#Medical Device manufacturing

Explore tagged Tumblr posts

Text

Explore recent advancements in wound closure materials and accessories for optimized healing

Wound closure has been part of the healing process, be it surgery, trauma, or some medical procedure. Lately, materials like surgical meshes used in closing wounds have seen quite a change and improvement. Thus showing much improvement regarding outcomes for most patients today.

#Original Equipment Manufacturer#Medical Device manufacturing#A global leader in MedTech#India based global medical device company#healthcare solutions worldwide

0 notes

Text

#Medical Device Manufacturing Outsourcing Market#Medical Device Manufacturing#Medical Device#manufacturing#outsourcing

0 notes

Text

Medical Device Design Engineers: Approaching Medical Device Design Explore the crucial role of mechanical engineers in medical device design. Learn about prototype evaluation, design development, validation, FDA compliance, risk management, and more.

#Medical Device Design Engineers#Medical Device Engineering#Mechanical Engineers in Healthcare#Medical Device Prototyping#Innovation in Medical Engineering#Medical Device Manufacturing#Healthcare Product Development#Mechanical Engineering Solutions

0 notes

Text

bingo picrew 🙂↕️

#its hard to make it clear that hes 38 through a picrew 😭#also he has a hood not a hat. the camp jacket just goes over the black hoodie#he also has just a plain black mask covering him. but all the nonmedical masks had marks#<- not a medical mask. like a military one 🙂↕️#my characters <3#bingo (oc)#one of the villians as i said before. still debating whether to post his whole thing#he isnt like... one of the main guys#and also i kinda scrapped a storyline with him. so hes kinda just off to the side now 😭#more of just a plot device as to how bullets are manufactured

9 notes

·

View notes

Text

Blood Transfusion Sets for Safe and Efficient Transfusions

iLife Medical Devices provides high-quality blood transfusion sets designed for safe and efficient blood transfer. Our sets ensure precise blood flow while maintaining sterility. Choose iLife for trusted, high-standard transfusion products that meet global medical regulations.

Contact us at: +91 120 3200663

#transfusion sets#transfusion set#Blood transfusion sets#blood transfusion set#Medical Devices#medical devices manufacturer#medical equipment#medical equipment manufaturers#medical equipment manufacturers

0 notes

Text

Buy Pulse Oximeter USA: A Trusted Medical Device for Health Monitoring

In today’s fast-paced world, maintaining optimal health is more important than ever. One of the most valuable tools for monitoring your health at home is a pulse oximeter. If you're looking to buy pulse oximeter USA, you’ll want to find a reliable and trusted source, like Medical Device Depot, to ensure you’re investing in a high-quality product that meets your needs.

What is a Pulse Oximeter?

A pulse oximeter is a small, portable device used to measure the oxygen saturation level in your blood and monitor your heart rate. This device clips onto your finger (or another part of your body) and uses light to assess the oxygen levels in your bloodstream. A healthy oxygen level typically ranges from 95% to 100%, and any significant drop below this threshold could be a sign of a health concern, such as respiratory or cardiac problems.

Whether you are managing a chronic condition, recovering from surgery, or just want to keep an eye on your health, a pulse oximeter is an essential tool to have on hand. If you’re ready to buy pulse oximeter USA, you can turn to Medical Device Depot, a trusted provider that offers a wide range of options to fit your specific needs.

Why Should You Buy a Pulse Oximeter USA?

There are several reasons why purchasing a pulse oximeter USA is beneficial. For starters, having a pulse oximeter at home allows you to easily monitor your oxygen saturation levels and detect early signs of health issues before they escalate. Whether you have asthma, COPD, sleep apnea, or any other condition that affects oxygen levels, this device can help you track your health status regularly.

Here are a few reasons why you should buy pulse oximeter USA:

Accuracy and Reliability: When you buy pulse oximeter USA, you are guaranteed to get a high-quality device that delivers accurate readings. Trustworthy manufacturers and suppliers ensure that their products meet medical-grade standards for precision.

Convenience: Monitoring your oxygen levels at home is incredibly convenient. Whether you're looking to keep tabs on your fitness levels, recovery after surgery, or general health, a pulse oximeter allows you to check your vitals at any time.

Affordable Health Monitoring: With the current healthcare climate, having a pulse oximeter USA provides a cost-effective way to monitor your health without frequent visits to the doctor. This device can give you peace of mind, especially if you have underlying health conditions.

Peace of Mind for Family and Caregivers: If you are caring for someone with a chronic illness or elderly relatives, a pulse oximeter is a fantastic tool. It helps caregivers ensure that oxygen levels stay within a healthy range, allowing for early intervention if levels drop unexpectedly.

Why Choose Medical Device Depot to Buy Pulse Oximeter USA?

When it comes to purchasing a pulse oximeter USA, Medical Device Depot is a trusted source offering a wide selection of high-quality medical devices, including pulse oximeters from top brands. Here's why:

Wide Selection: Medical Device Depot carries a broad range of pulse oximeters to suit your specific needs. From basic models for general use to advanced options with additional features, you can find exactly what you're looking for when you buy pulse oximeter USA.

Competitive Pricing: When you buy pulse oximeter USA from Medical Device Depot, you can rest assured that you’re getting a great deal. They offer competitive prices and various models that cater to different budgets.

Trusted Brands: The site offers pulse oximeters from well-known, trusted brands like Nonin, Contec, and ChoiceMMed. These manufacturers are known for their reliable and accurate devices, ensuring you receive a high-quality product.

Customer Support: Medical Device Depot prides itself on providing excellent customer service. If you have questions about which pulse oximeter is best for your needs, their team of experts is ready to assist you. They are also dedicated to helping you with setup and troubleshooting.

How to Use a Pulse Oximeter

Using a pulse oximeter is simple and quick. Here’s how to use one:

Prepare the Device: Turn on the pulse oximeter by pressing the power button.

Place on Your Finger: Gently clip the device onto your finger, ensuring it is snug but not too tight. Wait for the device to read your oxygen levels.

Wait for Results: Within a few seconds, you’ll see the oxygen saturation (SpO2) level and your pulse rate displayed on the screen.

Record the Data: Keep track of your readings over time, especially if you're monitoring a health condition.

If you’re ready to take control of your health, make sure to buy pulse oximeter USA from a reliable supplier like Medical Device Depot. The easy-to-use and accurate pulse oximeter is a must-have tool that can provide invaluable information about your health status.

Conclusion

In summary, a pulse oximeter is a vital tool for monitoring your health, and purchasing one from Medical Device Depot ensures you get a reliable and accurate device. Whether you’re managing a chronic condition or just keeping track of your overall health, buy pulse oximeter USA to help you monitor your oxygen levels and heart rate with ease. Make sure to visit Medical Device Depot for your next purchase of a pulse oximeter, and start taking proactive steps toward maintaining your health today. for more details visit our website : https://medicaldevicedepot.com/

0 notes

Text

The Evolution of PCB Manufacturing: From Basics to High-Performance Boards

PCB manufacturing has evolved from single-layer boards to high-performance, multi-layered designs, enabling innovation in automotive, healthcare, telecommunications, and aerospace. Learn how cutting-edge PCB technologies support modern electronics and drive UK industries forward. Explore advanced PCB solutions for your business today.

#PCB manufacturing evolution#high-performance PCBs#multi-layer PCB design#PCB for 5G networks#advanced PCB technology#UK PCB industry#flexible PCBs#PCB signal integrity#automotive PCB solutions#medical device PCBs#aerospace PCB manufacturing#PCB miniaturisation#HDI PCBs#thermal management in PCBs#next-gen PCB solutions#A-Gas Electronic Materials

0 notes

Text

Best Medical Equipment Online Store: Where to Buy Quality Medical Supplies Online

The demand for medical equipment is on the rise, and more people are turning to online stores to purchase quality medical supplies. Whether you're a healthcare professional, a caregiver, or an individual looking for home medical solutions, knowing where to buy the best equipment is crucial.

This guide will help you navigate the best medical equipment online stores, ensuring you make safe, informed, and cost-effective purchases.

1. Why Buy Medical Equipment Online?

Convenience & Accessibility

Buying medical equipment online eliminates the need to visit multiple physical stores. With just a few clicks, you can compare different brands, read reviews, and make a purchase from the comfort of your home.

Cost Savings

Many online stores offer competitive pricing, discounts, and bulk purchasing options that are often more affordable than traditional brick-and-mortar stores.

Wide Product Range

Online platforms provide access to a diverse range of medical equipment, including specialized tools that may not be readily available in local stores.

2. What to Look for in a Medical Equipment Store

Product Quality & Certification

Ensure the equipment meets industry standards, such as FDA approval or CE certification, to guarantee safety and efficacy.

Customer Reviews & Ratings

Checking feedback from previous buyers can help you assess the reliability of the seller and the quality of the products.

Return Policies & Warranties

A reputable store should offer clear return policies and warranties to protect your investment.

3. Best Online Stores for Medical Equipment

Top-Rated Platforms in 2025

Amazon Medical Supplies – Offers a vast selection of medical supplies, competitive pricing, and fast shipping for both professionals and consumers.

Medline – Specializes in high-quality, professional-grade medical equipment trusted by hospitals, clinics, and healthcare providers.

Henry Schein – A leading provider of healthcare supplies, offering a vast catalog and excellent customer service.

Health Products for You – Focuses on home healthcare solutions, including mobility aids, wound care, and therapy products.

Features & Benefits of Leading Stores

Each online store provides unique advantages such as bulk pricing, subscription discounts, responsive customer support, and same-day shipping options.

Comparing Pricing & Services

Comparison tools and customer reviews help buyers evaluate prices, warranties, and delivery services before finalizing a purchase.

Conclusion

Choosing the right medical equipment online store ensures you receive high-quality, reliable products at the best price. By considering product certifications, store reputation, and return policies, you can make safe and informed purchases.

As technology continues to evolve, online medical equipment sales will become even more efficient and accessible, making it easier than ever to find the right tools for your healthcare needs.

FAQs

Where can I buy FDA-approved medical equipment online?

Websites like Medline, Henry Schein, and Amazon (with FDA-approved filters) offer verified medical products.

How do I verify a medical equipment seller’s legitimacy?

Check for certifications, customer reviews, and Better Business Bureau ratings.

Are there financing options for medical equipment purchases?

Yes, many suppliers offer financing plans or leasing options.

What is the best website for affordable medical supplies?

Amazon Medical Supplies and Health Products for You often provide budget-friendly options.

Can I return medical equipment if it doesn’t meet my needs?

Most reputable stores have return policies, but always check the terms before purchasing.

What certifications should I check when buying online?

Look for FDA, CE, or ISO certifications to ensure product safety and effectiveness.

#medical laboratory devices#laboratory equipment supplier#lab equipment manufacturers#medical equipment online store#medical supplies online#buy scientific equipment online#laboratory equipment suppliers in usa

0 notes

Text

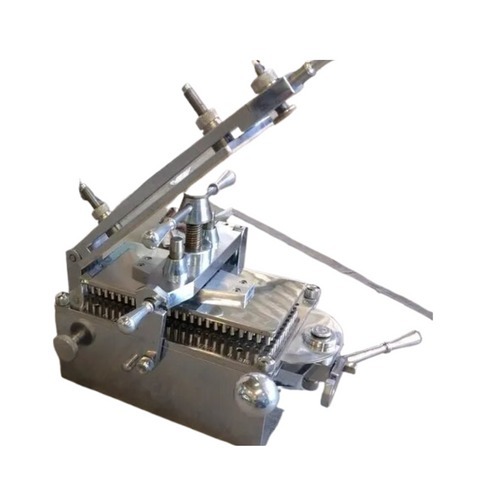

Surgical Instruments manufacturers in India

Discover top-quality surgical instruments made in India by leading manufacturers. Trust in their expertise and precision for your medical needs from Medi Era Life Science. All kind of surgical instruments manufacturers in India. Try out our service to get the best product and services at affordable price.

#surgical instruments in india#medical equipment manufacturers in india#hospital equipment manufacturers in india#educational equipment manufacturers in india#hospital furniture manufacturers in india#medical device manufacturers in india

0 notes

Text

Exploring Clinical Research Jobs in Hyderabad with Clinfinite Solutions

Hyderabad, a flourishing center point for the drug and medical services businesses, is quickly turning into a sought-after objective for clinical research jobs. The city's developing environment of exploration associations, medical clinics, and worldwide medical organizations offers a brilliant stage for experts trying to leave an imprint in clinical examination.

At Clinfinite Solutions, we perceive the potential and interest of talented people in the field of clinical exploration. With the rising spotlight on drug advancement, clinical preliminaries, and administrative consistency, the degree of clinical research jobs in Hyderabad has extended fundamentally. Experts in this field assume a fundamental part in guaranteeing the well-being and viability of medications, clinical gadgets, and restorative medications.

From clinical examination partners (CRAs) to preliminary facilitators and information experts, Hyderabad gives assorted vocations amazing open doors in this always developing industry. Organizations are effectively looking for competitors with project skill executives, patient enrollment, administrative rules, and preliminary checking.

Clinfinite Solutions is devoted to supporting hopeful competitors by offering to prepare projects and industry associations to assist them succeed in clinical research jobs in Hyderabad. Whether you are a new alumni or an accomplished proficient, our group guides you to foster the abilities vital for a fruitful profession in clinical examination.

Why Choose Hyderabad?

Hyderabad's rich mix of best-in-class research offices, first-rate instructive foundations, and a dynamic medical care scene makes it an optimal spot to fill in the clinical examination space. The city is home to driving Agreement Exploration Associations (CROs) and worldwide drug organizations, extending to adequate open positions.

Conclusion

For those enthusiastic about propelling clinical science and patient consideration, clinical research jobs in Hyderabad are a promising road. Clinfinite Solutions is here to help you in building a satisfying vocation in this powerful field. Remain associated with us for vocation open doors, direction, and updates on the clinical examination industry.

Embrace your true capacity and add to historic clinical headways with clinical research jobs in Hyderabad!

0 notes

Text

Explore Meril Life Sciences’ journey of innovation and global impact on their official Wikipedia page. Watch the video to learn more about their advanced medical solutions.

#meril life science#meril life#meril wikipedia#medical device#medical device manufacturer#medical technology#medtech#wikipedia

0 notes

Text

Surgical Meshes – Key factors to consider for choosing a Medtech provider

In the fast-paced world of medical technology, surgical meshes feature as a very significant aspect in improving the outcomes for patients undergoing surgery. Among other applications, such as hernia repair and pelvic organ prolapse surgery, surgical meshes support tissues to heal and continue intact structurally.

#Medical Device manufacturing#Top MedTech Companies#A global leader in MedTech#healthcare solutions worldwide#Surgical kits

0 notes

Text

#Medical Device Manufacturing Outsourcing Market#Medical Device Manufacturing#medical device#manufacturing

0 notes

Text

Medical Device Back-up Power Systems | BPE

Experience the power of reliability with ourmedical device back-up power. Engineered to meet the demands of medical environments, our BPE solution is a dependable source of power during emergencies. Keep critical equipment operational and safeguard patient well-being with our efficient and high-quality product.

Click here- https://bpee.com/

#Medical Device Back-up Power Systems#best online ups brands in india#best ups manufacturers company in india#best ups manufacturers india#buy ups online for home#smart power backup for hospitals#buy ups online for office#smart power backup for office#ups for home & office electronics#ups power supply for home#best online ups manufacturers in india

0 notes

Text

CDSCO Registration: Ensuring Quality in Healthcare Trade

Understand the importance of CDSCO registration for drugs, medical devices, and cosmetics. Enhance your business with global compliance and quality assurance.

#medical device registration#cdsco registration#cdsco import license#cosmetic manufacturing license#cosmetics import license

0 notes

Text

Best Medical Equipment and Hospital Mattresses Supplier in Texas - dme supply usa-Telemade

Telemade: Your trusted supplier of the best medical equipment and hospital mattresses and dme suppy usa in Texas. Quality products and reliable service for all your healthcare needs.

#dme supply usa#medical equipment manufacturers usa#hospital medical equipment suppliers texas#medical equipment supplies texas#medical equipment & supplies texas#medical device manufacturing near me#medical lifting equipment texas

0 notes