#Natural Rubber Market Development

Explore tagged Tumblr posts

Text

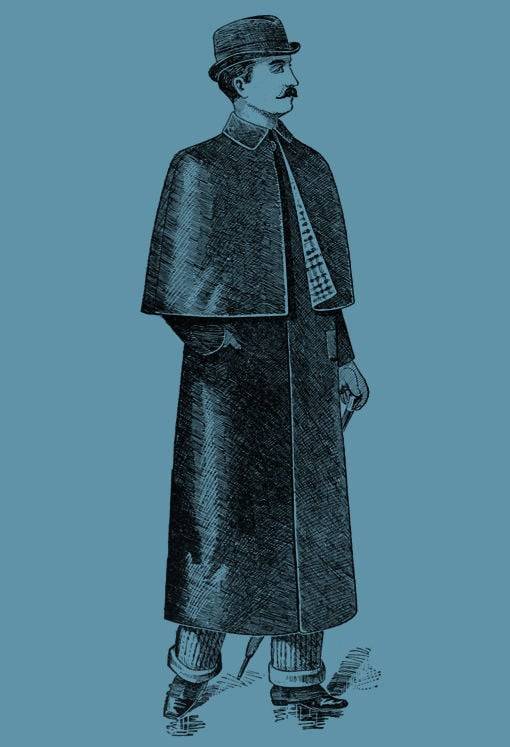

On June 17th 1823 Charles Macintosh patented the waterproof cloth he was using to make raincoats.

Mackintosh rubberized coats were not immediately successful. Although they were waterproof, they had a strong smell which most wearers found unpleasant. It was not until a fellow chemist, Thomas Hancock, invented a process involving vulcanized rubber that the problem was solved. Hancock became a partner in Macintosh��s business in 1834. This marked the real start of the iconic Mackintosh brand.

In 1824 an Arctic exploration team trialled rubber coated waterproof canvas bags, air-beds and pillows made by the Macintosh patented process. In 1841 the British army ordered waterproof clothing for all its troops. The rubberized coats and capes were functional and hard wearing and they soon became standard army issue.

After the death of Charles Macintosh in 1843, the company had a period of decline. But in 1851 the Mackintosh coat was shown at The Grand Exhibition at Crystal Palace, London. And the rest is history.

Of course just because you patent something it does not mean you actually were the first to invent it, controversy has followed the invention of the telephone since Alexander Graham Bell patented it, other inventions were questioned, the tyre, the television and the bicycle, all connected to Scotland and all have earlier versions that were thought of, or made beforehand, the “Mac” is no different.

James Syme, a surgeon and chemist based in Edinburgh, had discovered a derivative of coal tar (naphtha) could dissolve rubber and published his findings in Thomson's Annals of Philosophy five years before Macintosh came up with his idea.

It was the same process used by Macintosh following his own chemistry experiments with waste from Glasgow’s coal-gas works, and it has been claimed that the inventor had read Syme’s work before developing it for his own uses.

While Syme, uninterested in commercial matters, failed to patent his valuable discovery and continued to build a noteworthy career in surgery, Macintosh stamped his name on the idea in 1823, had Syme done so you might be calling the coats Symes.....it doesn’t have the same ring does it? Syme’s paper had not detailed the crucial sandwich-type construction employed by Macintosh, although this too was not completely new.

Spanish scientists previously used the method to make leak-proof containers for mercury, and renowned British balloonist Charles Green made a balloon envelope that applied the same principle in 1821.

French scientists also made balloons gas-tight and impermeable by impregnating fabric with rubber dissolved in turpentine and the use of rubber to waterproof fabric dates back to the Aztecs, who used natural latex.

But what made Macintosh’s invention revolutionary was its ease of manufacture and wear, seeing him swiftly launching into the production of cloth to be converted into coats and other garments by tailors in Glasgow.

Some of you might have picked up on the different spelling of the names in the first two paragraphs? Others will now be scrolling back to see what I mean! Well when As news of his invention spread, the repeated misspelling of the inventor’s name is thought to have popularised the description of the resulting coat as a “Mackintosh” – a name that has stuck to the present day.

Macintosh was elected as a fellow of the Royal Society for his contributions to chemistry and enjoyed considerable success before his death in 1843, aged 76.

First sold in 1824, his coat remains on the market in numerous forms across the world, it is now primarily a luxury brand still bearing its inventor’s name, even though it is spelled wrong!

11 notes

·

View notes

Text

[I]n Latin America and the Caribbean, [a]lthough significant tracts of these forests have disappeared, their history goes well beyond the much discussed deforestation that gathered such momentum starting in the 1960s and 70s. [...] In [...] the lower Amazon River Basin, [...] [after European arrival] the extraction of natural resources for external markets got underway. These forest products, known as drogas do sertão, varied enormously: sarsaparilla, vanilla, cinnamon, manatee meat and oil, turtle shells, and feathers were among the most important. [...] [T]his trade [...] did have other environmental consequences, such as the sharp decline in turtle and manatee populations. [...]

[I]n 1750, the Caribbean coast of what is today Nicaragua also exported sarsaparilla and turtle shells in addition to mahogany. To the south, the alluvial mines of Colombia’s Pacific region became the principal source of New Granada’s gold exports during the eighteenth century, well anticipating the recent wave of mining prospecting and exploitation.

---

The extractive economy, which began timidly during the colonial period, burgeoned during the second half of the nineteenth century [...]. The industrial revolution generated demand for raw materials, some of which could be derived from rainforest plants. The rubber boom, which took place primarily in the Amazon but also extended through the forests of Central America, is the quintessential example. There were other important booms, though they tended to affect very specific regions, such as that created by the demand for tagua, or vegetable ivory - the seed of various palm trees that grow in the forests of the Pacific coast between Panama and Ecuador [the “Choco” forest ecoregion] - which was used to make buttons before the invention of plastic.

In the case of the Petén Basin of Guatemala, the tapping of chicle, once the principal ingredient in chewing gum, also illustrates how natural resource extraction restructured regions during the boom period and, following the development of industrial substitutes, dramatically declined.

In the forests of Central America’s Caribbean coast, as exemplified by the case of Belize, logging precious woods and dyewoods was of great importance. But even more significant during the first half of the twentieth century was the expansion of banana plantations in old-growth rainforests. [...]

---

Rubber tappers in the Amazon cleared trails through the forest to connect one or two hundred Hevea trees that produced white rubber, the finest on the market. Every day they collected the latex [...]. The case of black rubber, however, was quite different. This rubber was derived from the latex of the Castilla genus, which is found both in the Amazon and in the forests of the Pacific coast and Central America. But because this latex dries upon contact with the air, rubber gatherers cut down the trees to “bleed” them all at once. In short order, therefore, the population of black rubber trees declined dramatically [...]. [T]he price crash in 1913, caused by the development of rubber plantations in Asia, ended such initiatives [...]. In the wake of these colonos came the establishment of state institutions, such as municipal authorities, and national ones [...]. Starting roughly from the mid-twentieth century, the colonization of tropical forests has been associated with large-scale deforestation. [...] After the 1964 coup, the Brazilian military made the Amazon Basin strategic to their plans for national development [...]. The ideology of civilization’s triumph over an intractable nature and wild population has been instrumental in the conquest of rainforest frontiers.

---

All text by: Claudia Leal. “Rainforest Frontiers.” In: “New Environmental Histories of Latin America and the Caribbean.” Edited by Claudia Leal, Jose Augusto Padua, and John Soluri. RRC Perspectives no. 7, 51-57. 2013. [Bold emphasis and some paragraph breaks/contractions added by me.]

#caribbean#really basic stuff here but i feel early forest product extraction in Latin American gets overshadowed or sidelined#compared to coastal plantations and spanish metals mining and post1960s deforestation#abolition#ecology#tidalectics#multispecies#indigenous#archipelaic thinking

55 notes

·

View notes

Text

The origin of art toys

Everyone has their own small world of toys.

In the process of human evolution, the tools that were repeatedly played with and gradually used should be the earliest forms of toys. It can be said that toys have served as experiments for human intellect and development.

In 2016, the global toy market reached an import and export scale of $78.7 billion, with over 43% comprising educational toys suitable for a wide age range, extending up to 80 years old. So, don't just play — let's delve deeper into understanding.

In the future, plastic products will surround humanity like air, becoming commonplace.

Libuše Niklová, a renowned Czech toy designer from the 1960s and 1970s, once said: "In the future, plastic products will surround humanity like air, becoming commonplace. Meanwhile, natural materials will increasingly resemble luxury items, objects of envy for people. Regardless, tomorrow belongs to plastic."

In the history of product design in the 20th century, her designed toys left a profound impact on a generation.

From the 1950s, Niklová began experimenting with plastic to create her series of whimsical and brightly colored characters and animals.

Her son, Peter, was fortunate to be the first player of these toys. He would play with every new item his mother brought home, and Niklová would refine her products based on his reactions.

In 1963, she pioneered the use of molded rubber, which featured a squeaking sound.

Some ask whether toys have already become a part of art. Certain art derivatives even circulate back into professional art auction markets, significantly increasing their collectible value. This trend also offers collectors more imaginative space, allowing more collectors to affordably own their own pieces. In this era, every circle is merging and evolving continuously.

2 notes

·

View notes

Text

### Eco-Friendly Shoes: Walking Towards a Sustainable Future

In recent years, the fashion industry has witnessed a significant shift towards sustainability, with eco-friendly shoes emerging as a crucial component of this movement. These shoes not only reduce environmental impact but also promote ethical practices, setting a new standard for the industry. In this article, we delve into the concept of eco-friendly shoes, exploring their benefits, the materials used, and the innovations driving their popularity.

#### Understanding Eco-Friendly Shoes

Eco-friendly shoes are designed with a focus on minimizing environmental harm. This involves using sustainable materials, reducing waste during production, and ensuring ethical labor practices. The aim is to create footwear that is not only stylish and comfortable but also environmentally responsible.

#### The Benefits of Eco-Friendly Shoes

One of the primary benefits of eco-friendly shoes is their reduced carbon footprint. Traditional shoe manufacturing processes often involve significant emissions and waste. In contrast, sustainable shoes utilize eco-conscious methods, resulting in lower greenhouse gas emissions and less pollution.

Additionally, eco-friendly shoes often prioritize fair labor practices. This means that workers involved in the production process are treated fairly, with safe working conditions and fair wages. By supporting brands that adhere to these principles, consumers can contribute to a more equitable and just fashion industry.

#### Materials Used in Eco-Friendly Shoes

The materials used in eco-friendly shoes are critical to their sustainability. Commonly, these include natural fibers, recycled materials, and innovative alternatives to traditional components.

1. **Natural Fibers**: Materials such as organic cotton, hemp, and bamboo are popular choices for eco-friendly shoes. These fibers are biodegradable, require fewer pesticides during cultivation, and have a lower environmental impact compared to conventional materials.

2. **Recycled Materials**: Many eco-friendly shoes incorporate recycled materials, such as recycled rubber, plastic bottles, and old textiles. By repurposing these materials, manufacturers can reduce waste and conserve natural resources.

3. **Innovative Alternatives**: In recent years, there has been a surge in the development of innovative materials for sustainable footwear. For example, Piñatex, made from pineapple leaf fibers, and Mycelium, derived from mushroom roots, are gaining traction as viable alternatives to leather and synthetic fabrics.

#### Innovations in Sustainable Footwear

The eco-friendly shoe market is continuously evolving, with new technologies and practices emerging to enhance sustainability. Some notable innovations include:

1. **3D Printing**: This technology allows for precise manufacturing, reducing material waste and energy consumption. Brands are utilizing 3D printing to create custom-fit shoes, improving comfort and extending the lifespan of the footwear.

2. **Biodegradable Soles**: Traditional shoe soles can take hundreds of years to decompose. Biodegradable soles, made from materials like natural rubber and plant-based polymers, break down much faster, reducing environmental impact.

3. **Circular Economy**: Some brands are adopting circular economy principles, where shoes are designed to be easily disassembled and recycled at the end of their life. This approach minimizes waste and encourages the reuse of materials.

#### The Future of Eco-Friendly Shoes

As consumer awareness of environmental issues grows, the demand for eco-friendly shoes is expected to increase. Brands are responding by investing in sustainable practices and materials, leading to a more diverse and innovative market.

Moreover, collaborations between fashion brands and environmental organizations are becoming more common. These partnerships aim to promote sustainability and drive positive change within the industry. For example, some brands are partnering with NGOs to plant trees for every pair of shoes sold, offsetting their carbon footprint.

In the future, we can expect to see even more advancements in sustainable footwear. Research into new materials, such as algae-based foams and lab-grown leather, holds promise for creating shoes that are both eco-friendly and high-performance.

#### How to Choose Eco-Friendly Shoes

When shopping for eco-friendly shoes, there are several factors to consider:

1. **Material**: Look for shoes made from sustainable materials, such as organic cotton, recycled plastics, and innovative alternatives like Piñatex.

2. **Production Practices**: Research the brand's manufacturing processes to ensure they prioritize sustainability and ethical labor practices.

3. **Certifications**: Certifications such as Fair Trade, Global Organic Textile Standard (GOTS), and the Forest Stewardship Council (FSC) can provide assurance that the shoes meet high environmental and ethical standards.

4. **Durability**: Choose shoes that are well-made and durable, reducing the need for frequent replacements and minimizing waste.

5. **Brand Transparency**: Support brands that are transparent about their sustainability efforts and practices. Many companies now publish detailed reports on their environmental impact and goals.

#### Conclusion

Eco-friendly shoes represent a vital step towards a more sustainable future. By choosing footwear that prioritizes environmental and ethical considerations, consumers can make a positive impact on the planet and support responsible brands. As the market continues to grow and innovate, eco-friendly shoes are becoming more accessible and diverse, offering stylish and sustainable options for every wardrobe. Embrace the change and take a step in the right direction with eco-friendly shoes.

In conclusion, the journey towards sustainable footwear is both exciting and essential. As we become more conscious of our environmental footprint, the choices we make in our daily lives, including the shoes we wear, play a crucial role. By supporting brands that prioritize sustainability and ethical practices, we contribute to a healthier planet and a more equitable society. Let us all walk towards a greener future, one step at a time, with eco-friendly shoes leading the way.

#nature#me#environment#enviroment art#plastic recycling#graphic design#green#greenliving#camping#peaceful#shower things#article#my writing#creative writing#perspective#peace#girl who kisses girls#beautiful#mine#myself#motivation#mo

3 notes

·

View notes

Text

the elusive hundred percent vegan

WHAT IS VEGANISM?

The term vegan was coined in 1944, by the Vegan Society. The following definition applies

[…] a philosophy and way of living which seeks to exclude—as far as is possible and practicable—all forms of exploitation of, and cruelty to, animals for food, clothing or any other purpose; and by extension, promotes the development and use of animal-free alternatives for the benefit of humans, animals and the environment. In dietary terms, it denotes the practice of dispensing with all products derived wholly or partly from animals.

(Updated 1979, The Vegan Society)

It is impossible to live in the world and avoid everything that uses animals in one way or another.

But we can take time to research manufacturers and producers and be able to make an educated decision on the products we buy and use.

Thanks to modern technology, we have greater access to retailers all over the country – even the world - and have wider choices.

As more and more people are made aware of the atrocities involved in everyday items, more people are looking for these.

If they don’t find them they will begin asking why not. Manufacturers and developers will see a market that has been created and will be motivated to make sweeping changes.

Living in the society we do, with advances that have had a huge impact on our daily lives, we should take the position that we will, whenever possible, only consume cruelty free alternatives.

I don’t believe that the issue here is one of being a perfect vegan.

Rather, it is a question of being the best vegan we can. And by making sure that every choice we make is one that is in the best possible interest of animals.

If we love animals, our priority should be to reduce their suffering as much as possible and to do our best to make a difference to their lives.

As long as we live in a world that is frighteningly dependent on animal products, we cannot be completely vegan. But we can put in a 100% effort to living as cruelty – free as possible.

Animal activist and lecturer Gary Yourofsky:

“I’ll just add briefly that our ability to achieve 100 percent vegan status really depends on our definition of vegan. If being vegan means striving to commit the least amount of harm possible, then one can be fully vegan. Unfortunately, as long as we are living, we will inadvertently cause harm to other living beings. But we can consistently strive to reduce this harm to the best of our abilities.”

Here are just some examples of non – essential (ie. not necessary to sustain life) products that may contain animal products or may make use of animal products in their production:

Antifreeze

Asphalt

Batteries

Biodegradable detergents

Books

Bricks

Cars (or any form of transport)

Cell phones

Cement

Chemicals

Computers

Explosives

Fireworks

Glue

Home insulation

Industrial oils and lubricants

Insulation material used to cool and heat houses

LCD screens

Many electronics

Musical instruments

Organic foods (manure used as fertilizer)

Paper

Pesticides

Plaster

Rubber

Sports equipment

Steel

Tools that have any moving parts

Tyres

Varnish

Wood

X-ray film

HOW TO IDENTIFY PRODUCTS THAT AREN’T CRUELTY FREE AND ALTERNATIVES (WHERE AVAILABLE):

ANIMAL INGREDIENTS LIST - WITH ALTERNATIVES WHERE AVAILABLE:

ANIMAL INGREDIENTS LIST

BEEF “BY PRODUCTS”

ETHICAL SHOPPING

With thanks to World Preservation Foundation, Vegan Society, Vegan Outreach, Natural Society, Treehugger, One Green Planet and Mother Nature Network.

2 notes

·

View notes

Text

Europe Crumb Rubber Market, Outlook and Forecast 2025-2030

Crumb rubber is a recycled rubber material derived from end-of-life tires through mechanical shredding and grinding processes. The material is classified based on particle size and is widely used across industries such as construction, sports surfaces, and asphalt modification. Due to its eco-friendly nature, cost-effectiveness, and durability, crumb rubber has become a crucial component in sustainable material applications.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/285600/europe-crumb-rubber-forecast-market-2025-2030-648

Market Size

As of 2024, the Europe Crumb Rubber market is valued at US$ 285.42 million and is projected to reach US$ 408.56 million by 2030, growing at a CAGR of 6.15% during the forecast period. The increasing focus on circular economy practices, stringent environmental regulations, and growing demand for sustainable construction materials have propelled the market’s expansion.

Market Dynamics

Key Market Drivers

Sustainability Initiatives: Regulatory bodies such as the European Union (EU) are pushing for increased recycling rates, encouraging industries to integrate sustainable materials like crumb rubber.

Technological Advancements: Improvements in tire recycling technology have enhanced the quality of crumb rubber by 36.5% over recent years, making it a viable alternative to traditional materials.

Economic Benefits: Cost-effective solutions compared to virgin rubber are driving adoption in industries such as automotive, infrastructure, and sports facility development.

Increased Adoption in Asphalt Modification: The use of crumb rubber in rubberized asphalt enhances road durability and reduces maintenance costs.

Market Restraints

Environmental Concerns: Despite its recycling benefits, concerns over microplastic pollution from crumb rubber used in sports fields have led to regulatory scrutiny.

Initial High Processing Costs: While cost-effective in the long run, setting up recycling plants involves significant investment in specialized equipment.

Limited Awareness in Some Regions: Emerging markets within Europe still lack the infrastructure and knowledge for effective crumb rubber utilization.

Opportunities

Innovative Applications: Expansion into tire-derived fuel, civil engineering applications, and industrial flooring presents significant growth opportunities.

Government Incentives: EU-backed funding for sustainable recycling projects supports further market growth.

Growing Demand for Green Infrastructure: Countries like Germany, France, and the UK are increasingly incorporating recycled materials into public infrastructure projects.

Challenges

Regulatory Compliance: Adhering to evolving EU waste management directives can be challenging for small- and medium-sized enterprises (SMEs).

Supply Chain Constraints: Fluctuations in the supply of waste tires impact raw material availability.

Market Competition: The presence of numerous regional and international players leads to price competition, affecting profit margins.

Regional Analysis

Germany

Market Share: 34.8%

Growth Drivers: Strong demand from the construction and automotive industries, along with strict waste management policies.

United Kingdom

Investments in sports infrastructure and government-led sustainability initiatives boost the market.

France

Public-private collaborations focused on eco-friendly urban development are driving demand.

Italy and Spain

Rapid adoption of crumb rubber-modified asphalt due to increasing investments in road construction.

Netherlands and Belgium

Pioneering nations in circular economy practices, with strong government backing for rubber recycling projects.

Competitor Analysis

Key Players in the Europe Crumb Rubber Market

Genan Holding A/S: Industry leader specializing in high-quality crumb rubber production.

Eldan Recycling A/S: Notable for advanced tire recycling machinery.

TRM Tyre Recycling Machinery & Equipment: Innovator in tire recycling technology.

Pyrum Innovations AG: Leading pyrolysis technology company transforming waste tires into valuable materials.

RubberGreen: Focuses on sustainable applications in construction and insulation.

Ecopneus scpa: Promotes tire recycling through awareness campaigns and efficient waste management solutions.

Market Segmentation (by Application)

Construction: 45.6% market share – Used in rubberized asphalt, flooring, and insulation materials.

Sports Surfaces: 32.4% market share – Includes synthetic turf infill and running tracks.

Asphalt Modification: 12.8% market share – Enhances durability and elasticity in road construction.

Market Segmentation (by Type)

Crumb Rubber from Passenger Cars

Crumb Rubber from Commercial Vehicles

Key Company

This report introduces in detail the market share, product portfolio, operational strategies, and financial performance of major players, helping stakeholders identify key competitors and their market positioning.

Geographic Segmentation

The Europe Crumb Rubber market is segmented geographically to provide a detailed breakdown of market performance, identifying high-growth regions and emerging opportunities.

Growth Opportunities and Future Prospects

Expansion in Emerging Applications: The use of crumb rubber in innovative applications like tire-derived fuel presents untapped potential.

Advancements in Recycling Technologies: Emerging cryogenic and ambient grinding techniques will enhance product quality and reduce costs.

Regulatory Support for Circular Economy: EU policies are expected to strengthen the market over the forecast period.

Urbanization and Infrastructure Development: Increasing demand for sustainable building materials is anticipated to drive future growth.

FAQ

What is the current market size of the Europe Crumb Rubber market?

➣ As of 2024, the market is valued at US$ 285.42 million and is expected to reach US$ 408.56 million by 2030, growing at a CAGR of 6.15%.

Which are the key companies operating in the Europe Crumb Rubber market?

➣ Major players include Genan Holding A/S, Eldan Recycling A/S, TRM Tyre Recycling Machinery & Equipment, Pyrum Innovations AG, RubberGreen, and Ecopneus scpa.

What are the key growth drivers in the Europe Crumb Rubber market?

➣ The market is driven by sustainability initiatives, technological advancements in recycling, increasing adoption in construction and sports applications, and economic benefits over virgin rubber.

Which regions dominate the Europe Crumb Rubber market?

➣ Germany leads with 34.8% market share, followed by the United Kingdom, France, Italy, Spain, Netherlands, and Belgium.

What are the emerging trends in the Europe Crumb Rubber market?

➣ Key trends include increasing investments in tire recycling technologies, expansion into new applications such as civil engineering, and stronger regulatory backing for circular economy practices.

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Crumb Rubber revenues in Europe market, 2019-2024 (Estimated), ($ millions)

Key companies Crumb Rubber revenues share in Europe market, 2023 (%)

Key companies Crumb Rubber sales in Europe market, 2019-2024 (Estimated),

Key companies Crumb Rubber sales share in Europe market, 2023 (%)

Key Points of this Report:

The depth industry chain includes analysis value chain analysis, porter five forces model analysis and cost structure analysis

The report covers Europe and country-wise market of Crumb Rubber

It describes present situation, historical background and future forecast

Comprehensive data showing Crumb Rubber capacities, production, consumption, trade statistics, and prices in the recent years are provided

The report indicates a wealth of information on Crumb Rubber manufacturers

Crumb Rubber forecast for next five years, including market volumes and prices is also provided

Raw Material Supply and Downstream Consumer Information is also included

Any other user's requirements which is feasible for us

Reasons to Purchase this Report:

Analyzing the outlook of the market with the recent trends and SWOT analysis

Market dynamics scenario, along with growth opportunities of the market in the years to come

Market segmentation analysis including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

Regional and country level analysis integrating the demand and supply forces that are influencing the growth of the market.

Market value (USD Million) and volume (Units Million) data for each segment and sub-segment

Distribution Channel sales Analysis by Value

Competitive landscape involving the market share of major players, along with the new projects and strategies adopted by players in the past five years

Comprehensive company profiles covering the product offerings, key financial information, recent developments, SWOT analysis, and strategies employed by the major market players

1-year analyst support, along with the data support in excel format.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/285600/europe-crumb-rubber-forecast-market-2025-2030-648

0 notes

Text

Zinc Oxide Market Elasticity Factors Impacting Demand, Supply, Pricing, and Growth Prospects Worldwide

The zinc oxide market plays a vital role in industries such as rubber, cosmetics, pharmaceuticals, and electronics. The elasticity of this market is influenced by various factors, including demand-supply dynamics, raw material costs, technological innovations, and regulatory frameworks. Understanding these elasticity factors helps businesses and investors anticipate market shifts and optimize their strategies for profitability.

1. Demand-Supply Dynamics

Market elasticity is significantly shaped by demand-supply imbalances. Zinc oxide is widely used in rubber manufacturing, personal care products, and coatings, leading to fluctuations in demand across different sectors. Key factors influencing demand include:

Growth in the automotive industry, increasing the need for ZnO in tire production.

Expansion of the cosmetics and skincare market, driving demand for zinc oxide in sunscreens and ointments.

Technological advancements in electronics, where ZnO is used in semiconductors and sensors.

On the supply side, disruptions in zinc ore mining, geopolitical factors, and trade policies affect the availability of zinc oxide, leading to price volatility.

2. Price Sensitivity and Raw Material Costs

Price elasticity of zinc oxide depends on raw material availability and production costs. Since zinc oxide is derived from zinc ore, fluctuations in zinc prices directly impact ZnO pricing. Factors affecting price elasticity include:

Mining regulations and environmental policies, restricting zinc ore extraction.

Energy and labor costs, influencing manufacturing expenses.

Alternative materials replacing ZnO in certain applications, affecting market stability.

Higher production costs make ZnO less elastic, meaning price increases may reduce demand in cost-sensitive industries.

3. Technological Innovations and Substitutes

Advancements in nanotechnology and eco-friendly ZnO production methods have made the market more adaptable. However, the availability of substitutes like titanium dioxide (TiO2) in cosmetics and silica in rubber production impacts the demand for ZnO. Factors affecting elasticity in this domain include:

Research on high-performance ZnO nanoparticles, expanding its use in electronics and healthcare.

Development of synthetic alternatives, reducing dependency on natural zinc oxide.

Sustainability concerns, leading to innovations in greener production methods.

4. Regulatory Policies and Trade Restrictions

Government regulations on zinc mining, emissions, and product safety standards also affect market elasticity. Stringent environmental laws can limit production, while tariffs and trade restrictions can impact international supply chains. Key influences include:

REACH regulations in Europe, controlling ZnO usage in consumer goods.

US and China trade policies, affecting import-export volumes.

Sustainable production incentives, encouraging the use of recycled zinc.

5. Macroeconomic Trends and Global Market Conditions

Macroeconomic factors like inflation, economic downturns, and currency fluctuations influence purchasing power and industrial production, thereby affecting ZnO market elasticity. Some key economic factors include:

Recession risks, leading to reduced industrial activity and lower ZnO consumption.

Currency exchange rates, impacting global trade and pricing strategies.

Infrastructure development, increasing ZnO demand in coatings and construction materials.

Conclusion

The elasticity of the zinc oxide market is driven by multiple interdependent factors, including supply chain constraints, price volatility, technological innovations, regulatory frameworks, and economic conditions. A thorough understanding of these factors is crucial for businesses and investors aiming to navigate market fluctuations and capitalize on emerging opportunities.

0 notes

Text

Best Agriculture Loan Services of Kannur, Kerala

Best Agriculture Loan Services of Kerala: Empowering Farmers for a Sustainable Future

Agriculture has been the backbone of Kerala’s economy for centuries. Known for its rich natural resources, favorable climate, and diverse crops, the state is home to farmers who are deeply committed to cultivating the land. However, despite their passion and resilience, many face financial challenges due to the high costs of agricultural inputs, unpredictable weather, and fluctuating market prices. In such a context, the importance of affordable and accessible agricultural loans cannot be overstated.

Best Agriculture Loan Services of Kerala play a crucial role in supporting farmers, ensuring that they can invest in necessary resources, enhance productivity, and ultimately, improve their livelihoods. These loans not only help farmers sustain their operations but also contribute to the growth of the agricultural sector, fostering food security and rural development in the region.

The Significance of Agriculture Loans in Kerala

Agriculture loans serve as a lifeline for farmers across Kerala, particularly in times of crisis or when undertaking new farming ventures. From purchasing seeds, fertilizers, and equipment to funding infrastructure development or meeting emergency expenses during a natural calamity, agricultural loans offer the financial flexibility needed for day-to-day farming activities.

In Kerala, the diversity of agriculture, which includes crops such as rubber, tea, coffee, spices, and rice, along with the cultivation of fruits and vegetables, presents unique challenges and needs. As a result, the Best Agriculture Loan Services of Kerala provide tailored financial solutions that consider the specific needs of these farmers. Whether it’s a short-term loan for seasonal cultivation or a long-term loan for capital investment in modernizing farming practices, these loan services cater to a wide range of requirements.

Types of Agriculture Loans Available in Kerala

The agricultural loan offerings in Kerala are diverse, ensuring that different types of farming ventures are supported. These loans are available through both government and private financial institutions, each offering a variety of loan products designed to meet the needs of individual farmers.

Crop Loans: Crop loans are short-term loans provided to farmers to meet their seasonal needs. They can be used to buy seeds, fertilizers, pesticides, and other inputs required for crop cultivation. These loans are typically offered at low-interest rates and have flexible repayment terms, which align with the harvesting season. In Kerala, where the agricultural calendar is influenced by the monsoon, crop loans are vital to ensure timely planting and harvesting.

#home loan#mortgage loan#loan against property#agriculture loan#new startup business loan#new startup project loan#new start up company loan#business loan#unsecured loan#secured loan

0 notes

Text

Vegetable Pitch Market, Global Outlook and Forecast 2024-2030 Professional Edition

The global Vegetable Pitch market size was valued at US$ 234.5 million in 2024 and is projected to reach US$ 312.6 million by 2030, at a CAGR of 4.9% during the forecast period 2024-2030.

The United States Vegetable Pitch market size was valued at US$ 61.5 million in 2024 and is projected to reach US$ 80.4 million by 2030, at a CAGR of 4.5% during the forecast period 2024-2030.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/281196/global-vegetable-pitch-forecast-edition-market-2024-2030-479

Natural bituminous material derived from vegetable sources, used in industrial applications for waterproofing and coating, featuring eco-friendly characteristics and specific adhesive properties.

Report Overview

This report provides a deep insight into the global Vegetable Pitch market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Vegetable Pitch Market, this report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Vegetable Pitch market in any manner.

Global Vegetable Pitch Market: Market Segmentation Analysis

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments.

Key Company

PanGu Group

Jinrui Lvyuan Biological Technology

Hebei Jingu Recycling Resources Development

East Huge Dragon Chemical

Jinduo Technology

Zhongke New Energy Technlogy

Oleochem

Market Segmentation (by Type)

Liquid Type

Paste Type

Market Segmentation (by Application)

Casting Adhesive

Rubber Softener

Cement Precast Isolation Agent

Other

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Vegetable Pitch Market

Overview of the regional outlook of the Vegetable Pitch Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players

The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

Customization of the Report

In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

Chapter Outline

Chapter 1 mainly introduces the statistical scope of the report, market division standards, and market research methods.

Chapter 2 is an executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the Vegetable Pitch Market and its likely evolution in the short to mid-term, and long term.

Chapter 3 makes a detailed analysis of the market's competitive landscape of the market and provides the market share, capacity, output, price, latest development plan, merger, and acquisition information of the main manufacturers in the market.

Chapter 4 is the analysis of the whole market industrial chain, including the upstream and downstream of the industry, as well as Porter's five forces analysis.

Chapter 5 introduces the latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry.

Chapter 6 provides the analysis of various market segments according to product types, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 7 provides the analysis of various market segments according to application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 8 provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and capacity of each country in the world.

Chapter 9 introduces the basic situation of the main companies in the market in detail, including product sales revenue, sales volume, price, gross profit margin, market share, product introduction, recent development, etc.

Chapter 10 provides a quantitative analysis of the market size and development potential of each region in the next five years.

Chapter 11 provides a quantitative analysis of the market size and development potential of each market segment (product type and application) in the next five years.

Chapter 12 is the main points and conclusions of the report.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/281196/global-vegetable-pitch-forecast-edition-market-2024-2030-479 Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Vegetable Pitch 1.2 Key Market Segments 1.2.1 Vegetable Pitch Segment by Type 1.2.2 Vegetable Pitch Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Vegetable Pitch Market Overview 2.1 Global Market Overview 2.1.1 Global Vegetable Pitch Market Size (M USD) Estimates and Forecasts (2019-2030) 2.1.2 Global Vegetable Pitch Sales Estimates and Forecasts (2019-2030) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Vegetable Pitch Market Competitive Landscape 3.1 Global Vegetable Pitch Sales by Manufacturers (2019-2024) 3.2 Global Vegetable Pitch Revenue Market Share by Manufacturers (2019-2024) 3.3 Vegetable Pitch Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Vegetable Pitch Average Price by Manufacturers (2019-2024) 3.5 Manufacturers Vegetable Pitch Sales Sites, Area Served, Product Type 3.6 Vegetable Pitch Market Competitive Situation and Trends 3.6.1 Vegetable Pitch Market Concentration Rate 3.6.2 Global 5 and 10 Largest Vegetable Pitch Players Market Share by Revenue 3.6.3 Mergers & Acquisitions, Expansion 4 Vegetable Pitch Industry Chain Analysis 4.1 Vegetable Pitch Industry Chain Analysis 4.2 Market Overview of Key Raw Materials 4CONTACT US: North Main Road Koregaon Park, Pune, India - 411001. International: +1(646)-781-7170 Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes

Text

How India's Recyclers Are Transforming Scrap Tyres into Valuable Resources

India, with its rapidly growing automotive industry, is now facing a new challenge: the disposal of millions of scrap tires. However, a new wave of innovative recyclers is transforming this waste stream into valuable resources, creating a circular economy and mitigating environmental concerns.

The Tire Waste Problem:

Environmental Impact: Discarded tires contribute to pollution in various ways:

Landfills: They occupy vast amounts of landfill space, releasing harmful chemicals into the soil and groundwater.

Fire Hazards: Tire piles are highly flammable, thus posing a significant fire risk.

Breeding Grounds: They can become breeding grounds for mosquitoes and other disease-carrying pests.

Resource Depletion: Tires contain valuable materials like steel and rubber, which are often wasted in landfills.

Innovative Recycling Solutions:

Indian recyclers are pioneering several innovative approaches to transform scrap tires into valuable products:

Retreading: Used tires are stripped, inspected, and resurfaced with new tread, extending their lifespan and reducing the demand for new tires.

Crumb Rubber: Tires are shredded into small pieces, known as crumb rubber, which has numerous applications:

Road Construction: Used in asphalt mixtures to improve road durability and reduce noise.

Sports Surfaces: Utilized in the construction of athletic tracks, playgrounds, and sports fields.

Industrial Applications: rubber mats and floorings and various industrial materials

Fuel Production- crumb rubber can be used in cement kilns and power plants

Pyrolysis: the art of burning tires in the absence of oxygen. This is brought about by pyrolysis and yields oil, gas, and carbon black, which can be sold or used in industries as raw materials.

Advantages of Tire Recycling

Environmental Protection: The reduction of waste in landfills, minimization of pollution, and conservation of natural resources.

Economic Growth: Job creation within the recycling industry and stimulation of new business developments.

Resource Recovery: Recovery of valuable materials from waste reduces the reliance on virgin resources.

Challenges and Opportunities:

Although so much has been achieved, much remains to be done:

Awareness: Limited awareness among the public and policy makers on the benefits of tire recycling.

Technological Constraints: Many of the recycling technologies are still in their development stage and require significant investments.

Market Growth: Growing market for recycled tyre products is required to sustain this recycling industry

Future of Tire Recycling in India

The future for tire recycling in India seems very bright. Continuing innovation, support from the government, and more public awareness could help India find a solution for the problem of waste tyres while establishing a circular economy that works.

0 notes

Text

On June 17th 1823 Charles Macintosh patented the waterproof cloth he was using to make raincoats.

While he was trying to find uses for the waste products of gasworks, Charle discovered that coal-tar naphtha dissolved india rubber. He took wool cloth and painted one side with the dissolved rubber preparation and placed another layer of wool cloth on top.

This created the first practical waterproof fabric, but the fabric was not perfect. It was easy to puncture when it was seamed, the natural oil in wool caused the rubber cement to deteriorate. In cold weather the fabric became stiffer and in hot weather the fabric became sticky. When vulcanized rubber was invented in 1839, Macintosh's fabrics improved since the new rubber could withstand temperature changes.

Of course just because you patent something it does not mean you actually were the first to invent it, controversy has followed the invention of the telephone since Alexander Graham Bell patented it, other inventions were questioned, the tyre, the television and the bicycle, all connected to Scotland and all have earlier versions that were thought of, or made beforehand, the “Mac” is no different.

James Syme, a surgeon and chemist based in Edinburgh, had discovered a derivative of coal tar (naphtha) could dissolve rubber and published his findings in Thomson's Annals of Philosophy five years before Macintosh came up with his idea.

It was the same process used by Macintosh following his own chemistry experiments with waste from Glasgow’s coal-gas works, and it has been claimed that the inventor had read Syme’s work before developing it for his own uses.

While Syme, uninterested in commercial matters, failed to patent his valuable discovery and continued to build a noteworthy career in surgery, Macintosh stamped his name on the idea in 1823, had Syme done so you might be calling the coats Symes.....it doesn’t have the same ring does it? Syme’s paper had not detailed the crucial sandwich-type construction employed by Macintosh, although this too was not completely new.

Spanish scientists previously used the method to make leak-proof containers for mercury, and renowned British balloonist Charles Green made a balloon envelope that applied the same principle in 1821.

French scientists also made balloons gas-tight and impermeable by impregnating fabric with rubber dissolved in turpentine and the use of rubber to waterproof fabric dates back to the Aztecs, who used natural latex.

But what made Macintosh’s invention revolutionary was its ease of manufacture and wear, seeing him swiftly launching into the production of cloth to be converted into coats and other garments by tailors in Glasgow.

Some of you might have picked up on the different spelling of the names in the first two paragraphs? Others will now be scrolling back to see what I mean! Well when As news of his invention spread, the repeated misspelling of the inventor’s name is thought to have popularised the description of the resulting coat as a “Mackintosh” – a name that has stuck to the present day.

Macintosh was elected as a fellow of the Royal Society for his contributions to chemistry and enjoyed considerable success before his death in 1843, aged 76.

First sold in 1824, his coat remains on the market in numerous forms across the world, it is now primarily a luxury brand still bearing its inventor’s name, even though it is spelled wrong!

6 notes

·

View notes

Text

Driving the Future: A Market Analysis of Sustainable Tires

In an era where sustainability is at the forefront of global industries, the automotive sector is undergoing a significant transformation. Among the many advancements in the automotive industry, sustainable tires stand out as a groundbreaking innovation due to their ability to significantly reduce environmental impact while maintaining high performance and durability. These eco-friendly alternatives are designed to enhance fuel efficiency, reduce carbon footprints, and contribute to a circular economy. Let’s delve into a detailed market analysis of the sustainable tires industry and its implications for the future.

What Are Sustainable Tires?

Sustainable tires are made from renewable, biodegradable, or recycled materials, reducing reliance on fossil fuels and non-renewable resources. Traditional tires are predominantly manufactured using synthetic rubber derived from petroleum, which has a high environmental cost. In contrast, sustainable tires incorporate natural rubber, recycled rubber, soybean oil, and even dandelion latex to create an eco-friendly alternative without compromising performance.

Market Overview

The global sustainable tires market is experiencing rapid growth, driven by rising environmental concerns, stringent government regulations, and increasing demand for fuel-efficient vehicles. According to industry reports, the sustainable tires market was valued at approximately $35 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.5% between 2023 and 2030.

Key Market Drivers

Increased Consumer Awareness: As people become more conscious of their carbon footprint, there is a rising demand for green automotive solutions.

Automotive Industry Shift: Major tire manufacturers are investing in research and development to produce sustainable alternatives.

Government Regulations: Many countries are imposing strict emission norms, promoting the adoption of environmentally friendly products.

Advancements in Material Science: Innovative materials such as bio-based elastomers and silica-infused rubber are revolutionizing tire manufacturing.

Growth in Electric Vehicles (EVs): The rapid adoption of EVs has further increased demand for sustainable tires, as they require low rolling resistance and high durability.

Market Segmentation

By Material Type:

Natural Rubber – Derived from rubber trees and biodegradable.

Recycled Rubber – Reduces waste by repurposing old tires.

Bio-Based Oils (Soybean, Orange Oil, etc.) – Used as an alternative to petroleum-based compounds.

Others (Silica, Dandelion Latex, etc.) – Newer innovations aiming to enhance sustainability.

By Vehicle Type:

Passenger Vehicles – Increasing adoption among consumers for personal transport.

Commercial Vehicles – Fleet operators are turning to sustainable options for cost savings and environmental benefits.

Electric Vehicles – Specially designed tires to complement EV performance and efficiency.

By Region:

North America: Strong regulatory push and consumer demand.

Europe: Leading the market with stringent environmental policies.

Asia-Pacific: Rapid urbanization and industrialization fueling market growth.

Rest of the World: Emerging economies adopting sustainable solutions at a steady pace.

Competitive Landscape

Several key players are driving innovation in the sustainable tires industry, including:

Michelin – Developing bio-based and airless tires.

Bridgestone – Focused on recycled rubber and natural rubber alternatives.

Goodyear – Leading in soybean oil-based tires.

Continental – Investing in dandelion rubber production.

Pirelli – Incorporating eco-friendly materials for high-performance tires.

Challenges and Future Prospects

Despite their benefits, sustainable tires face challenges such as higher production costs, limited consumer awareness, and the need for large-scale infrastructure changes. However, with continuous research and increased investments, the future looks promising. The integration of AI and smart tire technology is also expected to further enhance sustainability and efficiency in the coming years.

Final Thoughts

The sustainable tires market is not just a trend but a necessity in the modern automotive landscape. With increasing consumer demand, regulatory support, and technological advancements, eco-friendly tires are set to redefine the industry. Whether for personal vehicles, commercial fleets, or electric cars, the adoption of sustainable tires is a crucial step toward a greener and more sustainable future.

Stay ahead in the sustainability movement—consider making the switch to eco-friendly tires today!

0 notes

Text

surgical gloves manufacturers in Malaysia

Top Glove Manufacturers in Malaysia: Leading the Global Market

Malaysia has established itself as a global hub for the production of high-quality gloves, serving various industries worldwide. From medical applications to industrial needs, glove manufacturers in Malaysia are renowned for their quality, innovation, and competitive pricing. In this article, we will explore the leading glove manufacturers in Malaysia, including their offerings, specialties, and contribution to the global market.

The Rise of Malaysia as a Glove Manufacturing Hub

Malaysia’s dominance in the glove manufacturing industry can be attributed to several factors. The country’s strategic location, skilled workforce, and access to natural rubber have made it a preferred choice for international buyers. Additionally, advancements in technology and stringent quality control measures have propelled Malaysian glove manufacturers to the forefront of the industry.

Nitrile Gloves Manufacturers in Malaysia: Setting the Standard

Nitrile gloves have become a popular choice in medical and industrial applications due to their durability, flexibility, and chemical resistance. Leading nitrile gloves manufacturers in Malaysia produce a wide range of gloves that meet international standards, including ASTM and EN certifications. These gloves are ideal for healthcare workers, laboratory technicians, and industrial workers who require reliable hand protection.

Malaysian manufacturers invest heavily in research and development to ensure their nitrile gloves remain top-notch. Companies focus on producing gloves with enhanced tactile sensitivity, puncture resistance, and allergen-free properties, catering to diverse global needs.

Surgical Gloves Manufacturers in Malaysia: Ensuring Safety and Hygiene

Surgical gloves manufacturers in Malaysia are known for producing high-quality gloves designed for medical procedures. These gloves are made from materials like latex and nitrile, ensuring optimal safety, comfort, and precision for healthcare professionals.

Surgical gloves undergo rigorous quality checks, including testing for durability, sterility, and comfort. Malaysian manufacturers are committed to adhering to international medical standards, ensuring that their gloves are safe for use in hospitals, clinics, and surgical centers worldwide.

Gloves Company in Malaysia: Comprehensive Solutions

A gloves company in Malaysia typically offers a wide range of products, including:

Medical Gloves: Latex and nitrile gloves for examination and surgical use.

Industrial Gloves: Designed for heavy-duty tasks in industries like manufacturing, construction, and automotive.

Specialty Gloves: Electrician gloves, anti-static gloves, and more for specific applications.

These companies not only cater to the domestic market but also export their products globally, making Malaysia a leader in glove production.

Malaysia Gloves Manufacturer List: Industry Leaders

The Malaysia gloves manufacturer list includes some of the world’s largest and most trusted companies. These manufacturers are known for their innovative production techniques, sustainable practices, and commitment to quality. Some key players include:

Top Glove Corporation

Hartalega Holdings Berhad

Kossan Rubber Industries

Supermax Corporation

Careplus Group Berhad

These companies produce billions of gloves annually, supplying various industries such as healthcare, food processing, and electronics.

Electrician Glove Manufacturer Malaysia: Specialized Protection

For electricians, hand protection is crucial to ensure safety while working with electrical equipment. Leading electrician glove manufacturers in Malaysia produce gloves that provide insulation, durability, and resistance to electrical hazards. These gloves are meticulously designed to meet industry standards, ensuring the safety of professionals working in high-risk environments.

Sustainable Practices in the Malaysian Glove Industry

Sustainability is becoming a core focus for glove manufacturers in Malaysia. Companies are adopting eco-friendly practices, such as:

Reducing waste during production.

Using renewable energy sources.

Developing biodegradable gloves to minimize environmental impact.

These initiatives align with global efforts to promote sustainability in manufacturing and reduce the carbon footprint of the industry.

Why Choose Gloves from Malaysia?

Choosing gloves from Malaysia ensures access to products that meet the highest quality standards. Here are some reasons why Malaysian gloves are preferred:

Wide Range of Products: From medical to industrial gloves, there is something for every need.

Quality Assurance: Rigorous testing ensures reliability and safety.

Competitive Pricing: Cost-effective solutions without compromising on quality.

Global Reach: Malaysian manufacturers export to over 190 countries, making their products accessible worldwide.

Contact ManufacturerMalaysia.com for Your Glove Needs

If you’re looking for reliable glove manufacturers in Malaysia, ManufacturerMalaysia.com is your go-to platform. Located in Selangor, Malaysia, we connect you with the best manufacturers who specialize in medical, industrial, and specialty gloves. Our extensive network ensures you find the right products to meet your specific requirements.

Address: Selangor, Malaysia.

Work Hours: 9am – 6pm, Monday – Friday.

Contact: [email protected]

Conclusion

Malaysia’s glove manufacturing industry continues to thrive, setting benchmarks for quality, innovation, and sustainability. Whether you’re in need of medical, industrial, or specialty gloves, the country’s manufacturers are equipped to deliver. Explore ManufacturerMalaysia.com today to connect with top manufacturers and discover the perfect solutions for your needs.

0 notes

Text

Carbon Disulphide Prices, News, Trend, Graph, Chart, Forecast and Historical

The Carbon Disulphide market is a crucial segment in the global chemicals industry, influencing various sectors such as textiles, agriculture, and electronics. Over recent years, the prices of carbon disulfide have been influenced by several factors, including raw material availability, production processes, demand fluctuations, and international trade dynamics. Understanding the carbon disulfide price trends requires a deep dive into these aspects and how they interact with market forces. Carbon disulfide, a volatile, colorless liquid with a distinctive odor, is primarily used in the production of rayon, a type of fiber used in the textile industry. It also plays a significant role in manufacturing pesticides, rubber chemicals, and various other chemical intermediates. The market is highly sensitive to changes in the demand for these end-use products, making it vulnerable to both global economic conditions and regional supply-demand imbalances.

Get Real time Prices for Carbon Disulphide: https://www.chemanalyst.com/Pricing-data/carbon-disulphide-1248

Price fluctuations in the carbon disulfide market have often mirrored trends in the petrochemical industry, as Carbon Disulphide is predominantly derived from natural gas or oil-based feedstocks. As oil prices experience volatility, so too do the costs associated with the production of carbon disulfide. This link between energy prices and Carbon Disulphide production is particularly evident in regions where feedstocks are imported, such as Europe and parts of Asia. Conversely, regions with abundant natural gas or oil resources, like the United States and the Middle East, experience somewhat more stability in carbon disulfide pricing. Additionally, geopolitical tensions and natural disasters can disrupt the supply of these raw materials, causing sudden and often sharp price increases in carbon disulfide. Furthermore, regional economic performance heavily influences the price of Carbon Disulphide. In developing markets, where industries such as textiles and agriculture are growing rapidly, demand for carbon disulfide tends to increase, exerting upward pressure on prices. On the other hand, economic slowdowns or recessions in major consumer markets like the United States or China can lead to decreased demand, resulting in lower prices.

Another critical factor affecting carbon disulfide prices is the environmental regulations imposed on its production and use. As a toxic and hazardous chemical, carbon disulfide has been subject to increasing scrutiny due to its environmental and health impacts. Governments around the world are tightening restrictions on emissions from chemical manufacturing facilities, which has raised the cost of producing carbon disulfide in compliance with these new regulations. Companies that rely on Carbon Disulphide for their production processes must factor in these additional compliance costs, which can lead to price increases. The imposition of stricter safety standards also affects the market by limiting the number of suppliers, particularly smaller producers who may not be able to meet the new environmental requirements. This reduction in supply can drive prices upward, especially when demand for carbon disulfide remains strong.

Moreover, technological advancements in production methods have played a role in the carbon disulfide market. Innovations aimed at improving production efficiency and reducing emissions have allowed some manufacturers to lower their production costs. For instance, advancements in closed-loop systems and more efficient reactors have helped mitigate the negative environmental impacts associated with Carbon Disulphide production. These technological improvements, while beneficial from an environmental and cost perspective, are not always accessible to every producer, especially in emerging markets with limited access to advanced equipment. As a result, the price dynamics in these markets may differ from those in developed regions, where higher production costs due to stringent environmental regulations are often offset by technological innovations.

Trade policies and international relations also influence the carbon disulfide market. Countries that are net importers of Carbon Disulphide rely on the smooth functioning of international trade to secure stable supplies of the chemical. Any disruption in trade, such as tariffs or trade wars, can lead to price fluctuations. For instance, the imposition of tariffs on imports of carbon disulfide in key markets can significantly affect the cost structure of industries that depend on this chemical. Additionally, export restrictions in producing countries, whether due to domestic supply issues or political motives, can limit the global supply of carbon disulfide, driving up prices. The complexity of the global supply chain for carbon disulfide means that even small disruptions can have a cascading effect on the market, making it vulnerable to unpredictable price swings.

The demand for carbon disulfide also fluctuates with trends in end-use industries. One of the largest consumers of Carbon Disulphide is the textile industry, which uses it to manufacture rayon fibers. As global fashion trends shift, and as the demand for sustainable and eco-friendly fabrics rises, the carbon disulfide market can experience volatility. Similarly, the agriculture sector, which relies on carbon disulfide in the production of pesticides and fungicides, can see changes in demand based on agricultural trends, seasonal planting patterns, and pest outbreaks. The electronics industry, although a smaller consumer of carbon disulfide, also contributes to price fluctuations as it requires Carbon Disulphide in the manufacturing of semiconductors and other components. Shifts in technological development and global demand for electronic devices can, therefore, influence the price of carbon disulfide.

Furthermore, the increasing shift towards sustainable and green chemistry practices is beginning to shape the future of the carbon disulfide market. Researchers and industry players are working towards finding alternatives to Carbon Disulphide , either by improving its safety profile or developing entirely new chemical processes that eliminate its need. If these innovations succeed in providing viable substitutes for carbon disulfide, the demand for Carbon Disulphide could diminish, which would have a significant impact on its market prices. While such alternatives are still in the experimental or early commercial stages, they represent a potential long-term trend that could affect the stability of carbon disulfide prices.

In conclusion, the carbon disulfide market is shaped by a combination of global economic factors, regional demand and supply imbalances, environmental regulations, and technological advancements. Prices for this important chemical are highly volatile and subject to various external pressures, ranging from fluctuations in raw material costs to changes in international trade and government policies. Industry participants must closely monitor these factors to navigate the complexities of the carbon disulfide market and forecast pricing trends accurately. As the demand for sustainable alternatives grows and production processes evolve, the landscape of the carbon disulfide market may continue to change, impacting both prices and production methods in the coming years.

Get Real time Prices for Carbon Disulphide: https://www.chemanalyst.com/Pricing-data/carbon-disulphide-1248

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Carbon Disulphide#Carbon Disulphide Price#Carbon Disulphide Prices#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Dynemech Anti Vibration Solutions: Pioneering vibration control solutions for a stable industrial future.

Advancing Industrial Precision: Dynemech's Revolutionary DXO Series Reshapes Manufacturing Stability

In an era where manufacturing precision determines market leadership, Dynemech Anti Vibration Solutions celebrates its 23rd year of engineering excellence by introducing the groundbreaking DXO Series. This innovative vibration control system represents a quantum leap in industrial stability management, particularly for high-precision manufacturing environments and industrial machinery.

Engineering Innovation Meets Industrial Demands

Advanced Load Management System

The DXO Series introduces a revolutionary approach to load distribution through its proprietary multi-layer DHS1 insulation technology.

This system of rubber anti vibration mounts achieves:

Dynamic load handling capacity DXO1-SP1 7,000kg to DXO4-SP1 21,000 kg

Exceptional performance as heavy duty anti vibration pads for industrial applications

Precision-Engineered Stability Features

The system's architecture incorporates:

Reinforced composite damping elements

Multi-directional stability control mechanisms

Advanced elastic response management

Integrated thermal stability components

Vibration isolators for optimal performance

Revolutionary Applications in Heavy Manufacturing

Forging Press Implementation

The DXO Series transforms forging press operations through:

Active compensation for eccentric loading conditions

Reduced foundation stress by up to 85%

Optimal performance in confined spaces with limited footprint availability

Enhanced stability for power presses and forging hammers

VMC Machine Enhancement

For Vertical Machining Centres and CNC machines, the system delivers:

Precision stability during high-speed operations (up to 15,000 RPM)

Vibration reduction achieving 95% efficiency at critical resonant frequencies

Enhanced accuracy in micro-machining operations

Sustained precision during rapid axis movements

Effective Anti-Vibration Pad for machine tools and rotating machines

Technical Specifications and Performance Metrics

Core Technology Components

Multi-Layer DHS1 Insulation System

Proprietary composite materials

Variable density layering

Engineered stress distribution patterns

Incorporation of viscous damping and spring isolators

Lateral Stability Enhancement

Multi-directional restraint system

Progressive resistance characteristics

Self-aligning capabilities

Enhanced seismic protection and shock isolation

Performance Parameters

Isolation Efficiency: Up to 99% at frequencies > 7x natural frequency

Temperature Stability: Maintained performance across industrial temperature ranges

Chemical Resistance: Compatible with common industrial fluids and environments

Load Capacity: Optimized for a wide range of industrial machinery, including generators and motors

Industry-Specific Solutions

Heavy Engineering Sector

Custom anti vibration rubber mounts for press shops and foundries

Specialized configurations for metal forming equipment and textile machines

Adaptive systems for varying load conditions

Enhanced stability for high-impact operations like hammers and compressors

Precision Manufacturing

Ultra-stable platforms for measuring equipment

High-frequency isolation for precision machine tools

Custom solutions for clean room environments

Integrated monitoring capabilities for lathe machines and other precision equipment

Research and Development Excellence

Dynemech's commitment to innovation is evidenced by:

Continuous material research programs

Advanced finite element analysis implementation

Real-time performance monitoring systems

Custom solution development capabilities for specific antivibration needs

Installation and Support Services

Professional installation teams

Comprehensive site analysis

Custom foundation design support considering structural safety

Ongoing performance monitoring

Preventive maintenance programs

Emergency support services

Expert advice on foundation requirements for optimal performance of anti vibration mounts for machines

Quality Assurance and Certification

ISO 9001:2015 certified manufacturing processes

Individual load testing of all units

Comprehensive performance documentation

International compliance standards

Extended warranty programs

Experience With Dynemech Team in Imtex 2025

Live Demonstrations

Visit us at IMTEX 2025 in Bangalore to experience:

Real-time performance monitoring displays

Interactive load testing demonstrations

Comparative analysis presentations

Technical consultation sessions on anti vibration mounting pads

Location Details

Hall: 3A

Stall: A128

One-on-one consultation opportunities

Future-Ready Solutions

Dynemech's DXO Series represents more than just current technological excellence; it embodies our vision for the future of industrial stability. Our ongoing development programs focus on:

Industry 4.0 integration capabilities

Smart monitoring systems

Predictive maintenance features

Sustainable manufacturing practices

Vibration-reducing attachments for extended tool life and reduced machine operator fatigue

The DXO Series stands as a testament to Dynemech's 23 years of engineering excellence and unwavering commitment to manufacturing precision.

As we showcase this revolutionary vibration control system at IMTEX 2025, we invite industry professionals to experience firsthand how our advanced vibration damping solutions can transform their manufacturing operations.