of molds and cores for metal casting processes. Its refractory properties enable it to withstand high temperatures and thermal shock, making it an indispensable component in foundry applications. Moreover, Quartz Powder aids in achieving precise casting dimensions and surface finishes, ensuring the quality and integrity of cast metal components.

Pharmaceutical and Cosmetic Applications

Beyond industrial applications, Quartz Powder finds its way into pharmaceutical and cosmetic products due to its inert nature and fine particle size. In pharmaceutical formulations, it acts as a flow enhancer and lubricant in tablet manufacturing processes. Similarly, in the cosmetics industry, Quartz Powder is utilized in skincare products, powders, and foundations for its mattifying and absorbent properties.

Talc Powder: Another Versatile Mineral

Apart from Quartz Powder, Talc Powder emerges as another versatile mineral with diverse industrial applications. As a prominent Talc Powder exporter in India, the country contributes significantly to the global talc market. Talc Powder finds widespread usage in the plastics, paper, paint, and cosmetics industries, owing to its lubricating, anti-sticking, and reinforcing properties.

Conclusion

In conclusion, Quartz Powder stands as a cornerstone material in various industries, facilitating innovation, efficiency, and product excellence. As a leading Quartz Powder exporter in India, the country plays a pivotal role in meeting the global demand for this indispensable mineral substance. From construction to electronics, its applications span across diverse sectors, underscoring its significance in modern industrial processes. As industries continue to evolve, the demand for Quartz Powder is poised to grow, further highlighting its indispensable role in shaping the world of manufacturing and technology.

0 notes

Text

0 notes

Text

Enhance Your Home Decor with Decorative Laminates & Diamond Coatings Market

The global decorative laminates and diamond coatings market has witnessed remarkable growth in recent years. While serving distinct industries, these two sectors share standard features such as aesthetic appeal, durability, and versatility. This article will delve into the key aspects and emerging trends in the decorative laminates and diamond coatings markets, highlighting their applications, market dynamics, and future prospects.

Decorative Laminates Market is widely used in various residential, commercial, and industrial sectors, and we are thin, composite sheets made from resin-impregnated paper layers bonded under high pressure and temperature to create a durable, decorative surface. Our laminates provide an affordable and versatile alternative to natural materials like wood, stone, and ceramics.

The global decorative laminates market has experienced significant growth, driven by increasing construction activities, rising disposable income, and the growing preference for aesthetically appealing interior décor. Moreover, the advent of digital printing technology has enabled the production of laminates with intricate patterns, textures, and designs, further boosting their demand.

Diamond coatings are thin films of synthetic diamonds applied onto various substrates through chemical or physical vapor deposition processes. Our coatings provide exceptional hardness, wear resistance, and low friction, making them highly desirable for various industry applications.

The diamond coatings market has grown significantly due to their remarkable properties and extensive application areas. From cutting tools and industrial machinery to electronics and medical devices, diamond coatings enhance the performance and lifespan of various components, thereby driving their demand.

The Diamond Coatings Market is expanding beyond traditional applications, and the adoption of diamond coatings in sectors like aerospace, automotive, renewable energy, and biomedicine is increasing, driven by the need for superior performance, reduced friction, and extended product lifecycles.

Nanodiamond coatings, derived from nanocrystalline diamond particles, are gaining traction due to their unique properties and potential applications in electronics, optics, and biomedicine. Researchers are exploring the development of nanodiamond coatings with improved electrical conductivity, optical transparency, and biocompatibility.

Conclusion:

The decorative laminates and diamond coatings markets are witnessing robust growth, driven by technological advancements, changing consumer preferences, and expanding application areas. With a focus on sustainability, customization, and technological integration, manufacturers in these sectors are poised to tap into new opportunities and meet customers' evolving needs worldwide.

For more info:-

Decorative Laminates Market

Global Solid State Transformer Market

Converted Flexible Packaging Market

Telepresence Robots Market

Vibration Control System Market

Source URL:- https://sites.google.com/view/steam-boiler-system-/home

0 notes

Text

0 notes

Text

Transparent Ceramics Market Drives Itself towards Light

This high-tech industry relevant market intelligence report on global Transparent Ceramics market renders a comprehensive outline of the market with in-depth synopsis of core trends, growth initiators and dynamics.

Request a sample of this report at: https://www.adroitmarketresearch.com/contacts/request-sample/806

The competitive landscape of the market is illuminated here with presenting strong performing players, revenue analysis, and patterns. The report gives a clear understanding of the current market pattern which is an absolute way to predict future possibilities. The major findings and recommendations given in the report present the global Transparent Ceramics market’s most progressive business strategies thereby enabling the market players devise effective long-term initiatives.

The key vendors and innovators playing a crucial role in the market include:

Key players within the market include Koninklijke Philips N.V., II-VI Optical Systems, SCHOTT AG, CeramTec, American Elements, Surmet Corporation, Cilas, CeraNova, General Electric, CoorsTek Inc., Saint-Gobain, Morgan Advanced Materials, Konoshima Chemical Co., Ltd., KOITO MANUFACTURING CO., LTD., Optocity, Advanced Ceramics Manufacturing, Blasch Precision Ceramics, Inc., and Ceradyne among others.

The competitive landscape of the market is illuminated here with presenting strong performing players, revenue analysis, and patterns. Furthermore, the global Transparent Ceramics market report presents financial attributed of the industry such as pricing patterns, market shares, market size, profitability, etc.

The distinctive features of the global Transparent Ceramics market report include summary of the top-notch organizations. The competitive landscape of the top organizations is presented by analysing various characteristics of the organizations such as market revenue, production, capital, gross margins, innovations, technology integrations, mergers & acquisitions, and future potential based on current market status. The economic business aspects presented are supported by reliable facts, figures, and market standards.

Make an enquiry of this report at: https://www.adroitmarketresearch.com/contacts/enquiry-before-buying/806

This data provided in the study that helps the market entities gain deeper understanding of the workings of the global Transparent Ceramics market. Most importantly, the leading organizations and players demonstrating a sporadic growth and development in the market are studied in the report. This gives a brief understanding of the competitive landscape.

The global Transparent Ceramics market is classified into following important segments namely Product Types, applications, and key geographical regions. The market study covers the lucrative market scope of the key geographies such as MEA, Europe, APAC, South America, and North America. Study of these regions is done on the basis of productivity and contribution to the global market production and size. The major findings and recommendations given in the report for each regions presents the most progressive business strategies used in the region.

Table of Content:

Chapter 1. Executive Summary

Chapter 2. Research Methodology

Chapter 3. Market Outlook

Chapter 4. Global Transparent Ceramics Market Overview, By Fire Type

Chapter 5. Global Transparent Ceramics Market Overview, By Application

Chapter 6. Global Transparent Ceramics Market Overview, By Region

Chapter 7. Company Profiles

Browse the complete report at: https://www.adroitmarketresearch.com/industry-reports/transparent-ceramics-market

About Us:

Adroit Market Research is an India-based business analytics and consulting company. Our target audience is a wide range of corporations, manufacturing companies, product/technology development institutions and industry associations that require understanding of a market’s size, key trends, participants and future outlook of an industry. We intend to become our clients’ knowledge partner and provide them with valuable market insights to help create opportunities that increase their revenues. We follow a code– Explore, Learn and Transform. At our core, we are curious people who love to identify and understand industry patterns, create an insightful study around our findings and churn out money-making roadmaps. Our analysts have tracked high growth markets in chemicals & materials, healthcare & pharmaceuticals, semiconductor & electronics, energy & power, food & retail, consumer goods, technology, and machinery & equipment sectors across the world to identify new opportunities, potential customers, prepare go-to-market (GTM) strategies, identify segments for revenue growth for companies, and many more.

Contact Us:

US Headquarters 3131 McKinney Ave Ste 600 Dallas, TX 75204, U.S.A

Phone: +1 (214) 884-6068

Email: [email protected]

1 note

·

View note

Text

The Versatility of Quartz Powder: Applications and Properties

Quartz powder is an essential industrial material used in various applications such as ceramics, glass, cement, and many others. The demand for high-quality quartz powder has been increasing in recent years, leading to the emergence of numerous quartz powder suppliers in the market. Among them, Pratibha Refractory Minerals stands out as a leading supplier of quartz powder.

Applications of Quartz Powder

Quartz powder is a versatile material with a wide range of applications across various industries. Some of the major applications of quartz powder include:

Glass Production: Quartz powder is a crucial ingredient in the production of glass. It imparts thermal stability, chemical purity, and mechanical strength to glass, making it suitable for various applications.

Ceramics Production: Quartz powder is used in the production of ceramics due to its high melting point, low thermal expansion, and excellent electrical insulation properties.

Cement Production: Quartz powder is added to cement to enhance its strength and durability. It also reduces the shrinkage of concrete and enhances its workability.

Paints and Coatings: Quartz powder is used as a filler in paints and coatings to enhance their performance and improve their viscosity.

Oil and Gas Industry: Quartz powder is used as a proppant in the hydraulic fracturing process in the oil and gas industry. It helps in keeping the fractures open and improves the flow of oil and gas.

Electronics Industry: Quartz powder is used in the electronics industry as a substrate for the growth of thin films. It is also used as a component in various electronic devices such as transistors, oscillators, and filters.

Properties of Quartz Powder

Quartz powder is a fine-grained, crystalline material that is composed of silicon dioxide (SiO2). It is a naturally occurring mineral that is found in abundance in the Earth's crust. Some of the key properties of quartz powder include:

Hardness: Quartz powder is one of the hardest minerals on Earth with a Mohs hardness of 7. This makes it an ideal material for various industrial applications that require high abrasion resistance.

High Melting Point: Quartz powder has a high melting point of around 1650°C, making it an excellent refractory material that can withstand high temperatures.

Chemical Inertness: Quartz powder is highly resistant to chemical reactions and is chemically inert. This property makes it an ideal material for use in various chemical and industrial processes.

Electrical Insulation: Quartz powder is an excellent electrical insulator, which makes it suitable for use in various electronic devices such as transistors, oscillators, and filters.

Optical Properties: Quartz powder exhibits excellent optical properties such as high transparency and low refractive index. It is widely used in the production of optical lenses, prisms, and filters.

Thermal Expansion: Quartz powder has a very low coefficient of thermal expansion, which makes it ideal for use in various high-temperature applications.

Advantages of Choosing Pratibha Refractory Minerals as Your Supplier

High-Quality Products: Pratibha Refractory Minerals is committed to delivering high-quality products that meet the industry's standards.

Competitive Prices: The company offers its products at competitive prices, making it an ideal choice for businesses looking for cost-effective solutions.

Timely Delivery: The company has a robust logistics network that ensures timely delivery of the products to the customers.

Excellent Customer Service: We have a dedicated customer support team that provides excellent after-sales service to the customers.

Manufacturing Process

We follow a strict manufacturing process to produce high-quality quartz powder. The process starts with sourcing high-quality quartz from trusted vendors. The raw material is then washed, dried, and sorted based on size and purity. The sorted quartz is then crushed into fine powder using specialized equipment. The final product is then passed through various quality checks to ensure that it meets the industry's standards.

Quality Assurance

Quality is of utmost importance at Pratibha Refractory Minerals. The company has implemented strict quality control measures at every stage of the manufacturing process to ensure that the final product is of top-grade quality. The company's quality control team performs regular checks on the raw material, intermediate products, and final product to ensure that they meet the industry's standards.

If you are interested in purchasing high-quality quartz powder, Pratibha Refractory Minerals is a leading supplier in the industry. Our products are of the highest quality and are suitable for a wide range of applications across various industries. For more information and to get access to our products, Contact us now!

1 note

·

View note

Text

Unlocking the Potential of Quartz Powder in Manufacturing

Quartz powder, a finely ground form of crystalline silica, is an essential industrial material used in various sectors such as glass manufacturing, electronics, ceramics, construction, and more. It is highly valued for its physical and chemical properties, including durability, high melting point, low electrical conductivity, and resistance to wear. Industries across the globe are reliant on high-quality Quartz Powder Manufacturers to create products ranging from everyday household items to advanced technological components.

When it comes to sourcing premium-grade quartz powder, Sudarshan Group has established itself as a leading manufacturer and supplier in the market. With decades of experience and a commitment to innovation, Sudarshan Group has become a name synonymous with quality and reliability in the mineral industry. In this article, we will explore the importance of quartz powder, its applications, and why Sudarshan Group stands out among quartz powder manufacturers.

When it comes to sourcing premium-grade quartz powder, Sudarshan Group has established itself as a leading manufacturer and supplier in the market. With decades of experience and a commitment to innovation, Sudarshan Group has become a name synonymous with quality and reliability in the mineral industry. In this article, we will explore the importance of quartz powder, its applications, and why Sudarshan Group stands out among quartz powder manufacturers.

What is Quartz Powder?

Quartz powder is derived from natural quartz, a mineral composed primarily of silicon dioxide (SiO2). It is abundant in the Earth’s crust and occurs in a variety of forms, including large crystals, sand, and finely ground powder. Quartz has exceptional hardness, chemical stability, and optical properties, making it ideal for use in multiple industrial applications.

The process of creating quartz powder typically involves mining quartz deposits, crushing the raw material, and then grinding it to the desired particle size. High-purity quartz powder, which has fewer impurities such as iron and other trace minerals, is often used in specialized applications, especially in electronics and high-tech industries.

Applications of Quartz Powder

Glass Manufacturing: One of the most well-known applications of quartz powder is in the glass industry. Quartz is a key ingredient in the production of glass, contributing to the material’s strength, transparency, and resistance to high temperatures. The silica content in quartz powder acts as a flux, lowering the melting point of the raw materials used in glassmaking. This allows for the production of various types of glass, including soda-lime glass, borosilicate glass, and specialty glass used in laboratory equipment and optics.

Ceramics: In the ceramics industry, quartz powder is used as a filler material to enhance the mechanical strength of the final product. It helps improve the thermal shock resistance and overall durability of ceramic items, making them suitable for use in high-temperature environments. The fine particle size of quartz powder also ensures a smooth surface finish for ceramics, contributing to their aesthetic appeal.

Construction: Quartz powder is widely used in the construction industry, particularly in the production of concrete and mortar. The addition of quartz powder improves the strength, durability, and weather resistance of these materials, making them ideal for building structures that need to withstand harsh environmental conditions. In addition, quartz is used in engineered stone products, such as countertops and flooring, which combine beauty with practicality.

Electronics: High-purity quartz powder plays a critical role in the electronics industry. It is used in the production of semiconductors, integrated circuits, and solar cells due to its excellent electrical insulation properties. Quartz also has piezoelectric properties, meaning it can generate an electrical charge when subjected to mechanical stress. This makes it an essential component in devices like oscillators, sensors, and watches.

Paints and Coatings: In the paints and coatings industry, quartz powder is used as a filler material to improve the durability, gloss, and resistance of paints. It helps create coatings that are resistant to chemicals, heat, and wear, making them suitable for use in harsh environments. Quartz powder also enhances the adhesion of paint to surfaces, ensuring a long-lasting finish.

Foundry and Refractory Applications: Quartz powder is used in foundries to create molds for casting metals. Its high melting point and resistance to thermal expansion make it ideal for producing molds that can withstand extreme temperatures. In refractory applications, quartz powder is used to create heat-resistant materials that are essential for lining furnaces, kilns, and other high-temperature processing equipment.

Leading the Way in Quartz Powder Manufacturing

As one of the foremost quartz powder manufacturers, Sudarshan Group has a proven track record of providing high-quality quartz products to clients across various industries. Established with a mission to supply premium-grade minerals, Sudarshan has become a trusted name in the field of industrial minerals, especially quartz powder.

Commitment to Quality

Sudarshan Group prides itself on delivering quartz powder that meets the highest standards of purity and consistency. The company uses state-of-the-art technology in its mining and processing operations to ensure that the final product is free from impurities and has the desired particle size distribution. This commitment to quality is what sets it apart from other manufacturers.

The company also adheres to strict quality control measures throughout the production process, ensuring that every batch of quartz powder meets the specifications required by its clients. Whether it’s for glass manufacturing, electronics, or construction, Sudarshan quartz powder is designed to meet the demanding requirements of various industries.

Conclusion

Quartz powder is a versatile and essential material in a wide range of industries, from glass manufacturing to electronics and construction. As demand for high-quality quartz products continues to grow, manufacturers like Sudarshan Group play a crucial role in meeting this need. With a commitment to quality, sustainability, and customer satisfaction, it has earned its reputation as a leading quartz powder manufacturer. Whether you’re in the market for quartz powder for industrial or technological applications, it is a trusted partner that can deliver the products and support you need.

0 notes

Text

TAFAKKUR: Part 174

Little-Known Rare-Earth Elements

Will there be wars over elements like there have been over petroleum and water? What element have we been using in color televisions? What substance is used to make energy saving, environmental light bulbs?

Each of the elements found in the periodic table have their own characteristics. After they have been cooked in the pot of the universe, these substances that are offered to our service can be radioactive (like uranium), metallic (like magnesium) and even gaseous (like helium). Seventeen of the elements not easily found among the layers underground have unique properties. These elements are called rare-earth elements, because it is hard to discover and mine them.

Rare-earth elements are in many of our everyday devices. The data projected on a computer screen is transmitted via optic cables containing erbium. The light of a tablet device is generated by the phosphorescent element europium. We actually touch indium covered surfaces when we scroll our fingers on touch screen monitors. When listening through headphones, we are using neodymium magnets that are ten times stronger than iron magnets.

From space technologies to defense industries, from cell phones to LED lighting, many such rare-earth elements are used in every stage of our lives. These elements – many of which we cannot live without, even though we've never heard of them – were recorded into the Critical Materials Strategy Document published by the U.S. Department of Energy in 2010. In a public announcement, the department declared fourteen of the elements as specially significant regarding clean energy, listed six of them as critical, and the other four as near critical. Fifteen elements, beginning with lanthanum and ending with lutetium, numbered between 57 and 71, comprise lanthanides. Combined with scandium and yttrium, these make up the seventeen rare-earth elements.

The elements that we touch on screens

Indium (atomic number 49) gains the properties of electrical conductivity and optic transparency when combined with tin, which, at number 50, is indiums's neighbor on the periodic table. Optical transparency is a desired property for plasma screen and television technologies. Indium is also an important material for mobile phone touchscreens. Interestingly, when indium combines with cadmium, also as a neighbor at number 48, it loses the optical transparency. Instead, it is able to absorb light. Light harvesting is a very critical feature in the production of solar cells.

The relationship of indium with its two neighbors opens new horizons for scientists. In the near future, it is hoped that many unknown and interesting features will be unearthed by investigating the known elements of the periodic table. It is amazing that these elements have been around for thousands of years in the universe only to be discovered by technological advancements.

The need for rare-elements in the world is around fifty thousand tons. The current recorded reserve for rare-earth elements is 110 Million tons. Currently, 95% of the demand for rare-earth elements is supplied by China, yet the country only has 35% of the world's reserves. Therefore scientists are constantly searching for rare-earth element mines to eliminate the Chinese monopoly and to boost the production of these rare materials. In recent years, China has gotten into political debates with Japan and the United States by curbing rare-earth element exports. Economic journals covering these debates wondered if "element wars" were near. In 2010, a massive reserve of elements, enough to sustain worldwide demand, was discovered in the Pacific Ocean. Developed countries are now planning to recycle rare-earth elements from used devices due to low reserves.

Yttrium, europium, and terbium (atomic numbers 39, 63 and 65) have been known for a long time. Terbium and yttrium are named after the Swedish town of Ytterby. Yttrium is the first rare-earth element discovered, at the end of 18th century. Plastics containing europium are used to make laser products; it's also used as an element to provide the red color on television screens. Yttrium has a supplementary role that enhances europium's red color production. And terbium oxide activates the green phosphorescence of television tubes with its yellow-green phosphorescent property.

Terbium also enables an 80% reduction of energy consumption in light bulbs. This makes it one of the most wanted elements in the $2 billion rare-earth element market. Today, when we purchase class A type light bulbs, we are actually buying rare elements like terbium.

Neodymium (number 60), which emits a green light via laser pointers, is also used in the magnets of electric motors. When neodymium combines with boron and iron, it makes a magnet twelve times stronger than simple iron magnets. Because it is significantly less dense than iron, it makes electric motors and laptop computers much lighter. Another interesting feature of neodymium is that it enhances the data storage capacity of hard drives. Furthermore, neodymium is wanted for electrical devices and wind turbines.

The union of elements

Dysprosium was discovered in 1886 and can never be found in a free form in nature. This is because it exists in a compound form with other minerals, like gadolinite. Dysprosium is also known for its magnetic property, and when mixed with terbium and iron, it forms a substance called Terfenol-D. In a magnetic field, Terfenol-D has unique transformational abilities. Dysprosium is utilized in laser production together with vanadium, and it emits infrared radiation when used with cadmium.

The magnetic alloys of iron, boron, and neodymium lose their magnetic features beyond 300 degrees Celsius. However when this alloy is combined with dysprosium at a 5% ratio, that problem disappears. Therefore, these magnets are used for electric turbines and hard disc motors. Dysprosium also makes magnets in electric motors 95% lighter. And dysprosium and nickel mixed fillings are used as cooling rods in nuclear reactors.

The human mind becomes fascinated after seeing all the wisdom and properties involved in these lifeless elements. Either we conclude that these elements have doctorate degrees in physics and chemistry from Harvard University, or we may express our weakness and fascination in front of The Grand Creator who created and presented these elements for our benefit.

Is the yellow color in glasses from the planet Ceres?

Since Dell recalled four million laptop computers in 2006, because of a possible explosion caused by overheating battery, scientists' eyes have been focused on lanthanum and cerium. These two elements are considered to be safer than other alternatives. Lanthanum and cerium are used in electrical equipment and energy saving light bulbs, and are classified as critical elements in these processes, along with tellurium. Cerium, named after the planet Ceres, is responsible for the yellow coloration in glasses. Cerium is also used in polishes, ceramics, and petrol refineries. Tellurium is produced indirectly, unlike most other elements. The production of cadmium takes place during zinc production, and tellurium during copper refining. Tellurium is a cheaper element that has been used in combination with cadmium on solar cells since 2009; before then, most solar cells used expensive silicon panels.

Elements in our lives, from space rockets to ultrasound imaging

Hafnium, tantalum, erbium, and technetium are important elements, even though they are not listed critical. Even though hafnium and technetium are not rare-earth elements, they were still added to the critical material strategy document produced by the US Department of Energy. Hafnium is employed in space rockets for its resistance against extreme temperatures and wearing. Hafnium oxide is a valuable material for electronic transistors since it is a very effective electric insulator. It is 20% faster than the silicon oxide that is commonly used in transistors. A transistors length is around 65 nanometers when silicon oxide is used, but it is only 32 nanometers with transistors made of hafnium oxide. This 50% decrease enables smaller devices.

Touchscreens containing indium, laptop computers powered by lithium ion batteries, and cell phones with hafnium transistors are some of today's technological wonders. Would these inventions still be possible without these elements? Could we reach the high capacities in hard discs without the tantalum? Would we be able to protect ourselves from electric leakage in computers without high quality electric insulators such as tantalum oxide?

Radioactive technetium, which was discovered in 1937, is the first artificially produced element. The technetium 99 isotope is used in nuclear medicine. Technetium produced from uranium has a half life of 211,000 years, as opposed to the 6 hour half life of the technetium 99 isotope. The number of technetium based nuclear medicinal tests, like ultrasounds and x-ray imaging, is estimated to be above thirty million annually.

We take advantage of these elements in every stage of our lives, from medicine to technology. Could we become dependent upon elements the way we are upon petroleum? Only time will tell. Either these elements will be replaced by other materials, or other technologies will outdate the current technologies. It is also possible new elements will be discovered.

A majority of our modern technologies would not exist without these elements that were dispersed among the earth billions of years ago. These elements were placed here for our benefit, and so we could utilize them, and produce institutes of scientific research and education to study them.

#allah#god#prophet#Muhammad#sunnah#hadith#quran#ayah#islam#muslim#muslimah#hijab#help#revert#convert#religion#reminder#dua#salah#pray#prayer#welcome to islam#how to convert islam#new convert#new revert#new muslim#revert help#convert help#islam help#muslim help

1 note

·

View note

Text

Optical Ceramics Market Highlighting Regional Revenue Share Dominance During 2027

Stratview Research has launched a new report on the Optical Ceramics Market, which is segmented by Product Type, by Application Type, by Material Type, and by Region (North America, Europe, Asia-Pacific, and Rest of the World).

Download Sample Report @

The Optical Ceramics Market is likely to witness an impressive CAGR of 6.7% during the forecast period. The prime factor that is contributing to the demand for Optical Ceramics is the increasing demand for Optical Ceramics in various industries.

This report on the Optical Ceramics Market has been put together covering various companies of the industry from different geographies. The study is a perfect blend of qualitative and quantitative research highlighting vital market developments, challenges and competition that the industry might face, along with opportunities and trends available in the Optical Ceramics Market. The report intends to present a thorough analysis of the Optical Ceramics Market and provide cutting-edge market intelligence to help decision makers undertake a sound investment evaluation. Besides, the report also classifies and analyses the emerging trends along with major growth drivers.

Optical Ceramics Market Outlook

In the report, the market outlook section mainly encompasses fundamental dynamics of the market which include drivers, restraints, opportunities and challenges faced by the industry. Drivers and Restraints are intrinsic factors whereas opportunities and challenges act as extrinsic factors affecting the market. The report aims at answering several key questions concerning the overall profitability in the market.

Few key players operating in the Optical Ceramics Market are-

II-VI Optical Systems

CeraNova Corporation

CeramTec GmbH

Surmet Corporation

Schott AG

CoorsTek Corporation

Murata Manufacturing Co. Ltd.

Konoshima Chemicals Co. Ltd.

Kyocera Corporation

Saint-Gobain S.A.

Growth drivers and Market Value:

This report, from Stratview Research, studies the Optical Ceramics Market value and growth drivers over the trend period of 2022-27. According to the report -

Optical ceramics market is likely to witness an impressive CAGR of 14.8% during the forecast period. The key factor that is contributing to the demand for optical ceramics is mainly attributed to its increasing usage in various industrial applications, such as aerospace & defense, medical, and optics & optoelectronics.

Segment Analysis:

Based on Material Type:

Based on the material type, the market is segmented as sapphire, aluminum oxynitride, spinel, yttrium aluminum garnet (YAG), and others. The sapphire segment held the largest share of the market in 2021, and is expected to remain dominant during the forecast period. The widespread usage of sapphire as optical windows in military sensor systems to super market checkout windows, and as transparent armor to as sheets, tubes & rods in various industrial applications is driving the growth of this segment.

Based on Region:

In terms of regions, North America is estimated to be the largest market and is expected to remain the dominant region, fueled by the high demand for optical ceramics in the USA. The dominance of the region is attributed to the high demand from the USA’s defense department for transparent armor for personnel protection in both, air and ground vehicles and infrared windows for air reconnaissance applications. Asia-Pacific is expected to be the fastest-growing market for optical ceramics during the forecast period. China, Japan, and India are the major growth engines of the Asia-Pacific’s optical ceramics market during the forecast period.

Know more about the report, click here

To know more about the Research Methodology and other aspects of the research study, kindly get in touch with our sales team at – [email protected]

Customization of the Report

Along with this market report, our team provides a customization according to the client’s requirement. In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

Connect with us at – Stratview Research Call @: +1-313-307-4176 Mail Us: [email protected]

0 notes

Text

Global Top 14 Companies Accounted for 67% of total Head-Up Display market (QYResearch, 2021)

Head-up Display (HUD) is a digital transparent image that displaying the same information you would get from the dashboard. This can include everything from your current speed to the revs on your engine, and even various temperature gauges.

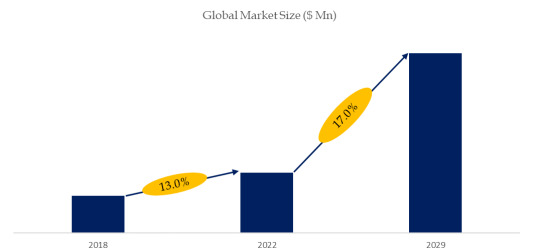

According to the new market research report “Global Head-Up Display Market Report 2023-2029”, published by QYResearch, the global Head-Up Display market size is projected to reach USD 4.04 billion by 2029, at a CAGR of 17.0% during the forecast period.

Figure. Global Head-Up Display Market Size (US$ Million), 2018-2029

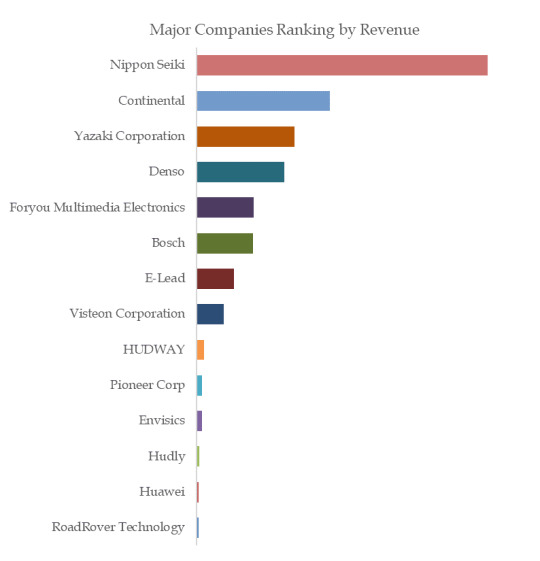

Figure. Global Head-Up Display Top 14 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Head-Up Display include Nippon Seiki, Continental, Yazaki Corporation, Denso, Bosch, Visteon Corporation, E-Lead, Foryou Multimedia Electronics, Huawei, HUDWAY, etc.

In 2022, the global top five players had a share approximately 67.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes