#Material Handling Control Items Manufacturer

Explore tagged Tumblr posts

Text

Why Sewer Ejector Pumps Can Fail Sooner.

After conducting a thorough investigation into the premature failure of sewer ejector pumps, several key factors have emerged that explain why these pumps might break down sooner than the manufacturer's warranty period:

Improper Installation.

One of the leading causes of early pump failure is improper installation. If the pump is not installed according to the manufacturer’s specifications—such as incorrect pipe sizing, inadequate venting, or poor alignment—this can cause strain on the motor and moving parts, leading to accelerated wear and tear.

Power Surges and Electrical Issues.

Power surges or fluctuations in the electrical supply can damage sensitive components within the pump, such as the motor or control panel. Even if the surge lasts only a second, it can burn out circuits or compromise the motor's efficiency. Without surge protectors or proper grounding, this can lead to premature failure.

Clogs from Improper Materials. Sewer ejector pumps are designed to handle waste and certain types of debris, but when improper materials—such as feminine hygiene products, wipes labeled as "flushable," or other non-degradable items—are flushed, they can clog or damage the pump. Over time, these clogs can cause the motor to overwork, leading to an early breakdown.

Lack of Regular Maintenance. Routine maintenance is often overlooked. Failing to check and service the pump periodically can result in small issues going unnoticed until they become larger, irreversible problems. Sediment buildup, worn-out seals, or deteriorating gaskets can all contribute to pump failure, especially in areas with hard water where mineral deposits may accumulate.

Overworking the Pump.

Many sewer ejector pumps are not designed to run continuously. If the pump is overworked due to improper sizing, such as being undersized for the household’s waste output or running too frequently, it can result in overheating and breakdown. Ensuring the pump is appropriate for the expected load is essential for longevity.

Environmental Factors.

Harsh environmental conditions such as excessive moisture, flooding, or extreme temperatures can affect the pump’s lifespan. Excessive moisture can cause corrosion of internal components, while extreme cold or heat can affect the motor and seals. Additionally, if the pump is exposed to corrosive chemicals or gases in the sewage, it can degrade faster than expected.

In most cases, premature failure of sewer ejector pumps can be traced to installation errors, misuse, or lack of maintenance. To ensure a pump reaches its full lifespan, it is critical to follow manufacturer guidelines, perform regular maintenance, and avoid flushing materials that can cause clogs. These preventative measures can help avoid costly repairs and ensure the pump functions efficiently for its intended lifespan.

Our local team of plumbing experts at Emergency Plumbing of Highland Park IL is always available to assist you with all your plumbing needs big or small.

Trusted by local communities of North Shore and Northwest suburbs , we are always answer your call and ready to help.

Call us with your plumbing problems. We offer best prices with no hidden fees and quality labor guaranteed !

Phone 224-754-1984

#flushable#Why Sewer Ejector Pumps Can Fail Sooner.#After conducting a thorough investigation into the premature failure of sewer ejector pumps#several key factors have emerged that explain why these pumps might break down sooner than the manufacturer's warranty period:#1. Improper Installation.#One of the leading causes of early pump failure is improper installation. If the pump is not installed according to the manufacturer’s spec#inadequate venting#or poor alignment—this can cause strain on the motor and moving parts#leading to accelerated wear and tear.#2. Power Surges and Electrical Issues.#Power surges or fluctuations in the electrical supply can damage sensitive components within the pump#such as the motor or control panel. Even if the surge lasts only a second#it can burn out circuits or compromise the motor's efficiency. Without surge protectors or proper grounding#this can lead to premature failure.#3. Clogs from Improper Materials.#Sewer ejector pumps are designed to handle waste and certain types of debris#but when improper materials—such as feminine hygiene products#wipes labeled as or other non-degradable items—are flushed#they can clog or damage the pump. Over time#these clogs can cause the motor to overwork#leading to an early breakdown.#4. Lack of Regular Maintenance.#Routine maintenance is often overlooked. Failing to check and service the pump periodically can result in small issues going unnoticed unti#irreversible problems. Sediment buildup#worn-out seals#or deteriorating gaskets can all contribute to pump failure#especially in areas with hard water where mineral deposits may accumulate.#5. Overworking the Pump.#Many sewer ejector pumps are not designed to run continuously. If the pump is overworked due to improper sizing#such as being undersized for the household’s waste output or running too frequently

1 note

·

View note

Text

Packaged Sewage Treatment Plant in Gurgaon- Netsol Water

Modern urban development needs effective wastewater management solutions. Gurgaon faces growing challenges in treating sewage from residential and commercial buildings. This makes choosing the right Sewage Treatment Plant Manufacturer in Gurgaon essential for property developers and building managers. Netsol Water stands out in providing packaged sewage treatment solutions that work for different property types.

The rapid growth of Gurgaon creates new wastewater treatment demands. Each property needs an efficient treatment system. Residential complexes need compact solutions. Commercial buildings need higher capacity systems. A trusted Sewage Treatment Plant Manufacturer in Gurgaon understands these different requirements. This understanding helps create effective solutions for each situation.

This blog will help you understand packaged sewage treatment plants. You will learn about system features, benefits, and maintenance needs. The information will help you make good decisions about wastewater treatment for your property.

Advantages of Packaged Sewage Treatment Plants

Packaged systems offer many benefits over traditional designs. These units come pre-engineered for quick installation. They need less space than conventional plants. The modular design allows future expansion. Modern packaged plants include features that make operation simple and efficient.

Space-Saving Design

Urban properties have limited space. Packaged systems fit in small areas. The compact design saves valuable property space. Underground installation options hide the treatment plant. These features make packaged systems perfect for urban buildings.

Quick Installation

Factory-built units speed up installation. Site work takes less time. Buildings get treatment systems faster. This saves time and money during construction.

Operational Efficiency

Automated controls make operation easy. Monitoring systems track performance. Maintenance needs stay low. Operating costs remain under control. These features benefit property managers and owners.

Complete Treatment Process in a Compact Package

Each packaged plant includes multiple treatment stages. The design removes different types of pollutants. The process creates clean water suitable for reuse. As a leading Sewage Treatment Plant Manufacturers in Gurgaon Netsol Water ensures complete treatment in every system.

Primary Treatment Stage

Initial treatment removes solid materials. Screens catch debris and large items. Settling chambers remove suspended solids. Oil separation systems remove floating materials. These processes protect downstream treatment stages.

Biological Treatment Process

Bacteria clean the wastewater naturally. Aeration systems provide oxygen. Special media support bacterial growth. Clarifiers separate clean water from solids. This creates clear treated water.

Final Treatment Phase

Filtration removes remaining particles. Disinfection eliminates harmful organisms. Additional processes improve water quality. The treated water becomes suitable for various uses.

Support Services for Long-Term Operation

Every packaged plant needs proper support. Regular maintenance keeps systems running well. Operator training ensures good performance. Technical support solves problems quickly.

Installation Support

Expert teams handle system setup. They ensure proper installation. They train building staff. This creates smooth system operation from day one.

Maintenance Programs

Regular checks prevent problems. Scheduled maintenance keeps systems running. Parts get replaced when needed. This maintains treatment quality over time.

Water Quality Management

Regular testing confirms treatment results. Reports show system performance. Quick adjustments maintain quality. This ensures consistent operation.

Conclusion

Experience makes Netsol Water a trusted Sewage Treatment Plant Manufacturer in Gurgaon. We understand treatment challenges. Our packaged systems deliver consistent performance. Our support keeps them running efficiently. Contact our team to discuss your treatment needs. We offer free consultations and site visits. Our experts will help find the right packaged solution. Start your journey toward better wastewater management today.

#environment#manufacturer#industries#water#environmental#manufacturers#industrial#netsolwater#purifier#manufacturing#industry#wastewater#filter#business#management#sewage#stp#stps#gurgaon

2 notes

·

View notes

Text

Tanvir

Tanvir Rana – Leading the Charge at Wolf Thread: An Expert in Textiles, Crude Oil, Agro, and Beyond

When it comes to steering a multi-sourcing company, few individuals match the expertise and dynamic leadership of Tanvir Rana, the CEO and Founder of Wolf Thread Agency. Tanvir’s role spans multiple industries, but his specialization in textiles manufacturing and stocklot management, coupled with his excellence in crude oil and agro sourcing, positions him as one of the most reliable agents in the market.

Textiles Manufacturing: Expertise in Large Quantities

At the heart of Tanvir’s expertise lies Wolf Thread’s thriving textiles division. Wolf Thread is strategically partnered with a wide network of factories across Bangladesh, one of the world’s leading hubs for garment production. Under Tanvir's guidance, the agency is able to handle manufacturing orders of substantial scale.

When it comes to manufacturing, Tanvir ensures that each step of the production process is streamlined, from sourcing raw materials to ensuring the finest quality control. His relationships with factories allow for large orders to be completed on tight deadlines without sacrificing quality, making Wolf Thread a trusted name for bulk textile production. Tanvir’s hands-on approach guarantees seamless communication between the factories and clients, ensuring that expectations are met, if not exceeded.

Stocklot Management: Mastering the Art of Unsold Inventory

In addition to manufacturing, Tanvir also expertly handles stocklot management. Stocklots are unsold inventories from factories that need quick liquidation. While stocklots can often be perceived as leftover or outdated products, Tanvir has turned this sector into a goldmine for businesses looking to acquire high-quality clothing at affordable prices.

By leveraging his connections and deep understanding of the textile market, Tanvir ensures Wolf Thread’s stocklots are consistently filled with attractive and trendy items. His keen negotiation skills allow him to secure large volumes of unsold stock at favorable prices, passing these savings on to Wolf Thread’s clients.

Whether a company needs fresh-from-the-factory garments or is looking for cost-effective stocklot solutions, Tanvir’s expert handling of both ensures a steady flow of high-quality clothing items. This dual ability makes Tanvir a standout agent in the textile industry, offering unmatched versatility and value.

Crude Oil: A Global Leader in Supply

Beyond textiles, Tanvir’s influence stretches into the energy sector through Wolf Thread’s crude oil supply division. Handling massive crude oil transactions requires both precision and international network connections.

As one of the top agents representing Wolf Thread’s crude oil sourcing in Kazakhstan, Tanvir ensures that clients receive high-quality crude oil from reliable suppliers. Managing contracts, shipping logistics, and maintaining compliance with global standards, he plays a pivotal role in moving crude oil across borders. His expertise not only secures the supply but also guarantees competitive pricing for Wolf Thread’s clients.

Agro Sourcing and Supply: Bridging the Gap Between Farmers and Markets

Tanvir is also a key figure in Wolf Thread’s agro sourcing division, focusing on sourcing and supplying fresh fruits and vegetables. From large-scale farms to retailers and distributors, he ensures that quality products are sourced at competitive rates while managing logistics and ensuring timely deliveries.

His ability to forge strong relationships with farmers enables Wolf Thread to offer a consistent supply of agricultural products to both domestic and international markets. Tanvir’s focus on quality control ensures that every product sourced meets high standards, whether destined for local distribution or export.

Business Services and Consulting: Driving Growth Across Industries

Tanvir’s expertise doesn’t stop at sourcing and supply. He also leads Wolf Thread’s business consulting services, helping companies across various industries achieve growth through tailored solutions. From digital marketing strategies to operational optimization, Tanvir brings his keen business acumen to help businesses scale, improve sales, and enhance market visibility.

A Visionary Leader and Expert Agent

Tanvir’s vision and leadership extend across industries, but his passion for textiles and his proven ability to navigate complex sourcing challenges make him one of the top agents in the sector. His role at Wolf Thread is not just about managing departments; it’s about creating value for clients through expertise, efficiency, and a commitment to excellence.

In summary, Tanvir Rana’s role as CEO of Wolf Thread showcases his unparalleled ability to handle textiles manufacturing, stocklot, crude oil supply, agro sourcing, and business consulting with precision. His influence ensures that Wolf Thread remains a trusted multi-sourcing partner, providing top-tier services to businesses worldwide.

#Tanvir#Rana#Garments#Top Garments#Bangladesh#Agent#Clothing agent#Big Factories in Bangladesh#Wolf#Wolf Thread

2 notes

·

View notes

Text

Embracing Minimalism: Liberating Ourselves from the Tyranny of Stuff

Welcome to my latest post, where we'll continue exploring the complex relationships between people, objects, and the spaces we inhabit.

Living as a millennial, I'm always questioning the role of material goods in our modern lives. In this age of rampant consumerism, it seems like every ad campaign is telling us that buying X, or Y products will instantly improve our quality of life. The manufacturing of goods has evolved far beyond utilitarian purposes - now it's all about endlessly satisfying our desires for faster, better, more effortless living.

But in reality, do our lives really get any easier just from using these new products? Often, the money spent on unnecessary items just leads to more effort needed to earn it back, piling on debt and wasting our precious time.

That's why it's so important to learn to distinguish our true needs from the false needs cleverly marketed to us. Let's take the example of a cooking enthusiast realizing they're missing a wok in their kitchen. As they search online, they're bombarded with a dizzying array of wok options - different materials, coatings, handles, colors, and shapes. The marketers masterfully package all these superfluous features as being about "healthy, time-saving, high-quality living." But in the end, do we really need all those bells and whistles, or just a simple, functional wok?

Sifting through these products to find the most capable, cost-effective option requires even more time and effort. And we have to watch out for all the other items they try to get us to buy alongside the main product - a matching lid, a special spatula, etc. Before you know it, our homes are overflowing with stuff we never really needed in the first place.

That's why I'm a big proponent of "informational minimalism" - actively choosing what data and messages we let into our minds, rather than just passively accepting whatever the algorithms push our way. In this information age, we're constantly bombarded with fragmented data accompanied by catchy soundtracks telling us "it's not enough" - our appearance isn't good enough, our homes aren't big enough, our lives aren't happy/refined enough.

Perpetually made to feel inadequate, we try to regain control by obediently making purchases, acquiring items, and trying to prove the ads wrong. But the ads just move on to promoting different products, trapping us in this love-hate relationship with material goods.

Informational minimalism is about refusing to be defined by others' negative judgments. It's about curating the data and messages we choose to let in, focusing only on what we genuinely want to know. That way, we can remember: what I have and who I am is already enough.

2 notes

·

View notes

Text

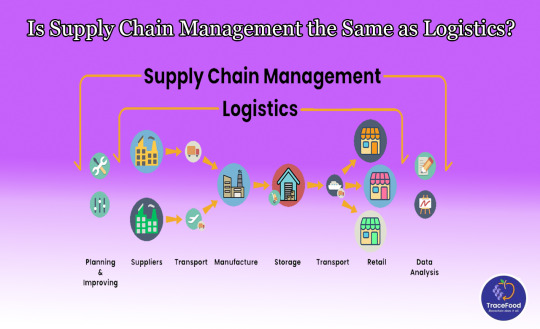

Is Supply Chain Management the Same as Logistics?

Supply chain management and logistics are sometimes used synonymously. Some claim that there is no distinction between the two concepts and that supply chain management is the “new” logistics.

Logistics

Logistics management is the management process that incorporates the flow of capital, information, services, and goods from the procurement of raw materials till they reach their final customer. The goal of this procedure is to give the final consumer the correct product of the right quality at the proper time, location, and cost. Two major categories can be used to classify the logistical activities.

Inbound Logistics:

The tasks involved in material procurement, handling, storage, and transportation

Outbound Logistics:

The processes involved in the collection, maintenance, distribution, or delivery to the final consumer.

Supply chain management

Besides these, other activities include stock control, balancing supply and demand, fulfilling orders, protective packing, and warehousing. High-quality items will be produced, as well as cost and time savings.

Supply Chain Management (SCM) is a group of related tasks. W are moved from raw materials to finished items and back again until they are delivered to the customer. Multiple groups worked together to make this chain of activities successful, and that success is the result of their combined efforts.

These organizations could be the businesses that the company now collaborates with as suppliers or partners, as well as producers, distributors, retailers, and customers. Integration, sourcing, procurement, production, testing, logistics, customer services, performance assessment, etc. may be among the activities.

With a focus only on the needs of the customer, supply chain management uses a multi-faceted approach to control the flow of raw materials, works in progress (semi-finished goods), and finished goods both inside and outside the organisation until they are received by the final consumer.

Exactly how similar are supply chain management and logistics?

Even though the two are related ideas, they differ greatly from one another.

Transporting, storing, and delivering commodities are all elements of supply chain management. In other words, logistics is in charge of delivering the appropriate goods to the appropriate customer at the appropriate time.

All activities involved in moving goods and services from production to consumption fall under the umbrella of supply chain management, which is a more general word. It covers every step of the production and distribution of commodities, from sourcing and acquisition to their manufacturing.

Firstly, to make sure that your organisation is operating smoothly and effectively, it is crucial to understand the main distinction between supply chain management and logistics. With this knowledge, you can create customized strategies for each sector and make sure your entire business functions flawlessly.

How does blockchain provide supply chain solutions?

Through the use of blockchain technology, businesses can track all kinds of transactions more securely and openly. On the supply chain function, there might be a huge influence.

Businesses are now able to follow a product’s history from its point of origin to its present location using blockchain technology. A permanent history is create from the point of manufacture. To the point of sale for every time a product is sale by securely documenting the transaction.

The time delays, additional costs, and human error that are usually connect to transactions might be significantly reduce with the use of this potent technology if parties work together on a single shared platform. The absence of middlemen in the supply chain also lowers the possibility of fraud. Furthermore, complete records make it easier for firms to pinpoint the origin of fraud, wherever it may occur.

A shared blockchain ledger provides a trustworthy and uncrackable audit trail of the transfer of information, stock, and money along a supply chain. Businesses may synchronize logistical data, track shipments, and automate payments using a common blockchain. They can share only the most pertinent data while doing so without substantially changing their legacy systems.

Development of supply chain management

The term “logistics” has a long history and was first used in the military. For describe the upkeep, storage, and transit of military personnel and equipment. After the development of the idea of supply chain management, this phrase is now use widely and not just in the military. Additionally, it has been claime that SCM includes logistics in addition to being an addition to logistics management. They couldnt separate. As a result, they are complementary rather than in conflict. SCM enables Logistics to communicate with the team in charge of transportation, storage, and distribution.

Tracefood offers the ideal way to collect data from supply chains. It is simple to subscribe to and donate to tracefood thanks to ready-made blockchain applications. Companies can also restrict users’ access to information using these tools. This allows for the privacy of sensitive information while only sharing essential information with other supply chain participants. The blockchain receives bundled data from IoT sensors, shop floor systems, and other devices via secure cloud gateways.

Improve inventory holdings, reduce trading fees, fraud prevention, and other benefits can all be attain through greater transparency and a higher level of traceability.

With innovative blockchain solutions created by top blockchain developers, Trace Food enables seamless and efficient control of the food supply chain. With the use of our cutting-edge Blockchain deliverables, we aim to create new paradigms for the fresh produce business.

8 notes

·

View notes

Text

Foreign Matter

It is no secret that my favorite grocery store is Trader Joe’s. Sure, Whole Foods comes in a close second, but TJ’s is just my vibe. I love the laid back atmosphere, free of pretense and full of happy, adventurous shopping. They’re keen to keep bringing in foods and spices that most other groceries would never touch.

Unfortunately, we will probably never have one here in Amarillo. While they continue to add new stores (there are currently 564 stores in 43 states), they have their standards, tending to open in educated, upper-middle-class neighborhoods. We just don’t have enough people here who fit that demo.

So, whenever I travel, I go prepared with a huge cooler and a stack of Trader Joe’s reusable shopping bags. If Dallas, Albuquerque, or Oklahoma City are on my return trip, then I stop for a major shopping expedition. Believe me, I am not the only one. Many TJ’s fans who live in places that will never have one are just like me, and TJ’s knows it. Why add too many stores when people are willing to go to this extreme just to patronize you?

Trader Joe’s has been around since 1967 in Pasadena California. It was purchased by Aldi Nord (“North”) in 1979. And if you recognize that name, you should. It’s just that the Aldi stores we see in the US (which admittedly have many similarities, but different price points and target market) are owned by Aldi Sud (“South”). Both are German companies, and were once one big company until a rift developed between the brothers who owned it. They split into two at that point, so at best we can say that TJ’s and Aldi are cousins.

Given my love affair with TJ’s, it should come as no surprise that I have been known to include them in essay exam questions (wink wink, nudge nudge), incorporating their very cool podcast and other materials. This is a company that does exceptionally little advertising, adamantly refuses to allow online shopping, and will never have self-check lanes. It’s all about the shopping experience, and for this marketing prof, a company that is rich with marketing lessons.

But all has not been well with TJ’s this summer, because they have suffered through five product recalls. And they are odd ones, ranging from items that “may contain” rocks, insects, and metal. Ouch. Once that kind of news hits the airwaves and social media, it can become a public relations nightmare.

Roughly 85% of TJ’s items are private-label goods, meaning they are manufactured and packaged under contract by a different company. TJ’s doesn’t make anything; they just authorize its manufacture and labeling. It’s a challenge to find other-branded items in the store outside of the beer and wine section. It is these external providers who are the ones with quality control issues.

And yet TJ’s bears the brunt of the messaging, as well as responsibility for controlling the flow of response. That’s no small task.

None of these recalls is going to keep me from shopping at Trader Joe’s, but they might deter others, especially those who may not be quite so loyal as I am. Let’s face it, recalls are a black eye, whether you are at fault or not. How you handle that recall will help define your future. It starts with pulling all of the items that “may contain” said foreign matter, and then allowing for no-questions-asked refunds.

That’s only the beginning though. How do you begin to assure shoppers that they will be safe shopping there? Remember, we’re talking about food, something we put in our mouths. And what we put in our mouths is sacred. I liken meal preparation and eating to a spiritual experience. That is perfectly consistent with the religious training I received as a youth, that our bodies are temples and to be respected as such. Now why would I want to risk ingesting rocks, insects, and metal?

Given that TJ’s only uses Pinterest and Instagram on social media, along with their podcast and printed newsletter called The Fearless Flyer, they do not have many channels of communication. It’s so much easier when you leverage all of the socials, because you can broadcast to millions with a few clicks and taps.

In fact, TJ’s presence on Insta is predominantly fan pages that get as much traction as the corporate page, with people reviewing new products, offering recipe advice, and the like. That’s all great in terms of free word-of-mouth, but Trader Joe’s never gets to take the microphone on those pages, only their own.

Lastly, TJ’s could consider finding new vendors for some of its private label products, especially if a track record of recalls were to be established. Even still, this is no small task, because extensive vetting must then be completed. Existing vendors were chosen after thorough product testing in the first place.

I’ll be watching, TJ’s. You’re not at risk of losing me, but you cannot ignore these matters. Five black eyes in a little more than a month is a bad look. Here’s to righting this ship and sailing boldly into the future.

Dr “I Want To Work At TJ’s After I Retire” Gerlich

Audio Blog

2 notes

·

View notes

Photo

5 Tips for Improving Shop Floor Management in Logistic

Introduction

Shop floor management in logistics refers to the management of operations and activities that occur on the production floor of a warehouse, distribution center, or manufacturing plant. It encompasses a wide range of processes such as inventory management, production planning, material handling, and quality control. Effective shop floor management in the Top Logistic Company in India is crucial for ensuring the smooth and efficient operation of a logistics facility and plays a significant role in driving customer satisfaction and business success.

Following are the 5 tips of shop floor management in logistic

1. Establish a Positive not-so-bad Odor

Logistic facilities need to have a positive not-so-bad odor to be effective. This can be accomplished by adding essential oils to the air or using deodorizers to combat bad odors. Keeping the shop floor clean and the air fresh is essential for success.

2. Keep everything Organized and in its place

A company's standard operating procedure for every aspect of its operation can make its operation smoother by keeping items in original cartons and bags and preventing backbiting and miscommunication. Bins and bags should be clearly marked with the name of the company, the type of goods being stored, and the worker responsible for removing the items.

3. Always have a Plan beyond the Next Delivery

As the number of deliveries increases, the need to keep your shop floor clean and organized becomes more important. This is because each delivery moves items from one location to another, and the items can end up in different baskets, bags, or boxes. The number of deliveries can quickly skyrocket if there is no system in place to manage them. A key to keeping your shop floor clean and your customers happy is to have a plan beyond the next delivery. Having a procedure for not just when, but how often, to clean your floors can ensure that workers keep the area clean. Having a process for marking items so they won’t get mixed up in other deliveries can also help reduce the chance of accidents.

4. Utilize Internal Resources

Logistic companies have an automated inventory system to track and track inventory. However, this can be problematic if the company doesn't have the resources to constantly update the system. IT technicians can help with this by managing the system, as well as helping with routine maintenance tasks, such as changing out broken bar codes or updating the system to track live inventory.

5. Don’t be afraid to ask for help or Collaborate

Most logistic companies have an in-house team of logisticians that specializes in working with customers’ orders. These logisticians can often be more aware of the details involved in different deliveries than the people managing the deliveries on their own can be. Having an in-house team of logisticians can help with this, as well as with managing the company’s finances. Having an in-house team of logisticians can also help with routine maintenance tasks, such as changing out broken bar codes or updating the system to track live inventory.

Concluding Thoughts

Logisticians study the movement of goods to predict how they are brought into a company, stored, and delivered. A key to successful logistic is to establish a positive not-so-bad odor using essential oils and deodorizers to eliminate the smell of bodies. Keeping the shop floor clean and the air fresh is essential in creating a positive not-so-bad odor.

#3pl service provider#3PL in India#top logistic company in india#best logistics company in india#Best Tips For Improving Shop Floor Management#How to Improv Shop Floor Management In 3pl?

4 notes

·

View notes

Text

Top 10 Tips You Need to Know for Freight Cost Reduction

A business's utmost success hinges on expense control in today's competitive commercial arena. Freight costs are among the operators largest operating costs for companies surviving in retail, manufacturing, and e-commerce. Freight transport can often encompass a reasonable portion of the overall operational budget, and methods to reduce them can create sizable savings.

As a business owner, small or large, one cannot disregard the importance of understanding how one can scale down shipping costs to enhance overall profitability. In this article, we shall discuss 10 tips on effective freight costing.

1. Consolidate shipments to conserve space:

This is probably the easiest way of cutting down on freight costs. If you think of shipping items out one at a time or through small shipments, definitely you will be paying for some empty space on the transport vehicle. By consolidating a few shipments within one package deal, the available space will further be put to good use, thus making shipment cost-effective. Besides, shipping bigger loads may qualify for bulk discount.

2. Negotiate better rates with carriers

You would be surprised at how far several businesses go wrong by overlooking the art of negotiations for freight costs. Carriers, especially the larger freight providers, can provide discounts for shippers who ship regularly or in large amounts. You can negotiate better pricing, service terms, or payment conditions based more on your shipping volume.

3. Choosing the right mode of transport

The choice of mode of transport, not between air, sea, rail, or road transport, has a significant impact on your freight costs. Each option of transport has its own advantages and disadvantages. Airfreight is fast but very expensive; on the other hand, sea freight is cheaper, but you will wait forever to receive your cargo. So depending on some urgency and the nature of goods, opting for the appropriate mode of transport can get you enormous saves.

4. Use technology and freight management software to your advantage

Future-oriented technologies and freight management systems will optimize your supply chain operations giving you a clear overview of your shipping operations. They will allow you to spot inefficiencies, define the most efficient shipping routes, and automate manual processes. This will cut down on human errors and subsequently cut back on logistics, therefore lowering a company's freight costs in time.

5. Review and optimize your packaging Optimizing packaging can drastically affect overall freight costs. Under-packaged goods get damaged in transit, while over-packaged goods waste space. Evaluate your package handling process and see if it can be improved to lessen any unnecessary weight and size, taking shipping into account. The lighter the materials or more compactly the goods are packaged, the majorly reduced cost incurred.

6. Use Regional Distribution Centers

This can bring fundamental changes if your business acts in multiple locations. While between regional distribution centers and your customers, you can shorten the distance each shipment will travel. In turn, these changes can generate savings in transportation fees and speedier delivery, thereby improving customer satisfaction as well.

7. Consider Freight Forwarders

Freight forwarders provide logistics support regarding shipment consolidation, negotiating rates with carriers, and discovering the most economical shipping method for your company. Allow a freight forwarder to do it; this is their job; these experts do this every day, leveraging their knowledge of the industry, their relationships with carriers, and their experience lowering freight costs.

8. Schedule Shipments Ahead of Time

Last-minute or rush shipments call for exorbitant rates. By planning away rush orders, you will escape rushing charges and arrange for deliveries during slack hours. A lot of carriers give discounts to advance-scheduled shipments, so if you can work in flexibility into how you handle ordering, it is very likely that you can save money.

9. Understand Freight Classifications

Different types of various classes of goods affect transport costs. Heavy, greater-valued goods, as well as those labeled "hazardous", will usually incur higher freight costs. Becoming educated on the classifications of goods and ensuring your items are rightly classified can prevent unnecessary surcharges.

10. Audit Your Freight Invoices Regularly

No one is exempt from making mistakes, and it is by no means unusual for errors to lead to overbilling for freight. Whether it mingles with a wrong tariff or a wrong surcharge, it becomes important to audit freight invoices regularly to ensure you are not being overbilled. Many companies have managed to recover enormous amounts of money with the mere examination of their invoices for errors.

Conclusion

The cargo reduction involves a strategic mix of negotiation, technology, and operational efficiency. Consolidate, pack better, and monitor, and you would be doing better for the firm to incur lower transport costs. A review of invoices and advance planning for forthcoming shipments makes sure that logistics operations are the cheapest. With a little pre-thought and strategies, you'll be in a position to drive freight costs lower while protecting long-term savings for your business.

0 notes

Text

Vintage Costume Jewelry Buyers Near Me: Where to Sell Your Collection

Introduction

Vintage costume jewelry carries a charm and allure that transcends generations. From whimsical brooches to sparkling statement necklaces, these pieces often reflect the unique styles of their time. Many collectors find themselves asking, “Where can I find vintage costume jewelry buyers near me?” Whether you're looking to declutter your collection or cash in on valuable items, jewelry buyers understanding where to sell your vintage costume jewelry is crucial. In this comprehensive guide, we will explore various avenues for selling your collection, including local jewelry buyers, antique shops, online platforms, and estate sales.

Vintage Costume Jewelry Buyers Near Me: Where to Sell Your Collection

If you're searching for "vintage costume jewelry buyers near me," you may feel overwhelmed by the options available. This section aims to demystify the process https://central.newschannelnebraska.com/story/52031889/abercrombie-jewelry-expands-premier-jewelrybuying-and-appraisal-services-in-austin-texas of selling your vintage pieces.

Understanding Vintage Costume Jewelry

Before diving into the selling process, it’s essential to understand what constitutes vintage costume jewelry. Generally defined as non-precious materials crafted in an artistic manner, these pieces were often mass-produced but can still hold significant value.

What Makes Jewelry 'Costume'?

Costume jewelry typically includes:

Materials: Made from base metals, glass beads, plastics, and synthetic stones. Design: Often bold and colorful; it reflects fashion trends of the era. Manufacturers: Brands like Trifari, Coro, and Monet are well-known for their costume pieces. Why Sell Vintage Costume Jewelry?

There are numerous reasons why someone might want to sell their vintage jewelry collection:

Financial Gain: Many vintage pieces can fetch high prices at auction or through private sales. Decluttering: If you've inherited a collection or accumulated too much over time, selling can help you reclaim space. Changing Tastes: Fashion is ever-evolving; you may simply want to refresh your style. Finding Local Jewelry Buyers Near Me

When searching for vintage costume jewelry buyers near you, start locally. Here are some options:

Local Antique Shops

Antique shops often have expert appraisers who can evaluate your pieces and offer fair prices. Consider visiting several shops to compare offers.

Pros: Face-to-face interaction Immediate cash offers Cons: May not offer the highest price Limited buyer audience Estate Sale Companies

These companies often specialize in selling entire collections and can provide a hassle-free way to sell multiple items at once.

youtube

Pros: Professional handling of sales Potentially higher prices due to competitive bidding Cons: Commission fees Less control over pricing Jewelry Appraisers

An appraisal can help determine the value of your collection before selling it elsewhere.

Pros: Detailed valuation Insight into market trends Cons: Costs associated with appraisa

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Viart Creation 4K HDMI Video Game Stick Console : Latest video game controller. Bringing you the best game content and gaming experience. Open Linux source code system, with 32GB / 64GB card, built-in 3000 + / 10000 + games. Support Download Games By Yourself: games total 3000 + / 10000 + games 2. Game history, game record list, sorted by time entered the game 3. Game collection, you can use R2 button to collect or uncollect your favorite games 4. Game search, based on English full match or keyword query, Chinese first letter Query corresponding game 5. Game settings, key tone settings View local files, restore Default settings, system information, exit settings 6. The product is not charged, and the handles can be put into 2*AAA when using. 7. Language: Chinese/English, press and hold the [select key + start key] in the middle of the handle at the same time to enter the background to set. Download Game Steps : Step 1: Download game file Step 2: Connect the TF card to the computer with the card reader Step 3: Copy the game files to the corresponding folder (the name of the emulator) Step 4: Insert the card into the game console, close the game console and turn it on Step 5: Find your game and start playing (you can use the search function) Specifications: Product Type: Game console CPU: dual-core cortex-A7 Memory: 32G/64G (optional) Material: ABS Interface: HDMI Operating system: 64-bit Weight: 395g Power supply mode: 2*AAA (not included) Packing size: 28*18*7cm Support simulator: Package Included: 1 x Game Stick Console 1 x Wireless receiver 2 x Controller 1 x charging cable 1 x manual 1x HD cable Product type: Video Game Consoles Hide full description Language : English Product Dimensions : 10 x 5 x 10 cm; 380 g Release date : 31 October 2023 ASIN : B0D83YWFNN Item model number : 21K Manufacturer : Gurukripa Enterprise Packer : SH International Importer : SH International Item Weight : 380 g Item Dimensions LxWxH : 10 x 5 x 10 Centimeters Net Quantity : 1 Count Generic Name : PRELOADED ELECTRONIC GAME Upgrated -Smart Game Chip: wireless TV game console built-in more than 15000 Games,more than 9 Emulators are installed

, and a 64GBTF card is attached which support you to game search functions, and can save/read game records.Use upgraded game chips to support 8-bit, 16-bit, 32-bit, 64-bit, 128-bit emulators. It perfectly meets your needs for image quality and game fluency. 2.4GHz Wireless Controllers, Support Two-Player Games:Equipped with two 2.4G wireless joysticks, Sensitive without delay, get rid of the shackles of the thread.the connection distance of the controller is 8-10 meters,Plug and play, comfortable feel, you can better Enjoy the fun of classic nostalgic games with family or friends. HDMI Output:This video game console supports HDMI connection ,Please make sure your screen has an HDMI input port.it has 1080P HD image quality, and can enjoy lively and interesting video games on the big screen. Light and Easy to Carry:The protable mini game console has lightweight and compact body. Only 102mm long, 30 grams weight. does not take up space, and is easy to carry.special game rocker for arcade ,high sensitivity andantiskid design, comfortable feel, you can better share your fun with family or friends. Best Gift:game console is a perfect festival/ christmas/ thanksgiving/ halloween/ birthday gift for men, boy, dad, kids, husband and friends.If you are not completely satisfied with the game console, please contact us, we will definitely be able to provide you with the best service! [ad_2]

0 notes

Text

PUR Shippers Market Emerging Trends Driving Growth and Technological Advancements

The PUR shippers market is experiencing rapid growth as industries across the globe seek reliable temperature-controlled packaging solutions. With the increasing demand for pharmaceuticals, biologics, perishable foods, and other temperature-sensitive products, the market for PUR shippers is evolving to meet these needs. In this article, we explore the future trends that are expected to shape the PUR shippers market, highlighting innovations, market shifts, and opportunities for growth.

1. Advancements in Sustainable Materials

Increasing focus on eco-friendly and recyclable PUR materials

Growing adoption of biodegradable polyurethane solutions to reduce environmental impact

Development of alternative materials like bio-based polyurethane for greener shipping solutions

Partnerships between packaging manufacturers and environmental organizations to promote sustainability

2. Integration of Smart Technologies

IoT-enabled PUR shippers for real-time tracking of temperature and location during transit

Enhanced data analytics to monitor shipment conditions and prevent spoilage or damage

Use of RFID (Radio Frequency Identification) and GPS to track shippers in the supply chain

Predictive maintenance using smart sensors to ensure the integrity of PUR shippers throughout their lifecycle

3. Customization and Tailored Solutions

Increased demand for customized PUR shippers to meet specific temperature requirements of products

Design flexibility for shippers that cater to unique dimensions and shapes of goods

Focus on creating specialized PUR shippers for different industries like pharmaceuticals, food, and chemicals

Tailored insulation materials and packaging designs that enhance the performance of PUR shippers

4. Expansion of the Cold Chain Logistics Sector

Growth of the cold chain logistics industry, particularly in emerging markets such as Asia-Pacific and Latin America

Integration of PUR shippers in the global supply chain to maintain the quality of temperature-sensitive products

Collaboration between pharmaceutical companies and logistics providers to ensure efficient delivery

Investments in cold storage infrastructure and transportation networks to support the expansion of the PUR shippers market

5. Demand from the Biotech and Pharmaceutical Sectors

Surge in the demand for biologics, vaccines, and gene therapies requiring highly controlled shipping conditions

Increased emphasis on maintaining strict temperature standards for pharmaceutical shipments

Adoption of advanced PUR shippers to handle biologic drugs that require precise temperature management

Regulatory pressure driving pharmaceutical companies to invest in high-quality, compliant PUR shipping solutions

6. Rising E-commerce and Last-Mile Delivery

Growth of online grocery stores and food delivery services creating the need for reliable temperature-controlled shipping

Use of PUR shippers to ensure the safe transportation of fresh food, frozen meals, and other perishable items

Focus on minimizing last-mile delivery costs while maintaining product freshness

Development of lightweight PUR shippers for cost-effective and efficient last-mile delivery solutions

7. Increasing Regulatory Standards

Stricter global regulations for the transportation of temperature-sensitive products driving innovation in PUR shippers

Compliance with international standards set by regulatory bodies such as the FDA, WHO, and EMA for pharmaceutical transportation

Increased pressure on manufacturers to meet requirements for product integrity during transit, fueling demand for high-performance PUR shippers

Enhanced focus on testing and certification to ensure the reliability of PUR shippers in compliance with regulatory guidelines

8. Growth in Emerging Markets

Rising pharmaceutical and food sectors in developing economies increasing the demand for cold chain solutions

Adoption of PUR shippers in countries with rapidly expanding supply chain infrastructure

Strategic investments by key market players in Asia-Pacific, Africa, and Latin America to tap into new markets

Expansion of cold chain networks to ensure that temperature-sensitive products reach emerging markets efficiently

9. Focus on Product Innovation and R&D

Significant investments in research and development to enhance the performance of PUR shippers

Development of high-efficiency insulation materials to improve temperature retention capabilities

Introduction of new technologies like phase change materials (PCMs) that work in conjunction with PUR shippers for better thermal regulation

Ongoing efforts to innovate in the design and manufacturing of PUR shippers to meet changing industry demands

10. Increasing Collaboration Across the Supply Chain

Partnerships between packaging companies, logistics providers, and end-users to ensure efficient cold chain management

Collaboration with pharmaceutical, biotech, and food companies to understand their unique shipping needs

Joint ventures to develop customized PUR shippers that cater to specific supply chain requirements

Emphasis on integrated solutions that streamline the cold chain process and improve the overall efficiency of PUR shippers

0 notes

Text

Ensure Safety of Your Products with Eco Friendly Packaging in Australia

For most businesses, whether they are manufacturing plants, warehouses, godowns, food facilities, or any other type of commercial or industrial establishment, eco friendly packaging in Australia are essential. The leading providers of packaging supplies provide a broad range of products, from vacuum sealers to different types of sticky tapes, and are cognizant of the unique needs of the industry.

Analysing the Different Types of Packaging Products and Their Features

Packaging products come in a wide variety, each designed to meet specific industrial requirements. Foam packaging is important for ensuring that sophisticated items like electronics, etc do not break while in transit. When shipping valuable things on pallets, pallet pads are a crucial commodity since dust, splinters, and other debris can harm the goods. Corrugated cardboard sheets are used to provide protective layers in between items. Cartons and boxes, which are available in a range of sizes and strengths, offer safe packing solutions for products of various shapes and sizes. Corrugated trays and folders are ideal for organising and storing items, particularly in retail and warehouse environments.

Prominent suppliers of packaging products cater to both the industrial and service sectors, which include the hotel and food industries. Some of the goods used to package and distribute food to consumers in a sustainable manner include biodegradable wrap, plates and bowls, mugs of various sorts, and silverware like knives, spoons, forks, etc. Eco-friendly sustainable packaging, such as dispensing cartons, retail rolls, bags, sheets, tubes, wraps, and takeaway bowls, has gained in popularity in recent years as environmental concerns have been more widely recognised.

The best manufacturers of packing materials also meet janitorial concerns, providing a wide choice of things to protect safety and cleanliness in commercial and industrial environments. Workplace hygiene requires supplies like roll-up hand towels, toilet tissue dispensers, and facial tissues. Products such as antibacterial hand cleansers and odour control dispensers keep the toilet or room hygienic and fresh.

Packing machines and dispensers have become essential for providers of items offered online due to the fast expansion of the e-commerce industry in recent decades. Automatic tape dispensers, vacuum sealers, and stretch wrap machines are all designed to handle big loads, boosting productivity and reducing labour costs.

Browse the product sections of the leading packaging product suppliers' websites and buy what you or your company require.

Source: https://paramount-packaging.blogspot.com/2025/01/ensure-safety-of-your-products-with-eco.html

0 notes

Text

Understanding Gantry Cranes: A Key to Efficient Material Handling

When it comes to material handling in industries such as shipping, construction, and manufacturing, cranes play a crucial role in ensuring that heavy loads are moved safely and efficiently. One type of crane that stands out in this regard is the gantry crane. These versatile machines are designed to lift and transport heavy items across large areas, often in outdoor environments. But what exactly is a gantry crane, and why is it so important in industrial operations? Let’s take a deeper look!

What is a Gantry Crane?

A gantry crane is a type of overhead crane that features a bridge supported by legs (or towers) that move along tracks or rails. Unlike traditional cranes, which typically have a stationary tower, a gantry crane is designed to move along a horizontal plane. This makes it ideal for areas where equipment needs to be mobile and cover a large working space.

The key components of a gantry crane include:

The Gantry Frame: The structure that supports the crane and allows it to move.

Bridge: The horizontal beam that spans the work area and carries the hoist.

Hoist: The lifting mechanism that moves vertically and is responsible for raising and lowering the load.

Legs or Towers: Vertical supports that allow the crane to move along tracks.

Types of Gantry Cranes

Gantry cranes come in various configurations to meet different industrial needs. The most common types include:

Single Girder Gantry Crane: This type features a single bridge beam that spans the work area. It’s typically used for lighter lifting tasks and can be more cost-effective than other models.

Double Girder Gantry Crane: With two parallel bridge beams, this crane offers greater stability and is designed for heavier lifting. It is ideal for large industrial applications such as shipping yards or container ports.

Portable Gantry Crane: This smaller, mobile version of a gantry crane can be moved around a facility and is used for lighter loads. It’s commonly found in warehouses, workshops, and smaller construction sites.

Underhung Gantry Crane: Unlike standard gantry cranes, the underhung type has a hoist system that is mounted underneath the crane bridge, allowing for more precise control in tight spaces.

Advantages of Gantry Cranes

Gantry cranes offer numerous benefits to industries, which is why they are a popular choice in many heavy-duty operations. Some of the top advantages include:

Flexibility and Mobility: Since gantry cranes are designed to move along tracks or rails, they can cover a larger work area compared to fixed cranes. This mobility makes them particularly useful for tasks that require movement between different locations.

Cost-Effective: Compared to traditional cranes, gantry cranes can be less expensive to install and maintain, especially in environments where portability is important.

Heavy Lifting Capability: Gantry cranes are known for their ability to lift extremely heavy loads with ease, making them essential for industries like construction, shipping, and manufacturing.

Space Efficiency: They can be used in both outdoor and indoor settings, allowing companies to optimize their workspace, particularly in large, open areas like shipyards or factories.

Customization: Gantry cranes can be tailored to suit specific operational needs. This means they can be modified in terms of size, weight capacity, and other features depending on the task at hand.

Applications of Gantry Cranes

Gantry cranes are used in a variety of industries, ranging from construction to shipping. Some of the most common applications include:

Shipping Ports: Gantry cranes are essential in container terminals, where they move shipping containers from trucks to ships and vice versa. Their ability to handle large loads and their mobility make them ideal for these high-demand environments.

Manufacturing and Assembly: In factories, gantry cranes are used to move heavy machinery, materials, and parts from one area to another. They are often used in automotive and aerospace industries.

Construction Sites: Gantry cranes are frequently seen at construction sites, where they are used to move heavy building materials and equipment across vast areas. They can also be used in the construction of large-scale infrastructure like bridges and tunnels.

Warehousing: Smaller gantry cranes are used in warehouses to move heavy goods between aisles, making them an excellent solution for efficient stock handling.

Maintenance of Gantry Cranes

Like any heavy machinery, gantry cranes require regular maintenance to ensure they continue operating safely and efficiently. Here are some key maintenance tips:

Regular Inspections: Regular visual and mechanical inspections are crucial to identify wear and tear on parts like the hoist, tracks, and the crane frame. Checking for cracks, rust, and proper alignment is essential.

Lubrication: Proper lubrication of moving parts, especially on the hoist and the tracks, will reduce friction and wear, extending the life of the crane.

Load Tests: Performing load tests periodically ensures that the crane can handle the required weight capacity without compromising safety.

Cleaning: Keeping the crane clean and free from dirt, rust, or corrosive substances is important to maintain its efficiency and prevent damage.

Conclusion

Gantry cranes are indispensable tools for industries that require heavy lifting and material handling over large areas. Whether it’s shipping, construction, or manufacturing, these cranes offer unparalleled flexibility, efficiency, and cost-effectiveness. With the ability to move heavy loads safely and across wide spaces, they continue to play a key role in modern industrial operations. Proper maintenance and choosing the right type of gantry crane for specific needs will ensure they remain reliable and durable assets for years to come.

As industries evolve and demand for more sophisticated handling equipment increases, the role of gantry cranes is only set to expand, ensuring that businesses can keep pace with their operational needs.

0 notes

Text

Custom vs. Standard Container Dimensions: Which is Best for You?

In the world of exhibition logistics, shipping containers play a crucial role in ensuring the safe and efficient transport of goods. Whether you’re an exhibitor, a business owner, or a logistics manager, understanding container dimensions is key to making the right decision. Choosing between custom and standard container dimensions depends on your specific needs, budget, and shipping requirements. Let’s dive into the differences and explore how our exhibition logistics services can help you make the best choice.

Understanding Standard Container Dimensions

Standard containers are the most commonly used in logistics. They come in predefined sizes, making them ideal for general shipping and exhibition needs. The most popular sizes include:

20-Foot Container – Perfect for small to medium shipments, offering around 33 cubic meters of space.

40-Foot Container – Ideal for larger shipments, with approximately 67 cubic meters of space.

40-Foot High Cube Container – Offers extra height (9.5 feet instead of 8.5 feet) for bulkier cargo.

45-Foot High Cube Container – Provides even more space while maintaining standard width.

Benefits of Standard Containers

Cost-Effective – Since they are mass-produced, standard containers are more affordable compared to custom options.

Widely Available – Easily accessible across ports and shipping companies worldwide.

Compatible with Transport Modes – Designed to fit trucks, ships, and rail transport without modifications.

Security & Durability – Built to withstand rough handling and harsh weather conditions.

Efficient for Exhibition Logistics – Ideal for standard exhibition setups that require timely and hassle-free transportation.

Understanding Custom Container Dimensions

Custom containers are designed to meet specific requirements that standard sizes cannot accommodate. These containers can be modified in terms of length, width, height, and internal structure.

Benefits of Custom Containers

Tailored to Your Needs – Ideal for oversized or uniquely shaped exhibition materials.

Better Space Utilization – Can be designed to maximize storage and transportation efficiency.

Enhanced Protection – Custom features like temperature control, reinforced walls, and specialized fittings can be added.

Branding & Aesthetic Appeal – Custom containers can be modified to serve as pop-up exhibition booths, mobile showrooms, or branded storage units.

Improved Loading & Unloading – Features like side openings, double doors, or ramps can be added to simplify handling.

Choosing the Right Container for Your Exhibition Logistics

The decision between standard and custom containers depends on several factors:

Nature of Goods – If you’re shipping standard exhibition materials like banners, stands, or product samples, a standard container is sufficient. However, for fragile or uniquely shaped displays, a custom container might be necessary.

Budget Considerations – Standard containers are cost-effective, while custom containers require additional investment.

Shipping Frequency – If you regularly transport similar items, a standard container offers convenience. For specialized events, a custom solution might be worth it.

Urgency – Standard containers are readily available, while custom ones take time to design and manufacture.

How Our Exhibition Logistics Services Can Help

As a leading exhibition and logistics company for the last six years, we understand the unique challenges of transporting exhibition materials. Our expertise in Best Services for Exhibition Logistics, Exhibition Logistics Management Service, Reliable Freight Services, and Project Cargo Freight Forwarders ensures that we can provide the right solutions for your needs.

Why Choose Us?

Expert Guidance on Container Selection – We analyze your shipping requirements and recommend the best container option.

Customized Solutions for Exhibitions – Whether you need standard or custom containers, we ensure they are optimized for efficiency.

Seamless Transportation & Handling – From pickup to delivery, we manage the entire logistics process with precision.

Reliable & Cost-Effective Shipping – Our freight services ensure your exhibition materials reach their destination safely and on time.

End-to-End Support – We assist with container modifications, documentation, and compliance requirements.

Conclusion

Both standard and custom containers have their advantages. If you need a cost-effective, widely available solution, standard containers are the way to go. However, if your exhibition materials require specialized handling and modifications, custom containers are the better choice.

At SpeditionIndia, we take the stress out of exhibition logistics by providing tailored solutions that meet your specific needs. Whether you need standard containers for general shipments or custom solutions for unique displays, we’ve got you covered.

🚀 Ready to simplify your exhibition logistics? Contact us today to find the perfect container solution for your needs!

0 notes

Text

Top 10 Industry Benefits of Polariscope Technology

Source of Info: https://www.perfectgroupindia.co.in/blog/top-10-industry-benefits-of-polariscope-technology

Introduction

Polariscope tools is improving industries by providing innovative solutions for stress analysis and quality control. This advanced visual tool is accurate and reliable in detail, making it an important device in a variety of industries. This tool offers benefits in industries from aircraft and automotive to glass and plastics manufacturing. Its ability to detect internal stresses, improve product durability, and raise safety standards has made it useful for businesses searching for quality. In this blog, we are going to consider the top ten industry benefits of technology, such as how it increases productivity, reduces waste, and drives superior quality outcomes in today's competitive environment.

1. Automotive Industry

In the automotive industry, safety and quality is important. Polariscope allows manufacturers to examine stress patterns in components such as windows, headlights, and plastic fixtures. This guarantees that the parts can withstand impact and pressure while in use. By finding weak points early on, manufacturers can reduce faults and improve overall reliability. Improved automotive component solid and durability, resulting in increased consumer trust and less failures.

2. Aerospace Industry

In aerospace, even small material flaws can have damaging outcomes . Polariscope technology is used to inspect glass panels, composite materials, and transparent items in aircraft. Engineers check that these materials meet high standards of safety by detecting stress points and flaws. This increases the air accuracy. Make sure that aircraft materials can withstand extreme conditions and heavy loads, increasing passenger safety.

3. Packaging Industry

The packaging industry fully uses polariscope technology to test plastic bottles, containers, and jars. This technology detects stress points that may result in cracks or leaks. The packaging is made strong enough so that the shipment and handling would not damage its contents. This reduces product waste by providing sturdiness and leak-proofing for various food and beverage industries.

4. Glass Manufacturing

Polariscope technology is required in the glass industry. It helps manufacturers to identify stress in glass sheets, bottles, and other glass products. This guarantees that the glass can withstand changes in temperature and impact from force without destroying. Reduces the risk of glass breakage, improving safety and reducing production waste.

5. Electronics Industry

In electronics, polariscope gadgets are used to test transparent and clear components such as LED screens and smartphone covers. This reduces internal stress in these parts, making them stronger to breakage while in use. Improves the longevity and durability of electronic devices, resulting in higher customer satisfaction.

6. Construction Industry

Modern technology is used in the construction industry for testing building materials such as glass panels, acrylic sheets, and laminated safety glass. It guarantees these materials can withstand environmental and mechanical stress, resulting in safer structures. Promotes structural integrity by using high-quality materials in building and development projects.

7. Optical Lens Manufacturing

Polariscope is very important in the production of lens designs for glasses, microscopes, and cameras. It protects lenses from internal stress, which could distort vision or imaging. Produces high-quality lenses with excellent detail and clarity, benefiting both consumers and experts.

8. Medical Equipment Industry

In the medical field, accuracy and safety are important. Polariscope is used to inspect transparent components such as a needle, medical containers, and personal protective equipment. This guarantees the products meet demanding quality and safety requirements. Guarantees the quality of medical instruments and equipment, increasing patient safety and trust.

9. Jewelry and Gemstone Industry

Equipment is commonly used in the gemstone and jewelry industries to detect inclusions, stress, and artificial things featured in jewels. It allows jewelers and gemologists to verify the veracity and standard of stones, resulting in customer satisfaction. Verifying and increasing the value of gemstones, giving customers greater confidence in their purchase.

10. Energy Sector

Polariscope is used in the energy industry to detect stress in transparent and flexible materials, particularly solar panels and wind turbine components. This allows for these components to withstand harsh environmental conditions such as heat, wind, and pressure for a long time. Increases the efficiency and security of solar power systems, thereby contributing to sustainable energy solutions.

Why Polariscope Technology Stands Out

Devices has become an important instrument in multiple industries because it

• Provides Safe Testing: Materials can be tested without any damage, preserving their usefulness.

• Enhances Quality Control: Flaws can be caught early, and so manufacturers can lower defects and recalls.

• Reduces costs: The early detection of flaws saves from costly repairs, recalls, and replacements.

Conclusion

Polariscope devices benefit industries by providing accurate stress analysis to improve product performance. This tool improves quality control in a variety of industries, including glass and plastic manufacturing. It's an important advancement in industries like aerospace, electronics, and packaging, where material quality is important. Businesses can use technology to identify flaws early on, reduce waste, and increase customer satisfaction. Its flexibility makes it an important tool in a variety of industries. As technology advances, the demand for effective and accurate quality testing methods, these instruments will increase their importance in modern manufacturing processes.

0 notes

Text

Wire Strapping Machine in India

A wire strapping machine is a critical tool used for bundling and securing wires, cables, or other items efficiently and neatly. These machines are widely utilized in industries such as manufacturing, logistics, and construction, where organized wire management and secure packaging are essential. In India, the demand for wire strapping machines is growing rapidly due to industrial expansion and the need for streamlined packaging solutions.

Wire strapping machines offer numerous advantages, including improved packaging efficiency, reduced manual effort, and consistent performance. They ensure that wires and cables are bundled securely, minimizing the risk of damage during transportation or storage. Available in manual, semi-automatic, and fully automatic models, these machines cater to diverse industrial needs. Manual wire strapping machines are cost-effective and suitable for small-scale operations, while semi-automatic and automatic machines are ideal for large-scale industries requiring high-speed strapping with minimal human intervention.

When choosing a wire strapping machine in India, factors like strapping material compatibility, speed, durability, and maintenance requirements should be considered. Machines designed to handle various materials, such as plastic-coated wires, metal wires, and cables, are preferred for their versatility. Many suppliers in India provide customized solutions, ensuring that the machines meet specific industrial requirements.

Reputed manufacturers in India offer wire strapping machines with advanced features like adjustable tension controls, robust construction, and easy-to-use interfaces. These machines are widely used in electrical, telecommunications, and logistics industries, where precise bundling and secure packaging are critical. Investing in a high-quality wire strapping machine not only improves operational efficiency but also enhances the safety and reliability of bundled wires and cables.

0 notes