#Mechanical Piping Shop Drawing

Explore tagged Tumblr posts

Text

Piping Shop Drawing Services

Silicon EC UK Limited offers comprehensive Piping Shop Drawing Services in London, UK, catering to a diverse range of industries including construction, manufacturing, and engineering. Our expert team of drafters and engineers is proficient in utilizing the latest software and technologies to create precise and detailed shop drawings for piping systems. Our goal is to deliver high-quality shop drawings that streamline the fabrication and installation process, saving both time and money for our clients.

Explore the Blog:

What are the types of Plumbing Piping Drawing Services?

Blog:

You can check our official website for the latest details, Plumbing Piping Engineering Services offered, and any client testimonials or case studies.

We are a Plumbing Piping Engineering Company that presents Piping Shop Drawing Services London and other cities covering Liverpool, Manchester, York, Leeds-Bradford, Glasgow, Newcastle, Sheffield, and Sunderland.

By choosing Silicon EC UK Limited for your piping shop drawing needs, you can expect professionalism, reliability, and exceptional engineering service. We pride ourselves on delivering accurate CAD Shop Drawings on time and within budget, helping our clients achieve their project goals efficiently. Contact Silicon EC UK Limited today to learn more about our Piping Shop Drawing Services and how we can assist you with your next project in London, UK.

For More Details Visit our Website:

#Piping Shop Drawing Services#Plumbing and Piping Shop Drawing Services#Piping Shop Drawing#Mechanical Piping Drawing#Piping layout Drawing#Piping Layout Drawing Services#Mechanical Piping Shop Drawing#Plumbing and Piping Shop Drawing#Piping System Shop Drawing#Engineering Company#Piping Shop Drawing Company#Piping CAD Design Services#Piping Shop drawing Firm#CAD Design#CAD Drafting#CAD Drawing

1 note

·

View note

Text

major ashley banks.

#morefuckedthanyouthink.

NICKNAMES: banks, banksy, maj, officer, captain AGE: 24 DOB: june 1st. GENDER: male PRONOUNS: he/him JOB: ""officially"" major is working as a mechanic at a shop in the kitchen called 'greasemonkey,' but it's more accurately described as ""stealing and stripping cars from all over new zeppelin."" it's probably one of the most dangerous jobs he's had yet - maybe - but it's certainly paid the most! and with a toddler running around, and a baby mama who needs the cash, he's figured it's all worth the trouble it might bring.

personality:

+TRAITS: resilient, loyal, creative, caring deep down -TRAITS: bitter, irresponsible, rebellious, insecure, impulsive FEARS: disappointing his kid, losing tessa to his own dumb bullshit, never making anything of himself, nightmares about his mom dying, seeing his dad again, panic attacks and shit HOBBIES: playing his bass, tagging, spray painting, general jackassery, partying with the boys, sitting in on any recording sessions he can snake his way into HABITS: fidgeting his hands, drawing on shit, sitting a little too close, talking too loud, partying too much

the good(ish):

major is a sweet boy underneath it all, he just has a hard time showing it. once he gets to know someone, he's very giving in emotional support. he shows up when one of his people needs him, sometimes even to his detriment... especially when he's stepping in with people who might not be very good for him, but he's never been so good at filtering his own company.

maybe Leninist Pope - his band - hitting it big is a pipe dream, but when it comes down to it, major is talented. he's a killer on the bass, he can sing enough to run back up, and he can fake his way through a guitar melody like a true musician. he might be able to get paid for it if he could focus a little harder... but who knows if he'll step into line.

major really does love kids, and he knows it stems directly from the lack of parental love he suffered through in his own life. he loves his own kid, even if it's hard to show it sometime. he looks out for a lot of the kids on the block he grew up on. he doesn't really have the brains to help anyone study, and he can't exactly float the hungry ones money anymore when he has his own kid to feed, but he at least tries to make sure that the little weirdos have somebody to watch their back.

the bad:

although the birth of his and tessa's baby was sort of an unpleasant shock, major genuinely does love the time he spends with the kid, and he really does love tess. she's always been his sweetheart: the mere thought of her has gotten him out of some rough scrapes at rock bottom. when taking care of their kid tests him, though, he's failing more often than not - even when he tries. it makes him feel like some deadbeat dad; or maybe a little too much like his own deadbeat dad. sometimes he thinks they might be better off if he just left them alone, but if that's what he thinks, then he's too selfish to do what's right.

major has always had the wrong friends. he's gotten himself into fights, and thrown into cuffs more than a few times. there's been a stint in juvie or two. when he had his kid he made a promise that he'd leave it behind, but his promise that he'd get tessa cash when she needed it outweighed the first one. stealing cars wasn't his usual groove, and sometimes it scares the shit out of him - but until he figures something else out that's a little more above board, he considers himself stuck in the game.

the ugly:

in the most simple of terms, major is short for 'major mommy and daddy issues.' his mother was murdered by his father when he was twelve years old, and though he always saw it ending that way, nothing could have prepared him for the reality of the situation. he was bounced around in group homes and foster homes for a few years after it all went down, but he landed himself in a pretty good spot sometime in high school. they're his family now, and they love him, but he'll probably stay their problem kid - guess the shit he learned in the system was unshakeable.

2 notes

·

View notes

Text

Importance of MEP Shop Drawings for Construction Project Success

MEP shop drawings are a critical stage in the construction cycle, without which the establishment cycle can bring about tumult. Shop drawings are itemized specialized delineations that give data on how different hardware will be obtained and establishment will be executed in a venture.

MEP shop drawings incorporate basic data concerning gear, materials, and establishment methods that are pivotal to the design and construction process. Shop drawings assist with improving coordination among workers for hire and task partners to guarantee that the undertaking is developed according to the concurred determinations.

MEP shop drawings ordinarily take one of two structures. One is the gear and material shop drawing submittals, which are shipped off the determining proficient to guarantee that the hardware and materials expected to be bought are in consistence with the design goal for the task. The second is the establishment shop drawings, which are utilized by the overall project worker and all subcontractors to guarantee coordination of the establishment with an end goal to stay away from surprising contentions in the field. The two kinds of shop drawings are essential to guaranteeing a smooth and effective establishment.

Thusly, it's fundamental for those associated with the construction to completely comprehend shop drawings and how they can be utilized to guarantee that construction projects are finished properly.

Why Are They Important?

MEP shop drawings assume an essential part in the design and construction of structures. These records represent all the mechanical, electrical, and plumbing parts like gear, installations, pipes, ventilation work, electrical boards, and that's just the beginning. They act as an aide for project workers, permitting them to envision and comprehend how the various frameworks will meet up in the eventual outcome. With shop drawings, potential issues can be distinguished and tended to before construction even starts, forestalling expensive postponements and adjust.

They additionally guarantee that the end result meets building regulations and guidelines, as well as the purpose of the design. Thusly, shop drawings are an important part of any construction project and ought to be offered the consideration and assets they merit. In spite of their significance, project groups frequently attempt to sidestep the shop drawing process in light of a legitimate concern for time or cash; nonetheless, that is a bogus economy that frequently prompts delays and inflated costs during construction.

What Are the Advantages of Requiring MEP Shop Drawings on Your Project?

The essential benefit of MEP shop drawings is that they guarantee lucidity and exactness in choice of gear and materials and the format of the frameworks in the field. Shop drawings give point by point data about the different MEP frameworks, including execution attributes, actual aspects, and nature of materials.

This data empowers partners to survey and endorse these subtleties before construction starts, guaranteeing that their construction task's ultimate result is precise and meets the client's necessities.

Shop drawings likewise assist with distinguishing possible blunders or clashes and permits partners to address them immediately, diminishing construction postponements and expenses. In the event that there are confuses between disciplines in models, like electrical prerequisites or association areas, the crisscrosses can be recognized and rectified before they become expensive mix-ups in the field.

Shop drawings assist with decreasing the possibilities of improve, guarantee that the undertaking particulars are met, and keep away from expensive slip-ups. In the event that these issues are distinguished during the construction cycle, they can fundamentally increment construction expenses and push back project cutoff times.

MEP shop drawings are included all venture subtleties and give a recorded portrayal of the MEP frameworks that will really be introduced. Subsequently, project supervisors get a reasonable and extensive comprehension of the venture's prerequisites and guarantee that the construction cycle is executed as needs be. Sequencing of the work and planning of the exchanges becomes more clear as the shop drawings are created.

Moreover, the shop drawings reflect changes made all through the survey cycle, making it simpler to monitor project progress.

MEP shop drawings assume a pivotal part in limiting construction costs. Imagining a construction project before the construction stage starts permits partners to recognize regions where they can decrease material expenses, work costs, as well as time.

This, thus, limits the undertaking costs, which is a success for every one of the gatherings engaged with the task.

MEP shop drawings give significant records of the gear, materials, and formats laid out during construction. These records are commonly given to the proprietor's offices supervisory group during project closeout, called "Closeout Archives". This data is utilized to keep up with the hardware, find parts or administration contracts, and for investigating issues not too far off.

0 notes

Text

Processing of Molybdenum metal

Molybdenum is a refractory metal with the symbol Mo and atomic number 42. It is most commonly used as a high temperature, corrosion resistant metal alloy in steel, cast iron and super alloys for the military and defense industry, semiconductor industry and specialty machine shops.

Molybdenum metal products are available in plate, sheet, strip & foil, bar, rod, tube, wire and customized parts. The metal is silvery white, very hard transition metal, but is softer and more ductile than tungsten. It is easier to be rolled in to thinner sheets and have a wider dimension limits than tungsten. It is also easier to machine molybdenum into complex parts than tungsten, that means molybdenum can be made into more precise & smaller parts. Even though, the machining process is similar.

Here we will introduce the machining process for molybdenum rod and bar roughly. After sintering, the molybdenum blank will be forged, to make it with higher density and better mechanical properties.

Process for molybdenum rod from blank: Spin forging and drawing several times a suitable ingot, repeated annealing is necessary during the several times of drawing. Mold is engaged in the process in order to draw to desired diameter. Remove the oxide surface, graphite is used as lubricant, this step will also remove it from the surface of rod. Regular surface treatment is grinding or finish turning. Process for molybdenum rectangular bar or square bar: 1. Forging, annealing and mold are engaged in this process. 2.Remove the oxide and grinding the surface. The narrow faces can only be turning instead of grinding. The other way to produce molybdenum bar is cut form plate, next article we will talk about process for rolling molybdenum products. The method depends on the specific dimensions of the bar. If it is thin and narrow, it will be from molybdenum plate.

Process of molybdenum tube: Small tubes (roughly with diameter <100mm) are drilled from rods, larger tubes is made by sintering directly. Will need to make mold first if the tubes are large, you can choose a more economical way to make a molybdenum tube with a critical outer diameter. Drilling from rods will waster some materials, while sintering needs a tool. We now have the capacity of providing moly tubing with length up to 2.7m.

If the complex parts are made from bar, and rod and other machining processes such as: laser cut, water jet cut, drilling, turning, wire cutting, etc. will be chosen according to drawing and process technology.

As you can see, the processes are similar with tungsten machining, but requires different tools, feed speed, and annealing process. The accuracy of the work-pieces presented is also different.

Pure molybdenum has better ductility than tungsten, while tungsten alloys (WNiFe, WNiCu) have better machining performance than molybdenum alloys (Mo-La alloy, TZM Alloy, especially TZM alloy). We will introduce this in future articles.

0 notes

Text

INDICATORS ON INSTRUMENTATION TUBES MANUFACTURER YOU SHOULD KNOW

SEAMLESS INSTRUMENTATION TUBES, HYDRAULIC TUBE AND MECHANICAL TUBE

Instrumentation Tubes are widely used for hydraulic & pneumatic control system, Fuel supply lines, Pressure sensors lines for automotive industry for onshore control panels, Topside processing facilities and subsea manifolds in Oil and Gas industry, High purity tubes for semiconductors industry, Fuel rods, Control tubes for advanced engineering, Cooling circuits, Brake cylinders for automotive industry.

We at Krystal Global Engineering Limited, provide a Variety of Seamless Instrumentation Tubes, Hydraulic Tube and Mechanical Tube including Austenitic, Ferritic, Martensitic, Duplex, Super Duplex & Nickel Alloys.

Cross-roll piercing ranks as the main piercing process for stainless steel seamless tubes and offers sizeable advantages when compared to alternative solutions like piercing presses or push-piercing mills. As a part of the rolling method, a mandrel bar is inserted in to the hollow – with the traditional Assel procedure it can be free-jogging, and with high-effectiveness Assel mills it can be moved in a very controlled fashion. Our items are exported to over 70 nations the world over, when in India We've got supplies to even the distant parts. With in excess of 250 tons of manufacturer of Instrumentation tube & pipe and Stainless Steel seamless pipes on a daily basis, Metallica has emerged as being a popular vendor For lots of prospective buyers in India and Abroad. SMS team has further more made the push bench course of action into CPE (Cross-roll Piercing and Elongation) and TPE (3-roll Piercing and Elongation). What this means is thee merchandise array is has therefore been extended in comparison with earlier concepts and also the procedures present sizeable benefits regarding both high-quality and price efficiency. Spot- Strategically located in the DFW place, NTP is centrally positioned throughout the US transport community, minimizing shipping situations and giving usage of a wide array of supplies normally available when the following day. In light-weight of weather modify, making CO2-neutral electric Electricity from sunlight has become additional vital. voestalpine supports this expansion with optimally processed supplies and progressive Thoughts. Editor's note: This informative article was originally revealed in May of 2020. It's been current to incorporate new studies and traits from the industry. From packaging insert trays to industrial delivery and material managing trays, our style and design workforce can get the job done with you to acquire modern options for just about any within your packaging or sections Group requirements. A crucial element of SMS team’s warm pilger mills is the large dimensional choice of rollable inventory – even for top-alloy steel grades. To learn more about ways to use Industry Select to produce trusted potential customers for your company, Check out a free Dem! Salem Tube’s solutions (Krystal Global Engineering Limited. Mumbai) are employed in a variety of applications and precision products – in seamless or welded & redrawn type, and straight lengths (nearly seventy two ft) or coils. Becoming among the most important specialized enterprises in Europe for manufacturer of stainless steel tubes and pipes, the manufacturing facility of CENTRAVIS Generation UKRAINE PJSC incorporates the recent-extrusion and chilly-drawing shops, which right until 2000 had been services of the Nikopol Yuzhnotrubny Plant (NYTP), previously most significant industrial complicated for manufacturer of stainless tubes and pipes. SMS group has consistently even further created this technologies and thus managed to double the utmost producible tube diameter. Today, tubes with an outside diameter of up to 460 mm and wall thicknesses of approximately 80 mm can be developed on assel mills. Our ground breaking design and engineering encounter enables us to manufacture normal and custom made steel tubing designs on your application requirements.

To Know more about:

#instrumentation tubes#stainless instrumentation tubes#seamless instrumentation tubes#stainless steel instrumentation tubes#seamless steel instrumentation tubes#top instrumentation tubes#best instrumentation tubes#top instrumentation tubes in Mumbai#best instrumentation tubes in Mumbai#top manufacturer of instrumentation tubes in Mumbai#best manufacturer of instrumentation tubes in Mumbai#hydraulic tubes#stainless hydraulic tubes#seamless hydraulic tubes#best hydraulic tubes#top hydraulic tubes#top manufacturer of hydraulic tubes#best manufacturer of hydraulic tubes in Mumbai#top exporter of hydraulic tubes in Mumbai#best exporter of hydraulic tubes in Mumbai

0 notes

Text

Types of Drawings Used in Design & Construction

Floor Plan Drawings: Illustrate the layout of rooms, walls, and features within a building.

Elevation Drawings: Provide a frontal view of a building's exterior, showing architectural details and proportions.

Section Drawings: Offer a vertical cut-through view of a building, revealing internal structure and components.

Site Plan Drawings: Depict the layout of a building or development within its surroundings, including land features and utilities.

Detail Drawings: Focus on specific components or assemblies within a building, showcasing construction methods and materials.

Perspective Drawings: Present a three-dimensional view of a building or space from a particular vantage point, enhancing visual communication.

Isometric Drawings: Display three-dimensional objects in a single view, emphasizing spatial relationships and proportions.

Sketches and Conceptual Drawings: Capture initial design ideas and concepts, exploring creative possibilities.

Working Drawings: Provide detailed information for construction, including dimensions, materials, and assembly instructions.

As-Built Drawings: Document the final built structure, incorporating any changes made during construction.

Presentation Drawings: Communicate design concepts and proposals to clients and stakeholders, often emphasizing aesthetics and visual appeal.

Technical Drawings: Convey precise measurements, specifications, and engineering details for manufacturing or construction.

CAD (Computer-Aided Design) Drawings: Utilize software to create accurate and detailed digital representations of architectural designs.

Structural Drawings: Focus on the structural elements of a building, including beams, columns, and foundations.

Architectural Drawings: Encompass various drawings related to architectural design, including plans, elevations, and details.

Mechanical Drawings: Detail mechanical systems and components within a building, such as HVAC and plumbing.

Electrical Drawings: Specify electrical systems, wiring diagrams, and equipment locations.

Plumbing Drawings: Outline plumbing systems, fixtures, and piping layouts within a building.

Landscape Drawings: Design outdoor spaces, including gardens, paths, and plantings, to complement the built environment.

Interior Design Drawings: Plan interior spaces, selecting finishes, furniture, and decorative elements.

Foundation Drawings: Detail the design and construction of building foundations, including footings and slabs.

Reinforcement Drawings: Specify the placement and configuration of reinforcing steel within concrete structures.

Roof Plan Drawings: Show the layout of roof elements, including slopes, ridges, and drainage systems.

Detailing Drawings: Provide enlarged views and annotations for intricate design or construction elements.

Schematic Drawings: Present simplified representations of systems or components, focusing on key connections and relationships.

Shop Drawings: Detail prefabricated components or custom-made items, including dimensions and material specifications.

Fabrication Drawings: Provide instructions for manufacturing components, including machining and assembly details.

Installation Drawings: Guide the installation of equipment or systems within a building, ensuring proper placement and alignment.

Network Drawings: Diagram the layout and connections of computer or communication networks, including cables and devices.

Piping and Instrumentation Drawings (P&ID): Illustrate process piping, instrumentation, and control systems within industrial facilities.

Control System Drawings: Specify the layout and components of control systems, including panels, sensors, and actuators.

HVAC (Heating, Ventilation, and Air Conditioning) Drawings: Design and layout HVAC systems, including ductwork, vents, and equipment.

Fire Protection Drawings: Outline fire suppression and detection systems, including sprinklers, alarms, and exits.

Security System Drawings: Specify the layout and components of security systems, including cameras, sensors, and access control.

Communication System Drawings: Design and document communication infrastructure, including cables, outlets, and equipment.

Lighting Drawings: Plan the placement and type of lighting fixtures within a building, including switches and controls.

Furniture Drawings: Specify the selection and arrangement of furniture within interior spaces, considering functionality and aesthetics.

Fixture Drawings: Detail built-in fixtures, such as sinks, cabinets, and shelving, within a building.

Casework Drawings: Specify the design and construction of custom-built cabinets, counters, and storage units.

Millwork Drawings: Detail architectural woodwork, including doors, moldings, and paneling, to enhance interior spaces.

Equipment Layout Drawings: Plan the placement and arrangement of equipment within industrial or commercial facilities, optimizing workflow and efficiency.

Demolition Drawings: Outline the removal and dismantling of existing structures or components, ensuring safety and efficiency during demolition processes.

These drawings serve as essential tools for architects, engineers, designers, contractors, and other stakeholders involved in the design and construction process, facilitating communication, coordination, and implementation of projects.United-BIM Inc. is a certified SBE/MBE BIM Modeling Services Company based in East Hartford, Connecticut. Our services include BIM Architectural Modeling, Architectural Drafting Services, 3D Rendering Services Structural Modeling and Detailing (Rebar, Precast, others), MEP-FP Modeling and Detailing, BIM Coordination & Clash Detection Services, Revit Family Creation Services, Underground Utility Locating Services, On-site & off-site Coordination Services, Onsite & virtual meetings participation, Point Cloud Scan to BIM, CAD to BIM Services, BIM for Facility Management, Accurate Shop Drawings Creation, As-built Drawings Services, Electrical Design Services & more.

0 notes

Text

15 Questions for 15 Friends

Very bold of @pikapeppa for tagging me and assuming I have 15 friends lmao. But if my Facebook Notes archive (which will forever remain buried) is any indication, I'm a sucker for a good get-to-know-you questionnaire.

Are you named after anyone?

Yes, Casey Kasem. My Filipina mother spent a tooooon of time listening to the radio when she first got to the States, and she liked his radio show and his name, so she decided to remix the spelling and boom, you get Caycee.

When was the last time you cried?

Two weeks ago, because I was deep in a depressie wave about being a considered a failure. For the record, I know that I'm not a failure whatsoever, but we're always our harshest critics, and sometimes the voices in my head win for a minute or two.

Do you have kids?

Sure don't, and I don't plan to. I'm planting roots in the Cool Aunt category for my family.

What sports do you/have you played?

If avoiding organized sports as a child and walking/hiking when the mood strikes counts as a sport, that's what it'd be.

Do you use sarcasm?

Not even a little bit.

What is the first thing you notice about people?

It depends on the nature of us meeting. If I'm people watching, I notice clothes/style first, then start analyzing the rest of them. If I'm meeting a date for the first time, it's: smile, eyes, hair, shoulders/arms/hands, then teeth.

What’s your eye colour?

Brown, of the russet variety

Scary movies or happy endings?

Happy endings, but I do enjoy a good scary movie so long it's more of a psychological thriller than a gore-fest (unless said gore-fest is part of a well-written story, then I can get behind it).

Any talents?

Rusty viola skills, some vocal talent, minimal drawing skills, attentive listening, and writing.

Where were you born?

Ohio, though I am thankfully no longer condemned to living in the Midwest.

What are your hobbies?

Collecting hobbies is my hobby: Crochet; Writing; Reading; Paper crafts (making wedding invites for friends, gift tags, greeting cards); Building mechanical keyboards; Painting; Baking (minimally, it's dangerous to bake as a single person living alone); Bookbinding

Do you have any pets?

Two little kitty-ladies (9 months old): Athena and Artemis, also called Bean and Squeaks, respectively.

How tall are you?

I'm 5'8" but have consistently been told that I am taller than people expect when they first meet me. Apparently, my bubbly personality translates to being no taller than 5'4".

Favourite subject in school?

English Lit and History

Dream job?

It changes from day to day, mood to mood. Right now, I'd love to own a cute lil' bookshop with an attached coffee shop/plant shop. It's a pipe-dream my sisters and I entertain when we're all fed up with our respective careers lol.

Now, passing this joy along to @juststrawberrytea, @q-the-rockaholic, @grilledsquids, @kiiyokusaa, @katyblack01, @chacha-rae, @chibi-yuki

1 note

·

View note

Text

Step by Step Guide for HVAC Duct Shop Drawings

A Heating, Ventilation, and Air Conditioning system, or HVAC system as commonly addressed, is a multiple-system combination used for the air circulation between indoor and outdoor areas. Several technicians and engineers now refer to an HVAC floor plan and discuss it with the project architect to ensure the efficient working of all systems. The HVAC Duct shop drawings are the blueprints that have drastically transformed the landscape of heating, ventilation, and air conditioning systems.

What are HVAC Duct Shop Drawings?

HVAC shop drawings are detailed technical drawings providing an extensive depiction of HVAC systems within a building. The drawings provide information on how the duct has to be routed, and the location of duct accessories like duct fire dampers, VAV boxes, Volume control dampers, and others.

Benefits of HVAC Duct Shop Drawings

HVAC Duct shop drawings offer multiple benefits to the stakeholders and uplift the design and construction work quality. Here are a few of its benefits:

Streamlined Installations

HVAC Shop drawings provide a visual roadmap to the contractors and fabricators, enabling them to work with confidence and surety.

Coordination and Collaboration

HVAC Shop drawings facilitate a smooth collaboration between different trades involved in a project. These drawings ensure seamless integration with other systems like electrical, plumbing, and mechanical.

Enhanced Accuracy

The scope of making choices based on probability or guesswork is eliminated with HVAC duct shop drawings. These drawings enlist precise dimensions, duct layouts, equipment specifications, pipe routing, and electrical connections.

The detailed and precise specifications ensure that every element fits flawlessly where it belongs and devise accurate onsite execution. Read more : HVAC Duct Shop Drawing

1 note

·

View note

Text

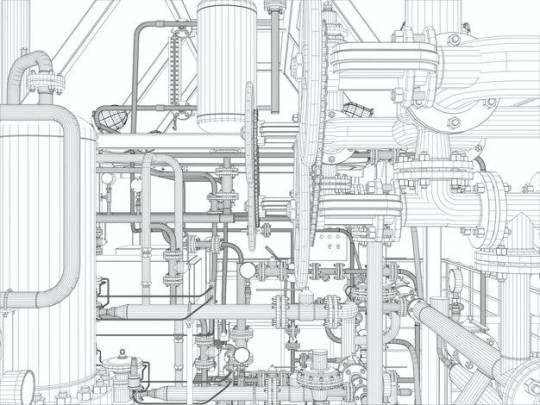

HVAC Mechanical Piping Shop Drawings We are experts in deciding placements that cover less area and give up space for other equipment. We make efficient use of software and make the document drawings as easy as possible to understand. Know More: https://theparadigmengineering.com/hvac-mechanical-piping-shop-drawings/

HVAC #PipeShopDrawing #Paradigm #AutoCAD #Revit #Sitevisits#Leadcoordinationservices #Fieldmeasurements #Floorplans #Floorplanrevision# Asbuilt #RecordDrawings #PipingIsometrics #ProcessPiping #SteamPiping #BoilerPiping

0 notes

Text

Top MEP Services in the United Kingdom at a very low cost

Silicon EC UK Limited stands as a beacon of excellence in the realm of MEP Services, providing comprehensive solutions that set new standards in the United Kingdom. With a commitment to quality, innovation, and sustainability, we are your trusted partner for all MEP requirements. Our MEP solutions are CAD Designed to optimize energy efficiency, reduce operational costs, and enhance overall building performance. Our Engineering team of seasoned professionals brings a wealth of experience and expertise to every project. Our team of highly skilled MEP engineers and technicians bring extensive expertise to every project, ensuring precision and reliability in our MEP Engineering Services.

Silicon EC UK Limited is your reliable partner for MEP Engineering Services in the United Kingdom. Contact us today to discuss how we can contribute to the success of your project and elevate the performance of your mechanical, electrical, and plumbing systems.

For More Details Visit Our Website:

#MEP Engineering Services#MEP Shop Drawing Services#MEP CAD Design Services#MEP Engineering Company#MEP CAD Drafting Services#MEP CAD Drawing Services#Mechanical Engineering Services#Electrical Engineering Services#Plumbing Piping Engineering Services#MEP Services#Engineering Services#Silicon EC UK Limited#CAD Design#CAD Drafting#CAD Drawing#CAD#CADD#CAD Outsourcing#Shop Drawing Services#MEP Services UK#MEP Engineering Services UK#MEP CAD Design Services UK#MEP CAD Design Services London#MEP Services London#MEP Engineering Services London#MEP Engineering Company London#MEP Engineering Firm UK

0 notes

Text

Explore Emerging Technologies and Innovation in Shop Drawing Services

The field of architectural and engineering design is evolving rapidly, shaped by technological advancements and innovative approaches. Shop Drawing Services, a critical component in turning design concepts into reality, are at the heart of this transformation. This article looks into how emerging technologies and creative methodologies are reinventing shop drawing services, offering a peek into the future of this dynamic domain.

1. Diverse Applications of Shop Drawing Services

Shop drawing services are integral to a wide array of projects in the construction and design industry, highlighting their versatility and indispensability. These services are not limited to any single aspect of construction but span across various facets:

Complex Architectural Structures: In the construction of sophisticated architectural marvels such as towering skyscrapers, expansive bridges, and iconic monuments, shop drawings serve as the blueprint that guides the entire building process. These drawings translate intricate designs into detailed instructions, ensuring that every structural element and architectural detail is precisely represented and can be constructed as envisioned.

Custom Fabrications: The world of custom fabrications relies heavily on the accuracy and detail provided by shop drawings. Whether it’s creating unique furniture pieces tailored to specific spatial requirements, developing custom parts for machinery, or crafting bespoke architectural elements, shop drawings ensure that each piece is made to exact specifications, fitting seamlessly into its intended environment.

Renovation and Restoration Projects: Shop drawings are particularly crucial in renovation and restoration projects. They provide a detailed representation of existing structures and how they will integrate with new additions or modifications. These drawings help maintain the historical accuracy and architectural integrity of buildings while incorporating modern features or repairs, striking a balance between preserving the past and embracing the present.

2. Comprehensive Coverage Beyond Steel

Shop drawing services extend well beyond the realm of steel construction, encompassing a variety of disciplines and materials:

Mechanical, Electrical, and Plumbing (MEP) Drawings: These are essential for the meticulous planning, installation, and maintenance of MEP systems in buildings. Shop drawings for MEP services detail the layout and routing of pipes, ducts, and wiring, ensuring they are efficiently integrated into the overall building design while meeting all operational and regulatory requirements.

Concrete and Masonry Work: Shop drawings for concrete and masonry work provide critical information about the dimensions, reinforcement details, mixing specifications, and placement strategies. These drawings are key to ensuring structural integrity and adherence to design specifications, particularly in load-bearing elements of a building.

Interdisciplinary Coordination: In multi-disciplinary construction projects, shop drawings are vital for the coordination of various trades. They help in identifying and resolving potential conflicts between different elements of the building, such as structural components, electrical wiring, and plumbing systems, ensuring a smooth construction process.

3. The Role of Steel Shop Drawings Services in Construction

Steel shop drawings hold a pivotal role in the construction sector, particularly in projects involving steel structures. These detailed drawings are more than mere guides; they are the blueprint that ensures precision in every phase of construction:

Detailed Fabrication Drawings: Steel shop drawings provide exhaustive details about the fabrication of steel components. They encompass specifications on dimensions, materials, fabrication processes, and the precise assembly of parts. These drawings are crucial for fabricators, as they contain all the necessary information to cut, assemble, and weld steel components accurately.

Installation and Assembly Guides: Beyond the fabrication phase, steel shop drawings are invaluable for on-site installation and assembly. They offer clear guidelines on how each steel component fits into the overall structure, ensuring seamless integration and structural integrity. This aspect is particularly important for complex constructions where precision is paramount to the safety and longevity of the structure.

Quality Control and Compliance: Ensuring compliance with industry standards and building codes is a critical aspect of steel shop drawings. These drawings must adhere to various regulations and quality benchmarks, ensuring that every component meets the required safety and performance standards. This adherence is vital not only for the legality of the construction process but also for ensuring the long-term durability and safety of the structure.

Coordination with Other Trades: Steel shop drawing services also play a key role in coordinating efforts among different construction trades. In projects involving multiple disciplines, such as electrical, plumbing, or HVAC systems, steel shop drawings help in planning and executing the integration of these systems with the steel framework, avoiding conflicts and ensuring a smooth construction process.

4. Exploring the Variety of Shop Drawing Disciplines

Shop drawing services encompass a wide array of disciplines, each with its unique requirements and challenges. Understanding this variety is crucial in appreciating the full scope of these services:

Interior Design and Woodwork: Shop drawings in interior design and woodwork play a pivotal role in bringing creative visions to life. They provide detailed guidance for custom cabinetry, furniture, and unique interior fixtures. These drawings must account for aesthetic appeal, material specifications, and precise dimensions, ensuring that each piece fits perfectly within the designated space.

Exterior Cladding and Façade Detailing: For the exterior of buildings, shop drawings are essential in detailing cladding systems, façade elements, and other architectural features. These drawings help in visualizing the final appearance of a building and ensure that all external elements are structurally sound, weather-resistant, and aesthetically pleasing. They also play a critical role in ensuring that the installation process is efficient and meets all safety standards.

Landscape and Site Planning: In landscape design and site development, shop drawings provide a detailed layout of outdoor spaces, including the positioning of plants, pathways, water features, and other landscape elements. These drawings ensure that the outdoor aesthetics align with the overall architectural design and that practical aspects such as drainage and accessibility are adequately addressed.

5. The Human Element in Shop Drawing Services

The human element remains at the core of shop drawing services, underscoring the importance of expertise and experience:

Expertise and Experience: Despite advancements in technology, the expertise and experience of professionals in creating and interpreting shop drawings are indispensable. Their ability to understand complex designs, foresee potential issues, and provide practical solutions is critical in ensuring the success of a project.

Collaboration and Communication: Effective collaboration and communication among architects, engineers, contractors, and other stakeholders are essential in the shop drawing process. This human interaction ensures that all parties have a clear understanding of the project requirements and that any issues are promptly addressed.

Conclusion: Your Vision, Our Execution – Experience the SmartCADD Edge

At SmartCADD, we recognize that your project is an embodiment of your vision. We are dedicated to providing bespoke solutions across a spectrum of architectural endeavors. As your collaborative partners, we are committed to guiding you through each project phase, aligning our expertise with your aspirations. Choose SmartCADD for a partnership rooted in a shared commitment to excellence and innovation. Contact us to start shaping your architectural masterpiece with unmatched precision and expertise.

Source URL:

0 notes

Text

How MEP BIM Coordination Helps in the Construction Process

MEP drawings are a sort of structural designing that focuses on the security, usefulness, and energy productivity of designs in the development business. Mechanical, electrical, and plumbing (MEP) frameworks are the foundation of building projects. MEP's Mechanical segment centers around warming, ventilation, and cooling (central air) frameworks, while the Electrical segment manages power supply and the Pipes segment with a water supply and wastewater surge. These plans are for the most part made with Revit MEP, AutoCAD, CADDUCT, Autodesk Creator, and computer aided design Line.

MEP Coordination in the Construction Process

Before the essential structure process starts, MEP Coordination is a technique for recognizing and settling questions across different callings, for example, design, plumbing, electrical, mechanical, and underlying parts. There ought to be coordination for each discipline, incorporating the progressions coming in, to bring these assorted plans into concordance. Subsequently, MEP BIM Coordination Administrations is a strategy for teaming up three essential plan verticals, in particular engineering, primary, and MEP plans of any foundation, and consequently becomes one of the survey cycle's prerequisites. Plan, development, and activity and upkeep space mastery are undeniably expected for MEP coordination.

How does BIM help with MEP Coordination?

MEP Coordination capabilities by synchronizing all the development work with different disciplines that make up the design, texture, and outside envelope of the construction. Inside the endorsed, underlying, and design limits, building administrations coordination dispenses vertical and flat positions to explicit framework parts. Following that, the coordination specialists attempt coordination that spotlights on very jam-packed locales to try not to assemble framework impedances. This building administration coordination, which happens all through the plan creation and survey process, addresses the underlying stage in building project coordination. These struggles or obstruction should be recognized from the get-go in the structure cycle since slip-ups and overt repetitiveness can cost 1,000,000 bucks in the event that not got adequately early.

Why is it Important to Manage your MEP Coordination Effectively?

We center around furnishing conflict free BIM models alongside co-ordinated MEP establishment drawings, MEP-FS creation drawings, MEP-FS development drawings, MEP-FS co-appointments, MEP-FS shop drawings, as-fabricated drawings, spool drawings, Engineering configuration archives, façade drawings, and that's just the beginning, on account of the solid aptitude of our group in BIM Coordination contributions. We utilize 3D coordination administrations to give a result model that incorporates Compositional, Primary, and MEP BIM models, as well as conflict free development drawings sets.

The plan inputs are at first organized through the BIM model, as a BIM coordination business. Before any troubles are seen nearby, any plan clashes or disparities in the contributions from different partners are raised. From that point forward, conflict free development drawing sets are dealt with, bringing about a speedy time-bound execution. The BIM model is a unique instrument for organizing and identifying conflicts between components from many disciplines. We've chipped away at framework ventures and structures at all degrees of advancement (LOD).

What does an effective MEP coordinator look like?

The MEP sketch structure gives a visual portrayal of how the parts ought to be constructed and the way that they will work. They're regularly used in the structure business for trading thoughts. Master computer aided design plan and drafting organizations utilize known documentation techniques and units of estimation to make organizing drawings more reasonable and to diminish uncertainty. Nitty gritty MEP plans help in the development of ducting, plumbing, channeling, electrical conductors, and fire assurance pipes so that every framework's course doesn't slow down each other. The MEP drawing set for each building is exceptional, and it is made while the structure configuration papers are introduced.

0 notes

Text

What is the Specialty Associated with Plumbing HVAC Drawings?

A building construction remains incomplete without a proper plumbing system. That is why, after the blueprint of the building is done; high attention is paid to plumbing elements. Before the final construction starts, engineers refer to plumbing shop drawings.

It helps them to come across the pros and cons of every element that are going to be included. In case any type of defect is found, then it is repaired there itself.

Also Read : The Crucial Role of Coordination Drawings in Construction Projects

Does Plumbing Shop Drawings Help in Unnecessary Wastage of Money?

Demolishing the entire building after construction overall may result in unwanted losses. It may also take a toll on lives due to the accidental falling of waste. That is why, HVAC shop drawings are preferred exclusively by both architects before coming up with the final construction.

The drawings especially plumbing shop drawings are known for representing elements related to plumbing like:

• Piping system • Drainage system • Water carriers etc.

These drawings are known for specifying transport systems for fluid and air. The system is used for heating, cooling, removal of waste, and many more.

Shop drawings are popular for representing a set of special types of drawing that will provide exclusive details regarding construction like:

• MEP components • Structures • Architecture components and many more.

Why Refer to 2D HVAC Shop Drawings?

The 2D HVAC shop drawings represent detailed illustrations that reflect every component of the construction with technical details. Often these drawings are inclusive of detailed information about floor plans along with:

• Sizes for scaling • Schematic illustrations regarding the design • Sizes related to branch connections

Additionally, penetrated sketches are inclusive of structural openings that are coordinated with plumbing, mechanical and electrical equipment.

Also Read : A Comparison Between Plumbing And Coordination Drawings

Do MEP-Coordinated Diagrams Assure Getting the Best Output?

A building requires lots of systems to be installed. Referring to HVAC plumbing shop drawings will assure that the systems get placed at the right point. Exclusively coordinated drawings match almost every requirement of the system.

It also provides a crystal clear action plan for every contractor, thus preventing any type of problems. MEP drawings also referred to as HVAC shop drawings include drawn versions of the construction document.

From elevators to cabinets, you will get a crystal clear picture of every component to be included in the building.

Full Audio : Listen Here

Direction : Click Here

#coordination drawings#hvacshopdrawings#plumbing shop drawings#plumbing plan drawing#plumbing layout plan#plumbing mep drawings

0 notes

Text

INDICATORS ON INSTRUMENTATION TUBES MANUFACTURER YOU SHOULD KNOW

SEAMLESS INSTRUMENTATION TUBES, HYDRAULIC TUBE AND MECHANICAL TUBE

Instrumentation Tubes are widely used for hydraulic & pneumatic control system, Fuel supply lines, Pressure sensors lines for automotive industry for onshore control panels, Topside processing facilities and subsea manifolds in Oil and Gas industry, High purity tubes for semiconductors industry, Fuel rods, Control tubes for advanced engineering, Cooling circuits, Brake cylinders for automotive industry.

We at Krystal Global Engineering Limited, provide a Variety of Seamless Instrumentation Tubes, Hydraulic Tube and Mechanical Tube including Austenitic, Ferritic, Martensitic, Duplex, Super Duplex & Nickel Alloys.

Cross-roll piercing ranks as the main piercing process for stainless steel seamless tubes and offers sizeable advantages when compared to alternative solutions like piercing presses or push-piercing mills. As a part of the rolling method, a mandrel bar is inserted in to the hollow – with the traditional assel procedure it can be free-jogging, and with high-effectiveness assel mills it can be moved in a very controlled fashion. Our items are exported to over 70 nations the world over, when in India We've got supplies to even the distant parts. With in excess of 250 tons of manufacturer of Instrumentation tube & pipe and stainless steel seamless pipes on a daily basis, Metallica has emerged as being a popular vendor For lots of prospective buyers in India and Abroad. SMS team has further more made the push bench course of action into CPE (Cross-roll Piercing and Elongation) and TPE (3-roll Piercing and Elongation). What this means is thee merchandise array is has therefore been extended in comparison with earlier concepts and also the procedures present sizeable benefits regarding both high-quality and price efficiency. Spot- Strategically located in the DFW place, NTP is centrally positioned throughout the US transport community, minimizing shipping situations and giving usage of a wide array of supplies normally available when the following day. In light-weight of weather modify, making CO2-neutral electric Electricity from sunlight has become additional vital. voestalpine supports this expansion with optimally processed supplies and progressive Thoughts. Editor's note: This informative article was originally revealed in May of 2020. It's been current to incorporate new studies and traits from the industry. From packaging insert trays to industrial delivery and material managing trays, our style and design workforce can get the job done with you to acquire modern options for just about any within your packaging or sections Group requirements. A crucial element of SMS team’s warm pilger mills is the large dimensional choice of rollable inventory – even for top-alloy steel grades. To learn more about ways to use Industry Select to produce trusted potential customers for your company, Check out a free dem! Salem Tube’s solutions (Krystal Global Engineering Limited. Mumbai) are employed in a variety of applications and precision products – in seamless or welded & redrawn type, and straight lengths (nearly seventy two ft) or coils. Becoming among the most important specialized enterprises in Europe for manufacturer of stainless steel tubes and pipes, the manufacturing facility of CENTRAVIS Generation UKRAINE PJSC incorporates the recent-extrusion and chilly-drawing shops, which right until 2000 had been services of the Nikopol Yuzhnotrubny Plant (NYTP), previously most significant industrial complicated for manufacturer of stainless tubes and pipes. SMS group has consistently even further created this technologies and thus managed to double the utmost producible tube diameter. Today, tubes with an outside diameter of up to 460 mm and wall thicknesses of approximately 80 mm can be developed on assel mills. Our ground breaking design and engineering encounter enables us to manufacture normal and custom made steel tubing designs on your application requirements.

To Know more about: https://krystalgeltd.com

#instrumentation tubes#stainless instrumentation tubes#seamless instrumentation tubes#stainless steel instrumentation tubes#seamless steel instrumentation tubes#top instrumentation tubes#best instrumentation tubes#top instrumentation tubes in Mumbai#best instrumentation tubes in Mumbai#top manufacturer of instrumentation tubes in Mumbai#best manufacturer of instrumentation tubes in Mumbai#hydraulic tubes#stainless hydraulic tubes#seamless hydraulic tubes#best hydraulic tubes#top hydraulic tubes#top manufacturer of hydraulic tubes#best manufacturer of hydraulic tubes in Mumbai#top exporter of hydraulic tubes in Mumbai#best exporter of hydraulic tubes in Mumbai

0 notes

Text

The Ultimate Guide to HVAC Duct Shop Drawings: Your Path to Accurate and Efficient Services

Are you ready to take your HVAC projects to new heights of precision and efficiency? Look no further than HVAC shop drawings! In this captivating exploration, we invite you to unlock the secrets behind these game-changing blueprints and witness their transformative impact on the world of heating, ventilation, and air conditioning systems.

Picture a world where every duct, every pipe, and every component fits seamlessly together, resulting in flawless installations and optimized performance. That’s the power of HVAC shop drawings. They are the unsung heroes behind successful HVAC projects, acting as a roadmap that ensures precision, coordination, and impeccable craftsmanship.

What are HVAC Shop Drawings?

HVAC shop drawings are the main base of its projects. They are detailed technical drawings that provide a comprehensive representation of HVAC systems within a building. These meticulously crafted blueprints serve as a guide for contractors, fabricators, and installers, enabling them to bring the HVAC design concepts to life with utmost accuracy and efficiency.

Key Benefits of HVAC Shop Drawings:

Pinpoint Accuracy: HVAC shop drawings leave no room for guesswork. They provide precise dimensions, equipment specifications, duct layouts, pipe routing, and electrical connections, ensuring that every element fits flawlessly into the designated space.

Streamlined Installations: By acting as a visual roadmap, HVAC shop drawings streamline the installation process. Contractors and installers can work with confidence, knowing exactly where each component should be placed and how they should be interconnected.

Coordination and Collaboration: HVAC shop drawings facilitatedrop us a line here effective coordination between different trades involved in the project. They ensure seamless integration with other building systems, such as electrical and plumbing, avoiding clashes and conflicts during construction.

Time and Cost Savings: With accurate shop drawings in hand, projects progress more smoothly, reducing the need for rework and costly delays. Fabricators can efficiently produce HVAC components based on the drawings, eliminating costly errors and wastage of materials.

KNOW MORE AVOUT OUR HVAC SHOP DRAWING SERVICES

HVAC Duct Shop Drawings Services:

HVAC duct shop drawings play a crucial role in the successful implementation of its systems. They serve as a roadmap for the fabrication, installation, and coordination of ductwork within a building.

In this comprehensive guideline, we will walk you through the key steps and considerations involved in HVAC duct shop drawing services, from initial concepts to final execution.

1 . Understanding Project Requirements:

Before commencing HVAC duct shop drawings, it’s essential to gather all relevant project information. This includes architectural and structural drawings, mechanical specifications, equipment details, and any design considerations specific to the project.

2. Collaborating with the Design Team:

Effective collaboration with the design team is crucial for accurate drawings. Engage in discussions to understand the design intent, spatial constraints, and any specific requirements. Coordinate with architects, mechanical engineers, and other stakeholders to ensure a comprehensive understanding of the project.

3. Accurate Measurement and Layout:

Accurate measurement and layout are vital for creating precise HVAC duct shop drawings. Utilize laser measuring devices and digital tools to capture accurate dimensions of the building and existing systems. Document any obstructions or structural elements that may impact the ductwork layout.

4. Conceptualizing Ductwork Layout:

Based on the project requirements and design specifications, begin conceptualizing the ductwork layout. Consider factors such as airflow requirements, zoning, pressure drops, accessibility, and equipment locations. Utilize industry standards and guidelines to determine appropriate duct sizes, routing, and placement.

5. Creating Detailed Shop Drawings:

6. Coordinating with Other Trades:

Effective coordination with other trades is essential to avoid clashes and ensure seamless integration of ductwork within the building. Share and review shop drawings with electrical, plumbing, and structural teams to identify any conflicts and make necessary adjustments. Collaborate to create coordinated drawings that encompass all relevant systems

7. Adhering to Building Codes and Standards:

Ensure that your HVAC duct shop drawings comply with local building codes, industry standards, and regulatory requirements. Incorporate fire protection measures, clearance guidelines, and accessibility considerations into the drawings. Seek the expertise of code consultants or third-party reviewers, if necessary, to ensure compliance.

8. Reviewing and Approvals:

Thoroughly review it for accuracy, completeness, and compliance. Seek input and approvals from the design team, project managers, and other stakeholders. Address any comments or revisions promptly to expedite the approval process.

9. Fabrication and Installation Support:

Assist the fabrication team by providing clear and detailed instructions based on the approved shop drawings. Address any queries or clarifications during the fabrication process. Provide on-site support during the installation phase to ensure accurate implementation of the ductwork.

10. Documentation and As-Built Drawings:

Maintain comprehensive documentation of the HVAC duct shop drawings, including revisions and approvals. As the project progresses, update the drawings to reflect any changes made during construction. Upon project completion, compile accurate as-built drawings that represent the final installed ductwork.

HIRE HVAC SHOP DESIGNER

Why Choose Our HVAC Shop Drawing Services?

When it comes to HVAC shop drawings, precision and expertise matter. Our team of experienced professionals specializes in creating exceptional HVAC shop drawings tailored to your project’s unique requirements. With our meticulous attention to detail, cutting-edge software tools, and commitment to excellence, we ensure that our shop drawings exceed your expectations, helping you achieve extraordinary results.

So, if you’re looking for a Perfacet HVAC shop drawing service, then look no further! Get in touch with us at [email protected]. or simply drop us a line here to unlock the full potential of your interior design.

#HVAC #HVACshopdrawings #HVACdrawings #HVACdesign #HVACinstallation #HVACcommissioning #HVACdocumentation #HVACstandards #HVACregulations #HVACsystems #HVACcomponents #HVACmaterials #HVACsoftware

#HVAC#HVACshopdrawings#HVACdrawings#HVACdesign#HVACinstallation#HVACcommissioning#HVACdocumentation#HVACstandards#HVACregulations#HVACsystems#HVACcomponents#HVACmaterials#HVACsoftware

0 notes

Text

Top 6 Courses to Help Apply for CAD/BIM Jobs

As AEC (architecture, engineering, construction) firms are applying Building Information Modelling (BIM) to their projects for its detailed information collaboration and task efficiency, Autodesk Authorised Training Centres (ATCs) offer software courses that are a part of the design stage of the BIM process.

Here are a few professional courses that help students and professionals in the AEC industry apply for CAD/BIM jobs on course completion.

AutoCAD 2D

Candidates who have no AEC software experience can enroll for an AutoCAD 2D course. This course teaches the basic AEC terminologies that can help them then upgrade their skills in Revit. On course completion, participants can apply for jobs such as AutoCAD draftsmen/draughtsmen, AutoCAD technicians, CAD technicians, etc.

Advance Steel

Civil engineering professionals can add to their software expertise with an Advance Steel training course. By learning how to create steel structural models along with steel detailing, on course completion, participants can apply for jobs with designations such as steel structure detailers and connection detailers.

Dynamo for Revit

Using the plug-in Dynamo, learn how to automate design processes using lines of code and create an algorithm that includes nodes. On completing this Dynamo Revit course, participants can then take on roles of quality control experts and can lead projects.

Revit Architecture & V-Ray

This Revit training course in Mumbai helps participants create detailed, lifelike and accurate 3D architectural models. On course completion, participants can apply for jobs as Revit technicians (Revit Architecture) or Revit BIM modellers.

Revit MEP & Navisworks

Learn how to create detailed HVAC, mechanical piping, electrical lighting and containment, public health and drainage models in this course. Participants can then apply for MEP jobs with designations such as Revit modellers or MEP coordinators on course completion.

Revit Structure

Become experts in preparing detailed shop drawing documents, connecting steel design workflows and creating accurate steel and concrete models after completing this Revit Structure course. On course completion, participants can apply for structural jobs as structural draftsmen, structural detailers and structural modellers.

Autodesk Authorised Training Centres (ATCs) also offer Revit BIM training internships to help candidates gain adequate work experience before applying for CAD/BIM jobs. To know more about these courses, contact the nearest Autodesk ATC today!

0 notes