#Optical Brightening Agent Manufacturer

Explore tagged Tumblr posts

Text

How to Find the Best Optical Brightening Agent Manufacturer?

What are Optical Brightening ?

Optical brightening agents (OBAs), also known as fluorescent brightening agents (FBAs), are chemical compounds that give whitening effect to fabric. They do this by absorbing light in the ultraviolet and violet regionand re-emit the light in the blue region.

This blue light reduces the yellow colour of the substrate and give a brightened look. Unlike bleaching, it doesn’t leave ayellowish tinge and gives a much pleasing whiter-than-white appearance.

Such a property sets Optical brightening Agent Manufacturer apart and makes it a much coveted thing in industries such as Textiles, Plastics, Paper, and Cosmetics.

It is important to find the best lighting manufacturers to ensure the quality and effectiveness of your products. Here are the basics to help you find the right manufacturer:

Do research online

Finding the Optical brightening Agent Manufacturer : Use search engines and industry directories to find top Brightening manufacturers.

Search for reviews and reviews: Look for customer reviews and reviews on websites such as Google, LinkedIn, and industry.

Check your experience and knowledge Years of experience:

Choose a builder with a proven track record.

Technical skills: Make sure they have specific expertise in the type of printing services you need.

Look at the quality of the products Sample request:

Obtain samples to test product quality and suitability.

Quality Certification: Certifications such as ISO and GMP certification.

Look at customer testimonials and case studies Read testimonials:

Look for testimonials on the manufacturer’s website and third-party websites.

Look for case studies: Look for case studies that demonstrate how well they use their products.

Ensure compliance Check for compliance:

Confirm that the manufacturer is in compliance with all relevant industry regulations.

Ask for safety data sheets: Make sure their products are safe and meet standards.

Compare pricing and value Get Quotes:

Ask for quotes from multiple manufacturers.

Determine value: Consider the overall value of the product including quality, customization and other services.

Check the reliability of the supplies Check lead time:

Make sure the manufacturer can reliably meet your lead time.

Global reach: Choose a company with a strong international distribution network if needed. By following these steps, you can find a reliable printing service that meets your quality, legal and business needs. This ensures that your product gets what you want and maintains a high standard.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Presto! kitchen tissue rolls are made from 100 percent natural virgin paper. They are soft to touch and highly absorbent. This pack of 2 ply kitchen rolls comes with 60 sheets per roll. These paper towels are safe for contact with food and can be used to line containers before keeping food in them or to blot excess oil from cooked food. Product Dimensions : 19 x 9.5 x 21.5 cm; 315 g Date First Available : 27 August 2018 Manufacturer : GREAT DIVINE PULP AND PAPER INDIA PVT LTD ASIN : B07GVNGGM1 Item model number : P_HPC_KT_PO2 Country of Origin : India Manufacturer : GREAT DIVINE PULP AND PAPER INDIA PVT LTD, GREAT DIVINE PULP AND PAPER INDIA PVT LTD, Plot No. 122-B, Sector - 6, HSIIDC, Industrial Growth Centre, Bawal - 123501, Dist. Rewari (Haryana); Email: [email protected] Packer : GREAT DIVINE PULP AND PAPER INDIA PVT LTD, Plot No. 122-B, Sector - 6, HSIIDC, Industrial Growth Centre, Bawal - 123501, Dist. Rewari (Haryana); Email: [email protected] Item Weight : 315 g Item Dimensions LxWxH : 19 x 9.5 x 21.5 Centimeters Net Quantity : 120 count Included Components : 2 rolls of Kitchen Tissue Tissues made from 100 percent natural virgin paper 2 ply tissues with 60 sheets per roll Free from optical brightening agent (oba) Highly absorbent tissues that soak up spills quickly Soft touch tissues which can be used as table napkins Safe for contact with food Pack of 2 kitchen tissue rolls [ad_2]

0 notes

Text

BS Masterbatch: A Leading Masterbatch Company in India

India has become one of the largest manufacturing hubs in the world, with the plastics industry playing a pivotal role in this transformation. As businesses look for ways to enhance the quality, performance, and sustainability of their products, the demand for high-quality masterbatches has risen dramatically. Among the key players in this sector, BS Masterbatch has established itself as a trusted masterbatch company in India, delivering innovative and high-performance solutions for various industries.

What is Masterbatch?

Masterbatch is a concentrated mixture of pigments, additives, and carriers that are incorporated into plastics during processing to enhance the properties of the final product. Masterbatches are used to add color, improve functionality, and enhance the durability of plastic products, making them essential for a wide range of applications. These are crucial in industries like packaging, automotive, textiles, consumer goods, and electronics.

BS Masterbatch provides a range of masterbatch solutions, including color masterbatch, additive masterbatch, and specialty compounds, catering to the needs of diverse markets both in India and globally.

BS Masterbatch: A Leader in the Indian Masterbatch Industry

With years of experience in the polymer industry, BS Masterbatch has carved out a reputation as a leading masterbatch manufacturer in India. The company has built a strong foundation on the principles of quality, innovation, and customer satisfaction. Their state-of-the-art manufacturing facilities and commitment to research and development ensure they are able to meet the ever-evolving demands of the market.

Here are some key reasons why BS Masterbatch is one of the top masterbatch companies in India:

Wide Range of ProductsBS Masterbatch offers a comprehensive range of masterbatches that cover a variety of needs:

Color Masterbatch: From vibrant shades to subtle tones, BS Masterbatch produces high-quality color masterbatches that deliver consistent, long-lasting color to plastic products.

Additive Masterbatch: These include antioxidants, UV stabilizers, flame retardants, antistatic agents, and antibacterial additives, which improve the performance and lifespan of plastic products.

Specialty Masterbatches: Designed for specific applications, these masterbatches offer advanced properties such as high temperature resistance, conductivity, and optical brighteners.

Whether it’s for film extrusion, injection molding, blow molding, or fiber production, BS Masterbatch ensures that each product is tailored to meet the unique requirements of the end application.

Quality and ConsistencyQuality is at the core of BS Masterbatch’s operations. The company uses the latest technology and equipment to produce masterbatches that deliver consistent performance. Each batch undergoes stringent quality control checks to ensure uniform dispersion of pigments and additives, ensuring that the final product performs as expected and maintains its quality over time.

Customization to Client NeedsOne of the reasons BS Masterbatch has earned a strong customer base is its ability to customize formulations according to specific client requirements. Whether a customer needs a particular shade of color, a specialized additive, or a masterbatch for a unique polymer, BS Masterbatch’s team works closely with clients to deliver the right solution. Their flexibility and willingness to tailor products for different processing techniques make them a valuable partner for businesses across India.

Sustainability CommitmentAs sustainability becomes increasingly important in the manufacturing sector, BS Masterbatch has committed to providing eco-friendly solutions. The company emphasizes the use of recyclable and sustainable materials in its masterbatch products. By reducing waste and minimizing the environmental footprint of their production process, BS Masterbatch is helping clients meet environmental regulations and sustainability goals.

Research and InnovationBS Masterbatch stays at the cutting edge of the masterbatch industry by investing in continuous research and development. Their R&D team is constantly working on developing new products, improving existing formulations, and finding ways to enhance the performance of masterbatches. Whether it’s for improving heat resistance, UV stability, or processing efficiency, BS Masterbatch’s innovation ensures that their products meet the highest standards.

Affordable Pricing and Global ReachWhile BS Masterbatch offers high-quality products, they are also committed to providing cost-effective solutions. Their efficient manufacturing process helps keep costs competitive, making them an attractive option for businesses looking to optimize their production costs. Moreover, BS Masterbatch has expanded its footprint beyond India, with a growing presence in international markets, thanks to the consistent quality and reliable performance of their products.

Industries Served by BS Masterbatch

BS Masterbatch serves a wide range of industries across India and around the world. Some of the key sectors include:

Packaging: Masterbatches are used in packaging films, containers, and bottles, ensuring excellent color, strength, and UV protection.

Automotive: BS Masterbatch produces masterbatches used in automotive interior and exterior components, offering durability, UV stability, and color consistency.

Consumer Goods: BS Masterbatch’s products enhance the quality and appearance of consumer products, including electronics, appliances, and toys.

Textiles: Masterbatches used in synthetic fibers and fabrics improve color fastness, strength, and processing efficiency.

Agriculture: From greenhouse films to agricultural containers, BS Masterbatch provides solutions that protect against UV degradation and improve product performance.

Why Choose BS Masterbatch?

Reliability: BS Masterbatch has built a reputation for reliability, consistently delivering high-quality products that meet customer expectations.

Technical Support: The company offers technical expertise to help clients select the right masterbatch for their specific application, ensuring the best results every time.

Timely Delivery: With an efficient supply chain and logistics system, BS Masterbatch ensures that customers receive their orders on time, every time.

Strong Customer Relationships: BS Masterbatch places a strong emphasis on customer service, building long-term relationships through transparency, communication, and responsiveness.

Conclusion

BS Masterbatch has established itself as a leading masterbatch company in India, offering high-quality, customizable, and sustainable solutions for a variety of industries. With a focus on innovation, quality, and customer satisfaction, BS Masterbatch is poised to continue its growth and leadership in the Indian and global masterbatch markets.

Whether you are looking for color masterbatches, additive solutions, or specialty compounds, BS Masterbatch is the partner you can rely on to meet your production needs with excellence and efficiency.

0 notes

Text

How to Maintain Your Hotel White Sheets for Longevity and Comfort

Maintaining the pristine quality of white hotel sheets is essential to hotel management, contributing directly to guest satisfaction and overall comfort. Hotel guests often associate clean, crisp white sheets with luxury and professionalism, so it’s critical for hoteliers to ensure that their linens are well cared for. Maintaining white sheets is about keeping them clean and ensuring longevity, softness, and fresh appearance.

Here, we will explore how to properly care for white hotel sheets, covering topics such as washing, drying, and training housekeeping staff to maximize the lifespan of these linens.

1. Choose High-Quality Sheets from the Start

Before you dive into the maintenance tips, I would like to point out that the quality of the sheets plays a significant role in their longevity. Investing in high-quality cotton sheets with a high thread count can ensure durability. Egyptian cotton, for example, is highly regarded for its durability and softness, making it an excellent choice for hotel bedding. High-quality sheets are more resilient to frequent washing and maintain their luxurious feel over time. This is particularly important in hospitality, where sheets are washed after every guest.

2. Pre-Treating and Sorting Linens

One of the first steps in maintaining white sheets is pre-treating any stains before washing. Whether it’s makeup, coffee, or wine, dealing with stains as quickly as possible is crucial to preventing them from setting into the fabric. Use a commercial-grade stain remover designed for white linens and follow the manufacturer’s instructions for optimal results.

Additionally, make sure to separate white linens from colored fabrics during washing. Mixing them could lead to color transfer, causing white sheets to appear dull or gray over time. Using a color-safe bleach or a whitening agent can help maintain the sheets' bright, white appearance without damaging the fibers.

3. Optimal Washing Practices

The way hotel sheets are washed has a significant impact on their longevity and comfort. Proper washing techniques can help preserve the quality of the fabric, ensuring they remain soft and luxurious for as long as possible.

a. Water Temperature

Washing white sheets in hot water helps to kill bacteria, remove stains, and maintain the crisp appearance of the fabric. A temperature of around 140°F (60°C) is ideal for most hotel-grade sheets. However, be sure to follow the manufacturer's washing instructions to avoid shrinking or damaging the fabric. While hot water is generally recommended for white linens, very delicate materials might require cooler temperatures.

b. Detergent Selection

Choosing the right detergent is crucial when it comes to maintaining white sheets. A high-quality, pH-neutral detergent is ideal as it prevents the breakdown of the fabric while effectively removing dirt and stains. Avoid using harsh chemicals or heavy-duty detergents that can weaken the fibers over time. Opt for a detergent specifically designed for white fabrics, which often contains optical brighteners that help maintain the sheets’ fresh appearance.

c. Avoid Overloading the Washing Machine

Overloading the washing machine can lead to improper cleaning and cause sheets to become tangled or stretched. This can wear out the fabric faster and cause pilling. Washing small batches at a time ensures that the detergent and water circulate effectively, allowing each sheet to be thoroughly cleaned and rinsed.

d. Use of Bleach

While bleach can help whiten sheets, excessive use can weaken the fibers over time. Instead of relying on bleach after every wash, use it sparingly or consider alternative whitening agents such as oxygen-based bleach, which is gentler on the fabric.

4. Proper Drying Techniques

Proper drying of hotel sheets is as important as washing them. Improper drying can lead to shrinkage, wear, and a stiff texture, making sheets less comfortable for guests.

a. Dry on Low Heat

Drying white sheets on high heat can cause damage to the fibers, leading to shrinkage and a rough texture. Instead, use a low heat setting to maintain the softness and integrity of the sheets. If your hotel has the option of line-drying, this is even better as it helps to avoid the harsh heat of a tumble dryer while also preserving the fabric’s fibers.

b. Use Dryer Balls

Dryer balls or tennis balls can help reduce drying time and prevent sheets from clumping together during the drying process. This method helps to keep the sheets soft and fluffy, which enhances the comfort for hotel guests.

c. Avoid Overdrying

Overdrying can lead to sheet damage and shrinkage. Be mindful of the drying time and remove the sheets as soon as they are dry. Overdrying can cause the fibers to become brittle, making them more prone to wear and tear.

5. Ironing and Storing Sheets

Ironing white hotel sheets creates a crisp, professional appearance and helps smooth out wrinkles and maintain their softness. Iron the sheets while they are slightly damp, using a medium heat setting for best results. Ironing can also help eliminate any lingering bacteria or germs that may have survived the washing process.

Once the sheets are clean and pressed, store them in a cool, dry place. Avoid stacking too many sheets on top of one another as this can lead to wrinkles. Store linens in a way that allows for proper air circulation to prevent the buildup of moisture and mildew.

6. Regularly Rotate Linens

Rotate your white hotel sheets regularly to extend their lifespan. By ensuring that no single set of sheets is used more frequently than others, you can prevent overuse and maintain an even level of wear across all your linens. This simple practice can go a long way in ensuring that your sheets maintain their quality and comfort over time.

7. Training Housekeeping Staff

Training your housekeeping staff is one of the most critical steps in ensuring the proper maintenance of white hotel sheets. They must understand the importance of carefully handling linens and following specific washing and drying instructions. Providing them with detailed training on proper laundering techniques, stain removal, and storage procedures will help maintain the quality of your linens and reduce the need for premature replacement.

Housekeeping staff should also be trained to inspect linens for any signs of wear or damage. Sheets that are torn, heavily stained, or worn should be removed from circulation immediately to ensure that only high-quality sheets are provided to guests.

8. Implementing a Linen Management System

A linen management system can help hotels monitor their sheets, ensuring that they are rotated properly and replaced when necessary. Such a system can also track the number of washes each set of sheets has undergone, helping hotel management determine when linens are nearing the end of their lifespan. By keeping a close eye on the condition of your white sheets, you can maintain their luxurious quality and avoid any negative impact on guest satisfaction.

9. Replacing Linens When Necessary

No matter how well-maintained your hotel sheets are, they will eventually need to be replaced. Over time, even the highest quality linens will wear out, becoming less comfortable and aesthetically pleasing. It’s essential to have a schedule to replace your sheets to ensure that your guests are always sleeping on clean, cozy bedding.

Most hotels replace their sheets every 18 to 24 months, depending on usage and laundering practices. However, regular inspections can help identify sheets that need to be replaced earlier.

Conclusion

Maintaining white hotel sheets for longevity and comfort requires a combination of proper laundering techniques, staff training, and consistent monitoring. By investing in high-quality sheets, following best practices for washing and drying, and training your housekeeping team, you can extend the lifespan of your linens and ensure a consistently comfortable experience for your guests. Maintaining your hotel’s reputation for cleanliness and luxury starts with something as simple as the perfect white sheets.

0 notes

Text

Optical Brighteners Market to Reach Value of US$ 2.6 Bn by 2031

The global optical brighteners market is prognosticated to reach a value of US$ 2.6 Bn by the end of 2031. Furthermore, the study highlights that the market is expected to develop at a CAGR of 4.9% during the forecast period, from 2022 to 2031.

The optical brightener’s market outlook by TMR delivers exhaustive assessment on key factors influencing the market growth. Thus, readers gain exhaustive insights on the growth drivers, restraints, opportunities, R&Ds, and emerging trends of the optical brighteners market. In addition, the report sheds light on important statistics such as volume, share, revenues, and sales of optical brighteners market.

Optical brighteners are easy to use and they help in making the fabric softer. Owing to these advantages, the use of these products is being increasing in the recent years. They are also known as artificial whiteners. Optical brighteners are being used in the textiles, laundry detergents, plastics, and papers. This wide product application suggests that the global optical brighteners market is prognosticated to expand at notable pace during the forecast period, notes a TMR study.

Request Sample Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=13883

Optical Brighteners Market: Key Findings

Optical brighteners find wide application in the laundry care. Laundry detergents are gaining immense popularity owing to their ability to impart a blue light effect to the clothes and make them look white, notes a TMR study on the optical brighteners market. Hence, optical brighteners in detergent are used to make cloths appear brightener and whiter. Moreover, optical brighteners are gaining traction owing to their ability to make cloths resistant to chemical reactions and heat.

The demand for laundry and detergent is being increasing in the recent years owing to a rise in the global population. This factor is expected to boost the sales growth in the global optical brighteners market during the forecast period. Moreover, optical brighteners are widely utilized in hospital laundry sections owing to the increasing use of white fabrics in hospitals and the healthcare industry.

In the paper industry, optical brightening agents are being utilized as an additive that helps in advancing the natural whitening properties of paper. Hence, the expansion of the paper industry is anticipated to fuel the sales growth in the global optical brighteners market during the forecast period.

Optical Brighteners Market: Growth Boosters

Increase in worldwide utilization of laundry detergents is expected to boost the demand growth in the optical brighteners market

Surge in the product use in the uncoated and coated paper industry is projected to lead to largest opportunity for optical brighteners market

Optical Brighteners Market: Regional Analysis

The optical brighteners market is expected to gain significant avenues for business in Asia Pacific during the forecast period owing to a surge in the application of optical brighteners in emerging economies including India and China

The market for optical brighteners is expected to gain notable growth prospects in Europe in the near future owing to the presence of many key manufacturers in the region

Optical Brighteners Market: Key Players

Some of the key players profiled in the report are:

Huntsman International LLC

Dayglo Color Corp

Clariant AG

BASF SE

Aron Universal Limited

Rudolf GmbH

Meghmani Group

Archroma Brand & Performance Textile Specialties

Blankophor GmbH & Co. KG

Brilliant Group

Kolorjet Chemicals Pvt Ltd.

Paramount Minerals & Chemicals Limited

Optical Brighteners Market Segmentation

Chemical

Stilbene

Coumarin

Diphenyl Pyrazoline

Others

Application

Detergents

Textiles

Papers

Cosmetics

Plastics

Others

Regions Covered

North America

Latin America

Europe

Asia Pacific

Middle East & Africa

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=13883<ype=S

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Hydra Professional Whitening Pet Shampoo, 5 Liter

Whether you want a fresh-from-the-groomer feeling for your pet or you are a professional groomer, our whitening wash is the perfect addition to your pet supplies. This shampoo contains oatmeal extract and provides relief for itchy and sensitive skin. Oatmeal also helps reduce irritation while promoting moisture and hydration. This shampoo's natural ingredient list will leave you feeling confident that you are using high-quality ingredients on your pet. No more harsh chemicals that overpower and dry out your pet's skin—this product has no bleaching agents, only safe ingredients that promote the whitening and brightening of coats. It is an optical brightener that reduces reds, yellows, and oranges in the coat. Made specifically with pH balance in mind, our pet shampoo for dogs and cats will leave your pet's skin hydrated and their fur soft and shiny. The natural and subtle scent is not overpowering; instead, it leaves a pleasant scent that will have you loving your pet even more! This formula also helps hair and fur to dry quicker, resulting in less stress for pets. Our pet shampoo will be a great addition to your pet's bathing supplies, and you will be jealous that you can't buy the same products for humans.

Hydra offers professional shampoos for dogs, puppies, cats, and kittens. Hydra uses salon-grade materials and ingredients that are sourced and created with the same standards of safety found in human-grade skin and hair-care products. Our products are salt-free, so they won't cause dryness in the skin or coat. Hydra Professional offers products for specialized services and coat enhancement, including restructuring keratin treatments, deep-conditioning hair masks, colour enhancement, and more.

Features:

This wash will revitalize your pet's coat, leaving it bright and shiny while also reducing the yellowing of the coat. Our formula does not contain any bleach, only salon-grade ingredients like oatmeal extract.

Hydra's private facilities manufacture and test during every step of production. They source the safest, most effective ingredients and quality test products before they leave our facilities. Feel assured that your pet is using only the best.

Easy rinse and fast-drying formulas reduce the time spent bathing and drying, making for a quick and stress-free bathing experience.

Benefits:

As the shampoo contains Jasmine extracts, it maintains skin hydration and softens the dog’s hair

It reduces coat split ends and breakage

The jasmine as well as other natural ingredients of the shampoo helps to eliminate dog odour and makes your dog feel fresh

Also provides relief from itchy and sensitive skin

The shampoo has a fragrance infused with hints of Jasmine, Amber, Peach, and Citrus

Specifications:

Professional–grade shampoo designed for professional quality results

Infused with Salon–Grade Ingredients for a luxurious grooming experience for Pets and professional

Ingredients:

Water, Sodium Laureth Sulfate, Cocamidopropyl Betaine, Glycol Distearate, Sodium Cocoamphoacetate, Cocamide MIPA, Fragrance, Saccharomyces Ferment, Avena Sativa Seed Extract, Polyquaternium-10, Preservatives, PEG-120 Methyl Glucose Dioleate, and CI 16185

Directions:

Wet coat thoroughly with warm water. Dilute the Hydra Odour Neutralizing Shampoo in up to 10 parts of water and apply it to the coat. Massage well. Rinse thoroughly. Repeat, if necessary. Finish the bath with Hydra Moist Conditioner for best results. Recommended for pets older than 4 weeks.

0 notes

Text

Clean Clothes, Clean Conscience: Navigating the Liquid Laundry Detergent Market

In the quest for clean and fresh-smelling clothes, liquid laundry detergents have become a staple in households around the world. As consumers become more conscious of the environmental impact of their choices, there is a growing demand for liquid laundry detergents that not only deliver superior cleaning performance but also minimize harm to the environment. This article explores the dynamics of the liquid laundry detergent market, highlighting key trends, innovations, and considerations for environmentally conscious consumers.

Liquid laundry detergents are versatile cleaning agents formulated to remove dirt, stains, and odors from fabrics during the washing process. Unlike traditional powder detergents, liquid formulations dissolve easily in water, ensuring even distribution and efficient cleaning. They are suitable for use in both high-efficiency (HE) and standard washing machines, offering convenience and flexibility for consumers.

One of the primary considerations for consumers when choosing a liquid laundry detergent is its cleaning efficacy. Modern formulations are designed to tackle a wide range of stains and soils, from everyday dirt and grime to tough food, grease, and grass stains. Advanced enzymes, surfactants, and cleaning agents work together to break down and remove stains effectively, leaving clothes looking and smelling fresh.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS21952

Moreover, consumers are increasingly concerned about the environmental impact of their laundry detergents, prompting a shift towards eco-friendly and biodegradable formulations. Manufacturers are responding to this demand by developing liquid laundry detergents that are free from phosphates, optical brighteners, and synthetic fragrances, which can be harmful to aquatic ecosystems and human health.

Another trend shaping the liquid laundry detergent market is the rise of concentrated formulations, which offer greater cleaning power in smaller doses. Concentrated detergents require less packaging and water for manufacturing, reducing their environmental footprint and transportation costs. Additionally, compact packaging helps save shelf space and minimize waste, appealing to environmentally conscious consumers.

Furthermore, the liquid laundry detergent market is witnessing innovations in packaging design and materials to enhance sustainability and reduce plastic waste. Manufacturers are exploring alternative packaging options such as recyclable bottles, refillable pouches, and packaging made from recycled materials. Some brands are also offering bulk refill stations or subscription-based delivery services to reduce packaging waste further.

As consumers become more educated about the environmental and health impacts of their purchasing decisions, they are seeking transparent labeling and certification from trusted third-party organizations such as the Environmental Protection Agency (EPA) and the United States Department of Agriculture (USDA). These certifications provide assurance that the product meets stringent environmental and safety standards, giving consumers peace of mind.

In conclusion, the liquid laundry detergent market is evolving to meet the changing needs and preferences of environmentally conscious consumers. With a growing focus on cleaning efficacy, sustainability, and transparency, manufacturers are innovating to develop eco-friendly formulations and packaging solutions that deliver clean clothes without compromising on performance or the planet. As consumers continue to prioritize sustainability in their purchasing decisions, the demand for environmentally friendly liquid laundry detergents is expected to grow, driving further innovation and advancement in the market.

0 notes

Text

The Crucial Role and Importance of Textile Finishing Agents in Enhancing Fabric Properties

In the world of textiles, the journey from raw material to finished product involves intricate processes that significantly impact the quality, appearance, and functionality of fabrics. Among these processes, textile finishing—particularly the application of finishing agents—plays a pivotal role in enhancing and augmenting various fabric properties. These agents are instrumental in transforming raw fabrics into versatile, market-ready materials by imparting specific qualities that meet consumer demands and industry standards.

Textile finishing agents encompass a diverse range of chemical substances applied to fabrics post-manufacturing. Their primary purpose is to modify and improve the properties of fabrics, addressing various aspects such as aesthetics, durability, comfort, and functionality.

One of the key roles of textile finishing agents is to enhance the aesthetic appeal of fabrics. These agents can be employed to achieve desired effects like softness, smoothness, sheen, or texture, thereby elevating the visual and tactile qualities of the fabric. Finishing agents like optical brighteners can enhance color brightness, while softeners can impart a luxurious and comfortable feel to the fabric.

Durability is another significant aspect addressed by these agents. They can reinforce fabric strength, improve resistance to abrasion, and enhance the fabric's ability to withstand environmental factors such as moisture, heat, and UV radiation. This enhances the overall lifespan and performance of the textile product.

Moreover, textile finishing agents contribute significantly to improving functional properties. For instance, water-repellent or water-resistant finishing agents can be applied to fabrics, making them suitable for outdoor wear or protective clothing. Flame retardants can be employed to enhance the fabric's fire resistance, ensuring safety in various applications.

The importance of these agents extends to enhancing fabric comfort. Moisture management finishes, for example, regulate the absorption and release of moisture in textiles, ensuring a more comfortable experience for the wearer by keeping them dry and cool.

Additionally, the choice of finishing agents plays a crucial role in aligning fabrics with sustainability goals. Eco-friendly and biodegradable finishing agents have gained traction in the textile industry. Innovations in finishing technologies aim to reduce environmental impact by employing fewer chemicals, conserving water, and minimizing energy consumption during the finishing processes.

The significance of textile finishing agents lies not only in their ability to enhance specific fabric properties but also in their adaptability to various types of textiles. From natural fibers like cotton and silk to synthetic materials such as polyester and nylon, these agents offer tailored solutions that cater to the unique characteristics of each fabric type.

However, the application of finishing agents requires careful consideration and expertise. Improper use or excessive application can lead to adverse effects such as reduced breathability, alteration of natural fabric properties, or environmental hazards due to chemical residues. Thus, stringent regulations and adherence to safety protocols are crucial in the textile finishing process.

In conclusion, textile finishing agents serve as indispensable tools in the textile industry, enhancing fabric properties and meeting diverse consumer needs. Their role in improving aesthetics, durability, functionality, comfort, and sustainability of textiles underscores their importance in the production of high-quality and versatile fabrics that cater to evolving market demands. As advancements continue, the synergy between technology, innovation, and sustainable practices will further revolutionize the realm of textile finishing agents, shaping the future of the textile industry.

0 notes

Text

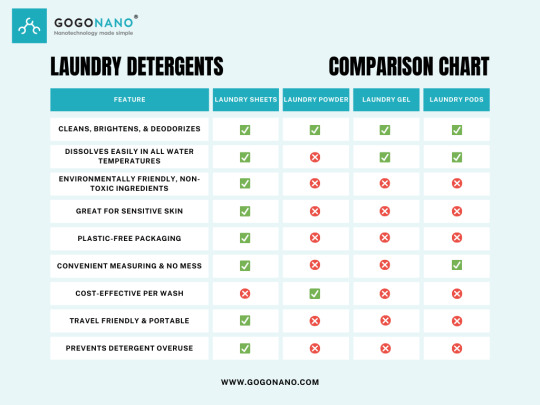

Laundry Sheets Versus Traditional Detergents: Assessing the Superior Cleaning Solution

In the quest for clean clothes, consumers are faced with a choice: traditional laundry detergents or the newer, eco-friendly laundry detergent sheets. This guide delves into the world of laundry care, comparing these two options in terms of production, usage, and environmental impact, providing you with the knowledge to make an informed decision.

Understanding the Basics

Understanding the fundamental differences between traditional detergents and the newer laundry sheets is essential. Traditional detergents have long been the go-to choice, with their tried-and-tested formulas designed to combat a wide array of stains and odors. On the other hand, laundry sheets represent the cutting edge of laundry technology, offering an eco-friendly, convenient solution that caters to the needs of the environmentally conscious consumer without compromising on cleaning power.

What Are Traditional Laundry Detergents?

Traditional laundry detergents have been the cornerstone of laundry care for decades. These detergents come in various forms, including powders, liquids, and pods, and contain a mix of surfactants, enzymes, bleaches, and builders to tackle different stains and odors. They are designed to work in a range of water temperatures and are packaged in plastic jugs or cardboard boxes.

What Are Laundry Sheets?

Laundry detergent sheets are an innovative addition to the laundry aisle. These thin, biodegradable sheets are infused with concentrated detergent and dissolve completely in water. They offer a pre-measured, mess-free alternative to traditional detergents and are typically hypoallergenic, free from harsh chemicals, and come in recyclable or compostable packaging.

Production and Manufacturing

Exploring the contrast in laundry detergent production, this section examines the resource-intensive traditional methods and the sustainable practices shaping the future of laundry care.

How Traditional Detergents Are Made?

The creation of traditional laundry detergents is an intricate process carried out in expansive industrial complexes. It starts with producing synthetic surfactants, the primary cleaning agents, often derived from petrochemicals through energy-intensive reactions. These surfactants are combined with a host of other chemicals like builders to soften water, enzymes to tackle proteins and starches, and additional agents such as fragrances and optical brighteners for aesthetic appeal. While these ingredients enhance the cleaning properties and sensory experience, they can be environmentally persistent and potentially harmful to aquatic ecosystems upon entering water bodies.

Considerable water is used in making liquid detergents, and the energy consumed in heating and transporting these products adds to their carbon footprint. The packaging of these detergents, predominantly plastic, presents further environmental challenges. Many of these plastics are not fully recyclable, leading to an accumulation of waste in landfills and oceans, where they can take centuries to break down, leaking pollutants and posing risks to wildlife. The environmental impact of these practices has led to a push for more sustainable laundry products that prioritize biodegradable ingredients, reduced packaging, and energy-efficient production.

The Creation of Laundry Sheets

Laundry sheets are developed through eco-friendly processes that significantly reduce the consumption of water and energy. Active ingredients are applied onto sheets made from biodegradable materials, allowing them to decompose naturally and lessen the environmental impact. The production of these sheets focuses on a minimalist approach, not only in the product design but also in the packaging, which utilizes materials that are recyclable or compostable, aligning with a commitment to sustainability.

Chemical Composition and Skin Sensitivity

This section delves into the chemical makeup of laundry detergents and their implications for skin sensitivity. We’ll uncover how the traditional detergent industry’s reliance on harsh chemicals contrasts with the emerging trend of laundry sheets that prioritize skin health and environmental sustainability. Additionally, we’ll highlight the innovative formulations of laundry sheets that are setting new standards for gentle, skin-friendly cleaning.

Chemicals in Traditional Detergents

Traditional detergents can contain a variety of chemicals that may cause skin irritation or allergic reactions in sensitive individuals. Phosphates, which are often used to soften water and improve cleaning efficiency, can lead to skin problems and have a detrimental effect on aquatic life when they enter waterways.

How Does Traditional Laundry Detergent Harm The Environment

Laundry detergent is far more than just a basic cleansing soap. It contains a huge number of harmful chemicals that have a serious impact on our environment. Some of the most concerning ones are:

Phosphates – linked to cardiovascular (heart) disease as well as osteoporosis. These toxins are particularly damaging to the marine environment when dispersed in wastewater from your wash.

Bleach – often used to brighten whites, its toxic fumes cause respiratory distress and on contact with skin and eyes it is able to cause caustic burns.

Formaldehyde – A chemical usually associated with the preservation of dead bodies. This toxic ingredient as classified by the EPA, is a class B1 probable carcinogen. This means it has been linked with an increased risk of cancer.

Ammonium Sulfate and Ammonium Quaternary Sanitizers – harsh cleansing agents that are corrosive and toxic. They can cause eye, skin and lung damage even with minimal exposure.

Dioxane (1,4 Dioxane/ Diethylene Dioxide/ Diethylene Ether/ Dioxan) is quite possibly one of the worst additives. Dioxane is also a carcinogen and has been known to pose a combustion risk. Exposure to this toxin can damage your kidneys, lungs, central nervous system, eyes, skin and respiratory function.

The Hypoallergenic Nature of Laundry Sheets

Laundry sheets are intentionally formulated with a minimalistic chemical composition, often utilizing natural ingredients and plant-based surfactants. This streamlined approach not only reduces potential skin irritants but also caters to those with sensitive skin or allergies. Unlike traditional detergents, which may contain a plethora of synthetic chemicals, laundry sheets opt for milder cleaning agents that provide effective cleaning without the risk of allergic reactions. Their hypoallergenic properties make them a preferred choice for consumers seeking a skin-friendly laundry solution.

Moreover, the gentleness of laundry sheets extends to the care of fabrics. They are designed to clean without compromising the textile’s structure, thereby preserving the longevity of clothing. The environmental benefits are equally significant; the biodegradable nature of these sheets means they break down naturally without leaving harmful residues in water or soil, aligning with eco-conscious practices and reducing the ecological impact of laundry activities.

Usage and Efficacy

Laundry sheets are redefining fabric care with their innovative approach to efficacy and usage. These eco-friendly alternatives to traditional detergents deliver effective cleaning power in a pre-measured, dissolvable sheet, minimizing waste and preventing the common issue of detergent residue. While traditional detergents offer a broad spectrum of enzymes for various stains, laundry sheets maintain a competitive edge with their simplicity and suitability for both hot and cold water cycles, catering to the needs of the environmentally and health-conscious consumer.

Effectiveness of Traditional Detergents

Traditional detergents have been optimized for performance across a spectrum of conditions. They are formulated to work in various water temperatures, from cold to hot, and are effective for different load sizes. The presence of specific enzymes and other chemicals in these detergents means they can tackle a wide range of stains, from protein-based to grease and oil.

However, the effectiveness of traditional detergents can be influenced by the hardness of the water and the accuracy of the dosage. Overuse is common, leading not only to wasted detergent but also to potential residue on clothes and in machines.

Performance of Laundry Sheets

Laundry sheets are designed for convenience and simplicity. They dissolve easily in both hot and cold water and are pre-measured to avoid the issue of overuse. While they may not contain the same range of targeted enzymes as traditional detergents, many users find them effective for general laundry needs and appreciate the added benefit of fabric care due to their gentle formulation.

Comparative studies and consumer feedback suggest that laundry sheets perform well in everyday laundry scenarios, though heavily soiled items may require additional treatment or a double dose of the product.

Environmental Impact

The Ecological Footprint of Traditional Detergents

The environmental impact of conventional laundry detergents is increasingly recognized. These detergents often fail to fully biodegrade, releasing harmful substances into our water systems, including rivers and oceans. Toxic elements such as cadmium and arsenic, which are sometimes present in detergents, can pose significant risks to aquatic ecosystems. Research indicates that phosphates, frequently used in these cleaning products, accumulate in bodies of water, causing eutrophication. This process results in excessive algal growth, which depletes oxygen in the water and can suffocate aquatic life, including fish and plants.

The Sustainable Advantage of Laundry Sheets

Laundry sheets are at the forefront of sustainable fabric care, distinguished by their environmentally conscious components and manufacturing process:

Plant-Based Surfactants: Unlike traditional detergents that rely on petrochemicals, laundry sheets use surfactants derived from renewable plant sources, which offer effective cleaning while being more gentle on the environment.

Biodegradable Fibers: The structural material of the sheets is composed of biodegradable fibers that break down naturally, leaving no harmful residues in the ecosystem.

Natural Enzymes: To tackle various stains, laundry sheets incorporate enzymes sourced from natural organisms, ensuring biocompatibility and reducing the risk of aquatic toxicity.

Minimalist Packaging: Emphasizing sustainability, the packaging of laundry sheets is designed to be either fully recyclable or compostable, contributing to waste reduction goals.

Carbon Footprint Reduction: The compact and lightweight format of laundry sheets significantly lowers the carbon emissions associated with their transportation and distribution.

Water Conservation: By providing a pre-measured amount of detergent, laundry sheets eliminate the common problem of overuse, saving water and reducing the frequency of purchasing new detergent.

Cost Analysis

The Economic Costs of Traditional Detergents

When considering the economic implications of traditional detergents, the initial purchase price represents just a fraction of the actual cost. Consumers often use more detergent than necessary, influenced by the misconception that more soap equals cleaner clothes. This habit of overuse not only increases household expenses over time but also accelerates the depletion of detergent supplies, necessitating more frequent purchases. Furthermore, the environmental degradation caused by these detergents, including water pollution and the energy-intensive production process, incurs hidden costs that are absorbed by communities and ecosystems.

These hidden environmental costs have far-reaching economic consequences. The pollution of waterways necessitates additional treatment for safe use, which can strain municipal budgets and lead to increased utility bills for residents. Waste management becomes more complex and costly as well, with plastic packaging from detergents contributing to the growing volume of refuse that requires processing. Over time, these environmental and societal costs can lead to higher taxes and living expenses, illustrating that the true cost of traditional detergents extends well beyond their shelf price.

Cost-Effectiveness of Laundry Sheets

Laundry sheets offer a more economical alternative to traditional detergents over time. Their pre-measured design eliminates the guesswork and prevents the common issue of detergent overuse, ensuring optimal use of every sheet. This not only conserves the product but also translates into direct savings for consumers, who will purchase laundry detergent less frequently. Additionally, the compact and lightweight nature of laundry sheets reduces manufacturing and shipping costs. These savings can be passed on to the consumer, making laundry sheets a cost-effective choice.

The environmental advantages of laundry sheets also contribute to their cost-effectiveness. By minimizing the use of plastics in packaging and reducing the reliance on harsh chemicals, laundry sheets lessen the burden on waste management systems and decrease the need for environmental remediation efforts. These reductions have a ripple effect, potentially lowering community expenses related to waste processing and health care costs linked to chemical exposure. Thus, the economic benefits of laundry sheets extend beyond immediate savings, contributing to broader financial advantages for both individuals and society.

Consumer Convenience and Accessibility

Accessibility of Traditional Detergents

Traditional detergents enjoy a stronghold in the marketplace, largely due to their pervasive presence across various retail environments. From expansive supermarkets to modest corner shops, these detergents are readily available, making them a convenient choice for the everyday shopper. The extensive distribution network of these products ensures that they are within easy reach for most consumers, contributing to their continued popularity.

This market saturation is underpinned by years of established brand presence and consumer loyalty, which have been cultivated through persistent marketing efforts and ongoing product innovation. Such brand familiarity reassures consumers, often making traditional detergents a default purchase. The result is a self-reinforcing cycle of accessibility and demand, maintaining the status quo of traditional detergents as a household staple.

The Rising Popularity of Laundry Sheets

Laundry sheets are a relatively recent innovation in the home care market, but they are quickly carving out a significant niche. Their appeal lies in the combination of user-friendly convenience and a strong eco-conscious ethos, which aligns with the values of a growing segment of consumers. The shift towards environmentally responsible products has been a key driver in their burgeoning popularity.

Moreover, the advent of e-commerce has played a pivotal role in making laundry sheets more accessible to a wider audience. They are prominently featured on various online shopping sites, dedicated platforms for sustainable goods, and are increasingly making their way onto the shelves of traditional retail outlets. This expanding availability is a testament to the changing consumer preferences and the evolving landscape of the household cleaning market, where sustainability is becoming as important as efficacy.

Disposal and Recycling

Disposal Issues with Traditional Detergent Containers

The disposal of traditional detergent containers poses significant challenges. While many are technically recyclable, the reality is that a substantial portion ends up in landfills due to contamination or improper disposal. The impact of this plastic waste is far-reaching, contributing to the growing problem of environmental pollution and the depletion of resources required to produce new plastic containers.

Disposal of Laundry Sheets

In contrast, laundry sheets offer a more environmentally friendly end-of-life scenario. Their packaging is often designed to be compostable or recyclable, aligning with zero-waste principles. The sheets themselves, being biodegradable, leave no trace once they dissolve in water, which significantly reduces their environmental impact compared to traditional detergents.

The Future of Laundry Detergents

Innovations in Traditional Detergent Formulations

The landscape of the detergent industry is dynamic, with continuous advancements shaping the future of laundry care. Recognizing the growing environmental concerns, many detergent brands are actively seeking to minimize their ecological footprint. This pursuit of sustainability has led to the creation of highly concentrated detergent formulas, which deliver the same cleaning power in smaller doses, thereby reducing the need for excessive packaging.

Alongside concentration, there’s a shift towards incorporating plant-derived ingredients, which are gentler on the environment and often renewable. These natural components are increasingly replacing their synthetic counterparts, contributing to a cleaner production process and a safer product for both consumers and the planet. Additionally, the industry is experimenting with refillable detergent systems, aiming to cut down on single-use plastic containers and encourage a reuse mindset among consumers, further aligning product design with environmental responsibility.

The Evolution of Laundry Sheets

Laundry sheets stand at the forefront of innovation within the home care sector, with their trajectory set towards expansion and refinement. Technological advancements are paving the way for these products to boast enhanced cleaning efficacy, catering to a variety of fabric types and stains with greater precision. As the industry evolves, consumers can anticipate a wider selection of fragrances and specialized features tailored to specific laundering needs, from delicate care to robust stain removal.

The environmental aspect of laundry sheets is also expected to improve, with ongoing research into even more sustainable materials and manufacturing processes. The commitment to eco-friendliness is a strong selling point that resonates with the modern consumer, and as awareness of environmental issues grows, so does the demand for products that align with a sustainable lifestyle. This growing consumer consciousness is likely to drive further innovations in laundry sheets, ensuring they not only clean clothes effectively but also contribute positively to the health of our planet.

Final Thoughts

Throughout this guide, we have delved into the complex world of laundry care, examining the strengths and weaknesses of both traditional detergents and the emerging laundry detergent sheets. We’ve seen how the tide is turning in favor of sustainability in our cleaning habits, a change driven by increased global awareness and responsibility. As the public becomes more attuned to the environmental ramifications of their choices, laundry sheets emerge as a beacon of innovation, offering a path to a more sustainable and environmentally considerate future in home care. Embrace the change and join the movement towards a cleaner planet—make the switch to GoGoNano laundry detergent sheets today and be part of the solution for a greener tomorrow.

#nanotechnology#ecofriendly#sustainability#zerowaste#laundry sheets#laundry detergent sheets#laundry strips#plastic free laundry detergent#cleaning guide#gogonano

0 notes

Text

Optical Brighteners Market: The Radiant Role in Water Treatment

Optical brighteners, also known as fluorescent whitening agents or optical brightening agents (OBAs), play a significant role in various industries, including textiles, paper, detergents, cosmetics, and plastics. These compounds are used to enhance the appearance of products by increasing their perceived whiteness and brightness. Optical brighteners absorb ultraviolet (UV) light and re-emit it as visible blue light, making materials appear brighter and more vibrant. The global optical brighteners market has witnessed steady growth over the years, driven by the increasing demand for bright and attractive products across various sectors.

Market Dynamics

Growth Drivers

a. Textile Industry: The textile industry is one of the primary consumers of optical brighteners. These compounds are used to enhance the whiteness and brightness of fabrics, making them more appealing to consumers. As the textile industry continues to expand, the demand for optical brighteners market is expected to grow.

b. Paper Industry: Optical brighteners are crucial in the paper industry to improve the brightness and optical properties of paper products, including printing papers, packaging materials, and tissues. With the rise in e-commerce and packaging demands, the paper industry is experiencing a surge in optical brightener usage.

c. Detergent Industry: Detergent manufacturers incorporate optical brighteners to make clothes appear whiter after washing. With the increasing focus on cleanliness and hygiene, the demand for detergents with optical brighteners is on the rise.

d. Plastics Industry: In the plastics industry, optical brighteners are used to enhance the appearance of various plastic products, including packaging materials, automotive components, and consumer goods. As the plastics industry continues to grow, so does the demand for optical brighteners.

Market Restraints

a. Environmental Concerns: Some optical brighteners can have adverse environmental impacts when they enter wastewater and ecosystems. This has led to increased regulations and a push for eco-friendly alternatives.

b. Fluctuating Raw Material Prices: The cost of raw materials used in the production of optical brighteners can fluctuate, affecting the overall production costs for manufacturers.

c. Market Consolidation: The optical brighteners market has seen some degree of consolidation, with larger companies acquiring smaller ones. This can limit competition and innovation.

Market Segmentation

The optical brighteners market can be segmented based on various factors, including application, product type, and region.

By Application

a. Textiles: This segment includes applications in the textile industry, such as clothing, home textiles, and industrial fabrics.

b. Paper: Applications in the paper industry, including printing papers, specialty papers, and packaging materials.

c. Detergents: Optical brighteners used in laundry detergents and fabric softeners.

d. Plastics: Applications in the plastics industry, such as packaging, automotive components, and consumer goods.

e. Others: This category may include applications in cosmetics, paints, and coatings.

By Product Type

a. Stilbene Derivatives: Stilbene-based optical brighteners are widely used in various applications.

b. Coumarin Derivatives: Coumarin-based optical brighteners are used in specific applications, including cosmetics.

c. Dibenzothiophene Derivatives: Dibenzothiophene-based optical brighteners are used in the paper industry.

d. Others: This category may include other types of optical brighteners with unique properties.

By Region

a. North America: The United States and Canada have a significant market share due to the presence of key industries.

b. Europe: European countries like Germany and the UK are major consumers of optical brighteners.

c. Asia-Pacific: This region, particularly China and India, is witnessing rapid growth in the textile, paper, and plastics industries, driving the demand for optical brighteners.

d. Latin America: Countries in this region are also experiencing growth in various industries, contributing to the optical brighteners market.

e. Middle East and Africa: The market in this region is driven by the demand for optical brighteners in the textile and detergent industries.

Competitive Landscape

The global optical brighteners market demand is characterized by the presence of both established and emerging players. Some of the key players in the market include BASF SE, Huntsman Corporation, Clariant AG, Eastman Chemical Company, and Archroma. These companies often focus on product innovation, eco-friendly alternatives, and strategic partnerships to maintain their competitive edge.

Conclusion

The optical brighteners market is poised for continued growth as various industries strive to meet consumer demands for brighter and more attractive products. While environmental concerns and market consolidation pose challenges, technological advancements and a growing emphasis on sustainability are likely to drive innovation in the optical brighteners industry. As industries expand and consumer preferences evolve, the market for optical brighteners is expected to remain dynamic and responsive to changing demands.

#Optical Brighteners Market Share#Optical Brighteners Market Growth#Optical Brighteners Market Demand#Optical Brighteners Market Trend#Optical Brighteners Market Analysis

0 notes

Text

How Functional Dyes Contribute to Smart Textiles and Wearable Technology?

Smart textiles, the result of a combination of textile science and technology, are not simply clothes; they interact with us and our surroundings in ways that are really astonishing. The key to this invention is the use of Dyes that imbue fabrics with functionality, turning common textiles into materials that are sensitive and intelligent.

Visit Full Blog Functional Dyes

#pharmaceutical packaging manufacturer#pharmaceutical packaging industry#direct dyes#acid dyes#reactive dyes manufacturers#direct dyes manufacturers#solvent dye suppliers in gujarat#optical brightening agents#reactive dyes#crop protection chemicals

1 note

·

View note

Text

Textile Full Dyeing Process

The art of dyeing fabric involves imparting color onto textile materials, including yarn or finished fabric. This process dates back to at least 2600 BCE, with references found in historical texts. Initially, natural sources such as plants and animals were used to extract dyes and colors. However, from the mid-1800s, humans began developing synthetic dyes to expand the spectrum of available colors and increase the longevity of the dyeing process. There are a number of textile machinery manufacturers in India that offer best and efficient machineries to fulfil the textile manufacture needs and Weavetech is one amongst them. Weavetech is one of the best textile machinery manufacturers located in Gujarat which is a one stop solution for all your textile needs. With a quarter of a century of experience under its belt, Alidhra Weavetech is a prominent global entity that specializes in providing weaving and twisting machinery solutions. The organization has earned its reputation by offering innovative and locally developed designs that have been supplied to various parts of the world.

Textile Colorants

Dyes and pigments are colorants with distinct properties that greatly affect their application to textiles. Dyes are substances that color fabric and are typically used in a dissolved state, which then binds to the fabric. They are classified based on their chemical structure and usage, with each type of fibre requiring a specific dye. To ensure durability, dyes must possess the property of being "fast" or chemically stable, which means they should not wash away with soap and water or fade when exposed to sunlight. Dyes bind to fabrics through primary (ionic or covalent bonds) and secondary (hydrogen bonding) forces during the dyeing or printing process. Unlike dyes, pigments are insoluble and do not have an inherent attraction to textile fibres. If you are searching for textile machinery manufacturers in India, then you must get in touch with Weavetech as we have excellence and great expertise in this industry.

In the past, natural dyes sourced from various natural materials were the primary means of obtaining colors. However, with advancements in technology, synthetic dyes have gained more prominence due to their enhanced dependability, affordability, and ease of availability. Even so, certain natural dyes, including haematoxylin, carmine, and orcein, are still used today. Synthetic dyes, which are manufactured from either organic or inorganic substances, can be categorized into various types, including Direct, Acid, Basic, Reactive, Mordant, Metal complex, Vat, Sulfur, Disperse, or other types of dyes.

Dyeing Process

The techniques used for dyeing have remained relatively consistent over time and typically involve submerging textiles in a specialized solution containing dyes and other chemicals. Water is mainly used for cleaning, dyeing, applying auxiliary chemicals, and rinsing fabrics. The dyeing process comprises three primary stages, namely preparation, dyeing, and finishing, during which undesirable impurities are removed from the materials prior to the dyeing stage. To remove stains and natural color from fabrics, different cleaning methods can be employed such as using alkaline chemicals, detergents, or enzymes. Hydrogen peroxide or chlorine-based compounds are commonly used to bleach fabrics, especially when a white color is desired. Additionally, optical brightening agents may be added to enhance the whiteness of the textile before it is sold.

Textile dyeing is a process of coloring fabrics with water-based dyes, often performed under high temperatures and pressures. To ensure the dye evenly penetrates the fabric and resists fading, various chemical substances such as surfactants, acids, bases, electrolytes, carriers, leveling agents, chelating agents, emulsifying oils, and softening agents are added during the dyeing process. These chemical aids play a crucial role in achieving a uniform depth of color that is long-lasting and appropriate for the fabric's intended use.

Dyeing- The Imparting Colour

Dyeing is the art of imparting color to textiles, including fabrics, fibers, and yarns, and has been practiced by humans for millennia. Dyes are available in powder, paste, crystal, and liquid dispersion forms and dissolve readily in aqueous solutions. During dyeing, the textile material is immersed in the dye solution, and the dye molecules bond to the fibers through absorption and diffusion, which are influenced by temperature and other factors. Hand or machine dyeing can be used based on the fabric type, and it's crucial to select appropriate dyes for each fabric type. Weavetech is one of the best textile machinery manufacturers located in Gujarat and offering best quality of textile machineries.

Dyeing Methods

When it comes to dyeing textiles, the method used can either be batch or continuous. The optimal dyeing procedure depends on several factors such as the type of material being dyed (fiber, yarn, fabric, clothing), the type of fiber used, the desired quality of the dyed fabric, and the size of the dye batch. In batch dyeing, the textile material is loaded into a dyeing machine and allowed to reach equilibrium with the dye solution, whereby the dye molecules transfer from the solution into the fibers due to their affinity for the fibers. This process ensures that the textile is evenly and thoroughly dyed, resulting in high-quality dyed fabric.

If you are a textile manufacturer looking to improve the efficiency and productivity of your dyeing process, it's time to consider upgrading your dyeing machinery. Investing in Weavetech dyeing machines can significantly improve the quality of your dyed fabric, reduce dyeing time, minimize wastage, and increase your production output. Don't settle for outdated machinery that hinders your growth and profitability. Take action now and invest in advanced dyeing machinery to stay ahead of the competition and meet the ever-increasing demands of the textile industry.

This Blog Originally Posted:

https://www.weavetech.com/blog-detail/36/textile-full-dyeing-process/

0 notes

Text

Latest Research Report on L(+)-Lactic Acid Market by Application, Industry Share, End User, Opportunity Analysis 2030 with top players Naturework, Corbion, Galactic, Henan Jindan Lactic Acid Technology, COFCO Biochemical (AnHui), etc

The L(+)-lactic acid market refers to the industry involved in the production, distribution, and sale of L(+)-lactic acid, which is a naturally occurring organic acid. Lactic acid exists in two optical isomers, L(+) and D(-), with L(+) being the biologically active form.

L(+)-lactic acid is primarily produced through the fermentation of carbohydrates by certain strains of bacteria, mainly Lactobacillus and Bacillus. It is widely used in various industries and applications due to its versatile properties. Some key applications of L(+)-lactic acid include:

Free Download Link:-https://www.marketinforeports.com/Market-Reports/Request-Sample/499660

Food and beverages: L(+)-lactic acid is used as an acidulant, flavoring agent, and preservative in the food and beverage industry. It provides a sour taste and helps enhance the flavor and shelf life of products such as dairy products, confectionery, sauces, dressings, and beverages.

Pharmaceuticals: L(+)-lactic acid is used in the pharmaceutical industry for the production of various drugs, including antimicrobial agents, antacids, and excipients. It is also used as a pH regulator and solubility enhancer in pharmaceutical formulations.

Personal care products: L(+)-lactic acid is widely used in the cosmetic and personal care industry as an ingredient in skin care products, hair care products, and oral care products. It is valued for its exfoliating, moisturizing, and skin brightening properties.

Bioplastics: L(+)-lactic acid serves as a building block for the production of biodegradable and compostable polymers known as polylactic acid (PLA). PLA is used in the manufacture of bioplastic products, packaging materials, disposable cutlery, and fibers.

Industrial applications: L(+)-lactic acid is employed in various industrial applications, such as the production of environmentally friendly solvents, cleaning agents, and as a raw material in the synthesis of chemicals and biodegradable polymers.

The growth of the L(+)-lactic acid market is driven by factors such as increasing consumer demand for natural and eco-friendly products, growing awareness of the health benefits of lactic acid in food and beverages, and the shift towards sustainable packaging materials. Additionally, advancements in fermentation technologies and the development of cost-effective production processes have contributed to the expansion of the market.

Major producers in the L(+)-lactic acid market include companies like Corbion N.V., Galactic, Jungbunzlauer Suisse AG, and Henan Jindan Lactic Acid Technology Co., Ltd. These companies invest in research and development to improve production efficiency, expand their product portfolios, and meet the evolving demands of various industries.

In conclusion, the L(+)-lactic acid market is experiencing significant growth due to its wide range of applications across industries such as food and beverages, pharmaceuticals, personal care products, bioplastics, and industrial sectors. The market is driven by the increasing demand for natural and sustainable solutions, as well as advancements in production technologies.

0 notes

Text

Optical Brightener importer in India

MDPC is india’s premier Importer, Exporter and Trader. An ISO Certified company established in 2015 in Delhi. We are the best importer of optical brightener, Uvitex Optical brightener and TITANIUM DIOXIDE RUTILE GRADE.

1 note

·

View note