#Manufacturing of the components

Explore tagged Tumblr posts

Text

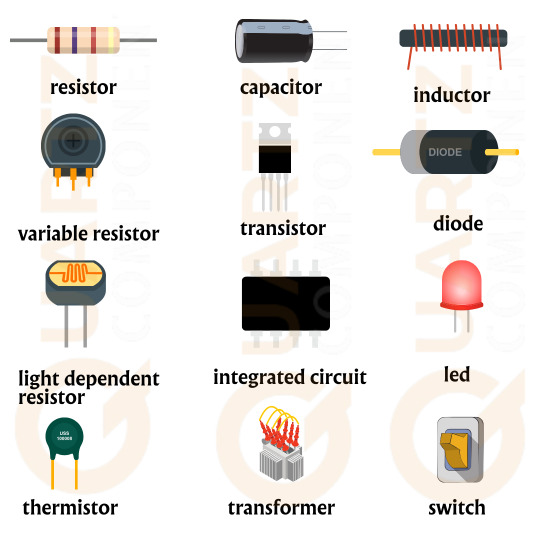

Electronics Components #components #electronics #engineering #electrical #arduino #electronic #innovation #design #robotics #electroniccomponents #raspberry #technology #manufacturing #industrial #gaming #school #learningbydoing #solar #bahrain #pc #pcb #budaiya #muhharaq #manama #engineeringforkids #saar #riffa #makersgonnamake #isatown #summerprogram

#Electronics Components#components#electronics#engineering#electrical#arduino#electronic#innovation#design#robotics#electroniccomponents#raspberry#technology#manufacturing#industrial#gaming#school#learningbydoing#solar#bahrain#pc#pcb#budaiya#muhharaq#manama#engineeringforkids#saar#riffa#makersgonnamake#isatown

13 notes

·

View notes

Text

J-Cube Technologies Inc.

J-Cube Technologies Inc. is an organization that specializes in the production of printed circuit boards (PCBs).

Our company is based in Montreal, Canada, and has been active in the industry for over a decade. Through our success in Asian infrastructure development and the expansion of our engineering and technical manufacturing expertise, we have grown to be a world-class provider of comprehensive and reliable electronic solutions.

#jcubetech#jcubetechca#J-Cube Technologies Inc#metal pcb#metal core pcb manufacturer#metal core printed circuit board#aluminum core pcb#mcpcb#LED MPCB#Ceramic PCB#mcpcb manufacturer#Quick turn mpcb#pcb core#Printed Circuit Board#Analog circuit#Bare board#Blind via#Component#Dip Trace#Schematic Capture#Library Pane#Schematic Pane

2 notes

·

View notes

Text

PCB Manufacturing-PCB Assembly-Hitech Circuits

Hitech Circuits is a lеаding PCB Manufacturing & PCB Assembly company with more than 20 years experience in the electronics manufacturing industry. We focus on PCB Design, PCB Layout, Circuit board fabrication, Turnkey PCB assembly, and electronic parts sourcing services.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

We offer a full range of Electronic manufacturing services.

-LED PCB

-Heavy Copper PCB

-Multilayer PCB

-HDI PCB

-Flexible PCB

-Rigid-Flex PCB

-High Speed PCB

-High Frequency PCB

-PCB Reverse Engineering

7 notes

·

View notes

Text

Top 5 Automotive Companies and How Metalman Auto Ltd. Supports Them

The automotive industry is dominated by several key players that lead the market in terms of innovation, production, and market share. The top five automotive companies globally are typically considered to be Toyota, Volkswagen Group, Daimler AG (Mercedes-Benz), Ford Motor Company, and General Motors (GM).

How Metalman Auto Ltd. Supports These Automotive Giants

As a leading supplier of high-quality automotive components, Metalman Auto Ltd. is well-positioned to support these top automotive companies. Our expertise in metal fabrication and assembly allows us to provide critical components that meet the specific needs of these manufacturers.

Our Value Proposition:

High-Precision Components: We provide parts that are essential for the safety and performance of vehicles, adhering to the exact specifications required by these top manufacturers.

Collaborative Approach: We work closely with OEMs to understand their needs and provide innovative solutions that enhance vehicle performance and safety.

Sustainable Manufacturing: Our commitment to sustainable practices ensures we contribute positively to the automotive industry’s environmental goals.

By partnering with Metalman Auto, these top automotive companies can enhance their supply chain efficiency and maintain their competitive edge in the global market.

#EV components supplier#Electric car parts manufacturer#Battery components supplier for EVs#Electric vehicle drivetrain parts supplier#EV charging components manufacturer#Electric motor parts supplier#EV battery management system supplier#Electric scooter parts manufacturer#general motors#vintage automobiles#chevrolet#Volkswagen Group#automotive industry#automotive#automotive components#metal fabrication#oems#oemparts#oem manufacturing#oem#metal parts supplier#India automotive components manufacturer#Automobile parts production in India#OEM parts manufacturing in India#Indian automotive parts supplier#Vehicle parts manufacturing industry in India#Made in India automotive components#Indian car parts production#India-based automotive parts manufacturer"

2 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Your trusted source for CNC turned components. High-quality, customized CNC turned parts solutions for precision engineering needs.

2 notes

·

View notes

Text

#Stainless Steel Pin Manufacturer in Delhi#Stainless Steel Pins Manufacturer#Hinge Pins Manufacturer#Dowel Pins Manufacturer#KNURLED PINS Manufacturer#Precision CNC Turned Component Manufacturer#Precision Turned Component Manufacturer

2 notes

·

View notes

Text

I've decided I'm going to slowly buy my computer piece by piece, rather than all at once.

And of course, the GPU I want keeps coming back in stock and then disappearing by the time I click the stock notification link.

Are a lot of people building midrange gaming PCs right now, or is there another stupid crypto boom I have to worry about?

#tech yearning#I'm gonna buy the GPU first since it's the most expensive component#The slightly pricier one I placed as a second choice is still in stock via the manufacturer's newegg page#Whichever one is easily available when I get paid next is what I'm gonna go with#this is annoying af

5 notes

·

View notes

Text

Multilayer SMT Manufacturing PCBA Board

For a Express PCB prototype assembly quote, please email the following files to [email protected] :

BOM list

Gerber files

Quantity required

Our team is qualified to manage the complete process, which includes the sourcing of all components (PCB and Components), online order tracking and their management, PCB assembly, quality control and delivery.

We have specialized experts to deliver fast-turnaround, prototype printed circuit board assembly with surface-mount (SMT), through-hole (THT) and mixed-technology components. Our efficient and express PCBA prototyping service team can assemble printed circuit boards in as little as 24 hours.

5 notes

·

View notes

Text

Daily Semiconductor Industry Information By Lansheng Technology

1. At the VLSI Symposium 2023, which will be held next month, Intel will demonstrate the PowerVia technology verification chip.

2. On May 5th, Samsung Electronics is expected to surpass its main competitor TSMC in the field of chip foundry within 5 years.

3. According to media reports, Meta recruited a team from the British artificial intelligence chip company Graphcore. The team previously worked in Oslo, Norway, and was developing AI networking technology at Graphcore until late last year.

4. On May 5, 2023, semiconductor product companies Alpha and Omega Semiconductor once fell by 11.64% in intraday trading, and once touched $20.64. The stock price hit a new low since November 18, 2020.

5. Following in the footsteps of #Samsung, SK Hynix and Micron, the US chip giant Qualcomm’s latest quarterly revenue fell -16.9% year-on-year to US$9.275 billion, and its net profit fell sharply -41.9%. The three major business segments of mobile phones, automobiles and IoT All have declined to varying degrees, and its forecast data for the third fiscal quarter is also lower than market expectations.

Lansheng Technology Limited (https://www.lanshengic.com/) is a global distributor of electronic components that has been established for more than 10 years, headquartered in Shenzhen China, who mainly focuses on electronic spot stocks

6 notes

·

View notes

Text

Shaping the Future: The Rise of Stainless Steel Components Manufacturers in India

In recent years, India has emerged as a powerhouse in the manufacturing sector, particularly in the production of stainless steel components. This surge can be attributed to various factors, including technological advancements, evolving market demands, and a skilled workforce. Stainless steel components play a crucial role in numerous industries, including automotive, construction, and aerospace, due to their durability, corrosion resistance, and aesthetic appeal.

One of the key drivers behind the growth of stainless steel components manufacturing in India is the country's abundant availability of raw materials, particularly stainless steel. With the government's emphasis on initiatives like "Make in India," there has been a significant push to boost domestic manufacturing and reduce dependency on imports. This has led to the establishment of numerous stainless steel component manufacturing units across the country, catering to both domestic and international markets.

Amidst this growth, companies like Meck Industries have played a pivotal role in shaping the landscape of stainless steel component manufacturing in India. Established in 1990, Meck Industries has carved a niche for itself as a leading provider of precision turned parts. Specializing in CNC machining and automatic screw machines, Meck Industries has earned a reputation for its commitment to quality, reliability, and innovation.

With a state-of-the-art facility located in G.I.D.C. Makarpura, Vadodara, Meck Industries is well-equipped to meet the diverse needs of its clientele. The company's skilled workforce, coupled with its investment in cutting-edge technology, has enabled it to deliver superior stainless steel components to various industries, including electrical, automotive, and sheet metal.

Moreover, Meck Industries' dedication to customer satisfaction and continuous improvement has been instrumental in driving its growth and success. By adhering to stringent quality standards and embracing innovative manufacturing processes, Meck Industries has positioned itself as a trusted partner for stainless steel component requirements, both domestically and internationally.

Looking ahead, Meck Industries remains committed to pushing the boundaries of excellence in stainless steel component manufacturing. With a focus on leveraging technology, fostering innovation, and expanding its global footprint, Meck Industries is poised to continue shaping the future of the industry and contributing to India's manufacturing prowess on the world stage.In conclusion, the rise of stainless steel components manufacturers in India, exemplified by companies like Meck Industries, underscores the country's growing dominance in the global manufacturing arena. With a blend of tradition, innovation, and excellence, Indian manufacturers are poised to lead the way in shaping the future of stainless steel component manufacturing worldwide.

1 note

·

View note

Text

E Rickshaw Spare Parts

Nanya is an established business name in India, which came into inception in 1935. The company is an age-old traditional business family, which has emerged as one of the leading manufacturers and suppliers of E-Rickshaws Parts in India.

Nanya Erickshaw is a leading provider of spare parts for electric rickshaws, electric bikes, and electric scooters. Our products are designed to meet the needs of e-vehicle owners and operators, offering top-quality parts and accessories that enhance the performance, safety, and durability of their vehicles.

As a reliable supplier of e-vehicle spare parts, we offer a wide range of products that cater to the diverse needs of our customers. Whether you need spare parts for your e-rickshaw, e-bike, or e-scooter, we have you covered. Our inventory includes high-quality batteries, controllers, motors, brake systems, suspension systems, lighting systems, and much more.

We are reputable manufacturers and our products subjected to rigorous quality control checks to ensure their reliability and safety. We understand the importance of having access to high-quality spare parts that are compatible with your e-vehicle, which is why we strive to provide only the best products on the market.

Our team of experts is committed to providing exceptional customer service and technical support to help you find the right spare parts for your e-vehicle. Whether you are a fleet owner, a repair technician, or an individual e-vehicle owner, we are here to help you find the products you need to keep your e-vehicle running smoothly and efficiently.

At Nanya Erickshaw, we are dedicated to helping our customers achieve their goals of reducing their carbon footprint and promoting sustainable transportation. By providing top-quality spare parts for e-vehicles, we aim to contribute to the growth of the e-vehicle industry and make it more accessible to people worldwide.

If you are looking for reliable and high-quality spare parts for your e-rickshaw, e-bike, or e-scooter, look no further than Nanya Erickshaw. We are committed to providing the best products and services to our customers and helping them achieve their transportation goals.

#E-Rickshaw Spare Parts#E-Rickshaw Spare Parts and Components Price#E Rickshaw all spare parts#ई रिक्शा स्पेयर पार्ट्स दिल्ली#Best Manufacturer and Supplier of E-Rickshaw Spare Parts in India#E Rickshaw Motor#E Rickshaw Motor and Spare Parts#E Rickshaw Hardware and Components#E-Rickshaw Body Parts and Accessories#E-Rickshaw Body Parts and Accessories Price#e rickshaw auto parts

5 notes

·

View notes

Text

Grinding Power Tool Switches Market Report Includes overview,key points,reseason to buy, and Application 2017 – 2032

Overview of the Grinding Power Tool Switches Market:

The grinding power tool switches market deals with the switches used in power tools specifically designed for grinding applications. These switches are essential for controlling the operation of grinding power tools, ensuring user safety and convenience.

Here is an overview of the grinding power tool switches market and its key factors:

Growing Demand for Power Tools: The overall demand for power tools, including grinding tools, is increasing due to their versatility and efficiency in various industries such as construction, manufacturing, automotive, and DIY (do-it-yourself) applications. This rising demand directly drives the market for grinding power tool switches.

Safety and User Convenience: Grinding power tool switches play a critical role in ensuring the safety of operators and users. They provide control over the tool's operation, allowing users to start or stop the grinding process as needed. Switches with safety features like lock-on buttons or paddle switches that require continuous pressure contribute to user convenience and prevent accidental activation of the tool.

Government Regulations and Safety Standards: Various government regulations and safety standards exist to ensure the safe operation of power tools. Manufacturers of grinding power tools need to comply with these regulations, including the use of approved and certified switches. Compliance with these regulations drives the demand for reliable and compliant switches in the market.

Technological Advancements: The grinding power tool switches market has seen advancements in switch technology. These advancements include the development of switches with improved durability, reliability, and ergonomics. Features such as dust resistance, vibration resistance, and enhanced switch life contribute to the market growth.

Replacement and Aftermarket Demand: As power tools and their components, including switches, undergo wear and tear with usage, there is a constant need for replacement switches. The aftermarket demand for grinding power tool switches contributes significantly to the market, as users seek to replace damaged or worn-out switches to maintain the functionality of their power tools.

Industry-specific Applications: The grinding power tool switches market caters to various industry sectors where grinding operations are performed, such as metal fabrication, woodworking, construction, and automotive repair. The specific requirements of these industries, such as ruggedness, water resistance, or dust resistance, drive the demand for switches designed to withstand harsh operating conditions.

Increasing DIY and Home Improvement Projects: The rise in DIY culture and home improvement projects has boosted the demand for power tools, including grinding tools. Consumers engaging in DIY activities or small-scale projects often purchase power tools for their personal use. This contributes to the overall market growth of grinding power tool switches.

Emerging Markets: The demand for grinding power tool switches is also influenced by the growth of emerging markets, especially in developing regions. Increasing urbanization, industrialization, and infrastructure development projects in these regions contribute to the market expansion as the demand for power tools and related components rises.

Overall, the grinding power tool switches market is driven by the growing demand for power tools, emphasis on safety and user convenience, compliance with regulations and standards, technological advancements, replacement and aftermarket demand, industry-specific applications, the rise of DIY culture, and the growth of emerging markets.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/grinding-power-tool-switches-market/6586/

Market Segmentations:

Global Grinding Power Tool Switches Market: By Company

• Defond

• Marquardt GmbH

• Weida Machinery

• HUAJIE

• Kedu Electric

• CPX Switch

• Chuanmu Electric

• Tyco Electronics

• Yueqing Jlevel Electrical

• Guosheng Instrument

• TACLEX

• Baokezhen

• Shunfa

• Bremas

• Superior Electric

Global Grinding Power Tool Switches Market: By Type

• DC and AC Speed Control Switch

• Single Speed Switch

• Micro Switch

• Trigger Switch

• Rocker Switch

• Others

Global Grinding Power Tool Switches Market: By Application

• Wired Grinding Power Tool

• Wireless Grinding Power Tool

Global Grinding Power Tool Switches Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Grinding Power Tool Switches market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/grinding-power-tool-switches-market/6586/

Reasons to Purchase Grinding Power Tool Switches Market Report:

• To gain insights into market trends and dynamics: this reports provide valuable insights into industry trends and dynamics, including market size, growth rates, and key drivers and challenges.

• To identify key players and competitors: this research reports can help businesses identify key players and competitors in their industry, including their market share, strategies, and strengths and weaknesses.

• To understand consumer behavior: this research reports can provide valuable insights into consumer behavior, including their preferences, purchasing habits, and demographics.

• To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.

• To make informed business decisions: this research reports provide businesses with data-driven insights that can help them make informed business decisions, including strategic planning, product development, and marketing and advertising strategies.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Grinding Power Tools#Power Tool Switches#Power Tool Accessories#Power Tool Components#Power Tool Switching Mechanisms#Switches for Grinding Tools#Grinding Tool Switches#Power Tool Safety#Power Tool Controls#Switching Solutions#Industrial Switches#Electrical Switches#Power Switches#Power Tool Manufacturers#Power Tool Suppliers#Power Tool Distributors#Power Tool Retailers#Power Tool Market#Grinding Equipment#Switching Technology#Power Tool Industry#Grinding Power Tool Switching Solutions.

2 notes

·

View notes

Text

Get ready to experience Metalman Auto like never before! 🚀

Our new website is set to launch with a UI Experience and immersive 360-degree product views. This fresh digital experience is designed to showcase our strengths, capabilities, and commitment to quality in the automotive and non-automotive sectors. 🔧 What to Expect:

A sleek and modern user interface

Detailed 360-degree views of our top products

Enhanced navigation and a user-friendly experience

Comprehensive insights into our services and expertise

At Metalman Auto, we are constantly innovating to deliver excellence in metal fabrication, tubular solutions, and OEM partnerships. And now, we are bringing that innovation online! Stay tuned as we prepare to unveil a new chapter in Metalman Auto’s digital journey. Be the first to explore our innovations, discover our solutions, and connect with us like never before. 📅 Launch Date: Coming Soon! . #MetalmanAuto #AutomotiveIndustry

#automobile#automotive#car accessories#automotive parts#automotive industry#automotive tools#automotive art#vehicle#oem#oemparts#oem manufacturing#factory#heavy metal#metalman auto#Two-Wheeler Parts Manufacturer#Three-Wheeler Components Supplier#Passenger Vehicle Parts Manufacturer#Automotive Metal Components Supplier#Custom Metal Fabrication for OEM#metal fabrication#steel fabrication#fabricationservices#manufacturer#newport fabrication inc in canada#supplier#Electric Vehicle (EV) Parts Supplier#electric vehicles#hyundai#evs#electric car

3 notes

·

View notes

Text

Loving the spirit of this but rather than simply letting third parties copy whatever thing I'd much rather that these things specifically become public goods.

Relying on private individuals to upload and maintain media with no accountability is annoying and also what got us into this mess. Luckily, we Have institutions in place already to do this - Libraries are Right There. Let them run a database of online movies, books, and other such things that are no longer available for whatever reason. Not only is it free, its safe, and accessible, and not likely to be shut down out of the blue.

law idea: products that are not currently and will not be purchasable from the parent company for the foreseeable future are not counted as "copywritten" in regard to the sharing, reproduction, and other "piracy" claims in court of law.

if you aren't selling them your customer doesn't have to buy

this is in regards to all copyright, if someone starts a factory producing clones of iPhone and iMac chips for the purpose of repairing devices, that's not copyright infringement, because apple does not sell those chips :)

if they want to keep their copyright they can put their repair chips on the public market, continue matinance of old products, etc

Nintendo will hate this law the most I'm sure.

widows is surprisingly robust to this law as you can actually buy every copy of windows ever produced right now on windows website, albeit you might have a hard time finding it because they'd PERfer you didn't.

streaming companies dropping original content from their service for tax purposes can expect to find it on YouTube the next day for free no ads

I think you all will be able to see how this will have a hotting effect on the market, where as now copyright holders have the power to delete content from the legal sphere, under this law they cannot do that. they can sell it themselves or they can give it away for free.

no more manufactured scarcity for the sake of inflating already inflated prices

#i also feel like letting third parties manufacture expired parts is not the way to go#but its a decent bandaid for the problem#which is much more comprehensive and has to do with planned obsolecense#the seesaw between software and hardware enabled by the lack of sufficient software regulations#and the colonialism and exploitation of the african countries where most of the physical components used to make such devices are located#the main idea though is that software should work on its original hardware ad infinitum#updates should be Upgrades and should be optional#critical updates should come with an apology and should be free

15K notes

·

View notes

Text

0 notes