#Omron Automation

Explore tagged Tumblr posts

Text

#robotics#AI#IoT#Omron Automation#Manufacturing#Automation#Innovation#SmartManufacturing#electronicsnews#technologynews

0 notes

Text

To the engineer who always finds solutions to every problem. Happy #National #Engineers Day 2023 to all the engineers! Your innovation and dedication continue to amaze us. Keep building a better world!

www.balajiswitchgears.com

Mail: [email protected]

#National#Engineers Day#Engineer#EngineersDay#innovation#technology#Schneider Electric#LAPP#Socomec Group#KEI Wires and Cables#Omron Automation#Connectwell Industries#Telemecanique Sensors

0 notes

Text

The Omron J7KNA-AR-40 Contactor Relay is a reliable and efficient solution for industrial automation needs. Designed for seamless integration, it offers robust performance in controlling electrical circuits. This compact contactor relay ensures precise operation with low power consumption, making it ideal for demanding environments. Its durable construction guarantees longevity, reducing maintenance costs and downtime. The J7KNA-AR-40 supports a wide range of applications, including motor control and system automation. With Omron's trusted quality, this relay ensures consistent and safe operation for industrial systems. Choose the Omron J7KNA-AR-40 from Auto2mation to optimize your automation processes and enhance system reliability.

#auto2mation#industrial equipment#industrial and marine automation#industrial spare parts#marine spare parts#marine automation#automation#industrial and marine automation equipment#industrial automation#industrial automation equipment#omron#relay#contactors

0 notes

Text

The Omron SDV-FH2T Voltage Sensor 24 VDC ESWB.0109.010 is a reliable and precise device designed for monitoring and measuring voltage levels in various industrial applications. Operating at 24 VDC, this sensor ensures accurate detection and response to voltage fluctuations, enhancing system stability and safety. Its compact design and robust construction make it suitable for integration into diverse environments, offering consistent performance and long-term durability. Ideal for automation and control systems, the Omron SDV-FH2T is a dependable solution for voltage monitoring needs.

0 notes

Text

0 notes

Text

Health technology investor Glen Tullman has launched 62 Ventures, a new $100M fund

- By InnoNurse Staff -

Glen Tullman, Transcarent's current CEO, has launched 62 Ventures, a new venture fund worth around $100 million. The fund will be used to invest in firms that are not strictly focused on digital health, as his well-known fund 7wireVentures does.

Read more at STAT

///

Other recent news and insights

OMRON has acquired Luscii Healthtech to boost remote patient monitoring (Digital Health) Steer Health's digital kiosk aims to drive revenue, efficiency, accuracy, and patient satisfaction (Steer Health/PRNewswire)

#vc#startups#health tech#digital health#medtech#omron#Luscii Healthtech#remote patient monitoring#rpm#steer health#automation

0 notes

Text

BLIIoT | New Multi-Protocol PLC Gateway BL104 Converts PLC to Cloud/Server for Remote Monitoring

Introduction

With the rapid development of Industry 4.0, it is deeply recognised that real-time, reliable and secure data transmission is crucial in industrial production and life. In this context, high-performance industrial automation PLC data transmission solutions - protocol conversion gateway came into being, widely used in industrial automation systems, PLC remote monitoring and IoT application environment.

BLIIoT always insists on the core of the user's needs, and constantly expands its applications in a variety of industrial fields. Recently, we have developed a new series of BLIIoT industrial PLC protocol gateways, which not only have excellent stability and anti-interference ability, but also explore the application of industry segments, aiming to bring users a new experience of industrial automation data acquisition and conversion.

Product Description

PLC Gateway BL104 is a specially developed for PLC connect MQTT and OPC UA system and remote PLC program uploading and downloading debugging.

The downlink protocol supports PLC protocols such as Mitsubishi, Siemens, Omron, Delta, Schneider, etc. and Modbus protocol.

The uplink protocol supports Modbus RTU, Modbus TCP, MQTT and OPC UA, access to Cloud, Server, SCADA, MES, ERP and other systems.

PLC Gateway BL104 hardware interfaces include 2 or 6 RS485/RS232 serial ports, 2 network ports and 1 WiFi wireless transmission interface, which realises seamless communication between PLC and OPC UA system.

The PLC gateway BL104 has an industrial-grade design to ensure reliability in harsh environments. BL104 is suitable for industrial automation systems, PLC remote monitoring and IoT applications.The PLC gateway BL104 connects to the future of the industry and provides users with a trusted, low-cost, stable and reliable PLC to Modbus, MQTT and OPC UA solution.

By using its own patented rail-clip technology, the installation process is simplified and the utility of the gateway is ensured.

Product features

Supported protocols: Downlink protocol: Modbus RTU, Modbus TCP, Mitsubishi, Siemens, Omron, Delta, Schneider and other mainstream PLC protocols.Uplink protocol: Modbus RTU, Modbus TCP, MQTT, SNMP and OPC UA.

Hardware interface: 6*RS485/RS232 serial ports: The serial ports are independent of each other. Each serial port parameter can be set to collect different protocols. The serial port can also set the master-slave relationship independently. It can be configured as either a master station or a slave station.2*network ports: used for data collection and forwarding. The LAN port has a routing function and provides a channel for other devices to connect to the external network.1*4G or WiFi wireless transmission interface: Provides diverse communication options to adapt to different industrial environment need

Data security:Support data TSL/SSL, X.509 certificate, SNMPV1/V2, key encryption and other security gateway functions.

Remote Configuration Support: Support remote PLC programming and program uploading and downloading, saving travelling costs and improving service response speed. Support remote configuration, providing users with convenient management and monitoring methods, no longer need to visit engineers, saving maintenance costs.

Product Size: L x W x H: 30 x 83 x 110mm

Safety and Stability:

Industrial-grade design: Durable shell material meets industrial environment requirements.

Stability: Efficient communication protocol conversion ensures stable operation of the system.

Environmental adaptation:

Operating temperature range: -40~80℃, adapting to various industrial environments. Protection grade: IP30, ensuring the reliability of the equipment in harsh environments.

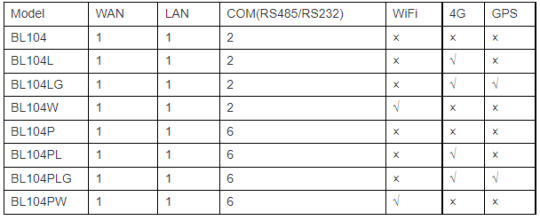

Model List

Application scenarios

Meet the needs of PLC protocol to Modbus MQTT OPC UA in industrial automation and industrial IoT scenarios.

More information about BLIIoT New PLC to Modbus MQTT OPC UA Gateway BL104: https://www.bliiot.com/industrial-iot-gateway-p00415p1.html

#PLC Gateway#Industrial Automation#IoT#Modbus#MQTT#OPC UA#SNMP#Siemens#Omron#Schneider#Delta#mitsubishi

0 notes

Text

Allen Bradley PanelView 800 HMI

HMI Module No:-

2711R-T4T | Allen Bradley | PanelView 800 Touch Screen HMI

2711R-T7T | Allen Bradley | PanelView 800 7-Inch HMI Terminal

2711R-T10T | Allen Bradley | PanelView 800 HMI Terminal

🌐Website :- https://asteamtechno.com

👉Contact us :- +919537840404

📧Email :- [email protected]

#trending#tumblr trends#viralpost#automation#viral#trendingnow#bestdeals#allen bradley#plc#HMI#power supply#industrial automation#omron#hm interesting

1 note

·

View note

Text

#bdengineeringsolution#bd engineering#industrial automation#industrial engineering#industrial equipment#plc#hmi#vfd#siemens#delta#mitsubishi#omron

0 notes

Text

#bd traders mart#industrial automation#industrial engineering#industrial equipment#plc#hmi#vfd#siemens#delta#mitsubishi#omron

0 notes

Text

#Omron Automation#highspeed#automated#X_ray#semiconductor_industry#power_semiconductors#technologynews

0 notes

Photo

Together, we overcome every problem and challenges which have now become the milestones for us.

We are honoured to receive the Relay Champion (MY Series) and Proximity Sensor Champion (E2B Series) awards from OMRON 2023 conclave.

We would like to express our deep gratefulness to the Customers, Stakeholders, Employees, and Partners.

www.balajiswitchgears.com.

1 note

·

View note

Text

The Omron Sysmac C200H-CPU21-E, C200H-ID212, and C200H-ME831 PLC Module Rack is a reliable automation solution designed for industrial control systems. Featuring a robust C200H-CPU21-E processor, the setup ensures efficient data processing and seamless control. The C200H-ID212 input module offers precise digital input capabilities, while the C200H-ME831 memory module provides secure storage for program data and configurations. This modular system is ideal for versatile applications in manufacturing, packaging, and process automation. Known for its durability and compatibility with various Omron components, it supports reliable, scalable, and cost-effective industrial automation. Perfect for maximizing operational efficiency in any industrial environment.

#auto2mation#industrial automation#industrial equipment#marine spare parts#industrial and marine automation#industrial spare parts#industrial and marine automation equipment#marine automation#industrial automation equipment#automation#Omron Sysmac

0 notes

Text

We offer SCADA-compatible products, including Honeywell, Danfoss, ABB, and OMRON components, for seamless system integration. Conclusion: Your Partner for Industrial and Marine Solutions At Ram Automations, we are dedicated to delivering top-quality automation parts and SCADA solutions to help your business succeed. Explore our products today and experience the benefits of quality and service tailored to your needs.

0 notes

Text

Omron Electronic Components for Precise Automation and Control

Choose Omron electronic components for exact control in your automation systems. With a wide range of components such as sensors, switches, and controllers, Omron provides reliable, efficient, and scalable solutions for all your industrial automation needs.

0 notes