#Oil Filtration System

Explore tagged Tumblr posts

Text

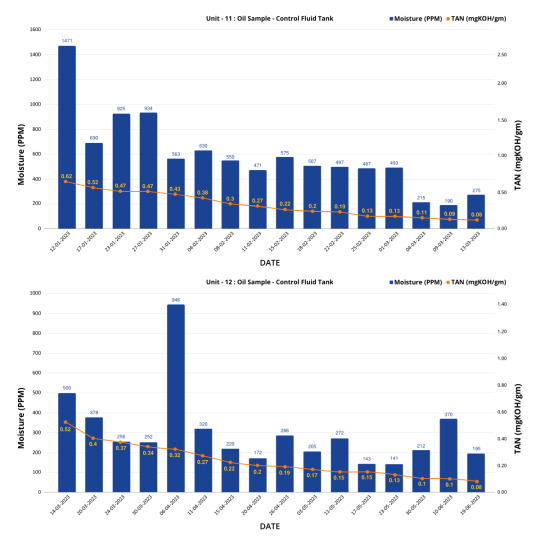

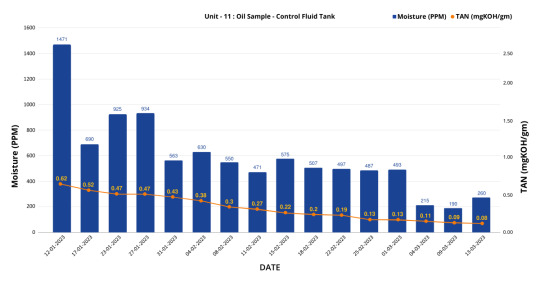

Effectively reducing the TAN Levels of 32kl of FRF Oil

Abating TAN Levels: Minimac's Tailored Solution for Critical Oil Values at India's 9th Largest Coal-Fired Power Plant

Synopsis

In Singrauli, MP, stands a colossal thermal power plant, one of the largest PSUs and the 9th largest coal-fired power station at 4760 MW capacity. Recently, it faced a formidable challenge - high TAN Levels in two 16kl control fluid tanks. To prevent a potential disruption and subsequent shutdown, Minimac provided a customized solution by deploying a specialized machine to lower TAN levels, address moisture, solid contamination and implement effective Nitrogen Blanketing.

Initial Findings

Problems

The client encountered increased TAN levels in two of their Control Fluid Tanks which had a detrimental impact on the operation of servo valves leading to reduced responsiveness, erratic behavior, increased wear and tear, and potential valve malfunction.

Client’s Requirements

To Purify 32kl of FRF Oil

To remove the TAN, Moisture and Solid Contaminants.

To Achieve NAS: ≤ Class 5.

To Achieve TAN: ≤ 0.10 (mg KOH/g).

To Achieve Moisture: ≤ 500 ppm.

Customized Solution.

Solutions

Deploying Minimac’s customized machine at the site along with trained and skilled engineers.

TAN Reduction Systems(20 LPM) equipped with the ion exchange resin to filter and eliminate acid components of oil.

Low Vacuum Dehydrator (100 LPM) to maintain consistent moisture levels in the oil using the vacuum dehydration ensuring smooth turbine operation in its active state.

Oil filtration system(150 LPM) to bring the NAS level of oil to the desired range.

Nitrogen blanketing system to maintain an inert space above the oil in the tank, serving as a barrier between the moisture-laden external air and the FRF oil inside the tank.

Along with the equipment’s installation, our Service Engineer trained the client’s team on the functioning and effective handling of the machine.

Job executed within a limited time-span on the running unit without hindering the client’s operations and control fluid tank system.

Value TypeControl Fluid Tank at UNIT 11Control Fluid Tank at UNIT 12BeforeAfterBeforeAfterNASClass 8Class 4Class 7Class 4TAN0.62 mg KOH/g0.08 mg KOH/g0.52 mg KOH/g0.08 mg KOH/gMoisture Level561PPM275 PPM500 PPM184 PPM

Benefits

Prevented the environment from harm by averting the emission of 3,84,000 kg of CO2e.

Saved 32 kl of Oil from being incinerated.

Extended Oil Life.

Reduced TAN Levels.

Elimination of Oil Replacement Costs.

Cost Saving

This Plant managed to save:

Cost of Oil Replacement: ₹7 Cr. Approx.

Cost of Downtime : ₹1 Cr. Approx.

CO2e Savings

Total Savings =3,84,000 kg of CO2e/0.384 gigagrams of CO2e

Graph

Pictorial Representation

Right to left( LVDH:100LPM, FS :150LPM, TAN Reduction Skid Ion Exchange :20LPM)

Resin Skid-TAN REDUCTION M/C (Ion Exchange 20 LPM)

Before and after oil sample

Know More About - https://www.minimacsystems.com/ Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#contamination#lube oil filter#hydraulic oil filter#chemical cleaning flushing#chemical cleaning#oil filteration#oil filters#oil industry#oil and gas#oil#oil analysis#power industry#steel#mining#metal#oil filtration system#oil filtration machine#oil filtration systems#oil dehydration systems#frf condition systems#frf machine#coalser separator#elc

0 notes

Text

Oil filter cap for N54 engines: high-quality replacement for optimal performance

The oil filter cap for N54 engines is a critical component designed to ensure your engine operates efficiently. Specifically engineered for the N54 engine, this cap provides a secure seal for the oil filter, preventing leaks and contamination of the engine oil. By using a durable and reliable oil filter cap, you can maintain the proper flow of oil through the engine, ensuring it runs smoothly and remains protected from debris and impurities. Regularly replacing the oil filter cap is essential for optimal engine performance and longevity, especially in high-performance engines like the N54.

0 notes

Text

Oil filtration systems

Optimizing Efficiency and Longevity: The Role of Oil Filtration Systems

In the realm of industrial machinery and automotive engines, oil filtration systems stand as unsung heroes, diligently safeguarding performance and durability. These systems play a critical role in maintaining the health of engines and equipment by effectively removing contaminants from lubricating oils. Let’s delve into the intricacies of oil filtration systems and their indispensable contributions.

Understanding Oil Filtration Systems:

Oil filtration systems are engineered to trap and remove particles, debris, and impurities that accumulate in lubricating oils during operation. These contaminants, if left unchecked, can cause abrasive wear, corrosion, and operational inefficiencies, ultimately leading to costly repairs and downtime.

Functionality and Components:

At the heart of an oil filtration system lies the filter element, designed with materials and structures tailored to capture particles of varying sizes. Modern systems often incorporate high-efficiency filters, magnetic separators, and centrifuges to ensure comprehensive purification of the oil. The filtration process may utilize depth filtration, surface filtration, or a combination of both methods to achieve optimal cleanliness levels.

Benefits of Effective Filtration:

The benefits of employing robust oil filtration systems are manifold. Firstly, they extend the lifespan of machinery and engines by minimizing wear on critical components such as bearings and pistons. Secondly, clean oil enhances operational efficiency by maintaining proper viscosity and thermal stability, thereby improving fuel economy and performance. Moreover, reduced contamination translates to lower maintenance costs and fewer unplanned shutdowns, contributing to overall operational reliability.

Applications Across Industries:

From heavy machinery in construction and mining to precision equipment in manufacturing and aerospace, oil filtration systems are indispensable across diverse industrial sectors. Automotive engines also rely heavily on oil filtration to ensure optimal performance and meet stringent emission standards.

Technological Advancements:

Advancements in filtration technology continue to drive improvements in efficiency and effectiveness. Innovations such as bypass filtration systems, electrostatic oil cleaners, and real-time monitoring sensors enhance the precision and reliability of oil purification processes, catering to the evolving needs of modern industrial applications.

Environmental and Economic Considerations:

Beyond operational benefits, effective oil filtration systems contribute to environmental sustainability by reducing waste oil disposal and minimizing the ecological footprint associated with manufacturing new oils. Economically, the upfront investment in quality filtration systems proves cost-effective in the long run, offering substantial returns through enhanced equipment longevity and performance.

Conclusion:

In conclusion, oil filtration systems are not mere accessories but essential components that safeguard the vitality of machinery and engines across industries. By investing in advanced filtration technologies and proactive maintenance practices, businesses can ensure prolonged equipment life, reduced downtime, and optimized operational efficiency. As industries continue to evolve, the role of oil filtration systems remains pivotal in shaping a sustainable and productive future.

In essence, these systems epitomize the adage that prevention is better than cure, preserving the heartbeats of mechanical giants and driving performance to new heights.

1 note

·

View note

Text

🚨🚨🚨New Blog 🚨🚨🚨

Oil Filtration Unit: A Comprehensive Guide

When it comes to maintaining the performance and longevity of machinery and equipment that rely on oil for lubrication, an oil filtration unit plays a vital role. In this article, we will delve into the world of oil filtration units, exploring what they are, the types of oil filtration systems, the part that holds the oil filter, and the process of filtrating oil.

#oil#oil filter#oil filtration#oil filtration unit#filtration unit#filtration system#oil filtration system

1 note

·

View note

Text

🏭 Best Turbine Oil Cleaning System & Oil Filtration Machines in India ⚙️

Looking for high-performance oil filtration solutions? 🌍 OilFilterMachineIndia.com is a trusted manufacturer and supplier of advanced oil filtration systems designed for industrial applications. From Turbine Oil Cleaning Systems to Transformer Oil Filtration Plants, we provide top-notch filtration solutions to enhance machinery efficiency and oil purity.

🔥 Our Premium Oil Filtration Solutions

We specialize in manufacturing, supplying, and exporting a wide range of oil cleaning machines and filtration systems to meet industrial needs.

🔹 Turbine Oil Cleaning System ⚙️ 🔹 Oil Cleaning Machines 🏗️ 🔹 Turbine Oil Cleaning Systems 🔥 🔹 Oil Filtration Plant 🛢️ 🔹 Gear Oil Filtration Systems ⚙️ 🔹 Industrial Oil Filter Machine 🛠️

🔹 Oil Filtration Systems 🏭 🔹 Double Stage Oil Transformer Machine 🚀 🔹 Oil Filtration Elements 🔩 🔹 Oil Filtration Machine 🔥 🔹 Oil Filtration & Cleaning Systems 🛢️ 🔹 Thermic Oil Filtration Systems 🌡️ 🔹 On-Site Oil Testing 🧪 🔹 Online Oil Cleaning Systems 🔍 🔹 Hydraulic Oil Online Filters 🔧 🔹 Mobile Oil Filtration Plant 🚚 🔹 Portable Oil Filtration Plant 🏭 🔹 Portable Oil Filtration System ⚙️ 🔹 Turbine Oil Filtration Plant 🏗️ 🔹 Turbine Oil Filtration Machine 🌍 🔹 Transformer Oil Filtration System 🔥 🔹 Transformer Oil Cleaning Systems 🏭 🔹 Evacuation System for Transformers 🛢️ 🔹 Transformer Oil Filtration Plant 🚀 🔹 Two-Stage Transformer Oil Filtration Plant 🔩 🔹 Transformer Evacuation System ⚡ 🔹 Transformer Oil Filtration Machine ⚙️ 🔹 Transformer Oil Filter Machine 🏗️ 🔹 Turbine Oil Flushing System 🔥 🔹 Centrifugal Oil Cleaner 🏭 🔹 Oil Testing Equipment 🧪 🔹 Visgage Oil Test Kits 🔍 🔹 Karl Fischer Moisture Measurement Equipment 🌡️ 🔹 Online Inline Particle Counters 🔧 🔹 Online Oil Contamination Sensors 🏭 🔹 Laser Particle Counters 🚀 🔹 Industrial Filters 🏗️ 🔹 Transformer Oil Reclamation Units ⚙️ 🔹 Industrial Oil Filters 🛢️

✅ Why Choose Us?

✔ High-Efficiency Oil Cleaning & Filtration Solutions ✔ Advanced Technology for Oil Purity & Equipment Protection ✔ Customized Oil Filtration Plants for Industrial Applications ✔ Reliable Exporters & Suppliers Across India

🔗 Explore Our Full Range of Oil Filtration Machines Here 👉 OilFilterMachineIndia.com

📞 Get in Touch Today! ✉️ #OilFiltration #IndustrialFiltration #TransformerOilCleaning #TurbineOilCleaning #OilPurification #HydraulicOilFilters #IndustrialOilFilterMachine 🚀

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

Environmental Advantages of Modern Oil Filtration Systems

In today’s world, where environmental sustainability has become a pressing priority, industries and individuals are seeking innovative ways to minimize their ecological footprint. One such solution gaining widespread attention is the use of modern oil filtration systems. These systems offer an array of environmental benefits by reducing waste, conserving resources, and promoting cleaner energy practices. This blog will explore how modern oil filtration systems contribute to environmental sustainability and why they are becoming indispensable in various sectors.

Reducing Oil Waste

Oil filtration systems play a vital role in reducing waste by extending the life of lubricants, hydraulic oils, and other fluids. Traditional oil management often involves frequent oil changes, which generate large quantities of waste oil. This waste, if not properly disposed of, can harm the environment, contaminating soil and water sources.

Modern oil filtration systems, equipped with advanced filtration technologies, remove contaminants such as dirt, metal particles, and water from used oil, making it reusable. By minimizing the need for frequent oil replacements, these systems significantly cut down the volume of waste oil that ends up in landfills or is incinerated. This not only reduces pollution but also lessens the demand for fresh oil production, a process that itself has environmental implications.

Conserving Natural Resources

The extraction, refining, and production of new oil require considerable amounts of energy and natural resources. From drilling and transportation to processing, each step leaves a carbon footprint. Modern oil filtration systems address this issue by allowing industries to reuse oil multiple times.

By reducing the dependency on virgin oil, these systems help conserve natural resources like crude oil, water, and energy. In the long run, this conservation effort contributes to a more sustainable ecosystem, ensuring that future generations can enjoy the planet's natural wealth.

Lowering Greenhouse Gas Emissions

The oil production process releases significant greenhouse gases (GHGs) into the atmosphere, contributing to global warming and climate change. By extending the usable life of oil, modern filtration systems decrease the need for new oil production, which in turn reduces associated GHG emissions.

Additionally, properly filtered oil ensures that machinery operates more efficiently. Efficient operation results in reduced energy consumption, further cutting down carbon emissions. This dual benefit makes oil filtration systems an effective tool in combating climate change.

Preventing Environmental Contamination

Improper disposal of waste oil can have catastrophic effects on the environment. Waste oil contains hazardous substances like heavy metals and toxins that can seep into the ground and water sources, posing risks to wildlife and human health. Modern oil filtration systems help mitigate this risk by encouraging the reuse of oil and reducing the volume of waste generated.

Some advanced filtration systems also include features for capturing harmful by-products and contaminants, ensuring that they are safely removed and disposed of without harming the environment.

Promoting Circular Economy Practices

Modern oil filtration systems align with the principles of a circular economy, where waste is minimized, and resources are reused and recycled. Instead of discarding used oil after a single use, industries can filter and reuse it, creating a more sustainable cycle of consumption.

This practice not only reduces the environmental impact but also offers economic advantages, as companies save money on purchasing new oil and disposing of waste. The combination of environmental and financial benefits makes oil filtration systems an attractive option for businesses aiming to adopt eco-friendly practices.

Supporting Cleaner Energy Solutions

The advancements in oil filtration technology have paved the way for its integration into cleaner energy solutions. For instance, renewable energy sectors, such as wind and solar power, rely on lubrication systems for their machinery. Oil filtration systems ensure that these lubricants remain effective, reducing the environmental impact of maintaining renewable energy infrastructure.

Furthermore, by keeping industrial equipment in optimal condition, filtration systems reduce energy wastage caused by inefficient machinery. This contributes to a cleaner and more sustainable energy landscape.

Conclusion

Modern oil filtration systems are more than just a maintenance tool—they are a crucial component in the fight for environmental sustainability. By reducing oil waste, conserving natural resources, lowering greenhouse gas emissions, and preventing environmental contamination, these systems address multiple ecological challenges. Their ability to support circular economy practices and cleaner energy solutions further highlights their significance in creating a greener future.

As industries and individuals increasingly prioritize sustainability, investing in modern oil filtration systems is a step in the right direction. Not only do these systems promote environmental stewardship, but they also enhance operational efficiency and cost-effectiveness, making them a win-win solution for both the planet and its inhabitants.

0 notes

Text

Enhancing Oil Quality with Industrial Oil Purification Systems

Efficient oil purification is critical to ensuring the longevity and performance of industrial machinery. At Conserve Your Oil, we provide cutting-edge Industrial Oil Purification Systems designed to meet the stringent demands of modern industries. Recognized as one of the leading Industrial Oil Purification System manufacturers and suppliers in India, we offer solutions that prioritize efficiency, reliability, and cost-effectiveness.

What is an Industrial Oil Purification System?

An Industrial Oil Purification System is an advanced technology designed to remove contaminants such as water, gases, and solid particles from industrial oils. These systems are essential for maintaining the quality of oils used in various machinery, ensuring operational efficiency and extending equipment lifespan.

Why Choose Our Industrial Oil Purification Systems?

As a trusted manufacturer and supplier in Pune and across India, we deliver high-performance oil purification systems that offer:

Enhanced Productivity: Clean oil reduces wear and tear, leading to improved machinery efficiency.

Cost Savings: Prolonged oil life reduces the need for frequent replacements.

Environmental Benefits: Minimized waste and sustainable oil usage.

Our Expertise in Oil Filtration Solutions

We specialize in a range of oil purification technologies, including:

Industrial Oil Filtration Plants: Comprehensive systems for large-scale industrial operations.

Oil Filter Machines: Compact and efficient devices for precise filtration.

Oil Filtration Machines: Versatile solutions tailored to various applications.

Oil Filtration Plants: Advanced setups for high-volume filtration needs.

Leading Manufacturer, Supplier, and Exporter

At Conserve Your Oil, we are proud to serve as a leading:

Industrial Oil Purification Systems Manufacturer in Pune and India

Industrial Oil Purification Systems Suppliers in Pune and across India

Exporter of Industrial Oil Purification Systems in Pune and globally

Our systems are engineered to meet international standards, making us a preferred choice for clients worldwide.

Applications of Industrial Oil Purification Systems

Our systems cater to diverse industries, ensuring seamless integration into existing operations:

Power Plants: Maintain the quality of turbine oils for uninterrupted performance.

Automotive Industry: Ensure the efficiency of hydraulic oils and lubricants.

Manufacturing Units: Prolong the life of machinery with clean and purified oil.

Innovative Features of Our Systems

High Efficiency: Removes contaminants with precision.

Robust Construction: Built for demanding industrial environments.

Customizable Solutions: Tailored designs to meet specific requirements.

Easy Maintenance: Simplified operations for hassle-free upkeep.

Trusted for Quality and Innovation

We take pride in our reputation as a leading provider of Industrial Oil Purification Systems in Pune, India, and internationally. Our commitment to innovation and quality has made us the go-to choice for businesses looking to enhance their operational capabilities.

Why Conserve Your Oil?

Experience and Expertise: Years of delivering reliable oil purification solutions.

Comprehensive Product Range: From oil filter machines to industrial oil filtration plants.

Global Reach: Recognized as a trusted exporter of Industrial Oil Purification Systems.

Customer-Centric Approach: Solutions tailored to your unique needs.

#Industrial Oil Purification System Manufacturers#Industrial Oil Purification System Suppliers in India#industrial oil filtration plant#Industrial Oil Purification Systems manufacturer in pune#Industrial Oil Purification Systems suppliers in pune#Industrial Oil Purification Systems exporter in pune#Industrial Oil Purification Systems manufacturer in india#Industrial Oil Purification Systems exporter in india#Industrial oil filtration machines#Industrial oil filtration plant#Oil filter machines#Oil filteration plants#Oil filtration machines

0 notes

Text

938967Q Hydraulic Oil Filter: Replacement for Parker Filter and Gearbox Applications

Are you tired of high filter replacement costs or suboptimal filtration in your industrial systems? The 938967Q hydraulic oil filter is a superior replacement for the Parker filter, designed to meet rigorous industrial standards for filtration in hydraulic systems and gearboxes. With outstanding performance and durability, it’s the ideal choice for efficient system operation.

Key Features

Superior Filtration Efficiency

Removes contaminants such as dirt, debris, and moisture, protecting your hydraulic systems and gearboxes from damage.

High Durability

Built with premium materials to withstand high pressure and temperature, ensuring long-lasting performance even in demanding industrial conditions.

Perfect Compatibility

Precisely engineered to replace the Parker 938967Q filter, ensuring seamless integration and reliable operation.

Cost-Effective Alternative

Combines excellent performance and affordability, reducing operational costs without compromising quality.

Customizable Options

Available in various sizes and specifications to meet your unique industrial requirements, ensuring compatibility with diverse equipment.

Applications

Hydraulic Systems

Protects pumps, valves, and other components by maintaining clean hydraulic oil, extending equipment life.

Gearbox Filtration

Designed for filtering lubricants in industrial gearboxes, reducing wear and ensuring smooth operation.

Industrial Machinery

Reliable for a wide range of equipment in manufacturing, power generation, and heavy-duty industries.

Oil Processing and Storage

Ideal for maintaining clean oil in storage tanks and processing lines.

Why Choose Us?

With years of expertise in the filtration industry, we offer a high-quality replacement for Parker's 938967Q filter. Our filters deliver exceptional performance and reliability at a competitive price. Additionally, we provide customization services to tailor our products to your specific needs.

Contact Us

For more details or to discuss your filtration requirements:

Email: [email protected]

WhatsApp: https://wa.me/+8615137395395

Website: www.dcgindustry.com

#ParkerFilterReplacement#HydraulicOilFilter#GearboxFilter#IndustrialFiltration#HeavyDutyFiltration#HydraulicSystemFilter#CustomFiltrationSolutions#DCGIndustry#PowerPlantFilter#IndustrialGearboxMaintenance#CostEffectiveFiltration#filtration#industrial filtration#oil filtration systems#filtrationsolutions#water filtration

1 note

·

View note

Text

Oil Purification Systems | VATS Filtration Technologies Pvt. Ltd.

For some industries, Centralised oil purification systems, e.g. the test rig or end of line testing systems in an automobile plant, need to be designed particularly for the specific case. These elaborate skidded systems are complete with their own Dirty oil and Clean oil tanks, an array of filter housings for different duties, and control panels for operation and monitoring of the system.

VATS offers Fluent Total, the perfect solution for your central systems.

0 notes

Text

Industrial Filter Market Poised for High Growth Owing to Rising Demand from Process Industries

Industrial filters are devices that are designed to remove solid, liquid, and gaseous contaminants from water, air, process fluid, oils or other industrial fluids or gases by means of a medium that is porous or has a filter bed. Industrial filters are engineered for use in a wide range of applications across different industries including food & beverage, chemical, pharmaceutical, power generation, pulp & paper, marine, oil & gas. Industrial filters offer advantages such as reducing maintenance costs, improving performance, enhancing compliance with environmental and industrial standards. Growing industrialization around the world has led to increased demand for industrial filters from various process industries requiring stringent filtration standards. The Industrial Filter Market is estimated to be valued at USD 3.94 Bn in 2024 and is expected to reach USD 6.12 Bn by 2031, growing at a compound annual growth rate (CAGR) of 6.5% from 2024 to 2031.

Key Takeaways Key players operating in the Industrial Filter Market are Valmet Corporation, Sefar AG, Lydall AG, Ahlstrom-Munksjö, 3M, Clear Edge Filtration Inc., Freudenberg, Fibertex Nonwovens, Nordic Air Filtration, Sandler AG, Johns Manville Ashland, Filtcare, Industrial Filter Manufacturers, Inc., Bee Ess Industries, Industrial Filter Corporation, Anand Filters, Enviro Tech Industrial Products, Vizag Filters, Engineered Filtration, Inc, and Filter Concept. Key players are focusing on new product launches, strategic partnerships and acquisitions to gain momentum in the market. The Industrial Filters Market Demand provides significant opportunities such as rising investments in process industries, stringent regulations pertaining to industrial emissions, and advancements in filtration technologies. The market is witnessing increased adoption of high-efficiency and multi-functional filtration systems across various industries. Globally, the market is expected to witness high growth in Asia Pacific region owing to rapid industrialization and increasing manufacturing activities in countries such as China and India. North America and Europe are also expected to present lucrative opportunities for Industrial Filter manufacturers over the forecast period. Market Drivers The main driver propelling the growth of the Industrial Filter Market is the stringent emission control regulations imposed by environmental agencies on process industries. Various industries require compliance with regulations and emission norms related to air, water and hazardous pollutants which is accelerating the demand for industrial filters. Additionally, increasing investments in expansion and capacity addition of manufacturing facilities in process industries will augment the growth of Industrial Filter Market over the forecast period.

PEST Analysis Political: Governments across many countries have implemented laws and regulations regarding industrial emissions. This drives demand for filters that help factories and industrial plants meet emission standards. Economic: When the overall economy is growing, industrial production and capital investment tend to rise as well, boosting demand for new and replacement industrial filters. However, during economic downturns, filter sales may decline as plants scale back operations or delay equipment upgrades. Social: As environmental and health standards continue to increase worldwide, communities expect stricter controls on pollution from industrial activities. This social factor contributes to long-term filter market growth. Technological: Advancements in filter media and filtration system designs allow for higher efficiency at removing smaller particles from industrial exhaust and waste streams. Some new filters also enable real-time monitoring of filter performance. Geographical Regions with High Market Concentration The industrial filter market is highly concentrated in regions with large manufacturing and industrial bases such as North America, Europe, and Asia Pacific. In terms of value, North America currently accounts for the largest share of the global market, led by the United States. Europe and Asia Pacific also represent major regional markets, with countries like China, Japan, Germany and India among the world's leading producers and consumers of industrial filters. Fastest Growing Regional Market The Asia Pacific region, excluding Japan, is projected to experience the fastest market growth during the forecast period. This is driven by rapid industrialization and expansion of manufacturing capacities across developing economies in Southeast Asia, India and China. Stringent new emissions rules also fuel the need for better filtration systems as industry modernizes across the region.

Get more insights on Industrial Filters Market

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Coherent Market Insights#Industrial Filters Market#Industrial Filters#Filtration Systems#Air Filtration#Water Filtration#Liquid Filtration#Dust Collection#Oil Filtration#Industrial Equipment

0 notes

Text

Keep Your Hydraulics Running Smoothly with Sumesh Petroleum

Ensure optimal performance and extend the life of your hydraulic systems with top-notch filtration machines from Sumesh Petroleum. We offer a comprehensive range of machines designed to remove contaminants, improve oil quality, and minimize downtime. Contact us today to discuss your specific needs and discover how Sumesh Petroleum can keep your hydraulics running smoothly. If you are interested then tap on the link hydraulic oil filtration machine manufacturers.

#Online Transformer Oil Filtration System Manufacturers#hydraulic oil filtration machine manufacturers

0 notes

Text

Oil reconditioning project for India’s largest coal-based power producer

Team Minimac successfully executed a critical project to recondition the control fluid (two tanks of capacity 16 kiloliter each) for India’s largest energy conglomerate and coal-based power producer with a capacity of 4760 MW.

Synopsis

The plant was built and is in service as a thermal power generating station, in Vindhyachal. There was a problem with higher Total Acid Numbers (TAN), observed typically when moisture content exceeds the permissible range. They were facing difficulties in stable unit operation because of the sluggish and erratic behavior of the turbine governing system. It was a significant threat to unit outage and generation loss. The situation was examined by Minimac Operations and Maintenance Service (MOMS). Resin skid - Minimac- FS-20-TRIX- 8-25 ltr-1S-FRF-DOL was deployed to address the issue.

Before Oil purification, the TAN value was≥ 0.62 mgKOH/gm, NAS ≥ 8, and Moisture ≥ 1471 PPM. After Oil purification, the recorded parameters were TAN value = 0.08 mgKOH/gm, NAS ≤ 4, and Moisture ≤ 260 PPM. The major challenge faced during the execution was if we charged resin, TAN would reduce, but moisture would increase. So, an analysis was done and implemented to control the moisture first, then charged the second resin cycle. Minimac gave a 100% customized and balanced solution within time.

Problems

The tank capacity was 16 kiloliters, which is huge. The biggest challenge was to execute the project while the system was in operation. Water contamination bubbles were forming, leading to the fluctuation in NAS - as for moisture control, it was necessary to turn off the system. Resin charge in Ion exchange was done intermittently to control moisture increase, and our motto was to hold moisture below 500 PPM so we could plan for the next cycle of resin charge.

Client’s Requirement

To purify the control fluid.

To reduce the TAN value from 0.62 to < 0.10 mgKOH/gm.

To bring down the moisture level < 500 PPM.

To achieve NAS < 5.

Smooth and timely execution without any downtime.

Tailor-made solution.

No oil loss because of processing or spillage.

Solutions

Resin skid - Minimac- FS-20-TRIX- 8-25 ltr-1S-FRF-DOL for NAS & moisture reduction was installed.

Before the oil conditioning process, the TAN ≥ 0.62 mgKOH/gm, which was reduced after oil purification to TAN ≤ 0.08 mgKOH/gm.

The Nitrogen generation unit (TMR 100) was deployed and installed at the client’s site.

For further improvement in TAN, the oil vapor extraction fan (OVEF) was throttled in the range of 70%, with the support of the user.

Minimac provided trained manpower and other consumables under the MOMS (Minimac Operations and Maintenance Service) offering. Minimac had given results far better than the KPIs.

Cost Saving

This plant managed to save:

Cost of oil replacement: ₹ 3.2Cr. approx/ $ 32 Million approx

Cost of downtime: ₹ 3.15 Cr. approx/ $ 31.5 Million approx

By investing ₹ 21 lakh approx/ $ 25.65k approx only.

CO2 e Saving

1,92,000 kg of CO2 e / 0.192 gigagrams of CO2 e

Benefits

Extended in-service oil life.

The smooth functioning of the machines.

Elimination of new oil replacement cost.

Avoiding the risk of fire and explosion.

Reduction in the possibility of product degradation due to blanketing.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#contamination#lube oil filter#hydraulic oil filter#lube oil flushing#lube oil#chemical flushing#oil and gas#metal#mining#oil filtration system#transformation oil purification#transformer oil#transformer oil cleaning#transformer oil filtration#transformers#oil purification system#oil purification machine#oil purification system#oil purification#oil dehydration systems#mlc lvdh#lvdh full form#lvdh

0 notes

Text

OMAKHEATERS - PLATİN

Omak Heaters: Your Trusted Partner in Heating Solutions

When it comes to reliable and efficient heating solutions for various industrial applications, Omak Heaters stands out as a leading provider of top-quality products. Specializing in IBS tank heaters, barrel heaters, filter heaters, satellite dish heaters, and more, Omak Heaters offers innovative and dependable heating solutions to meet the diverse needs of its customers.

IBC Tank Heaters:

Omak Heaters offers a wide range of IBC tank heaters designed to provide consistent and uniform heating for industrial storage tanks. Whether you need to maintain the temperature of liquids or chemicals stored in tanks, our IBC tank heaters ensure optimal heating performance, enhancing operational efficiency and productivity.

Barrel Heaters:

For heating applications involving barrels and drums, Omak Heaters offers high-performance barrel heaters engineered to deliver efficient and uniform heat distribution. Our barrel heaters are designed to withstand harsh industrial environments and provide reliable heating solutions for various applications, including oil and chemical processing.

Filter Heaters:

Omak Heaters also specializes in filter heaters designed to prevent freezing and maintain optimal operating temperatures for filtration systems. Our filter heaters are built to deliver consistent and reliable heating performance, ensuring uninterrupted operation and prolonging the lifespan of filtration equipment.

Omak Heaters Quality Assurance:

At Omak Heaters, quality and reliability are our top priorities. All our heaters are manufactured using premium-quality materials and advanced manufacturing techniques to ensure superior performance and durability. Our team of experienced engineers and technicians conducts rigorous quality control tests at every stage of production to guarantee the highest standards of quality and reliability.

Customer-Centric Approach:

Omak Heaters is committed to providing exceptional customer service and support. We work closely with our customers to understand their unique heating requirements and offer customized solutions tailored to their specific needs. From product selection to installation and ongoing technical support, our dedicated team is here to assist you every step of the way.

Contact Omak Heaters Today:

Whether you're in need of IBS tank heaters, barrel heaters, filter heaters, or satellite dish heaters, Omak Heaters has the expertise and products to meet your heating needs. Contact us today to learn more about our comprehensive range of heating solutions and discover how we can help optimize your industrial heating processes.

625 notes

·

View notes

Note

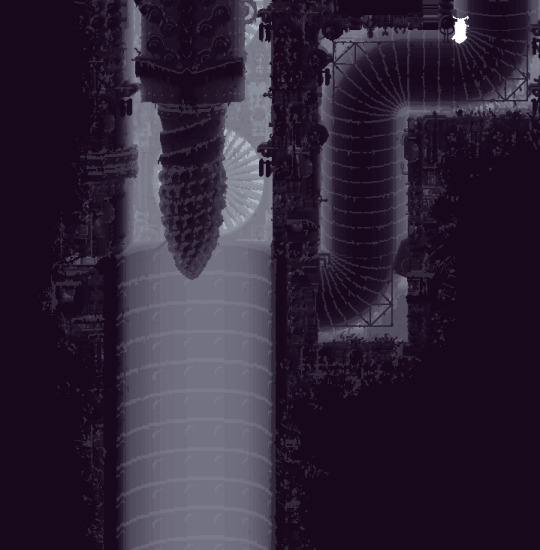

You've done excellent analyses of the mechanics of the Farm Arrays crop harvesters and the iterator labs, and I've wanted to ask. How do you think the void fluid drill silos functioned? Because I have no clue what all these bits&bobs could be for.

Here's the filtration system drill for reference (in an easier to see palette)

Here's also the region art for reference

I think this part is the engine, the part that powers up the drill's spin

And it could also be an automatic assembly point, more on that in a moment

Now, the screw-like shaft, which I thought was a different kind of drill at some point, could have that shape in order to transmit momentum

Now, as for where is all that shaft retracted to, it could be a telescopic mechanism

Or it could be soft when stored in the pipe behind the engine then harden in exposure to air, like noodlefly stingers

Or it could be assembled from base materials on the engine itself, meaning the engine could be a purposed organism creating the shaft like snail creates its shell (but likely faster)

Iterators likely do this at a large scale in the memory conflux assembly, and their components were likely made this way

... although, this assembly theory would only explain the great length and segmented look, and would not be particularly compatible with retracted drills like the one in filtration system, which would still require something like the first two theories. Maybe a combination of these is what's happening

The corncob-like looking tip is definitely the actual drill

Now, I don't know why this one has two engines

Maybe it split in half, maybe an extra one was added because it needed an extra boost (even though this one is shallower than the others)

Maybe the engine or part of it also goes down to install the walls of the holes as it goes deeper

Void fluid seems to have been collected through these holes into the corresponding pipes to be filtered and moved around, rather than absorbed directly through the drill

If I knew how exactly drilling for oil works I'd probably be able to say more here

Maybe I'll add more in a reblog after I inform myself with that

44 notes

·

View notes

Note

Why is everyone suddenly getting taller?

-🌊

Thank you for your questions, and please accept our apologies for the delayed response.

To answer the current question Magic.

To answer your other inquiry on water pollution:

At Drake Industries and Wayne Enterprises, we are deeply committed to restoring Gotham’s environment, with a particular focus on rehabilitating its polluted waters. For decades, industrial byproducts have been irresponsibly dumped into Gotham Harbor, causing significant environmental damage. Compounding this issue are the frequent attacks by rogue elements, which have introduced highly toxic substances such as Joker Toxin and Fear Toxin into the water. These cumulative factors have led to severe ecological degradation, resulting in the loss of marine life and the alteration of the harbor’s natural ecosystem.

To address this critical challenge, we collaborate closely with the U.S. Environmental Protection Agency (EPA) to develop and implement more effective methods for cleaning Gotham’s waters. Currently, we employ a wide range of advanced treatment systems, including but not limited to oil skimmers, sorbents, booms and barriers, dispersants, bioremediation agents, filtration systems, chemical treatments, ion exchange units, reverse osmosis systems, electrocoagulation systems, and vacuum trucks. While the number of systems in use may seem extensive, the severity of historical and ongoing pollution in Gotham’s waters necessitates such a comprehensive approach. Furthermore, we continue to innovate and develop new technologies to enhance our efforts and achieve long-term environmental restoration.

Thank you for your interest in this vital work if any further detail is needed please send another ask or message us at [public business email I'm too lazy to make up].

We remain dedicated to safeguarding Gotham’s environment for future generations.

Tim Drake

16 notes

·

View notes

Text

🏭 Turbine Oil Cleaning System in India – AR Engineering ⚙️

Looking for the best Turbine Oil Cleaning System in India? 🌍 AR Engineering is an ISO-certified company and India’s most trusted brand in Turbine Oil Cleaning Systems, Industrial Oil Purification Systems, and Oil Filtration Machines. Our advanced oil purification solutions help industries improve machinery performance and extend oil life.

🔗 Explore our top-notch oil filtration solutions 👉 Turbine Oil Cleaning System

🔥 Our High-Performance Oil Filtration & Cleaning Solutions

We specialize in manufacturing, supplying, and exporting oil filtration and cleaning systems for industrial applications.

🔹 Turbine Oil Cleaning System 🏗️ 🔹 Oil Cleaning Machines 🔩

🔹 Turbine Oil Cleaning Systems ⚙️ 🔹 Oil Filtration Plant 🚀 🔹 Gear Oil Filtration Systems 🏭 🔹 Industrial Oil Filter Machine 🛢️ 🔹 Oil Filtration Systems 🔧 🔹 Double Stage Oil Transformer Machine 🔥 🔹 Oil Filtration Elements 🔍 🔹 Oil Filtration Machine 🏗️ 🔹 Oil Filtration & Cleaning Systems 🌡️ 🔹 Thermic Oil Filtration Systems 🔩 🔹 On-Site Oil Testing 🧪 🔹 Online Oil Cleaning Systems 🏭 🔹 Hydraulic Oil Online Filters 🛢️ 🔹 Mobile Oil Filtration Plant 🚚 🔹 Portable Oil Filtration Plant 🏗️ 🔹 Portable Oil Filtration System ⚡ 🔹 Turbine Oil Filtration Plant 🔥 🔹 Turbine Oil Filtration Machine 🏭 🔹 Transformer Oil Filtration System 🌍 🔹 Transformer Oil Cleaning Systems 🛢️ 🔹 Evacuation System for Transformers ⚙️ 🔹 Transformer Oil Filtration Plant 🚀 🔹 Two-Stage Transformer Oil Filtration Plant 🔧 🔹 Transformer Evacuation System 🏭 🔹 Transformer Oil Filtration Machine 🛢️ 🔹 Transformer Oil Filter Machine 🔥 🔹 Turbine Oil Flushing System 🏗️ 🔹 Centrifugal Oil Cleaner ⚙️ 🔹 Oil Testing Equipment 🧪 🔹 Visgage Oil Test Kits 🔍 🔹 Karl Fischer Moisture Measurement Equipment 🌡️ 🔹 Online Inline Particle Counters 🛢️ 🔹 Online Oil Contamination Sensors 🔧 🔹 Laser Particle Counters 🚀 🔹 Industrial Filters ⚙️ 🔹 Transformer Oil Reclamation Units 🏭 🔹 Industrial Oil Filters 🔩

✅ Why Choose AR Engineering?

✔ ISO Certified & Industry Leader in Oil Filtration ✔ High-Efficiency Oil Cleaning & Purification Solutions ✔ Advanced Technology for Industrial Applications ✔ Trusted Manufacturer & Supplier in India

🔗 Get the Best Turbine Oil Cleaning Solutions Now 👉 Turbine Oil Cleaning System

📞 Contact Us Today! ✉️ #TurbineOilCleaning #OilFiltration #IndustrialOilFilters #TransformerOilFiltration #HydraulicOilFilters #OilPurification 🚀

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes