#MetalExpansionJoints

Explore tagged Tumblr posts

Text

Resistoflex Metal Expansion Joints absorb thermal expansion, reduce stress, and minimize noise and vibration in piping systems, ensuring long-lasting performance in demanding environments.

.

.

.

For more Info Connect with us:

📧 Email: [email protected]

🌐Website: https://www.resistoflex.in/

.

.

.

.

#reduce stress#MetalExpansionJoints#ThermalExpansion#PipingSystems#StressReduction#NoiseControl#VibrationMitigation#IndustrialSolutions#Resistoflex#EngineeringExcellence#DurablePerformance#HeavyIndustry#Infrastructure#FluidHandling#MechanicalEngineering#MaintenanceSolutions

0 notes

Text

What is the difference between Metal VS Rubber expansion joints?

The facts and differences will help you choose rubber or metal expansion joints to keep your piping systems safe from any thermal changes. For more details visit the website

0 notes

Link

56 notes

·

View notes

Link

4 notes

·

View notes

Text

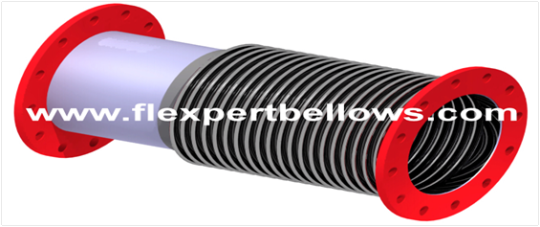

Universal Expansion Joints

What Is The Universal Expansion Joint? Expansion joints are simply an assembly of bellows with other components to form a product that can contain movements caused by stress, thermal stress, and other seismic activities. They can be classified into multiple types based on their design, functions, and so on. Some of the common types are axial, lateral, hinged, gimbal, universal, elbow pressure balanced expansion joints and so on. Universal expansion joints are one of the most important and most used types of expansion joint The reason behind the widespread usage of universal expansion joints is that unlike a lot of the other types, these can contain movements in all 3 directions namely lateral, axial, and angular. Also known as a double bellow expansion joints, these are made with 2 bellows that are connected by a spool or pipe section. Another major advantage of using this over others is that large amounts of lateral deflection can be absorbed with this. If the capacity has to be increased, this can be done by increasing the length of the pipe section connecting the 2 bellows. In certain cases, tier rods may be attached to limit the axial expansion. If 2 tie rods are used, it can take in good lateral and angular expansion. By using more than 2, you can make the expansion joints to contain only lateral expansion.

Feature

Vibration and oscillation absorption

Low maintenance cost

Compact and light

Abrasion-resistant

Corrosion-resistant

Eliminated pressure thrusts

Installation

Since the universal expansion joints are made from thin material, it is extremely necessary to ensure that they are not damaged during the installation. Also, for correct functioning and fitting, it is important to follow correct procedures during the process.

Installation process

Be careful while handling the product. It is important to ensure that there are no dents, weld splatter, etc on them.

The joint is not made to rectify misalignments in the piping system. As a result, you must not use them to do the same. Imposing unnecessary movements to align can reduce the life cycle and capability.

If any sleeves, flanges, etc. are required, you must attach them properly.

Do's and Don'ts before the test

Store in a cool dry place and not exposed to heavy traffic and a damaging environment.

While lifting, do not use ropes or rods through the holes. Use proper lugs instead.

Install the product in the direction of flow.

Do not subject it to heaving torsional forces.

Do not use steel wire, mesh, and other abrasive cleaning products on the surface.

Before testing, ensure that you remove all the shipping devices and packaging.

Align the bolt holes with ones matching on the mounting flange.

Do not use cleaning products that contain Chlorides

Do not expose the product to more than one and a half times its rated working pressure.

Inspection During and After Test

Check for any evidence of leakage or loss of pressure.

Check for any distortion of the expansion joint hardware, the bellows and other piping components.

Check for any possible squirm in the product.

If there are any abnormalities during the testing, it must be evaluated by the concerned authority.

Universal Expansion Joints

0 notes

Text

Get to know more about Pipe Expansion Joint in India

What is piping Expansion Joint?

A rubber expansion joint pipe is a flexible connector of two pipes. It provides stress relief in a piping system due to thermal and mechanical vibration or movements. … Retaining Ring – Used to compress the expansion joint flange to the mating flange to create a seal. Also called as clamp bars or backing bars.

Expansion Joint Piping

What is the use of Expansion Joint Piping?

Piping Expansion Joint or Expansion Bellows are highly engineered and mechanical devices containing more than one metal/ rubber bellows. Expansion Joints use to absorb dimensional changes that are caused by thermal expansion or contraction of the pipeline, duct, or vessel or while containing the system pressure

What are the benefits of Expansion piping?

· Simple in design and function

· Space Reduction

· Weight Reduction

· Cost Reduction

· Better Flexibility of piping Layout

· Reliable and proven in the field

#Expansionjoint#metalexpansionjoint#Expansionbellows#Bellows#pipingsystem#expansionpiping#rubberbellows#catalogue

0 notes

Link

SSJB Metal Expansion Joint#رول_ورق #پرس_عدسی#لبه_کشی #flexiablehoses #edgewelding #welding #industrialdesign #tigwelder #weldporn #bellows #metalexpansionjoints #expansionjoints #flange #fabricationlife #engineering #manufacturing #tubing #metalhose#جوش_زیرپودری

— Liwei Group (@liweigroup) June 17, 2019

June 17, 2019 at 12:11PM

1 note

·

View note

Text

Our Resistoflex Metal Expansion Joint is designed to absorb thermal expansion and reduce stress on your system

Get in Touch:

📧 Email: [email protected]

🌐Website: https://www.resistoflex.in/

.

.

.

.

.

#MetalExpansionJoint#ThermalExpansion#PipelineSolutions#Engineering#IndustrialEquipment#ExpansionJoints#Resistoflex#MechanicalEngineering#SystemDesign#StressReduction#PipeSupport#EngineeringSolutions#IndustrialTech

0 notes

Text

Metal Expansion Joint Manufacturer

Be it aerospace, automobile, electrical, power generation, or any other, there is a need to transfer fluids safely and conveniently. To cater to this specific need, metallic bellow expansion joints are used. These metal expansion joints use metal bellows to ensure that the transfer system has the capacity to withstand the high temperature and pressure as well as withholds the stress caused by these. Kwality Products are one of the leading metal bellow companies, manufacturing various types of metal expansion joints and metal bellows as per the specific requirements of our valuable clients.

What are Bellow Expansion Joints?

Bellows expansion joints comprise of a bellow, end fittings, control rods, liners, and other components to form an entire unit that can withstand the forces developed by the fluid to ensure an uninterrupted and safe flow. Bellows can be made using a metal or rubber as per the requirement. The metallic bellow is made by rolling a thin sheet into a cylindrical form and then welding the seam. Depending upon the required specifications, plies are added. After this, circumferential convolutions are made onto the body. The shape of these is designed in order to contain the pressure developed inside and deform accordingly. When the pipe is subjected to high pressure, the bellows compress, and alternately, when there is a vacuum, the bellows expand accordingly thereby protecting the whole arrangement.

Kwality Products is a metal expansion joint manufacturer that uses state of the art mechanical expander and hydroforming machines to manufacture bellow joints as per the design parameters required by the client industry.

Use of Metal Bellows

The bellow expansion joints have found uses in a plethora of industries ranging from water/wastewater plants to even nuclear applications. Some other applications of the bellows are in -

Power generation plants

Infrastructure

HVAC

Solar technology

Electrical systems

Cryogenic/industrial gases applications

Metal/steel mills

Measurement and control systems

Fuel cell power system

Pulp and paper industry

Oil and gas

OEM engines

Shipbuilding and repair

Automotives, etc.

Benefits of Metal Expansion Joints

The benefits of choosing metallic expansion joints can be specified as below -

Vibration isolation: Unnecessary vibrations in systems can damage the system as well as the surrounding equipment severely. Metal expansion joints help in isolating these vibrations, as well as dampening noise and pressure surges.

Wide temperature ranges: These can be used to convey fluids, solids, or abrasive media at high as well as low temperatures safely.

Low maintenance: By using durable and corrosion-resistant materials, metallic expansion joints require very little maintenance and have a long life cycle.High temperature and pressure resistance.

Features of Metal Expansion Joints

There are various features of metal expansion joints depending upon the type. The main features are as follows -

Absorbs vibrations and oscillations

Absorbs mechanical movements

Low maintenance cost

Compact and lighter, thereby saving space

An array of design possibilities

Better flexibility for the pipe layout

Better performance than traditional pipe bends, loops, etc.

Abrasion-resistant

Corrosion-resistant

Types of Metal Expansion Joints

Based on different parameters such as the direction of movements, location the joint is placed, the function of the joint, etc, there are a few different types of expansion joints. These are as follows -

Axial Expansion Joints: These are expansion joints that are used to contain the movement in the axial or longitudinal direction. When used in between two pipe sections, due to the thermal expansion, this joint compresses and expands along the length as required, thereby protecting the pipeline.

Lateral Expansion Joints: This type of metallic expansion joints is used to compensate for all the movements in the lateral (perpendicular to the central axis) direction. With the help of control rods attached, the lateral expansion joints also control the pressure thrust.

Hinged Expansion Joints: A hinged expansion joint is used where there is a need to constrain angular deflections in a single plane controlled by a hinge. These are used in piping systems where there is a change in the direction of the flow.

Universal Expansion Joints: Universal expansion joints, also sometimes known as a double bellow expansion joint is a device that is made up of 2 bellows attached together by a pipe section. As a result, this can absorb movements that cannot be absorbed in normal axial expansion joints and can also contain deflections in axial, lateral, and angular directions.

Gimbal Expansion Joints: Gimbal expansion joints or the angular expansion joints are used to absorb movements in multiple angular directions. With the help of multiple hinges or gimbal, these can constrain the deflections in all the planes.

Inline Pressure Balanced Expansion Joints: Inline pressure balanced expansion joints are designed to absorb axial movement without putting a load on the pipe system. This is done by using two bellows in line together and acting in opposite directions. It is mainly used in systems where any pressure on the piping system can prove to be fatal, and therefore must be avoided.

Elbow Pressure Balanced Expansion Joints: This type of pressure balanced expansion joint is used in systems where it is not acceptable to transfer pressure on to the piping system and also there is a change in the direction of the flow. These absorb axial movement without imposing pressure loading on the system.

0 notes

Photo

Metal Expansion Joints Manufacturer and global exporter of expansion joints

8 notes

·

View notes

Text

Manufacturing Process Of Metal Bellows

What are Metal Bellows? Manufacturing Process of Metal Bellows

Metal bellows are metallic vessels which are elastic in nature which gets compressed when pressure is applied to its sides whereas they extend under vacuum. This elastic nature of the bellows is due to its design where convolutions or also know as piles are made by deforming /compressing a metallic tube and using water under high pressures going up to 250

The manufacturing process of the metal bellow starts with the designing process itself. First, a metallic tube is designed and then made/manufactured by shearing a sheet of metal and then rolling it into the desired sizes. Then, the desired life cycle of the bellow to be made with the expansion joint is first identified. This lets the designer determine the bellow thickness as he understands the working conditions, the pressure under which the expansion joint and thus ultimately the metal bellow will be working. After these calculations, the number of piles to be used is then determined. It is up to the engineer of the joint that the number of piles will be set for each bellow. The hydroforming process is implemented and the bellow is thus taken out. After this, longitudinal cuts are made on the piece and the neck is thus cut to the desired size or shape. Many manufacturing industries produce metal bellows as they are required in loads of situations where expansion joints are used.

There are many metal bellows manufacturers out there but Pliant Bellows manufacture strong and sturdy metal bellows to be used directly on expansion joints as per the order and the desired requirement.

http://bit.ly/2tgvwPs

#metalbellows#manufacturing#manufacturingprocess#metallicvessels#hydroformingprocess#expansionjointsmanufacturer#metalbellowexpansionjoints#universalexpansionjoints#metalexpansionjoints#expansionbellows#expansionjointbellows#SSbellows

0 notes

Text

Bellows Elements Expansion Joints

Bellows Elements Expansion Joints Bellows Elements Expansion Joints are exclusively manufactured to meet the customer drawings and are provided with collars at both ends.

https://flexpertbellows.com/bellows-elements-for-expansion-joints/

0 notes

Text

Externally Pressurized Expansion Joint

Externally Pressurized Expansion Joint Absorbs a large amount of axial movement under high pressure at Flexpert Bellows Pvt Ltd.

Externally Pressurized Expansion

Absorbs large amount of axial movements without squirm

Eliminates Main Anchor

Minimum guiding for Externally pressurized Expansion Joint

An Externally Pressurized Expansion Joint takes pressure from the outside of the bellows element rather than on the inside as in a conventional expansion joint. In conventional type of expansion joints with internally pressurized bellows it is not possible to accommodate large axial movements due to the squirm associated with the higher bellows length.

The stabilizing effect of the external pressure increases the bellows capacity to absorb high axial movements without squirm making the externally pressurized expansion joints the best solution for applications involving very high axial movements.

To know More visit our website today:

https://flexpertbellows.com/externally-pressurized-expansion-joint/

0 notes

Link

We are the best manufacturer in India of Expansion bellows, We provide good quality of product at a reasonable cost.

#BellowsManufacturers#ExpansionBellowsManufacturers#MetalExpansionJoints#MetallicBellowExpansionJoints#MetallicExpansionJointCompany

0 notes

Link

What are expansion joints bellows? don't know? Get full info about expansion joints bellow through bellow expansion joints very easily

#ExpansionJoints#BellowExapansionJoints#MetalExpansionJoints#BellowExpansionJoints#MetallicBellowExpansionJoints

0 notes

Link

What are expansion joints bellows? don't know? Get full info about expansion joints bellow through bellow expansion joints very easily

#ExpansionJoints#BellowExapansionJoints#MetalExpansionJoints#BellowExpansionJoints#MetallicBellowExpansionJoints#MetalBellowCompany

0 notes