#Copper Bonded Electrode

Explore tagged Tumblr posts

Text

Earthing Solutions, Earthing Electrodes, GI Earthing Electrodes, Chemical Earthing Rod, Pune, India

We Are The Pune Based ISO Certified Chemical Earthing Manufacturer and Supplier of Earthing Solutions, Earthing Electrodes, GI Earthing Electrodes, Chemical Earthing Rod, Pune, India.

#Earthing Solutions#Earthing Systems#Earthing Electrodes#GI Earthing Electrodes#Chemical Earthing Rod#Copper Earthing Rod#Pure Copper Earthing Electrodes#Copper Bonded Electrode#Copper Bonded Earthing Electrodes#Backfill Compound#Earthing Pit Cover#ESE Lightning Arrester#Conventional Lightning Arresters#Copper Bonded Solid Rod With Baseplate#GI Earthing Strips#Turnkey EPC Projects#Earth Pit Testing#Soil Resistivity Test#Earthing Resistance Test#All Range Of Gi Strip#Lightning Arrestor#Chemical Earthing#Maintenance Free Earthing#Copper Terminal Earthing Electrodes#Turnkey Earthing Solution#Pune#Maharashtra#India

0 notes

Text

True Power Earthing is a leading Lightning Arresters manufacturer in Noida India. There are several distinct types of lightning arresters. The architecture of lightning arrestors varies depending on the type, but the principle of operation remains the same. It provides a low-resistance channel for surges traveling toward the ground. The major purpose of this arrester is to keep the apparatus safe from the elements. Rod, sphere, horn, multi gap, electrolyte, and metal oxide are examples of lightning arresters. It is known as the Conventional Lightning Arrester, ESE Lightning Arrester, Lightning Protection System, Copper Lightning Arrester

Contact us:

Call us: 8318455691

Email us:[email protected]

Address: D 242, Sector 63 Rd, D Block, Sector 63, Noida, Uttar Pradesh 201301

For more information visit: https://www.truepowergroup.in/true-power-noida.html

True Power Earthings Private Limited

#lightning arrester#lightning arrester for home#lightning arrester price#lightning arrester types#lightning rod price#zinc oxide lightning arrester#lightning arrester for building price#earthing arrester#lightning resistor#lightning arrester for house#multi gap arrester#lightning arrester types for building#copper bonded electrode#pure copper earthing electrode#chemical earthing#earth pit cover#ese lightning arrester#electrode#copper earthing electrode#earthing#earthing products

0 notes

Text

Everything You Need to Know About Copper Bonded Earthing Rods

Before we come to the main core of this article which is copper bonded earthing rod price, specification, manufacturers, etc are you aware of the earthing process? Well, we know that somehow once in your lifetime you must have encountered the issue of getting an electric shock. So before we commence with copper-bonded earth rods it is better to understand what actually the term earthing means so that the base is cleared first.

Earthing is a process in which with the help of low-resistance wire immediate electrical energy chargers are transferred to the earth. When the chargers are distributed equally with the earth or soil then it is called earthing. It helps to avoid any current leakage and makes sure that there is no damage to your electrical appliances. For secure safety and enabling no harm to the people or electrical devices earthing is done by earthing systems such as the copper-bonded earthing rod.

Copper Bonded Earthing Rods Explained - Hope you understood what earthing is so that eventually it will be easy for you to comprehend Copper Bonded Earthing Rods. It is always advisable to clear the basics before you jump onto the main topic as it makes your understanding process easy. Now you must be thinking what are Copper Bonded Earthing Rods?

What is a Copper Bonded Earth Rod and How Does it Work? Copper Bonded Earth Rods sets the earthing system at its best in overhead, underground electricity distribution, and transmission networks. With the help of copper-bonded earth systems, there is a provision of ground contact in soil conditions such as high voltage towers, power distributions, and channels. They suffice you with the best quality standards with many international utilities approved by them.

They have a low-carbon steel core and are constructed with 99.9% pure electrolytic copper. These rods are typically used in high salt and high resistivity soil conditions because they have greater mechanical tensile strength and corrosion resistance than solid copper or stainless-steel rods.

Now you must be thinking about copper-bonded earth rod specification, what is the copper-bonded earth rod manufacturing process or copper-bonded earth rod hs code, or else the copper-bonded earthing rod price? So to answer these questions we have given you each and every detail that might help you to understand and make the perfect choice for your electrical appliances.

Features of Copper Bonded Earth Rod: The Copper Bonded Earth Rods and resistance to corrosion are improved by copper bonding. The copper and steel core are molecularly bonded for a very long time thanks to the electroplating process. It is not damaged even when the electrode is driven deeply into the harsh ground, making installation simpler.

To increase conductivity and, consequently, fault current excess, earthing electrodes are specifically created and copper bonded. Its lifetime also increases significantly as a result of the increased corrosion resistance, and it is now suitable for all types of soil.

Rods are designed to be used in all types of soils and are ideal for places like substations and factories, which require efficient fault current excess. For more information check out our website.

Benefits of Using a Copper Bonded Earth Rod for Earthing Systems: Now specifically talking about the benefits of rod in comparison to that of the galvanized rod. So that you can differentiate it for better usage and make the right choice.

Conductivity: Copper Bonded Earth Rods have better conductivity power as compared to that of galvanized iron which serves the least conductivity. Corrosion Resistant: Galvanised Iron has a lead component present in it which invites corrosion that is not so good for corrosion resistance. While copper-bonded earth rods act as pure copper which is corrosion-resistant.

Steel Strength: On the other hand, the copper-bonded rod maintains the high strength of steel even more than pure copper because it is the formation of an electrolytic process in which copper and high-tensile steel construct a powerful copper-bonded rod. Galvanized steel automatically triggers dezincification during the mixed components with yellow brass. Installation: The underground installation of GI rods is quite exhausting as it should never be used without covering which means it requires proper coverage near the rod during an installation. In the case of copper-bonded earth rods, it has high mechanical strength that eases the installation process.

Cost-Effective: Although the price of the copper bonded earthing rod is a bit more expensive than the galvanized rod, the repairing charges of the galvanized rod can cost you higher in the upcoming time. So instead of buying a thing that is cheap now but can cost you later, it is better to choose the product that will be your one-time investment with no regret.

Lifespan: As per the research conducted by the National Electrical Grounding Research Project the lifespan of copper-bonded earth rods is more than 40 years while that of Galvanised rods can only reach 8-10 years maximum. By concluding all the characteristics you can completely understand how significant Copper Bonded Earth Rod is to Galvanised rod. It is evident from the facts which are more beneficial than the rest. Also, the copper-bonded rod is destined to be the best as per many standards globally. It complies with IEEE 80, UL 467, and IS 3043 standards which determine its quality and makes it unique.

1 note

·

View note

Text

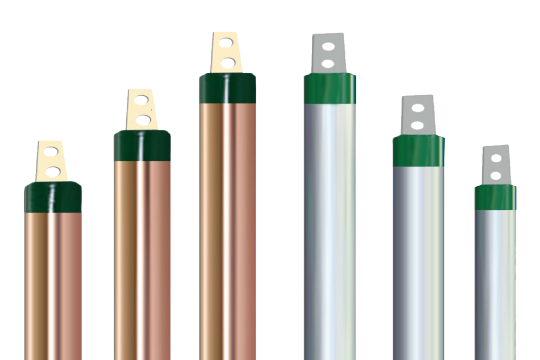

Top Quality Pure Copper Bonded Electrode

Veraizen Earthing is one of the top leading Pure Copper Bonded Electrode Suppliers and Manufacturers in India.Our prestigious clients have access to a variety of solutions for Copper Earthing Electrode. Pure Copper Earthing Electrode is frequently used in a wide range of products. Veraizen Earthing is one of the top producers and suppliers of Copper Bonded Electrode in India.

Veraizen Earthing is the most reputed manufacturer and supplier of Copper Earthing Electrode in India. We are a leading provider and manufacturer of Earthing Electrodes in India. We modify this product to satisfy the requirements of our customers.

With increased oxidation resistance and a longer product life than regular GI Earthing Electrodes, Copper Bonded Electrode is a highly developed product based on global technology.

For more

Website: veraizenearthing.com

For more details visit: https://veraizenearthing.com/copper-bonded-electrode.php

You may also like: Copper Plates , lightning arrester

#Pure Copper Earthing Electrode#Pure Copper Earthing Electrode Suppliers#Copper Earthing Electrode#Copper Bonded Electrode#lightning arrester#GI Earthing Electrodes

0 notes

Text

#Earthing contractors in India#copper bonded earthing electrode dealer#Pit cover in Lucknow#Earthing clamp Lucknow

0 notes

Text

"Renown Power Trusted Experts in Earthing & Lightning Protection Systems"

Renown Power offers a range of high-quality earthing products and lightning protection solutions. With a focus on safety and reliability, we ensure that our copper-bonded, GI, and chemical earthing systems protect your property and equipment from electrical faults.

For more info : www.renownpower.com

#Electrical Safety#Earthing Systems#Chemical Earthing#Lightning Protection#Copper-Bonded Electrodes#Industrial Earthing Systems#Lightning Arresters#Earthing Electrodes

0 notes

Text

0 notes

Text

Copper Bonded Earthing Electrode Manufacturers In Hyderabad

The Role of Copper Bonded Earthing Electrode Manufacturers in Hyderabad

Hyderabad has emerged as a hub for industrial innovation, including electrical and earthing solutions. The Copper Bonded Earthing Electrode manufacturers in Hyderabad are known for their cutting-edge technology and adherence to international standards. They provide customized earthing solutions tailored to the unique requirements of their customers.

These manufacturers ensure that their products undergo rigorous quality testing, ensuring long-term performance even in challenging environments. Their focus on customer satisfaction and technical expertise has made them leaders in the earthing industry.

#Copper Bonded Earthing Electrode Manufacturers in Hyderabad#Copper Bonded Electrode Manufacturers in Hyderabad#Copper Bonded Earth Rod Manufacturers in Hyderabad#Copper Bonded Electrodes Manufacturers in Hyderabad#Copper Bonded Earthing Rod Manufacturers in Hyderabad#Copper Bonded Chemical Electrode Manufacturers in Hyderabad#Copper Bonded Earthing Electrode Suppliers in Hyderabad#Copper Bonded Electrode Suppliers in Hyderabad#Copper Bonded Earth Rod Suppliers in Hyderabad#Copper Bonded Electrodes Suppliers in Hyderabad#Copper Bonded Earthing Rod Suppliers in Hyderabad#Copper Bonded Chemical Electrode Suppliers in Hyderabad

1 note

·

View note

Text

Pure Copper Earthing Electrode | Copper Bonded Threaded Electrode | GI Pipe In Strip | Verazien Earthing

Veraizen Earthing is the largest copper earthing electrode manufacturer in India. Copper Earthing Electrodes are also constructed from Hot Dip Galvanized Pipes, with a copper termination and 20 mm copper inside.

Pure Copper Earthing Electrode - https://veraizenearthing.com/pure-copper-earthing-electrode.php

Copper Bonded Threaded Electrode - https://veraizenearthing.com/copper-bonded-threaded-electrode.php

GI Pipe In Strip - https://veraizenearthing.com/gi-pipe-in-strip.php

0 notes

Text

Best Lightning Arrester in Coimbatore

Protect your assets with the best lightning arrester solutions from Rig Earthing Solutions in Coimbatore. Our lightning arresters safeguard your structures from lightning strikes, reducing damage risks. We offer a variety of arresters to meet different protection needs. Trust our expertise for top-notch lightning protection.

Visit https://www.rigearthing.com/ or call us at 8072400392 for more information on our lightning arresters.

#gi chemical earthing electrode#copper chemical earthing#ese lightning arrester#copper bonded earthing electrode#maintenance free chemical earthing#chemical earthing manufacturer in coimbatore

0 notes

Text

Best Chemical Earthing & Lightning Arresters in Noida are provided by True Power under one roof including all World Class Earthing Electrodes and Earthing Accessories.

True Power, an RDSO/CPRI Approved, UL Listed, and NABL accredited Earthing Electrodes, Earthing Accessories, Back Fill Compounds, Polyplastic Earth Pit Covers, Lightning arresters, and Lightning Protection Systems Welcomes You!

Our Maintenance Free Earthing Electrodes, including Pure Copper Earthing Electrodes, Copper Earthing Electrodes, Copper Bonded Earthing Electrodes, GI Earthing Electrodes are the best in the industry."

Contact us: Call us: 8318455691 Email us:[email protected] Address: D 242, Sector 63 Rd, D Block, Sector 63, Noida, Uttar Pradesh 201301 For more information visit: https://www.truepowergroup.in/true-power-noida.html True Power Earthings Private Limited

#Earthing#Copper Earthing#Earthing Electrode#True Power Earthing#Copper Earthing Electrode#Copper Earthing Electrode Manufacturer#Copper#Electrode#True Power#Earthing products#chemical earthing#electrode manufacturer#copper bonded electrode#copper bonded rods#pure copper earthing electrode#gi chemical electrode#manufacturers and suppliers#earth electrode#Earth pit cover#backfill compound#lightning arrester#gi earthing strips#surge arrester#earthing products#installation of earthing products#grounding accessories#copper terminal#inner strips#chemical compounds#chemical earthing price

0 notes

Text

How does earthing protect solar panels from electrical faults?

The main function of the earth bond is that it protects the solar panel system from out of proportion electrical currents and electrical faults. When there is a threat of an electrical fault, the earth bond quietly directs the electricity through the ground to the ground, thereby preventing any damage to the solar panels and its associated equipment. In addition, Earthing also helps in keeping the voltage of the solar panel system stable, thereby ensuring the correct functioning and continuity of the system.

Understanding Electrical Faults:

Before explaining how to protect solar panels from electrical faults, it is important to understand the nature of these faults. Electrical faults involve various abnormalities in the electrical current in a system. These faults can arise due to various factors, such as insulation breakdown, equipment not working, or external influences such as lightning strikes. Undetected, electrical faults pose significant risks, including fire, equipment damage, and even death by electrocution.

The Role of Earthing:

Earthing, also known as grounding, is a fundamental safety measure employed in electrical systems, including solar panel installations. At its core, earthing involves connecting the electrical system to the earth through conductive materials like copper rods or plates buried underground. This connection establishes a low-resistance path for fault currents to dissipate harmlessly into the ground, thereby preventing the buildup of dangerous voltages.

Best Practices in Earthing for Solar Panel Installations:

To harness the full protective potential of earthing, solar panel installers must adhere to best practices in system design and installation. Some key considerations include:

Proper Selection of Earthing Electrodes: Choose high-quality copper or galvanized steel electrodes with adequate corrosion resistance and conductivity for long-term reliability.

Adequate Grounding System Design: Design the grounding system to meet the specific requirements of the solar panel installation, considering factors such as soil resistivity, fault current levels, and site conditions.

Regular Inspection and Maintenance: Conduct routine inspections of the earthing system to ensure its integrity and effectiveness. Check for signs of corrosion, physical damage, or loose connections that could compromise performance.

Compliance with Standards and Regulations: Adhere to relevant industry standards and regulations governing earthing practices in solar panel installations, such as NEC (National Electrical Code) guidelines in the United States.

Integration of Surge Protection Devices: Install surge protection devices (SPDs) at critical points within the solar panel system to suppress transient over voltages and enhance overall protection against electrical faults.

Conclusion

In the ever-evolving landscape of renewable energy, the safety and reliability of solar panel installations are non-negotiable imperatives. Earthing emerges as a cornerstone of this safety framework, providing vital protection against electrical faults and ensuring the longevity of solar panel systems. By understanding the principles of earthing and adhering to best practices in its implementation, solar panel installers can fortify their installations against potential hazards and foster a sustainable energy future.

0 notes

Text

Type of GI Earthing Electrode.

Earthing electrodes are crucial components in grounding systems, designed to provide a low-resistance path for the dissipation of fault currents to the ground. There are several types of Grounding (GI) electrodes commonly used for earthing purposes:

GI Pipe Electrode:

A galvanized iron (GI) pipe can be used as an earthing electrode. It is typically buried vertically in the ground. The length and diameter of the GI pipe depend on the soil resistivity and the electrical system requirements.

GI Plate Electrode:

A GI plate is another common type of earthing electrode. It is usually buried horizontally in the ground. The size of the plate is determined based on soil resistivity and the specific requirements of the grounding system.

GI Strip Electrode:

Similar to the GI plate, a GI strip can be used as an earthing electrode. The strip is buried horizontally in the ground, and its dimensions are determined based on the grounding system requirements.

GI Electrode with Backfill Compound:

Some grounding electrodes are treated with special backfill compounds to enhance their conductivity and reduce soil resistivity. This helps in achieving lower resistance to earth.

Chemical Earthing Electrode:

In chemical earthing systems, a compound or mixture is used around the electrode to improve conductivity. This type of electrode is designed to maintain a low resistance value over time, even in high-resistivity soils.

Copper-Bonded Electrode:

While not made of pure GI, copper-bonded electrodes have a thin layer of copper bonded to a steel core. This combination provides the benefits of both copper and steel, offering good corrosion resistance and electrical conductivity.

Cast Iron Electrode:

Cast iron electrodes are less common but are used in some specific applications. They are durable and have good corrosion resistance.

The choice of the earthing electrode depends on various factors such as soil resistivity, space availability, local regulations, and the specific requirements of the electrical system. It's essential to consider these factors to ensure an effective and reliable grounding system. Consulting with a qualified electrical engineer or following local electrical codes and standards is recommended when designing and installing an earthing system.

#advanced gel earthing electrode#copper bonded earthing electrode#earthing electrode#earthing strip#galvanized iron#lighting arrester#earthing rod copper

0 notes

Text

#Copper bonded earth electrode#Earthing material supplier in India#Earthing clamps and couplers in India#Ese lightning protection system Lucknow#Conventional lightning arrester India

0 notes

Text

Renown Earth: India’s Leading Copper Bonded Rod Manufacturer

Renown Earth is a leading Indian manufacturer and supplier of high-quality Copper Bonded Rods, designed for superior conductivity, corrosion resistance, and durability. These rods, created through advanced electroplating techniques, are ideal for grounding and earthing systems, ensuring reliable performance across varying soil and environmental conditions. Known for their efficiency and low maintenance, Renown Earth's Copper Bonded Rods are trusted worldwide.

Visit More : renownpower.com

#Copper Bonded Rod#Earthing Solutions#Electrical Safety#Grounding Systems#Copper Bonded Electrodes#Industrial Earthing

0 notes

Text

The Power of Copper Bonded Earthing Electrode in Engineering Sectors

The primary function of a Copper-Bonded Earthing Electrode is to ensure the safe breakdown of electrical currents into the ground, preventing the accumulation of voltage that might threaten people, property, or machines. Copper is the preferred material for grounding systems due to its higher capacity for electricity, toughness, and anti-corrosion properties.

0 notes