#Non-Liquid Coating Industry

Explore tagged Tumblr posts

Text

Non-Liquid Coating Market to Witness Significant Growth by Forecast

Non-Liquid Coating Market Information:

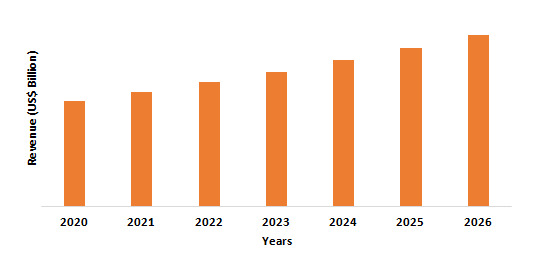

New York, United States: Non-Liquid Coating market report is an expert's study that focuses mostly on businesses, categories, applications, regions, and other subcategories. In addition to this, the reports include an analysis of sales and revenue, as well as trade, competition, investment, and projections. According to straits research the Non-Liquid Coating Market will grow at a CAGR of % during the forecast period. Non-Liquid Coating Market Research studies explore the effects of COVID-19 on the upstream, midstream, and downstream sectors of the industry. In addition, this analysis provides extensive market estimations by putting an emphasis on data covering numerous factors that encompass market dynamics such as market drivers, market barriers, market opportunities, market risks, and industry news and trends.

Competitive Players

Some of the key players operating in the Non-Liquid Coating market are PPG Industries Inc., Jotun Powder Coating, Asian Paints Limited, Axalta coating systems LLC, AkzoNobel NV, The Sherwin -Williams Company, Kansai Paints Company Ltd., Evonik Industries, and RPM International, Inc

Get Free Request Sample Report @ https://straitsresearch.com/report/non-liquid-coating-market/request-sample

The Non-Liquid Coating market report helps a wide range of businesses figure out what their consumers truly want by doing extensive market research. When it comes to new products, every company owner wants to know how much demand there is, and this report is a great resource. Additional benefits include ensuring that the most recent market developments are covered. You may keep a close check on key rivals and their company growth tactics by reading the Non-Liquid Coating market research. It also does an in-depth research for the years 2022-2030 in order to provide company owners with new business options.

This research also provides a dashboard view of prominent Organization, highlighting their effective marketing tactics, market share and most recent advances in both historical and current settings.

Global Non-Liquid Coating Market: Segmentation

By Resin Type:

Thermoset

Polyester

Epoxy polyester hybrid

Epoxy

Acrylic

Polyurethane

Fluoropolymer

Thermoplastic

Nylon

Polyolefin

Polyvinyl chloride (PVC)

Polyvinyl fluoride (PVF)

By Coating Method

Electrostatic Spray

Fluidized Bed

By Substrate:

Metallic

Non-metallic

By End-Use Industry:

Appliances

Automotive

General Industrial

Architectural

Furniture

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/non-liquid-coating-market

Key Highlights

In order to explain Non-Liquid Coating the following: introduction, product type and application, market overview, market analysis by countries, market opportunities, market risk, and market driving forces

The purpose of this study is to examine the manufacturers of Non-Liquid Coating, including profile, primary business, and news, sales and price, revenue, and market share.

To provide an overview of the competitive landscape among the leading manufacturers in the world, including sales, revenue, and market share of Non-Liquid Coating percent

In order to illustrate the market subdivided by kind and application, complete with sales, price, revenue, market share, and growth rate broken down by type and application

To conduct an analysis of the main regions by manufacturers, categories, and applications, covering regions such as North America, Europe, Asia Pacific, the Middle East, and South America, with sales, revenue, and market share segmented by manufacturers, types, and applications.

To conduct an investigation into the production costs, essential raw materials, and production method, etc.

Principal Motives Behind the Purchase:

To get deep analyses of the industry and to have a complete comprehension of the commercial landscape of the global market.

Analyse the production processes, key problems, and potential solutions in order to reduce the potential for future problems.

The goal of this study is to get an understanding of the most influential driving and restraining factors in the Non-Liquid Coating industry as well as the influence that this market has on the worldwide market.

Gain an understanding of the market strategies that are now being used by the most successful firms in their respective fields.

In order to have an understanding of the market's future and potential.

Trending Report:

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: +1 6464807505, +44 203 318 2846

#Non-Liquid Coating Market#Non-Liquid Coating Market Share#Non-Liquid Coating Market Size#Non-Liquid Coating Market Research#Non-Liquid Coating Industry#What is Non-Liquid Coating?

0 notes

Text

The Claw

The executive power of the Pale Garden. The Claw is a small group of mysterious individuals that are tasked with clearing up the mess of a Representative Corp's fall or going after bounties placed on the heads of those who oppose the Pale Garden. They show zero remorse during their operations and care not about civilian lives. If bystanders have to die, they will.

Appearence

The Claw is known for their very businesslike attire with all members wearing either black trenchcoats or suits.

All members are required to hide their faces in some way.

Executioner Gideon

Gideon serves as the 'leader' of The Claw.

Nothing is known about his past other than that he has been alive since the Old World.

This means that his body has likely been replaced by a cybernetic one, allowing him to live over a thousand years. He seems to be well built underneath his attire, standing at a height of 6'2 (187cm).

Appearence-wise Gideon wears a black belted trench coat, a neck tie by his collar, and metallic helmet (or simply his head (?)) that resembles tree bark with 6 holes for his eyes. On his left arm he carries a custom made Asiyah Association Claw, codename "YHWH".

Personality is something Gideon has little of. Those who have encountered him could only hear a word or two leave his body before their torso hit the ground.

Asiyah Association Claw codename "YHWH".

Claw of the Executioner Gideon, custom made by the Asiyah Association by the orders of the Pale Garden.

"Razor sharp, long, blade like fingers. Grip strength comparable to an industrial press, Asiyah Association technology that allows for dimensional travel... Through the wires and, one might just call them veins, runs a liquid version of our Dimension Rift technology. It took us months of non stop work to develope this liquid. All it takes is to activate the liquid and a slice through the air to open a portal. When entering said portal, the carrier is protected by a shield that the claw covers the carrier in before entering... I am sorry for those who will fall to this thing. The human body is not meant for crossing dimensions, let alone hundreds in mere seconds. I can not imagine getting grabbed and sent through hundreds of dimensions and feeling my mind and body explode from within... This world is a horrible place indeed. Yet, when Sir Gideon himself came to look at our work, he said nothing but a single 'Thank you'. That was the first time i had heard those voices ever since i was born." - Project Files

4 notes

·

View notes

Text

The Role of Cleaning Chemicals in Maintaining Hygiene and Safety

In today’s world, maintaining hygiene and cleanliness is more critical than ever. Cleaning chemicals play a pivotal role in ensuring environments—whether homes, offices, hospitals, or industrial facilities—are not only clean but also safe and healthy. These chemicals are designed to effectively remove dirt, germs, and other contaminants, contributing significantly to overall public health.

Best Cleaning chemicals products are provide by Safenshine: Visit for more details. Black Phenyl ,Dishwash Liquid , Floor Cleaner, etc

Importance of Proper Use

While cleaning chemicals are effective, their improper use can lead to health risks and environmental damage. It’s essential to follow manufacturer guidelines for dilution, application, and disposal. Overuse or incorrect mixtures can result in toxic fumes, skin irritation, or damage to surfaces.

Personal Protective Equipment (PPE): When using strong cleaning chemicals, it is crucial to wear appropriate PPE such as gloves, masks, and eye protection to prevent contact with skin and eyes and avoid inhaling harmful fumes.

Environmental Impact: Many cleaning chemicals, if not used or disposed of properly, can harm the environment. Some contain volatile organic compounds (VOCs) that contribute to air pollution, while others may contaminate water supplies. The shift towards eco-friendly and biodegradable cleaning products is gaining momentum as businesses and consumers become more environmentally conscious.

Innovations in Cleaning Chemicals

The cleaning industry is constantly evolving, with new formulations and technologies being developed to improve efficiency and reduce environmental impact. Some of the latest innovations include:

Eco-Friendly Cleaners: These are made from natural, biodegradable ingredients that are less harmful to the environment. They are free from harsh chemicals like phosphates and chlorine, making them safer for both users and the planet.

Enzymatic Cleaners: These use natural enzymes to break down organic matter such as food stains and pet messes, offering an effective and non-toxic cleaning solution.

Antimicrobial Coatings: After cleaning, some surfaces can be treated with antimicrobial coatings that provide long-lasting protection against germs and bacteria, reducing the frequency of cleaning needed.

Concentrated Formulas: To reduce packaging waste and carbon footprint, manufacturers are producing highly concentrated cleaning solutions that require less product for the same level of cleaning power.

Conclusion

Sanitizers are important tools in the effort to maintain cleanliness and safety in facilities. Understanding appropriate use, potential risks, and the importance of environmentally friendly alternatives can help individuals and businesses make informed choices. As the industry continues to innovate, future detergents will likely focus on balance and sustainability, ensuring if we clean up the environment we will not compromise the health of our planet.

#housekeeping#house cleaning#cleaning#houseclean#housecleaners#cleaning product#best housecleaning products

2 notes

·

View notes

Text

Summer Wine (Diluc x F!Reader)

WARNINGS: slight yanedre, soft yandere, non-explicit sex, alcoholism, fluff, angst, jealousy, dubcon, sex under the influence, misogyny (period typical), lore mentions

///

“It’s a pleasure to meet you.” Diluc offers his best, practised smile, reaching out for your hand with a gentle touch, and raising it to his lips. He tries not to think about the way your eyes widen, glittering under the lights like an intricate constellation of yourself.

///

Diluc had never acquired a taste for wine.

He’d spent far too many hours searching for an answer as to why . It's pungent smell that seemed to linger around him like a sour perfume? It's thick texture that dried on his tongue, leaving a coating of something all too unpleasant? Or it’s cunning, inconspicuous way of fusing into your veins, tainting them until your brain is sullied with lies, and your heart beats it in fast, powerful thuds. Until it pours from your eyes and drips off your tongue.

Until it’s staining white fabric red, before his very own eyes.

It’s his job now, to run the winery; as one heavy weight was lifted from his arms, dripping red and lifeless, another was thrust into them. And he, at the heart of the wine industries of Teyvat, bore its burdens.

He would probably have crippled under the pressure, he thinks, if it weren’t for Kaeya.

Not directly him , of course. It had been a long time since he and his brother had parted ways, and now the thread of a relationship between the two men only existed in the traces of fruit and the scarlet ring left around the rim of a glass. But rather, through Kaeya, and his nightly stupors of drinking himself to sleep, Diluc often finds himself meeting new people.

New people like Bennet, whom Diluc had been introduced to not too long ago at a function the Knights of Favonius had attended in Mondstadt’s Adventure Guild, in which Kaeya had introduced Bennet as a young man he had been training. A determined adventurer, it seemed, and adopted son of none other than the members of the guild themselves. Boyish, determined and free; Diluc saw something of his younger self in Bennet’s fires.

New people like Albedo, the odd, but undoubtedly charming alchemist that Kaeya had brought along to a meeting to discuss new development plans for Mondstadt. Diluc had been the prime benefactor, and Albedo, with his genius craftsmanship and insightful comments, had been the one to propose over half of the final designs. He had gained Diluc’s respect, if not only for his intelligence, for his respectful manner.

New people like you .

Hanging off Kaeya’s shoulder with bright eyes, dulled only by the alcohol pounding through your system.

It’s improper for a lady, one part of Diluc nags, to be so bold. The part that was brought up in a traditional household, motherless and privileged with a maid to wait on his every request, assesses the proximity of you and Kaeya with distaste. But the other part, the part that entails barstools and the drunken chatter of Mondstadt locals, tells him that it’s not his place to judge. That the red wine that trickles from your lips and down your skin in a single droplet is an appreciation, of some form, of his craft. It’s his wine that you’re drinking yourself dumb to, his efforts that you consume. His passion that flows through your bloodstream as your eyes burn at him with a flame that’s rivalled only by his own, curious and oh-so charming.

He appreciates it, he really does.

The grape juice in his glass that he was so carefully tendering to is ignored for small, secret glances at your figure. He notes the more-than-familiar way you grip his brother’s arm, your laugh a little too loud for his dreams of a peaceful life, but the warm sound elicits a small smile from his mouth that he is in no rush to smother.

Your voice is rich like the liquid that seeps down his throat. As your eyes travel over to meet his once more, he brings his glass to his lips, downing the scarlet juice in one swift gulp.

And as he drinks, he’s sure someone must’ve switched his drink for wine, because in the low light of his manor, he could swear you look angelic. Deific. No archon’s touch could have crafted you from the finest jade, he’s certain.

Kaeya introduces you later that evening, not unaware of the stolen glances between the two of you throughout the night. Diluc recognises that it’s cliché- a little too much like a fairytale book he’d read in his library as a child- but you fit into the scenario too well; a beautiful princess meeting none other than her own Prince Charming

‘Kaeya has found another one’, is his first thought. Another young woman, innocent and gentle, seduced by Kaeya’s mystery and allure, and goaded on by the drowsy voice in your head that tells you that maybe you’re special. So, naturally, he’s rather taken aback to learn that you’re a traveller. That you’ve seen Teyvat, walked the same paths as him, fought monsters and emerged victorious. You, with your sweet laugh and angelic eyes that stare up at him without a single conscious thought. A traveller.

It seems as though the two of you met during a raid of some sort that week. Kaeya’s bold claims of being ‘indebted’ to you are loud amongst the chatter of other guests, and you warm slightly at the praise.

“I proposed I pay her back with your finest wine.” Diluc doesn't miss the sparkle in Kaeya’s eyes as he looks down at you, or the way his gaze travels from your eyes to your lips, and finally to meet Diluc’s own gaze, with a wink that tells him Kaeya knows more than he should. Diluc could almost scoff at how appropriate it was. Kaeya always did know too much.

“It’s a pleasure to meet you.” Diluc offers his best, practised smile, reaching out for your hand with a gentle touch, and raising it to his lips. He tries not to think about the way your eyes widen, glittering under the lights like an intricate constellation of yourself.

You greet him at a volume that confirms you’ve had more than enough of his wine for one night, emphasising just how much you’ve enjoyed it with slurred compliments as you smile up at him. You stumble slightly, and Diluc feels a pinch of irritation at the way Kaeya is content to watch you with amusement rather than lend out a hand to steady you, but he stays silent.

Those cunning, blue eyes glint under the soft lighting. “It seems we’d best be going. Y/N can hardly stand, and as Cavalry Captain I think it’s only right she be left in my care.” Diluc remains unaffected by his brother’s provocations and cheap insinuations, far too familiar with them to give in like he had as a child. Kaeya hooks a hand under your legs, hoisting you up from the floor in one fluid motion, to rest in his arms. Diluc’s heart warms at your light yelp. “I fear she may like your wine a little too much, from the looks of it. But what can I say? It always was your most likeable asset.”

He can ignore the petty insult if only to focus on your body in Kaeya’s arms as he carries you through the door, whispering something close to your ear that makes Diluc burn in an irrational envy; your eyes fluttering closed in fatigue.

—-

He humours himself that it’s fate that the two of you meet again. At first, only a brief encounter ensues. Diluc recognises you’re in a hurry to rush off somewhere that morning- no doubt answering to the beck and call of the Knights of Favonius. How unfortunate that you’d find yourself tangled up in such a mess so quickly. On his own adventures, Diluc had been able to experience the culture and history his surroundings had to offer, but it seems to him that you have little chance to recognise the beauty of his own region on your travels. He’d like to show you them sometime.

The greeting is only quick, a brief thank you for the wine and a rather embarrassed apology for your conduct the night before, which Diluc assures you was perfectly fine, and that there was no need to worry for such formalities. And then, with a final thank you, you’re gone, winding your way through the labyrinth of the streets.

Diluc finds himself out on another early stroll the very next day, following the same route, for no particular reason he was willing to admit. He can pretend he doesn’t find a smile appearing on his face as you come round the corner, basket in hand and shielding your eyes from the sunshine. This time, you stop and talk. Diluc’s face amongst the locals sparks smiles and discounts for you as you purchase your necessities, which has you thanking everybody profusely, and failing to hide the wide grin that cracks across your face.

“Perhaps I should ask you to accompany me every time I visit the market” you tease, a little more comfortable in his presence, swinging your basket and looking up at him with a smile.

“Perhaps” he offers.

As it turns out, you’re running out of money, so Diluc’s presence that morning had been entirely beneficial. You tell him how wonderful you think it is that he has such respect from the locals, and how great a man he must be because of it, neither of which Diluc denies, with an uncontrollable smirk at the praise. He offers you financial aid, enquiring as to the lack of support you seem to receive from the Knights of Favonius, which you brush away lightly before refusing his money, in fear you may ‘impose’ on him. He assures you it would be no burden, but you’re stubborn in your finality, though it doesn’t stop him from buying you a parting gift of the freshest strawberries in the market, which you eat as you walk away.

The two of you part that morning with smiles.

Upon the third encounter, you’re touring Monstadt together. It starts in the city, a history of its church, the people and their archon, and then spills into walks to nearby villages that lead to his manor. You spend some time amongst the vinery, Diluc detailing the processes of wine that you enquire into with interest, and finally decide you’d be better tasting the drink, rather than making it.

The two of you walk round to the stables, where you each find a horse. You’re slightly unsteady, explaining that you’ve never had a talent for horse riding, but with Diluc’s support you find yourself travelling at a steady pace, discovering beauty in a land you’ve never seen before. Diluc himself seems enthusiastic to share the history of his region, and you find yourself slightly taken aback at just how much the two of you talk, having found him to be a rather conserved man. But you listen in awe as you’re told of the Four Winds, Dvalin and Barbatos.

Diluc, you learn, is descended from the noble Ragvindr clan, who’s history plays a large part in the development of Mondstadt. It’s all fascinating to you, such strong history ingrained into the city’s society. You can feel some sort of partiality growing within you for the land of wind and song, and those you have met within it.

Finally, Diluc leads you to Starsnatch Cliff, where the two of you sit to rest amongst the flowers. He points to some far off island with the promise of a trip there some time in the future, if you’d be willing to take his offer. You tell him you’ll consider it. He watches you momentarily, admiring the tranquillity of the scene before him. You look peaceful, but he can sense there’s something more to the silence you’ve settled in.

“How long do you plan to stay in Mondstadt?” Diluc finds his mouth moving before he can contemplate the words he speaks.

There’s a moment of silence, almost tense between the two of you as he watches you stare at the flowers. You pluck one from the ground, eyes distant. They hold sadness as you answer him.

You don’t know. For as long as you must. For as long as you can.

He can only hope it’s long enough.

The dandelion clock sways in the breeze, and suddenly its seeds find flight, spurred on by the gentle breaths you let out. One. Two. Three. Four. Five. And then they’re all gone, carried away by the wind.

—-

There’s a warm breeze in the air as he reads through his paperwork of the day, numbers scattered along the edges of pages and small notes jotted in ink on his notepad. The clock ticks away behind him, steady and constant; a sound Diluc finds comfort in on days spent working in his office. His hand moves fluidly on the page, scrawling words with little thought as his mind drifts away.

As he’s signing off for a final shipment of wine, he hears a ringing faintly from the hallway. It’s the same as any other day- three, high-pitched chimes from the bell hanging above the door- but he knows instantly it’s you. He stands up abruptly, calling to Adelinde in a deep voice to allow him to answer it, and instructing her to take the rest of the day off, along with any other maids working. He can see the surprise on the stoic face of his Head Maid, but he can hardly blame her- he can acknowledge that it’s rare for him to have a visitor to whom he gives such personal attention. Nonetheless, she nods in understanding, bowing once as she leaves to instruct the other maids to return home. He makes a mental note to give each of them a bonus upon their return.

As he turns towards the door at the sound of the bell once again, there’s a momentary worry clouding his mind that he’ll answer the door and it will be someone else.

But you’re standing there, looking sheepish and tugging at the hem of your dress as you stare up at him.

Something about running out of money and having nowhere else to go, no one else to turn to. You really are playing into the ‘damsel in distress’ role, Diluc thinks. But he is most certainly deserving of his title as a gentleman, so who would he be to refuse?

You, of course, thank him profusely, making your way into his manor with soft steps across the polished floors.

There’s little said between the two of you, but Diluc can sense there’s something more wrong.

Small conversations echo in the halls of his manor as Diluc leads you into his sitting room. He offers you a drink, which you graciously accept, following him to his own private bar, just in the corner of the room. You sit down on a stool as he walks behind the counter, a fresh smell of pine in the air. The room is spacious, and the bar itself stretches down an entire length of the wall, stocked full with coloured bottles and crystal glasses that sit in perfect, meticulous rows.

He has a beautiful house, you tell him. He simply thanks you, turning to inspect the many glasses behind him, before reaching for one in the centre. It’s an elegant glass, as far as the beauty of a wine glass can go, with the stem carved into vines that disappear at the base. Hand carved, he tells you.

You don’t say much as you sip the drink, but Diluc finds himself amused at how unsubtle your glances are. It’s such a contrast, he notes, from previous encounters, and he can’t decide which side of you he likes better. He’s intimidating, he knows it. Dark and mysterious with just a little too much ice, like an unfamiliar drink one would normally avoid. But as he watches you raise the glass to your lips, he’s reminded once again you hold the courage of an experienced traveller.

Perhaps he shouldn’t have poured you that third glass of wine, but you had insisted as soon as he'd told you it was a specialty still in the works, untouched by any other but himself. And, having a preference for non-alcoholic beverages, naturally he would need another’s opinion.

Your lips reach the rim of the glass slowly, making a drunken show of concentrating hard, which elicits a smile from Diluc. As you take your first sip, it’s almost like the forming of a contract between the two of you, and he feels a sudden heat igniting in his chest that spreads like a wildfire to his lungs and across his skin, its flames dying off to leave a light warmth on his cheeks and a smile tugging at his lips.

‘Summer wine’ , he calls it. Perhaps another cliché, but you laugh and say it’s perfect.

Not ten minutes later, and you finally lead him up the stairs, hand gently encompassing his own as you turn to look back at him, your bright smile lighting up your eyes, which hold just a tint of something darker; some deep lust beneath your drowsy expression. Your hushed giggles resound through the empty halls.

It’s illicit. The two of you have never mutually formed a relationship, but maybe that’s why Diluc finds it all the more thrilling. He’s fallen into a deep chasm of want, drowning in all-consuming lust.

It starts off slow, and he relishes in the taste of your mouth as he lays you down on his bed. Your body is warm against his, and your hands clasp his neck as you bring him closer to your face in a crushing heat. He could almost laugh at your eagerness, he finds it so enthralling , so addicting and so, so you .

You giggle when he separates from you, kissing the top of your nose gently before reaching up to unfasten the buttons of his silk shirt. It clings to his muscles perfectly under the light, and as he slowly removes it, his pale skin comes into view; corded with muscle and scars, but perfect, like a sculpted statue of marble. His eyes fall onto you in a moment of adoration.

Sprawled out on the bed, you’re a painting come to life; bathed in the orange light that cracks through his windows, your skin glowing in the sunset and your breaths heavy in the air. The sheets crinkle around your form with an intended precision, hair like a halo as he stares down, his own form towering over you. The veins in his arms flex with every movement as he moves towards the bed once again, his body finding its way on top of yours.

Your skin is so soft and warm under his touch, rough hands tracing delicate shapes down your stomach. His teeth find your neck, kisses staining your skin with soft bite marks and blossoming bruises that he selfishly wishes would leave you marred. Your moans gradually grow louder, and he can feel your body melting beneath him.

Those hands, so rough and calloused, are soft on your body. They envelop your thighs, parting your legs so gently to deliver the heat of his mouth. He pushes you down further as your fingers find their way to his soft locks, eliciting a groan from beneath you as you grip them tightly, which sends a shiver throughout your body.

He wants to savour you, to worship you as he would his own archons.

He brings you to your peak, not letting go of your legs until you’re squealing above him and calling out his name in breathy pleas that spark something deep inside of him. But he allows you a moment of rest, instead opting to plant kisses on the inside of your thighs in gentle intimacy.

Your breathing slowly becomes regular again and you move yourself to be on top of him. He’s by no means small, and he can’t help staring as you slowly sink down onto him. His hands grasp your sides, coming up to tug at your breasts as you move on top of him, the two of you in tandem. The warmth of the summer sun settles on your skin.

Your hips move in a steady rhythm, but it’s not enough. Diluc grabs your body, manoeuvring the two of you so that he’s above you. Your eyes are wide with shock, and only widen in pleasure as he allows himself to thrust into you with force. He can hear the pounding of the bedrest on the wall, can almost visualise the way the wallpaper will be scuffed the next morning, but he’s unable to care. His grip is on the fat of your hips, tight and borderline painful, but addicting nonetheless. He’s far too deep in a labyrinth of pleasure to think about anything but you and the way you feel around him- so wet, so hot, and so tight.

For you, it’s the most pleasure you’ve ever experienced with another, but for Diluc it’s something else. In the most unholy of intimacies, Diluc resolves that he is wholly in love with you. In his resolution he reaches for your jaw, pulling you up with fervour to meet his lips once again, a deep, wet kiss that the two of you moan into in the silence of the manor. Your bodies ache, breathing heavy and skin sticky from sweat and each other.

He can feel that you’re coming to your peak once again, and he’s not far behind. Your walls clench around him desperately and just as you cry out his hips begin to stutter. He pulls out just in time, coating your stomach with a groan. He stares down at your face, panting. You’re smiling up at him, eyes groggy and lids fluttering.

Diluc finds himself offering a rare smile to the fatigue that overcomes him.

—-

His dream is engulfed in an orange tint, low and warm. It’s you and him in a sea of dandelions that roll in the breeze like a calm tide. You’re telling him something with a tired look on your face as the seeds rise above you like stars in the sunset.

When he wakes, it’s to that familiar orange glow breaking through the white of the silk curtains. Morning heat lingers in the air, and the blossomed bruises ache along his neck as he tilts his body to face you, and the empty pillow that lays beside him, cold and bare.

You’re long gone. To where, he doesn’t know.

As his tongue traces over his lips, he finds the faint taste of something, its intoxicating aroma surrounding him.

An addiction he can never feed.

Summer wine.

#genshin#diluc#diluc x reader#yandere#yandere genshin#soft yandere#tw: alcohol consumption#tw: dubcon#tw: misogyny#tw: jealousy#smut#fluff#genshin x reader

19 notes

·

View notes

Text

From mushroom to luxury handbag: will fungi soon take over from leather?

In the search for alternatives to animal leather, fungi seem to be the new ecological gold. Will they soon hang in our wardrobe?

A shoe, handbag or wallet that naturally recovers from a scratch? For that tour de force, the fashion sector looks to fungi.

Research into mushrooms (or fungi, those are synonyms) as an ecological alternative to leather is on the rise. The possibilities sound futuristic: from self-healing material to 3D printing techniques. Fashion brands such as Balenciaga[1], Stella McCartney[2], PVH[3] (the parent company of Tommy Hilfiger, among others) and Hermès have all entered into partnerships with companies that use fungi.

Or rather: on mycelium[4]. The true potential lies in that network of hyphae, explains Professor of Bioscience Engineering Eveline Peeters (VUB). “Mushrooms are the tip of the iceberg. You can compare the hyphae with the fruit, such as an apple. Mycelium, that's the tree itself.”

9,000 euros coat

How is fungi leather created? First you grow the fungus. A small amount of fungus is added to large containers of nutrient liquid. If you leave it for two weeks at the right humidity and temperature, a layer of hyphae will grow on it.

‘We call that layer the skin,’ says Peeters. "After two weeks it is harvested and treated to make it look like leather." Two weeks of production time is considerably less than the three years that you have to count on average for leather.

Moreover, you need less than a hundred litres of water per square meter of mycelium. For the same amount of leather, that is about 10,000 litres. An interesting advantage for fashion companies that want to get rid of the large ecological footprint of leather. "And then you haven't even mentioned animal suffering," says Peeters.

All this means that many brands trip over each other to test mycelium, especially in the luxury segment. In 2022 Stella McCartney released a first handbag, for his winter collection of 2022 it was Demna Gvasalia at Balenciaga who released a first coat in the material. An oversized, long black coat, with a wink to the movie The Matrix.

But between a limited edition jacket worth €9,000 and a mass-produced product, there are still years of research, says Maurizio Montalti, co-founder of Sqim[5], the company that produced the material for Balenciaga's jacket. It is probably the largest European producer of mycelium with several thousand sheets of one square meter per year. “Within six years we hope to be able to produce on an industrial scale. Scaling up a biological process cannot be done in the blink of an eye,” says Montalti.

Elite ecology

The fact that you can make mycelium in a lab makes it interesting and complex at the same time. "I compare it to antibiotics," says Peeters. “It took years of intensive research to perfect it.”

One of the variants with which the researcher achieves the best results comes from a fungus that one of her students picked in a forest in Linkebeek[6], near Brussels. "How many other varieties would be even better, we have no idea yet."

Mycelium may be more environmentally friendly than leather, but it is not cheaper. Currently, it costs about the same as high-quality leather[7], the leading fashion website Business of Fashion (BoF) reports.

That price tag prevents the material from quickly reaching the general public. ‘And that is a pity,’ says sociologist Aurélie Van de Peer (KU Leuven), who studies the mechanisms behind ecological fashion. “Ecology takes on an elitist side, it becomes a status symbol. That can't be the intention.”

Doubts as to whether mycelium will meet customer expectations also seem to dampen the fashion companies' initial eagerness. In 2021, starting companies that worked on non-animal leather raised almost 900 million euros. A year later that had already dropped to 420 million dollars. This is evident from a report by think tank Material Innovation Initiative[8]. ‘While more research is needed,’ says Montalti.

As good as leather?

Hermès, maker of luxury handbags, invested 125 million dollars in Mycoworks[9], a California company, in early 2022. But apart from some photos of a prototype, we don't see anything on the shelves. The launch was delayed several times.

An official reason is not given, but presumably the end result did not correspond to what luxury brands such as Hermès want to offer: timeless heirlooms that are passed down from generation to generation.

That customers do not adjust their expectations for ecological alternatives, designer Stella McCartney experienced with her first handbag, she told BoF[10]. “To make mycelium a success story, customers should not feel that it is a compromise. From the way it looks to the way it feels, there should be no difference from leather. As long as that is not the case, many brands will not take the plunge.”

Source

Karlien Beckers, Van paddenstoel uit Linkebeek tot luxehandtas: nemen schimmels het straks over van leer?, in: De Standaard, 13-04-2023, https://www.standaard.be/cnt/dmf20230412_94376113

[1] Read also: https://www.tumblr.com/earaercircular/664321527312957440/from-dirty-to-vintage-luxury-embraces?source=share

[2] Read also: https://www.tumblr.com/earaercircular/676457111952179200/fashion-brands-are-launching-buy-back-programs-in?source=share & https://www.tumblr.com/earaercircular/672470746450345984/sustainable-luxury-between-recycling-and?source=share

[3] PVH Corp., formerly known as the Phillips-Van Heusen Corporation, is an American clothing company which owns brands such as Tommy Hilfiger, Calvin Klein, Warner's, Olga and True & Co. The company also licenses brands such as Kenneth Cole New York and Michael Kors.PVH is partly named after Dutch immigrant John Manning Van Heusen, who in 1910 invented a new process that fused cloth on a curve.

[4] Read also: https://www.tumblr.com/earaercircular/667314088734507008/mushrooms-as-raw-material-for-leather-accessories?source=share

[5] SQIM is founded on the belief that innovative natural materials, grown by means of microbial fermentation, hold the promise for the creation of a near future where human activities and the rhythms of the larger ecosystem are not in conflict with each other. Accordingly, SQIM co-designs with nature to develop cutting edge technologies and deliver naturally grown products with superior properties, employing fungal mycelium as its engineering and manufacturing platform. https://www.sqim.bio/

[6] Linkebeek is a Belgian municipality in Flanders, part of the province of Flemish Brabant, and in the administrative district of Halle-Vilvoorde. The municipality only comprises the town of Linkebeek proper. As of 1 January 2006, Linkebeek has a total population of 4,759. The total area is 4.15 km² which gives a population density of 1,147 inhabitants per km².

[7] SARAH KENT, Would You Buy a Mushroom Handbag? In: BOF, 23-05-2022, https://www.businessoffashion.com/articles/sustainability/would-you-buy-a-mushroom-handbag/ For the first time, brands including Stella McCartney, Balenciaga and Hermès are bringing products made of mushroom-based materials to market, an early test for whether the next-generation fabrics could one day hit the mainstream.

[8] 2022 STATE OF THE INDUSTRY REPORT: NEXT-GEN MATERIALS. Next-gen material companies raised at least US$456.75 million from 28 publicly disclosed deals in 2022. The 2022 State of the Industry Report: Next-gen Materials highlights the investments, innovation, and industry partnerships that significantly impacted the next-gen materials industry in 2022. 16-2-2023, https://materialinnovation.org/reports/2022-state-of-the-industry-report-next-gen-materials/

[9] MycoWorks is a biotechnology company based in Emeryville, California, with the mission to create the highest quality materials using mycelium. The company was founded in 2013 by Philip Ross, Sophia Wang, and Eddie Pavlu. https://www.mycoworks.com/

[10] SARAH KENT, Would You Buy a Mushroom Handbag? In: BOF, 23-05-2022, https://www.businessoffashion.com/articles/sustainability/would-you-buy-a-mushroom-handbag/

2 notes

·

View notes

Text

Plethysmometer: Unlocking the Secrets of Volume Measurement

The world of scientific research and development relies heavily on accurate and precise measurements. Whether you're dealing with the minute volumes of pharmaceuticals or the larger scale production of materials, having the right tools can make all the difference. One such tool that often flies under the radar but plays a crucial role in various fields is the plethysmometer.

What is a Plethysmometer?

A plethysmometer is a specialized instrument designed to measure volume changes in an enclosed space. It works by detecting changes in air pressure within a sealed chamber containing the object of interest. This makes it particularly useful for measuring the volume of irregular or complex shapes, which can be difficult to determine using traditional methods.

Applications Across Industries

The versatility of the plethysmometer is evident in its wide range of applications across various industries:

Pharmaceuticals: In drug development, precise volume measurements are critical for ensuring accurate dosages and consistent drug delivery. Plethysmometers are used to measure the volume of tablets, capsules, and powders, ensuring quality control and efficacy. This is often a crucial step after materials are processed using a pelletizing machine to create uniform drug pellets.

Material Science: When developing new materials, understanding their density and porosity is essential. A plethysmometer can accurately measure the volume of solid materials, including those with complex geometries, providing valuable insights into their physical properties. This data can be critical when applying coatings with an R&D coater to ensure optimal adhesion and performance.

Biological Research: Plethysmometers are used to measure changes in the volume of organs or tissues in response to various stimuli. This is particularly useful in studies related to inflammation, edema, and drug effects.

Food Industry: In food production, maintaining consistent product size and quality is crucial. Plethysmometers can help measure the volume of food items, ensuring uniformity and compliance with industry standards.

Advantages of Using a Plethysmometer

High Accuracy: Plethysmometers offer high accuracy in volume measurement, even for irregular shapes.

Non-destructive: The non-destructive nature of the measurement allows for repeated measurements on the same sample.

Versatility: Can be used to measure the volume of solids, liquids, and even gases.

User-Friendly: Modern plethysmometers often feature automated data acquisition and analysis, simplifying the measurement process.

Plethysmometer vs. Other Measurement Techniques

While other methods like water displacement or caliper measurements can be used to determine volume, the plethysmometer offers distinct advantages:

Water displacement is unsuitable for porous materials or those that react with water.

Caliper measurements can be inaccurate for complex shapes and rely on operator skill.

The Future of Plethysmometry

As technology continues to advance, we can expect further improvements in plethysmometer design and functionality. This may include increased automation, improved sensitivity, and integration with other analytical techniques. These advancements will further solidify the plethysmometer's role as a vital tool in research and development across various industries.

Conclusion

The plethysmometer, while perhaps not as well-known as the pelletizing machine or R&D coater, is a powerful tool that provides invaluable data for researchers and developers. Its ability to accurately measure volume, even for complex shapes, makes it an indispensable asset in fields ranging from pharmaceuticals and material science to biology and food production. As industries continue to push the boundaries of innovation, the plethysmometer will undoubtedly play a key role in unlocking new discoveries and advancements.

0 notes

Text

Exploring the World of Pigment Dispersions: Applications, Benefits, and Innovations

Pigment dispersions are an essential element in various industries, from automotive and cosmetics to printing and coatings. These finely ground pigments are suspended in liquids to create vibrant, stable, and high-performance products. As demand for more sustainable and efficient solutions grows, the role of pigment dispersions in product formulations has become even more crucial. In this blog, we’ll explore what pigment dispersions are, their applications, the benefits they offer, and the latest innovations that are transforming the industry.

What Are Pigment Dispersions?

Pigment dispersions are concentrated mixtures of pigments (coloring agents) suspended in a liquid medium, usually water or oil-based. The dispersion process involves breaking down the pigment particles to a small size and evenly distributing them throughout the liquid. The result is a stable, uniform suspension of pigments that can be easily incorporated into various products.

The size and quality of the pigment particles in a dispersion are key to the final product's color intensity, durability, and performance. Manufacturers use different techniques, such as high-speed mills and dispersing agents, to achieve the ideal particle size and prevent agglomeration.

Applications of Pigment Dispersions

Paints and Coatings The most well-known application for pigment dispersions is in paints and coatings. Pigments provide the desired color and opacity, while dispersions ensure smooth application, even coverage, and long-lasting results. Whether for automotive finishes, industrial coatings, or interior paints, pigment dispersions are integral to achieving high-quality, durable, and vibrant coatings.

Printing Inks In the printing industry, pigment dispersions are vital in producing the rich, bright colors seen in everything from packaging to newspapers. Dispersions are used in offset, flexographic, and gravure printing processes to ensure the ink flows smoothly and produces accurate, vibrant images on various materials, including paper, cardboard, and plastics.

Cosmetics and Personal Care In the cosmetics sector, pigment dispersions are used in a wide range of products like foundation, lipsticks, eye shadows, and blushes. These dispersions help achieve smooth, even application while ensuring that the colors stay true, vibrant, and long-lasting. Moreover, modern pigment dispersions in cosmetics often feature skin-friendly, non-toxic ingredients that adhere to safety standards.

Textiles and Leather Pigment dispersions are used to impart color to textiles, leather, and other materials. Whether in the production of clothing, upholstery, or fashion accessories, pigment dispersions ensure that the materials retain their color even after multiple washes or exposure to sunlight.

Plastics In the plastics industry, pigment dispersions are used to color a wide range of products, from household items to industrial components. These dispersions are essential for achieving consistent, long-lasting colors that won’t fade over time.

Benefits of Pigment Dispersions

Improved Stability and Consistency One of the primary advantages of pigment dispersions is their ability to ensure color consistency across batches. The dispersion process minimizes the risk of pigment settling, allowing for a uniform color that performs reliably every time.

Enhanced Performance Pigment dispersions allow for greater control over the quality of the final product. With better pigment distribution and smaller particle sizes, the resulting formulations are more durable, have better coverage, and can withstand wear and tear over time. This is particularly important in industries such as automotive coatings, where high-performance results are critical.

Environmental Benefits Many pigment dispersions are now available in water-based forms, reducing the need for solvents that can be harmful to the environment. As sustainability becomes a central focus in many industries, these eco-friendly formulations are gaining popularity due to their low VOC (volatile organic compound) content, which reduces air pollution and contributes to greener manufacturing practices.

Customization and Flexibility Pigment dispersions offer a high level of customization, allowing manufacturers to create products that meet specific color requirements and performance standards. With a wide range of pigments and dispersion techniques available, formulators can tailor their products to suit different applications, from vibrant shades to subtle hues.

Innovations in Pigment Dispersions

As industries evolve, so does the demand for more innovative, high-performance pigment dispersions. Here are some exciting developments in the field:

Nanotechnology Nanotechnology has opened new frontiers in pigment dispersion by allowing for the creation of pigment particles on a nanoscale. This provides better color vibrancy, more durable coatings, and enhanced lightfastness (resistance to fading). The ability to manipulate particles at the nanometer scale also offers greater efficiency in formulation and better material properties.

Sustainable Pigment Dispersions With the increasing emphasis on sustainability, the development of bio-based and renewable pigment dispersions is gaining momentum. These dispersions use plant-based or non-toxic ingredients, reducing reliance on petroleum-based products and minimizing environmental impact. The use of sustainable pigments and eco-friendly dispersing agents ensures that the end products are safer for both consumers and the planet.

High-Performance Coatings Innovations in pigment dispersion technologies are also driving the development of high-performance coatings. These coatings offer improved weather resistance, UV protection, scratch resistance, and anti-corrosion properties. This is especially beneficial in the automotive and industrial sectors, where durability and long-lasting performance are crucial.

Smart Pigments Another exciting innovation is the development of smart pigments, which change color in response to environmental stimuli such as temperature, light, or pH. These pigments have applications in a variety of industries, including packaging, fashion, and healthcare, offering both functional and aesthetic benefits.

Conclusion

Pigment dispersions are a vital component in numerous industries, helping to create products with vibrant colors, superior durability, and enhanced performance. From paints and coatings to cosmetics and textiles, pigment dispersions play an essential role in ensuring the quality and longevity of the final product. As innovation continues to drive the industry forward, the future of pigment dispersions looks bright, with sustainable solutions and cutting-edge technologies leading the way to even more efficient and eco-friendly formulations.

By understanding the applications, benefits, and innovations in pigment dispersions, businesses can make more informed decisions when selecting materials for their products, resulting in improved performance, greater customer satisfaction, and a more sustainable future.

0 notes

Text

Galvanized Steel Water Tanks: The Perfect Solution for Rainwater Storage

Galvanized Steel Water Tanks: The Perfect Solution for Rainwater Storage

Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) is proud to be a leading provider of galvanized steel water tanks, offering world-class solutions for rainwater storage. These versatile tanks have become an essential component in rainwater harvesting systems, serving a wide range of commercial and residential applications globally.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Galvanized Steel Water Tanks for Rainwater Storage?

1. Superior Corrosion Resistance

Galvanized steel water tanks are designed with a zinc coating that protects the steel from rust and corrosion, making them highly durable even in harsh environments. This ensures long-term performance and reliability, no matter the climate.

2. Eco-Friendly Solution

Rainwater harvesting is a sustainable practice that helps conserve water, reduce reliance on municipal supplies, and mitigate stormwater runoff. By using galvanized steel tanks, users can store rainwater efficiently and support environmentally friendly initiatives.

3. High Strength and Durability

The robust construction of our galvanized steel tanks ensures they can withstand external pressures, such as heavy rainfall and strong winds, providing dependable rainwater storage in various conditions.

4. Versatile Applications

Residential Use: Ideal for collecting and storing rainwater for gardening, household cleaning, and other non-potable uses.

Commercial Use: Widely used in industries, farms, and institutions for large-scale water storage and irrigation systems.

Urban and Rural Applications: Perfect for communities where rainwater harvesting is key to water sustainability.

5. Modular Design for Easy Installation

The prefabricated panels of our galvanized steel tanks allow for quick and straightforward on-site assembly. This modular design also enables easy transportation and installation in areas with limited access.

6. Cost-Effective

Galvanized steel tanks offer excellent value due to their durability, low maintenance requirements, and long lifespan, making them a cost-effective choice for rainwater storage.

Advantages of Galvanized Steel Water Tanks in Rainwater Harvesting Systems

Flexible Capacity Options: Available in various sizes to accommodate different storage needs, from small household systems to large commercial setups.

Customizable Designs: Tanks can be tailored to match specific site requirements, ensuring optimal integration into existing systems.

Low Maintenance: The zinc coating reduces the need for frequent repairs, keeping maintenance costs to a minimum.

Aesthetic Appeal: The sleek design of galvanized steel tanks blends seamlessly into urban and rural environments, offering a visually pleasing storage solution.

Applications of Galvanized Steel Water Tanks

Our galvanized steel water tanks are widely used in:

Rainwater Collection Systems: Efficiently capturing and storing rainwater for later use.

Irrigation Systems: Providing a reliable water source for agricultural fields and gardens.

Stormwater Management: Mitigating flooding risks by storing excess rainwater.

Emergency Water Supply: Ensuring a backup water source during droughts or water shortages.

Why Center Enamel?

Unmatched Expertise

With over 30 years of experience, Center Enamel is a trusted name in the storage tank industry, delivering reliable and innovative solutions to customers worldwide.

Global Reach

Our galvanized steel water tanks are used in more than 100 countries, catering to diverse rainwater harvesting needs across different climates and terrains.

Commitment to Quality

We adhere to strict international standards, ensuring the highest quality and performance in every tank we manufacture.

Take the First Step Toward Sustainable Water Storage

Center Enamel’s galvanized steel water tanks are the ultimate choice for rainwater harvesting, combining durability, versatility, and cost-efficiency. Whether for residential or commercial applications, our tanks are designed to meet your specific rainwater storage needs.

Contact us today to learn more about how our galvanized steel tanks can support your sustainable water management efforts. Let’s work together to make every drop count!

0 notes

Text

MS ERW B/Weld Tee: Reliable Industrial Pipe Fitting

The MS ERW B/Weld Tee is a robust and reliable pipe fitting designed for demanding industrial and commercial piping systems. Manufactured with precision and high-quality mild steel, it ensures leak-proof performance and seamless connections. In this article, we’ll examine the key features, benefits, and applications of the MS ERW B/Weld Tee while highlighting Udhhyog’s premium product range.

What is an MS ERW B/Weld Tee?

The MS ERW B/Weld Tee is a T-shaped fitting made using Electric Resistance Welding (ERW). It facilitates the connection of three pipelines and is particularly suitable for high-pressure environments. Its welded construction enhances durability and ensures optimal flow distribution.

Applications of MS ERW B/Weld Tee Fittings

MS ERW B/Weld Tee fittings are widely used in:

Industrial Pipelines: Ensuring reliable connections for transporting liquids and gases.

Petroleum and Gas Industries: Supporting efficient flow distribution in complex networks.

Water Supply Systems: Ideal for municipal and industrial water distribution.

Chemical Processing Plants: Handling corrosive and non-corrosive substances safely.

Power Plants: Supporting high-pressure steam and cooling systems.

MS ERW B/Weld Tee Products at Udhhyog

Udhhyog offers a range of high-quality MS ERW B/Weld Tee fittings, including:

MS ERW B/Weld Tee: Designed for heavy-duty industrial applications.

VS MS SW Reducing Tee: A versatile alternative for specific pipeline needs.

Key Features of MS ERW B/Weld Tee Fittings

Durable Construction: Manufactured with high-quality mild steel for longevity.

Leak-Proof Design: Ensures secure connections in high-pressure environments.

Corrosion Resistance: Coated to withstand harsh conditions and prevent rusting.

Precision Engineering: Guarantees a seamless fit and efficient flow distribution.

Versatile Applications: Suitable for diverse industrial and commercial setups.

Why Choose Udhhyog for MS ERW B/Weld Tee Fittings?

Uncompromised Quality: Every product meets rigorous industry standards.

Extensive Range: Solutions tailored to diverse pipeline requirements.

Custom Options: Fittings designed for unique project specifications.

Expert Support: Professional guidance for selecting the perfect fittings.

#MSERWBWeldTee#IndustrialPipeFittings#UdhhyogProducts#DurableFittings#FlowControl#PipeSolutions#HighPressureFittings

1 note

·

View note

Text

Empty Capsules Market Size, Share, Competitive Landscape and Trend Analysis Report Global Opportunity Analysis and Industry Forecast, 2024-2034

Empty capsules are a significant part of the pharmaceutical and nutraceutical industries. They are commonly used for encapsulating medicines, vitamins, and supplements in various forms such as powders, liquids, and granules. Their advantages, including masking unpleasant tastes, ease of swallowing, and precise dosing, make them a preferred choice among consumers and manufacturers.

The market for empty capsules is expected to reach a value of USD 3,230 million in 2023 and, with a linear growth pattern, reach USD 5,130 million by 2033, with a compound annual growth rate (CAGR) of 6.7% from 2023 to 2033.

Click the link to get a sample copy of the report: https://wemarketresearch.com/reports/request-free-sample-pdf/empty-capsules-market/1320

Market Growth Drivers

Rising Demand for Nutraceuticals: Consumers are increasingly turning to dietary supplements, boosting the demand for empty capsules.

Pharmaceutical Advancements: The growing prevalence of chronic diseases has led to a surge in the production of capsule-based medications.

Technological Innovations: Improved capsule designs, such as enteric-coated and extended-release capsules, are enhancing drug delivery efficiency.

Market Restraints

Vegetarian and Vegan Preferences: The demand for plant-based capsules is growing, creating challenges for manufacturers dependent on gelatin capsules.

Raw Material Costs: Fluctuations in the cost of gelatin and hydroxypropyl methylcellulose (HPMC) impact production costs.

Emerging Trends

Plant-Based Capsules: HPMC and pullulan capsules are gaining traction due to their vegetarian and vegan compatibility.

Personalized Medicine: Advances in precision medicine drive the demand for capsules tailored to individual patient needs.

Sustainability: Capsule manufacturers are exploring eco-friendly raw materials and production processes.

Challenges and Opportunities

Challenges:

Stringent regulations regarding the use of animal-derived products.

High competition in pricing among manufacturers.

Opportunities:

Increasing use of capsules for probiotics, essential oils, and herbal products.

Untapped markets in developing countries with expanding healthcare infrastructure.

Empty Capsules Market Competitive Analysis:

The Empty Capsules Market is dominated by a few large companies, such as Lonza, Qualicaps, Suheung Co., Ltd, Roxlor Llc, Natural Capsules Limited, Nectar Lifesciences Ltd, Healthcaps India Ltd., Sunil Healthcare Limited, Bright Pharma Caps, Snail Pharma Industry Co. Ltd, Medi-Caps Ltd.

Global Empty Capsules Market Segments

By Type

Gelatin

Non-Gelatin Capsules

Hydroxypropyl Methylcellulose (HPMC)

Others

By Functionality

Immediate Release

Sustained Release

Delayed Release

By Application

Vitamin & Dietary Supplements

Antibiotic & Antibacterial Drugs

Cardiac Therapy Drugs

Antacids & Anti-flatulent preparations

Others

By End-User

Pharmaceutical Companies

Nutraceutical Manufacturers

Others

Regional Analysis for Empty Capsules Market

Asia-Pacific as a Growth Hub:

The market for empty capsules is expanding rapidly in the Asia-Pacific area as a result of expanding pharmaceutical companies, improved healthcare infrastructure, and a growing emphasis on preventative healthcare. Both the pharmaceutical and nutraceutical industries are growing significantly in nations like China and India.

North America and Europe Lead the Market:

North America's established pharmaceutical sector and growing demand for dietary supplements have led to the region's dominance in the market. However, in Europe, there is a significant push for vegetarian and non-gelatin capsules as consumers become more conscious of environmental and ethical products.

Conclusion

The empty capsules market is poised for robust growth, fueled by increasing consumer demand for convenient and effective drug delivery solutions, as well as the rising popularity of dietary supplements. With innovations in capsule technology, a shift toward plant-based and sustainable options, and the expansion of healthcare infrastructure in emerging markets, the industry is set to witness significant advancements. However, manufacturers must navigate challenges such as regulatory complexities and fluctuating raw material costs. By embracing innovation and sustainability, the industry is well-positioned to meet evolving consumer needs and contribute to the future of healthcare and wellness.

0 notes

Text

Sodium Silicate Powder in the Paint Industry: Enhancing Durability and Quality

Why Do Paint Formulations Matter?

When you think about paint, you likely focus on its color and aesthetic appeal. But have you ever wondered what makes some paints last longer, resist harsh weather, and maintain their vibrant finish over time? The answer often lies in the formulation. In recent years, sodium silicate powder has emerged as a game-changing ingredient in the paint industry, offering unique properties that enhance both durability and quality.

What Is Sodium Silicate Powder, and How Does It Work in Paints?

Sodium silicate powder, commonly known as liquid glass in its dissolved state, is a compound made from silica and sodium carbonate. It has a broad spectrum of industrial applications, thanks to its excellent binding, adhesive, and protective properties. In paint formulations, sodium silicate acts as a multi-functional additive, contributing to improved durability, resistance to environmental factors, and cost-efficiency.

When incorporated into paint, sodium silicate forms a chemical bond with the substrate, creating a protective layer that enhances adhesion and strength. Its alkaline nature also helps neutralize acidic components, reducing the risk of paint degradation.

How Does Sodium Silicate Improve Paint Durability?

Durability is one of the most sought-after qualities in any paint, especially for industrial, automotive, and outdoor applications. Sodium silicate powder significantly improves durability by forming a hard, water-resistant layer. This layer shields the painted surface from moisture, UV radiation, and temperature fluctuations—key culprits behind paint peeling and fading.

Moreover, sodium silicate’s anti-corrosive properties make it a valuable ingredient in protective coatings. Whether it’s safeguarding metal structures or enhancing the lifespan of building exteriors, sodium silicate-based paints offer long-lasting performance.

Can Sodium Silicate Powder Help Reduce Maintenance Costs?

Frequent repainting can be a costly and time-consuming affair. By enhancing the longevity of paint, sodium silicate reduces the need for maintenance and repainting. Industries such as construction and transportation benefit immensely from this cost-saving advantage. For instance, sodium silicate-based paints on bridges or industrial equipment can withstand years of wear and tear, lowering overall maintenance expenses.

What Role Does Sodium Silicate Powder Play in Eco-Friendly Paints?

As industries pivot toward sustainable practices, sodium silicate has gained attention for its eco-friendly attributes. Unlike many chemical additives, sodium silicate is non-toxic and has low VOC (volatile organic compound) emissions. This makes it an ideal ingredient for eco-friendly and water-based paints. Its natural fire-retardant properties also align with the growing demand for safer, environmentally responsible products.

How Is Sodium Silicate Powder Used in Specialty Paints?

Beyond its use in general paints, sodium silicate plays a critical role in specialty paints and coatings. Here are some examples:

Fire-Resistant Coatings: Sodium silicate’s fire-retardant properties make it a key ingredient in paints used for fireproofing buildings and industrial equipment.

Reflective Paints: Used in road markings and signage, sodium silicate enhances reflectivity and durability.

Marine Paints: In the maritime industry, sodium silicate-based paints protect ship hulls from saltwater corrosion and fouling by marine organisms.

These niche applications highlight the versatility and importance of sodium silicate in modern paint formulations.

What Are the Limitations of Sodium Silicate Powder in Paints?

While sodium silicate offers numerous benefits, it’s not without limitations. For instance, its high alkalinity may limit compatibility with certain pigments and additives. Additionally, improper formulation can lead to issues like cracking or brittleness. However, these challenges can be mitigated through advanced formulation techniques and proper testing, ensuring optimal performance.

Industries Benefiting from Sodium Silicate-Based Paints

Construction: Sodium silicate-based paints are widely used in concrete sealers and protective coatings for building exteriors.

Automotive: These paints provide corrosion resistance for undercarriages and other metal components.

Marine: Ships and offshore structures benefit from sodium silicate’s anti-corrosive and anti-fouling properties.

By exploring these industries, it’s evident that sodium silicate powder delivers tangible benefits across diverse applications.

What’s Next for Sodium Silicate in Paints?

What advancements can we expect in sodium silicate-based paint technologies?

Research and development in sodium silicate-based paints continue to unlock new possibilities. For instance, nanotechnology is being explored to enhance its protective capabilities further. Additionally, innovations in hybrid formulations are making sodium silicate compatible with a broader range of materials, paving the way for more versatile and efficient paints.

Conclusion: Is Sodium Silicate the Key to Better Paints?

Sodium silicate powder is undoubtedly a transformative ingredient in the paint industry. From enhancing durability and reducing maintenance costs to contributing to sustainability and specialty applications, its advantages are both practical and impactful.

If you’re looking to incorporate high-quality sodium silicate powder into your paint formulations, Noble Alchem is your trusted partner. With years of expertise in manufacturing top-grade sodium silicate products, we help industries achieve superior results. Contact us today to learn more about our solutions and how we can elevate your paint formulations to the next level.

0 notes

Text

Understanding Pharmaceutical Colors: Types and Applications

Pharmaceutical Colors are essential in the pharmaceutical industry, serving purposes far beyond mere aesthetics. These colors contribute significantly to the identification, differentiation, and branding of medicines.

They also play a pivotal role in improving patient compliance by making medicines more appealing and easier to recognize. From tablets and capsules to syrups and ointments, pharmaceutical colors are carefully selected and regulated to ensure safety and consistency.

Pharmaceutical colors can be classified into various types, each with unique attributes and applications. Natural colors, derived from sources like plants, minerals, and insects, are widely appreciated for their eco-friendly and non-toxic properties.

Examples include carotenoids for yellow and orange hues and chlorophyll for green shades. On the other hand, synthetic colors, which are man-made, offer a broader spectrum of vibrant and stable colors. These synthetic options, such as FD&C dyes, are commonly used due to their cost-effectiveness and reliability in various formulations.

Another type, known as lakes, are insoluble pigments created by combining dyes with metallic salts, ideal for products requiring stability in coating applications.

Mineral pigments, such as titanium dioxide and iron oxides, are also prevalent due to their opacity and durability. The applications of pharmaceutical colors are diverse and impactful. They play a critical role in drug identification, helping to distinguish medications that may otherwise appear similar, thereby minimizing the risk of errors.

Pharmaceutical companies also leverage unique color combinations to establish brand recognition, ensuring their products stand out in a competitive market. Moreover, colors enhance patient compliance, as visually appealing medicines are more likely to be consumed as prescribed.

For liquid formulations like syrups, pharmaceutical colors, paired with flavors, help mask unpleasant tastes, making the medications more palatable.

In essence, pharmaceutical colors are indispensable in ensuring the functionality, safety, and appeal of medicines. Their significance will continue to grow as innovations in drug formulations evolve.

0 notes

Text

Step-by-Step Process of Copper Recycling Services in San Angelo

Recycling is an essential practice for a sustainable future, and Copper Recycling stands out as a crucial contributor to reducing waste and conserving natural resources. In San Angelo, a city known for its eco-conscious community, the demand for copper recycling services has grown significantly. But what exactly does the process involve? Let’s break it down step-by-step, so you can understand how your old copper items are given a new lease on life.

Step 1: Collection of Copper Scrap

The journey of Copper Recycling begins with the collection of scrap copper. Individuals, businesses, and construction companies in San Angelo often gather copper items such as old wiring, pipes, plumbing materials, and electronic components. These materials are brought to local recycling facilities or scrap yards, which serve as the first stop in the recycling process.

Recycling centers in San Angelo make it convenient for residents to drop off their copper waste. Many facilities also offer pickup services, making the process hassle-free for larger contributors like contractors and industrial businesses.

Step 2: Sorting and Grading

Once the copper scrap reaches the recycling facility, it undergoes a thorough sorting and grading process. This step ensures that only high-quality copper is used for recycling. Workers or automated systems separate copper based on its type—pure copper, copper alloys, or contaminated copper.

Copper is also graded according to its purity. Clean, uncoated copper fetches a higher value compared to coated or mixed materials. In this step, the copper is prepared for the next stages by removing any attached materials like rubber, plastic, or other metals.

Step 3: Cutting and Shredding

After sorting and grading, the copper is cut and shredded into smaller pieces. This makes it easier to handle and speeds up the melting process in later stages. Shredding also increases the surface area, allowing for efficient removal of impurities during the refining phase.

For larger pieces like pipes or wiring, industrial-grade shredders are used to break the copper down into manageable chunks. This step reduces the energy needed for processing and enhances the overall efficiency of the recycling operation.

Step 4: Melting and Refining

The shredded copper is now ready for the most critical step: melting. In high-temperature furnaces, the copper is melted into a liquid form. During this process, impurities such as dirt, paint, or non-metallic materials are removed. Advanced refining techniques ensure that the molten copper achieves the desired purity level.

Once melted, the copper is poured into molds to create ingots, sheets, or other standardized forms that can be reused in various industries. This process ensures that the recycled copper retains the same quality as newly mined copper, making it an excellent alternative for manufacturing needs.

Step 5: Manufacturing New Products

The final step in the Copper Recycling process is transforming the refined copper into new products. Recycled copper is highly versatile and finds its way into a wide range of applications. From electrical wiring and plumbing systems to construction materials and even art pieces, recycled copper is in high demand.

Industries in San Angelo and beyond benefit from the cost-effectiveness and environmental advantages of using recycled copper. By utilizing this valuable resource, businesses reduce their reliance on mining and promote sustainability.

Conclusion

The step-by-step process of Copper Recycling in San Angelo highlights the importance of turning waste into a valuable resource. From collection and sorting to melting and manufacturing, each stage plays a vital role in creating a sustainable recycling ecosystem. By participating in copper recycling, you’re not just discarding scrap—you’re contributing to a cleaner environment and a more sustainable future.

If you have copper items lying around, don’t let them go to waste. Take them to a local recycling center in San Angelo and be part of the change. Together, we can make a significant impact, one piece of copper at a time.