#Mechanical Drawings

Explore tagged Tumblr posts

Text

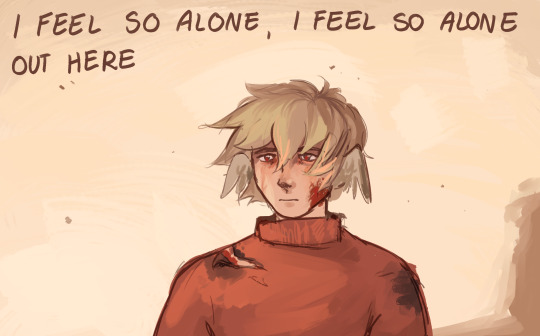

My favorite games of all time... i really love Half-Life, specially HL2, these games mean a lot for me, since i was 10, i loved this series in the same way i insanely love Transformers, Medarot, Megaman, Guilty Gear, DC Comics or Alien/Predator

A little late, but i made both draws for their anniversaries

I love you, Half-Life

#half life#hl2#half life 2#hl3 when#gordon freeman#alyx vance#gman#half life gman#barney calhoun#adrian shephard#black mesa#pls play black mesa#mechanical drawings#robot art#artists on tumblr#art#traditional art#taking commissions#valve games

283 notes

·

View notes

Text

The Ultimate Guide to Mechanical Maintenance: Strategies for Success

Photo by William Warby on Unsplash

Mechanical maintenance is fundamental to the smooth operation and longevity of machinery across various industries. Effective maintenance practices can significantly reduce downtime, improve efficiency, and extend the lifespan of equipment. This guide explores the intricacies of mechanical maintenance, offering strategies and best practices to ensure optimal machinery performance.

The Essence of Mechanical Maintenance

Mechanical maintenance involves a series of actions aimed at keeping machinery in peak condition. These actions include regular inspections, timely repairs, and preventive measures to avoid unexpected failures. The primary goal is to ensure that all mechanical systems function efficiently and safely.

Types of Mechanical Maintenance

Preventive Maintenance: Scheduled maintenance activities designed to prevent equipment failures. Tasks include regular inspections, lubrication, and replacing worn components. The objective is to keep machinery running smoothly and avoid unexpected breakdowns.

Predictive Maintenance: This approach uses real-time data and monitoring tools to predict when maintenance should be performed. Techniques like vibration analysis and thermal imaging help identify potential issues before they lead to equipment failure.

Corrective Maintenance: Also known as reactive maintenance, this involves repairing equipment after a failure has occurred. While this can be more costly and disruptive, it is essential for addressing unexpected issues that preventive measures did not catch.

Condition-Based Maintenance: Maintenance activities are conducted based on the actual condition of equipment. Sensors and monitoring devices provide continuous data, allowing for maintenance to be performed precisely when needed, rather than on a fixed schedule.

Key Components of Effective Mechanical Maintenance

Regular Inspections: Conducting systematic checks to identify early signs of wear, tear, or malfunction. Using detailed checklists ensures all critical components are evaluated.

Lubrication: Ensuring all moving parts are adequately lubricated to minimize friction and wear. The correct type and amount of lubricant are crucial for maintaining machinery efficiency.

Cleaning: Keeping machinery clean prevents contamination and ensures optimal performance. Regular removal of dust, debris, and other contaminants is essential.

Calibration: Regular calibration of tools and equipment ensures accuracy and precision in operations. Standardized procedures and tools help maintain consistent performance.

Component Replacement: Timely replacement of worn or damaged parts prevents further damage and ensures continuous operation. Keeping an inventory of critical spare parts allows for quick replacements when necessary.

Best Practices for Mechanical Maintenance

Develop a Maintenance Schedule: A detailed maintenance schedule that outlines routine inspections, servicing, and part replacements is essential. Adherence to this schedule ensures no maintenance tasks are overlooked.

Utilize Maintenance Management Software: Implementing software to track and manage maintenance activities improves efficiency. These tools can schedule tasks, record maintenance history, and generate performance reports.

Train Maintenance Personnel: Regular training ensures maintenance personnel are up-to-date with the latest techniques and technologies. Continuous learning enhances their skills and effectiveness.

Implement Safety Protocols: Establishing and enforcing safety protocols protects both maintenance personnel and equipment. Proper training and protective gear are essential components of a safe maintenance environment.

Conduct Root Cause Analysis: Identifying the root causes of equipment failures helps in implementing effective corrective actions. This prevents recurrence and improves the overall reliability of machinery.

Challenges in Mechanical Maintenance

Resource Constraints: Limited availability of skilled personnel, tools, and spare parts can hinder maintenance activities. Effective resource management and planning are crucial to overcoming these challenges.

Unplanned Downtime: Unexpected equipment failures can lead to significant production stoppages and increased costs. Implementing predictive and preventive maintenance strategies can mitigate these risks.

Data Management: Managing and analyzing large volumes of maintenance data can be challenging. Ensuring data accuracy and leveraging advanced analytics tools can enhance decision-making.

Aging Equipment: Older machinery often requires more frequent maintenance and can be less reliable. Balancing the cost of ongoing maintenance with the potential benefits of upgrading to newer equipment is a key consideration.

Case Studies and Real-World Examples

Preventive Maintenance in Manufacturing: A manufacturing plant implemented a rigorous preventive maintenance program, resulting in a 20% reduction in equipment downtime and a 15% increase in production efficiency. Regular inspections and timely component replacements were key to these improvements.

Predictive Maintenance in Power Generation: A power generation company utilized predictive maintenance techniques, such as vibration analysis and thermal imaging, to identify potential failures before they occurred. This approach reduced maintenance costs by 25% and significantly improved equipment reliability.

Corrective Maintenance in the Automotive Industry: An automotive company experienced a sudden equipment failure on the production line. Through corrective maintenance, the faulty component was swiftly replaced, minimizing downtime and preventing substantial production losses.

Condition-Based Maintenance in Aviation: An airline implemented condition-based maintenance for its fleet, using advanced sensors and data analytics to monitor the condition of critical components. This strategy improved safety, reduced maintenance costs, and increased aircraft availability.

Conclusion

Effective mechanical maintenance is vital for the smooth operation and longevity of machinery across various industries. By understanding the different types of maintenance, implementing best practices, and addressing common challenges, businesses can enhance equipment reliability, reduce downtime, and achieve operational excellence. Regular inspections, proper lubrication, timely component replacement, and the use of maintenance management software are key strategies for ensuring optimal performance and longevity of mechanical systems.

Explore More Topics

If you found this post insightful, you might also be interested in exploring our other topics that have garnered millions of views:

Mechanical Tools and Their Uses Discover the comprehensive guide to mechanical tools, covering everything from basic hand tools to advanced machinery. Learn about the names and uses of essential tools every mechanical engineer needs.

Forging Tools and Their Uses Explore the various forging tools and their applications. Understand the different types of forging processes and the tools required to achieve precision and efficiency in forging operations.

Mechanical engineering is a challenging yet rewarding field, and with the right mindset and tools, you can navigate its complexities and build a successful career.

Visit our website for more insights: Mech Forged

#artificial intelligence#mechanical pencil#mechanical drawings#mecha#the mechanisms#mechanophilia#robotics#machinery#mecha art#marvin's marvelous mechanical museum#adeptus mechanicus#robot#cybernetics#autos#design#entrepreneur#success

3 notes

·

View notes

Text

2024/07/24 CNC machining in GD Prototyping

#design#autos#business#cnc machining#prototyping#precision machining#prototype#prototype machining#rapid prototyping#machining parts#cnc part#metal products#metal machining#industrial design#industrialengineering#industrial metal#mechanical drawings#mechanical design#mechanical engineering

6 notes

·

View notes

Photo

Quinn the Fox, “How to Rebuild a Heart [BLACK HEART EDITION]”, A4 (210 X 297mm), 2023. In this life, I have been betrayed 5 times: once by family, twice by friends, once by someone who I thought was a friend and once by someone I didn’t know. Each time, after picking up the pieces and rebuilding my heart, I never know if the process has made it steelier or just more fragile.

quinnthefox.com

andyhau.com

#Illustration#illustrator#fox#quinn the fox#art#artists on tumblr#isometric#mechanical drawings#drawing#aesthetic#betrayal#heart#broken heart#heartbreak

8 notes

·

View notes

Text

gem n joel the strongest duo (family) that you are

and of course. her

#geminitay#smallishbeans#gem#joel#gemjoel#gempearl#wild life smp#why are they just building gorgeous things while everyone around them dies#trafficblr#life series#eydidraws#my art#additional notes: i tried to give joel some racer pants#also very pleased i finally got to draw him with the two toe boot thing#everytime i see those kinds of shoes i think of joel for some reason#also fun fact joel is one of the first hermits i ever drew ! him and lizzie but they were a lot more . anime-y back then#but yes i wanted to give gem a more mechanic vibe and joel the more racer vibe#which is a bit ironic bec i think their roles currently as of session 2 is the opposite lol#mcyt

11K notes

·

View notes

Text

0 notes

Text

All you need to know about Essential Drawings for Building Design

Architectural design is a dynamic field that blends creativity with precision. To bring a building from concept to reality, various drawings play a critical role. These drawings are the blueprints of any construction project, guiding every step from planning to execution. Understanding the different types of drawings used in building design is essential for architects, engineers, and construction professionals.

This guide covers the essential drawings used in building design, including architectural, structural, mechanical, electrical, and plumbing drawings. Learn how each type contributes to the overall success of a construction project.

1. Architectural Drawings

What Are Architectural Drawings?

Architectural drawings are the primary tools used by architects to convey their vision. These drawings include floor plans, elevations, and sections, detailing every aspect of the building’s design.

Types of Architectural Drawings

Floor Plans: Show the layout of rooms and spaces from a top-down view.

Elevations: Depict the exterior faces of the building.

Sections: Provide a vertical cut-through view of the building.

Importance of Architectural Drawings

Architectural drawings ensure that the design intent is communicated clearly to all stakeholders, including clients, contractors, and regulatory bodies.

2. Structural Drawings

What Are Structural Drawings?

Structural drawings provide detailed information about the load-bearing elements of a building. These drawings are essential for ensuring the building’s stability and safety.

Types of Structural Drawings

Foundation Plans: Show the layout and details of the building’s foundation.

Framing Plans: Detail the construction of floors, walls, and roofs.

Detail Drawings: Provide specific information on joints, beams, and columns.

Importance of Structural Drawings

Structural drawings are crucial for guiding the construction of a safe and stable structure. They ensure that the building can withstand various loads and stresses.

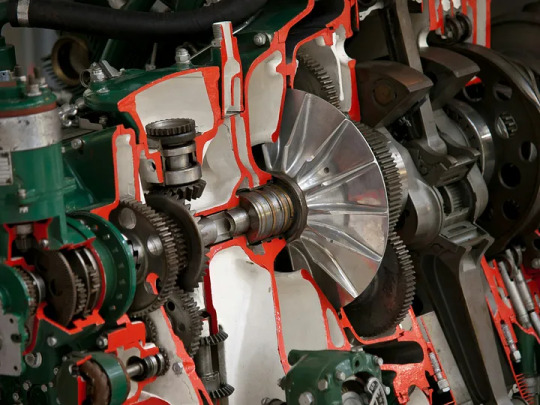

3. Mechanical Drawings

What Are Mechanical Drawings?

Mechanical drawings illustrate the building’s mechanical systems, such as HVAC (heating, ventilation, and air conditioning). These drawings are essential for ensuring the comfort and efficiency of the building’s interior environment.

Types of Mechanical Drawings

HVAC Plans: Show the layout of heating, ventilation, and air conditioning systems.

Ductwork Drawings: Detail the pathways for air distribution.

Equipment Schedules: List the specifications for mechanical equipment.

Importance of Mechanical Drawings

Mechanical drawings ensure that the building’s HVAC systems are designed and installed correctly, contributing to the overall comfort and energy efficiency of the building.

4. Electrical Drawings

What Are Electrical Drawings?

Electrical drawings provide detailed information about the building’s electrical systems, including power distribution, lighting, and communication systems.

Types of Electrical Drawings

Power Plans: Show the layout of electrical circuits and outlets.

Lighting Plans: Detail the placement and type of lighting fixtures.

Riser Diagrams: Illustrate the vertical distribution of electrical systems.

Importance of Electrical Drawings

Electrical drawings are essential for ensuring that the building’s electrical systems are safe, efficient, and comply with regulations.

5. Plumbing Drawings

What Are Plumbing Drawings?

Plumbing drawings illustrate the building’s plumbing systems, including water supply, drainage, and waste systems. These drawings are vital for ensuring proper sanitation and water management.

Types of Plumbing Drawings

Water Supply Plans: Show the layout of pipes for hot and cold water.

Drainage Plans: Detail the pathways for wastewater and rainwater.

Fixture Schedules: List the specifications for plumbing fixtures.

Importance of Plumbing Drawings

Plumbing drawings ensure that the building’s water systems are designed and installed correctly, preventing issues such as leaks and blockages.

By mastering the different types of drawings used in building design, architects, engineers, and construction professionals can collaborate effectively and create buildings that are not only aesthetically pleasing but also structurally sound and efficient.

Conclusion

An integral part of this process is precise CAD drafting, which serves as the backbone of accurate and efficient project execution. Shalin Designs offers comprehensive CAD drafting services that cater to all aspects of building design, ensuring each drawing type is meticulously crafted to enhance the project’s overall quality and coherence. Their expertise in creating detailed and reliable CAD drawings significantly aids in minimizing errors and streamlining the construction process.

Ready to take your building design skills to the next level? Contact Shalin Designs today to learn how our expert CAD services can bring your project to life. Whether you need detailed architectural drawings or comprehensive structural plans, our team is here to help you achieve excellence in every aspect of your construction project. Let’s build something amazing together!

#Architectural Drawings#Structural Drawings#Mechanical Drawings#Electrical Drawings#Plumbing Drawing#CAD Drawings#Shalin Designs

0 notes

Note

71 with Scar?

#71 - A House in Nebraska / Ethel Cain

bro you have no idea how much this was destined for me, I have always associated them with this song. for all my fellas who've never gotten over 3rd life. I'm still in that sand castle.

#coping mechanisms: drawing the 3rd life ending over and over and over#life series#traffic smp#3rd life#secret life#desert duo#grian#goodtimeswithscar#blood tw#death tw#spotify wrapped challenge#ethel cain#highly recommend listening to the full lyrics and thinkng about desert duo

5K notes

·

View notes

Text

first tumblr post of 2025 & its mouthwashing fanart. unbelievable

btw the comic was inspired by this absolute nutcase comic:

#mouthwashing#captain curly#jimmy mouthwashing#nurse anya#mechanic swansea#daisuke mouthwashing#polle the pony#dooble moment#my art#idk if this is how jimmy would actually act on swansea’s communal bday party but i thought it was funny anyways so. yeah#also nooooo i totally didnt steal the backgrounds from screenshots of the game no siree :^)#mouthwashing characters are neat to draw me thinks

6K notes

·

View notes

Text

it fit them too well to not draw it

#art#digital art#fanart#one piece#one piece fanart#zosan#incorrect one piece quotes#comic#im in the middle of writing a huge essay and i want to vomit actually#drawing zosan and watching game grumps is my coping mechanism atm i guess idk send help

4K notes

·

View notes

Text

Mechanical Drawings | Mechanical Patent Drawings | Digital Suntech

Mechanical drawing stands as an indispensable cornerstone in the vast landscape of engineering and design. Through meticulous lines, arcs, and annotations, it translates abstract concepts into tangible blueprints that breathe life into innovation. In its essence, mechanical drawing serves as the visual language of engineers, architects, and inventors, bridging the gap between imagination and realization with unparalleled clarity and precision.

#mechanical patent drawings#mechanical drawings#technical drawings#patent drawings#digital suntech#intellectual property

0 notes

Text

YELLOW DEVIL!

#megaman#mega man#rockman#rock man#mechanical drawings#robot art#artists on tumblr#art#traditional art#alternate universe#taking commissions#megaman fanfic#megaman art#megaman au#all-star megaman#yellow devil

121 notes

·

View notes

Text

#lean manufacturing#mechanical drawings#manufacturing#entrepreneur#success#design#artificial intelligence#machinery#robotics#mechanical pencil#autos#manufacturer#structure#factory#building

0 notes

Text

Precision CNC processing in low volume manufacturing

#design#autos#business#cnc machining#prototyping#precision machining#prototype#prototype machining#rapid prototyping#machining parts#cnc part#cnc precision machining#cnc processing#cnc manufacturing#high precision#auto parts and accessories#auto parts#automotive products#mechanical engineering#mechanical drawings#mechanical parts

1 note

·

View note

Text

The brightness of the Sun will give me just enough

To bury my love in the Moondust

#okay okay I know I'm sorry#I know we're trying to ignore ans forget this chapter#but my only coping mechanism is making more angst#sorry again#I'll try to draw smth cute next time#bnha#mha#my hero academia#boku no hero academia#bkdk#bakudeku#katsuki bakugo#izuku midoriya#togachako#ochako uraraka#himiko toga#fanart

7K notes

·

View notes

Text

7 Important Types of Construction drawings

Construction drawings are essential documents used in the construction industry to communicate design and construction details to various stakeholders involved in a project.

#types of construction drawings#construction details#Architectural Drawings#structural drawings#mechanical drawings#electrical drawings#plumbing (MEP) drawings#civil drawings#fire protection drawings#interior design drawings#landscape drawings#drafting and design#drafting services

1 note

·

View note