#Marine Engine Equipments India

Explore tagged Tumblr posts

Text

#Marine Engine Spare Parts Supplier#Marine Engine Equipments India#Ship Engine Spare Parts Supplier in India#Maritime Mart

1 note

·

View note

Text

Dasset Engineering: Your Trusted Partner for High-Performance Crankshafts in India

Crankshafts are a critical engine component, serving as the backbone of power transmission and converting linear piston motion into rotational motion. Whether you’re running an automotive engine, stationary machinery, marine engines, or agricultural equipment, the quality of the crankshaft can significantly impact performance, efficiency, and reliability. At Dasset Engineering, we specialize in providing top-tier crankshafts tailored to meet the diverse needs of various industries, making us the best crankshafts manufacturer and supplier in India.

Why Choose High-Quality Crankshafts?

The crankshaft is subjected to immense pressure, high temperatures, and constant motion. Therefore, it must be designed with the utmost precision and constructed from high-quality materials to withstand these stresses. A well-engineered crankshaft minimizes vibrations, reduces engine wear, and ensures optimal performance. That’s where Dasset Engineering comes in, offering a wide range of forged and cast crankshafts to suit every requirement.

Our Crankshaft Solutions: Forged and Cast Crankshafts

At Dasset Engineering, we pride ourselves on delivering high-performance crankshafts that cater to a broad spectrum of applications:

Forged Crankshafts: Forged crankshafts are manufactured through a process that compresses and molds the metal, resulting in a denser, more durable component. These crankshafts are ideal for high-performance engines, such as those in race cars, heavy-duty trucks, and industrial machinery, where strength and resistance to fatigue are paramount. The forging process ensures minimal internal defects, offering excellent structural integrity and superior tensile strength.

Cast Crankshafts: Cast crankshafts are produced by pouring molten metal into a mold, allowing it to cool and solidify into shape. They are suitable for applications where moderate performance and cost-effectiveness are essential. Our advanced casting techniques produce crankshafts with uniformity, precision, and a smooth surface finish. Cast crankshafts are often used in standard automotive engines, air compressors, and other moderate-duty applications.

Both types of crankshafts are available in fully finished or semi-finished conditions. This flexibility allows us to cater to your specific needs, whether you require a crankshaft ready for installation or one that can be customized further to fit unique engine requirements.

Applications of Dasset Engineering Crankshafts

Our crankshafts are designed to deliver optimal performance across various industries and applications:

Automotive Engines: Our crankshafts provide the strength and balance necessary for passenger cars, commercial vehicles, and racing engines, ensuring smooth operation and longevity.

Stationary Engines: For generators, pumps, and industrial equipment, we supply crankshafts that deliver consistent power and reliability.

Marine Engines: In harsh marine environments, our crankshafts offer superior corrosion resistance and durability.

Agricultural and Industrial Engines: Used in tractors, earthmovers, and heavy machinery, our crankshafts are built to handle tough conditions with ease.

Air and Refrigeration Compressors: We provide crankshafts for compressors that demand high precision and balance to maintain performance and reduce vibration.

Why Dasset Engineering Stands Out

Dasset Engineering has earned a reputation as the best crankshaft manufacturer and supplier in India for several reasons:

Commitment to Quality: We use only the finest materials and the latest technologies to produce crankshafts that meet international quality standards.

Expert Engineering: Our team of skilled engineers ensures each crankshaft is meticulously designed and manufactured to deliver peak performance.

Customization Options: We provide both standard and custom solutions to fit the specific needs of our clients, offering flexibility in terms of design, materials, and finishes.

Stringent Testing: Every crankshaft undergoes rigorous quality control tests to ensure it meets our high standards for durability, performance, and reliability.

Conclusion

Dasset Engineering is your trusted partner for high-performance crankshafts in India. Whether you need forged crankshafts for a high-power application or cast crankshafts for cost-effective solutions, we provide products that promise quality, performance, and longevity. Our crankshafts are designed to drive efficiency and reliability, making us the preferred choice for automotive, marine, industrial, and agricultural applications.

Choose Dasset Engineering for all your crankshaft needs and experience unmatched quality and service. Contact us today to learn more about our offerings and how we can support your business!

#Best crankshaft manufacturer in India#High-performance crankshafts for automotive engines#Forged crankshafts supplier for industrial engines#Cast crankshafts for marine and agricultural applications#Crankshaft manufacturer for air compressors in India#Top crankshaft suppliers for tractors and earthmovers#Buy high-quality forged crankshafts in India#Custom crankshafts for industrial and stationary engines#Durable crankshafts for refrigeration compressors#Crankshafts for heavy machinery engines in India#High-strength crankshafts for race cars and heavy-duty trucks#Fully finished and semi-finished crankshafts suppliers#Affordable cast crankshafts for automotive applications#Leading supplier of crankshafts for agricultural equipment#Customized crankshaft manufacturing services in India

0 notes

Link

Narayan Marine Tech Pvt. Ltd. has a team of experts who are experienced in the marine industry and are dedicated to providing excellent customer service. They work closely with their clients to understand their requirements and provide them with the best possible solutions. They also offer installation, repair, and maintenance services for their spare parts to ensure that they function optimally and have a long lifespan.

#Refurbished Marine Spares in India#Used Marine Engines in Gujarat#Used Marine Equipments Exporters in Gujarat#Narayan Marine Tech Pvt. Ltd.

0 notes

Text

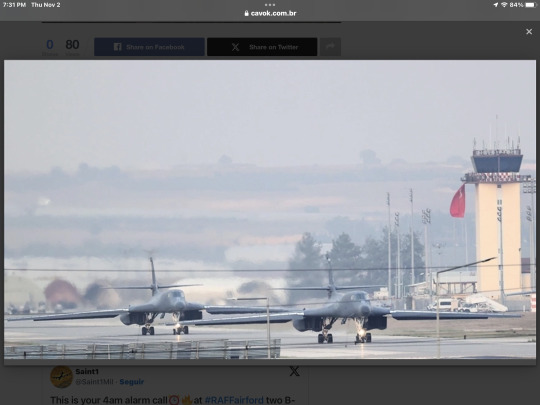

IMAGES: B-1 bombers make a historic visit to Turkey

Turkish Air Force integrates with U.S. bombers on a long-planned mission.

Fernando Valduga By Fernando Valduga 11/02/2023 - 12:56in Military

Two U.S. Air Force B-1B Lancers bombers assigned to the 9º Expeditionary Bomber Squadron arrived on Tuesday (10/31) at Incirlik Air Base, Turkey, for a historic hot-pit refueling as part of the long-planned bomber task force training mission.

A hot-pit refueling refers to the tactic of refueling aircraft while the engines are still running. This marks the first time that U.S. Air Force B-1 has been replenished in this way at Incirlik Air Base. The aircraft stayed at the base for less than two hours before leaving for a training mission with the Turkish Air Force.

TAP TITLE BAR TO VIEW VIDEO ☝️

The Deputy Commander of the Wing of the 39ª Air Base, Colonel Robert Schoeneberg of the U.S. Air Force, and the Chief Command of the Wing of the 39ª Air Base, Chief Sergeant. Kevin Helms greeted the Commander of the 9º EBS, U.S. Air Force Colonel Lieutenant Ryan Stillwell, and the Sub-Commander of the 489º Bombing Group Command, U.S. Air Force Lieutenant Colonel Andrew Marshall on the flight line.

The B-1s integrated with the Turkish military, including the KC-135R Asena refuelers and the F-16 Fighting Falcons, for training missions planned well in advance to practice Joint Terminal Attack Controller (JTAC) procedures and close air support training missions.

“Teamwork with our Turkish air force partners has demonstrated the interoperability and professionalism of NATO aviators,” Stillwell said. “Thank you to the 10ª Tank Base and 39ª Wing Team Titan Air Base for their specialized support and hospitality.”

Incirlik Air Base is one of the largest military facilities in Turkey and its strategic location makes it a center for NATO integration and the defense of NATO's southern flank.

“We are excited to support and celebrate this historic refueling operation in Incirlik,” Schoeneberg said. "This demonstrates the unique capabilities and strategic positioning of this base. In addition, it highlights for everyone that Turkey is a critical member of the NATO alliance and that Team Titan is open to business."

Tags: Military AviationB-1B LancerNATO - North Atlantic Treaty OrganizationTAF - Turkish Air Force / Turkish Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

MILITARY

IDF: More than 12,000 targets were attacked in Gaza

02/11/2023 - 10:48

MILITARY

Indian Navy retires its Il-38 Sea Dragon

01/11/2023 - 19:40

MILITARY

Sale of F-16 to Turkey is not yet completed, even with Sweden's entry into NATO continuing

01/11/2023 - 16:00

HELICOPTERS

Airbus naval unmanned air system is tested at sea from a French frigate

01/11/2023 - 14:00

ARMAMENTS

Pentagon plans to develop new variant of the B61 gravitational nuclear bomb

01/11/2023 - 11:00

MILITARY

India informs France of its decision to acquire 26 Rafale Marine jets

01/11/2023 - 09:00

12 notes

·

View notes

Text

Charting Careers: Exploring Maritime Training Institute in India

Introduction –

In the vast expanse of the maritime industry, where opportunities stretch as far as the horizon, finding the right path can be like navigating uncharted waters. This is where a reputable Maritime Training Institute in India becomes the guiding star for aspiring mariners, offering a beacon of knowledge, information, skills, and opportunities.

The School of Maritime Studies at Centurion University is the right educational institution for individuals wishing to pursue a career in the maritime industry. Explore the world of the Indian Maritime Training Institute at the School of Maritime Studies, where careers are built and dreams come true.

1) Understanding the Importance of Maritime Training Institute in India –

The maritime industry is a dynamic and diverse field, encompassing everything from shipping and logistics to offshore exploration and marine engineering. As a nation with a rich maritime history and a significant presence in the global shipping industry, India recognizes the importance of nurturing skilled maritime professionals.

A reputable institute like the School of Maritime Studies at Centurion University not only imparts theoretical knowledge but also provides hands-on training and industry exposure, preparing students for the challenges of a career at sea. . This institute serves as lighthouses guiding students through the complex waters of the maritime world, equipping them with the skills and knowledge needed to navigate their careers successfully.

2) The School of Maritime Studies: A Pillar of Excellence in Maritime Education –

One of the leading names in maritime education is in India is the School of Maritime Studies at Centurion University. Renowned for its commitment to quality education, excellence and practical training this institution has earned its reputation as a premier Maritime Training Institute in India, shaping the future of mariners for years.

Through a combination of comprehensive curriculum, state-of-the-art facilities, experienced faculty, and industry collaborations, the School of Maritime Studies provides students with a holistic learning experience that covers all aspects of maritime education. From navigation and ship operations to safety protocols and industry regulations, the institute ensures that graduates are well-prepared for the challenges of the maritime industry.

3) Centurion University: Fostering Maritime Talent –

As a prominent player in the field of higher education, the School of Maritime Studies at Centurion University recognizes the importance of maritime education in India's growth as a maritime nation. The university prepares aspiring mariners not just for jobs but for fulfilling and rewarding careers in the maritime sector.

Through its Maritime Training Institute in India, the School of Maritime Studies at Centurion University focuses on experiential learning and industry collaboration, offering a range of programs tailored to meet the diverse needs of the industry. From diploma courses in nautical science to degree programs in marine engineering, the university provides students with the tools they need to thrive in the competitive maritime landscape. The university's state-of-the-art facilities and experienced faculty further enhance the learning experience, making it a preferred choice among maritime aspirants.

4) Maritime Education: A Gateway to Success –

For those considering a career in the maritime industry, investing in quality education is the first step towards success. A Maritime Training Institute in India like the School of Maritime Studies at Centurion University offers the perfect blend of academic rigor and practical training, setting students on the path to a fulfilling career at sea.

The School of Maritime Studies, Centurion University integrates classroom instruction with real-world simulations and on-the-job training opportunities. Through a combination of classroom lectures, hands-on exercises, and industry internships, students gain a comprehensive understanding of the maritime sector and develop the necessary skills to excel in their chosen field.

Whether aspiring to be deck officers, marine engineers, or naval architects, the institute provides the necessary tools and resources to turn aspirations into reality. Students have access to ship simulators, engine rooms, and training vessels, where they can apply their theoretical knowledge in practical scenarios. This hands-on approach not only enhances learning but also prepares students for the challenges they will face in their future careers.

5) Industry Collaboration: Bridging the Gap –

One of the hallmarks of a reputable Maritime Training Institute in India is its collaboration with the industry. Through strong partnerships with leading shipping companies, port authorities, maritime organizations, and research institutions, institutes like the School of Maritime Studies at Centurion University ensure that their curriculum remains relevant and up-to-date with industry standards.

These partnerships provide students with valuable insights into industry trends, practices, and technologies. By bridging the gap between education and employment, these collaborations also open doors to internships, job placements, and networking opportunities, giving students a head start in their maritime careers.

Conclusion –

As the maritime industry continues to evolve, the demand for skilled professionals is on the rise. A quality education from a reputable Maritime Training Institute in India like the School of Maritime Studies at Centurion University is the key to unlocking a world of opportunities in this dynamic field. By providing a blend of academic excellence, practical training, industry collaboration, and global exposure, these institutes empower aspiring mariners to chart their course towards a successful and fulfilling career at sea.

#Maritime Training Institute in India#School of Maritime Studies#Centurion University#maritime industry#maritime education#marine engineering

3 notes

·

View notes

Text

Monel K500 Round Bar Exporters

Are you searching for top-notch corrosion-resistant materials in India? Look no further than Monel K500 Round Bars, the ultimate solution for your demanding industrial needs. Monel K500 is a high-performance alloy renowned for its exceptional corrosion resistance, making it the ideal choice for critical applications in various industries.

Unmatched Corrosion Resistance: Monel K500 is primarily composed of nickel and copper, with small additions of aluminum and titanium. This unique alloy composition offers extraordinary resistance to a wide range of corrosive environments, including seawater, acids, alkalis, and more. In India's diverse climate and industrial landscape, Monel K500 Round Bars ensure your equipment and structures remain robust and reliable for years to come.

Excellent Mechanical Properties: Beyond its corrosion resistance, Monel K500 offers outstanding mechanical properties. Its high tensile strength and durability make it suitable for a multitude of applications, from marine components to chemical processing equipment. Whether you're operating in the bustling cities of Mumbai or Chennai or the rugged terrains of the Himalayas, Monel K500 Round Bars are engineered to withstand the toughest conditions.

Exceptional Thermal Stability: Monel K500 retains its mechanical integrity even at elevated temperatures, making it perfect for high-temperature applications. Whether you're in the steel industry of Jamshedpur or the textile industry of Coimbatore, you can trust Monel K500 Round Bars to perform reliably in your specific environment.

Cost-Effective Solution: While Monel K500 Round Bars offer premium performance, they also provide long-term cost savings. Their extended service life and reduced maintenance requirements ensure that your investment pays off over time, allowing your business to thrive in the competitive Indian market.

Customized Solutions: We understand that every project is unique, which is why we offer customizable Monel K500 Round Bars to suit your exact specifications. Whether you require specific sizes, shapes, or quantities, we can deliver tailor-made solutions to meet your needs.

Compliance and Quality: Our Monel K500 Round Bars adhere to international quality standards, ensuring you receive a product of unmatched quality and consistency. We prioritize safety and reliability, making us the trusted choice for businesses across India.

In conclusion, Monel K500 Round Bars are the ideal choice for industries across India, offering unparalleled corrosion resistance, exceptional mechanical properties, thermal stability, cost-effectiveness, and customized solutions. Elevate your projects, enhance your equipment's longevity, and ensure the success of your business with Monel K500 Round Bars. Contact us today and experience the excellence of Monel K500 for yourself.

4 notes

·

View notes

Text

Best Industrial Flange Suppliers in India

Industrial flanges are crucial components in piping systems, providing secure connections between pipes, valves, pumps, and other equipment. Selecting the right supplier ensures high-quality materials, durability, and performance. This guide highlights the best industrial flange suppliers in India.

Top Industrial Flange Suppliers in India

1. XYZ Flanges Pvt. Ltd.

Products: MS Flanges, SS Flanges, Forged Flanges

Features: ISO-certified, corrosion-resistant

Industries Served: Oil & Gas, Chemical, Power Plants

2. ABC Engineering Works

Products: Weld Neck Flanges, Slip-On Flanges, Blind Flanges

Features: High-pressure tolerance, precision engineering

Industries Served: Construction, Water Treatment, Petrochemical

3. DEF Industrial Solutions

Products: Carbon Steel Flanges, Alloy Flanges

Features: Heat-resistant, custom sizes available

Industries Served: HVAC, Marine, Automotive

Factors to Consider When Choosing a Flange Supplier

Material Quality: Ensure durability and corrosion resistance.

Certifications: Look for ISO and industry compliance.

Customization: Availability of custom sizes and specifications.

Pricing & Delivery: Competitive rates and timely shipment.

Customer Support: Reliable after-sales service and technical assistance.

FAQ Section

1. What are the different types of industrial flanges?

Industrial flanges include weld neck, slip-on, socket weld, blind, lap joint, and threaded flanges. Each serves specific applications based on pressure and temperature requirements.

2. Which material is best for industrial flanges?

Stainless steel and carbon steel are commonly used due to their strength, corrosion resistance, and durability.

3. How do I choose the right flange for my application?

Consider factors like pressure rating, temperature conditions, material compatibility, and industry standards.

4. Where can I buy industrial flanges in India?

You can purchase from reputed suppliers such as XYZ Flanges, ABC Engineering, and DEF Industrial Solutions, known for their quality and reliability.

SEO-Optimized Title & Meta Description

Title: Best Industrial Flange Suppliers in India – Top Manufacturers & Exporters

Meta Description: Find the best industrial flange suppliers in India. Compare top manufacturers offering high-quality MS, SS, and forged flanges for various industries.

#IndustrialFlanges#FlangeSuppliers#PipeFlanges#Manufacturing#PipingSolutions#Engineering#OilAndGas#Construction#StainlessSteel#CarbonSteel

0 notes

Text

Precision Engineered 11 Ton Hollow Hydraulic Cylinder 700 Bar | Marineshopseven

Discover the Precision Engineered 11 Ton Hollow Hydraulic Cylinder 700 Bar from Marineshopseven. Designed for high-performance applications, this durable and reliable hydraulic cylinder ensures maximum efficiency and strength. Ideal for industrial and marine use, it delivers superior force with precision. Upgrade your equipment with the best 11 Ton Hollow Hydraulic Cylinder 700 Bar today!

#11TonHollowHydraulicCylinder700Bar#CaterpillarHydraulicHollowCylinder#HiForceHydraulicHollowCylinder#MegaHydraulicHollowCylinder60Tons#SpxPowerSingleActingHydraulicHollowCylinder

0 notes

Text

Hastelloy Prices, News, Trend, Graph, Chart, Monitor and Forecast

The market for Hastelloy prices has garnered significant attention in recent years, driven by the growing demand across various industries such as aerospace, chemical processing, marine, and power generation. Hastelloy, known for its exceptional resistance to corrosion and high-performance capabilities in extreme environments, is a crucial material in manufacturing components that must withstand harsh conditions. The pricing dynamics of Hastelloy are influenced by several factors, including the cost of raw materials like nickel, cobalt, and molybdenum, global supply chain trends, demand from end-use sectors, and geopolitical developments that affect metal mining and distribution.

Raw material costs play a pivotal role in determining Hastelloy prices. Nickel, a primary component of most Hastelloy grades, experiences price fluctuations due to mining output variations, global economic conditions, and policy changes in major nickel-producing countries such as Indonesia and the Philippines. When nickel prices surge, Hastelloy costs follow suit, making the market highly sensitive to global metal price movements. Similarly, molybdenum and cobalt, essential elements in specific Hastelloy grades, impact pricing when their availability or extraction costs are affected by external factors like labor strikes, environmental regulations, or changes in extraction technology.

Get Real time Prices for Hastelloy: https://www.chemanalyst.com/Pricing-data/hastelloy-1372

Global demand from key industries significantly influences Hastelloy prices. The aerospace industry, for instance, requires high-performance alloys like Hastelloy for jet engines, turbine blades, and exhaust ducts due to its strength and heat resistance. As the aviation sector recovers post-pandemic and new aircraft orders increase, the demand for Hastelloy rises, pushing prices upward. Chemical processing industries also contribute to the demand surge, as Hastelloy's corrosion resistance is indispensable for equipment handling aggressive chemicals. With the expansion of chemical manufacturing facilities in Asia-Pacific and North America, the material's consumption has increased, further impacting price trends.

Supply chain dynamics are another critical factor in Hastelloy price movements. Disruptions in the global supply chain, such as shipping delays, container shortages, or transportation costs, can cause price volatility. The COVID-19 pandemic exposed vulnerabilities in metal supply chains, leading to temporary price surges. Even post-pandemic, the market remains susceptible to similar disruptions, especially with geopolitical tensions affecting international trade. Sanctions on major metal-producing countries or tariffs on imports and exports can lead to supply shortages, thereby driving prices higher.

Technological advancements and innovation in manufacturing processes also contribute to pricing trends in the Hastelloy market. The development of cost-effective production techniques and recycling technologies can help stabilize prices by reducing dependency on freshly mined materials. Companies investing in advanced manufacturing methods aim to enhance efficiency and lower production costs, potentially influencing market pricing patterns over time. Furthermore, the adoption of automation and digital tools in metallurgy is streamlining production, impacting both costs and market competition.

Regional market trends offer further insight into Hastelloy pricing. Asia-Pacific has emerged as a dominant player in the market, with countries like China, Japan, and India investing heavily in infrastructure, chemical manufacturing, and renewable energy projects. China's aggressive push for industrial growth and its role as a major importer of raw materials significantly shape global Hastelloy prices. In North America and Europe, increasing investments in aerospace and defense applications contribute to sustained demand, although economic slowdowns or policy changes in these regions can create temporary market fluctuations.

Environmental regulations and sustainability initiatives are influencing Hastelloy prices as well. Stringent environmental standards in mining and metal production are leading to increased operational costs for manufacturers. The shift toward sustainable practices, such as recycling scrap metals and reducing carbon emissions, adds additional costs to production but also opens opportunities for innovation. Companies that adopt eco-friendly processes may find themselves better positioned to navigate regulatory landscapes while maintaining competitive pricing.

The role of international trade policies and currency fluctuations cannot be overlooked when examining Hastelloy price trends. Trade agreements, tariffs, and sanctions impact the global flow of raw materials and finished products, causing price variations. Currency exchange rates, especially the strength of the US dollar, affect import and export costs, as most metal transactions are conducted in dollars. A strong dollar typically makes metals more expensive for international buyers, influencing global demand patterns.

Market analysts predict continued growth in Hastelloy demand, particularly in sectors like renewable energy, where high-performance materials are required for equipment such as geothermal and solar power plants. As the world transitions toward cleaner energy sources, the need for corrosion-resistant alloys like Hastelloy is expected to rise. However, market participants must remain vigilant about potential risks such as geopolitical instability, resource scarcity, and evolving regulatory frameworks.

In conclusion, Hastelloy price trends are shaped by a complex interplay of factors, including raw material costs, industrial demand, supply chain dynamics, technological advancements, regional market activities, environmental regulations, trade policies, and currency movements. With growing applications across diverse sectors and ongoing innovations in alloy manufacturing, the market for Hastelloy remains dynamic. Stakeholders must continuously monitor these factors to make informed decisions in a market characterized by both opportunities and uncertainties.

Get Real time Prices for Hastelloy: https://www.chemanalyst.com/Pricing-data/hastelloy-1372

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Hastelloy#Hastelloy Price#Hastelloy Prices#Hastelloy Pricing#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

The Role Of Ship Stores Suppliers In India: Keeping Vessels Well-Stocked

The presence of numerous ports and a long coastline enhances India's importance in the international shipping sector. One of the most important aspects of this industry is the ship stores suppliers in India, who ensure that provision, equipment and spare parts are procured and stored on the vessels. Their function is important for the smooth running of the ships and the operations of ship chandlers, ship repair services, and marine services in the country.

Who Are Ship Stores Suppliers?

Ship stores suppliers are specialized providers addressing the requirements for all types of vessels, including cargo ships or even luxury yachts. From providing food, fresh water, safety gear, and spare parts, they do it all. These suppliers cooperate with ship chandlers who ensure that ships are supplied at different ports with the needed products and accessories of appropriate quality within the defined time limits.

Significance of The Ship Chandelling Business Store Suppliers in India

Port cities and towns like Mumbai, Chennai, Kochi, and Visakhapatnam have the increased need for shipping activity to be accompanied by a reliable supply chain. The role of stores suppliers in India is as follows :

1. Augmenting Business Productivity : There are essential items like food, lubricant fuel, and spare parts that ship vessels need to consume repeatedly. If there is no supply chain available, vessel operations across different parts can be adversely impacted.

2. Enabling Supply For More Ship Chandlers : Ship Suppliers Stores aid the ship chandlers by supplying goods and services, and in turn ship chandlers help them by making sure that those goods and services are reasonably priced and readily available. Their collaboration guarantees that vessels waiting in the Indian ports are supplied rapidly and without spawn of delays.

3. Increasing Safety on Board of Ship : Items such as major navigation equipment, emergency vessel rations, etc. are procured from ship stores, which work with specific suppliers to guarantee the vessels safety, the crew and ship.

4. Providing Aid For Ship Repair Services : In ship repair, vessels need specific tools and spare parts for proper and effective service. Here, store suppliers play an important part by supplying vital and critical materials for quick repair and maintenance.

5. Miscellaneous Marine Fuel Supply : Part of the chain of marine stores suppliers are marine fuel suppliers in India, who provide adequate fuel for the travel of a vessel. Marine fuel of the highest grade enables a ship to operate efficiently, minimizing cost and conserving the environment.

Ship Store Suppliers Services

The variety of products offered by ship stores suppliers in India comprise of :

Provisions : Food and drink items, both dried and fresh, together with other important items for cooking.

Deck And Engine Stores : Ropes, paint, cleaning detergents, and oils.

Safety and Fire Fighting Equipment : Life jackets, fire extinguishers, and basic medical kits.

Spare Parts And Tools : Machinery parts, nuts and bolts, screws, and fittings and electrical appliances.

Marine Fuel And Lubricants : Fuel and oil suitable for the efficient operations of the ship.

Ship Stores Supplier Selection : Tips and Suggestions

Choosing a trusted ship stores supplier in India is imperative for owners and operators of drills. Things to keep in mind include :

Prompt And Scheduled Delivery : They should be able to render satisfactory service without unnecessary delays to aid in smooth functioning of the ships.

Quality Guarantee : The standards of food, fuel, and machinery must be of the highest grade to take care of the crew and enhance the efficiency of the ship.

Diversity In Product Offering : An extensive stock enables ships to be serviced at one location.

Conclusion

The ship stores suppliers in India ensures that ships are always well supplied with the necessary commodities and fully operational. Their role augments the maritime industry by making sure that there is a steady flow of vital supplies. Their collaboration with ship chandlers, ship repair services, and marine fuel suppliers in India consolidates the agricultural economy of the country, making it an important place for international shipping business. An appropriate supplier improves the efficiency, safety, and cost-effectiveness of operating a vessel.

#Ship Supplier#Ship Chandler#Marine Services#Marine Paints#Ship Provisions#Ship Repair#Top ship chandlers in India#Best ship supply company in India#Marine fuel suppliers in India#Ship Stores suppliers in India

0 notes

Text

Leading Flange Suppliers in India | High-Quality & Affordable Pricing

India is home to top flange suppliers, providing high-quality stainless steel, carbon steel, and alloy flanges for oil & gas, petrochemicals, power, and construction industries. These suppliers meet global standards like ASME, ANSI, and API, ensuring durability, strength, and precision engineering.

Top Flange Suppliers in India

1. Aashish Steel

✅ Supplier of SS, duplex, and super duplex flanges. ✅ Exports to over 40+ countries. ✅ Offers bulk order discounts.

2. Petromat Oil & Gas Equipment Pvt. Ltd.

✅ Specializes in pipeline and industrial flanges. ✅ Supplies to oil & gas, power, and chemical industries. ✅ Custom machining and fast delivery.

3. Rajendra Industrial Corporation

✅ Stockist of ANSI, ASME, API, and DIN-standard flanges. ✅ Large inventory for quick dispatch. ✅ High-pressure and customized flanges available.

4. Kiah Metallurgical India

✅ Distributor of carbon steel, alloy steel, and SS flanges. ✅ ISO 9001:2015 certified supplier. ✅ Competitive pricing and nationwide shipping.

Types of Flanges & Their Applications

Flange TypeDescriptionCommon ApplicationsSlip-On FlangeSlides over the pipe and welded.Low-pressure pipingWeld Neck FlangeHigh-stress and pressure applications.Oil & gas pipelinesBlind FlangeCloses pipe ends securely.Pressure vessels, testing systemsThreaded FlangeScrewed onto pipes without welding.Small-diameter pipingSocket Weld FlangeSocket fitting for strength.High-pressure systemsLap Joint FlangeWorks with stub ends for easy dismantling.Piping that requires maintenanceLong Weld Neck FlangeExtended hub for high-temperature use.Power plants, chemical industriesOrifice FlangeUsed with orifice plates to measure flow.Fluid control in industries

Key Factors When Choosing a Flange Supplier

Material Quality – Stainless steel, carbon steel, and alloy steel options.

Certifications – Look for ASME, ANSI, API, DIN, JIS, ISO 9001.

Product Availability – Suppliers with large inventories ensure quick delivery.

Customization Options – Size modifications, coatings, and drilling patterns.

Pricing & Discounts – Bulk orders often come with lower rates.

Industry Experience – Established suppliers offer better reliability.

Industries That Use Flanges

Oil & Gas – Refineries, pipelines, offshore rigs.

Power Plants – Steam, nuclear, and gas-based power stations.

Chemical & Petrochemical – High-pressure chemical handling systems.

Water Treatment – Wastewater management, desalination plants.

Marine & Shipbuilding – Offshore platforms, ship pipelines.

Food & Beverage – Hygienic and sanitary-grade piping systems.

SEO & Digital Marketing Strategy for Flange Suppliers

Google My Business (GMB) Optimization – Maintain an updated business profile.

Strong Backlink Strategy – List products on TradeIndia, Justdial, IndiaMART, and industry blogs.

Schema Markup Implementation – Improve search rankings with FAQ & Product Schema.

Content Marketing – Publish technical guides, case studies, and whitepapers.

Social Media Promotion – Use LinkedIn, Facebook, and Instagram for brand awareness.

FAQs

Q1: What are the most durable flange materials?

A: Stainless steel (SS 304, SS 316) offers excellent corrosion resistance, while carbon steel is preferred for high-strength applications.

Q2: How do I choose the right flange for my application?

A: Consider factors like pressure rating, pipe size, and industry standards.

Q3: What certifications should a good flange supplier have?

A: Look for ASME, ANSI, API, ISO 9001:2015, and PED compliance for high-quality assurance.

Q4: Do Indian suppliers offer custom flanges?

A: Yes, many suppliers provide customized sizes, finishes, and drilling patterns based on project needs.

#FlangeSupplier#FlangeManufacturer#IndustrialFlanges#SteelFlanges#PipingSolutions#OilAndGasIndustry#PetrochemicalIndustry#PipelineSolutions#EngineeringSupplies#MadeInIndia#StainlessSteelFlanges#CarbonSteelFlanges#ASMEFlanges#ANSIFlanges#IndustrialSupplier#FlangeExporters#B2BManufacturing#GMBOptimization#TradeIndia#Justdial#IndiaMART

1 note

·

View note

Text

The Ultimate Checklist for First-Time Yacht Owners

Sailing in a yacht is a luxurious as well as enthralling experience in itself. Whether you need a yacht for sport or leisure, buying a yacht can be quite a process. It is always better to map out all the prerequisites before buying a yacht So, in order to make your investment worth it, we, Navnit Marine-Boats and Yacht dealers in Mumbai, are here for you to give you a comprehensive guide on how to sail through with your perfect yacht.

1. Set Your Budget and Financial Plan

First, decide how much you want to invest. Yachts come in a range of prices, from small boats to large luxury vessels. Be sure to include additional costs such as maintenance, dry docking, insurance, fuel, crew (if required), etc. Having a financial plan will help you

narrow down your options so you can choose a yacht that suits both your desires and your financial situation.

2. Understand Your Needs

Different types of yachts serve different purposes: decide whether you want a sailing yacht, a motor yacht, or a combination of both (motorsailer). Consider the size of the yacht, the number of people you want to accommodate, the activities you will use it for (e.g., cruising, fishing, entertaining), and the geographic areas you will be sailing in. Understanding your specific needs will make it easier to choose the right yacht.

3. Research the Market

It is important to learn about the market before making a decision. Research the different makes and models of yachts and their reputations. When choosing a yacht, inquire about resale value, build quality, and durability of the brand. In Mumbai, India, Navnit Marine, a renowned boat and yacht dealer, is a trusted name in the industry. They offer a wide range of yachts and boats that meet a variety of needs and tastes, and a luxurious yacht with a more affordable option.

4. Inspect the Yacht Thoroughly

Once you have narrowed down your shortlist of potential yachts, arrange for a thorough inspection. Hiring a marine inspector will help you assess the condition of the yacht and

ensure it is seaworthy and there are no hidden issues. Our experts will inspect vital aspects such as the hull, engine, electrical system, safety equipment, etc. This step is crucial to avoid unexpected expenses and ensure your yacht is ready for a safe voyage.

5. Verify Documentation and Legalities

Make sure all necessary paperwork is in order. This includes checking the yacht's registration, ownership history, and compliance with local maritime laws. New yacht owners would be wise to hire an attorney experienced in maritime law to review contracts and ensure everything is legal and compliant.

6. Choose a Reliable Yacht Dealer

Buying a yacht through a reputable dealer can make the process easier. A dealer like Navnit Marine, which has earned a good reputation in Mumbai and India, can provide expert advice, show you the different models, and arrange the necessary paperwork. Their experience and market knowledge will help you make an informed decision.

7. Consider Yacht Maintenance and Service

Owning a yacht means staying on top of its maintenance. Regular care is essential to keep the yacht running smoothly and prolong its lifespan. Some dealers, like Navnit Marine, a renowned boat and yacht dealer, offer after-sales services, including maintenance and repair, which can be an added benefit. Establish a relationship with a local marina or yacht service provider to help with regular check-ups and repairs.

8. Plan for Insurance

Yacht insurance is essential to protect your investment. It is important to have coverage for a variety of aspects, including yacht damage, liability, and personal injury. Work with an insurance broker who specializes in marine insurance policies to find a plan that meets your needs and provides adequate coverage for your yacht.

9. Learn Basic Yacht Handling Skills

Even if you have sailed before, sailing a yacht requires special knowledge and skills. Take a yacht handling and safety course to familiarize yourself with the intricacies of this vessel, navigation, safety procedures, and emergency procedures. Many yacht clubs offer courses to help new owners familiarize themselves with their yacht.

10. Prepare for Ongoing Costs

As mentioned above, owning a yacht comes with many ongoing costs. Consider budgeting for fuel, crew salaries (if needed), maintenance, repairs, mooring fees, and insurance. Consider how much you will spend on the yacht each year, beyond the initial purchase.

11. Be Prepared for Ownership Responsibilities

Owning a yacht is an important obligation. It must be practical for yacht maintenance, travel planning, and logistics management. If you can't manage everything yourself, it's an option to hire a crew or to be in charge of yacht management services.

12. Enjoy the Lifestyle

Finally, once the purchase is complete and everything is ready to go, it's time to enjoy your new yacht. Explore new waters, welcome friends and family on board—the possibilities are endless. Yachting offers a unique lifestyle of freedom, relaxation, and adventure.

Conclusion

In order to become the first owner of the yacht price setting, it is important to approach with cautious planning and preparation. According to this control list, by cooperating with experienced dealers such as Navnit Marine, a renowned boat and yacht dealer, you can make the right decisions for your needs and start a yacht trip with confidence. Be sure to prioritize factors like budget, research, maintenance, and legal issues to avoid any surprises along the way. With the right preparation, your new yacht will provide you with years of unforgettable experiences on the water.

Happy sailing!!!!!

Navnit Marine

#Navnit Marine#best boats and yachts dealers in india#bayliner boat#a renowned boat and yacht dealer

0 notes

Text

IPCS GLOBAL KANNUR

Explore the World of IPCS

IPCS started as an Automation Service provider in 2008 and has grown beyond even our loftiest expectations. along with our growth, our dreams also grew. We aspire to be the one-stop technological solution for all job aspirants as well as recruiters. What makes IPCS different is just a one-word reply: ‘Improvisation.’ We at IPCS, make sure that we are changing with time, from matters of Technical Training to Sales or from Team Management to Student Support.

Our curriculum and training methods keep getting updated every year to match the latest trends in the market, thus making our candidates the most suitable ones. The dream of Team IPCS is to eradicate the technical skill gap, making a world where all job aspirants can reach the top with our support. Our Practical Training and On Project Training methodologies ensure that all our students reach their maximum potential.

Why Choose Us?

IPCS Global is a research-oriented and progressive approach that offers perfect automation solutions to a vast array of industries which include but are not confined to software, marine and construction engineering. Our Expertise is in Process Automation, Factory Automation, Machine Automation, CNC solutions, Building Management Systems, Energy Management, the Internet Of Things, Robotics, Industrial Calibration and testing, We have been providing industries with services ranging from proposing and installing to absolute commissioning of automated systems, completely adhering to industry standards.

IPCS provides its customers with a plethora of products- HMI systems, Programmable Logic Controllers (PLCs), DCS systems, Supervisory Control and Data Acquisition (SCADA), drives, sensors, DCS systems and much more. Apart from all these, we conduct numerous training programs in corporate companies and also for professionals in the areas of PLC, SCADA, DCS, HMI, Drives, Panel Designing, Process Control, Electric Controls, Embedded, Robotics, Industrial Networking, Internet of Things, IT and Digital Marketing Industrial Networking.

Who we are

IPCS, established in 2008 in Kochi, the historic port city of Kerala, India, began its journey in a modest office, undertaking industrial automation projects for esteemed clients. Recognizing the imperative for skilled professionals in the automation industry and driven by our commitment to empowering the youth, we launched our inaugural training centre in Kozhikode in 2009. Renowned for its age-old trade ties with the Arab world and Western Europe, Kozhikode served as an ideal location.

Through our unswerving dedication to excellence, we garnered participants from diverse regions in India and Saudi Arabia. Today, our training centres have expanded across India, UAE, and the KSA, earning us the discrepancy of being official training partners for esteemed universities, with our centres situated within their campuses. Our relentless pursuit of quality led to ISO certification in 2014, a testament to our unwavering technical standards and organizational integrity. Our students make us proud-thousands of IPCS-trained professionals now thrive in prominent global enterprises.

About IPCS Kannur

Kannur, renowned as the vibrant heartland of Theyyam, Kerala’s celebrated folk art, is now home to a significant new development: IPCS Global. This move marks a pivotal step in enhancing the city’s technological landscape, making advanced training opportunities more accessible to students in Kannur, in line with other major cities across Kerala. At IPCS Global, we are dedicated to elevating Kannur’s educational standards by offering a wide range of specialized programs designed to meet the demands of today’s competitive job market. Our state-of-the-art facilities are fully equipped to provide comprehensive training in cutting-edge fields, including:

Industrial Automation: Dive into the world of automated systems and technologies that drive modern industries.

Building Management Systems (BMS): Master the integration and management of systems that control a building’s infrastructure.

Digital Marketing: Explore the dynamic world of online marketing strategies and tools to boost brand visibility and engagement.

Python Programming and Data Science: Gain proficiency in Python and uncover the power of data science to analyze and interpret complex data sets.

IPCS Global is committed to delivering top-tier, career-focused coaching with a strong emphasis on practical knowledge and skills. Our promise extends beyond training, offering 100% placement assistance to ensure our students not only learn but also secure rewarding career opportunities in their chosen fields.

By choosing IPCS Global in Kannur, students are not just investing in education but are embarking on a journey toward a successful and fulfilling career. Join us to be part of a transformative experience that brings global standards of education and training right to your doorstep.

Courses Offered in Kannur Branch: Automation Course in Kannur, BMS and CCTV Course in Kannur , Digital Marketing Course in Kannur ,Embedded & IoT Course in Kannur, Python Course in Kannur ,Artificial Intelligence Course in Kannur, Software testing training in Kannur

Our Values

Holding Tightly to professional ethics and moral values ,we leave no stone unturned to assure complete client satisfaction.We believe in the power of team spirit de corps.The members here coordinate process together right from the receiving of orders to the product delivery.An environment of mutual respect and professionalism is maintained through out.

Our Goals

Our Ultimate goal is to surpass the expectation of our customers and elevate ourself as the best automation solution provider for diverse sectors.Reach us and elevate experience from crust to core.

0 notes

Text

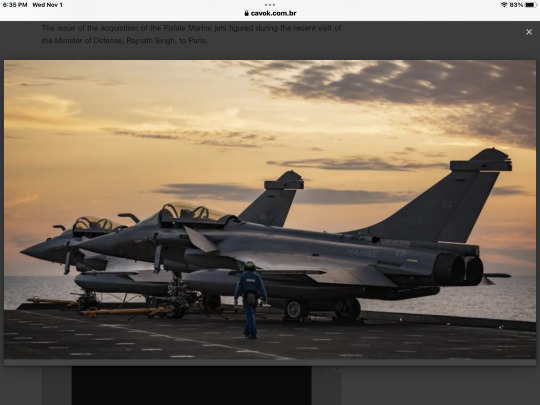

India informs France of its decision to acquire 26 Rafale Marine jets

Fernando Valduga By Fernando Valduga 01/11/2023 - 09:00 in Military

India formally communicated to France its decision to acquire 26 naval variants of the Rafale fighter for the Indian Navy, starting the acquisition process under an intergovernmental structure, people familiar with the matter said on Friday.

In July, the Ministry of Defense approved the purchase of Rafale Marine jets from France, mainly for deployment on board the locally built aircraft carrier INS Vikrant.

The issue of the acquisition of the Rafale Marine jets figured during the recent visit of the Minister of Defense, Rajnath Singh, to Paris.

India sent a letter of requisition to the French government, formally communicating its decision to acquire Dassault Aviation jets under the government-to-government structure.

Negotiations on prices and other details are expected to take place after the Ministry of Defense receives a response from the French side, people familiar with the matter said.

Earlier this month, the president and CEO of Dassault Aviation, Eric Trappier, visited New Delhi and discussed various aspects of the proposed acquisition by India.

The Ministry of Defense said in July that the acquisition of the jets along with associated auxiliary equipment, including weapons systems and spare parts, would be based on an intergovernmental agreement (IGA) and that the price and other terms of purchase will be negotiated with the French government after taking into account all relevant aspects.

The Indian Air Force bought 36 aircraft in flight conditions. There is an opinion in the IAF that it should opt for at least two more Rafale jet squadrons.

Defense and strategic ties between India and France have increased in recent years.

In July, India and France announced a series of innovative defense cooperation projects, including the joint development of jet engines and helicopters and the construction of three Scorpene submarines for the Indian Navy.

The two strategic partners also expressed a commitment to cooperate in the co-development and co-production of advanced defense technologies, including for the benefit of third countries.

Source: PTI

Tags: Military AviationDassault AviationDassault Rafale MIndian Navy

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

MILITARY

Lockheed Martin guarantees contract to modernize Chilean Air Force F-16 fighters

01/11/2023 - 08:44

MILITARY

Spanish Navy awaits urgent decision to purchase F-35B fighters

31/10/2023 - 19:25

MILITARY

Ecuador orders additional C295 transport aircraft

31/10/2023 - 16:00

MILITARY

Elbit Systems will establish drone production center in the Czech Republic

31/10/2023 - 14:00

Iranian Army test fires Haydar air-to-ground missile from a Bell 214 attack helicopter of the Islamic Republic of Iran Army Land Force.

ARMAMENTS

Iranian army tests Heydar air-to-ground missile from an attack helicopter

31/10/2023 - 11:30

MILITARY

Russian Su-57 fighter gets new compact air-to-air missile with a range of 300 km

31/10/2023 - 08:42

8 notes

·

View notes

Text

Buy High-Quality SS Perforated Sheets, Rods, and Fasteners in Ernakulam from Marthilo Tradex

Stainless steel (SS) products are essential in various industries, including construction, manufacturing, and infrastructure development. The demand for high-quality ss perforated sheet dealer in ernakulam, rods, and fasteners has been growing steadily in Ernakulam, Kerala. Marthilo Tradex India Pvt Ltd has established itself as a reliable dealer, offering top-grade stainless steel products to meet industrial and commercial requirements.

About Marthilo Tradex India Pvt Ltd

Marthilo Tradex India Pvt Ltd is a trusted name in the stainless steel industry, known for providing premium SS products with excellent durability, corrosion resistance, and strength. With years of experience and a commitment to quality, the company has become a leading supplier in Ernakulam and surrounding areas.

Their extensive inventory and customer-centric approach make them the preferred choice for businesses and individuals looking for superior stainless steel solutions.

SS Perforated Sheets in Ernakulam

What Are SS Perforated Sheets?

SS perforated sheets are stainless steel sheets with evenly spaced holes or patterns, offering versatility in various applications. They are widely used in architectural designs, filtration systems, and industrial settings due to their durability and aesthetic appeal.

Applications of SS Perforated Sheets

Architecture & Interior Design: Used in facades, ceilings, and decorative panels.

Filtration & Ventilation: Commonly found in air and liquid filtration systems.

Automotive Industry: Used for soundproofing and ventilation panels.

Industrial & Machinery Uses: Ideal for machine guards, enclosures, and sieves.

Why Choose Marthilo Tradex India Pvt Ltd for SS Perforated Sheets?

High-quality stainless steel material with excellent corrosion resistance.

Variety of patterns, hole sizes, and thicknesses available.

Customization options to meet specific client requirements.

Competitive pricing with timely delivery.

SS Rods in Ernakulam

What Are SS Rods?

ss rod dealer in ernakulam are cylindrical metal bars known for their strength and durability. They are widely used in construction, marine applications, and industrial manufacturing due to their resistance to rust and high temperatures.

Applications of SS Rods

Construction & Infrastructure: Used in bridges, buildings, and heavy structures.

Automobile & Aerospace: Utilized in engine components and high-performance machinery.

Marine Industry: Essential in shipbuilding due to their corrosion resistance.

Industrial Manufacturing: Used in machine components, fasteners, and tools.

Why Choose Marthilo Tradex India Pvt Ltd for SS Rods?

Wide range of sizes and grades available (SS 304, SS 316, etc.).

Superior tensile strength for long-lasting durability.

High corrosion and heat resistance.

Reliable supply chain ensuring uninterrupted availability.

SS Fasteners in Ernakulam

What Are SS Fasteners?

ss fastener dealer in ernakulam include bolts, nuts, washers, and screws, which are essential in assembling various components in construction, manufacturing, and engineering industries.

Applications of SS Fasteners

Construction & Civil Engineering: Used in structural connections and frameworks.

Automobile & Aerospace: Ensures secure fastening of vehicle parts.

Marine & Offshore: Resistant to seawater corrosion, making them ideal for shipbuilding.

Industrial & Machinery: Used in assembling heavy-duty equipment.

Why Choose Marthilo Tradex India Pvt Ltd for SS Fasteners?

Availability of different types and grades of fasteners.

Precision-engineered products ensuring superior strength and reliability.

Resistance to environmental factors such as corrosion and extreme temperatures.

Bulk supply options for industrial and commercial needs.

Why Marthilo Tradex India Pvt Ltd Is the Best Choice in Ernakulam

Marthilo Tradex India Pvt Ltd has built a strong reputation for delivering high-quality stainless steel products in Ernakulam. Here’s why they stand out:

Unmatched Product Quality: They offer only the best-grade stainless steel products that meet international standards.

Extensive Inventory: A comprehensive range of SS perforated sheets, rods, and fasteners is available.

Competitive Pricing: Their products are affordably priced, ensuring value for money.

Customization Services: Ability to cater to specific industrial requirements with tailored solutions.

Reliable Customer Service: A dedicated team provides guidance and support for selecting the right SS products.

Timely Delivery: Efficient logistics ensure products are delivered promptly.

Conclusion

For businesses and individuals in Ernakulam seeking high-quality SS perforated sheets, SS rods, and SS fasteners, Marthilo Tradex India Pvt Ltd is the go-to dealer. With their commitment to quality, customer satisfaction, and a wide range of products, they have positioned themselves as a leading supplier in the stainless steel industry. Whether you need materials for construction, manufacturing, or specialized industrial applications, Marthilo Tradex India Pvt Ltd is your trusted partner.

For more information, visit their website or contact their sales team to explore their product range and services.

#ss perforated sheet dealer in ernakulam#ss rod dealer in ernakulam#ss fastener dealer in ernakulam#ss weld mesh dealer in ernakulam#ss sheet dealer in ernakulam kerala

0 notes

Text

Hydraulic Torque Wrench Applications: Revolutionizing Industrial Bolting Solutions

In the world of precision bolting, hydraulic torque wrenches have become an indispensable tool, offering accuracy, efficiency, and enhanced safety. With industries demanding higher productivity and reliability, advanced bolting solutions are more crucial than ever. Shingare Industries Pvt Ltd is at the forefront of delivering high-performance hydraulic torque wrenches tailored for various applications.

Key Applications of Hydraulic Torque Wrenches

1. Oil & Gas Industry

Hydraulic torque wrenches play a critical role in the oil and gas sector, ensuring secure and leak-free flange connections in pipelines, refineries, and offshore platforms. Properly torqued bolts prevent costly downtime and enhance operational safety.

2. Power Generation

From wind turbines to nuclear power plants, precise torque application is essential for assembling and maintaining heavy-duty machinery. Hydraulic torque wrenches help prevent mechanical failures, ensuring seamless energy production.

3. Heavy Equipment & Mining

Mining and construction equipment rely on secure bolted connections to withstand extreme loads and vibrations. Hydraulic torque wrenches provide the necessary clamping force for structural integrity and longevity of machinery.

4. Aerospace & Manufacturing

In high-precision industries like aerospace and heavy manufacturing, consistent and accurate torque application is a must. Hydraulic torque wrenches aid in assembling large structures and critical fastening applications, minimizing human error.

5. Shipbuilding & Marine

Shipyards and marine industries utilize hydraulic torque wrenches for hull assembly, engine maintenance, and securing large mechanical components. Proper torque ensures durability and safety in harsh marine environments.

6. Infrastructure & Construction

Bridges, stadiums, and skyscrapers require robust bolted joints. Hydraulic torque wrenches enable precise torque control, ensuring structural stability and longevity of critical infrastructures.

Why Choose Shingare Industries?

At Shingare Industries, we provide industry-leading hydraulic torque wrenches designed for reliability, efficiency, and precision. Our cutting-edge technology ensures that your bolting applications meet the highest standards of safety and performance. Whether it's maintenance, assembly, or heavy-duty bolting, we offer tailored solutions to fit your needs.

Final Thoughts

With industries evolving rapidly, investing in the right bolting solutions can significantly impact productivity and safety. Hydraulic torque wrenches are a game-changer across multiple sectors, and Shingare Industries is committed to providing top-tier solutions for all your industrial needs.

For expert consultation and premium-quality hydraulic torque wrenches, contact Shingare Industries today!

1 note

·

View note