#Manufacturer of Pneumatic piping

Explore tagged Tumblr posts

Text

Shift Air India as a Leading Manufacturer of Pneumatic Airlines

Shift Air India is a renowned manufacturer of pneumatic airline, catering to a wide range of industries. The pneumatic airlines made by the organization are made to be effective, dependable, and long-lasting to ensure optimal performance and lifespan.

At Shift Air India, we manufacture our pneumatic airlines using cutting-edge technology and sophisticated production methods. Prior to delivery to our consumers, we also make sure that our items are rigorously inspected for quality and safety.

Our pneumatic airlines are appropriate for a variety of applications because they are available in a range of sizes and specifications. In order to specifically satisfy customer needs, we also provide customized solutions. We are known as a top producer of pneumatic airlines in India thanks to our dedication to quality and client satisfaction.

#Manufacturer of Pneumatic piping#Manufacturer of Pneumatic airline#Manufacturer of Air line#Manufacturer of Industrial piping

0 notes

Text

Internal Pneumatic Line-up Clamp Self USA,Mexico,UAE,Turkey,Egypt,Australia&Russia.

Internal Pneumatic Line-up Clamp is extremely robust and built to special high standards to withstand pipeline spread operations. Clamps are adjustable for any wall thickness or size within the specified range—independently operated pneumatic jaws allow the line-up of pipes with different wall thicknesses. When correctly used, Line-up Clamp will not damage or “bell end” the pipe.

Internal Pneumatic Line-up Clamp travels through the pipe to the next joint under its power. We are an Internal Pneumatic Pipe Line-up clamp manufacturer, supplier & Exporter in Russia, USA, UAE, Australia, and Malaysia. It requires compressed air at 100-145 psi (7-10 bars). The maximum safe working pressure is 175 psi (12 bars).

The Internal Pneumatic Line-up Clamp is a versatile tool used in oil and gas pipeline construction. Its adjustable clamps can adjust pipes of different sizes and thicknesses, making it a flexible and most important piece of equipment for Oil and Gas Pipeline Construction.

#internal pneumatic line-up clamp#internal hydraulic line-up clamp#pipeline roller#pipe roller manufacturer#cross country pipeline equipment

1 note

·

View note

Text

About Anjney

Anjney is the leading manufacturer of Non-Metallic Industrial Pipes and Fittings with an innovative concept of ENERGY SAVING. We are 'the pioneers of the piping industry since last 22 years. With our rock-solid experience, R & D and keeping in mind our customer's expectations, we at Anjney constantly strive to launch new and ground-breaking technologies in the market.

Living up to our Motto, we have developed new futuristic products with high precision, new technology and premium grade components. This provides longer life to the product, reduces payback period of the investments and almost nil maintenance throughout the life of the product. Thus, our products are designed to deliver and they live up to every detail of complete customer satisfaction.

#PPCH Pipe#PPR Pipe#PPRC Pipes#PPRCT Pipes#glass reinforcement pipe#Thermal FR Composite Pipes#multilayer pipe#fiberglass pipe#polymer pipe#ppch fr pneumatic pipes#Fitting#Manufacturers#Exporters#PPCH PIPE#Pipe#tube#anjney#ppr#pprc#pprct#ahmedabad#india#anjney pipe

0 notes

Text

Flange Tool Kit | Subzero solutions

We Subzero Solutions are Portable pipe beveling machine and Flange Tool Kit manufacturers in Mumbai. This Machine is suitable for workshop and on-site application due to its portable design We carry extensive stock of our standard products to ensure we meet our customer's needsin the quickest turnaround time. Our aim is to give complete package for our customers from advising industry- leading solutions to giving customised products for specific applications within the committed time frame. For More Details Visit Our Website https://subzerosolution.com/flange-tools/

0 notes

Text

DP2 - Wandering Earth

Week 19:

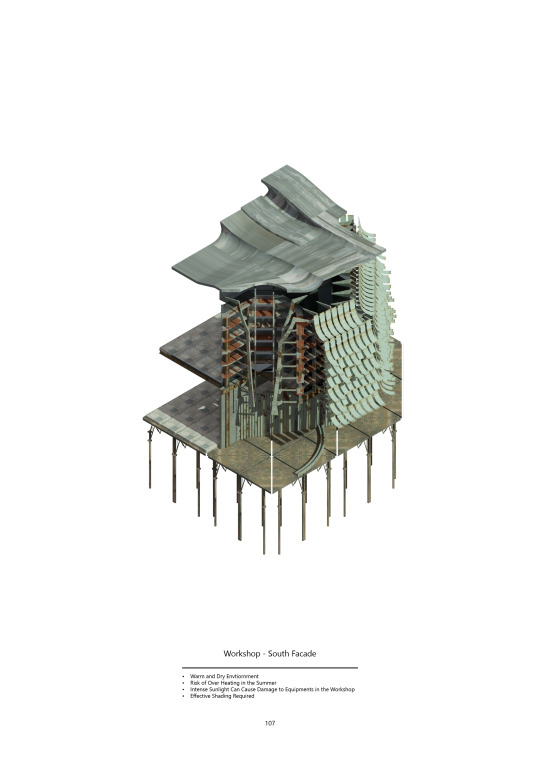

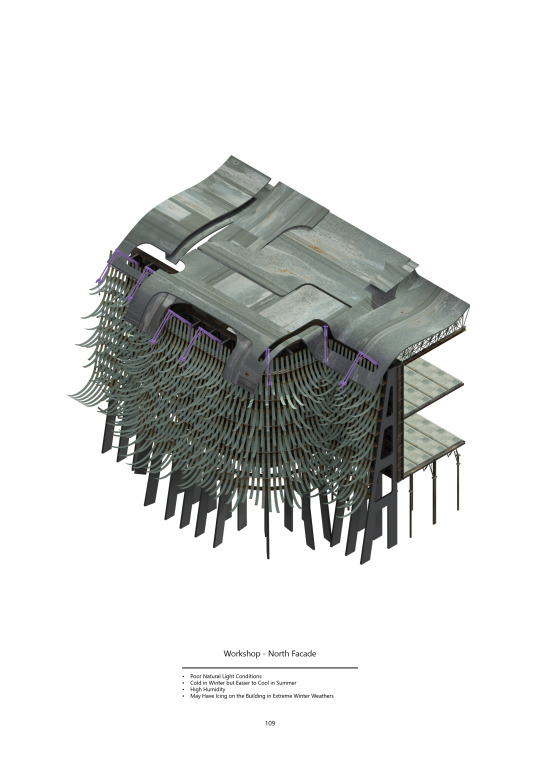

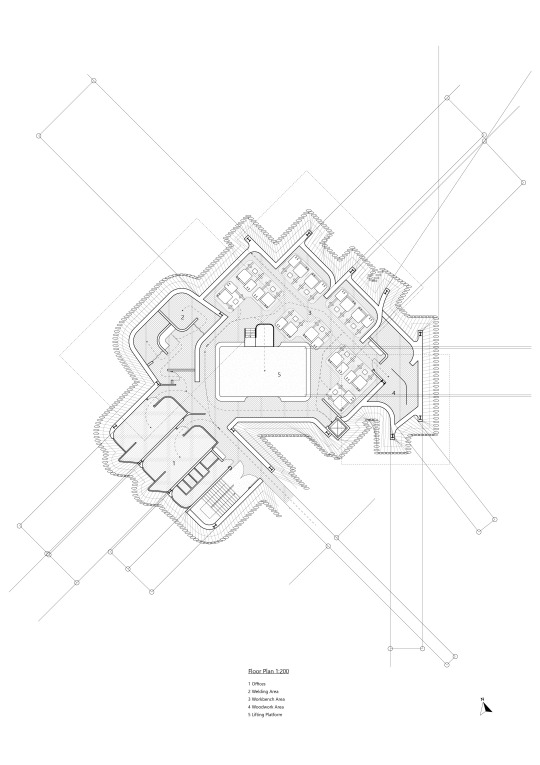

This week I kept focusing on the workshop by first improving on the plan and then choosing three zones from the plan and designed the roof, facade and structural systems specifically to the environmental conditions required by each zone:

The south facing facade receives the highest level of solar radiation and activities including cutting and drilling take place in this zone, which can lead to overheating in the space, especially at summer. Therefore a layered strategy is implemented on the facade with dense and wide rain-fuel/solar panels acting also as shading devices which can result in effective cooling off the space.

The East Facing Facade provides excellent natural light in the morning and has a good view down the hill towards the city, therefore there are voids on the facades to provide opportunities for a balcony area. The facade panels are more curled up to further provide natural lighting and views as there are workbenches behind the east facade.

The North Facade in 2050 will encounter more severed environmental conditions as it receives poor natural light and is normally cold and damp. Therefore the facade panels are less dense to allow more light entering the space and more gaps on the roof to provide lighting. Deicing systems inspired by the aviation industry extends out from the roof to clean the icing that may form on the facade.

The Roof has different levels and grooves to direct the rainwater to drip down onto the facade elements and utilises its potential energy to regenerate energy; but also recycled into the bathroom to be reused. The roof has a curved shape that rises at certain points for lighting purposes.

I should keep working on these three design modules and use line drawings in combination with these renders to reveal the HVAC, structural and water systems of the space. Doing lighting and heating simulations on the interior space to prove the systems function properly

Key ideas mentioned:

Hollow tiles for heating and ventilation systems running through

shape the tiles so it guides the cool down streaming air around the furniture in the room

Pneumatically designed air exhaustion systems for manufacturing area (Reference to Zaha Science Museum)

Shelving systems on the facade to hang and dry the pieces manufactured in the workshop

Light pipes bringing light to the working area that is integrated with the furniture

furniture suspended from the ground with localized heating, water running through the furniture

Ramps connecting the buildings that extend out into the forest and foreshadowing the theme and emotions that the next building is going to bring to the visitors. Buildings get cut through similarly to canyons.

When presenting, show how spatial organization, facade systems and furniture systems are designed differently according to the hot and cold environment and lux levels.

8 notes

·

View notes

Text

The Craftsmanship behind Fittings Manufacturing

Fittings like plastic fittings China are connectors that connect pipes, tubes, or hoses. They are intended to form a secure and leak-proof connection, allowing for the uninterrupted passage of liquids, gasses, or even solid objects. Plumbing, HVAC systems, hydraulic and pneumatic machinery, oil and gas pipelines, and other applications all employ fittings. These little components are the unsung heroes of numerous sectors, keeping together contemporary society's complicated architecture.

Fittings: An Art Form Manufacturing

Manufacturing fittings is a complex procedure that necessitates accuracy and attention to detail. Here's a rundown of the stages required in making fittings:

Material Selection: The selection of materials is critical in the manufacture of fittings. diverse materials, such as brass, stainless steel, PVC, or copper, are required for diverse uses. The material used must be corrosion-resistant, long-lasting, and suitable for the contents transported.

Engineers design fittings with accuracy, taking into account parameters such as pressure ratings, temperature, and flow needs. To generate precise and trustworthy products, the design process may use computer-aided design (CAD).

Machining: Machining procedures like as turning, milling, and drilling are commonly used to make fittings from metal fittings manufacturer. These operations shape and refine the material into the correct shape, guaranteeing that the fitting will work properly.

Quality Control: Throughout the production process, stringent quality control methods are employed. Inspections, testing, and monitoring are performed to ensure that the fittings fulfill industry standards and requirements.

Surface Finish: Depending on the application, fittings may be polished, plated, or coated to improve their durability and appearance.

Manufacturing Fittings Innovations

In recent years, the field of fittings production has undergone considerable developments. These advancements seek to boost efficiency, decrease environmental impact, and increase product performance. Among the significant advancements are:

3D Printing: Additive manufacturing, including 3D printing, is becoming more popular for producing complicated, bespoke fits with minimal material waste.

Sustainable Materials: To lessen its environmental imprint, the industry is investigating eco-friendly materials and manufacturing procedures.

Rapid prototype: Computer-aided design and rapid prototype techniques enable the creation and testing of novel fitting designs to be completed more quickly.

IoT technology is being integrated into fittings from plastic fittings manufacturers to monitor and optimize fluid flow, identify leaks, and increase system performance.

Follow our Facebook and Twitter for more information about our product.

#Metal fittings manufacturer#Metal fittings manufacturer China#Professional Metal Manufacturer#Metal Manufacturer China

2 notes

·

View notes

Text

Hydraulic Manifold valve manufacturer in india by hydrofittings

In addition, an Air Manifold With Valves allows the set up of more than one solenoid valves in a centralized vicinity. A unmarried air deliver and port are shared by means of numerous valves. Manifold take a look at Valve acts as a primary distribution point for aircraft that have dual dry air pumps. If one pump of Manifold Pneumatic fails it’s miles designed to isolate the failed pump and provide continuous airflow from the operating pump. Water Manifold With Valves is designed to distribute water and has built-in ports in a section of pipe. They act as manage facilities of water distribution within the house. Solenoid Valve Manifold has a most preferred stress of 6000 psi at a hundred ranges F and has a mounting hollow that enables inside the self-supporting software. Hydraulic Valve Manifold Has a stainless steel pin that forestalls the bonnet from detaching itself from the frame due to vibration. Ball Valve Manifold has a burr-loose thread that reduces inner floor leaks accordingly offering accurate transmitter read. No O-ring is used bonnet to body pressure Transmitter Manifold seal. It is a steel-to-metallic seal. Hydraulic Valve Manifold Block has the choice of panel mounting. There are one of a kind sorts of Manifold Valves to be had within the market but the maximum typically used ones are the two valve, three valve, and 5 valve assemblies. Swagelok Manifold is designed mainly for liquid stage, static stress, and differential stress packages. Smc Valve Manifold has a blended isolating and venting in a single valve that eliminates the want for tubing and fitting. Festo Valve Manifold is simple to gather and set up and is dependable. They’ve dirt caps fitted on them that comprise stem lubricant and save you the ingress of contaminants. Rosemount 305 Manifold gets rid of the need for a flange because it suits immediately to the patented Rosemount. Why to choose hydrofittings ? About us – The briefcase of our company consists of numerous additions which include, – clever hydraulics, engineering, and digital answers. With the guide of 80 personnel, our company works like a well-oiled system to deliver most effective the very best fine product to our buyers. Proper from the responsibly sourced product by way of our procurement team to our nice manage team, many agencies have lauded our work. And that they admire the fact that we’re transparent in all our dealings. With a properly-mounted channel of communique, our customers can connect with us anytime. Our control and our body of workers, together form a competent and ambitious crew. The readability and high stage of performance make us one of the most modern but sought after manufacturers. And because we fee initiative behavior, we adore to have our studies and development crew collaborate with the opposite teams to recognize the current requirements of the hour. We frequently have checking out and great exams to maintain brilliant requirements.

An global provider of

TO KNOW MORE ABOUTS US VISITE OUR WEBSITE www.hydrofittings.com

3 notes

·

View notes

Text

How Can I Control Contaminants in My Industrial Air Compressor System?

Maintaining a clean and contaminant free industrial air compressor system is essential for ensuring efficiency, extending equipment lifespan, and maintaining product quality. Contaminants in compressed air can harm your business in more ways than one. They reduce product quality, damage manufacturing equipment, and even pose health risks to customers and end users. The good news? You can control these harmful particles before they impact safety or your bottom line. But first, let’s explore what these contaminants are, where they come from, and the problems they cause—so you can tackle them effectively.

Common contaminants in industrial air compressors

Several contaminants can enter an industrial air compressor system, affecting its performance. The most common include:

Moisture (Water vapour and condensation)

Moisture is the number one enemy of compressed air systems. Condensed water and aerosols can rust pipes, reduce efficiency, and increase maintenance costs. Without proper drying and filtration, your system’s performance takes a hit. If not removed, this moisture can lead to:

Corrosion of pipes and system components

Growth of bacteria and mold

Reduced efficiency of pneumatic tools

Particulates (Dust, dirt, and debris)

Rust, pipe scale, dust, and microorganisms slink into your system despite filtration. These tiny particles wear down components, damage equipment, and shorten the lifespan of an industrial air compressor. These contaminants can:

Block filters and valves

Damage moving parts inside the industrial air compressor

Contaminate end products in sensitive industries (e.g., food and pharmaceuticals)

Oil contamination

Many India compressor use oil for lubrication, cooling, or sealing. But when oil enters the system as a vapour, aerosol, or liquid, it mixes with moisture, turning acidic. This leads to rust, potential system failures, and even product contamination., leading to:

Damage to air-operated tools and machinery

Health hazards when used in breathing air applications

Reduced efficiency of pneumatic processes

Microorganisms and bacteria

Warm and humid environments inside air compressors create a breeding ground for bacteria, fungi, and mould. These can:

Contaminate production processes

Cause foul odors in compressed air output

Lead to product spoilage in food and beverage industries

Effective strategies to control contaminants in industrial air compressor

Use High-quality air filters:

Air filters are the first line of defence against airborne contaminants. Air compressor manufacturers can use different types of filters to remove specific pollutants:

Particulate filters: Catch dust, dirt, and solid debris.

Coalescing filters: Remove oil aerosols and fine particles.

Activated carbon filters: Absorb oil vapours and odors for higher air purity.

Best methods for air filters:

Inspect and replace filters regularly.

Use multiple filters in sequence for enhanced protection.

Ensure filters match the required air purity standards for your industry.

Execute air dryers to remove moisture:

Moisture is one of the most damaging contaminants in a compressed air system. Installing air dryers can help control excess water.

Types of air dryers:

Refrigerated dryers: Cool the air to condense and remove moisture.

Desiccant dryers: Absorb moisture using chemical desiccants.

Membrane dryers: Use selective permeable membranes to dry compressed air.

Install automatic drain valves:

Even with air dryers, condensation can collect in the system. Automatic drain valves help remove this moisture from an industrial air compressor, tanks, and filters.

Drain valve guidance:

Use electronic or timer-based drain valves for automatic moisture removal.

Install drains at multiple points, including air tanks and low-lying sections.

Maintain oil-free compressed air where necessary:

In industries such as food processing and medical applications, oil-free air is necessary. Using oil-free compressors or advanced filtration can ensure minimal oil contamination.

Oil-free solutions:

Use oil-free air compressors if the application requires pure air.

Install oil removal filters and coalescing filters in oil-lubricated systems.

Monitor and maintain system components regularly:

Routine maintenance plays an essential role in controlling contaminants. Regular inspections and servicing prevent buildup and maintain system efficiency.

Key maintenance tips:

Check and replace filters, dryers, and drain valves regularly.

Inspect air lines for leaks and corrosion.

Conduct regular audits to monitor air quality and performance.

Ensure proper air intake placement:

Where the air compressor removes air from affects contamination levels. Placing the intake in a clean, dry area away from dust, fumes, and pollutants minimizes contamination.

Air intake placement tips:

Keep air intake away from exhaust fumes and chemical storage areas.

Install pre-filters if the air source contains excessive dust.

Summary:

Controlling contaminants in industrial air compressor systems is essential for optimizing efficiency, ensuring product quality, and extending equipment life. By executing proper filtration, drying techniques, regular maintenance, and following industry standards, you can significantly reduce the risk of contamination. Choosing high-quality air compressor manufacturers and reliable filtration solutions will also enhance system performance and safety. With the right strategies in place, you can maintain clean, high-quality compressed air that meets the demands of your industry.

#compressed air#air compressor manufacturers#industrial air compressor#air compressors#air compressor manufacturers in india

0 notes

Text

Flat Flange Mono, Blind Mono Flange, Butt Weld Adapter, Mumbai, India

Manufacturer and Supplier of Flat Flange Mono, Blind Mono Flange, Butt Weld Adapter, Integrated Threaded with O Ring, Mumbai, India.

Quick Release Coupling, Quick Release Couplings, Ball Valve, Ball Valves, Gemel Ball Valves, Industrial Ball Valves, Quick Coupling, Quick Couplings, Camlock Coupling, Camlock Couplings, Camlock Quick Coupling, Camlock Quick Couplings, Micro Hose, Micro Hose For High Pressure, Micro Hose For Pressure Fittings, Test Coupling, Test Couplings, Minipress Test Coupling, Minipress Test Couplings, Test Point Coupling, Test Point Couplings , Threaded Test Coupling, Threaded Test Couplings, Bulkhead Test Coupling, Bulkhead Test Couplings, Female Swivel Test Coupling, Female Swivel Test Couplings, Plug in Test Coupling, Plug in Test Couplings, Pressure Gauge Adaptors, Cartridge Valve, Cartridge Valves, Hydraulic Hoses, Hydraulics Hose, Hoses Crimped Hydraulic, Hydraulic Systems, Pneumatic Systems, Hydraulic Accessories, Hydraulic Couplings, Hydraulic Fitting, Hydraulic Fittings, SS304 Hydraulic Fittings, SS316 Hydraulic Fittings, CS Hydraulic Fittings, DIN 2353 Fittings, Pressure Gauge, Pressure Gauges, Industrial Valves, Coupling Valves, Hydraulic Components, Inline Valve, Inline Valves, Inline Flow Indicator, Inline Flow Indicators, Portable Hydraulic Crimping Machine, Portable Hydraulic Crimping Machines, Portable Hydraulic Instrument, Portable Hydraulic Instruments, Pressure Gauge Anti Shock Valve, Pressure Gauge Anti Shock Valves, Stainless Steel Hydraulic Components, High Pressure Check Valve, High Pressure Ball Valve, High Pressure Flow Control Valve, High Pressure Needle Valve, Non Return Valve, Gemels Italy Ball Valves, Holmbury Uk Couplings, Minipress Italy Couplings, Oleoweb Italy Valves, SS304 Csermeto Fittings, SS316 Csermeto Fittings, Flat Face Coupling, Quick Connect Disconnect Coupling, Screw Coupling 1000 Bar, Dust Cap, Test Point, Test Hose, Test Point Coupling, Test Point Hose, SAE Flange Ball Valve, Rotating Union, Hose Burst Check Valve, Compensated Load Control Valve, Compensated Flow Control Valve, Load Shuttle Ball Valve, End Stroke Valve, Single Acting Pilot Check Valve, Double Acting Pilot Check Valve, Double Cross Line Direct Acting Relief Valve, Single Cross Line Direct Acting Relief Valve, Sequence Valve, Single Counter Balance Valve, Dual Counter Balance Valve, Hand Pumps, Tube Clamp, Instrumentation Fittings, Lubrication Fittings, PP Pipe Clamp, Dowty Seal Copper Washer, Bonded Seal, Nut, Ferrule, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, navi mumbai, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon

0 notes

Text

Honeywell TP970B2002 Reverse Acting 2-Pipe Single Temperature 60°F-90°F | PartsHnC

Manufacturer Name: Honeywell Product Number: TP970B2002 OEM Part Number: TP970B2002 Product Description: R/A 2Pipe 60-90F Single Temp Weight:0.41lbs/185.97g

Honeywell's TP970B2002 is a Remote Bulb, Two-Pipe Thermostat that allows for accurate temperature control in heating systems. This thermostat is used in baseboard heaters and radiators, among other heating equipment.

For an efficient and reliable HVAC system, the Honeywell Pneumatic Thermostat is a great choice for optimal system performance.

#TP970B2002#Honeywell#Honeywellparts#PartsHnC#PartsHnCBuzz#HVACParts#FurnaceParts#AirConditionerParts

0 notes

Text

Leading Manufacturer of Air line

Shift Air India is a reliable high-quality Manufacturer of Air line products. To meet a variety of industrial needs, they provide a wide range of products, including air cylinders, valves, filters, and regulators. Businesses frequently choose their products because of their efficiency and durability.

1 note

·

View note

Text

Rubber Products Manufacturer: A Comprehensive Overview

Arvico is one of India’s leading rubber products manufacturers, exporters, and suppliers specializing in producing rubber diaphragms, rubber sleeves, PTFE components, rubber couplings, and rubber O-rings, among others. With over 50 years of experience, our brand offers customized components that precisely match your needs. We take pride in never compromising on quality, ensuring customer satisfaction and trust.

With a combined rubber industry experience spanning several hundred years, our team takes full ownership of rubber product manufacturing and its applications. We are dedicated to supporting you at every stage, ensuring high-performance solutions tailored to various industries. Passionate about our field, we are committed to delivering innovative rubber solutions that help businesses grow.

Industries Served

Arvico serves a diverse range of industries, including:

Pharmaceutical

Packaging

Oil & Gas

Food Processing

Nuclear

Electrical

Paper Industry

Chemical Processing

Textile Industries

Engineering

Medical & Life Sciences

Construction

Rubber Products and Applications

Rubber Diaphragms

Rubber diaphragms are flexible barriers that provide pressure control in mechanical and fluid systems. Manufactured using high-quality rubber compounds, they are essential in regulating flow, ensuring sealing, and preventing contamination in critical environments. These diaphragms are widely used in pumps, valves, actuators, and control systems where precision and durability are paramount.

Applications:

Utilized in automotive braking systems to enhance pressure modulation.

Used in industrial pumps to maintain fluid integrity and prevent leaks.

Found in medical equipment to enable controlled fluid dispensing.

Rubber Sleeves

Rubber sleeves serve as protective barriers against environmental damage, electrical currents, and mechanical wear. They offer resistance to high temperatures, chemicals, and abrasion, ensuring long-term functionality in demanding applications. Manufactured in various sizes and compositions, rubber sleeves help safeguard critical components across industries.

Applications:

Used in electrical insulation to prevent current leakage and improve safety.

Applied in industrial machinery to reduce vibration and mechanical wear.

Incorporated into automotive systems to protect wires and hoses from external damage.

PTFE Components

PTFE Components are known for their exceptional chemical resistance, high thermal stability, and low friction properties. PTFE (Polytetrafluoroethylene) are widely used in demanding applications where exposure to harsh chemicals, extreme temperatures, and pressure fluctuations is common.

Applications:

Found in chemical processing plants to ensure corrosion-resistant piping systems.

Used in food and beverage manufacturing to maintain hygiene and prevent contamination.

Integrated into medical devices to enhance biocompatibility and durability.

Rubber Couplings

Rubber couplings are essential for flexible power transmission, helping to absorb shocks, vibrations, and misalignments in mechanical systems. These couplings improve operational efficiency while reducing maintenance needs and extending equipment lifespan.

Applications:

Used in industrial machinery to ensure smooth torque transmission and minimal vibration.

Found in automotive drive systems to enhance flexibility and reduce mechanical stress.

Employed in HVAC systems to prevent misalignment issues and ensure smooth operation.

Rubber O-Rings

Rubber O-rings are crucial for sealing applications, preventing leaks, and ensuring fluid retention in hydraulic and pneumatic systems. Available in various elastomeric materials, they provide excellent resistance against heat, chemicals, and pressure fluctuations.

Applications:

Used in hydraulic cylinders and pumps to create airtight seals.

Applied in aerospace engineering for fuel system integrity.

Essential in medical equipment to prevent contamination in fluid-handling systems.

Rubber Expansion Joints

Rubber expansion joints help absorb movement, reduce vibration, and compensate for thermal expansion in piping systems. They provide flexibility while maintaining system integrity, making them indispensable in fluid transport applications.

Applications:

Installed in HVAC duct systems to prevent stress from thermal expansion.

Used in chemical plants to manage pipeline movement and reduce strain.

Applied in bridge construction to allow structural expansion and contraction.

Rubber Bearing Bushes

Rubber bearing bushes act as vibration dampeners and shock absorbers in mechanical assemblies. Their ability to isolate noise and motion makes them essential in precision engineering and heavy-duty machinery.

Applications:

Used in automotive suspension systems to enhance ride comfort.

Incorporated into industrial equipment to mitigate mechanical stress.

Found in railway applications to improve track stability and reduce maintenance needs.

Rubber Gaskets

Rubber gaskets provide excellent sealing properties, preventing leaks and protecting machinery from contamination. They are manufactured in various shapes and sizes to meet the specific needs of different applications.

Applications:

Used in engines and machinery to prevent oil and coolant leaks.

Applied in pipelines to ensure tight sealing in high-pressure environments.

Essential in the food industry to maintain hygiene and prevent cross-contamination.

Extruded Rubber Profiles and Cords

Extruded rubber profiles and cords are custom-shaped elastomeric components used in sealing, insulation, and impact absorption. Their versatility allows them to be used across various industries.

Applications:

Utilized in construction to provide weatherproofing for doors and windows.

Found in marine applications to prevent water ingress in boats and ships.

Applied in automotive seals to enhance durability and noise reduction.

Moulded Rubber Parts

Moulded rubber parts are custom-designed components manufactured to meet specific industrial requirements. These parts ensure high precision and durability in various applications.

Applications:

Used in aerospace engineering for vibration damping and sealing solutions.

Found in agricultural machinery to enhance performance and longevity.

Integrated into electronic devices for insulation and impact resistance.

Rubber Hoses

Rubber hoses facilitate fluid transfer, offering flexibility, pressure resistance, and chemical stability. They are used in various sectors, from automotive to industrial processing.

Applications:

Essential in fuel delivery systems to ensure leak-proof fluid transport.

Used in hydraulic systems for efficient power transmission.

Incorporated in firefighting equipment to handle high-pressure water discharge.

Rubber Sheets

Rubber sheets offer high resistance to abrasion, impact, and environmental factors. They are used for flooring, insulation, and protective applications.

Applications:

Used in industrial flooring to provide slip resistance and cushioning.

Applied in gasket manufacturing to create custom sealing solutions.

Essential in construction to prevent structural wear and corrosion.

Conclusion

Arvico takes pride in offering top-quality rubber products that cater to a wide range of industries. Our commitment to innovation, durability, and performance has positioned us as a leading rubber product manufacturer in India. Whether you require custom rubber components or industry-specific solutions, Arvico is your trusted partner in delivering excellence.

youtube

0 notes

Text

Mechanical Descaler Machine: How to Make the Right Choice and Maximize Benefits

Mechanical descalers are essential tools in industries that deal with heavy machinery, pipelines, and manufacturing processes where scale buildup is a common issue. Choosing the right mechanical descaler machine ensures efficient operation, reduces maintenance costs, and prolongs equipment lifespan. This guide will help you understand how to select the best descaler for your needs and how to maximize its benefits.

Pre Drawing Machine Manufacturers

Understanding Mechanical Descalers

A mechanical descaler machine is designed to remove rust, scale, and other deposits from surfaces such as pipes, boilers, and industrial equipment. It operates through various methods, including brushing, scraping, or high-pressure cleaning. The efficiency of a descaler depends on its power, compatibility with different materials, and its ability to handle varying levels of scaling.

Factors to Consider When Choosing a Mechanical Descaler

1. Type of Scaling and Surface

Before selecting a descaler, assess the type of scaling you need to remove. Heavy rust or thick mineral deposits require a high-powered mechanical descaler, whereas lighter scaling can be removed with simpler tools. Also, consider the material of the surface—some descalers work best on metal, while others are suitable for delicate surfaces.

2. Power Source and Portability

Mechanical descalers can be powered by electricity, compressed air, or hydraulics. If your work requires mobility, opt for portable electric or pneumatic descalers. For heavy-duty industrial use, stationary hydraulic descalers may be more effective.

3. Efficiency and Speed

A high-speed descaler can clean large surfaces quickly, saving time and labor costs. Look for machines with adjustable speed settings to accommodate different types of scaling.

Mechanical Descaler Machine Manufacturers

4. Durability and Maintenance

A robust machine made from high-quality materials will last longer and require less maintenance. Stainless steel components are ideal for corrosion resistance. Also, check for easy-to-replace parts and availability of servicing to keep your machine running efficiently.

5. Safety Features

Since mechanical descaling involves abrasive processes, choose a machine with safety features such as protective shields, automatic shut-off functions, and ergonomic handles to reduce strain on operators.

6. Cost vs. Long-Term Benefits

While budget is a key factor, investing in a high-quality descaler can save money in the long run by reducing equipment downtime and maintenance costs. Compare different brands and models based on performance, warranty, and overall value rather than just the initial price.

How to Maximize the Benefits of Your Mechanical Descaler

1. Regular Maintenance and Cleaning

To keep your descaler running efficiently, perform regular maintenance such as lubricating moving parts, replacing worn-out components, and ensuring it is stored properly when not in use.

Pre Drawing Machine Manufacturers

2. Use the Right Attachments and Accessories

Many descalers come with different brushes, blades, or nozzles. Use the correct attachment for the type of scaling you’re dealing with to enhance efficiency and prevent surface damage.

3. Train Operators Properly

Ensure that workers using the descaler are trained on proper handling, safety measures, and maintenance procedures. This minimizes accidents and extends the machine’s lifespan.

4. Monitor Performance and Adjust Settings

Some modern descalers come with adjustable speed and pressure settings. Monitor performance and make necessary adjustments based on the material being cleaned and the severity of scaling.

5. Combine with Chemical Treatments if Necessary

For stubborn scaling, you can combine mechanical descaling with chemical descaling solutions. However, ensure compatibility to avoid damaging equipment or harming the environment.

Mechanical Descaler Machine Manufacturers

Conclusion

Choosing the right mechanical descaler machine depends on factors like the type of scaling, power source, durability, and safety features. Investing in a high-quality descaler and maintaining it properly can increase efficiency, reduce downtime, and prolong equipment lifespan. By selecting the best machine for your needs and following best practices, you can maximize its benefits and ensure smooth operations in your industry.

#Mechanical Descaler Machine Manufacturers#Descaler Machine Manufacturers in Tamil Nadu#Pre Drawing Machine Manufacturers#Descaler Machine Manufacturers Tamil Nadu#Descaler Machine Manufacturers

0 notes

Text

Johnson Controls T-4002-301 2 Pipe DA Thermostat Beige with Cover and Conversion Kit | PartsHnC

Manufacturer Name: Johnson Controls

Product Number: T-4002-301

OEM Part Number: T-4002-301

Product Description: 2Pipewhitedastatw/Cvr&Conv.Kit

Weight:1.65lbs/748.43g

The Johnson Controls T-4002-301 is a pneumatic thermostat designed to regulate temperature in commercial and industrial buildings. It employs compressed air pressure to indicate a pneumatic valve or damper actuator to control the heating or cooling capacity to achieve a particular temperature variation.

For an efficient and reliable HVAC system, the Johnson Controls 2 Pipe DA Thermostat Beige with Cover and Conversion Kit is a great choice for optimal system performance.

0 notes

Text

6 types of industrial dampers and when to use them

In industrial settings, precise control of airflow, gas flow, or other fluids is crucial for optimizing processes, ensuring safety, and maintaining environmental compliance. Industrial dampers are essential components in achieving this control. Parth Valves and Hoses LLP, a trusted provider of high-quality industrial equipment, offers a range of dampers designed for various applications. This blog post explores six common types of industrial dampers and provides guidance on when to use them.

What are Industrial Dampers?

Industrial dampers are mechanical devices used to regulate or completely block the flow of air, gases, or other fluids within ducts, flues, and other ventilation or process systems. They are essential in industries ranging from HVAC and power generation to cement production and chemical processing.

industrial Dampers

6 Common Types of Industrial Dampers:

Butterfly Dampers: These industrial dampers feature a rotating disc (the “butterfly”) within the flow path. They are relatively inexpensive and suitable for on/off control or throttling applications with low to medium pressure drops. Use them for: HVAC systems, isolation dampers in ductwork, and general airflow control.

Louver Dampers: Composed of multiple blades (louvers) that rotate in unison, these industrial dampers provide precise airflow control and are suitable for modulating flow. Use them for: HVAC systems, air intake and exhaust systems, and applications requiring fine-tuning of airflow.

Multi-Louver Dampers: Similar to louver dampers but with a larger number of blades, these industrial dampers offer even finer control over airflow and better shut-off capabilities. Use them for: Applications requiring precise airflow regulation and minimal leakage when closed.

Guillotine Dampers: These industrial dampers feature a sliding blade that completely blocks the flow path when closed. They provide excellent shut-off and are ideal for applications requiring absolute isolation. Use them for: Isolating equipment for maintenance, preventing backflow in ductwork, and applications requiring airtight sealing.

Poppet Dampers: These industrial dampers use a poppet valve (a disc that moves perpendicular to the flow) to control flow. They are suitable for on/off control and can handle high temperatures and pressures. Use them for: Boiler applications, flue gas systems, and applications requiring quick and reliable shut-off.

Diverter Dampers: These industrial dampers are used to divert flow from one duct or channel to another. They are commonly used in systems with multiple outlets or processes. Use them for: Diverting exhaust gases in power plants, directing airflow in HVAC systems with multiple zones, and controlling flow in process piping.

Choosing the Right Industrial Dampers:

Selecting the appropriate industrial dampers depends on several factors:

Application Requirements: Consider the specific requirements of your application, including flow rate, pressure, temperature, and the type of media being handled.

Operating Environment: The damper material must be compatible with the operating environment, including temperature, humidity, and the presence of corrosive substances.

Control Requirements: Determine the level of control required (on/off, throttling, modulation) and choose the appropriate actuation method (manual, electric, pneumatic).

Parth Valves and Hoses LLP: Your Trusted Dampers Supplier

Parth Valves and Hoses LLP offers a variety of high-quality industrial dampers, including Diverter Dampers, Poppet Dampers, Butterfly Dampers, Multi-Louver Dampers, and Guillotine Dampers. Our dampers are manufactured with premium materials in a hygienic setting and have complete material batch traceability. We also offer a 12-month product guarantee on our damper assemblies, reflecting our commitment to quality and customer satisfaction.

Conclusion:

Selecting the right industrial dampers is crucial for optimizing industrial processes and ensuring safety. By understanding the different types of dampers and their applications, you can make informed decisions and choose the best solution for your needs. Contact Parth Valves and Hoses LLP today to discuss your damper requirements and benefit from our expertise and high-quality products.

0 notes

Text

Meghmani Metal Industries is a Manufacturer and Pneumatic Fittings Supplier in Maharashtra. Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India. Pneumatic fittings are specialized components that enable the connection of pipes, hoses, or tubes in pneumatic systems. We proudly provide top-quality pneumatic fittings engineered for performance, longevity, and efficiency. These fittings play a critical role in ensuring that compressed air or gas flows efficiently throughout the system, maintaining system pressure and reducing the risk of leaks. Pneumatic fittings come in various forms, including push-in, thread-in, and quick-connect, among others. Meghmani Metal Industries offers high-quality pneumatic fittings that ensure durability, efficiency, and leak-free performance. Manufacturers design pneumatic fittings for various pressure ratings and materials to accommodate specific industrial requirements. Why Choose Pneumatic Fittings from Meghmani Metal Industries? High-Quality Materials: We make our pneumatic fittings from durable materials like stainless steel, brass, and high-quality alloys, ensuring longevity and optimal performance in any working environment. Precision Engineering: We manufacture fittings designed to provide a perfect seal and maintain high efficiency, reducing air leaks and system failures. Customization: At Meghmani Metal Industries, we understand that each industry has unique requirements. We offer customizable pneumatic fittings that we can tailor to your specific needs. Reliable Supply: We commit to delivering high-performance pneumatic fittings promptly and cost-effectively, ensuring smooth operations for our clients. Applications: Automotive Packaging Industry Manufacturing Plants Food and Beverage Processing Pharmaceutical Material Handling FAQs: What are the most common types of pneumatic fittings? The most common types are straight fittings, elbow fittings, tee fittings, union fittings, and compression fittings. What materials are pneumatic fittings made from? Manufacturers commonly make pneumatic fittings from stainless steel, brass, aluminum, and high-performance plastic, depending on the application. Meghmani Metal Industries is a Manufacturer and Pneumatic Fittings Supplier in Maharashtra, India Including Mumbai, Pune, Nagpur, Thane, Pimpri-Chinchwad, Nashik, Kalyan-Dombivli, Vasai-Virar, Aurangabad, Navi Mumbai, Solapur, Mira-Bhayandar, Bhiwandi-Nizampur, Jalgaon, Amravati, Nanded-Waghala, Kolhapur, Ulhasnagar, Sangli-Miraj-Kupwad, Malegaon, Akola, Latur, Dhule, Ahmednagar, Chandrapur, Parbhani, Ichalkaranji, Jalna, Ambarnath, Bhusawal, Panvel, Badlapur, Beed, Gondia, Satara, Barshi, Yavatmal, Achalpur, Osmanabad, Nandurbar, Wardha, Udgir, Hinganghat. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

0 notes