#Nitrogen Generators

Explore tagged Tumblr posts

Text

The Role of Nitrogen Generators in Food Packaging

In the food industry, maintaining product freshness and extending shelf life are critical factors in delivering quality products to consumers. Nitrogen gas plays a vital role in food packaging by creating a protective atmosphere that preserves the quality and integrity of food items. Traditional methods of nitrogen supply, such as gas cylinders, have limitations that can impact efficiency and cost-effectiveness. However, nitrogen generators have revolutionized the way nitrogen is supplied, offering numerous advantages that benefit food manufacturers. In this blog, we'll explore the role of nitrogen generators in food packaging and why they are becoming essential for modern food production.

1. Extending Shelf Life

One of the primary benefits of using nitrogen gas in food packaging is its ability to extend the shelf life of perishable products. Nitrogen displaces oxygen within packaging, creating an inert atmosphere that slows down the oxidation process and prevents spoilage. This is particularly important for products like snacks, baked goods, and processed foods, where freshness is key to consumer satisfaction. By using nitrogen generators to produce nitrogen on-site, food manufacturers can ensure a consistent and reliable supply of nitrogen, which is crucial for maintaining product quality.

2. Maintaining Product Quality

In addition to extending shelf life, nitrogen helps maintain the quality of food products by preventing the growth of aerobic bacteria and molds. When food is exposed to oxygen, it can undergo chemical changes that affect its taste, texture, and appearance. Nitrogen generators allow manufacturers to control the nitrogen atmosphere within packaging, ensuring that products retain their original quality throughout their shelf life. This control over the packaging environment is essential for delivering high-quality food products to consumers.

3. Reducing Packaging Costs

Using nitrogen generators can lead to significant cost savings in the food packaging process. Traditional nitrogen supply methods, such as gas cylinders, involve recurring costs for purchasing, transporting, and storing nitrogen. On-site nitrogen generation eliminates these expenses, as the gas is produced directly at the point of use. This not only reduces packaging costs but also minimizes the logistical challenges associated with managing nitrogen supplies. The cost savings realized from on-site nitrogen production can be reinvested into other areas of the business, enhancing overall profitability.

4. Enhancing Food Safety

Food safety is a top priority for manufacturers, and nitrogen generators contribute to a safer production environment. By producing nitrogen on-site, manufacturers reduce the risk of contamination associated with handling and transporting gas cylinders. Nitrogen generators provide a clean and consistent source of nitrogen, which is critical for maintaining the safety and integrity of packaged food products. Additionally, the use of nitrogen generators reduces the need for chemical preservatives, allowing manufacturers to offer cleaner label products that appeal to health-conscious consumers.

5. Supporting Sustainable Packaging

Sustainability is becoming increasingly important in the food industry, and nitrogen generators support environmentally friendly packaging practices. Traditional nitrogen supply methods can have a significant carbon footprint due to the energy-intensive processes involved in producing and transporting the gas. Nitrogen generators produce nitrogen using ambient air, which is a more sustainable and energy-efficient method. By reducing the environmental impact of nitrogen supply, food manufacturers can enhance their sustainability credentials and meet the growing demand for eco-friendly packaging solutions.

Conclusion

The role of nitrogen generators in food packaging is crucial for maintaining product freshness, extending shelf life, and ensuring food safety. By providing a reliable and cost-effective supply of nitrogen, nitrogen generators help food manufacturers optimize their packaging processes and deliver high-quality products to consumers. Additionally, the use of nitrogen generators supports sustainability efforts by reducing the carbon footprint associated with nitrogen supply. For food manufacturers looking to enhance their packaging operations, investing in a nitrogen generator is a smart and sustainable choice.

0 notes

Text

Ensuring Quality and Safety: Nitrogen Generators Transforming Food Packaging

Nitrogen generators are changing the food packaging game, providing many benefits such as better product quality, longer shelf life, and less food waste. These innovative machines create a controlled environment that preserves the freshness of perishable foods by replacing oxygen with nitrogen. With consumers demanding fresh, high-quality food, nitrogen packaging has become an important advancement in meeting these needs. Using nitrogen generators also improves the sustainability and efficiency of the food supply chain for manufacturers and retailers.

I also cover this topic in my latest blog, read at https://absstem.com/nitrogen-generator-a-game-changer-in-food-packaging/

0 notes

Text

Discover the versatility of nitrogen gas generation and how it can revolutionize operations and cut costs in 10 key industries. Visit our website to learn more, https://adgastech.com/

#nitrogen gas generation#nitrogen generators#nitrogen generating systems#PSA nitrogen gas generators#Membrane nitrogen gas generators

0 notes

Text

0 notes

Note

We’d all like the rest of your butterfly facts, please.

I have SO MANY; I'm not even sure how to share them all.

Butterflies and moths are not taxonomic or cladistic groups; they're colloquial terms to refer to lepidoptera (the taxonomic order butterflies and moths belong to) that have different characteristics and behaviors. That said:

Moths tend to be nocturnal

Moths tend to have fuzzy bodies, butterflies are sleek

Moths tend to have fuzzy antennae, butterflies just have straight plain ones

The additional fuzz on months allows them to sense what's around them, which is helpful because they're not seeing as much because they're nocturnal

Moths tend to build chrysalises with silk but also leaves and mud, etc. These are known as cocoons. Butterflies only use silk and don't have cocoons (either are known as chrysalis)

The Atlas Moth has the biggest wingspan of any lepidoptera

The Atlas Moth usually emerges from its cocoon without a mouth. It can only breed and die

The Atlas Moth caterpillar lives for months. It's generally in the cocoon for months! But it only lives as an adult moth for a few days (because it can't even eat!)

Inside their chrysalises, caterpillars don't just grow wings and longer legs. They liquify completely and reform.

Caterpillars have six legs called "true legs" that mirror the six legs butterflies have. Then they have additional nubs farther down their bodies that help them move around.

Butterflies taste with their feet. If they land on you, they're tasting you!

Butterflies can only eat liquid. They primarily eat nectar and juice from fruit. Rotten fruit is easier for them because rotten fruit is juicy.

The butterfly mouth is called a proboscis. It curls up when not in use and uncurls when the butterfly eats. It's like a straw.

The word "proboscis" can sometimes refer (as a joke!) to nose, but butterflies can't smell with their proboscis. They smell with their antennae!

Like many insects, butterflies have faceted eyes. But unlike the movies, they probably don't see the same image over and over, because their vision isn't refined enough for that. What faceted eyes allow them to see are big patches of color, which is useful considering they eat fruit and flowers. If you want a butterfly to land on you, wear something colorful.

Butterflies don't have lungs. Like most insects, they breathe through holes in their bodies called spiracles.

Incidentally, this is why insects are so small. If they were giant, these holes would have to be bigger or there would have to be many more of them, and that would mean their exoskeleton was not stable!

Oh, yeah, butterflies do not have bones. Like all insects, they have an exoskeleton.

Butterflies do not have blood. Like all insects, they had a fluid that moves most nutrients through their bodies. It's called hemalymph. It carries hormones, nutrients, and waste. It's blue!

Male butterflies tend to be smaller and more colorful than female butterflies. This is the same style of sexual dimorphism present in most insects. Also in birds!

Male monarch butterflies have distinctive dark spots on the lower wings that female monarch butterflies don't have. The spots are scent glands that help them attract mates.

Most butterflies migrate. Like birds.

Monarch butterflies in North America east of the Rocky Mountains have one of the most impressive migration patterns of any animal. They may travel up to 3,000 miles from Canada to Mexico, but what is most spectacular about it is that almost all of them end up in just a few spots relatively close together on some mountain peaks in Central Mexico. The monarchs are so dense that you can't see the trees.

Butterflies are great for studying evolutionary adaptations in coloration and appearance because they are so striking. Camouflage is the adaptation present when an animal blends in with its surroundings. Mimicry is the adaptation that makes an animal look like a different animal.

The owl butterfly is a great example of mimicry because it has two big owl eyes on its wings. The Atlas moth wing tips look like snake heads.

"Batesian mimicry" is named after Henry Walter Bates, who studied mimicry in butterflies. Batesian mimicry means that one species who is harmless looks like another species that is not harmless. Mullerian mimicry is when several species that are harmful all look like each other, so the warning to predators is stronger. Butterflies have great examples of both types of mimicry.

Monarch butterflies and viceroy butterflies were once thought to exhibit Batesian mimicry, because it was thought that vicroys weren't toxic, but it turns out both butterflies are poisonous and so the species have evolved to mimic each other in an example of Mullerian mimicry.

Monarch butterflies are poisonous because the milkweed caterpillars eat is poisonous

The best way to attract butterflies is to grow native plants.

#butterflies#i actually have lots more facts about how butterfly houses work#i also have a lot of random science knowledge that is accessible and interesting to the public!!!!#ask about these subjects#whales in general#whale evolution#naked mole rats#the physics of sound#microorganisms#tide pools#stars#nutrition#ocean acidification#planets#liquid nitrogen#bubbles#blowing things up#snakes#volcanoes#dinosaurs#climate change#long post

49 notes

·

View notes

Text

pages 225 and 226 - has my life been productive?

No kids that I know of. No party I could say no to. Working just enough (see previous answer). Minimal responsibility for destruction of the rain forest (had a bit of a passion for açaí berries in the mid oughts I will admit). Tried to feel good. Tried to make others feel good.

But I don't remember starting any factories, so I guess the answer is no.

But I don't get it MAN.

This person is called screaming debbie by the way, because those orbs come screaming at you when you're playing the game orbs.

#biology#biologist#zoology#zoologist#text#textbook#weismanns idea#relationship between germ plasm and somatic cells#zygotes#body cells#next generation#circles#round#drawing circles#fertilization in parascaris#parascaris#fertilization#fertilize#fertilizer#nitrogen#phosphate#sperm#egg#nucleus#chromosomes#evolution#modern evolutionary theory#mother#birth#queen

12 notes

·

View notes

Text

Yall (vastards) forget about ozone and other atmospheric gases way too much.

- this post was made by the atmospheric chemistry squad-

#no but ozone is so cool#and nitrogen#and hydrogen#yall could be making so many scientist ocs and as far as i can tell you’re not!!!#mine became an avatar after finding a leitner whos text only revealed itself under ozone exposure#grew completely obsessed with it#made a fucked up overpowered ozone generator to try and read it#and died from ozone poisoning#she just constantly exhales it now and bleeds the dark blue liquid it condenses into#tma#the magnus archive#the magnus archives#tma the vast#the magnus archives the vast#the vast

33 notes

·

View notes

Text

CARNIVOROUS PLANTS CANNOT JUST GET EVERYTHING THEY NEED FROM THE SUN. YES THEY CAN STILL GET LIGHT (AND CONVERSELY ANY NON-GREEN PLANTS ARE GENERALLY PARASITIC BECAUSE THEY CANNOT GET ENERGY FROM THE SUN) FROM THE SUN BUT PHOTOSYNTHESIS CANNOT REPLACE IMPORTANT NUTRIENTS PLANTS GET FROM THE SOIL. THAT IS WHY THEY EAT THE BUGS. THANK YOU FOR LISTENING TO THIS IMPORTANT MESSAGE.

#photosynthesis allows for the manufacture of sugars from co2 and water#but you do need more chemicals than carbon oxygen and hydrogen to make organisms#like nitrogen. most plants cannot get nitrogen (which they need!) from the air#as well as phosphorus ect ect#there’s a reason carnivorous plants are generally in VERY nutrient-poor soils

45K notes

·

View notes

Text

Efficient PSA Nitrogen Plants by Trimech India

Trimech India specializes in designing and manufacturing PSA nitrogen plants that deliver high-purity nitrogen efficiently and cost-effectively. Our PSA nitrogen generator employs advanced twin-tower technology with Carbon Molecular Sieve (CMS) to separate nitrogen from atmospheric air. With capacities ranging from 5 NM3 to 1000 NM3/Hr, these compact, low-maintenance systems eliminate the need for N2 cylinders, making them ideal for industries like pharmaceuticals, food processing, and electronics. Backed by robust after-sales service, including user training and warranty support, Trimech India ensures reliability and customer satisfaction. Choose us for a sustainable and economical nitrogen generation solution!

0 notes

Text

Figure 12.3 shows a portion of a hypothetical structure of a generic humate molecule.

It is, of course, essential to realize that Fig. 12.3 does not depict a specific humate molecule and, in fact, there is no such thing as a single specific humate species in any of the three classes.

"Environmental Chemistry: A Global Perspective", 4e - Gary W. VanLoon & Stephen J. Duffy

#book quotes#environmental chemistry#nonfiction#textbook#humic substance#humate#hypothetical#aliphatic#aromatic#functionality#polymer#generic#hydrogen#carbon#oxygen#nitrogen

0 notes

Text

PSA Nitrogen systems generate a continuous flow of nitrogen at desired concentrations for various commercial markets.

Produce nitrogen with an AirSep nitrogen plant with 99.9-99.99% product concentrations.

Any AirSep gas generating plant can be designed/customized for a wide range of applications and containerized options are available for easy installation.

AirSep nitrogen plants are cost-effective, economical, and power-efficient, requiring just enough amounts of energy to power up the nitrogen compressor which in turn supplies air to the system.

For more information » on Airox Technologies Ltd, Visit us & give us a call now » at +91 9764634964 or mail us at [email protected] »

0 notes

Text

there's a youtube channel called 'Dive Talk' run by two experienced diving instructors who do a great job demystifying cave and deep-water diving, including critiquing other channels' videos that sensationalize or outright make shit up about cases where people have died while diving.

(I still would never want to go cave diving myself, mind, but now I at least understand the appeal and have a better idea of when someone talking about diving is full of shit, which is cool)

I know people on tumblr looove stories of underwater cave diving, but I haven't seen anyone talk about nitrogen narcosis aka "raptures of the deep"

basically when you want to get your advanced scuba certification (allowing you to go more than 60 feet deep) you have to undergo a very specific test: your instructor takes you down past the 60+ foot threshold, and she brings a little underwater white board with her.

she writes a very basic math problem on that board. 6 + 15. she shows it to you, and you have to solve it.

if you can solve it, you're good. that is the hardest part of the test.

because here's what happens: there is a subset of people, and we have no real idea why this happens only to them, who lose their minds at depth. they're not dying, they're not running out of oxygen, they just completely lose their sense of identity when deep in the sea.

a woman on a dive my instructor led once vanished during the course of the excursion. they were diving near this dropoff point, beyond which the depth exceeded 60 feet and he'd told them not to go down that way. the instructor made his way over to look for her and found a guy sitting at the edge of the dropoff (an underwater cliff situation) just staring down into the dark. the guy is okay, but he's at the threshold, spacing out, and mentally difficult to reach. they try to communicate, and finally the guy just points down into the dark, knowing he can't go down there, but he saw the woman go.

instructor is deep water certified and he goes down. he shines his light into the dark, down onto the seafloor which is at 90 feet below the surface. he sees the woman, her arms locked to her sides, moving like a fish, swimming furiously in circles in the pitch black.

she is hard to catch but he stops her and checks her remaining oxygen: she is almost out, on account of swimming a marathon for absolutely no reason. he is able to drag her back up, get her to a stable depth to decompress, and bring her to the surface safely.

when their masks are off and he finally asks her what happened, and why was she swimming like that, she says she fully, 100% believed she was a mermaid, had always been a mermaid, and something was hunting her in the dark 👍

#one of the other factors with deep-water diving is you don't breathe regular air#you gotta use what's called trimix: oxygen nitrogen and helium#you can't breathe pure O2 beyond a certain depth without risking oxygen toxicity from the pressure#but if you only added nitrogen you'd get zooted the way op describes#so the helium dilutes the oxygen and nitrogen plus makes breathing take less effort#the tradeoff for helium is 1. it's pricey 2. it makes you lose body heat more quickly#so you have to tinker your personal mix based on what depth you're going to#but also by testing out stuff like your specific breathing rate above water#so if someone who has open-water dived a ton but then decides to go deeper than 60 ft. without the proper training or kit. and dies#and the news tries to fearmonger about diving in general#just know that they're two very different ability levels

105K notes

·

View notes

Text

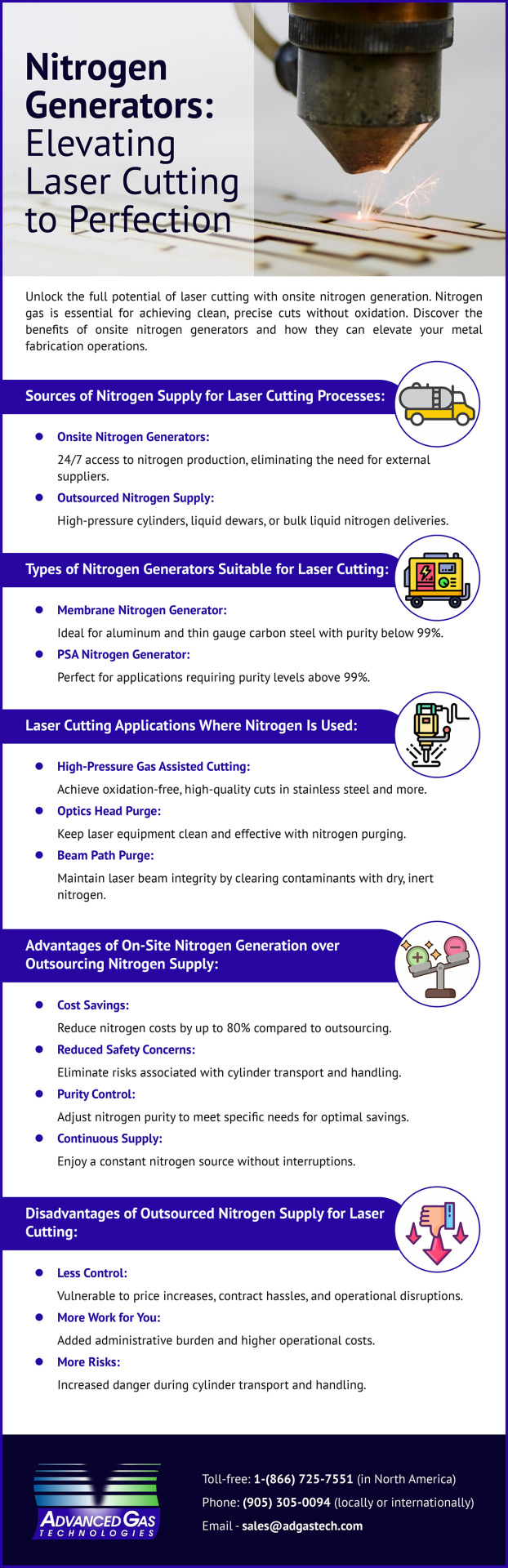

Unlock the full potential of laser cutting with onsite nitrogen generation. Nitrogen gas is essential for achieving clean, precise cuts without oxidation. Discover the benefits of onsite nitrogen generators and how they can elevate your metal fabrication operations. Learn more at https://adgastech.com/

#Nitrogen gas#nitrogen gas for mining industry#nitrogen gas generator#Nitrogen generators#nitrogen generating systems#onsite nitrogen generation

0 notes

Text

Leading the Way as Oxygen and Nitrogen Gas Generator Manufacturers

In this blog i will provide you Top class Nitrogen and Oxygen manufacturers in India. PSG Engineering Company, a leading Oxygen Gas Generator Manufacturer and Nitrogen Gas Generator Manufacturer, has been at the forefront of providing innovative, efficient, and reliable gas generation systems to businesses across the globe. With a strong commitment to quality and customer satisfaction, PSG Engineering is renowned for offering advanced solutions that meet the specific needs of different sectors.

Why Choose On-Site Gas Generation?

The traditional method of obtaining gases like oxygen and nitrogen involves purchasing from large suppliers in bulk, a practice that can be costly and lead to supply chain disruptions. On-site gas generation has emerged as a more efficient, cost-effective, and reliable alternative. By using state-of-the-art oxygen and nitrogen gas generators, industries can now produce the exact amount of gas they need on-demand, right at their facility. This not only saves costs but also ensures a continuous and uninterrupted gas supply, which is essential for many industrial applications.

PSG Engineering Company specializes in designing and manufacturing high-performance Oxygen Gas Generators and Nitrogen Gas Generators that offer industries a secure, cost-effective, and sustainable solution for on-site gas production. Their products are engineered to meet the rigorous demands of various sectors, from healthcare to manufacturing, with flexibility and scalability.

Oxygen Gas Generators: Vital for Medical and Industrial Applications

Oxygen is a crucial gas used in numerous fields. In healthcare, it plays a life-saving role for patients in need of respiratory support, while in industrial settings, it is used in processes such as combustion, welding, metal cutting, and chemical reactions. PSG Engineering’s Oxygen Gas Generators are designed to cater to both medical and industrial needs, offering unmatched reliability and purity.

Medical Oxygen Generators: Ensuring Life-Saving Support

For hospitals, clinics, and healthcare providers, an uninterrupted supply of oxygen is vital. PSG Engineering Company provides medical oxygen generators that deliver high-purity oxygen (typically 93% ± 3%) in a reliable, cost-efficient manner. These systems eliminate the need for bulky and expensive oxygen cylinders or frequent deliveries, providing healthcare facilities with a constant and dependable source of oxygen. The on-site production capability ensures that healthcare professionals have the necessary gas supply during critical moments, without the anxiety of supply shortages.

These generators are equipped with advanced filtration and purification systems to ensure that the oxygen produced is free from contaminants. The systems are also compact, easy to operate, and require minimal maintenance, ensuring seamless performance over long periods.

Industrial Oxygen Generators: Enhancing Productivity and Efficiency

In industrial applications, oxygen plays a pivotal role in enhancing productivity. Whether it is in the metal fabrication industry for cutting and welding or in chemical processing for oxidation reactions, oxygen is a critical component of many processes. PSG Engineering’s industrial oxygen generators are built to provide a continuous and consistent supply of oxygen, ensuring high efficiency and reducing operational costs. These generators are available in various capacities to suit businesses of all sizes and are designed to work in harsh industrial environments.

The PSA (Pressure Swing Adsorption) technology used in PSG Engineering��s industrial oxygen generators allows for efficient oxygen separation, providing businesses with high-quality oxygen at a fraction of the cost of traditional supply methods. The systems are designed with energy efficiency in mind, reducing operational costs and minimizing environmental impact. With minimal downtime and maintenance, PSG’s oxygen generators contribute to better productivity and profitability for industries that rely on oxygen for their operations.

Nitrogen Gas Generators: Cost-Effective and Sustainable Solutions

Nitrogen gas is one of the most widely used industrial gases, with applications ranging from food preservation and packaging to electronics manufacturing and pharmaceuticals. PSG Engineering Company, as a leading Nitrogen Gas Generator Manufacturer, offers advanced nitrogen generation systems that cater to the diverse needs of industries.

On-Site Nitrogen Generation: The Smart Choice for Industries

PSG Engineering’s nitrogen gas generators provide a sustainable, cost-effective alternative to the traditional method of purchasing nitrogen from bulk suppliers. With on-site nitrogen production, businesses can eliminate the hassle and cost associated with cylinder deliveries, as well as the risk of supply disruptions.

The nitrogen generators manufactured by PSG Engineering utilize advanced PSA (Pressure Swing Adsorption) and membrane separation technology to generate nitrogen on-demand. This technology allows for the separation of nitrogen from the air, producing high-purity nitrogen ranging from 95% to 99.999%. The ability to generate nitrogen on-site eliminates the need for storage tanks or cylinder management, reducing logistical challenges and improving operational efficiency.

Whether used in food packaging to preserve freshness or in the electronics industry for inerting and soldering applications, PSG Engineering’s nitrogen generators offer industries a reliable, uninterrupted supply of nitrogen at an affordable price.

Customized Solutions for Every Industry

PSG Engineering understands that each industry has its own set of requirements when it comes to nitrogen generation. Whether you need a generator for a small-scale laboratory or a large industrial plant, PSG Engineering provides customized solutions that match your specific needs. The nitrogen generators can be tailored to deliver varying purity levels and flow rates, ensuring that each customer receives a solution that best fits their application.

Why PSG Engineering Company?

PSG Engineering’s reputation as an industry leader in oxygen and nitrogen gas generator manufacturing is built on a foundation of innovation, quality, and customer service. Here are several reasons why businesses around the world trust PSG Engineering:

Expertise and Innovation: With years of experience in the gas generation industry, PSG Engineering brings unmatched expertise and cutting-edge technology to its products. Their team of engineers works closely with clients to design and build systems that meet exacting standards of quality, reliability, and performance.

Reliability: PSG Engineering’s oxygen and nitrogen generators are built to perform reliably in demanding industrial environments. With robust designs and minimal downtime, businesses can count on these systems for uninterrupted gas supply.

Cost-Effectiveness: By providing on-site gas generation systems, PSG Engineering helps businesses save on the high costs of gas supply and transportation. This translates into significant long-term savings and improved bottom lines.

Customer-Centric Service: From installation to after-sales support, PSG Engineering ensures that customers receive exceptional service. They offer comprehensive maintenance, training, and troubleshooting support, ensuring that systems operate at peak efficiency.

Conclusion

PSG Engineering Company, leading manufacturer of oxygen and nitrogen gas generation, if you have any enquiry regarding seals you can feel free content Us!

Email :- [email protected] , [email protected] Contact No. :- +91-8126173604, +91-9899123075, 0122-3588093 Website: https://www.psggasplant.co.in/

0 notes

Text

How energy-efficient are compressed air nitrogen gas generators?

Compressed air nitrogen gas generators are essential for industries requiring a steady and reliable supply of nitrogen. Their energy efficiency is a crucial factor, especially for businesses seeking cost-effective and sustainable solutions. By generating nitrogen on-site, these systems eliminate the need for nitrogen delivery, reduce energy consumption in logistics, and enhance operational efficiency. Here’s a deeper look into their energy efficiency and contributing factors.

Energy Efficiency in Nitrogen Generators

Compressed air nitrogen gas generator typically operate using Pressure Swing Adsorption (PSA) or membrane separation technology. Both processes rely on compressed air as the feed source to produce nitrogen gas, and the energy efficiency of the generator is closely tied to how effectively this compressed air is utilized.

Optimized Air Utilization advanced nitrogen gas generators are designed to maximize the conversion of compressed air into nitrogen. PSA systems, for example, use adsorbent materials like carbon molecular sieves to separate nitrogen from oxygen efficiently. In well-designed systems, up to 80-90% of the compressed air can be converted into usable nitrogen, ensuring minimal wastage.

Energy Savings Compared to Cylinder Supply Producing nitrogen On site medical oxygen generators eliminates the energy-intensive processes associated with traditional nitrogen supply methods. In cylinder or liquid nitrogen delivery, energy is consumed during compression, liquefaction, and transportation. In contrast, on-site generators streamline the process, reducing the overall energy footprint.

Variable Purity Options Compressed air nitrogen gas generators allow users to customize nitrogen purity levels (typically ranging from 95% to 99.999%). Lower purity requirements demand less energy, making the system more efficient for applications that do not need ultra-pure nitrogen.

Reduced Energy Losses Modern nitrogen generators incorporate energy-efficient components, such as low-pressure drop filters and advanced air compressors, to minimize energy losses. Some systems also integrate energy recovery mechanisms to further improve overall efficiency.

Factors Influencing Energy Efficiency

Several factors impact the energy efficiency of compressed air nitrogen gas generators:

Quality of the Air Compressor The air compressor is the primary energy-consuming component in the system. Energy-efficient compressors, such as variable speed drive (VSD) compressors, adjust their output based on demand, reducing energy consumption during low-load periods.

System Design Proper system design, including optimized piping and effective air filtration, ensures minimal pressure drops and maximizes efficiency. Poor design can lead to energy losses and higher operating costs.

Maintenance Practices Regular maintenance, such as replacing filters, cleaning adsorbent beds, and checking for leaks, keeps the generator operating at peak efficiency. Neglecting maintenance can reduce system performance and increase energy consumption.

Environmental Conditions Ambient temperature, humidity, and altitude can influence the efficiency of a nitrogen generator. High humidity, for example, requires additional energy for air drying before compression, affecting the system’s overall energy efficiency.

Environmental and Economic Benefits

The energy efficiency of compressed air nitrogen gas generators translates directly into reduced operational costs and environmental benefits. Lower energy consumption means lower utility bills, while minimizing the carbon footprint of nitrogen production supports sustainability goals. Furthermore, the independence from delivery trucks and packaged nitrogen reduces reliance on fossil fuels, aligning with global environmental standards.

Conclusion

Compressed air nitrogen gas generators are an energy-efficient solution for industries requiring consistent nitrogen supply. By optimizing air utilization, leveraging advanced technology, and adhering to proper maintenance practices, these systems ensure a balance between cost savings and environmental responsibility. For businesses in manufacturing, food processing, pharmaceuticals, and beyond, investing in energy-efficient nitrogen generators can deliver long-term value and sustainability.

0 notes

Text

My nuanced opinion on the subject of the hard sciences hierarchy is that chemistry and biology are marking out with tongue and that physics is mostly just there to watch.

Okay something that bothers me is the fact physics is seen as the more prestigious of the three main sciences, with biology at the bottom and chemistry in the middle. Like. I doubt most people could name a famous biologist, but they could name 5 famous physicists. Why are Albert Einstein and Stephen hawking household names but Norman Borlaug and Jonas Salk aren't?

Not to dismiss the accomplishments of Einstein or Hawking, or their genius, but their actual tangible contributions to society have been miniscule compared to that of Borlaug or Salk who have each saved LITERALLY hundreds of millions, if not billions, of lives each. Half the food on your plate was probably grown thanks to Borlaug and Salk is the reason half your siblings didn't die of polio as a kid.

Sure Einsteins theory of relatively is important for modern satellite communications but really though how can it compare?

This is coming from someone who studied physics. I love physics, and years ago when i was at uni I looked down at biology and so did everyone else studying physics. And I know others did too. Retroactively of course I know this was so very wrong.

If society as a whole started treating biology with more respect then maybe more students would go into that field. If we had rockstars of medicine and agricultural science that were household names rather than just physicists? think of how many more lives could be saved, how many more lives could be improved.

I'm not saying physics isn't important, and more scientists of any kind is always good, but proportionally I think societies priorities are a little skewd.

#my BIASED opinion as a chemist is that chemistry does not get enough cred#I know this is technically about the prestige of the field and how that seems to be generally inversely related to practical use but#If not for chemistry the world wouldn’t be short 1 billion people it would be short 4 billion#80% of the nitrogen in your body likely came from the Haber Bosch process#the amount of chemistry going on in the background of our lives is insane

52K notes

·

View notes