#Oil Industry Alloy Electrode

Explore tagged Tumblr posts

Text

Chemical Earthing & Lightning Arrester Manufacturers in Noida-True Power India’s №1

We are Lightning Arrester Manufacturers & Lightning Arrester Suppliers. We have Lightning Arrester Dealers in Noida too.

True Power RDSO/CPRI Approved, UL Listed, and NABL accredited Earthing Electrodes, Earthing Accessories, Back Fill Compounds, Polyplastic Earth Pit Covers, Lightning arresters, and Lightning Protection Systems are manufactured in compliance with national and international standards.

These Maintenance Free Earthing Electrodes, including Pure Copper Earthing Electrode, Copper Earthing Electrodes, Copper Bonded Earthing Electrodes, GI Earthing Electrodes, Back Fill Compounds, and Earthing Pit Covers, are the most relied Earthing Electrodes across industries, Govt. Sectors, PSUs, and the Private sector.

Our Lightning Protection Systems, with more than a Lakh installation using Copper Lightning Arresters, Surge Arresters, Chemical Earthing, Earthing Strip, GI Earthing Strip, and other True Power Earthing Equipment & Accessories, have become a must for every installation, home, office, building, and all structures.

Types of Lightning Arrester in Noida

Chemical Earthing & Lightning Arresters Suppliers in Noida with the Best Prices, Extended Warranty, and Longer Service Life.

True Power, the renowned Chemical Earthing & Lightning Protection Solution provider, is the Best Lightning Arrester Supplier in Noida .

We supply all types of Maintenance Free Chemical Earthing Electrodes and Back Fill Compounds to help get correct earth resistivity.

Our Lightning Protection Systems using ESE Lightning Arresters and Copper Lightning Arresters provide 360-degree protection around our installed Lightning Arresters.

Our Back Fill Compounds are the best Earth Enhancing Back Fill Compounds and provide a stable and Low-resistance earthing for years, no matter where they are used.

Earth Pit Covers are a must for all types of earthing to protect the installed earthing from vandalism, connecting earthing strips, adding aesthetics, or preventing theft.

True Power Chemical Earthing & Lightning Protection System Advantages. Why it has become a must for every Installation?

Chemical Earthing provides a Stable Low Resistance Earthing throughout its service Life.

It is Maintenance free and doesn’t require any addition of chemicals or water.

Our Chemical Earthing Back Fill Compound neither corrodes the soil nor spoils the groundwater.

Lightning Protection System Protects your Property, Structure, and Lives from Lightning Strikes.

ESE Lightning Arresters with better protection coverage are better than Copper Lightning Arresters.

It’s our responsiblity to provide adequate safety cover to ourselves and all our surroundings.

Thank You Clients for sending us Your Valuable Feedback

Features we provide

Affordable Prices to meet all Budgets

We are known for our Pre-sales Service and the Best Prices.

Under One Roof Complete Solutions

We Manufacture all from Main Products to accessories.

Assurance of 50+ Approvals from Central & State Govt

We are RDSO/CPRI Approved,UL Listed & RoHS Compliant

Prompt Response without fail

We are a customer-oriented company and reply within 24 hours.

Customised Solutions for all

Contact us:

Call us: 8318455691

Email us:[email protected]

Address: D 242, Sector 63 Rd, D Block, Sector 63, Noida, Uttar Pradesh 201301

For more information visit: https://www.truepowergroup.in/earthing-electrode.html

True Power Earthings Private Limited

#earthing equipment#Earthing Accessory#Earthing Electrode#Maintenance Free Earthing Electrode#Copper Bonded Earthing Electrode#Copper Bonded Electrode#Pure Copper Earthing Electrode#Copper Earthing Electrode#GI Earthing Electrode#Galvanized Iron Earthing Electrode#Gel Safe Earthing Electrode#Maintenance Free Earthing#Maintenance Free Chemical Earthing Electrode#Maintenance Free Electrode Earthing#Gel Earthing Rod#Chemical Earthing#Alloy Electrode#Oil Industry Alloy Electrode#Lightning Arresters#ESE Lightning Arrester#Lightning Protection System#Copper Lightning Arrester#Surge Arresters#Earthing Pit Cover#Polyplastic Earth Pit Cover#FRP Earth Pit Cover#Earth Pit#FRP Earth Pit Chamber#Copper Electrode#Earthing Equipment & Accessories

0 notes

Text

Tungsten Rod Specifications: Features and Applications

Tungsten rods are key components in a variety of industrial applications due to their unique physical properties. Tungsten's high density, high melting point, high strength, wear resistance, and corrosion resistance make it an excellent choice for a variety of engineering applications. In this article, we will take a deep dive into the specifications of tungsten rods, their performance characteristics, and different applications.

Specification Overview

Tungsten rods are available in a variety of grades and diameters, with pure tungsten rods and tungsten alloys being the most common. Tungsten rod specifications include size, purity, tensile strength, conductivity, and other relevant properties. Tungsten rods typically range in size from 0.01 to 12 inches in diameter and in lengths from 1 to 600 feet.

Performance Characteristics

Tungsten rods perform excellently in high-temperature applications due to their high melting point and resistance to high-temperature oxidation. Tungsten's high density also ensures that it remains dimensionally stable during heating and cooling cycles. In addition, tungsten's high strength and wear resistance make it suitable for heavy-duty applications.

Applications

a. High-Temperature Furnaces

Tungsten rods are often used as heating elements in high-temperature furnaces due to their high conductivity and high-temperature strength. These furnaces are used in a range of industries such as the production of steel, cement, glass and ceramic products.

b. Welding Electrodes and Tips

Tungsten rods are used as welding electrodes and tips due to their high electron density and atomic number. They provide efficient heat transfer and ensure that weld joints are clean with minimal spatter. Tungsten rods are commonly used in laser welding, electron beam welding and gas tungsten arc welding.

c. Electronic Components

Tungsten rods are used in a range of electronic components such as filaments, X-ray targets and resistors due to their high electron density and resistance to high temperature oxidation. These components are essential in a variety of electronic devices such as vacuum tubes, light bulbs and medical imaging systems.

d. Aerospace and Defense Applications

The high strength and wear resistance of tungsten rods make them suitable for use in aerospace and defense applications. They are commonly used in aircraft engines, rocket propulsion systems and armor plates due to their ability to withstand high temperatures and mechanical stresses.

e. Deep Sea and Underwater Applications

Tungsten rods are used in deep sea and underwater applications such as submarine cables and oil pipelines due to their high strength, corrosion resistance and ability to withstand high pressures. These cables and pipelines are essential in underwater communications, energy transmission and fluid delivery.

0 notes

Text

8 Common Mistakes in Aluminium Welding and How to Avoid Them

In industries like automotive, aerospace, and construction, aluminium welding is essential but often overlooked. It’s like a complex puzzle with unique challenges. The metal's high thermal conductivity, pesky oxide layer, and risk of contamination need careful handling. For many welders, especially those transitioning from steel, the learning curve can be steep. Mistakes can lead to weak joints, unsightly porosity, and a poor finish.

Let’s look at common pitfalls and provide practical solutions to help you tackle aluminium welding in Sydney.

1. Improper Surface Preparation

The Mistake:

One of the biggest blunders in aluminium welding in Sydney? Ignoring surface prep! Aluminium develops a pesky oxide layer, boasting a melting point far above the base metal. If this stubborn shield isn’t banished, it blocks proper fusion—resulting in welds that lack strength and durability.

How to Avoid It:

Scrub the aluminium surface well before you start. For that, you can use a stainless steel wire brush designed for aluminium. Then, wipe it down with acetone. This solvent removes oil, grease, and grime easily.

2. Using the Wrong Filler Material

The Mistake:

Selecting the wrong filler material is like inviting trouble. It can lead to dismal mechanical properties, unsightly cracks, or fragile welds. Wby, because many welders mistakenly believe any filler metal will do. However, it doesn't!

How to Avoid It:

Dive into welding charts or consult an expert in aluminium welding in Sydney. This will lead you to the ideal filler metal for your chosen alloy. Among the stars of the filler world are ER4045, ER5356, and ER4043. Each one shines uniquely, perfect for different applications. A wise choice of filler metal means strong, lasting welds—ensuring your work stands the test of time.

3. Inadequate Heat Control

The Mistake:

Aluminium, a heat conductor par excellence, swiftly dissipates warmth. Apply too little heat, and the weld simply skates along the surface, lacking proper penetration. Conversely, crank up the heat, and you risk a recipe for disaster: burn-through, warping, or excessive distortion await. Balance is key to a weld that shines.

How to Avoid It:

Harness the power of balanced heat for your aluminium’s thickness. For delicate, thin sheets, consider pulse welding; it deftly tames heat.

4. Incorrect Shielding Gas Selection

The Mistake:

Some welders stroll down the wrong path with shielding gas for aluminium. This misstep leads to porosity, dodgy welds, and unsightly oxidation.

How to Avoid It:

Pure argon is the champion gas for aluminium welding in Sydney, ensuring arc stability. It guards against contamination like a vigilant sentry. For thicker materials, blend **argon and helium** to enhance penetration. Steer clear of CO2 and mixed gases meant for steel welding; they invite defects to the party.

5. Welding Too Fast or Too Slow

The Mistake:

Speed serves as the very heartbeat of aluminium welding. Go too slow, and the metal melts into a puddle, warping like a funhouse reflection. Yet, go too fast, and you risk creating joints that are weak and tired. Striking that ideal rhythm is crucial, forging robust connections without compromise.

How to Avoid It:

Keep your welding speed steady and under control for optimal fusion. Watch the weld pool like a hawk, adjusting your pace as needed. This ensures consistent penetration and keeps distortion to a delightful minimum.

6. Ignoring Proper Electrode and Polarity Settings (For TIG Welding)

The Mistake:

Many welders choose the wrong electrode or set the polarity incorrectly. This causes unstable arcs and results in poor weld quality.

How to Avoid It:

For TIG aluminium welding in Sydney, choose a pure tungsten (green) or lanthanated tungsten electrode. Opt for **AC (Alternating Current)** polarity; this helps dissolve the oxide layer. A well-tuned AC current promotes proper fusion for stunning results. Setting the controls right guarantees a clean, stable arc and deeper penetration.

7. Overlooking Gas Flow Rate

The Mistake:

Perfecting your welds requires just the right breath of shielding gas. A delicate balance is key; too much gas kicks up turbulence, inviting unwelcome contaminants. Conversely, a timid flow leaves your weld exposed, vulnerable to porosity and contamination. Strive for harmony to shield your masterpiece!

How to Avoid It:

Tune the shielding gas flow to the manufacturer’s sweet spot—typically 15-25 CFH for argon. Check for leaks in gas lines; a little drift can ruin a lot. Ensure your welding area is calm, free from strong breezes to guarantee success.

8. Ignoring Post-Weld Treatment

The Mistake:

Neglecting post-weld cleaning is like leaving a secret admirer hidden. Oxides and contaminants linger, turning your welds into ticking time bombs. Left untreated, they invite corrosion, gradually weakening the joints. Don’t let your hard work rust away; clean up to preserve strength.

How to Avoid It:

Post-welding, give your weld area a thorough scrub with a wire brush. If needed, treat it with a protective coat to fend off corrosion. For structural components, think about extra safeguards like anodizing or painting.

Conclusion

Aluminium welding is a tricky tightrope walk, but don't fret! Steering clear of the above common pitfalls leads to brilliantly strong, durable welds. For more information or practical support, reach out to Prestons Welding and Engineering.

0 notes

Text

Welding Quality and Weding Inspection: A Critical Aspect of Manufacturing Excellence

Welding is an essential process in various industries, from construction and automotive manufacturing to aerospace and shipbuilding. It involves joining materials, usually metals, by applying heat and pressure to create strong, durable bonds. The importance of welding quality cannot be overstated, as improper welds can lead to failures that affect safety, performance, and the longevity of the products. To ensure high-quality welds, rigorous inspection techniques are used to detect flaws and prevent costly errors. This article will explore welding quality, inspection methods, and the role they play in enhancing product integrity. Furthermore, we will touch on how companies like Mecaweld Technology LLC are contributing to welding excellence.

The Importance of Welding Quality

Welding quality is critical because even minor defects in welds can lead to catastrophic consequences. For instance, structural failures due to weak or defective welds can result in accidents, equipment downtime, and damage to valuable machinery. In industries like aerospace, automotive, and oil and gas, the stakes are particularly high as components often experience extreme stresses, temperatures, and environments.

Welding quality is not only about ensuring the strength of the welded joint but also about enhancing the aesthetic appearance, ensuring dimensional accuracy, and achieving the desired physical properties. High-quality welds ensure that a product performs as intended throughout its lifecycle, thus reducing maintenance costs and enhancing overall reliability.

Factors Influencing Welding Quality

Several factors affect welding quality, and understanding them is crucial for producing top-tier welds. These include:

1. Materials Used

Different materials react to welding processes differently. Metals such as steel, aluminum, and titanium have different thermal properties, which affect how they melt and fuse. For instance, high-strength alloys may be more prone to cracking or distortion during welding, requiring precise control over the heat and welding parameters.

2. Welding Process

There are several welding processes, including arc welding, MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and stick welding. Each process has its advantages, limitations, and ideal applications. Choosing the right welding technique for a specific material and application is essential for achieving a high-quality weld.

3. Welding Parameters

Welding parameters such as voltage, current, welding speed, and electrode type significantly influence the quality of the weld. Too much heat can cause warping or burn-through, while insufficient heat can result in weak or incomplete bonds. Maintaining the optimal settings for each welding scenario ensures the best possible result.

4. Welder Skill and Experience

Welding is as much an art as it is a science. A skilled welder can produce high-quality welds even in challenging conditions. The experience of the welder plays a vital role in ensuring that the weld is executed correctly and that all variables are managed properly.

5. Environmental Factors

Environmental conditions, such as temperature, humidity, and wind, can affect the welding process. For example, excessive moisture in the air can cause hydrogen to get trapped in the weld, leading to cracks. Similarly, wind can disrupt shielding gas flow in processes like MIG and TIG welding.

Welding Inspection: Ensuring Quality

Welding inspection is the process of examining a welded joint to detect any defects that might compromise its integrity. Proper inspection ensures that the weld meets required standards, regulations, and specifications. Several methods are available for inspecting welded joints, and choosing the appropriate technique depends on the type of inspection required and the nature of the weld.

1. Visual Inspection

Visual inspection is the most common and straightforward method of weld inspection. It involves examining the weld surface for any visible defects, such as cracks, porosity, undercuts, or inadequate fusion. While this method is fast and inexpensive, it has its limitations, as it cannot detect internal flaws or issues that are not visible on the surface.

2. Non-Destructive Testing (NDT)

Non-destructive testing (NDT) methods are used to detect internal flaws without damaging the welded structure. These methods are particularly important in high-stakes industries where safety and product performance are paramount. Some common NDT methods include:

Ultrasonic Testing (UT): This method uses high-frequency sound waves to detect internal defects. The sound waves travel through the weld and reflect off any flaws, providing information about their location and size.

X-ray or Gamma Ray Testing: This method uses X-rays or gamma rays to penetrate the weld and reveal internal defects, such as voids, cracks, or inclusions. It is highly effective but requires the use of specialized equipment and safety precautions.

Magnetic Particle Testing (MT): This method is used for detecting surface and near-surface defects in ferromagnetic materials. It involves magnetizing the weld and applying fine particles to the surface. If a defect is present, the magnetic field will cause the particles to accumulate at the flaw.

Dye Penetrant Testing (PT): This method involves applying a liquid dye to the surface of the weld and then examining it under ultraviolet light. The dye seeps into surface cracks, making them visible.

3. Destructive Testing

Destructive testing involves physically breaking or altering the welded joint to evaluate its strength and performance. While this method is less commonly used in production settings due to its cost and time requirements, it provides invaluable data for determining the material properties and structural integrity of a weld. Examples of destructive testing include tensile testing, bend testing, and impact testing.

4. Automated Inspection

With advancements in technology, automated welding inspection systems have become increasingly popular. These systems utilize robotics, sensors, and artificial intelligence to conduct inspections quickly and efficiently. Automated inspection offers high precision and can reduce human error, making it ideal for high-volume production environments.

The Role of Welding Standards

Welding standards are established by organizations such as the American Welding Society (AWS), the International Organization for Standardization (ISO), and the American Society of Mechanical Engineers (ASME). These standards set guidelines for welding practices, materials, procedures, and inspection methods. Compliance with these standards is essential for ensuring the safety and performance of welded products.

Challenges in Welding Quality Control

Despite advancements in welding technology and inspection techniques, several challenges remain in maintaining consistent welding quality. These challenges include:

Material Variability: Materials from different suppliers may have slight variations in composition, which can affect the welding process.

Human Error: Even with skilled welders, human error can still result in defects, especially in complex or challenging welding situations.

Cost and Time Constraints: In many industries, there is pressure to meet tight deadlines and budget constraints, which can sometimes compromise quality control measures.

Mecaweld Technology LLC: Advancing Welding Excellence

As industries continue to demand higher welding standards, companies like Mecaweld Technology LLC are leading the way in providing cutting-edge solutions. Mecaweld Technology LLC specializes in providing state-of-the-art welding technology and inspection services. With a commitment to quality, innovation, and customer satisfaction, Mecaweld Technology LLC has positioned itself as a trusted partner for businesses in need of advanced welding solutions.

Whether through advanced robotic welding systems, precision welding tools, or top-tier inspection services, Mecaweld Technology LLC ensures that every weld meets the highest standards of quality and reliability. Their team of experienced professionals works closely with clients to address specific needs, offering tailored solutions that improve both productivity and product quality.

In conclusion, welding quality and inspection are critical components of modern manufacturing, ensuring that products are safe, durable, and reliable. Through rigorous inspection methods and adherence to international standards, manufacturers can guarantee that their welded joints meet the required performance criteria. With companies like Mecaweld Technology LLC offering innovative solutions and services, industries can continue to meet the growing demands for superior welding quality.

0 notes

Text

Why E9018-B3 is the Preferred Choice for Critical Welding Applications

In industries where welding plays a crucial role in maintaining the integrity of structures and systems, selecting the right welding electrode is essential. For applications that demand high performance, particularly in elevated temperature and pressure environments, the E9018-B3 welding electrode has become the preferred choice. This low-hydrogen electrode is specifically designed for welding 2.25% Chromium-1% Molybdenum (Cr-Mo) steels commonly used in power plants, refineries, and other critical applications.

In this blog, we’ll explore why E9018-B3 is trusted by welders and engineers alike for demanding environments and critical applications.

E9018 welding rod

1. Superior High-Temperature Performance

One of the standout features of E9018-B3 is its exceptional performance in high-temperature environments. The 2.25% Cr and 1% Mo alloy composition of this electrode ensures that it can handle the intense heat associated with power generation and petrochemical processes without losing its mechanical properties.

This makes it ideal for welding materials used in boilers, pressure vessels, and piping systems that regularly operate at elevated temperatures. The electrode's ability to withstand thermal cycling and stress makes it reliable for long-term use, reducing the risk of failure in high-stress conditions.

2. Excellent Resistance to Creep and Corrosion

Creep resistance is vital in applications where components are subjected to high temperatures over extended periods. E9018-B3 offers excellent creep resistance, ensuring that welded joints maintain their strength and integrity even under prolonged heat exposure. This resistance is particularly important in industries such as oil and gas, where the materials are exposed to fluctuating temperatures and harsh conditions.

Additionally, the Cr-Mo alloy composition provides enhanced corrosion resistance. In environments where materials are exposed to corrosive gases or chemicals, the welds made with E9018-B3 remain durable and resistant to degradation, extending the life of equipment and reducing maintenance needs.

E9018 welding electrode

3. Low-Hydrogen Content for Crack Prevention

A key advantage of the E9018-B3 electrode is its low-hydrogen content, which significantly reduces the risk of hydrogen-induced cracking, also known as cold cracking. Hydrogen is often a cause of cracks in the weld metal, particularly in high-strength steels and critical welding applications. By using low-hydrogen electrodes like the E9018-B3, welders can ensure that the welds remain strong and free from defects, especially in applications where even minor flaws could lead to catastrophic failure.

This property is especially valuable in industries like pressure vessel manufacturing and power generation, where the safety and reliability of welded joints are non-negotiable.

4. High Tensile Strength for Critical Loads

The E9018-B3 electrode provides weld metal with a high tensile strength of 90,000 psi, ensuring it can handle heavy loads and stresses. This high strength is critical for applications where structural integrity is paramount, such as in the fabrication of steam boilers, piping systems, and heavy machinery.

Welds made with E9018-B3 are able to resist mechanical stresses, both during installation and while in service, making it a reliable choice for industries that cannot afford equipment failures or downtimes.

Welding electrode manufacturer

5. Versatile for Various Welding Positions

In critical welding applications, the ability to perform welds in multiple positions is often necessary. The E9018-B3 electrode is versatile and can be used in various welding positions, including flat, horizontal, vertical, and overhead positions. This makes it a preferred option in complex welding projects where accessibility may be challenging, and precision is key.

The electrode's versatility allows welders to achieve consistent, high-quality welds across a range of scenarios, from fieldwork in harsh outdoor environments to controlled conditions in manufacturing plants.

6. Compliance with Industry Standards

When it comes to critical welding applications, compliance with industry standards is essential. The E9018-B3 electrode meets stringent industry specifications, including those set by the American Welding Society (AWS). Its designation, E9018-B3, follows the AWS classification, which guarantees that the electrode has passed rigorous tests for its mechanical properties, performance, and composition.

This compliance ensures that welders and engineers can trust E9018-B3 to deliver the performance needed for projects that involve safety, regulatory, and structural integrity concerns.

Welding rod manufacturer

7. Enhanced Weld ability and Smooth Finish

In addition to its mechanical properties, the E9018-B3 electrode offers excellent weld ability. It has a stable arc and produces minimal spatter, which makes the welding process smoother and more efficient. The resulting weld beads are smooth and clean, requiring less post-weld clean-up and minimizing the chances of defects or imperfections.

The electrode also provides excellent penetration, ensuring that the welds achieve the necessary depth to bond materials effectively. This combination of weldability, penetration, and a smooth finish makes E9018-B3 a top choice for both high-quality and high-strength welds.

Conclusion

The E9018-B3 welding electrode is a trusted solution for critical welding applications due to its exceptional high-temperature performance, corrosion and creep resistance, low-hydrogen properties, and high tensile strength. Whether used in the fabrication of boilers, pressure vessels, or refinery components, this electrode offers the reliability and durability required for industries where failure is not an option.

Its compliance with industry standards, versatility in various welding positions, and ease of use further solidify its position as the go-to choice for welders and engineers working in demanding environments. For any application where safety, strength, and performance are paramount, E9018-B3 remains the preferred electrode.

0 notes

Text

Supplier of Stainless Steel Wire Rod in Jharkhand

Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Wire Rod in Jharkhand. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Products, including Stainless Steel Round Bars, Wires, Rods, Sheets, Coils, Pipes, Flat Bars, Square Bars, Hexagonal Bars, Angles, Flanges, and Alloy Steel. Stainless Steel Wire rod is a semi-finished product made from stainless steel. Our wire rods are produced in various diameters and grades to meet the specific needs of different industries. Key Properties: Corrosion Resistance: Resists oxidation and corrosion, making it suitable for various environments. Strength: Offers excellent mechanical strength and durability. Aesthetic Appeal: Maintains a polished and attractive appearance. Specification: Stainless steel Wire Rod Grades: ASTM: 201, 202, 204Cu, 301, 302, 303, 304, 304Cu, 304HC, 304L, 304H, 310, 310S, 312, 314, 316, d16L, 316LN, 316TI, 316LCu, 321, 410, 420, 430, 430L, 904L DIN/EN: 1.4301, 1.4306, 1.4307, 1.4310, 1.4401, 1.4404, 1.4567, 1.4841, 1.4842, 1.4541, 1.4845, 1.4570, 1.4571, 1.4578, 1.4597, 1.4362, 1.4370 and 1.4016 Size: 0.03mm to 16mm Heat Treatment: Solution Annealing for Austenitic Grades Normal Annealing for Martensitic Grades Finish: Black, Bright, Matte Finish, Soap Coated, Electro Polish Quality Other Special Grade: Electrode Grades: ER304, ER304L, ER307, ER307SI, ER308, ER308L, ER308LSI, ER310, ER316, ER316L, ER316LSI, ER347, ER347SI, ER309L, ER430 And ER420 Condition: Soft, 1/4 Hard, 1/2 Hard, Full Hard, HRP & Solution Annealed Packing: Simple 4-steel Strip Packing for Coil Poly Packing with Plastic Strip for HRP and HRAP Wrapping with Plastic Strip As Per Customer Requirements Testing: Computerized Tensile Testing Machine Bend Testing Wrap Testing Torsion Testing Machine Hardness Testing Machine IGC Testing Facilities Cold Upset Test Facility PMI Tester Chemical Composition Analyses Radioactive Contamination Testing Application: Construction and Architecture Automotive Industry Oil and Gas Industry Power Generation Arisa Impex is a Supplier of Stainless Steel Wire Rod in Jharkhand including locations like Ranchi, Bokaro, Jamshedpur, Dhanbad, Giridih, Hazaribagh, Ramgarh, Hazaribagh, Chirkunda, Mango, Chaibasa, Koderma, Sahibganj, Jhumri Telaiya, Jamtara, Dumka, Gumia, Madhupur, Phusro, Chakradharpur. Feel free to contact us for more information and inquiries. View Product: Click Here Read the full article

0 notes

Text

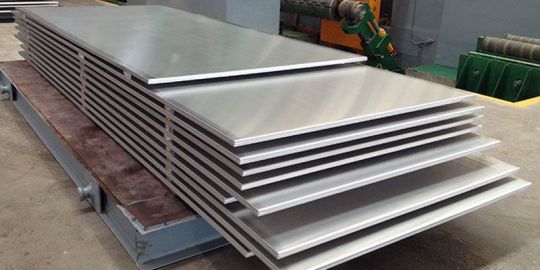

The Lifeline of Industrial Sector: Unveiling the Secrets of Steel Plate Manufacturing

Piping Projects is one of the most trusted Steel Plate Manufacturers in USA. Steel plates function efficiently in various environments and have good corrosion resistance. The most skilled workers are hard at work, ensuring that all quality standards satisfy the customer's demands. In addition to producing the best-quality steel plates, we are an official Jindal and ISMT dealer for providing carbon and alloy steel plates.

Steel Plate Manufacturers metal plates using steel that can be formed into more intricate products through cutting and fabrication. Steel plates come in a range of thicknesses and may be made to any desired width or length. The alloy steel plate acquires particular constraints and qualities by adding these components. Also, We lead Welding Electrode Manufacturers in USA.

We are also a market-leading provider of carbon steel, alloy steel, and Stainless Steel Plate with ASME Quality and ISO 9001:2015 Certifications. The AS plate is alloyed with 1% to 50% elements. Steel Plates production is necessary for a structure to be dependable and long-lasting. Because of their extreme robustness and durability, these plates are crucial for manufacturing, shipbuilding, and construction. Also, Check Our Steel Plate Weight Chart

The Significance of Steel Plate Manufacturing

The production of steel plates is essential to many different sectors. Its importance is seen in some ways:

Infrastructure Development: Steel Plate Suppliers, which are frequently used in the construction of buildings, bridges, and roads, provide the framework for the development of infrastructure. Steel plates' durability and adaptability guarantee the lifetime and safety of these kinds of constructions.

Automotive Industry: The transportation sector uses steel plates extensively because they give transport structure and body parts the strength and crash resistance they need. Steel plates' low weight and strength combination helps improve passenger safety and fuel economy.

Shipbuilding: Steel plates are a significant component of ships built in the marine industry. Because of their superior structural integrity and immunity to corrosion, these plates are perfect for withstanding opposing marine conditions and preserving sailors' safety.

Energy Sector: In the energy industry, steel plates are crucial, especially for offshore oil rigs, pipelines, and power plants. Their great tensile strength and tolerance to high temperatures and pressure make energy production efficient and dependable.

Cities We Supply Steel Plate

Steel Plate Manufacturer in Texas

These plates are thicker than foils but thinner than ordinary steel plates. Stainless steel plates are widely known for their strong resistance to corrosion and work very well in various challenging conditions. Texas's top steel plate supplier, PipingProjects.us, offers premium plates for various commercial and construction applications.

Steel Plate Manufacturer in California

Our experts are dedicated to maintaining the highest quality standards, making us a leading Steel Plate Supplier in California. The components in the steel plates are carefully alloyed, ranging from 1% to 50%. The alloy steel plate gains distinct qualities and tolerances from adding various components. The welding process used to join these plates is standard.

Steel Plate Manufacturer in Florida

We produce seamless and welded steel plates under stringent quality control guidelines and standards that provide good surface and near-dimensional tolerances. We are a market-leading Steel Plate Manufacturer in Florida, offering solutions on a worldwide scale, with ASME Quality and ISO 9001:2015 Certifications.

Steel Plate Manufacturer in New York

As among the best Steel Plate Suppliers in New York, we have experienced staff members dedicated to maintaining the best calibre requirements. The components in the steel plates are carefully alloyed, ranging from 1% to 50%. The alloy steel plate gains distinct qualities and tolerances from adding various components. These plates are welded using standard welding techniques.

Common Uses For Stainless Steel Plate

The planning and constructing a building's external features, such as the exterior, roof, railings, doors, and windows, is called architecture.

Equipment for meal preparation, sinks, and appliances are all part of the food service setup.

Oil and gas, chemical processing, medical, and shipping equipment.

Application, Energy Management, and Manufacturing Automation.

Producing steel plates is a multi-step, specialised procedure to provide high-quality plates appropriate for various industrial uses. Identifying the best raw materials determines the quality of Steel Plate Supplier in USA. Based on the intended use, manufacturers carefully evaluate strength, durability, and corrosion resistance when selecting the steel alloy.

To Know More, Visit us,

Product: Steel Plate Manufacturers USA

Website: pipingprojects.us

#Steel Plate Manufacturers in USA#Steel Plate Manufacturers#Welding Electrode Manufacturers in USA#Stainless Steel Plate#Steel Plate Weight Chart#Steel Plate Suppliers#Steel Plate Manufacturer in Texas#Steel Plate Manufacturer in California#Steel Plate Manufacturer in Florida#Steel Plate Manufacturer in New York#Steel Plate Supplier in USA

0 notes

Text

Pure Nickel Wire Market Trends: Navigating the Path to Success

Pure nickel wire is a thin rigid metallic wire usually composed of nickel. It has superior corrosion resistance along with excellent formability and strength as compared to other metals. Pure nickel wire finds wide application in making electrical contacts in batteries owing to its anti-corrosive nature as well as capability to retain strength even after repeated electrical stresses. The global pure nickel wire market is estimated to be valued at US$ 102.2 Mn in 2023 and is expected to exhibit a CAGR of 4.7% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Opportunity: The growing adoption of pure nickel wire in battery fields presents a lucrative opportunity for the growth of the pure nickel wire market. Pure nickel wire is extensively used in making battery electrodes and springs owing to its anti-corrosive properties and strength retention capabilities. With the rapid development of new battery technologies such as lithium-ion batteries and solid-state batteries, the demand for high purity nickel electrode materials has surged exponentially in recent years. The rising application of lithium-ion batteries in electrical vehicles and energy storage systems is further propelling the consumption of pure nickel wire. The unabated growth of the battery industry is thus estimated to drive the pure nickel wire market substantially over the forecast period. Porter's Analysis

Threat of new entrants: The pure nickel market requires high capital investments for production facilities limiting new entrants. Bargaining power of buyers: Large buyers can negotiate lower prices due to their high purchase volumes. Bargaining power of suppliers: The few manufacturers of pure nickel wire globally exert strong influence over prices. Threat of new substitutes: There are no close substitutes for nickel owing to its unique material properties. Competitive rivalry: The pure nickel market is moderately concentrated with established players competing on quality, reliability and customer service. SWOT Analysis

Strengths: Nickel offers high corrosion resistance, strength and ductility ideal for applications in aerospace, oil and gas industries. Weaknesses: Price volatility of nickel raw material increases production costs for manufacturers. Opportunities: Growing demand for nickel in manufacturing batteries and infrastructure construction presents new opportunities. Threats: Stringent environmental regulations on nickel mining and processing add to production challenges. Key Takeaways

The global pure nickel wire market is expected to witness high growth over the forecast period supported by increasing demand from end-use industries.

Regionally, North America holds the largest market share currently due to ongoing investments in infrastructure projects. However, Asia Pacific is poised to dominate market growth between 2023-2030 with countries like China and India ramping up manufacturing activities. Key players operating in the pure nickel wire market are ThyssenKrupp Materials NA, Inc., A.M. Castle & Co., Ulbrich Stainless Steels & Special Metals, Inc., California Fine Wire Company, Wire Products Company, Luma Metall AB, S and S Wire Products, Inc., Alloy Wire International Ltd., Kaye Corporation, Metal Associates, Brookfield Wire Company and Novametal Group.

0 notes

Text

"Empowering Solar Technologies: Key Insights into the Top 10 PV Ribbon Market Players"

PV ribbons are typically copper electrodes that have been coated with either hot-dipped solder or electrolytic tin and are used in solar panels. The ribbon interlocks solar cells in a photovoltaic solar module by fusing solar cells straight on silicon crystals. Copper is commonly used as a foundation material in PV ribbons, but aluminium alloys can be utilized as a base material on occasion.

𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐛𝐫𝐨𝐜𝐡𝐮𝐫𝐞 : https://www.alliedmarketresearch.com/request-toc-and-sample/13253

The coating structure and thickness are also important factors in defining the coating's dependability and robustness in PV ribbons. When developing PV ribbons, numerous key aspects must be addressed, including yield strength, elongation, camber, and winding. PV ribbons, solar modules, and the total solar energy system's performance are all affected by these elements. Solar cells with a low yield strength are less likely to break. As a result, optimising overall module power while retaining high elongation and minimal camber is desirable for the ribbon and module to perform properly.

Request for Customization of This Report at: https://www.alliedmarketresearch.com/request-for-customization/13253

Governments and authorities have been obliged to shift their focus away from fossil fuels like coal and crude oil and toward green and renewable energy sources due to increased energy demand and concerns about global warming. As a result, renewable energy sources such as solar, wind, hydro, and geothermal have grown in popularity and investment around the world. Solar is one of the major sources of renewable energy, in which countries are investing heavily. The PV ribbon is usually a copper conductor that has been coated with either hot-dipped solder or electrolytic tin and is used in solar panels. This growth in the renewable energy will be profitable for the PV Ribbon Market.

The PV Ribbon Market is expected to expand due to the rising attention of businesses in the energy and power industry on lowering their cost of operations in order to improve their profitability. COVID-19 has had a significant influence on the global PV ribbon market, primarily by disrupting production and demand facilities, causing supply chain and market disruption, and having a financial impact on enterprises and financial markets owing to global lockdowns.

Enquiry Before Buying : https://www.alliedmarketresearch.com/purchase-enquiry/13253

Key Benefits of the Report

This study presents the analytical depiction of the PV ribbon’ industry along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the PV ribbon market share.

The current market is quantitatively analysed to highlight the PV RIBBON market growth scenario.

Porter’s five forces analysis illustrates the potency of buyers & suppliers in the market.

The report provides a detailed PV ribbon market analysis based on competitive intensity and how the competition will take shape in coming years

PV Ribbon Market Report Highlights

By Type:

Connection

Bustar

By Application:

Solar battery

Solar modules to the junction box

Film substrate

Others

By End Use:

Aerospace

Defense & Government Service

IT & Telecommunication

Others

By Region:

North America (U.S., Canada, Mexico)

Europe (UK, Germany, France, Italy, Spain, Rest of Europe)

Asia Pacific (China, Japan, India, South Korea, Australia, Rest of Asia-Pacific)

LAMEA (Brazil, Saudi Arabia, South Africa, Rest of LAMEA)

Key Market Players:

Sanysolar

SHENMAO Technology

E Sun New Material

Jiangsu Sun Group

YourBuddy

Ulbrich Precision Flat Wire

Hitachi Cable

Kunming Sunlight Science and Technology

Bruker-Spaleck

Sveck

Baoding Yitong PV Science & Technology

0 notes

Text

Submerged Arc Welding In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Submerged arc welding is a wire-fed process generally used with stainless steels, carbon steels, and some nickel alloys. The submerged arc welding process is largely employed in heavy industrial applications in various industries such as shipbuilding, wind tower and rail car fabrication, pressure vessel, and offshore oil rig welding. The process has significant impact on the productivity and efficiency of manufacturing process in various end-user industries. The submerged arc welding process requires a continuously fed consumable solid or tubular (metal cored) electrode. The molten weld and the arc zone are protected from atmospheric contamination by being “submerged” under a blanket of granular fusible flux consisting of lime, silica, manganese oxide, calcium fluoride, and other compounds. When molten, the flux becomes conductive, and provides a current path between the electrode and the work. This thick layer of flux completely covers the molten metal thus preventing spatter and sparks as well as suppressing the intense ultraviolet radiation and fumes that are a part of the submerged arc welding process.

Top impacting factors: Market Scenario Analysis, Trends, Drivers, Opportunities, Restraints and Impact Analysis

Rise in adoption of submerged arc welding in the construction and automotive industries is expected to fuel the demand for submerged arc welding in the next few years. Rise in adoption of lean manufacturing practices to save time, labor, and human effort is a major factor anticipated to boost the growth of the global submerged arc welding market in the near future. Increase in shift from traditional engineering operations to advanced automated techniques boosts market growth. One restraining factor for the global submerged arc welding market is the growing popularity of laser welding technology. Laser welding is used in components that need to be manufactured using welding with minimal thermal distortion and at a fast rate. The opportunity for growth of the global submerged arc welding process comes from the increasing popularity and demand of electronic vehicles in the automotive industry.

The global submerged arc welding market trends are as follows:

Surge in large scale construction projects

With the rising construction activities across the globe, the use of structural steel has considerably increased in the recent years. Public infrastructure expansion and maintenance continue to grow. Private real estate development and individual residential construction are also going to continue growing as population and urbanization increases around the world. Schools, hospitals and other public interest facilities need to be built, expanded or updated. These myriad projects of varying scale and size will continue to aid the global submerged arc welding market as welding operations go hand in hand with such infrastructure growth. The implementation of this device in the system would optimize performance as it will increase the efficiency of the workers and increase precision and finishing quality. The overall bill of materials cost and total cost of solutions will also be lowered as these easy to use precision tools will help in less wastage of materials and time. This proves crucial in construction applications because, in these applications, precise and high-quality engineering is of paramount importance to the overall finish, look and usability of the end product.

Growth in global automotive industry to help the market grow

With the growth in the automotive industry worldwide, the demand for submerged arc welding machines is expected to go up as arc welding is a key operation in manufacturing vehicles. The auto sector in the emerging nations with increasing disposable income for the middle classes are forecast to grow at a much faster pace as consumers with higher disposable incomes will stimulate demand for motor vehicles. The implementation of submerged arc welding in the global automotive sector is wide and is vital to sheet metal work, fabrication, and other related operations. Submerged arc welding will continue to grow in popularity as the auto sector continues to flourish. With the advent and growing popularity of electronic vehicles in the global market, the global submerged arc welding market is expected to grow further in the future.

Full Report With TOC:-https://www.alliedmarketresearch.com/submerged-arc-welding-market-A09739

0 notes

Text

True Power Earthings is the most trusted Earthing Equipment Manufacturer in Delhi. We offer a wide range of Earthing Equipments that can make your premises shockproof and safer.

True Power Earthings is an Earthing Equipments provider company and Earthing Equipment Supplier in Delhi offer affordable, efficient, and premium Earthing Solutions. Our every product are designed and manufactured to fulfill every need of our client which they want in an Earthing product.

We deliver our products with immense care and safety. Get premium and durable Earthing Equipment in True Power Earthings . Our client’s satisfaction is our Top Priority and we are committed to delivering the best products to our clients.

Being the largest Earthing Equipment Exporter in Delhi, we have a responsibility to give our clients only the beneficial Earthing product that they needed. Our products are always in high demand due to their rich material and long shelf life.

If you have any queries about products or orders, feel free to call us. Our Call Executives are available 24/7 to assist you.

Contact us:

Call us: 8318455691

Email us: [email protected]

Address: D 242, Sector 63 Rd, D Block, Sector 63, Noida, Uttar Pradesh 201301

For more information visit: https://www.truepowergroup.in/earthing-electrode.html

#earthing equipment#Earthing Accessory#Earthing Electrode#Maintenance Free Earthing Electrode#Copper Bonded Earthing Electrode#Copper Bonded Electrode#Pure Copper Earthing Electrode#Copper Earthing Electrode#GI Earthing Electrode#Galvanized Iron Earthing Electrode#Gel Safe Earthing Electrode#Maintenance Free Earthing#Maintenance Free Chemical Earthing Electrode#Maintenance Free Electrode Earthing#Gel Earthing Rod#Chemical Earthing#Alloy Electrode#Oil Industry Alloy Electrode#Lightning Arresters#ESE Lightning Arrester#Lightning Protection System#Copper Lightning Arrester#Surge Arresters#Earthing Pit Cover#Polyplastic Earth Pit Cover#FRP Earth Pit Cover#Earth Pit#FRP Earth Pit Chamber#Copper Electrode#Earthing Equipment & Accessories

0 notes

Text

High-density tungsten alloy information summary

Tungsten heavy alloy is based on tungsten, with a small amount of Ni, Co, Mo and other elements added to it. It is a typical two-phase alloy and is also called "high-density alloy". According to different product uses and working environment requirements, the tungsten content of high-density tungsten alloy products is usually distributed in 79%W~97%W, and the density range is 15.00g/cm~18.50g/cm. At the same time, some rare metal elements (Co, Mo, Cr, etc.) can be added to improve some product properties, such as: hardness, ultimate tensile strength, yield strength, elongation, etc.

The most commonly used are: W-Ni-Cu and W-Ni-Fe two series. This material has remarkable characteristics in physical properties such as density, strength, hardness, ductility, conductivity/thermal properties, etc., so it is widely used in defense industry, aerospace industry, medical industry, electrical industry and other industries

Performance

High-density tungsten alloy is a kind of alloy with tungsten as the matrix (W content 85-99%) and added with elements such as Ni, Cu, Co, Mo, Cr, etc.

According to the composition characteristics and uses of the alloy, it is divided into main series such as W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu, W-Ag, etc. Its density is as high as 16.5-19.0g/cm3, and it is called high-density alloy by the world.

It also has a series of excellent properties, high specific gravity: generally 16.5-18.75g/cm3, high strength: tensile strength is 700-1000Mpa, strong radiation absorption ability: 30-40% higher than lead, high thermal conductivity: 5 times that of mold steel; small thermal expansion coefficient: only 1/2-1/3 of iron or steel, good electrical conductivity; good weldability and processability. In view of the above excellent functions of high specific gravity alloy, it is widely used in aerospace, aviation, military, oil drilling, electrical instruments, medicine and other industries.

Process flow

1. Mixing: tungsten powder, nickel powder, iron powder (if the product has magnetic requirements, copper powder can be added instead of iron powder and mixed evenly)

2. Mixing → vacuum drying → pressing and molding → pre-burning and degreasing → processing and molding → vacuum sintering → quality inspection → rough product → subsequent processing (oil immersion, machining, heat treatment, electroplating, rolling, forging, etc.) → fine grinding product → product delivery

Main products

1. Tungsten alloy fishing sinker series: bullet type, teardrop type, round tube type, semi-teardrop type, cylindrical hole type.

2. Tungsten beads, tungsten ball series: φ1.5mm -φ10mm accuracy ±0.01mm, used for fish sinker counterweights, submunitions, medical instrument counterweights, shotgun pellets; φ0.1mm-φ10mm accuracy ±0.1mm, used for oil drilling balance, shotgun pellets.

3. High-density tungsten-based alloy counterweight series: Mechanical counterweights; Flyweights; Oil drilling counterweights; Darts; Golf counterweights; Racing counterweights; Mobile phone and game console vibrators; Aerospace gyroscopes; Clock pendulums; Balanced counterweights; Anti-vibration knife bars.

4. Medical tungsten alloy radiation shielding material series:

(1) Tungsten alloy grating blades;

(2) Tungsten alloy protective tanks - used for medical radioactive shielding walls; Shielded needle tubes - used for medical radioactive liquid shielding; Tungsten alloy storage - used for cans, boxes and other containers for storing radioactive materials.

(3) Collimators - used for tungsten alloy series detection container systems in medical linear accelerators and nuclear technology applications; Co60 and other radiation shielding.

5. Electrical materials series: Electrodes for EDM and resistance welding; High-density electrical contacts, contacts in air circuit breakers.

6. Military series: armor-piercing projectiles; cluster bullets, balls, rods, square pellets, cylinders, other tungsten alloy electric upsetting blocks, tungsten alloys in nuclear technology applications.

0 notes

Text

Incoloy Pipe Welding Techniques - Tips and Tricks for Success

Pipe welding is an intricate process requiring expertise and accuracy. Any errors could cause leakages or damage to the payload.

Pipes used in industries from oil and gas to food and beverage must be welded correctly to guarantee reliability. Here are a few tips and tricks that welders can use to increase their success rates.

What is Incoloy Pipe?

Incoloy pipe is a nickel-chromium alloy with additional elements such as copper, iron and molybdenum. This age-hardenable superalloy boasts exceptional strength and corrosion resistance.

Its superior heat-treatment properties make it popular in industrial applications. Furthermore, this versatile material can be easily welded, forged and machined without fear of failure.

This alloy is ideal for oxidizing and reducing environments, making it suitable for dissolving residues from nuclear fuel elements in power plants due to its high nickel content, which increases corrosion resistance.

However, Incoloy isn't the only nickel-chromium superalloy available. Other outstanding superalloys include Inconel and Hastelloy.

The great thing about nickel-chromium superalloys is that they can be produced using the same processes and machines used for stainless steel pipes. Furthermore, these alloys come in various sizes and thicknesses to meet your requirements.

Citizen Metals offers an extensive selection of Incoloy 825 pipe fittings, stub ends, bends and other similar products. Contact us to request a quote for your project; our knowledgeable staff will assist in selecting the ideal product to meet your needs. Our commitment to customer satisfaction and positive ROI guarantees you an excellent experience when working with us.

Different Welding Methods

Pipe welding is an integral step in any construction project, and the pipes must be welded correctly. Improper welds can lead to leaks, which could result in severe property damage. Thus, understanding different welding techniques and how they can help you achieve superior results is paramount.

Metals of various properties or compositions may prove challenging to weld together, necessitating changes to the welding technique or filler metal used in the pipe.

For instance, if you're working on a project involving high-strength pipes, you must select a different filler metal than what would be appropriate for regular steel pipes. Choosing the suitable filler metal will help ensure your weld is strong and defects-free.

Some pipe welders prefer using specific techniques and procedures to guarantee their welds are as clean and perfect as possible. Utilizing the correct methods is essential for producing top-notch welds and saves you time on your job.

The three primary welding methods are arc welding, resistance welding and gas tungsten arc welding (GTAW). Arc welding uses a non-consumable tungsten filler to generate an electrically charged arc between an electrode and the joined metal. This process is most popular among nonferrous materials like aluminium and copper.

Tips and Tricks

Pipe welding is an intricate and precise process requiring great skill, care, and precision. While it plays a significant role in producing metal pipes, it also presents one of the most challenging challenges a welder must tackle since even one mistake can significantly diminish a pipe's quality.

The initial step in pipeline welding is to prepare the surface. This means eliminating all moisture, rust, scale, primer, oil or other materials which could interfere with welding operations.

After this, the pipeline is welded with a gas shielding gas and uses appropriate equipment. This process is repeated until the pipe's circumference has been covered.

Multipass welding is often employed. This method offers more control than manual equipment and allows for better-quality results.

Additionally, the multipass technique reduces the potential risks from pipes with any defects that could be hazardous. For instance, it prevents blowholes and craters.

Another common defect encountered during pipeline welding is cracking. This occurs when the weld is exposed to excessive internal stress that exceeds the strength of its base metal and weld metal components.

Conclusion

In conclusion, proper welding techniques are essential to ensure the durability and reliability of industrial pipes, particularly those made of nickel-chromium superalloys such as Incoloy. Welders must select the appropriate welding method and filler metal depending on the composition of the pipe to achieve optimal results. Preparing the surface and utilising multipass welding techniques can also prevent defects such as blowholes, craters, and cracking. At Citizen Metals, we offer an extensive selection of Incoloy and similar products to meet your project needs. With our commitment to customer satisfaction, you can trust us to deliver high-quality products and exceptional service.

0 notes

Text

E8018-B2: The Essential Welding Electrode for High-Temperature Applications

When it comes to welding in high-temperature environments, choosing the right electrode is crucial to ensure both the quality and durability of your welds. One of the most trusted and effective options in these demanding conditions is the E8018-B2 welding electrode. Known for its exceptional performance with low-alloy steels, particularly in environments subject to high temperatures, E8018-B2 is a go-to choice for critical industrial applications such as power plants, refineries, and chemical processing facilities.

In this blog, we’ll explore what makes E8018-B2 an indispensable electrode for high-temperature welding applications, highlighting its key properties, benefits, and ideal use cases.

E8018-B2 welding electrode

What is E8018-B2?

The E8018-B2 electrode is a low-hydrogen, iron powder electrode designed for welding 1.25% Chromium and 0.5% Molybdenum steels. These materials are commonly used in environments where high temperature and pressure are a constant, such as boiler tubes, pressure vessels, and piping systems. The unique composition of this electrode allows it to provide excellent resistance to heat, corrosion, and oxidation, making it highly suitable for applications where temperature fluctuates or remains elevated.

Key Properties of E8018-B2

High Tensile Strength E8018-B2 offers a tensile strength of 80,000 psi, making it an ideal choice for welding high-stress joints that need to withstand significant loads, especially under high temperatures.

Low Hydrogen Content This low-hydrogen electrode reduces the risk of hydrogen-induced cracking, which is particularly important when welding steels prone to embrittlement under high heat.

Heat Resistance The electrode is specifically designed to perform in environments where the material is subjected to high thermal cycles, ensuring the weld remains intact and durable over time.

Excellent Crack Resistance Due to its low hydrogen levels and robust metallurgical properties, E8018-B2 provides excellent resistance to cracking, even in thick-walled structures and high-temperature applications.

Versatility E8018-B2 can be used for both out-of-position welding and flat-position welding, providing flexibility in various industrial and field conditions.

Welding electrode manufacturer

Benefits of Using E8018-B2

Durability in Harsh Environments E8018-B2’s excellent resistance to heat and pressure makes it the electrode of choice for industries where welds are exposed to intense conditions. This includes not only high temperatures but also corrosive environments often found in chemical and petrochemical plants.

High-Quality Welds With its low-hydrogen content and high tensile strength, E8018-B2 delivers superior weld quality, reducing the risk of defects that could compromise the integrity of the welded structure.

Consistency and Reliability One of the standout benefits of E8018-B2 is its ability to produce consistent, high-quality welds in challenging environments, minimizing the risk of failure in critical joints over time.

Applications of E8018-B2 in High-Temperature Industries

Given its properties, E8018-B2 is frequently used in a wide range of industries that require reliable performance in high-temperature environments:

Power Generation E8018-B2 is ideal for welding boiler tubes and heat exchangers in power plants, where materials must endure extreme thermal cycles.

Petrochemical and Chemical Processing In refineries and chemical processing plants, E8018-B2 is used to weld pipelines and pressure vessels, providing the necessary strength and heat resistance to withstand corrosive substances and high pressure.

Oil and Gas The electrode's ability to resist cracking and embrittlement under high temperatures makes it a prime choice for welding components in the oil and gas industry, including pipelines and storage tanks.

Best Welding Electrode Manufacturers

Conclusion

When working in high-temperature environments, selecting the right welding electrode can make all the difference in the durability and integrity of your welds. E8018-B2 stands out as an essential electrode for welding low-alloy steels in challenging applications, offering excellent heat resistance, high tensile strength, and superior protection against cracking.

Whether you're involved in power generation, petrochemical processing, or any industry requiring robust welds in extreme conditions, E8018-B2 provides the reliability and performance needed to get the job done right.

#weldingelectrodemanufacturer#bestweldingelectrodemanufacturer#weldingrodmanufacturer#weldingconsumablemanufacturer

0 notes

Text

Top 10 Uses of Nickel Alloy 201 Perforated Sheets

Nickel Alloy 201 Perforated Sheets are metal sheets made from Nickel Alloy 201, a commercially pure nickel alloy known for its high corrosion resistance and excellent mechanical properties. These sheets feature a pattern of evenly spaced holes, allowing for the passage of fluids, gases, or light while providing structural strength.

Nickel Alloy 201 Perforated Sheets are commonly used in various industries such as chemical processing, automotive, architecture, and filtration systems. They offer superior resistance to corrosion, durability, customization options, and contribute to efficient processes in applications requiring filtration, sound absorption, or fluid flow control.

Nickel Alloy 201 perforated sheets hold significant importance due to their unique properties and versatile applications. Their corrosion resistance ensures reliable performance in harsh and corrosive environments. With their strength and durability, they provide long-lasting functionality, reducing maintenance and replacement costs.

10 Uses of Nickel Alloy 201 perforated sheets

Filtration Systems: Nickel Alloy 201 perforated sheets are commonly used as filter screens or elements in various filtration systems. They allow for the passage of fluids or gases while retaining solid particles or contaminants.

Architectural Applications: Perforated sheets made from Nickel Alloy 201 can be used in architectural designs, such as decorative panels, building facades, sunshades, or interior partitions, to add an aesthetic appeal and provide ventilation.

Acoustic Panels: Nickel Alloy 201 perforated sheets are used in the construction of acoustic panels or soundproofing systems. The perforations help in absorbing or diffusing sound waves, reducing noise levels in buildings or industrial spaces.

Automotive Industry: Nickel Alloy 201 perforated sheets find applications in the automotive industry, particularly in the manufacturing of exhaust systems, mufflers, or heat shields. The perforations allow for better airflow and heat dissipation.

Battery Components: Perforated sheets made from Nickel Alloy 201 can be used as electrode substrates or current collectors in batteries. The perforations help in the efficient flow of electrolytes and improve overall battery performance.

Chemical Processing: Nickel Alloy 201 perforated sheets are suitable for applications in the chemical processing industry. They can be used as catalyst supports, sieve plates, or reactor internals due to their corrosion resistance and high temperature tolerance.

Food Processing: Perforated sheets made from Nickel Alloy 201 are utilized in the food processing industry for applications such as drying or dehydrating trays, sieves, or screens, where corrosion resistance and hygienic properties are essential.

Petrochemical Industry: Nickel Alloy 201 perforated sheets find use in the petrochemical industry for applications such as oil and gas separators, well screens, or filtration elements, where resistance to corrosive environments and high temperatures is crucial.

Marine and Offshore Applications: Perforated sheets made from Nickel Alloy 201 are suitable for marine and offshore applications due to their resistance to seawater, salt spray, and harsh environmental conditions. They can be used as screens, grates, or covers in marine equipment or offshore structures.

Industrial Equipment: Nickel Alloy 201 perforated sheets have numerous applications in various industrial equipment, such as vibrating screens, sieves, or centrifuges, where particle separation or filtration is required.

0 notes

Text

The Nature of Steel Fabrication Company in Singapore

Steel is one of the essential building blocks of the fashionable world. Automobiles, appliances, bridges, oil pipelines, and buildings, all area unit created with steel. While steel fabrication has existed for centuries, the process of making steel in Steel Fabrication Company Singapore continues to evolve.

Goods and services:

Establishments during this trade manufacture steel by melting ore, scrap metal, and other additives in furnaces. The molten metal output is then solidified into semi-finished shapes before it is rolled, drawn, cast, and extruded to make the sheet, rod, bar, tubing, beams, and wire. Other establishments by Structural Steel Supplier in Singapore makes finished steel products directly from purchased steel. The least expensive technique of constructing steel uses trash as its base. Steel scrap from several sources—such as previous bridges, household appliances, and automobiles—and other additives are placed in an electric arc furnace, where the intense heat produced by carbon electrodes and chemical reactions melt the scrap, converting it into molten steel.

Establishments that use this technique of manufacturing steel area unit referred to as spark chamber (EAF) mills or mini-mills. While EAFs area unit is typically tiny, some are large enough to produce 400 tons of steel at a time. The growth of EAFs has been driven by the technology's smaller initial capital investment and lower operation prices.

Moreover, trash is found all told components of the country, therefore EAFs don't seem to be tied as closely to material deposits as area unit integrated mills and therefore will be placed closer to customers. ETFs now account for well over half of American steel production and their share is expected to continue to grow in the coming years as they move to produce higher-end merchandise by adding virgin ore to the combo of steel scrap and alternative additives.

The growth of EAFs comes partly at the expense of integrated mills. Integrated mills scale back ore to liquefied iron in blast furnaces. The iron is then sent to Associate in nursing atomic number 8 chamber, wherever it's combined with scrap to form liquefied steel. The steel made by Structural Steel Supplier in Singapore typically is taken into account to be of upper quality than steel from EAFs.

The higher quality production method is a lot of sophisticated and consumes a lot of energy, creating it a lot of expensive.

Industry organization. The Steel Fabrication Company in Singapore consists of EAFs and integrated mills that produce iron and steel from scrap or iron ore. Most of those mills even have finishing mills on-the-spot that convert iron and steel into each finished and unfinished merchandise. Some of the products made in finishing mills area unit steel wire, pipe, bars, rods, and sheets. In these finishing mills, products also may be coated with chemicals, paints, or other metals that give the steel desired characteristics for various industries and consumers.

While wire, steel reinforcing bars, and pipes are considered finished products, rolled steel is unfinished, meaning it is normally shipped to companies, such as automotive plants, that stamp, shape, and machine the rolled steel into car parts. The finished merchandise is also factory-made by alternative corporations during this trade that creates pipe and conduit, plate, strip, rod, bar, and wire from purchased steel. Competition from these mills has resulted in increasing specialization of production, as varied mills conceive to capture totally different niches within the market.

Also enclosed within the steel-producing trade area unit corporations that manufacture alloys by adding materials like semiconducting material and metallic element to the steel. Varying the amounts of carbon and alternative parts contained within the final product will yield thousands of various varieties of steel, every with specific properties fitted to a selected use. Recent developments. Steel Fabrication Company is an intensely competitive global industry. By continually improving its manufacturing processes and consolidating businesses, the U.S.

The steel industry has magnified productivity sufficiently to stay competitive within the world marketplace for steel. Investment in fashionable instrumentality and employee coaching reworked the trade. Over the past 25-30 years, Structural Steel Supplier Singapore has, in some cases, reducing the number of work-hours required to produce a ton of steel by 90 percent.

To achieve these productivity enhancements still as product enhancements, steel mills employ some of the most sophisticated technology available. Computers are essential to several of those advancements, from production scheduling and machine control to metallurgical analysis. For staff, modernization of integrated, EAF, and finishing mills often has meant learning new skills to operate sophisticated equipment.

As countries around the world conceive to scale back emissions and manufacture cleaner energy, the need for structural steel will increase. Steel will be needed for support towers as well as reinforcing rebar toward the construction of new power generation facilities. In addition, the transmission infrastructure needed to transport electricity also will result in greater demand for steel. The enlargement of fresh energy production is predicted to lead to demand for several varieties of steel merchandise.

1 note

·

View note