#Motor Lamination Market

Explore tagged Tumblr posts

Text

Motor Lamination Market is Driven by Surging Vehicle Sales

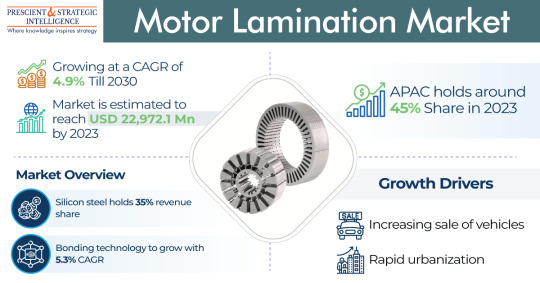

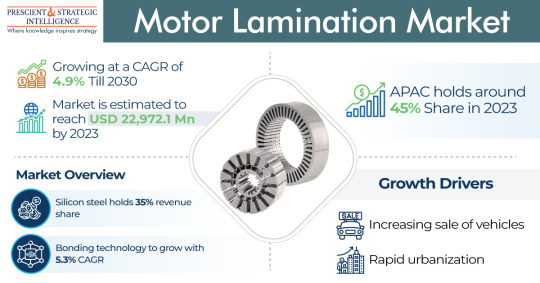

The motor lamination market is estimated to touch USD 22.9 billion in 2023, which will increase to USD 32.0 billion, with a 4.9% compound annual growth rate, by 2030.

The progression of this industry is because of the rising sale of automobiles, particularly those employing electricity as the secondary or primary propulsion source, across the globe. Furthermore, automobile, as well as equipment safety standards, are increasing, which is further boosting the requirement for motor laminations.

Additionally, to reduce operational duration and decrease fabrication expenses, lamination sheets have experienced different variations with time. The significant advancement in lamination technologies to improve the performance of motors is essentially likely to boost the industry in the coming years.

The bonding category, based on technology, will propel at the fastest rate, of 5.3%, during this decade. This is because it removes the necessity for magnetic core rivet joints to lessen interlaminar loss.

To download free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/motor-lamination-market-report/report-sample

Moreover, bonded cores don’t create hum sound, because of their exceptional thermal conductivity. Also, this technology is extensively employed because of its flexibility for personalized necessities.

Whereas, the welding category is also advancing at a significant rate, because of the employment of this procedure to manufacture strong and durable motors, by incorporating laminations together. Welding provides stronger efficiency, cost-effectiveness, and production to electric motors, the requirement for which is rising in practically every sector.

The silicon steel category, based on material type, is the largest contributor to the motor lamination market, with a 35% share. This is because it enhances the electrical resistivity, which means that it reduces the loss of current as well as decreases the conductivity.

The automotive category, based on industry, is the highest revenue contributor. This is because of the increasing need for comfortable and luxury automobiles with features like power steering & windows, retractable sunroofs, and HVAC equipment.

APAC is leading the industry, and it is further expected to remain leading, generating USD 10.3 billion, by 2030. This will be primarily because of the surge in the production of electric vehicles.

#Motor Lamination Market#Market Report#P&S Intelligence#Industry Trends#Analysis#Growth Forecasts#Market Dynamics#Electrical Motors#Lamination Materials#Global Motor Lamination Market#Market Research#Industry Overview#Competitive Analysis#Regional Analysis

0 notes

Text

Motor Lamination Market is Driven by Surging Vehicle Sales

Themotor lamination market is estimated to touch USD 22.9 billion in 2023, which will increase to USD 32.0 billion, with a 4.9% compound annual growth rate, by 2030. The progression of this industry is because of the rising sale of automobiles, particularly those employing electricity as the secondary or primary propulsion source, across the globe. Furthermore, automobile, as well as equipment…

View On WordPress

#efficiency#Electric motors#Electric vehicles#Energy consumption#Industrial machinery#Innovation#Investment Opportunities#Market dynamics#market trends#Motor lamination#sustainability#technological advancements

0 notes

Text

Introduction to Car Over Lamination

In this blog we will discuss about Car Over Lamination : In today’s world, in which vehicles are not just modes of transportation however additionally considerable investments, protective their appearance and value turns into paramount. One of the simplest approaches to safeguard your car against the elements is through the artwork of over-lamination. This option provides protection that goes beyond traditional options, ensuring the longevity and beauty of your car for years to come.

Understanding the Concept of Over Lamination

What is Over-Lamination? Over lamination is a protective technique in which a smooth or colored film is applied to the surface of automotive paint or materials. This film acts as a shield, protecting it from scratches, UV rays, dirt, and various external elements that may harm the vehicle.

How Does Over Lamination Work?

The over lamination system entails carefully adhering a thin layer of defensive film onto the surface of the auto. This film is specially designed to withstand various environmental stressors simultaneously and to provide clarity and robustness. Once applied, it blends seamlessly with the car’s paint to form an invisible barrier that supports both safety and aesthetics.

Benefits of Car Over Lamination

Protection Against Environmental Factors One of the main advantages of overcoating is its ability to protect the vehicle from a wide range of environmental hazards. Whether it’s road debris, bird droppings or harsh weather conditions, the protective film acts as a barrier, preventing damage and preserving the car’s pristine appearance.

Enhanced Aesthetic Appeal In addition to protection, over lamination also can decorate the visual appeal of the car. The obvious film continues the original coloration and shine of the paint at the same time as adding a sleek finish that accentuates the car’s curves and lines.

Maintenance of Resale Value By making an investment in over lamination, automobile proprietors can make sure that their cars retain their resale price over time. The defensive movie acts as a guard in opposition to put on and tear, minimizing the need for steeply-priced upkeep and maintaining the car’s market enchantment.

Types of Car Over Lamination

Clear Bra Car Over Lamination Clear bra over lamination is a famous choice among car owners seeking most safety without compromising aesthetics. This without a doubt invisible movie gives an extra layer of defense against scratches, chips, and different varieties of harm, all while preserving the authentic appearance of the car.

Vinyl Wrap Car Over Lamination Vinyl wrap over-lamination offers a more customizable approach to car safety. Available in lots of hues and finishes, this form of over-lamination lets in automobile proprietors to customize their cars whilst simultaneously safeguarding them from environmental dangers.

Choosing the Right Over Lamination for Your Car

When selecting an over-lamination option for your car, several factors should be considered:

Consideration of Budget Different forms of over-lamination range in fee, so it is essential to determine your budget earlier than you decide. While clear bra over-lamination may be extra pricey in advance, it often pays off in the long run with its superior safety and sturdiness.

Longevity and Durability The longevity and durability of the over laminated film are important issues, especially for those looking for long lasting protection. The clear bra over-lamination is known for its durability and resistance to yellowing, setting it apart from motors that withstand extreme conditions.

Desired Level of Protection The degree of protection required may range relying on elements which include wherein you live and how often you power. Clear bra over-lamination offers the highest level of protection against physical damage, making it perfect for day by day drivers and excessive-mileage automobiles.

The Over Lamination Process

Surface Preparation Before applying the over lamination film, the auto’s surface have to be very well cleaned and prepped to make certain proper adhesion. Any dirt, grease, or imperfections can affect the quality of the set up, so meticulous education is critical.

Application of Over-Lamination Film Once the surface is prepared, special tools and techniques are used to carefully apply the overblown film. The film is stretched and molded to the contours of the vehicle, providing complete coverage and a seamless finish.

Quality Assurance Once the overproduced film is loaded, a final inspection is carried out to ensure that the loading meets the highest quality standards. Any imperfections or air leaks are addressed and adjustments are made as necessary to achieve a flawless result.

DIY vs. Professional Installation

Pros and Cons of DIY Installation While some vehicle proprietors can also choose a DIY method to over-lamination, there are several drawbacks to keep in mind. DIY kits frequently lack the best and durability of professional-grade materials, leading to inferior consequences and capacity harm to the automobile’s surface.

Advantages of Professional Installation Professional installation offers several blessings, including get admission to to exceptional substances, expert craftsmanship, and a assure of delight. Trained technicians have the know-how and enjoy to make certain a best set up, maximizing the effectiveness and durability of the over-lamination.

Cost of Over-Lamination The price of over-lamination can range depending on several factors, together with the kind of film used, the dimensions of the vehicle, and the complexity of the set up technique. While it can represent an preliminary investment, the long-term advantages of over-lamination a ways outweigh the in advance fees.

Maintenance Tips for Car Over Lamination

Proper maintenance is essential to maximize the lifespan and effectiveness of the over-lamination film. Some tips for maintaining over-laminated cars include:

Proper Cleaning Techniques Use mild cleaning products and strategies to avoid destructive the protecting film. Avoid abrasive substances and cruel chemical compounds that could degrade the movie’s readability and durability.

Avoiding Harsh Chemicals Avoid parking your vehicle near commercial areas or production web sites wherein it is able to be uncovered to harsh chemicals or pollutants that might harm the protective film.

Periodic Inspection Regularly investigate your over-laminated car for any signs of damage or wear. Address any issues promptly to save you in addition damage and make certain ongoing protection.

Common Misconceptions About Car Over Lamination

Despite its numerous benefits, over-lamination is often misunderstood. Some common misconceptions include:

It’s Only for High-End Cars While over-lamination is famous among luxurious car owners, it is appropriate for automobiles of all makes and fashions. Whether you pressure a sports activities car or a own family sedan, over-lamination can assist shield your investment and preserve its value.

Over Lamination is Permanent While over-lamination is well-known amongst luxurious car proprietors, it’s miles suitable for cars of all makes and fashions. Whether you stress a sports activities sports automobile or a circle of relatives sedan, over-lamination can assist guard your funding and maintain its cost.

Over Lamination Hinders Paint Breathability Another common misconception is that over-lamination prevents the car’s paint from “breathing” and can increase moisture content. In fact, modern ultra-lamination films provide adequate ventilation, while still providing maximum protection.

Real Life Examples of Car Over Lamination Success Stories

Countless automobile owners have skilled the blessings of over-lamination firsthand. Testimonials from happy clients and earlier than-and-after visuals function compelling proof of its effectiveness in maintaining the advent and price of cars.

Environmental Impact of Car Over Lamination

As worries about environmental sustainability keep growing, it is critical to don’t forget the environmental impact of over-lamination. Fortunately, many manufacturers now provide eco-friendly alternatives crafted from recyclable substances, helping to limit waste and decrease carbon footprint.

Future Trends in Car Over Lamination

Looking in advance, the future of vehicle over-lamination is vibrant. Advancements in shielding movie era, including self-restoration coatings and anti-fouling residences, promise even greater ranges of protection and durability. Additionally, integration with clever technology, along with sensors and self-cleansing capabilities, could revolutionize the way we defend and maintain our automobiles.

Conclusion

In end, the art of automobile over-lamination offers a comprehensive solution for defensive your funding and retaining its cost. By understanding the benefits, types, and installation system of over-lamination, automobile proprietors can make knowledgeable choices that make certain lengthy-time period pleasure and peace of thoughts.

FAQs on Car Over Lamination

Q: Is over-lamination suitable for all types of cars? A: Yes, over-lamination is suitable for vehicles of all makes and models, from economy cars to luxury vehicles.

Q: How long does over-lamination last? A: The lifespan of over-lamination depends on various factors, including the type of film used, environmental conditions, and maintenance practices. However, with proper care, it can last for several years.

Q: Can over-lamination be removed? A: Yes, over-lamination can be safely removed if desired, without causing damage to the underlying paint.

Q: Does over-lamination affect the car’s paint color? A: No, over-lamination is transparent and does not alter the color of the car’s paint. It simply adds a layer of protection while maintaining the original appearance.

Q: Is over-lamination environmentally friendly? A: Many manufacturers now offer eco-friendly over-lamination options made from recyclable materials, helping to minimize environmental impact.

#car over lamination#protective film#vehicle protection#paint protection#scratch protection#UV protection#automotive accessories#car maintenance#car paint protection#car exterior protection#best car over lamination products

2 notes

·

View notes

Text

Electrical Steel Prices, News, Trend, Graph, Chart, Monitor and Forecast

The global market for electrical steel prices has garnered significant attention in recent years, driven by the increasing demand for energy-efficient materials in various industries. Electrical steel, also known as silicon steel or lamination steel, plays a crucial role in the performance of transformers, motors, and generators. Its unique magnetic properties, such as high permeability and low core loss, make it indispensable in the electrical and automotive sectors. The dynamics of the electrical steel market are influenced by several factors, including raw material costs, supply chain disruptions, regulatory policies, and evolving technological advancements. As the world continues to shift toward renewable energy sources and electric vehicles (EVs), the demand for high-quality electrical steel is expected to surge, leading to fluctuations in pricing.

One of the primary drivers of electrical steel prices is the cost of raw materials, particularly iron ore and silicon. Fluctuations in the prices of these materials have a direct impact on the final cost of electrical steel. Additionally, energy costs, which are significant in the steel production process, contribute to the overall pricing structure. With rising energy prices globally, manufacturers are compelled to adjust their pricing strategies to maintain profitability. Geopolitical tensions and trade policies further complicate the supply chain, influencing market dynamics. For instance, tariffs on steel imports in various countries can cause supply shortages or surpluses, impacting prices regionally.

Get Real time Prices for Electrical Steel: https://www.chemanalyst.com/Pricing-data/electrical-steel-1357

The automotive industry has emerged as a major consumer of electrical steel, especially with the growing adoption of electric vehicles. EV manufacturers require electrical steel for motors and battery systems, which has intensified demand. As countries implement stricter emissions regulations and promote clean energy vehicles, the need for electrical steel continues to rise. This increased demand exerts upward pressure on prices, particularly for high-grade non-grain-oriented (NGO) electrical steel, which is essential for efficient motor performance. Simultaneously, grain-oriented electrical steel (GOES), primarily used in transformers, witnesses price changes in response to power infrastructure developments worldwide.

Renewable energy projects also significantly influence electrical steel market prices. The expansion of wind and solar power generation requires transformers and generators that rely on electrical steel. Governments across the globe are investing in renewable energy to reduce carbon footprints, thereby boosting the demand for electrical steel. For instance, large-scale wind turbines utilize considerable amounts of electrical steel in their cores, and with the increasing number of such installations, the market experiences periodic price increases.

Regional market dynamics present a diverse picture of electrical steel pricing trends. In Asia-Pacific, particularly in China and India, rapid industrialization and infrastructure development fuel substantial demand for electrical steel. China, as a dominant player in the steel industry, significantly influences global prices through its production capacity and export policies. The Chinese government's policies on energy consumption and emission control have led to periodic production cuts, affecting the global supply and pricing. Meanwhile, Europe and North America experience pricing shifts due to infrastructure upgrades and the transition toward sustainable energy sources.

Technological advancements in steel manufacturing processes contribute to pricing trends as well. Innovations aimed at enhancing steel quality, reducing energy consumption, and minimizing production costs play a critical role in market competitiveness. The introduction of advanced high-grade electrical steels with superior magnetic properties has led to premium pricing compared to conventional grades. Manufacturers continuously invest in research and development to meet the evolving requirements of the automotive and energy sectors, resulting in dynamic pricing patterns.

The COVID-19 pandemic disrupted global supply chains, causing significant fluctuations in electrical steel prices. Lockdowns, transportation restrictions, and labor shortages hindered production and distribution, leading to supply-demand imbalances. As economies gradually recovered, the surge in demand, coupled with constrained supply, caused sharp price increases. The post-pandemic market continues to experience volatility as manufacturers navigate logistical challenges and shifting demand patterns.

Looking ahead, the electrical steel market is expected to witness continued growth, driven by the ongoing energy transition and the electrification of transportation. The push for carbon neutrality encourages investments in renewable energy infrastructure, further propelling demand for electrical steel. However, the market may face challenges such as raw material scarcity, regulatory changes, and geopolitical uncertainties. Stakeholders across the value chain must adopt flexible strategies to mitigate risks and capitalize on emerging opportunities.

In conclusion, electrical steel prices are influenced by a complex interplay of factors, including raw material costs, industrial demand, technological advancements, and global economic conditions. As the world moves toward a more sustainable and electrified future, the demand for electrical steel is poised to grow, potentially leading to price volatility. Monitoring market trends, investing in innovation, and adapting to regulatory changes will be essential for industry players to navigate the evolving landscape successfully. The continuous development of renewable energy projects and electric vehicles will remain pivotal in shaping the future trajectory of electrical steel prices on a global scale.

Get Real time Prices for Electrical Steel: https://www.chemanalyst.com/Pricing-data/electrical-steel-1357

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Electrical Steel#Electrical Steel Price#Electrical Steel Prices#Electrical Steel Pricing#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

1 note

·

View note

Text

Lounge Renovation Dubai: Transforming Spaces with Style and Sophistication

A lounge is more than just a room; it’s the heart of a home or a gathering space where people relax, connect, and entertain. Whether it's in a residence, office, or commercial establishment, the lounge sets the tone for comfort and style. In Dubai, where luxury and modernity meet, lounge renovation Dubai has become a popular trend for those seeking to enhance their interiors with elegance and functionality.

Why Renovate Your Lounge in Dubai?

Lounge renovation in Dubai is not just about upgrading aesthetics—it's about creating a space that reflects your personality and meets your lifestyle needs. Dubai's vibrant design scene and diverse culture make it an ideal city for blending innovative trends with timeless styles. Here are some key reasons to consider a lounge renovation:

Modernization Renovation breathes new life into outdated lounges. With Dubai’s fast-paced architectural advancements and design trends, many homeowners and business owners seek to upgrade their lounges with contemporary features, sleek furniture, and smart technology.

Enhanced Functionality A well-designed lounge optimizes space and improves functionality. Whether it's adding modular furniture, creating open layouts, or integrating storage solutions, renovations help maximize the potential of your lounge.

Improved Comfort Lounge renovations focus on comfort, making it easier to unwind after a long day. From ergonomic furniture to cozy fabrics, the right renovation elements can transform a lounge into a serene retreat.

Increased Property Value A beautifully renovated lounge adds significant value to a property. Whether you're planning to sell or lease, an updated lounge makes your property more appealing to potential buyers or tenants in Dubai’s competitive real estate market.

Personalization Renovation allows you to customize your lounge to suit your tastes and preferences. Whether you prefer a minimalist design, a cozy Bohemian vibe, or a luxurious contemporary look, you can tailor the lounge to reflect your unique style.

Key Elements of a Lounge Renovation

When renovating a lounge in Dubai, there are several factors to consider for a successful transformation:

Furniture and Layout Modern lounge designs prioritize clean lines, multifunctional furniture, and spacious layouts. Choose furniture that complements the overall theme of your home or office. Modular seating arrangements, recliners, and sleek coffee tables are excellent options for both comfort and style.

Lighting Lighting is a crucial element that can transform the ambiance of a lounge. Incorporate layered lighting with a combination of ceiling fixtures, floor lamps, and accent lighting to create a warm and inviting atmosphere. In Dubai, statement chandeliers and LED accents are popular choices.

Color Scheme A fresh coat of paint or new wallpaper can completely alter the vibe of a lounge. Neutral tones like beige, gray, and white remain timeless, while bold hues like emerald green or royal blue add a touch of luxury.

Smart Technology Smart lounges are gaining popularity in Dubai. From motorized curtains to voice-controlled lighting and entertainment systems, integrating smart technology ensures your lounge is not only stylish but also convenient.

Flooring and Carpets Flooring plays a significant role in lounge aesthetics. Choose from elegant marble, hardwood, or laminate flooring for a sophisticated look. Add plush area rugs or carpets for warmth and texture.

Accessories and Décor Add finishing touches to your lounge with stylish décor elements. Mirrors, artwork, throw pillows, and indoor plants can elevate the overall look and feel. In Dubai, gold accents, metallic finishes, and abstract art are often used to create a luxurious vibe.

Renovation Trends in Dubai

Dubai is known for its trendsetting approach to interior design, and lounge renovations are no exception. Here are some popular trends to consider:

Open-Concept Spaces: Removing walls and creating seamless transitions between the lounge, dining, and kitchen areas is a common trend for a more spacious feel.

Natural Materials: Incorporating wood, stone, and other natural materials adds warmth and elegance to lounge interiors.

Green Living: Adding greenery with vertical gardens or potted plants not only enhances aesthetics but also promotes a relaxing environment.

Bold Art Statements: Dubai’s art scene inspires the inclusion of eye-catching art pieces and sculptures in lounge spaces.

Hiring Professionals for Lounge Renovation in Dubai

Lounge renovation in Dubai requires careful planning and expertise. Hiring a professional interior designer or renovation company ensures your project is executed efficiently and meets your expectations. From conceptualization to execution, these experts can help you bring your vision to life while adhering to budgets and timelines.

Some reputable renovation companies in Dubai offer end-to-end services, including space planning, material selection, and custom furniture design. Whether you’re updating a residential lounge or revamping a corporate space, their expertise guarantees stunning results.

Conclusion

A lounge renovation Dubai is an opportunity to blend luxury, comfort, and functionality into one cohesive space. Whether you’re upgrading your home lounge to create a cozy retreat or transforming a commercial space to impress clients, a thoughtful renovation can elevate the ambiance and value of your property. With endless design possibilities and access to world-class materials and expertise, Dubai offers the perfect setting to bring your dream lounge to life.

0 notes

Text

Metal Stamping Market Analytical Overview and Growth Opportunities by 2034

The Global Metal Stamping Market is expected to increase at a compound annual growth rate (CAGR) of 4.2% between 2024 and 2034. Based on an average growth pattern, the market is expected to reach USD 326.38 billion in 2034. It is projected that the worldwide metal stamping market will generate USD 236.83 billion in revenue by 2024.

The metal stamping market involves a process where metal sheets are shaped into specific designs through stamping machinery. The demand for metal stamping is driven by its application in industries such as automotive, aerospace, electronics, and industrial machinery. Metal stamping helps create complex components with high precision and minimal waste, making it a cost-effective manufacturing solution.

Get a sample copy of this report: https://wemarketresearch.com/reports/request-free-sample-pdf/metal-stamping-market/1610

Metal Stamping Market Drivers

Growing Automotive Industry The automotive sector is a major end-user of metal stamping for producing body panels, chassis, engine components, and transmission parts. The increasing production of electric vehicles (EVs) further boosts demand for lightweight and precision-stamped parts.

Expansion of Consumer Electronics With the rising adoption of smartphones, wearable devices, and consumer electronics, the need for precise stamped metal components such as connectors, shielding cases, and microelectronic parts is growing.

Demand for Lightweight and Durable Components In industries such as aerospace and automotive, there is a significant demand for lightweight yet durable metal components, which is fueling the adoption of advanced stamping technologies.

Metal Stamping Market Drivers

Growing Automotive IndustryThe automotive sector is a major end-user of metal stamping for producing body panels, chassis, engine components, and transmission parts. The increasing production of electric vehicles (EVs) further boosts demand for lightweight and precision-stamped parts.

Expansion of Consumer Electronics With the rising adoption of smartphones, wearable devices, and consumer electronics, the need for precise stamped metal components such as connectors, shielding cases, and microelectronic parts is growing.

Demand for Lightweight and Durable ComponentsIn industries such as aerospace and automotive, there is a significant demand for lightweight yet durable metal components, which is fueling the adoption of advanced stamping technologies.

Metal Stamping Market Trends

Adoption of Advanced Stamping Technologies Technologies such as progressive die stamping and fine blanking are being increasingly adopted for high-volume production with enhanced precision.

Integration of Automation and Robotics Automated metal stamping systems and robotic arms are enhancing productivity, reducing labor costs, and improving quality control in the stamping process.

Sustainability in Metal StampingManufacturers are focusing on sustainable practices by adopting recyclable materials and minimizing waste through precision manufacturing processes.

Opportunities in the Metal Stamping Market

Rising Demand for Electric Vehicles (EVs) The transition toward EVs has created a growing need for lightweight metal components to improve vehicle efficiency and range. Metal stamping is integral in manufacturing parts like battery enclosures, motor laminations, and structural frames.

Advancements in Material Technologies The development of high-strength, lightweight alloys and composite materials is expected to unlock new possibilities in precision metal stamping, particularly in aerospace and medical device manufacturing.

Customization and Prototyping Increasing demand for custom-designed stamped components is driving the adoption of rapid prototyping and short-run stamping, allowing manufacturers to quickly adapt to changing customer requirements.

Growth in the Healthcare Sector Metal stamping is increasingly being used in the production of medical devices such as surgical instruments, implantable components, and diagnostic equipment, creating significant growth opportunities.

Key Challenges

Skilled Labor Shortage Operating advanced stamping machinery requires a highly skilled workforce. Companies are investing in employee training and collaborating with technical institutes to address this gap.

Stringent Regulatory Standards The metal stamping industry must comply with various safety and environmental regulations, which can increase operational costs. Implementing compliance automation systems can help manufacturers streamline the process.

Supply Chain Disruptions The global metal stamping market faces challenges from fluctuating raw material supply and logistics issues. Establishing multiple sourcing partnerships and local supply chains can mitigate risks.

Global Metal Stamping Market Segmentation

By Material Type:

Steel

Aluminum

Copper

Brass

By Process Type:

Blanking

Embossing

Bending

Coining

By End-Use Industry:

Automotive

Aerospace

Industrial Machinery

Electronics

Construction

Companies Covered: Metal Stamping Market

The Global Metal Stamping Market is dominated by a few large companies, such as

Acro Metal Stamping

Manor Tool & Manufacturing Company

D&H Industries, Inc.

Kenmode, Inc.

Klesk Metal Stamping Co

Clow Stamping Company

Goshen Stamping Company

Tempco Manufacturing Company, Inc

Interplex Holdings Pte. Ltd.

CAPARO

Nissan Motor Co., Ltd

AAPICO Hitech Public Company Limited

Gestamp

Ford Motor Company

Metal Stamping Market Regional Insights

North America The presence of major automotive and aerospace manufacturers in the U.S. and Canada contributes to high demand for metal stamping.

Europe Germany, being a hub for automotive production, plays a crucial role in driving the metal stamping market in the region.

Asia-PacificRapid industrialization and increasing electronics manufacturing in countries such as China, Japan, and India are driving the growth of the metal stamping market in this region.

Conclusion

The global metal stamping market is experiencing substantial growth due to its increasing applications across various industries, including automotive, aerospace, electronics, and industrial machinery. Technological advancements, such as automation and precision stamping, are transforming the market by improving efficiency, reducing waste, and enhancing product quality. While challenges such as fluctuating raw material prices and high initial investments persist, the shift toward lightweight materials, electric vehicles, and sustainable manufacturing practices presents lucrative growth opportunities. As key players continue to innovate and expand their production capabilities, the metal stamping market is expected to witness robust expansion in the coming years.

Frequently Asked Questions

What is the market size of Metal Stamping Market in 2024?

What is the growth rate for the Metal Stamping Market?

Which are the top companies operating within the market?

Which region dominates the Metal Stamping Market?

0 notes

Text

https://seo-48843047.hubspotpagebuilder.com/blog/south-korea-motor-laminations-market-by-application-size-trends-2025

0 notes

Text

The Best Features in Portable Sewing Machines for Beginners

Today’s machines boast of digital features and exceptional precision, and sewing machines are no exception. Beginners often look for a machine that’s simple, compact, and easy to use, but what’s more important for many users, especially beginners, is portability.

So it’s no surprise that a lot of sewing machine brands offer portable models that make it easy for sewists and quilters to bring their hobby with them wherever they go. But with countless options on the market, how do you choose the right one?

What Makes a Good Portable Sewing Machine?

A good portable sewing machine isn’t just compact. It needs to be reliable, versatile, and equipped with features that make sewing easy for beginners. The key features beginners need to consider include the following:

Compact Design

Smaller machines save space and make it easier to store when not in use.

Ease of Use

User-friendly controls and simple threading features make a big difference, especially for new users.

Weight and Portability

Lightweight machines are easy to carry to sewing classes or to store.

Built-in Stitch Options

A variety of stitches lets beginners explore without needing advanced settings.

User-Friendly Interface

LCD screens or labeled stitch charts simplify operation, helping beginners quickly get comfortable.

Why Portable Sewing Machines are Best for Beginners

If you find a sewing machine that has all of these, the next one you need to do is choose the one that suits your budget. You might be surprised to find that some sewing machines for beginners are quite expensive.

However, this is where portable sewing machines are ahead of the more traditional ones. Portable machines are often more affordable and priced at a lower rate than other sewing machines.

And since most beginners are trying to explore their options in this new hobby, it makes sense that most beginners prefer affordable machines. So the popularity of portable sewing machines among beginners isn’t surprising.

These machines have features that are similar to most machines, but are also easy to use. However, they have enough complexities that allow all users to reach their next sewing or quilting level without being discouraged.

Also, some of these machines also make precision and quality sewing easier to accomplish, even with the limited built-in stitches available.

Portable Sewing Machines Ideal for Beginners

Here are some of the best portable sewing machines that are perfect for beginners, each offering a unique blend of features and ease of use. These machines are excellent choices for beginners due to their user-friendly features, durability, and versatility across various sewing projects.

Janome HD3000

This machine is perfect for those who need a sturdy and powerful mechanical machine capable of handling light to heavy materials, like leather and upholstery. It includes 18 built-in stitches, a top-loading bobbin, and a powerful motor for smooth operation, making it ideal for beginners interested in durable and reliable sewing.

Consew Model CP206R

Known for its capability for sewing light to heavy materials and its versatility as a home or portable sewing machine, the Consew is designed for stitching materials for furniture and other equipment that use canvas, leather, and even laminated products. If you enjoy camping and sewing, you can get this one so you can care for your bags, tents, and even home upholstery.

Brother Innov-is NS80E

With its compact design, advanced needle threading, and LCD screen, this computerized machine is great for beginners on the go. Its 80 built-in stitches and adjustable speed control cater to new sewers seeking a portable yet feature-rich option.

Portability Makes Sewing Easier

Selecting the right portable sewing machine can make all the difference in your sewing hobby. Each model offers distinct features that cater to different needs, but the best choice is one that aligns with your sewing goals and budget.

For more information about Home Embroidery Machines and Coverstitch Machines please visit:- Premier Stitching DBA Sew Vac City

0 notes

Text

Economic Benefit Analysis of Glue Laminating Machines: A Comprehensive Evaluation from Investment to Return

Economic Benefit Analysis of Glue Laminating Machines: A Comprehensive Evaluation from Investment to Return

Introduction In today’s fiercely competitive market environment, businesses looking to introduce new equipment focus not only on technical parameters and production efficiency but also on investment return rates. Glue Laminating Machines, as highly automated devices, provide significant production efficiency improvements and cost savings for battery manufacturing companies. This article will comprehensively analyze the economic benefits of Glue Laminating Machines from investment costs, operational costs, production benefits, and investment return periods, helping enterprises make informed investment decisions.

Cost Structure Analysis

Equipment Procurement Costs The procurement cost of a laminating adhesive machine primarily depends on the model, configuration, and required level of automation. The price range of Glue Laminating Machines on the market is quite broad, from basic to high-end models, with prices ranging from hundreds of thousands to millions of yuan. For small and medium-sized enterprises, selecting the appropriate model and configuration can effectively control initial investment costs.

Operating Costs The operating costs of the equipment mainly include power consumption, maintenance fees, and consumable costs.

Power Consumption: Glue Laminating Machines utilize efficient motors and intelligent control systems, resulting in relatively low energy consumption.

Maintenance Fees: The modular design and high-durability materials of the equipment make daily maintenance simple. Regular maintenance costs mainly involve the replacement of wear parts and routine upkeep.

Consumable Costs: This includes adhesive films and cleaning agents, with intelligent adhesive film usage control reducing material waste.

Labor Cost Savings The introduction of automated equipment significantly reduces the need for manual operations. Traditional manual adhesive application processes require multiple operators, whereas Glue Laminating Machines can be operated and monitored by just 1-2 technicians. According to practical cases, the introduction of Glue Laminating Machines has allowed enterprises to reduce direct labor costs by over 60%, significantly decreasing training and management expenses.

Production Benefit Analysis

Increased Production Efficiency Glue Laminating Machines integrate multiple automation functions, enabling continuous operation on the production line and greatly enhancing production efficiency. Typically, the adhesive application speed of the equipment can reach 2 pieces per second, resulting in a production capacity of several thousand pieces per hour. This efficient production means higher output and shorter delivery cycles for enterprises.

Improved Product Quality The high-precision automated control system ensures the accuracy of each adhesive application, significantly reducing the defect rate. Statistics indicate that the defect rate can be controlled to below 1% after using a laminating adhesive machine, representing an 80% reduction compared to traditional manual operations. This not only enhances the consistency of product quality but also minimizes additional costs incurred from reworking and waste management.

Enhanced Operational Flexibility The multifunctionality and adjustability of the equipment enable the production line to respond quickly to market demand changes. Whether switching between different sizes of electrode sheets or changing adhesive film types, the laminating adhesive machine can complete adjustments and transitions within a short time, greatly enhancing the operational flexibility of enterprises.

Investment Return Period The investment return period for introducing a laminating adhesive machine is typically short, depending on the enterprise's production scale and efficiency improvement. Below is a return analysis of a practical case: Case Analysis: A battery manufacturing enterprise introduced a medium-sized laminating adhesive machine with an initial investment of 1.5 million yuan. After operation, production efficiency increased by 30%, and annual output rose by 500,000 pieces. Due to reduced defect rates and labor cost savings, the enterprise saves approximately 600,000 yuan annually. Based on these data, the enterprise recouped its equipment investment cost within 2.5 years and achieved significant cost savings and production benefits thereafter. This rapid return on investment not only enhances the company's cash flow but also provides strong support for its sustainable development. For larger-scale enterprises, the economic benefits and market competitiveness brought by the equipment are even more significant.

Comparative Analysis: Economic Benefits of Traditional Processes vs. Automated Equipment Compared with traditional manual adhesive application processes, the economic benefits of Glue Laminating Machines are primarily reflected in the following aspects:

Efficiency Advantage: Automated equipment's production efficiency is several times that of manual operations, significantly shortening production cycles.

Quality Advantage: Automated control greatly reduces the defect rate, minimizing economic losses due to quality issues.

Cost Advantage: Although the initial investment in equipment is high, savings on labor costs and increased efficiency result in lower total costs in the long run.

Through comparative analysis, it is evident that while the initial investment for Glue Laminating Machines is higher, they offer significant advantages in production efficiency, product quality, and cost control, making them a key investment for achieving sustainable development in enterprises.

Conclusion As an efficient automated production device, the laminating adhesive machine brings significant economic benefits to battery manufacturing enterprises. Through detailed analysis of equipment cost structures, production benefits, and investment return periods, it is clear that Glue Laminating Machines can help enterprises significantly improve production efficiency, reduce costs, and maintain a competitive edge in a highly competitive market. For businesses seeking greater competitiveness, investing in Glue Laminating Machines is a choice worth considering.

FAQ

Q1: What is the typical investment return period for a laminating adhesive machine? A: The investment return period is usually 1-3 years, depending on the enterprise's production scale, efficiency improvements, and the condition of equipment usage.

Q2: Are the operating costs of the equipment high? A: The operating costs mainly include power consumption, maintenance fees, and consumable costs. Overall, the operating costs are relatively low, and as production efficiency improves, the unit production costs will further decrease.

Q3: What are the long-term economic benefits of investing in a laminating adhesive machine for enterprises? A: Glue Laminating Machines can significantly improve production efficiency, reduce defect rates, and lower labor costs, providing long-term economic benefits for enterprises. The investment return period is short, making it an important means to enhance competitiveness in the long term.

Q4: Are Glue Laminating Machines suitable for all battery manufacturing enterprises? A: The equipment is suitable for most battery manufacturing enterprises that require adhesive film application processes, especially for soft-pack batteries. Enterprises should choose the appropriate equipment model based on their production scale and needs.

Q5: How can the investment return rate of the equipment be calculated? A: The investment return rate can be assessed by calculating the cost savings brought by the equipment (such as labor costs and reduced defect rates) and the economic benefits of efficiency improvements, combined with the initial investment cost. Typically, enterprises can recoup their investment and achieve profitability in a short time.

0 notes

Text

Fabric Based Laminates Market - Gowth Industry&Forecast, 2023–2030.

Fabric Based Laminates Market Overview:

The global Fabric Based Laminates Market size is estimated to reach $5.15 billion by 2030, growing at a CAGR of 4.1% during the forecast period 2023–2030. The fabric-based laminates market has experienced significant growth in recent years, driven by the increasing demand for lightweight, durable, and high-performance materials in various industries. Fabric-based laminates combine the strength and flexibility of fabrics with the added benefits of laminated structures, making them suitable for a wide range of applications.

Moreover, the fabric-based laminates market presents immense growth potential, fueled by the demand for lightweight, durable, and high-performance materials across various industries. While challenges related to cost and material availability exist, technological advancements and increasing awareness regarding the benefits of fabric-based laminates are expected to propel market growth.

Sample Report:

Fabric Based Laminates market — Report Coverage:

The “Fabric Based Laminates market — Forecast (2023–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Fabric Based Laminates Market.

COVID-19 / Ukraine Crisis — Impact Analysis:

● The laminated fabric market is expected to experience a significant decrease in demand due to the pandemic. This is due to the fact that stakeholders are heavily reliant on the supply chain, and the countries most affected by the pandemic, India, China and the United States, are expected to be at the forefront of the pandemic’s spread. Additionally, the closure of physical retail outlets around the world has had a significant effect on the industry, with labor constraints and an export-oriented focus. As a result, workers have returned to their countries of origin, resulting in a decrease in exports.

● The supply chain disruption due to the Russia-Ukraine war has impeded the Fabric Based Laminates Market growth. The disruption has increased freight charges, created container shortages and lowered the availability of warehousing space. This has resulted in inflationary issues in the aftermarket.

Inquiry Before Buying:

● Fastest Growth of Asia Pacific Region

The global market breakdown by regions is as follows: North America Asia-Pacific Europe South America Middle East & Africa Asia Pacific The construction sector is the main driver of the global market, with Asia Pacific accounting for the largest market share during the forecast period China is the world’s largest manufacturer of motor vehicles Upholstered Furniture Apparel & Accessories The coated fabrics market in China is driven by the industrialization of China and India Many manufacturing firms in Asia Pacific are expected to increase their demand for polymer coated cloth.

Schedule A Call :

● Market growth is expected to be driven by the growth of the automotive industry.

The automotive industry has a wide range of applications that rely on laminated / coated fabric and clothing, such as airbags, tyres cables, vehicle grab handles, windscreen wipers, radiator covers, and more. Plastic materials, particularly thermoplastic materials, are more commonly used in the vehicle sector. PA6 has a range of characteristics that make it an ideal material for automotive applications, such as corrosion resistance, high temperature resistance, chemical and electrical conductivity. Additionally, the use of laminated / coated fabrics and apparel has enabled the weight of spinning spares to be reduced while maintaining rigidity and carrying capacity, making them an ideal choice for automotive applications. In the coming decade, the demand for PA6 is expected to increase due to the expansion of the automotive market and the shift towards lighter vehicles with higher strength ratings.

● Growing Supply of Protective Garments to Meet Market Needs

Selecting appropriate attire plays a crucial role in safeguarding individuals against the prevalent biological and chemical hazards encountered in daily life. The protective clothing sector is poised for rapid expansion due to the substantial production expenses within the manufacturing industry and stringent government regulations, such as those mandated by OSHA and NIOSH, which mandate the use of protective attire. Polyurethane emerges as an exceptional material for crafting protective garments designed for high-altitude, fire-resistant, and chemical defense purposes. Its notable attributes include flexibility in frigid conditions, resilience against substantial impacts, and exceptional weather resistance. These qualities collectively contribute to the promising growth of the protective clothing industry.

● Concerns about the environment may impede market expansion

Laminating fabrics often involves the use of adhesives, coatings, and chemicals to bond layers together. Some of these chemicals can be harmful to the environment. For example, solvent-based adhesives can release volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and potentially harming human health. The production of laminated fabrics can generate waste materials, including excess adhesive, trimmings, and defective laminated fabrics. Disposing of these waste materials can have negative environmental impacts, especially if they are not managed or disposed of properly.

Buy Now:

Fabric Based Laminates Market Share (%) By Region, 2022

For More Details on This Report — Request for Sample

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships and collaborations are key strategies adopted by players in Fabric Based Laminates Market. The top 10 companies in this industry are listed below:

Serge Ferrari Group

Spradling International, Inc.

OMNOVO Solutions, Inc

Saint-Gobain SA

Sioen Industries NV

Robert Kaufman

Continental AG

Lamcotec

Trelleborg AB

Seaman Corporation

For More Chemicals and Materials Market Reports, Please Click Here

0 notes

Text

0 notes

Text

Adhesives & Sealants Market - Forecast(2024 - 2030)

Adhesives & Sealants Market Overview

Global Adhesives & Sealants market size is estimated to reach US$ 89.1 billion by 2027, after growing at a CAGR of 5.7% during the forecast period 2022-2027. Adhesives and sealants are the chemical products which are used to create a mechanical seal between components. Adhesives are the non-metallic materials used to hold two substances together, while sealants are material used to fill space between these substances and to provide a protective coating. Adhesives are of various types like polyurethane adhesives, cyanoacrylate adhesive and epoxy adhesives, while sealants consist of resin like silicon, acrylic and butyl. These materials are chemically made with the help of rheology modifiers which are used to improve their viscosity. Adhesives and sealants have high applicability in sectors like construction, automotive, paper, textile, electronics and wood. Their major applicability is in construction sector where adhesives are used in polycarboxylate for concrete production. Factors like growing construction activities, increase in production volume of automotive, increase in aircraft production and high consumption of clothing & apparel items are driving the growth of global adhesives & sealants market. However, adhesives and sealants manufacturing produce volatile organic compounds which can cause environment problems like pollution. The regulation imposed by government to restrict VOC emission can hamper the growth of global adhesives & sealants industry.

COVID-19 Impact

The wide spread of COVID-19 left a negative impact on the activities of various industrial sectors, as the necessary measures taken by countries like consequential lockdown led to lack of availability of labors and raw materials. This disrupted the functionality of various end users of adhesives and sealants like construction, automotive, textile, and aerospace. For instance, as per, International Construction and Infrastructure Surveys, the construction and infrastructure activities across all regions went down in Q1 of 2020 with China in the Asia-Pacific region having the sharpest workload contraction. Also, as per the International Organization of Motor Vehicle Manufacturing, in 2020 there was a 16% global decline in vehicles production. Further, as per the 2021 report of the General Aviation Manufacturers Association, the Global business jet deliveries declined 20.4% to 644 aircraft in 2020 due to the COVID-19 pandemic. Polycarboxylate is used in cement concrete application, cyanoacrylate adhesive is used in automotive interiors while acrylic sealants are used in aircraft to prevent corrosion and fuel leak. Hence, the decrease in productivity of such sector led to decrease in usage of adhesives and sealants in them.

Request Sample

Report Coverage

The report: “Adhesives & Sealants Market Report – Forecast (2022 – 2027)”, by IndustryARC, covers an in-depth analysis of the following segments of the Global Adhesives & Sealants Industry

By Type – Water Based Latex, Acrylic, Polysulfide, Silicone, Polyurethane, Epoxies, Polyamides, Cyanoacrylate, Polyethylene Glycol, and Others (Polyisobutylene, Dextrin, Butyl)

By Form – Water based (Solution, Polymer Dispersion), Solvent based (Wet Bonding, Contact Adhesives), Hot Melt, and Reactive

By Application – Bonding (Paper Bonding, Wood Bonding), Concrete Production, Countertop Lamination, Drywall Lamination, Transportation (Automotive Module Sealant, Anti-Fuel Leaking Agent, Anti-Corrosive Agent, Clothing & Apparel (Apparel Laminate, Fabric Combining) and Others (Self-Adhesives Bandages, Circuit Boards Encapsulants)

By End User – Automotive (Passengers Cars, Heavy Commercial Vehicles, Light Commercial Vehicles, Others (Three-Wheeler, Two-Wheeler)), Construction (Residential, Commercial), Aerospace, Wood Industry, Paper, Textiles (Woven, Non-woven), Electronic, Medical and Others (Marine, Plastics)

By Geography - North America (USA, Canada, Mexico), Europe (UK, Germany, France, Italy, Netherland, Spain, Russia, Belgium, Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, Rest of South America), Rest of the World (Middle East, Africa)

Key Takeaways

Asia-Pacific dominates the global adhesives & sealants industry as the region consist of major end users of adhesives and sealants like plastic, construction, automotive, electrical in major economies like China, South Korea, and Australia.

Rheology Modifier is used in water borne, solvent borne adhesives and sealants of all types, to control viscosity, provide coating performance and build thick adhesion between components.

In dentistry filed, polycarboxylate cement is used in the fixation of dental crowns, inlays, and along with cavity linings which provide a good adhesion to the tooth structure.

Inquiry Before Buying

Adhesives & Sealants Market Segment Analysis – By Type

Polyurethane held a significant share in global adhesives & sealants market in 2021, with a share of over 22.0%. Polyurethane adhesives are UV, water, and chemical resistant while polyurethane sealants provide long term elasticity and durable adhesion. Polyurethane adhesives are majorly used in automotive windshield while polyurethane sealants are used in sealing gaps and joints in components and structures. The rapid development in automotive and construction sectors has increased their scale of productivity which has positively impacted the usage of adhesives and sealants. For instance, as per European Automobile Manufacturers Association, the production and registration of passenger cars in the EU increased by 53.4% in 2021 with strong volume seen in Spain, France, and Germany. Further, as per US Census Bureau, in 2021, construction activities steadily increased in US, with residential construction showing an increase of 4.1% in November, up by 1% from 2020 same month. Such increase in productivity of these sectors will lead to more usage adhesives and sealants in the, which will positively impact the growth of global adhesives & sealants industry.

Adhesives & Sealants Market Segment Analysis – By End User

Construction sector held a significant share in global adhesives & sealants market in 2021, with a share of over 19.0%. Adhesives & sealants based of resins like polyamide, epoxy resin and plastisol are majorly used in construction sector as they have resistance to excessive sun, rainfall, provide good steel bonding, and act as cement dispersant. The rapid development in the construction sector in countries has increased the scale of construction activities and the undertaking of new infrastructure projects. For instance, as per European Union, in December 2021, construction of building increased by 4.6% and civil engineering by 3.3% compared to 2020. Also, in 2019 a total of US$ 102.3 billion worth of projects were processed across all GCC countries, compared to US$ 101.8 billion in 2018. Hence, such increase in the construction and infrastructure development activities will lead to more usage of adhesives in cement application while sealants will be used in blocking dust and heat transmission. This will have a positive impact on the growth of global adhesives & sealants industry.

Schedule a Call

Adhesives & Sealants Market Segment Analysis – By Geography

Asia-Pacific held the largest share in global adhesives & sealants market in 2021, with a share of over 27.0%. The region consists of major end-users of adhesives and sealants like construction, automotive, textiles, in major economies like China, India, Japan, and Australia with China having the largest automotive and construction sector. The economic development in these nations has led to increase in the industrial output of these sectors. For instance, as per the 2021 report of the European Automobile Manufacturers Association on global vehicle production, China produced 32% of 74 million cars manufactured worldwide with Japan & Korea producing 16%. Also, as per the State Council for the People’s Republic of China, in July 2021 China has approved projects related to the development of affordable rental homes. Further, as per October reports of Infrastructure Australia 2021, the major infrastructure activity relating to commercial buildings, civil infrastructure, and residential will double in the next three years. Cyanoacrylate adhesives are used in automotive roof pads, engine hose protectors and flex boards while acrylic and polyurethane based sealants are used to seal joints between components like concrete, steel, and masonry wall. Hence, the growing productivity of construction and automotive will lead to more usage of such adhesives and sealants in them, resulting in more growth of global adhesives & sealant industry.

Adhesives & Sealants Market Drivers

Growing Construction Activities

Emerging economies, rapid urbanization, and various infrastructural developments undertaken by countries have increased the scale of construction activity. For instance, in preparation for the 2021 Expo, Dubai awarded about 47 construction contracts with a total value of US$ 3 billion to local and foreign companies. In 2019 National Development and Reform Commission of China approved 26 infrastructure projects estimated to be completed by 2023. Also, in 2021, Oman’s Ministry of Housing and Urban Planning five new integrated projects that would provide 4800 housing units. Adhesives and sealants in building construction are used as the bonding layer for floor fixing, countertop lamination and wall covering. Hence, the increase in construction activities and infrastructure development projects will lead to more usage of adhesives and sealants, which will have a positive impact on the growth of the global adhesives & sealants industry.

Growing Production of Automotive

Automotive adhesives and sealants are used by automotive original equipment manufacturers (OEMs) to bond different substrate of metal, eliminating the need for welding and mechanical bolts, welds and rivets. The increase in purchase capacity, improvement in living standards, and rapid urbanization have led to an increase in the demand for new automotive vehicles, thereby increasing their production volume. For instance, as per the International Organization of Motor Vehicle Manufacturing, the global production volume of vehicles increased to 57 million in 2021 from 52 million in 2020. Also, as per the November 2021 report of the Europe Automobile Manufacturer Association, the new passenger car registration in the first ten months of 2021 increased up to 2.2% with an increase shown in European Union markets like Italy showed 12.7%, Spain showed 5.6% and France showed 3.1%. Such an increase in automobile production on account of high demand will increase the usage of adhesives and sealants like cyanoacrylate adhesives, which will have positive impact on growth of global adhesives & sealants industry.

Buy Now

Adhesives & Sealants Market Challenges

Stringent Government Regulation

One of the significant issues related to adhesives and sealants is that, their formation causes VOC emission which can lead to serious problems like skin irritation, sour throat and long-term damage to lungs & kidneys. Hence, in order prevent such problems various government organization have imposed certain regulation relating to VOC emission. For instance, Title 40, Code of Federal Regulations of US, Environment Protection Agency deals with EPA’s mission of protecting human health and the environment from VOC emission. Such regulation can restrict the production volume of adhesives and sealants, which can hamper the growth of global adhesives & sealants industry.

Adhesives & Sealants Industry Outlook

The companies to develop a strong regional presence and strengthen their market position, continuously engage in mergers and acquisitions. The global adhesives & sealants top 10 companies include:

Henkel Corporation

Sika AG

Arkema SA

Evonik Industries

Ashland Inc.

PPG Industries

RPM International Inc.

Wacker Chemie AG

Avery Dennison

Pidilite Industries

Recent Developments

In 2021, Creative Materials introduced 129-06 temperature-sensing conductive adhesive, coating in either one-component or two-component versions, and the product has high reliability due to low hysteresis, high flexibility and strong adhesion.

In 2020, Arkema acquired Fixatti, a manufacturer of thermos-bonding adhesives powder and such acquisition will strengthen the global offering of hot melt adhesives solution for niche industrial applications.

In 2019, Sika AG acquired China based Crevo-Hengxin a manufacturer of silicone sealants and adhesives, and such acquisition will expand the adhesives & sealant market share of Sika in China

#Adhesives & Sealants Market#Adhesives & Sealants Market Share#Adhesives & Sealants Market Size#Adhesives & Sealants Market Forecast#Adhesives & Sealants Market Report#Adhesives & Sealants Market Growth

0 notes

Text

Diving Deep in the Dynamics of Motor Laminations

Electric motor laminations have an important role to play in improving the decreasing losses in e- motors. These laminations are made with the use of numerous methods to meet precise application needs. For businesses involved in acquiring or making use of these products, comprehending the diverse manufacturing methods and materials used in e- motor laminations is vital. Motor laminations are…

View On WordPress

#Competitive Landscape#Efficiency Considerations#electric mobility#Global Market Dynamics#Growth drivers#Industry Professional#Investor#Market Challenges#market trends#Motor Lamination#Stakeholder#Strategic Opportunities#Technological advancements

0 notes

Text

DC motor manufacturers

DC motors are integral to most of the manufacturing industries. Without these motors, the machines would hardly perform, and the outputs would be scarcely realised. Hence, to make sure that your business runs minus any hassle and operational obstructions, choose from the list of the best DC motor manufacturers.

To settle for the best DC motor supplier, you need to keep certain aspects in mind while choosing one. Shri Rang Energy Efficient can be one name that you can trust without any doubt. We offer the best quality DC motors imbibing the latest technology to make sure that your business runs smoothly to push your production graph upwards.

Product Overview

DC motors are, by definition, nothing but a rotary electric motor that is capable of turning electrical energy into mechanical energy. Therefore, DC motors are integral for the smooth functioning of any machine that runs on a rotary electrical motor.

Twin Lobe Rotary Compressor, Ceramic Machine, Exhaust Fans, Solar Pump, Two Stage Medium Pressure Compressor, Solar Home Light, Multi-Stage Heavy Duty Pressure Compressor, Centrifugal Pumps, Back Pullout Pumps, etc., are some of the machines that come featured with DC motors. At Shri Rang Energy Efficient, we manufacture a plethora of varieties of DC motors to help you choose the fittest. Our top-rated products and reasonable prices make us one of the best DC motor dealers in the market.

Specifications of DC Motor

We keep the specification of the DC motors varied as well so that every industry gets something matching while choosing a DC motor for their specific usage.

Power : We manufacture Dc motors of varying power to match the requirement of different industries adequately

Voltage : While some of our DC motors are compatible with low voltage operations, some can withstand high voltage as well

Material : we manufacture each motor with equal care. Superior grade materials are used, and copper is often used to ensure performance and durability.

Features Guaranteed By the Best DC Motors Manufacturers

Our DC motors come made of a laminated yoke that makes it capable of excellent commutation

The skewed rotor construction of our motors ensure low noise

Each of our DC motors ensures superior insulation strength

Our DC motors come with excellent dynamic response

For smooth operation and durability, we keep the bearing of our DC motors large

All of our DC motors are energy efficient, precise in shape, and lightweight

All the DC motors are easy to fit

Applications

DC motors are primarily used in the textile industry, sugar mills, paper industry, cement mills, cable industry, printing machines, machine tools, etc. We keep our gamut of Dc motors varied to ensure that everyone gets the fittest choice. Every industry requires a different motor for operation, and we keep the same in mind while manufacturing the Dc motors.

Shri Rang Energy Efficient is one of the most trusted DC motor suppliers near you. We make sure that each requirement of your get fulfilled minus any hassle. No matter which variety of Dc motor you need, we offer the best at a reasonable price. Give us a call at +91 9409400048 / +91 8347008877 / +91 8347004433 or send us a mail at sales@shrirangenterprise. comfor any order or query. We always remain ready to listen to you.

Visit Shrirang Enterprise for more information

#dc motor manufacturers#electric motors#dc motor manufacturers in india#ac motors manufacturers in india#flame proof motor supplier#artists on tumblr#across the spiderverse#barbie#tefc motors

1 note

·

View note

Text

Integrated Packaging Solutions for Spices by Nichrome

Spice It Up with Nichrome: Your Packaging Partner in Flavor

In the bustling world of spices, where every pinch counts, ensuring that your aromatic treasures reach consumers in top-notch condition is crucial. This is where Nichrome steps in, adding a dash of magic to your secondary packaging needs. With our innovative machinery and integrated solutions, we ensure your spices are packaged with the precision and care they deserve. Let’s dive into how Nichrome spices up your packaging game.

Sizzle with Streamlined Spice Solutions

Nichrome’s spice packaging machines are the secret ingredient to your success. Whether it’s our versatile powder filling machines or the groundbreaking Flexiwrap 700 horizontal flow wrap machine, we have the tools to transform your packaging process. Our machines are designed to maximize efficiency and boost productivity, making your spices look as good as they taste.

Integrated Packaging: The Recipe for Success

At Nichrome, we know that packaging isn’t just about individual machines—it’s about creating a cohesive system. Our integrated solutions blend different packaging technologies into a harmonious line, ensuring your operations run smoothly. By optimizing efficiency and enhancing product presentation, we make sure your spices steal the spotlight on the shelves.

Precision and Quality: The Perfect Blend

Consistency and accuracy are non-negotiable in spice packaging. Nichrome’s machines are engineered for precision, ensuring each pouch is filled to perfection. Our technology preserves the integrity of your spices, maintaining their aroma and flavor, so every customer experience is a delightful one.

Sustainability: Spice Up the Planet

n today’s eco-conscious world, sustainability is key. Nichrome’s machines are designed to minimize waste and optimize resource use. With energy-efficient operations and eco-friendly solutions, we help you reduce your environmental footprint while delivering top-notch packaging.

Flexiwrap 700: The Star of the Show

The Flexiwrap 700 is a game-changer in spice packaging. This innovative horizontal flow wrap machine offers customizable pouch sizes, attractive sealing options, and advanced controls. It ensures your spices are securely packaged and ready to impress. With features like intermittent motion, quick change-over design, and the ability to store different recipes, the Flexiwrap 700 is your go-to for efficient, eye-catching packaging.

Features of the Flexiwrap 700

Intermittent Motion: Smooth and efficient operation.

Stainless Steel Contact Parts: Ensuring hygiene and durability.

Quick Change-Over Design: Easy transitions for different pouch sizes.

Recipe Storage: Streamlined changeovers with PLC program storage.

Servo Motor and Pneumatic Cylinder: Precise control for center and side seals.

Laminate Compatibility: Works with materials like BOPP/PPE.

Speed: Up to 60 ppm, adjustable based on pouch length.

Conclusion

Nichrome is your spice packaging partner extraordinaire. With our cutting-edge machines and commitment to sustainability, we help you elevate your packaging operations and exceed customer expectations. From powder filling to advanced flow wrap machines, Nichrome has the solutions you need to thrive in the competitive spice market. Spice up your packaging with Nichrome and taste the difference in quality, efficiency, and innovation. Learn More: https://www.nichrome.com/blog/integrated-spice-packaging-solutions/

#spice packaging machines#Spices Packing Machine manufacturers#Spices packing machine manufacturers in india

0 notes

Text

Laminate Wood Flooring Market Size, Share, Growth, Trends [2032]

Laminate Wood Flooring Market provides in-depth analysis of the market state of Laminate Wood Flooring manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Laminate Wood Flooring in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Laminate Wood Flooring Market Report:

The report offers a comprehensive and broad perspective on the global Laminate Wood Flooring Market.

The market statistics represented in different Laminate Wood Flooring segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Laminate Wood Flooring are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Laminate Wood Flooring.

Major stakeholders, key companies Laminate Wood Flooring, investment feasibility and new market entrants study is offered.

Development scope of Laminate Wood Flooring in each market segment is covered in this report. The macro and micro-economic factors affecting the Laminate Wood Flooring Market

Advancement is elaborated in this report. The upstream and downstream components of Laminate Wood Flooring and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/laminate-wood-flooring-market-100005

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Global Hydrogenated Bisphenol A MarketMarket Size

Global Blood Clot Retrieval Devices MarketMarket Growth

Global Swimming Pool Treatment Chemicals MarketMarket Size

Global Membrane Pressure Vessel MarketMarket Growth

Global Defibrillator MarketMarket Size

Global Semiconductor Production Equipment MarketMarket Growth

Global Shale Gas Processing Equipment MarketMarket Size

Global Digital Experience Platform MarketMarket Growth

Global RFID Smart Cabinets MarketMarket Size

Global Desktop CNC Machines MarketMarket Growth

Global CMP Pad Regulator MarketMarket Size

Global Unmanned Surface Vessels (Usv) MarketMarket Growth

Global Fresh Avocado MarketMarket Size

Global Heat Pump Water Heater MarketMarket Growth

Global Motor For Robots MarketMarket Size

Global Personalized Hydration Solutions MarketMarket Growth

Global Silver Powders And Flakes MarketMarket Size

Global Depaneling Machine MarketMarket Growth

Global Pv Solar Energy Charge Controller MarketMarket Size

Global Fleece Knitting Yarn MarketMarket Growth

Global Super Capacitor MarketMarket Size

Global Bird Detection System MarketMarket Growth

Global Predictive Genetic Testing and Consumer Genomics MarketMarket Size

Global Recreation Management Software MarketMarket Growth

Global Analog Cheese MarketMarket Size

Global Artificial Intelligence Software MarketMarket Growth

Global EV Charging Cables MarketMarket Size

Global Remote Sensing Services MarketMarket Growth

Global Education Technology (EdTech) MarketMarket Size

Global Transcatheter Heart Valve Replacement and Repair MarketMarket Growth

Global Cervical Total Disc Replacement Device MarketMarket Size

Global Biomass Boiler MarketMarket Growth

Global Door Closers MarketMarket Size

Global Silicone Elastomers For Medical Applications MarketMarket Growth

Global Energy Recovery Ventilation System MarketMarket Size

Pegaspargase Drugs MarketMarket Analysis

0 notes