#Motor Circuit Analysis

Explore tagged Tumblr posts

Text

Predictive Maintenance: Strategies for Enhancing Asset Performance and Reducing Costs

Meticulous Research®, a globally recognized market research firm, has recently released a comprehensive report titled “Predictive Maintenance Market by Offering (Software, Hardware), Deployment Mode, Organization Size, Technology (IoT, AI & ML), Application (Oil Analysis, Temperature Monitoring), End-use Industry, and Geography - Global Forecast to 2031.” This extensive study highlights the promising trajectory of the predictive maintenance market, which is expected to reach $79.1 billion by 2031, reflecting a remarkable compound annual growth rate (CAGR) of 30.9% from 2024 to 2031.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5936?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=29-10-24

Factors Driving Market Growth

The surge in the predictive maintenance market can be attributed to several pivotal factors, including the urgent need to reduce maintenance costs and enhance asset performance. The increasing complexity of infrastructure systems has necessitated the widespread adoption of predictive maintenance solutions. Despite the favorable outlook, the market grapples with significant challenges, particularly related to data privacy and security concerns. These issues pose potential barriers to growth, as organizations must navigate the complexities of compliance and consumer trust.

Another critical aspect of the market is the burgeoning demand for predictive maintenance solutions in healthcare devices and navigation systems. This trend presents valuable growth opportunities for companies operating within this sector. However, a notable challenge remains: the scarcity of skilled professionals capable of managing advanced predictive maintenance technologies. As organizations strive to adopt these sophisticated solutions, the lack of expertise may hinder their progress. Furthermore, emerging trends, such as the integration of digital twins and augmented reality (AR), are reshaping the market, introducing both innovative possibilities and operational challenges.

Market Segmentation Overview

The predictive maintenance market is meticulously segmented to provide a nuanced understanding of its various components. The key segments include:

Offering: Software, hardware, and services

Deployment Mode: Cloud-based and on-premise solutions

Organization Size: Large enterprises versus small and medium-sized enterprises (SMEs)

Technology: IoT, AI, machine learning, cloud connectivity, advanced analytics, and digital twins

Application: Vibration analysis, oil analysis, temperature monitoring, and other applications

End-use Industry: Manufacturing, healthcare, automotive, aerospace, and other sectors

Geography: North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa

This segmentation framework allows for a comprehensive analysis of market dynamics and growth drivers across various categories.

Discover More About Market Segmentation And Geographic Forecasts By Accessing The Full [PDF] Sample Research Report – https://www.meticulousresearch.com/request-sample-report/cp_id=5936?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=29-10-24

Offering: Software, Hardware, and Services

The segmentation of the predictive maintenance market by offering includes software, hardware, and services. In 2024, the software segment is projected to capture a substantial market share, exceeding 81% of total revenue. This dominance is driven by the increasing necessity for organizations to reduce maintenance costs. Moreover, predictive maintenance software plays a vital role in ensuring compliance by providing essential documentation of maintenance activities and adherence to maintenance schedules.

Conversely, the services segment is expected to witness the highest CAGR during the forecast period. This growth can be attributed to the increasing adoption of predictive maintenance services that analyze equipment data to identify potential issues. As organizations seek to minimize overall maintenance costs, the integration of IoT, AI, and machine learning technologies enables real-time monitoring and proactive maintenance.

Deployment Mode: Cloud-Based vs. On-Premise

The predictive maintenance market is also categorized based on deployment modes, distinguishing between cloud-based and on-premise solutions. In 2024, cloud-based deployments are anticipated to hold a significant market share, exceeding 58%. This trend is largely attributed to the growing preference for cloud solutions that offer flexibility, scalability, and the capability to analyze large volumes of data in real-time. Furthermore, cloud platforms often incorporate advanced analytics features, including machine learning and predictive modeling, enhancing their appeal to organizations seeking comprehensive maintenance solutions.

The cloud-based segment is also expected to register the highest CAGR throughout the forecast period, as more businesses recognize the strategic advantages of cloud technology in predictive maintenance.

Organization Size: Large Enterprises vs. SMEs

Another important segmentation criterion is organization size, which differentiates between large enterprises and small and medium-sized enterprises (SMEs). In 2024, large enterprises are projected to account for the larger market share, exceeding 74%. This dominance is primarily driven by the growing adoption of predictive maintenance as a strategy to mitigate costly unplanned downtime and repairs. Large enterprises leverage predictive maintenance to monitor equipment health, identify performance degradation, and take proactive measures to maintain optimal operating conditions.

In contrast, the small and medium-sized enterprise segment is expected to exhibit the highest CAGR during the forecast period. This growth is fueled by the increasing adoption of predictive maintenance solutions that automate monitoring and analysis of equipment health, thereby alleviating the burden on maintenance personnel. Additionally, predictive maintenance enables SMEs to meet regulatory requirements and enhance operational efficiency, further contributing to the segment's expansion.

Technology: IoT, AI, and Machine Learning

The predictive maintenance market is also segmented by technology, encompassing IoT, AI, machine learning, cloud connectivity, and advanced analytics. In 2024, the IoT segment is anticipated to dominate the market, capturing the largest share. This trend is driven by the widespread adoption of IoT-based predictive maintenance solutions, which facilitate the prediction of equipment failures and improve technician efficiency by providing real-time information on equipment performance.

However, the AI and machine learning segment is expected to achieve the highest CAGR during the forecast period. The growing integration of AI and ML in predictive maintenance contributes to real-time analytics, energy savings, and reduced environmental impact for industrial operations. By leveraging AI and ML algorithms to analyze vast amounts of data from sensors and equipment logs, organizations can identify patterns and trends that drive proactive maintenance strategies.

Have specific research needs? Request a customized research report- https://www.meticulousresearch.com/request-sample-report/cp_id=5936?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=29-10-24

Application: Vibration Analysis and Temperature Monitoring

The applications segment of the predictive maintenance market is categorized into various key areas, including vibration analysis, oil analysis, temperature monitoring, and more. In 2024, the temperature monitoring segment is projected to account for a substantial market share, exceeding 26%. This trend is driven by the increasing adoption of predictive maintenance practices aimed at anticipating equipment failures and facilitating timely notifications for maintenance personnel.

Conversely, the vibration analysis segment is expected to exhibit the highest CAGR during the forecast period. The growing emphasis on predictive maintenance for vibration analysis allows organizations to detect, measure, and analyze vibrations in rotating machinery parts, thus controlling downtime and enhancing product quality.

End-Use Industry: Manufacturing and Healthcare

The predictive maintenance market is further segmented by end-use industry, including manufacturing, healthcare, automotive, and other sectors. In 2024, the manufacturing segment is expected to dominate the market, accounting for over 30% of total revenue. This dominance is attributed to the increasing adoption of predictive maintenance strategies aimed at minimizing costs associated with unscheduled downtime, as well as the growing implementation of Industry 4.0 principles within the manufacturing landscape.

Conversely, the healthcare segment is anticipated to register the highest CAGR during the forecast period. This growth is primarily driven by the expanding utilization of IoT and telematics within healthcare facilities, as well as the increasing reliance on predictive maintenance to gather data on critical medical equipment parameters such as temperature and pressure. Predictive maintenance enables healthcare facility managers to schedule maintenance efficiently, ensuring the continuous operation of vital medical equipment.

Geographic Analysis: North America and Asia-Pacific

From a geographical perspective, the predictive maintenance market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2024, North America is projected to maintain its position as the market leader, accounting for over 33% of the overall share. This significant presence can be attributed to the rising demand for predictive maintenance solutions in the healthcare sector, coupled with the growing need to reduce equipment failure, maintenance costs, and downtime.

Conversely, the Asia-Pacific region is expected to exhibit the highest CAGR of over 32% during the forecast period. This growth is fueled by the rapid expansion of SMEs, increasing industrialization, and government initiatives aimed at enhancing operational efficiency. The emergence of Industry 4.0 in key countries, including China, India, and Japan, further propels the demand for predictive maintenance solutions.

Key Players in the Predictive Maintenance Market

The competitive landscape of the predictive maintenance market features several key players who are actively driving innovation and shaping the industry. These prominent organizations include:

International Business Machines Corporation (IBM) (U.S.)

ABB Ltd (Switzerland)

Hitachi, Ltd. (Japan)

Siemens AG (Germany)

Amazon Web Services, Inc. (a subsidiary of Amazon.com, Inc.) (U.S.)

Google LLC (a subsidiary of Alphabet Inc.) (U.S.)

Microsoft Corporation (U.S.)

Emerson Electric Co. (U.S.)

Oracle Corporation (U.S.)

Splunk Inc. (a subsidiary of Cisco Systems, Inc.) (U.S.)

Axiomtek Co., Ltd. (Taiwan)

Presage Insights Pvt Ltd (India)

XMPro Inc. (U.S.)

Faclon Labs Private Limited (India)

SenseGrow Inc. (U.S.)

These key players leverage their technological prowess, extensive industry experience, and innovative approaches to develop state-of-the-art predictive maintenance solutions tailored to meet the evolving needs of their clients.

Conclusion

The predictive maintenance market is on a promising growth trajectory, propelled by advancements in technology and the increasing demand for operational efficiency across various sectors. While challenges related to data privacy and workforce skills persist, the opportunities for expansion, particularly in emerging markets and industries, are substantial. With ongoing integration of advanced technologies such as IoT, AI, and machine learning, the predictive maintenance market is set to evolve, offering innovative solutions that address the diverse needs of businesses globally.

This landscape presents an opportunity for stakeholders to invest in predictive maintenance strategies that not only reduce operational costs but also drive sustainable growth and enhanced competitiveness in an increasingly dynamic market. As organizations continue to embrace the digital transformation journey, the role of predictive maintenance will become increasingly critical in ensuring asset reliability, performance, and longevity.

Read Full Report :- https://www.meticulousresearch.com/product/predictive-maintenance-market-5936

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Predictive Maintenance Market#Vibration Analysis#Oil Analysis#Acoustics Monitoring#Motor Circuit Analysis#Temperature Monitoring#Manufacturing#Oil & Gas#AI and Machine Learning#IoT#Data Acquisition Systems#Sensors

0 notes

Text

Motor Circuit Analysis: A Powerful Predictive Maintenance Technique

Motor circuit analysis (MCA) is an essential predictive maintenance technique utilized by equipment performance monitoring services to assess the condition of critical rotating machinery.

0 notes

Text

2026 Rewind - Grid x AudiDriver! Reader

Plot: After some devastating deaths within the F1 industry from unmistakable names in 2025, the FIA decide to make a plan to race at all of the old tracks that are iconic but haven’t been on the grid for a while.

A/N: this is racing heavy with only drivers name dropped, but if you want cool Ted and Crofty with Y/N vibes while learning more about some of the FIA Grade 1 Tracks, have a read!

“So Ted, let’s talk about this years line up. It’s just so iconic that I can’t bear it!” David Croft says as they are in the commentator box at pre-season testing.

“Yeah Crofty, obviously it’s so unfortunate the reason behind what we are calling the 2026 rewind because of some losses we had in the industry and this was the way the FIA decided to pay tribute to those people!" Ted explains before the onscreen for the year comes up.

"So, lets go through the year together and analyze it. We're starting of the season strong in the lovely Kuwait, here at Kuwait Motor Town, this is where we are kick starting off this season. It's a high speed track here just north of where we would typically start in Bahrain. This is a track consisting of 20 turns, and is 5.609km of racing ahead. I'm very excited as no-one in F1 history has raced here in an F1 car. Who do you think's going to do well here Ted?"

"Well, there's some really nice corners, and it's a similar temp to Bahrain so i think it's difficult to tell but I can imagine the Audi with Y/N now having done her rookie season learning all those key values about the F1 car and how it works. McLaren will also be good here, really tightening up the constructors championship this year!" Ted offers looking at all the onboard footage.

"Yes I agree, I think Red Bull tend to be quiet strong a the start of the year naturally and its a game for the other teams to be playing catch up!" Crofty agrees.

"Okay, then after Kuwait, we'll be travelling to and correct me if I'm saying this wrong but the Kyalami Circuit in South Africa near the wonderful capital Johannesburg. It's in replacement of the Saudi Arabian Grand Prix, we haven't raced in South Africa since 1993 and what a beautiful circuit this is, its got some really high speed corners and yeah, I think the Ferrari will really be great on those long straights." Ted says analysis the data of the cars in testing.

"And now here we have with us, Y/N Y/L/N Audi F1 driver here to talk through the rest of the tracks!" David says and points to the camera for you to smile and wave before he pulls out the microphone in front of you.

"Hello!" you grin and David and Ted both burst out laughing.

"What did I miss, I'm really sorry i was late!" you smile looking between them and they both nod in understanding of how tight the weekend schedule could be, they are shocked they actually have your time right now.

"It's completely okay, we understand! We've only introduced Kuwait and South Africa, we are about to move onto the changed Australia track! Your thoughts?" he exclaims and you smile.

"Yeah, obviously it's going to be exciting with all these new tracks that none of us have driven, so of course there was a lot of testing in the sims... but yeah its great to be here in Kuwait, and I'm excited to go to South Africa as well!" you smile.

"Yes, and how do you feel about Australia being changed from Albert Park in Melbourne to the Adelaide Street Circuit?" Ted asks with a grin on his face knowing how you felt about the Australian races.

"Well, after the spider incident in 2022, I've always been so scared to drive in Australia" you giggle, before Crofty pulls up the video of you in P4 of the Australian Grand Prix in 2022.

Y/N - Theres a fucking tarantula in my car Race Engineer - Copy that Y/N - No i dont think you guys get it, its on me

"And you ended up pitting there was no time to get it out of the car because of where it was, you were crying for the rest of the race and you were going so quick so you could just finish that you actually ended up winning your first race here and overtaking Charles Leclerc in, what back then was an Alfa Romeo." Crofty smiles and you nod.

"Yeah, so where ever that race is in Australia I know ill be on edge the whole time, I'll have my crew do like 6 inspections on my car before each session to make sure. It was traumatizing i tell you!" you admit.

"So after what will hopefully be a spider free stint in Adelaide on their street circuit we move on to south east Asia where we will exchange Suzuka Japan, for the Fuji SpeedWay, a truly iconic track before going back to an old favorite of some of the older driver on the grid like Lewis and Fernando in South Korea at the Korea International Circuit!" Ted says showing the line up for the races after Australia.

"I'm really excited for these, the atmosphere of the fans is always amazing and the tracks here are great I think Audi thrive on these sort of tracks and yeah, I'm excited to see what we can do there!" you smile, looking at the spinning track layout that popped up on screen.

You move on to Miami's replacement being the iconic Californian Long Beach Street Circuit.

"And we've been tipped of, by a certain Cash App driver that he'll be taking you to DisneyLand while out there?" he asks looking at you.

"Yes, Liam has already been once and when I said about wanting to go to radiator springs he and Daniel jumped on the opportunity to go, which then Yuki and Max wanted to come so it's now turned into this whole massive group trip!" you laugh knowing that half the grid would come with you guys.

"And of course much like the UK Italy is another pinnacle of Motorsport and we've had to change out two of the iconic track Monza and Imola. So for the first change of Italy we've changed it to the iconic Mugello track which I just really love, don't you Y/N?" Ted asks looking at you.

"Yeah I think Lando and Osc will be really strong there, I'd like to think me and Carlos are as well with the Audi this year... so yeah I'm excited for Mugello! Obviously they raced here in 2020 so it's the most recent of all the races this year to make a return so its only really me, Oscar, Logan, Fred, Theo and Kimi who haven't raced there" you smile analyzing the twisty track up on the screen.

"Yes, then we'll be moving onto, what was probably one of the toughest decisions of this year which was switching out Monaco and what to switch out such an exciting race with, so they didn't its the only race on the calendar this year that has remained unchanged!" David explains making you nod.

"I think, where this year is to show the history of F1 and what it means to all of us, the teams and the fans. And by keeping Monaco on there where its such a historic track, i think that's actually staying true to a rewind year!" you smile, you'd always loved the vibes in Monaco, from the fans to the track to how your car performed there.

"Yeah i agree i think it was the right choice keeping Monaco!" Ted exclaims also loving the vibes at Monaco.

"Okay, then moving all the way to the west, we'll be in Canada moving from Montreal over to Quebec at the second oldest track, the Mont-Tremblant Circuit!" David shows the new Canadian circuit on screen.

"Then after Canada we've got a really special double header with two Spanish Grand Prix's at different locations. We have the Valencia Street Circuit and Del Jarama Circuit. Both very exciting and it will be a long weekend in Spain!"

"I'm excited to see a street circuit in Spain, obviously we had Madrid for the last two years after Barcelona, so I'm excited for both Valencia as a street circuit and Jarama which is such an iconic track because of those tights turns and yeah I'm really excited for this one!" you smile.

"Obviously next one was another tough one, Silverstone again another iconic track and the UK has so many other iconic tracks that its hard to choose, there was talks of Aintree, Watkins Glen and Donington Park but ultimately they went with Brands Hatch what do you think on this?" Ted asks looking over to you, holding up a page showing all the different UK tracks.

"Yeah, I think there's some really iconic tracks in the UK, its my home so i grew up racing on a lot of those tracks in different motorsport categories, I think there's ones that are arguably better for Formula one, which is why Silverstone is the main circuit as it gives for the most interesting race, however for me it would have been a call between Brands Hatch and Watkins Glen so I'm glad that they chose Brands Hatch, I've got some great memories there at testing and showcasing the car or working with the Top Gear team, so I'm excited to race there!" you explain, the United Kingdom is the like Monaco in being both a founder and royalty when it comes to Motorsport.

"I 100% agree with that, however I just love Aintree so much and am gutted we wont see it!" David Croft admits.

"So after Brands Hatch we move to Monsanta in Portugal which we haven't raced in Portugal since 2021 because of the COVID restrictions but that was in Algarve so it'll be interesting to see the difference!" Ted offers looking at the next circuit floating on their screen as he zoom's in on turn 4.

"Then, again there another track we hate to see go even if its for one year but Spa, its so iconic and its one of the most dangerous circuits we race now and it's being swapped out for Circuit Zolder on the other side of Belgium! Thoughts?" David asks out in the open.

"I" you start.

"Well I think" Ted also starts and you both look at each other in shock before laughing. You let Ted go first to say his piece.

"Well, I think it's no where near interesting as Spa, and especially where its the last race before a break... I think it's going to be way more uneventful than Spa!"

"Y/N?" Crofty asks looking at you.

"I actually think the opposite most of the tracks have been very high risk with lost of turns and chicanes and hairpins that really catch you out, however this reminds me of the simplicity of Monza and everyone, everyone loves Monza. So i think it will really even out the mid field cars" you says observing the track that had nice long straights and minimal turns.

"I agree with you there Y/N! Next after Zolder we head over to the heavily missed Nurburgring in Germany, the last time we saw it was 2019 so again, up until our 2019 rookies would have driven there how'd you feel about this track Y/N?" David asks.

"Well, it's such an iconic track for so many reasons I really wanted to race there after I watched Lando, George and Alex all race there in 2019, I was actually there in the paddock that year with Ferrari as a part of their driver development programme" you nod, explaining to them how excited you were for it.

"Now next in the place of Monza which we just mentioned we have a complete wild card of the Scandinavian Raceway in Sweden! Now this, this is one I'm excited for it's a beautiful track and has the coldest track temps we'll probably get all season! So it'll be a real fight to see who can protect their tyres and manage them well!" Ted explains and you nod, knowing it would be an exciting race.

"Then after that we travel to France where we haven't been for a while, however the Bugatti Au Mans Track in France is iconic, there are so many great tracks in France like Paul-Ricard or the Charade Circuit or Dijon de Prenois, all of them are great but the Bugatti hasn't been done is so long and really means a lot historically to the sport" David offers, showing you one of the only tracks you didn't feel too excited a lean towards.

"Then, we move back across to Aisa, going to an age of favorite of the age old Sepang International Circuit in Malasiya which is one fans have been wanting to see back on the race calendar for a while so i wonder if this will stay into 2027!" Ted takes over, and you nod.

"I'm also very excited for Sepang! After Malaysia we move onto the first ever FIA grade 1 race track the Chang Circuit in Thailand, how to we feel about this?" David asks directly looking at you.

"Not only is it a beautiful track, but it means that Alex now has a chance to race at his home track while racing under his home flag and I think he's really excited for it. He's in a great car, the Williams has come leaps and bounds and are top midfield contenders and definitely will be up there fighting for race wins!" you smile, knowing Alex was so happy to have this opportunity to race in his home country.

"I agree Alex Albon to win in Chang Circuit, I've put my money on it! Our next circuit it one that NASCAR share with us in F1 taking it back to the Indianapolis Speedway, on the lower F1 circuit of course rather than the Oval that the NASCAR drivers use!" Ted explains.

"Yeah, that lower track is great, you got the nice curve and we'll be able to get to those really high speeds. It's an iconic US track just like COTA!" you admit, taking a sip of the water you'd brought with you.

"After Indi, we'll make our way a little further down south to the Rio de Janiro International Track in Brazil, which is instead of Sao Paulo" David explains looking at the second F1 track in Brazil, it was a nice track but Sao Paulo had been on the roster for so long.

"Then, we are back in Las Vegas, but not on the Strp track that was created in 2023, no we are going back to the Ceaser's Palace Track and I know many people complain about these Las Vegas Grand Prix's because of the timings and the drivers not really liking driving at 12pm!"

"Yeah, i agree they are really strenuous just like Qatar for the heat but I love the vibe Las Vegas brings and I like the whole weekend with all the activities in the fan zone and yeah I'm excited they used Ceaser's Palace rather than the Pheonix Street Circuit which i know they were considering.

"I agree. Our last two races, then consist of the Buddah International Circuit in India and rounding off instead of in Yas Marina in the Dubai Autodrome, which will be a really nice round off" David exclaims.

Slowly you end the interview up, needing to go down to the track to get into the car for you leg of pre-season testing.

What a year it would be.

Taglist:

@littlesatanicassholebitch @hockey-racing-fubol @laura-naruto-fan1998 @22yuki @simxican @sinofwriting @lewisroscoelove @cmleitora @stupidandunnecessary @clayra-g @daemyratwst @honey-belden @moonypixel @lauralarsen @vader-is-hot @ironcowboycopnickel @itsjustkhaos @the-untamed-soul @beebo86 @happylittlereader @ziejustme @lou-larcher5 @thewulf @purplephantomwolf @chasing-liberosis @chillyleclerc @chanthereader @annoyingmoonballoon @summissss @evieepepi08 @havaneseoger08 @celesteblack08 @gulphulp @fandom1ruined2me @celebstories @starfusionsworld @jspitwall @sierruhh @georgeparisole @dakotatankbig @youcannotcancelquidditch @zzonsbeek @tallbrownhairsarcastic @mellowarcadefun @ourteenagetragedy @otako5811 @countingstacksandpanicattacks @peachiicherries @formulas-bitch @cherry-piee @hopexcroc @mirrorball-6 @spilled-coffee-cup @mehrmonga @bigsimperika @blueberry64857959 @eiraethh @lilypadlover @curseofhecate @alliwantisadonut @the-fem1n1ne-urge @21stcenturytaegi @dark-night-sky-99 @spideybv28 @i-wish-this-was-me @tallrock35 @butterfly-lover @barnestatic @landossainz @darleneslane @barcelonaloverf1life @r0nnsblog @ilove-tswizzle @kapsylia @laneyspaulding19 @lazybot @malynn @cassielikereading @viennakarma @teamnovalak @landosgirlxoxo @marie0v @jlb20416 @yourbane @teamnovalak @nikfigueiredo @fionaschicken @0picels0 @seomako @urdad-hot @formula1mount @tinydeskwriter @butterfly-lover @ironmaiden1313

#f1 imagine#f1 x reader#formula 1 x you#formula 1#formula one#formula one fanfiction#lando norris imagine#lando norris#charles leclerc#charles lecrelc x reader#lewis hamilton#max verstappen x you#oscar piastri f1#alex albon fluff#alex albon imagine#lance stroll fanfic#lance stroll

286 notes

·

View notes

Text

Indycar - Social Media

Who, what, where to follow.

Social Media

NTT INDYCAR SERIES YouTube - videos go back 15 years. Twitter Instagram TikTok

Team Penske (Josef Newgarden, Scott McLaughlin, Will Power) YouTube - a mix of all the series Penske runs in. Go look for the Penske Games - they're hilarious. Twitter Instagram TikTok

Andretti Autosport (Colton Herta, Kyle Kirkwood, Romain Grosjean, Devlin DeFrancesco, Marco Andretti) YouTube Twitter Instagram TikTok

Arrow McLaren IndyCar Team (Pato O’Ward, Alexander Rossi, Felix Rosenqvist, Tony Kanaan) By far the most active and on-trend of the Indycar teams. YouTube Twitter Instagram TikTok

Chip Ganassi Racing (Scott Dixon, Marcus Ericsson, Alex Palou, Marcus Armstrong, Takuma Sato) YouTube Twitter Instagram TikTok

Rahal Letterman Lanigan Racing (Graham Rahal, Christian Lundgaard, Jack Harvey, Katherine Legge) YouTube Twitter Instagram TikTok

Juncos Hollinger Racing (Callum Ilott, Agustin Canapino) YouTube Twitter Instagram TikTok

Ed Carpenter Racing (Rinus Veekay, Ryan Hunter Reay, Ed Carpenter) YouTube N/A Twitter Instagram TikTok N/A

Dale Coyne Racing (David Malukas, Sting Ray Robb) YouTube N/A Twitter Instagram TikTok N/A

AJ Foyt Racing (Santino Ferucci, Benjamin Perdersen) YouTube N/A Twitter Instagram TikTok N/A

Meyer Shank Racing (Helio Castroneves, Simon Pagenaud) YouTube N/A Twitter Instagram TikTok N/A

Indianapolis Motor Speedway YouTube Twitter Instagram TikTok

Indy NXT (Indycar Junior series) YouTube Twitter Instagram TikTok

Media/other

RACER YouTube Twitter Instagram TikTok N/A

Marshall Pruett YouTube Twitter Instagram TikTok N/A

INDYCAR on NBC YouTube Twitter Instagram TikTok

Nathan Brown (IndyStar) YouTube N/A Twitter Instagram N/A TikTok N/A

Dalton Kellett (former driver) YouTube Twitter Instagram TikTok (tech explanations)

Speed You Later YouTube N/A Twitter Instagram TikTok N/A

TikTok

Misc Caterina Masetti Zannini (Callum Ilott's girlfriend) Behind the scenes and Indycar tech explained, some F1 content. James and Becky Hinchcliffe (hasn't been updated in some time) Honda Performance Development - features all series that use honda engines so you'l have to search for the Indycar stuff.

Drivers Pato O’Ward Conor Daly Callum Ilott Christian Lundgaard Alex Palou

Instagram

Misc PitFit (The gym a lot of drivers use)

Podcasts

Racer's Roots - A deep dive into the history of motorsports and the genealogy of the racers we know and love.

The B1tch Stop is a podcast about motorsport hosted by Charlotte, Almay and Steph: an exasperated sports fan who'd make a better team principle than half the paddock, someone that reads about the aerodynamics of cars for fun, and a woman with a lot of opinions and no driver's licence. Follow for biweekly breakdowns of major race series (including F1, 2 and 3, Formula E, W Series, F1 Academy and IndyCar), the judgement of professional drivers based on their birth chart, and very valid and correct opinions about which drivers would catfish each other.

The Race IndyCar Podcast Race reviews and analysis from the fastest circuit racing in the world. Jack Benyon hosts, ex-Indycar racer JR Hildebrand adds expert knowledge, while a host of special guests bring colour and insight. Join us for the ride!

The Week In IndyCar The Week In Indy Car features one or more guests to weave through the latest news in North America's premier open-wheel series and its related junior formula. Like The Week In Sports Cars show, it's an interactive affair driven by listener questions submitted via social media.

Motorsport101 - covers F1, MotoGP and FE as well as IndyCar

Did I miss anything? Have a podcast to recommend? Send me a message.

27 notes

·

View notes

Text

Top 10 Projects for BE Electrical Engineering Students

Embarking on a Bachelor of Engineering (BE) in Electrical Engineering opens up a world of innovation and creativity. One of the best ways to apply theoretical knowledge is through practical projects that not only enhance your skills but also boost your resume. Here are the top 10 projects for BE Electrical Engineering students, designed to challenge you and showcase your talents.

1. Smart Home Automation System

Overview: Develop a system that allows users to control home appliances remotely using a smartphone app or voice commands.

Key Components:

Microcontroller (Arduino or Raspberry Pi)

Wi-Fi or Bluetooth module

Sensors (temperature, motion, light)

Learning Outcome: Understand IoT concepts and the integration of hardware and software.

2. Solar Power Generation System

Overview: Create a solar panel system that converts sunlight into electricity, suitable for powering small devices or homes.

Key Components:

Solar panels

Charge controller

Inverter

Battery storage

Learning Outcome: Gain insights into renewable energy sources and energy conversion.

3. Automated Irrigation System

Overview: Design a system that automates the watering of plants based on soil moisture levels.

Key Components:

Soil moisture sensor

Water pump

Microcontroller

Relay module

Learning Outcome: Learn about sensor integration and automation in agriculture.

4. Electric Vehicle Charging Station

Overview: Build a prototype for an electric vehicle (EV) charging station that monitors and controls charging processes.

Key Components:

Power electronics (rectifier, inverter)

Microcontroller

LCD display

Safety features (fuses, circuit breakers)

Learning Outcome: Explore the fundamentals of electric vehicles and charging technologies.

5. Gesture-Controlled Robot

Overview: Develop a robot that can be controlled using hand gestures via sensors or cameras.

Key Components:

Microcontroller (Arduino)

Motors and wheels

Ultrasonic or infrared sensors

Gesture recognition module

Learning Outcome: Understand robotics, programming, and sensor technologies.

6. Power Factor Correction System

Overview: Create a system that improves the power factor in electrical circuits to enhance efficiency.

Key Components:

Capacitors

Microcontroller

Current and voltage sensors

Relay for switching

Learning Outcome: Learn about power quality and its importance in electrical systems.

7. Wireless Power Transmission

Overview: Experiment with transmitting power wirelessly over short distances.

Key Components:

Resonant inductive coupling setup

Power source

Load (LED, small motor)

Learning Outcome: Explore concepts of electromagnetic fields and energy transfer.

8. Voice-Controlled Home Assistant

Overview: Build a home assistant that can respond to voice commands to control devices or provide information.

Key Components:

Microcontroller (Raspberry Pi preferred)

Voice recognition module

Wi-Fi module

Connected devices (lights, speakers)

Learning Outcome: Gain experience in natural language processing and AI integration.

9. Traffic Light Control System Using Microcontroller

Overview: Design a smart traffic light system that optimizes traffic flow based on real-time data.

Key Components:

Microcontroller (Arduino)

LED lights

Sensors (for vehicle detection)

Timer module

Learning Outcome: Understand traffic management systems and embedded programming.

10. Data Acquisition System

Overview: Develop a system that collects and analyzes data from various sensors (temperature, humidity, etc.).

Key Components:

Microcontroller (Arduino or Raspberry Pi)

Multiple sensors

Data logging software

Display (LCD or web interface)

Learning Outcome: Learn about data collection, processing, and analysis.

Conclusion

Engaging in these projects not only enhances your practical skills but also reinforces your theoretical knowledge. Whether you aim to develop sustainable technologies, innovate in robotics, or contribute to smart cities, these projects can serve as stepping stones in your journey as an electrical engineer. Choose a project that aligns with your interests, and don’t hesitate to seek guidance from your professors and peers. Happy engineering!

2 notes

·

View notes

Text

hey if youre on turtle island or still tuesday and feel like trying a quick silly browser game you should check out tradle. (i think it updates at midnight based on time zones?) todays is real fun i prommy.

you get five guesses to figure out a country from its export data, and after each guess they tell you how far away you are and what direction the county youre looking for is. i know it sounds like a ridiculous challenge but this one has a bunch of easy hints and giveaways that are accessible to your average westerner

if its wednesday by now or you want to see the data presented differently check out this silly economy under the cut (bolded 'spoilers' ig)

total export value: 371b (usd)

gold: 86.7b (23%}

packaged meds: 48.5b (13%)

vaccines, blood, cultures, etc: 40.3b (11%)

base metal watches: 15.2b (4%)

nitrogen heterocyclic compounds: 14.2b (4%)

jewlery: 9.35b (2.5%)

precious metal watches: 8.97b (2.5%)

orthopedic appliances: 7.02b (2%)

hormones: 3.38b

coffee: 3.36b

electricity: 3.19b

medical instruments: 3.09b

machinery w indv functions: 3.04b

platinum: 2.54b

chemical analysis instruments: 2.27b

nucleic acids: 2.17b

valves: 2.17b

silver: 2.01b

electric motors: 1.78b

scented mixtures: 1.72b

sulfonamides: 1.71b

diamonds: 1.64b

planes, helicopters, and spacecraft: 1.63b

beauty products: 1.58b

other heating machinery: 1.43b

flavored water: 1.43b

gas turbines: 1.38b

low voltage protection eq: 1.34b

gas and liquid flow measuring inst: 1.3b

carboxyamide compounds: 1.26b

other measuring instruments: 1.24b

air pumps: 1.16b

motor vehicles, parts, and acc: 1.14b

petroleum gas: 1.12b

electrical transformers: 1.11b

aluminum plating: 1.07b

other plastic products: 1.01b

metal working machine parts: 988m

vitamins: 965m

polyamides: 963m

washing and bottling machines: 925m

chocolate: 887m

oxygen amino compounds: 885m

integrated circuits: 884m

iron fasteners: 881m

paintings: 873m

transmissions: 855m

special pharmaceuticals: 837m

insulated wire: 828m

electrical power accessories: 826m

plastic lids: 818m

cheese: 800m

antibiotics: 797m

liquid pumps: 797m

cars: 789m

ink: 752m

non mechanical removal machinery: 737m

trunks and cases: 734m

centrifuges: 730m

interchangeable tool parts: 728m

high voltage protection eq: 705m

hand saws: 693m

other edible preparations: 680m

electric heaters: 679m

electrical control boards: 672m

polyacetals: 664m

plastic pipes: 636m

electric soldering equipment: 616m

precious metal compounds: 608m

industrial fatty acids, oils, and alcohols: 608m

hot rolled iron bars: 590m

self propelled rail transport: 582m

refined petroleum: 577m

hydrazine or hydroxylamine derivatives: 565m

precious stones: 563m

rubber working machinery: 561m

unpackaged meds: 557m

other iron products: 553m

precious metal scraps 550m

computers: 545m

surveying equipment: 523m

other plastic sheetings: 519m

metal finishing machines: 516m

scrap copper: 514m

semiconductor devices: 511m

raw plastic sheeting: 494m

documents or title and stamps: 490m

rolled tobacco: 487m

malt extract: 469m

other electrical machinery: 467m

other paper machinery: 450m

oxygen heterocyclic compounds: 441m

non knit mens suits: 441m

synthetic coloring matter: 436m

locomotive parts: 432m

non knit womens suits: 428m

iron structures: 424m

leather footwear: 421m

industrial printers: 415m

lifting machinery: 415m

scrap iron: 412m

therapeutic appliances: 410m

office machine parts: 410m

other clocks and watches: 405m

metal molds: 403m

other furniture: 403m

glaziers putty: 377m

liquid dispersing machines: 376m

knitting machine accessories: 370m

other small iron pipes: 369m

broadcasting equipment: 367m

aircraft parts: 363m

industrial food prep machinery: 362m

glues: 357m

pesticides: 349m

oscilloscopes: 344m

raw aluminum: 344m

knit sweaters: 339m

optical fibers and bundles: 334m

excavation machinery: 332m

non iron/steel slag ash and residue: 319m

carboxylic acids: 315m

xray equipment: 315m

electric motor parts: 315m

watch straps: 313m

tanks and armoured vehicles: 310m

forging machines: 309m

cleaning products: 306m

metalworking transfer machines: 298m

animal food: 294m

combustion engines: 282m

engine parts: 271m

electric generating sets: 254m

scrap aluminum: 249m

laboratory reagents: 249m

perfumes: 244m

other rubber products: 241m

photo lab equipment: 240m

wheat: 236m

lubricating products: 234m

printed circuit boards: 233m

aluminum bars: 230m

explosive ammunition: 230m

brooms: 224m

lcds: 223m

refrigerators: 223m

motorcycles and cycles: 221m

large construction vehicles: 221m

coal briquettes: 221m

corn: 220m

aluminum cans: 219m

textile footwear: 217m

thermostats: 207m

coffee and tea extracts: 206m

other aluminum products: 204m

ball bearings: 203m

knives: 199m

machines for additive mnf: 195m

raw iron bars: 187m

delivery trucks: 185m

milling stones: 176m

aluminum foil: 170m

collectors items: 169m

soybean oil: 169m

wood fiberboard: 166m

other stainless steel bars: 164m

sculptures: 160m

cutting blades: 159m

baked goods: 150m

navigation equipment: 146m

hydrometers: 137m

watch cases and parts: 134m

laboratory ceramic wear: 134m

wood carpentry: 124m

mirrors and lenses: 117m

#the plastic lids is the most astonishing thing out of all this i think. 800m usd in exports.... to go on what??#i wanted to visualize the data by smaller category#ig sharing my autism again stayed up til 3 last night transfering this lol

2 notes

·

View notes

Text

Membanggakan, Pebalap Astra Honda Pastikan Juara Thailand Talent Cup 2023

BALIPORTALNEWS.COM, JAKARTA – Persembahan membanggakan untuk Indonesia diberikan secara sukses oleh pebalap binaan PT Astra Honda Motor (AHM) Decksa Almer Alfarezel yang berhasil pastikan uara di ajang balap Honda Thailand Talent Cup (TTC) 2023. Pada balapan putaran kelima yang dihelat di Chang International Circuit, Buriram, Thailand pada 22-23 September 2023, rekan setimnya Muhammad Kiandra Ramadhipa juga tak kalah membanggakan karena berhasil mengalahkan pebalap tuan rumah dan mendapat raihan podium tertinggi di balapan kedua. Decksa berhasil mempersembahkan penampilan apik di putaran TTC pada akhir pekan ini. Pada balapan pertama, Jumat (22/9/2023), Decksa memulai balapan pertama dari posisi ke-5. Pebalap berusia 15 tahun ini sempat berada di barisan depan namun persaingan sengit membuat pergantian posisi terus terjadi hingga akhirnya Decksa dapat mempersembahkan podium ketiga. Bertekad untuk memberikan hasil yang lebih baik, Decksa kembali memacu motornya dengan apik di balapan kedua, Sabtu (23/9/2023). Memulai balapan dari posisi ke-10 membuat Decksa harus lebih kompetitif. Berulang kali turun ke posisi bawah, Decksa bangkit menjelang akhir balapan hingga sempat menyentuh posisi kedua. Namun akhirnya pebalap muda ini harus menyelesaikan balapan di posisi ke-4 dikarenakan terkena track limit di tikungan terakhir menjelang garis finis. Berdasarkan pencapaian total poin klasemen sementara, Decksa berhasil mencapai 207 poin dan mengamankan gelar juara TTC pada musim ini meskipun balapan masih menyisakan satu seri lagi. “Saya sangat senang pada balapan kali ini berhasil mengamankan poin dan menjadi juara TTC musim ini. Terima kasih kepada semua yang telah mendukung saya selama ini. Saya bertekad untuk tetap tampil maksimal pada putaran terakhir TTC,” ujar Decksa. Sementara itu pebalap binaan AHM lainnya, Ramadhipa memulai balapan dari posisi ke-3 di balapan pertama. Semenjak Start, Ramadhipa langsung memacu Honda NSF250R memiliknya menuju barisan depan. Terjadi aksi saling menyalip yang menyebabkan ia harus turun posisi. Dengan tetap menjaga fokus dan ritme balap, Ramadhipa berhasil mencari celah dan kembali naik ke posisi kedua hingga garis finis. Momentum positif ini memberikan semangat tambahan bagi Ramadhipa untuk memacu performanya di balapan kedua. Memanfaatkan posisi start pertama, Ramadhipa menunjukkan kompetensi mumpuninya dan terus konsisten berada di posisi balapan terdepan. Aksi salip yang menegangkan terus terjadi hingga lap terakhir di mana Ramadhipa dapat menyentuh garis finis pada posisi pertama dengan gemilang sekaligus mencatatkan waktu lap tercepat yaitu 1:50.055. Raihan ini berhasil menambah pubdi-pundi poin yang dimilikinya menjadi 156 poin dan menempatkannya di posisi kedua klasemen sementara TTC. “Sepanjang balapan kedua saya terus berjuang untuk berada di barisan depan meskipun sempat beberapa kali tersalip. Pada tikungan terakhir saya mencoba untuk menyalip pebalap posisi pertama dan berhasil sehingga dapat menempati podium tertinggi. Pencapaian ini sangat berarti buat saya mengingat ini podium pertama bagi saya di TTC musim ini. Terima kasih kepada tim dan mekanik yang terus mendukung saya memberikan hasil yang terbaik,” ujar Ramadhipa. “Kami sangat mengapresiasi raihan membanggakan untuk bangsa yang dipersembahkan oleh pebalap binaan AHM di ajang TTC musim ini. Kami berharap konsistensi capaian positif yang membanggakan dari Decksa dan Ramadhipa dapat menginspirasi generasi muda Tanah Air untuk terus berkarya memberikan prestasi membanggakan untuk Indonesia,” ujar General Manager Marketing Planning and Analysis AHM, Andy Wijaya. TTC merupakan ajang awal para pebalap binaan Astra Honda untuk menunjukkan bakatnya di balap internasional. Di sini para talenta muda binaan ditantang untuk menunjukkan potensi dan kemampuan terbaik sebelum naik ke jenjang Asia lainnya yang lebih tinggi, bahkan sebelum masuk ke fase kelas dunia. Ajang ini menyisakan satu seri pamungkas yang akan dihelat di sirkuit yang sama pada bulan Desember 2023.(bpn) Read the full article

#AHM#AstraHondaMotor#BaliPortalNews#Buriram#ChangInternationalCircuit#Honda#HondaNSF250R#NSF250R#Thailand#ThailandTalentCup#TTC

2 notes

·

View notes

Text

Flexible Link and Jumper Manufacturers: The Key to Reliable Electrical Connections

In today’s fast-paced industries, efficient electrical connections play a crucial role in ensuring reliability, durability, and safety. Flexible links and jumpers are essential components in many industrial applications, offering robust and flexible electrical connectivity solutions. At LD Bhattar, we specialize in manufacturing high-quality flexible links and jumpers that cater to diverse industries, guaranteeing safe and efficient power transfer. This article delves into the importance, applications, and advantages of flexible links and jumpers in industrial settings.

What Are Flexible Links and Jumpers?

Flexible links and jumpers are conductive components designed to bridge electrical circuits with flexibility, ease, and stability. Typically manufactured using braided copper, tinned copper, or aluminum, they provide a reliable connection even in environments that require repeated movement or vibration absorption. Flexible links are commonly used in power distribution systems, grounding applications, battery connections, and various electrical setups to ensure consistent electrical conductivity.

The Manufacturing Process

Creating high-quality flexible links and jumpers requires precision and expertise. At LD Bhattar, we follow a meticulous manufacturing process to ensure each product meets international standards. The process involves:

Material Selection: We select premium conductive materials such as copper or aluminum based on the application requirements. Copper is often chosen for its excellent conductivity, while aluminum may be used in cases where weight reduction is a priority.

Braiding and Stranding: The conductive material is braided or stranded to create flexibility. This process enables the link or jumper to withstand bending, vibration, and movement without compromising its electrical properties.

Insulation and Coating: Insulation is added to provide protection against electrical hazards, and in some cases, we apply a tinned or silver coating to improve corrosion resistance, ensuring durability even in harsh environments.

Quality Control: Each batch undergoes stringent quality checks, including conductivity testing, mechanical flexibility analysis, and endurance testing to verify it meets industry standards.

Applications of Flexible Links and Jumpers

Flexible links and jumpers are essential in various industrial and electrical applications, including:

Power Distribution Panels: Flexible jumpers are widely used in power distribution panels to ensure efficient current flow between components and avoid rigid connections that may wear out over time.

Battery Connections: In energy storage systems, including renewable energy installations, flexible links allow secure connections that can handle significant load fluctuations.

Grounding and Bonding: Grounding applications require reliable conductive paths to prevent electrical failures. Flexible links are commonly used in grounding systems in electrical substations, industrial machinery, and building infrastructures.

Transportation and Automotive Industry: In electric vehicles (EVs) and public transportation systems, flexible jumpers are essential for connecting batteries, motors, and other components, offering both reliability and resilience under constant movement.

Advantages of Using Flexible Links and Jumpers

Enhanced Flexibility: The braided design provides excellent flexibility, allowing for installation in tight spaces and adjustment under dynamic conditions, such as in machinery that moves or vibrates frequently.

Vibration Resistance: Due to their structure, flexible links and jumpers absorb vibrations effectively, reducing the risk of damage or failure in industrial environments where equipment experiences constant motion.

Thermal and Electrical Stability: Quality materials and precision manufacturing ensure stable electrical conductivity and reduced heating, leading to lower energy losses and safer operation.

Corrosion Resistance: Coated options, such as tinned copper jumpers, provide extra resistance to corrosion, making them suitable for outdoor and high-humidity applications.

Cost-Efficiency and Durability: Flexible links are long-lasting and cost-effective solutions, reducing maintenance costs and downtime associated with rigid connections that are more prone to wear and tear.

Why Choose LD Bhattar as Your Flexible Link and Jumper Manufacturer?

At LD Bhattar, we understand the crucial role of reliable connections in industrial settings. Our team of experts leverages advanced technology, stringent quality control, and years of experience to produce high-quality flexible links and jumpers. Here’s why our clients trust us:

Customized Solutions: We offer a range of customizable options to meet unique requirements, whether it's material selection, sizing, coating, or insulation.

Industry Compliance: All our products meet industry standards, ensuring they’re safe, durable, and reliable for various applications.

Dedicated Support: We provide comprehensive support from the consultation phase through installation, ensuring our clients have the best possible solutions tailored to their needs.

Commitment to Quality: Every product goes through rigorous testing, ensuring it meets the highest standards of quality and performance.

Conclusion

Flexible links and jumpers are indispensable for efficient, safe, and durable electrical connections in industrial environments. At LD Bhattar, we are committed to delivering products that meet the demanding needs of today’s industries, ensuring high performance, reliability, and safety. Whether for power distribution, grounding, or energy storage, our flexible links and jumpers are crafted to support your operational excellence.

Explore our range of flexible links and jumpers, or contact us to discuss how we can meet your specific industrial needs.

0 notes

Text

According to a recent report by Meticulous Research®, the predictive maintenance market is expected to reach $79.1 billion by 2031, growing at a compound annual growth rate (CAGR) of 30.9% from 2024 to 2031. This rapid expansion is driven by the increasing need to reduce maintenance costs, enhance asset performance, and the rising adoption of predictive maintenance in complex infrastructure systems. The integration of predictive maintenance into healthcare devices and navigation systems presents new growth opportunities, although challenges like data privacy concerns and the shortage of skilled workers hinder market growth. Key market trends include the use of digital twins and augmented reality (AR), with the market being segmented by offering (software, hardware, services), deployment mode (cloud-based and on-premise), organization size, technology (IoT, AI, cloud connectivity, and advanced analytics), application (vibration analysis, oil analysis, temperature monitoring), and end-use industry (manufacturing, energy, automotive, healthcare, and others). The report also evaluates regional and country-level market dynamics and competitors.

#Predictive Maintenance Market#Vibration Analysis#Oil Analysis#Acoustics Monitoring#Motor Circuit Analysis#Temperature Monitoring#Manufacturing#Oil & Gas#AI and Machine Learning#IoT#Data Acquisition Systems#Sensors

0 notes

Text

Motor Circuit Analysis: A Powerful Predictive Maintenance Technique

Motor circuit analysis (MCA) is an essential predictive maintenance technique utilized by equipment performance monitoring services to assess the condition of critical rotating machinery. By performing a comprehensive series of electrical tests, MCA provides in-depth diagnostic data about the operating health and performance of motors, generators, servomotors and other electro-mechanical assets.

0 notes

Text

Where is the AC-DC Rectifier Used? Applications and Importance

DC rectifier is a crucial component in electrical and electronic systems, converting alternating current (AC) into direct current (DC). This conversion is essential because many devices and systems require a stable DC power supply to function correctly. The following article explores various applications of AC-DC rectifiers and highlights their importance in modern technology.

1. Power Supplies

AC-DC rectifiers are fundamental to power supplies that provide DC power to a wide range of electronic devices and equipment. In these power supplies, rectifiers convert AC from the mains into a usable DC voltage.

Applications:

Consumer Electronics: Rectifiers are used in power adapters for devices such as laptops, smartphones, and tablets, ensuring they receive the correct DC voltage for operation.

Home Appliances: Many home appliances, including refrigerators, microwaves, and televisions, use rectifiers to convert AC from the outlet into DC for internal circuits.

2. Battery Chargers

Rectifiers are integral to battery chargers, where they convert AC power into DC to charge batteries.

Applications:

Automotive: Car battery chargers use rectifiers to convert AC from the mains into DC for charging lead-acid batteries.

Consumer Devices: Battery chargers for portable electronics, including rechargeable batteries for cordless tools and gadgets, rely on rectification to ensure proper charging.

3. Industrial Equipment

In industrial settings, AC-DC rectifiers are used to power various types of equipment and control systems that require DC input.

Applications:

DC Motors: Many industrial machines use DC motors for precise control of speed and torque, which require DC power supplied by rectifiers.

Control Systems: Rectifiers are used in control systems for machinery and automation to provide a stable DC voltage for sensors, controllers, and other components.

4. Electric Vehicles

AC-DC rectifiers play a crucial role in electric vehicles (EVs), where they are used to convert AC power from charging stations into DC for battery charging and propulsion systems.

Applications:

Charging Stations: EV charging stations use rectifiers to convert AC from the grid into DC for charging the vehicle’s battery.

Onboard Systems: In electric vehicles, rectifiers convert AC power generated by the vehicle’s onboard systems into DC for use in various subsystems and accessories.

5. Communication Systems

Communication systems rely on AC-DC rectifiers to ensure a stable DC power supply for transmitting and receiving signals.

Applications:

Base Stations: Rectifiers are used in base stations for cellular networks to convert AC from the grid into DC for powering communication equipment.

Satellite Systems: Ground stations and satellite communication systems use rectifiers to provide reliable DC power for their operation.

6. Signal Processing

In signal processing applications, AC-DC rectifiers are used to convert AC signals into DC for measurement and analysis.

Applications:

Measurement Instruments: Oscilloscopes, multimeters, and other measurement instruments use rectifiers to convert AC signals into DC for accurate readings and analysis.

Data Acquisition Systems: Rectifiers are used in data acquisition systems to convert AC signals from sensors into DC for processing and recording.

7. Uninterruptible Power Supplies (UPS)

Rectifiers are essential components in uninterruptible power supplies (UPS), where they convert AC power from the mains into DC to charge batteries. During a power outage, the stored DC power is used to provide backup power to critical systems.

Applications:

Data Centers: UPS systems in data centers use rectifiers to ensure continuous operation of servers and network equipment during power interruptions.

Medical Equipment: Critical medical equipment, such as life-support machines, relies on UPS systems with rectifiers to maintain operation during power outages.

8. Renewable Energy Systems

In renewable energy systems, AC-DC rectifiers are used to convert AC power generated by renewable sources into DC for storage or further use.

Applications:

Solar Power Systems: Rectifiers convert AC from solar inverters into DC for storage in batteries or use in DC-based appliances.

Wind Power Systems: In wind turbines, rectifiers convert AC generated by the turbine into DC for use in the grid or battery storage.

9. Electric Arc Furnaces

Electric arc furnaces used in steel production require AC-DC rectifiers to convert AC power into DC for generating high temperatures needed for melting and refining metal.

Applications:

Steel Manufacturing: Rectifiers provide the necessary DC power for the electric arc used in steelmaking processes.

Conclusion

AC-DC rectifiers are indispensable components across a wide range of applications, from powering consumer electronics and industrial equipment to enabling renewable energy systems and electric vehicles. By converting AC power into a stable DC output, rectifiers ensure the reliable operation of many devices and systems that require precise and consistent power. Their versatility and importance underscore their role in supporting modern technology and infrastructure.

0 notes

Text

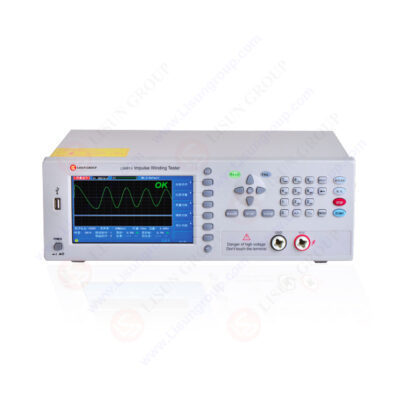

Principle and Applications of Impulse Coil Testers

Introduction to Impulse Coils Tester Impulse coil testers, also known as digital interturn insulation testers, are devices used for non-destructive electrical testing of coil-wound components. The operating principle involves applying the same pulse voltage to both a standard coil winding and the coil under test, then comparing their transient waveforms to evaluate the quality of the tested coil. Transient waveforms, or damped oscillation waveforms occurring within the coil, can be used to assess the inductance, quality factor, number of turns, and interturn short circuits of the winding. Additionally, in the presence of a core, the material differences can also be determined. The occurrence of corona discharge under high voltage pulses can be used to evaluate insulation deficiencies. LISUN LS8815 Series Impulse Coils Tester The LS8815 series impulse coil testers employ advanced, high-stability high-voltage impulse power sources, significantly improving testing accuracy. The instrument quantifies various waveform parameters using microcomputer technology, displaying and judging them through intuitive waveforms. This makes the device easy to operate, providing accurate judgments with a high degree of automation. LS8815 Impulse Winding Tester Working Principle The LS8815 series testers utilize a high-voltage charged small capacitor (low testing energy) to form an RLC parallel resonance with the coil under test. By analyzing the damped oscillation waveforms using precise sampling and processing technology up to 100Msps (customizable to 200Msps), the testers can detect insulation issues within the coil (such as interturn short circuits, layer-to-layer short circuits, and reduced insulation performance). This enables manufacturers and users to more effectively control product quality. Applications The LS8815 series impulse coil testers are characterized by fast measurement speed and good waveform repeatability, making them widely applicable in the following fields: • Motors: Assess the quality of motor windings to ensure reliable operation. • Power Frequency Transformers: Test the interturn insulation of transformer windings. • Relays: Evaluate the quality factor and insulation performance of relay coils. • Switching Power Transformers: Inspect the winding quality of switching power transformers. • Demagnetization Coils: Ensure good interturn insulation of demagnetization coils. • Automation Testing Systems: The LS8815 series instruments can also be integrated into automated testing systems to significantly enhance testing efficiency. Conclusion Impulse coil testers, particularly the LS8815 series, utilize high-stability high-voltage impulse power sources and advanced sampling and analysis technology to quickly and accurately assess the quality and insulation performance of coil windings. They have broad application prospects in fields such as motors, transformers, and relays. Their efficient, accurate, and automated features make them an indispensable tool in modern electronic and electrical testing. Read the full article

0 notes

Text

Principle and Applications of Impulse Coil Testers

Introduction to Impulse Coils Tester Impulse coil testers, also known as digital interturn insulation testers, are devices used for non-destructive electrical testing of coil-wound components. The operating principle involves applying the same pulse voltage to both a standard coil winding and the coil under test, then comparing their transient waveforms to evaluate the quality of the tested coil. Transient waveforms, or damped oscillation waveforms occurring within the coil, can be used to assess the inductance, quality factor, number of turns, and interturn short circuits of the winding. Additionally, in the presence of a core, the material differences can also be determined. The occurrence of corona discharge under high voltage pulses can be used to evaluate insulation deficiencies. LISUN LS8815 Series Impulse Coils Tester The LS8815 series impulse coil testers employ advanced, high-stability high-voltage impulse power sources, significantly improving testing accuracy. The instrument quantifies various waveform parameters using microcomputer technology, displaying and judging them through intuitive waveforms. This makes the device easy to operate, providing accurate judgments with a high degree of automation. LS8815 Impulse Winding Tester Working Principle The LS8815 series testers utilize a high-voltage charged small capacitor (low testing energy) to form an RLC parallel resonance with the coil under test. By analyzing the damped oscillation waveforms using precise sampling and processing technology up to 100Msps (customizable to 200Msps), the testers can detect insulation issues within the coil (such as interturn short circuits, layer-to-layer short circuits, and reduced insulation performance). This enables manufacturers and users to more effectively control product quality. Applications The LS8815 series impulse coil testers are characterized by fast measurement speed and good waveform repeatability, making them widely applicable in the following fields: • Motors: Assess the quality of motor windings to ensure reliable operation. • Power Frequency Transformers: Test the interturn insulation of transformer windings. • Relays: Evaluate the quality factor and insulation performance of relay coils. • Switching Power Transformers: Inspect the winding quality of switching power transformers. • Demagnetization Coils: Ensure good interturn insulation of demagnetization coils. • Automation Testing Systems: The LS8815 series instruments can also be integrated into automated testing systems to significantly enhance testing efficiency. Conclusion Impulse coil testers, particularly the LS8815 series, utilize high-stability high-voltage impulse power sources and advanced sampling and analysis technology to quickly and accurately assess the quality and insulation performance of coil windings. They have broad application prospects in fields such as motors, transformers, and relays. Their efficient, accurate, and automated features make them an indispensable tool in modern electronic and electrical testing. Read the full article

0 notes

Text

Robotics Classes in USA

The multidisciplinary area of robotics combines aspects of artificial intelligence, computer science, and engineering. It imparts creativity, critical thinking, and problem-solving skills. Learning robotics provides up a world of job prospects as robots become an essential element of industries including manufacturing, healthcare, agriculture, and even home duties. Additionally, the data analysis, mechanics, and coding abilities acquired in robotics are highly applicable to many other tech-related areas.

Robotics Education for Beginners

Elementary and Middle School Robotics Programs

Early encounters with robotics encourages curiosity and practical learning. STEM (Science, Technology, Engineering, and Mathematics) curricula are widely available in American schools, and many of them include robotics modules. These courses teach fundamental coding and mechanical design using platforms such as VEX Robotics, Raspberry Pi, and LEGO Mindstorms. Robotics matches, challenges, and collaboration exercises are also provided by summer camps and after-school organization.

High School Robotics Classes

More powerful robotics programs are seen in high schools, and they are frequently connected to national contests like the VEX Robotics Competition and FIRST Robotics Competition. Students can work on real-world projects in these sessions, creating robots that can carry out particular functions. Students have practical experience with circuit boards, sensors, and motors while learning how to program robots in languages such as Python, Java, and C++.

Online Robotics Classes and Certifications

Many online platforms provide flexible and cheap robotics classes for those who are unable to attend in-person classes. Professors from elite colleges teach robotics classes on websites like Coursera, edX, and Udemy. With the help of these platforms, students can study subjects like robotic sensors, robot programming, and machine learning applications in robotics at their own rate.

Benefits of Robotics Classes

Hands-On Learning Career Opportunities Teamwork and Collaboration In-Demand Skills

In the USA, kids can interact with modern technology and be ready for a career in a highly wanted profession by enrolling in robotics classes. There are programs and courses specifically designed to meet your goals, regardless of your level of experience—from elementary school beginners to university students hoping to specialize in robotics engineering. Investing in robotics education is a wise decision that opens doors to limitless possibilities in creativity and technology as robots continue to impact the future.

To know more click here:- Fortune Robotics

0 notes

Text

Top 10 FE Electrical Exam Sample Questions You Must Practice

Preparing for the FE Electrical Exam can be a daunting task. As one of the initial steps toward becoming a licensed professional engineer, this exam tests your understanding of fundamental electrical engineering concepts. To help you navigate your study journey, we’ve compiled a list of the top 10 FE Exam sample questions that you must practice to ensure thorough FE exam preparation.

Ohm’s Law Calculation

A classic question on the FE Electrical Exam involves applying Ohm’s Law. For example, you might be asked to determine the current flowing through a resistor given the voltage and resistance. Practicing questions that involve calculating voltage, current, and resistance will solidify your understanding of this fundamental principle.

Circuit Analysis

Questions related to circuit analysis are essential. You may encounter problems requiring the analysis of series and parallel circuits. Be prepared to solve for unknown values using techniques such as Kirchhoff's Voltage Law (KVL) and Kirchhoff's Current Law (KCL). Practice solving both simple and complex circuit problems to build confidence.

Power Calculation in AC Circuits

Understanding power in AC circuits is crucial. Sample questions might ask you to calculate real power, reactive power, and apparent power in various AC circuit configurations. Practice converting between different forms of power and understanding the implications of power factor.

Transformers and Their Operations

Transformers are a significant topic. You might face questions on transformer ratios, impedance, and efficiency. Practice problems related to the turns ratio and how it affects voltage and current in both ideal and practical scenarios.

Electrical Machines

Questions on electrical machines, including motors and generators, are common. Be prepared to solve problems related to the operation, characteristics, and efficiency of different types of machines. Understanding the basics of synchronous and asynchronous machines will be beneficial.

Digital Logic Circuits

FE Exam preparation often includes digital logic circuits. Sample questions might involve designing or analyzing combinational logic circuits, including AND, OR, and NOT gates. Practice designing truth tables and simplifying Boolean expressions.

Signal Processing

Questions on signal processing can appear in the exam. Practice problems related to Fourier transforms, Laplace transforms, and filtering techniques. Understanding how to manipulate and interpret signals will be essential.

Control Systems

Control systems questions test your knowledge of feedback, stability, and control strategies. Be prepared to analyze system responses, transfer functions, and stability criteria. Practice solving problems related to both open-loop and closed-loop systems.

Electrical Safety and Codes

Knowledge of electrical safety and codes is crucial. Sample questions might test your understanding of standards and regulations related to electrical installations. Familiarize yourself with the National Electrical Code (NEC) and other relevant safety guidelines.

Measurements and Instrumentation

Questions on measurements and instrumentation often focus on using various instruments to measure electrical parameters accurately. Practice questions related to voltage, current, resistance measurements, and the calibration of instruments.

Conclusion

Incorporating these FE Exam sample questions into your study routine will enhance your FE exam preparation. By practicing a diverse range of problems, you’ll build a solid foundation in electrical engineering principles and improve your problem-solving skills. Utilize resources such as study guides, online practice exams, and FE prep courses to complement your practice and ensure a comprehensive review. Remember, consistent practice and a thorough understanding of key concepts are crucial for success on the FE Electrical Exam. Good luck with your preparation!

For more resources and sample questions to aid your FE Exam preparation, visit Study For FE, where you'll find additional practice questions and study materials to help you succeed.

0 notes