#Main Components of Electric Cars

Explore tagged Tumblr posts

Text

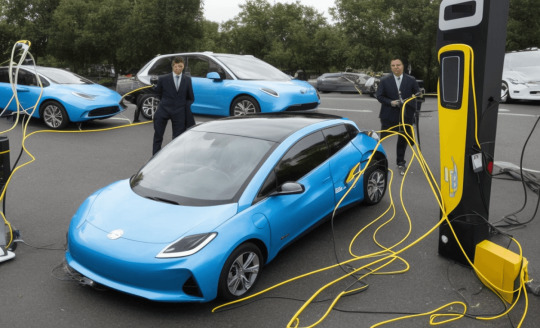

How To Test Electric Cars

How To Test Electric Cars

Testing electric cars involves a comprehensive approach that includes various key testing procedures. The goal is to ensure continuous improvement in the design and performance of the vehicle. Read about how to test electric cars.

Comprehensive Testing Approach

The comprehensive testing approach involves evaluating all aspects of the electric vehicle, including the electric battery, integrated circuit, electronic control unit, and the overall motor vehicle.

Key Testing Procedures

Key testing procedures include conformance testing, reliability engineering, and regulatory compliance checks. These tests are designed to ensure that the electric car meets all necessary standards and certifications.

Continuous Testing and Improvement

Continuous testing and improvement is an important aspect of electric vehicle development. It involves regular testing and refinement of the vehicle's components and systems to enhance its performance and reliability.

Electric Vehicles (EVs): Standards, Certifications, and Challenges

Electric vehicles must meet certain standards and certifications. These standards cover various aspects of the vehicle, including its energy development, environmental impact, and supply chain management.

Standards and Certifications for EVs

Standards and certifications for EVs are set by various regulatory bodies. They ensure that the vehicles are safe, efficient, and environmentally friendly.

Important Aspect of EV Standards

An important aspect of EV standards is the testing of electric cars. This involves evaluating the vehicle's electrical load, among other things.

Electric Cars are Vehicles

Electric cars are vehicles that use an electric motor for propulsion. They are an integral part of the automotive engineering landscape and are subject to the same laws and regulations as traditional motor vehicles.

Energy Development

Energy development in electric cars involves the use of electric batteries. These batteries store the electrical energy that powers the vehicle.

Conformance Testing

Conformance testing ensures that electric cars meet the required standards and certifications. It involves checking the vehicle's components and systems against the established criteria.

Electric Battery

The electric battery is a key component of an electric car. It stores the electrical energy that powers the vehicle.

Environmental Law

Environmental law plays a crucial role in the development and operation of electric cars. It sets the standards for emissions and energy efficiency that these vehicles must meet.

Original Equipment Manufacturer

The original equipment manufacturer, or OEM, is responsible for producing the components used in electric cars. This includes everything from the electric motor to the integrated circuit.

Automotive Engineering

Automotive engineering is the field of engineering that deals with the design, development, and manufacture of vehicles, including electric cars.

Supply Chain

The supply chain for electric cars involves the network of manufacturers, suppliers, and distributors that provide the components and materials used in the vehicle's production.

Integrated Circuit

The integrated circuit in an electric car controls the vehicle's electrical systems. It is a crucial component of the vehicle's electronic control unit.

Electronic Control Unit

The electronic control unit, or ECU, is the system that controls the various electrical systems in an electric car. It is a key component of the vehicle's operation.

Motor Vehicle

An electric car is a type of motor vehicle. It uses an electric motor for propulsion, rather than a traditional internal combustion engine.

Test Case

A test case in electric car testing is a specific scenario designed to test a particular aspect of the vehicle's performance or functionality.

Main Components of Electric Cars

The main components of electric cars include the electric motor, the electric battery, the electronic control unit, and the integrated circuit.

Reliability Engineering

Reliability engineering in electric car testing involves evaluating the vehicle's performance and reliability under various conditions.

Electrical Load

The electrical load in an electric car refers to the amount of electrical energy the vehicle uses during operation.

Testing Electric Cars

Testing electric cars involves a range of procedures designed to evaluate the vehicle's performance, safety, and reliability. This includes everything from conformance testing to reliability engineering.

Regulatory Compliance

Regulatory compliance in electric car testing ensures that the vehicle meets all necessary laws and regulations. This includes environmental laws, safety standards, and energy efficiency requirements.

International Electric Car is a platform dedicated to providing the latest news and information on electric cars, sustainable transportation, and clean energy vehicles. They aim to keep you updated on the advancements in electric vehicle technology. The website offers insights into electric cars, EV charging stations, renewable energy, and electric car batteries. They also provide information on electric car prices and incentives to make these vehicles more affordable and accessible. Whether you're an electric car enthusiast or a newcomer to sustainable transportation, "International Electric Car" invites you to join the electric vehicle revolution.

#electric car#Regulatory Compliance#Testing Electric Cars#Electrical Load#tumblr blog#Main Components of Electric Cars#Motor Vehicle#Automotive Engineering#Electric Battery#Conformance Testing#Electric Cars are Vehicles#Electric Vehicles (EVs): Standards#Certifications#challlenges#electric cars#How To Test Electric Cars

1 note

·

View note

Text

wacky alternate direction for Joule- make her a heated boxcar to complement Volta being a refrigerated one. They’re not as common irl but there was a famous Lionel toy based on them, and the irl basis was just as bright!

They carried potatoes, using onboard stoves to keep them from freezing in New England. Potato hauler sounds hilarious but hear me out: potato batteries are a thing. It even pairs with how citrus products are among the most famous refrigerated car products and also can be used as improvised batteries!

Not entirely sure how much they were electric-hauled irl, but they weren’t far from the northeastern electrified lines so they likely were to some degree.

(as a tragicomic bonus, these cars were lost in a yard somewhere by Penn Central and bankrupted a ton of people when most of the Maine potato crop was ruined, which fits with the popular fanon that Joule has ADHD. Losing things has a notable history with them…)

I’m partial to making the Components based on fast freight, especially if it has ties to the electric lines of the northeast US. It’s a job up there with “subway” that’s almost exclusively the domain of electric trains since the power needed to move heavier trains quickly is very hard to achieve if you’re hauling your own fuel/engine around (see how the CC 40100s were 5-6k horsepower vs “2700” and that’s low vs newer electric engines)

#stex#starlight express#people who well acktually about volta having diesel generators would throw a fit learninf these had solid fuel stoves#(the vast majority of freight trains even now have car-mounted generators because they sit in yards unconnected a lot.)#head end power is rare but not nonexistant on freight trains. it’s only mildly sci fi for the Components to be HEP equipped#especially since they’re a short enough train one engine could supply enough (HEP systems are usually designed for powering ~dozen cars)#Rail electrification isn’t this puritanical thing it’s OP for powering engines/EMUs and janky and fascinating to supply to unpowered cars#(See the madness of axle mounted generators and separate generator cars on passenger trains before HEP became standard)#if people ever want a post on supplying electricity to coaches/freight i’m open to it (won’t be comprehensive since it varies SO MUCH)#it’s a widespread practical issue that’s invisible to many but effects so much and isn’t too hard to understand just obscure

23 notes

·

View notes

Text

MANY RAIN WORLD SPOILERS AHEAD

yknow, what really are these module things you see attached to iterators?

i always assumed they were steam vents and thus make the torrential rains you experience, as when its rain time, they start steaming. but as ive played through more campaigns and revisited old areas, ive noticed some strange things about them

like whats up with this one on the bottom? why is it cut in half like that?

and sometimes the lighting makes these circle things in the background look like theyre protruding, so I assumed they were just the same steam vent things but viewed face-on, yet in this image (and in a lot of others) the lighting suggests the opposite - they're indentations on the structure. perhaps the vent things can be retracted in/out of the base?

yet here in the outer expanse you can find them on train cars, and the lighting looks like they're protruding, which would either mean the train cars are extremely wide or theres an extreme amount of clearance between the rail and the walls of the tunnel.

and even if it was retracted into its shell, that would mean the shell itself is super wide to be able to house an object that long. also the retractable theory in general starts to fall flat when you never actually see them retract or extrude, which if they are steam vents, then shouldnt they pop out of their shells when its rain time? this makes me think the circles facing head-on arent the same vent modules we see. perhaps they're some sort of "socket" or attachment point for some other component? im not sure.

but anyway, back to the main point. what are these things?

well, an important peice of evidence completely changes everything.

YOU CAN FIND THEM (and the circle background thingies) *INSIDE* OF ITERATOR CANS

(they're in/on moon's can as well, so there doesn't seem to be a difference between gen 1 and gen 3 iterator designs in regards to these modules)

but anyway. why are there steam vents inside of their processors???

and you cant just deduce that they arent steam vents, cus they definitely are (as shown in this video)

youtube

but at the same time the ones inside their cans dont produce any steam. or at least, no steam that we can see.

but this leads me to a theory, once you keep in mind another major thing about iterators: they need a shit load of water to function, yet you never see any of the neuronflies, inspectors, or other organisms inside drink. so where the heck is all the water? (besides the lymphatic system)

this makes me think that the steam vents we see inside of iterator structures are indeed steam vents, but the amount of steam they produce is a lot less. i assume they are basically giant humidifiers, which would saturate the air with so much moisture that the neuronflies and what not wouldnt need to "drink" as they would just constantly be absorbing water from the air. the moist air could also improve electrical conductivity between neurons.

so yeah that's my theory! it is kind of uncomfortable to think about the inside of iterator cans being absolutely muggy and miserable from the extreme humidity, but it makes sense knowing that being inside an iterator is basically like being inside a giant living organism's body; of course it's gonna be wet and slimy in there. it would also explain how the water pumped through the lymphatic conduits gets distributed to all the neurons and other purposed organisms - instead of having a separate pipe connecting every little creature to the water supply, you just saturate the air with it so they can "wirelessly" get water!

#rain world#rain world spoilers#rain world downpour#rain world downpour spoilers#five pebbles#looks to the moon#rain world five pebbles#rain world looks to the moon#iterator#rain world iterator#rain world iterators#rain world theory#rain world lore#Youtube

273 notes

·

View notes

Note

Big encouragement to tell us all about Ohma so I've got some questions to inspire a lore dump

Why does Ohma call Electra just 'Electra' but Porter 'dad'? The electric is seen as distant, but why's that?

What's Ohma's relationship with each of her parents?

How do others in the yard interact with Ohma?

How are trainlets created in your opinion? Is it a manufacturing process that somehow merges the two parents' characteristics/physical properties?

What are her relationships with other trainlets in the yard?

What does she look like? It there any references for her already? I'd love to draw her maybe

Feel free to yap, I'm super interested 😌

Serval I’m so eternally grateful for ur questions and I’m so grateful for you giving me the opportunity to yap 😭 thank you so much for asking!!!

This could get long and rambly so I’m gonna put this under the cut-

1 - Electra’s parental title) two main reasons! One is that there’s not really a gender neutral parent title that rolls off the tongue easily, and Electra’s fairly uncomfortable with both mum and dad. The other reason is that Electra isn’t really around when Ohma is learning how to talk, and all she hears is her dad talking about this Electra fellow, so once Electra enters her life properly, the name has stuck.

2 - distant electrics) Electra finds the whole ‘having a kid’ thing to be quite… alien? Ohma was very much a mistake on everyone’s part, and Electra is not in any way a natural parent, but Porter put his foot down and said that if they wanted to keep Porter around, they’d have to get used to the wee one too, so they’re trying their hardest to get used to it. Give it a few years and Ohma has them wrapped around her little finger.

3 - parentals) Porter is her primary parent, and he dotes on her as much as physically possible without spoiling her - she learned to skate late since he was too worried about her hurting herself, despite the fact that in this universe his main job is running a training centre to teach rehabilitated trains to skate again. Electra is a bit more tentative, especially when she’s super young, but once they begin to interact with her she’s attached to their hip whether they want her to or not. Both are incredibly protective of her - one much more obviously than the other.

4 - yard relationships) most of the trainlets in the yard are fairly well liked, since MOST of the rolling stock (looking at you here GB) know to put their rivalries aside to prevent literal blood feuds happening. She spends a lot of time with her cousins and her various aunts and uncles, which she has a lot of since all the freights, components, and coaches are at her beck and call - the only one that struggles with her is GB. I have another fankid OC that hasn’t shown up yet, a punky little greasedinah baby called Vulcan, and GB refuses to let her kid hang out with the child of ‘that gross electric’ (which is a bit of a problem when they become best of friends)

5 - creation methods) this is actually something I haven’t decided on! For the fic I wrote, I use Garnet’s system which is touched on more in her fics, but if I move forwards with my own universe for this it will probably be more akin to trainlets being made in a factory with aspects of both parents - Ohma was a bit of an experiment from Electra’s company to create a modern dynamometer car, but neither of them really realised quite what that entailed until Electra was presented with the kid, and they freaked.

6 - yard friends) she has 7 million cousins between the Tendersteam bunch (Gar’s universe has him oversee a bunch of ‘Kids’ in the form of experimental hydrogen rail projects since he’s a tanker and the oldest of any hydrogen project, and then him and Rusty build Blaze, as you met!) and however many random little wood trucks Lumber decides to adopt. Porter also takes her to work a lot once she’s old enough to entertain herself so she makes friends there, and eventually she’s thick as thieves with Vulcan, to the point where they become racing partners once they’re adults!

7 - image) I do have some art that I’ll link but you have to swear not to judge me because she was the first thing I’ve drawn since I gave up on art nearly 10 years ago 😂 for a brief description though, she’s a fairly short but strong component that visibly lacks the decorum of the other components, with fluffy hair that turns fire red at the tips and godawful posture. There’s also nothing happening behind her eyes - she’s quite spacey and oblivious unless she’s working, at which point she’s so locked in it’s almost impossible to lock her out again (guess what she inherited from her two autistic parents no I’m not projecting)

Rotating her 360 degrees in my brain… single handedly saves her parents relationship and forces them to talk to each other for the first time in their lives…

Thank you so so so so so much for the ask friend!!!!!!!

#rambles#stex oc#coalectra#UGH I love her and I’ve been trying to work out the best way to put her out into the world#thank you so much it genuinely shocks me every time someone pays the slightest bit of interest in my shit#and im so grateful you guys spare me the time of day#asks#crimsonservalite

12 notes

·

View notes

Text

gn robot reader/ f engineer doing repairs

1.9k words nothing explicit just flirty

--

Your protocols stipulated that you were to report to a human team member if you required repair or maintenance. You had an entire diagnostic system dedicated to running those checks. But ‘Requiring Repair’ is an incredibly subjective term.

It could be argued that a car approaching the recommended oil change date ‘Requires Repair’, or a car that had impacted a light pole perpendicularly and folded around it, crushing most remaining components, ‘Requires Repair’.

You had neither of these problems. You were having temperature regulation difficulties. You could even still regulate your temperature most days. It was just the occasional overheat that teetered on the edge of a forced shut down.

Obviously you've tried all the software fixes, limiting your background processes in the new summer weather, deleting some new programs you picked up recently in case they were too much strain. You even stopped wearing clothes entirely. It wasn't as though you had anything to hide, you were just a machine. You didn't need to sit on the couch in the break room next to your human coworkers. Cloth was an unnecessary use of resources and the energy that you'd have to redirect to keep yourself cool.

You knew what the last option was obviously. You could clear your external vents without too much trouble, but you didn't have authorization to check your internal fans on your own. That was a repair and had to be reported to a Human Team Member.

They would have to open your casing and see the issue and manually clean your fans. You would have to lie down immobilized on the build table like you had for weeks when they were first moving your program into your current body.

You didn't need a repair or maintenance, so you were fine for now, but once a malfunction was Actually occurring you would enter your Survival Protocol where all nonessential functions would be suspended until a repair occurred. This would, in all probability, be… unpleasant. You intended to, if possible, avoid this situation.

So late one night, long after your coworkers’ shifts ended, you turned down the temperature on the environmental controls in the main break room as low as they would go. You spent the minutes, as the air around you cooled, programming in a two percent efficiency decrease in the coolers for the coming week to compensate for the extra energy usage tonight.

You didn't need the lights or environmental controls, so they were usually deactivated during your coworkers' off hours. Tonight you would need both. Before you turned the lights on you took over the data stream from the security cameras in the room and played the video from last night.

You flicked on the lights and made your way to your improvised workstation. You had a repurposed office chair, a non-electric flat head screwdriver (rudimentary, but it wouldn’t set off your sensors the way unauthorized electric tools would), and a can of compressed air.

You settled backwards in the office chair, the front of your casing pressing into the backrest, your posterior maintenance panel facing the deactivated camera. You picked up the current video output from the camera, dropping the visuals from your eyes. Like this you could look down over yourself and see the seams on your back where you closed. Your vent appeared clear of dust externally at least.

That was a comfort, it would have been humiliating to be walking around trailing dead skin cells and lint behind you.

You could feel the increased processing already raising your temperature, but the cold air was doing its job. This would be fine, if you used manual tools your internal sensors wouldn't classify this a repair. You thought. It was the best theory you had.

So, bending your arms at an angle that you knew from experience frightened your human coworkers, you started trying to gently pry up the panel. A warning took over your visual data for a moment, marking the risk of panel damage. You did not let out a low growl of frustration, that would be a poor use of resources at the present moment. The sound you made was unrelated to the warning that you dismissed impatiently.

You tried another spot that seemed to have more of an edge you could slip the screw driver beneath and began again.

Finally finding enough grip, you began applying force… Just as the break room door slid open with a hiss. The surprise caused your calculated angle to redirect and sent the screw driver skittering with force across your back panel leaving behind a long silver scratch through your paint. You focused the camera on the door and saw her.

Her usual coveralls wer slipped off her shoulders and tied at the waist, leaving her in the sleepless undershirt. Her hair was tied up out of her face like she had been working on something.

"Team Lead," You greeted quickly, trying to simultaneously hide the screw driver, stand up, pick up your own visual data again, and drop the camera. In the end, you managed to do none of these but the last. The loss of visual data sent you tripping back into the rolling chair as you tried to push out of it, forcing you to steady yourself with both hands or end up on the floor . Thereby dropping the screw driver to the floor instead, in all likelihood, directly into her view.

"You can call me Dial," She reminds you, "I’m begging you to just call me Dial honestly." She had told you this many times before when the two of you were working together.

Finally you manage to get your eyes back.

"So what are you up to in here?" She asked, she had already made her way across the room to kneel for the screwdriver.

"Up to?" You say, buying time pretending to not recognize the turn of phrase.

"What are you doing?" She clarifies easily with none of the time consuming mocking others might have employed.

"I was..." Your mind spins with possible replies but the clock ticks down too fast leaving only a look of understanding on Dial's face as she spots the can on the table beside you.

"Right, you've been having an overheating issue right? Did you want a hand?"

You stilled. No you did not, but Dial was chief engineer on your development. If she declared it time for a repair that would be enough to put you in maintenance mode.

Coldly you say, "It is past working hours. Your assistance is not required."

"Yeah, of course, I meant more like... off the record? A hand, between friends?"

You zoomed in on her face trying to understand the expression there. Her pulse was a little fast and it looked as if she was chewing the inside of her cheek. Was she nervous?

"Off the record?" You repeated hesitantly.

"Not a repair. Just," She seemed to think for a moment, "exploratory observation of your internal components. If any impromptu tasks are performed and you want them logged for your database later I could do so at that point."

Her wording was so careful, carrying with it a complete awareness of what had been written into your code by the programmers on the team in early days.

"Exploratory observation would be acceptable," You agreed reluctantly.

Relief crossed her face, "Great! Great. Alright you- you should sit down, you're gonna need to be still. I've never opened you up when you're awake before. I don't want to risk jostling anything important while you're standing and could hit your head."

"Yes," you lowered yourself back into the chair and she circled behind you, tugging on her gloves. You glanced back as she dragged a chair over to sit behind you, then resettled facing forward. You heard her reach into her pocket where you knew she kept a small collection of electric tools.

Your casing warmed a few degrees where she placed her hand against it to steady you. There was a tap and a small tug as she opened you up.

"Did you want to pick up the camera feed again?" She said softly, she was very close behind you.

"How did you know about that?" You asked.

"Wouldn’t be the first time. Your not the most subtle. Just because you refuse to call me anything except ‘Team Lead’ doesn't change the fact that we've been friends for nearly two years. You always drop the visuals from your eyes when you need a wider angle. Of course you would do it for this."

“Ah…” Hesitantly you picked up the security cam again and watched as she carefully set your scratched panel aside on the ping pong table beside you.

She clicked her tongue, “Oh, I see why you’ve been having a hard time regulating.”

You fan kicked up in speed at this.

“Whoa hey, easy there, I gotcha,” Her free hand landed across the side of your torso, your sensors were very aware of the pressure of her hand moving up and down your side thoughtlessly as she leaned in to look over your components.

“Alright well, nothing for it but to start with the compressed air and then see where we're at,” She decided, picking up the can next to you, “This might be a little chilly. Tell me if you need me to ease up.”

“I'll be-” !

A surprised chirp left you as sudden temperature alerts startled through you.

“Hmm?” She said. Tone: Playful.

“I underestimated the temperature difference,” you admitted stiffly, feeling the difference in the way your fan was moving already.

Her feet were out in front of her, her ankles pressing against yours. Another shot of cool air came and you felt her gloved hand delicately reach inside you to move aside a bundle of wires that sat in the way of the angle she needed.

“Y-” You tried, but failed as sensory data registered from the wires she was moving, “You’re here later than usual.”

“Yeah well, I've been working on something for you. Of the clock.”

You wanted data on her facial expression. Her back was turned on your camera.

You tried to search for the right phrase. You wanted to know what she was working on but was that rude?

“You can ask,” She confirmed.

“What are you working on?”

“New ankles that, if I do it right, shouldn’t need to be replaced every three months from sand damage.”

!!! Ah. That was. Well that was very nice of her.

“Thank you.”

“‘Course. Anything to reduce table time right?” Tone: Compassionate.

“Right.”

“There you go,” She said, setting down the can, “Your internal temp is dropping already.” The backs of her fingers pressed against the still warm side of your processor. You went very still, trying to force your fan not to speed up and give you away. Her fingertips trailed lightly across the ports and withdrew.

You gave no sign of the disappointment that flared through you as she settled the part of your casing back in place, you sensors coming back online in that panel as she brushed one last touch across the silver mark that ran across your back now.

“We- we could,” You stopped. Letting your systems settle to stop the halting manner of your words.

“Do this again?” She asked, slipping her screwdriver back into her pocket, “Just you and I?” Tone: Hopeful.

“It would be nice,” You agree.

19 notes

·

View notes

Text

Excerpt from Sustainability by Numbers:

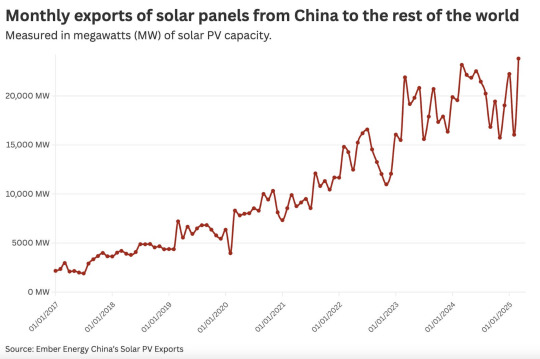

When it comes to clean energy technologies, China is crushing it.

It dominates the supply chain of the main energy minerals. It’s not only rolling out solar power rapidly at home, it’s also exporting huge amounts of solar panels elsewhere. Take a look at the chart [above], which shows solar PV exports from China to the rest of the world. Increasingly, these panels are going to low-to-middle income countries who are hungry for energy, and will go after whatever’s cheap: that’s Chinese solar.

It produces three-quarters of the world’s batteries. Its largest EV carmaker, BYD, is producing high-quality electric cars for as little as $10,000, and is growing rapidly in many markets across the world. BYD is now targetting the domestic battery market. CATL, the world’s largest battery manufacturer, is pushing the limits of battery technologies, with claims that it can add 300 miles of charge in just 5 minutes (I have some doubts about battery degradation, but I’d obviously love this to be true). The list goes on.

European and American manufacturers are being left in the dirt. One response has been protectionist policies: slapping on tariffs and implementing import quotas. A few newsletters ago, I argued that these were not good interventions if the goal was to increase the number of energy jobs in European and American markets. That’s because most clean energy jobs are in deployment and maintenance rather than manufacturing, and since higher costs slow down the rollout of renewables, increasing prices reduces the total number of people working in clean energy (even if the number working in manufacturing increases).

It produces three-quarters of the world’s batteries. Its largest EV carmaker, BYD, is producing high-quality electric cars for as little as $10,000, and is growing rapidly in many markets across the world. BYD is now targetting the domestic battery market. CATL, the world’s largest battery manufacturer, is pushing the limits of battery technologies, with claims that it can add 300 miles of charge in just 5 minutes (I have some doubts about battery degradation, but I’d obviously love this to be true). The list goes on.

China mainly dominates these markets because it has produced a long-term industrial strategy for these technologies and has honed an optimised, modern supply chain as a result.

The notion that China’s manufacturing output is purely the result of some centralised, governmental program is misguided; it has developed an incredibly competitive market with companies fighting for any edge to cut prices and beat competitors. The solar and battery industries are pretty brutal to be in, with slim margins.

Since China also refines a lot of the minerals and smaller components, its supply chains can become incredibly integrated, which also makes them more optimised.

The second big chunk is labour costs. Now, it’s undeniable that wages in the US are higher than they are in China. But this is not necessarily because Chinese salaries are abysmally low. Yes, they are low by American or European standards, but wages for factory roles are often higher than they are in the US’s southern neighbour, Mexico.

The biggest factor in labour costs is automation. The US uses six times as many workers per GWh (I initially found these numbers pretty shocking and hard to believe), so it’s not surprising that labour costs much more. China has invested heavily in automation, meaning many processes run with very little human input.

This is something else to keep in mind when considering the case for “bringing manufacturing jobs home.” There’s certainly scope for this, but it is at odds with the fact that low costs often rely on automation, not human labour. Especially with the growth of artificial intelligence, some manufacturing jobs could be increasingly vulnerable.

3 notes

·

View notes

Text

My Starlight Express HUMAN! Au: World plus citizens. Part one

General: Racecity, USA takes the place of the train yard and it’s centered around the 50s-60s. Racecity is the home of the Racing National Championship with it’s reigning champion being from Racecity.

-Richard “Rusty” McCoy

Rusty is 23 and is from a very religious and old fashion family. He lives with his father, Poppa McCoy (A former campion.) His mother, Belle McCoy and his brothers Fredrick McCoy(Flat-top) and Dustin McCoy (Hopper.) He dreams of winning the Championship with his father’s old racing car but is often bullied by the others. He has a major crush on Pearl

-Pearl DuPont

She is 22 and new to town and is from a rich and prominent family. She is friends with Dinah, Di, Buffy and Ashley and is often seen at the disco downtown. She is sought after by a certain new-comer in the race to be his partner, despite her promise to Rusty to be his partner.

-Derek “Greaseball” Russell

He is 26 and is the reigning champion of the National Racing Championship. He is pretty arrogant and self-centered and is the fiancé of Dinah (not to be confused with Di who is his sister’s girlfriend.) For all of his faults he is supportive of his sister’s sexuality. He is the main bully of Rusty. He is extremely proud of his diesel car engine that he says is faster than lighting. Is often seen around his fiancé and his gang. Has been undefeated for 10 years

-Gale “Greasy” Russell

She is 15 and is the little sister of Greaseball and is the girlfriend to Di. She is just under the age of qualification for the Championship but plans on playing in it next year. Her legal guardian is Greaseball and lives with him. She, like her brother is arrogant and self-centered. Works at the auto shop for some extra spending money (totally not because there’s a cute waitress at the dinner next door.)

-Dinah Campbell

She is 24 and is the fiancé to Greaseball. She works at the dinner and is a manager, she is the legal guardian of her distant cousin, Di. She is very loyal to Derek and has been his partner since she was 14 and he 16 (the partner qualifying age is 14.) Will often be seen at the disco. And will hang out with her fiancé and his gang (plus Gale)

-Dinah “Di” Humphrey

Di is 14 and is the girlfriend to Gale. She is nicknamed Di so that she doesn’t get mixed up with her Legal guardian and distance cousin who is also named Dinah. She works at the dinner where she is the newest waitress, but will often sneak out to see a certain champion’s little sister at the repair shop.

-Callum Benjamin “CB” Breaker

He is 24 and works for the McCoy’s at their scrap yard. And is a literal diagnosed psychopath who has unalived in the past sooo not the most qualified person for making sure breaks work properly. He has a type of obsession with Dinah (he’s been trying to sabotage Derek’s car so he can get with her.)

- Electra Futureman

22 and a newcomer to the Championship. He has more of a 80s aesthetic and look to him. His car is electric and is lighter than air making it more faster. Wants Pearl for his partner and travels with his own entourage (the components). Extremely full of himself and is a soar loser. Hostile towards Derek and Rusty.

What do y’all think? I decided to add both Bochum GB and Dinah and Wembley GB and Dinah because I really couldn’t decide. And I used a random name generator for both GB’s human names and used the first letter of the rest of the train’s names for the rest of it. More is to come!

Next part will be the rest of the freight trains and the coaches.

10 notes

·

View notes

Text

Is it possible to change turn signal lights to LEDs?

Yes, it is technically possible to replace your turn signal lights with LED lights, but it requires careful retrofitting to avoid electrical problems and violations. Here’s what you need to know:

✅ Benefits of LED Turn Signal Lights Lifespan: LED lights have a lifespan of 25,000-50,000 hours, while halogen lights have a lifespan of 500-1,000 hours.

Brightness: 200-300% more light output (up to 1,500 lumens).

Faster Response: Instant on/off for improved visibility.

Power Saving: Each bulb consumes about 0.5-1A, while halogen lights consume 2.0A per bulb.

⚠️ Main Challenges & Solutions Overclocked Flashing (Fast Flashing)

Cause: Halogen lights consume more power → the factory flasher relay expects this load. LEDs consume less power → the relay “thinks” the bulb is burned out.

Solution:

Load resistance: Add parallel resistors to simulate the power consumption of halogen lamps (e.g. 6Ω per bulb, 50W).

Disadvantage: Generates a lot of heat (needs heat sink/metal bracket).

LED flasher relay: Replace the factory relay with an electronic flasher (e.g. EP36 for GM, CF18 for Japanese cars).

CAN bus decoder: Must-have for modern cars (e.g. iJDMtoY/LASFIT kits). CAN bus system error

Problem: Modern cars monitor circuit resistance. Low LED current triggers "bulb off" warning/dashboard error.

Solution: Use CAN bus compatible LED bulbs with built-in resistors (e.g. SNGL, Philips Ultinon). Legal compliance

Colors: Amber (front/side) and red (rear) are legally mandatory in most areas. Pure white LED turn signals are illegal.

Beam Pattern: LED lamps must not cause glare (reflector housing bulb designs only - LEDs may not be used in projector housings unless DOT certified).

Photometric Standards: Must meet SAE/DOT or ECE R6 regulations (look for "SAE/DOT compliant" packaging).

Housing Compatibility

Avoid using halogen housing LED lamps that are not equipped with a beam cutoff. Glare can blind other drivers.

Solution: Replace the entire housing with an OEM/LED-specific component.

🔧 Step-by-Step Installation Guide Check Compatibility:

See your vehicle manual for bulb type/size (e.g., PY21W, 7440).

Use a compatibility tool (e.g., Google Lookup). Get Parts:

LED Bulbs: Front: Amber (e.g., SNGL 7443), Rear: Red (e.g., SNGL 7506).

Resistors/Relays: Use a kit such as the Lumen LM200 Resistor Kit. Installation:

Disconnect negative battery terminal.

Replace bulb: Unscrew socket → remove old bulb → install LED (align pins).

Place resistors across positive/negative wires of each bulb (use solder/heat shrink tubing).

Mount resistors on metal surface (not plastic/trim). Testing and debugging:

Turn on hazard and signal lights. Verify there is no overclocked flashing.

Scanner dial error (use OBD2 scanner).

📜 Legality Checklist Requirements: US EU/UK Color (frontlight): Amber or white¹ Amber only Color (rearlight): Red Red Intensity: ≤100–300 cd² ≤170 cd (sidelights) Beam diffusion: DOT/SAE compliant ECE R6 compliant

¹ Only factory-equipped turn signals are white (check individual state laws).

² Photometric testing of aftermarket bulbs is rare, but must be done on factory designs.

💡 Smart Alternatives Plug-and-play kits: Brands like OPT7/LASFIT include resistors and connectors.

Full LED taillight assemblies: Replace the entire assembly (e.g., modern factory LED upgrades).

Hybrid bulbs: Halogen/LED combos to avoid overclocked flicker (e.g., Philips X-tremeUltinon).

🛠️ Cost breakdown Component price range LED bulb (pair) 20–60 Load resistor (pair) 10–15 LED flasher relay 15–40 Professional installation 100–200

⚠️ Key risks to avoid Fire hazard: Never mount resistors on plastic. Use wire sleeves and thermal tape instead.

Warranty void: Modifying factory wiring may void dealer warranty.

Insurance issues: Non-compliant LEDs may complicate accident claims.

Recommendations: For classic cars: Resistors + standard amber LEDs.

For modern cars (2010 and later): CAN bus compatible bulbs + flasher relays.

When in doubt: Use the Philips Ultinon Pro6000 kit with built-in decoder.

Always test the beam pattern against a wall at night and verify compliance with local DOT/ECE standards. If DIY isn’t an option, specialty shops like CARiD can provide vehicle-specific kits.

#led lights#car lights#led car light#youtube#led auto light#led light#led headlights#led headlight bulbs#ledlighting#young artist#car rental#electric cars#classic cars#car#cars#porsche#truck#automobile#lamborghini#bmw#carlos sainz#autonomous vehicle headlights#overtake another vehicle#vehicle#older vehicles#auto mode#automobiles#auto#automotive#autos

6 notes

·

View notes

Text

All the Information You Need to Understand BIS Certification: An Explanation of ISI, CRS, and FMCS

In the globally competitive and safety-conscious world of today, product quality and regulatory compliance are not negotiable. In India, the country's organization tasked with product safety, quality, and standardization is the Bureau of Indian Standards (BIS). From consumer electronic products to industrial parts, certification by BIS has become a non-negotiable passport to the market and consumer confidence. We at Diligence Certification help foreign and U.S. manufacturers with BIS certification. This is a complete guide to three of the biggest types of BIS certification: BIS ISI Certification, BIS CRS Certification, and BIS FMCS Certification. If you are a business owner, a product manufacturer, or a compliance officer, you are going to learn with this guide what certification your product needs and how to get that done effectively.

What is the Bureau of Indian Standards (BIS)?

The BIS is India's national standards organization. It functions under the Ministry of Consumer Affairs, Food & Public Distribution. BIS was formed according to the BIS Act of 1986, which was further amended in 2016 to introduce more reforms. It is tasked with developing and sustaining standards, quality control, and certification in India.

Principal Objectives of BIS:

Develop Indian Standards (IS) for goods and services.

Certify goods to ensure quality and safety

Conduct factory inspections and inspect products.

Operate hallmarking and product certification schemes.

Encourage standardization and consumer education

BIS provides three main certification schemes for different types of manufacturers and products: ISI, CRS, and FMCS.

BIS ISI Certification: For Indian Manufacturers

What is BIS ISI Certification?

BIS ISI Certification is India's oldest and most reputable product certification scheme. It is mandatory for most products that are made in India and ensures that a product complies with a specified Indian Standard (IS). Upon certification, manufacturers can affix the ISI mark on their product, which assures that it complies with the safety and quality standards.

Products Needing ISI Mark

ISI mark is mandatory for over 350 products, including:

Electrical appliances such as fans, switches, and wires.

Cement

Pressure cookers

Steel bars and rods.

Car components

Bottled drinking water.

BIS ISI Certification Process

Application Submission Manufacturers have to apply using the MANAKonline portal.

Testing Products These samples are tested in BIS-recognized laboratories to verify conformity to the concerned Indian Standard.

Factory Inspection BIS officials go to the factory to check the manufacturing process and quality control.

Grant of License If both testing and inspection are acceptable, then BIS grants a license permitting the utilization of the ISI mark.

Surveillance & Renewal BIS conducts periodic inspections to ensure continuous compliance.

Documents Required:

Factory registration/license

List of manufacturing equipment

Quality control papers

Test reports of BIS-approved laboratories

Length and Renewal

It is issued for one year initially and can be extended if you comply with the regulations. We at Diligence Certification facilitate Indian manufacturers in making their documents, arranging with BIS labs, and clearing inspections with ease.

BIS CRS Certification: For IT and Electronic Products

What is BIS CRS Certification?

The Compulsory Registration Scheme (CRS) started in 2012 for electronics and IT equipment, which is a fast-growing industry in India. Both domestic and foreign manufacturers are covered under this scheme, making it an important regulation for entering the consumer electronics market.

Applicabilitiy

Products of CRS are:

LED bulbs and lights

Power adapters

Desktops and laptops

Cell phones and tablets

Bluetooth speakers

Lithium-ion batteries

Smartwatches

UPS/inverter systems

Over 75 product types are covered under this plan as of 2024.

BIS CRS Certification Procedure

Determine Applicability Check if the product is under the CRS notification.

Testing in BIS-Approved Laboratory It should be analyzed at a BIS-approved laboratory in India.

Application Submission The producers apply online via the MANAKonline portal.

Approval of Registration BIS verifies the test report and documentation prior to assigning a registration number.

Marking Rules The product label should have the BIS logo and registration mark.

Required Papers:

Factory registration

Product technical data

Indian Authorized Representative (overseas brands)

BIS laboratory test report

Duration & Renewal:

The registration is valid for 2 years and can be extended for up to 5 years. Both domestic and international brands can automate their operations with Diligence Certification and prevent delays due to incorrect paperwork or substandard testing processes.

BIS FMCS Certification: Foreign Manufacturers

What is BIS FMCS Certification?

Foreign Manufacturers Certification Scheme (FMCS) assists foreign manufacturers in obtaining BIS certification under the ISI mark regime. It ensures that the imported products meet Indian safety and quality standards prior to their sale in the Indian market.

FMCS is relevant to the majority of industrial and consumer goods, as opposed to CRS, which is mainly focused on electronics.

Steel and metal products

Plastics and chemicals

Food packaging

Electric appliances

BIS FMCS Certification Process

Product Standard ID

The producer locates the significant Indian Standard (IS).

Application Submission

Applications are sent to the BIS headquarters.

Test Samples

They are tested in BIS or BIS-approved testing labs.

Factory Audit

BIS officers check the foreign manufacturing site in person.

Agreement Signing

Manufacturer enters into an agreement with BIS and pays license and mark fees.

License Issuance

Upon all these requirements being fulfilled, authorization to apply the ISI mark is granted to the manufacturer.

Papers Required:

Business license

Factory layout and process flow

Data on quality control

Product specification sheets

AIR (Authorized Indian Representative) papers

Validity:

The FMCS license is valid for one year and is renewed every year.

With Diligence Certification, international brands are assisted by local agents, technical guidance, and full compliance management to get the ISI mark hassle-freely.

Why BIS Certification is Essential for Your Business

BIS certification is not only a regulatory mandate—it also contributes to brand image, customer confidence, and market competitiveness. The greatest advantages are:

Legal compliance: Avoid product bans and fines Market Access: Reach Indian consumers

Legally and rapidly Brand Trust: Customers view BIS-marked products as superior in quality and safer.

Competitive Advantage: Become selected by retailers and distributors.

Consumer Protection: Demonstrate commitment to quality standards and public safety.

How Diligence Certification simplifies BIS Certification

It can be difficult to work with the Bureau of Indian Standards, especially for businesses that do not know Indian regulations. This is where Diligence Certification is useful.

Our Services Include:

Product classification and mapping standards

Preparation and filing of application

Testing coordination with BIS-recognized laboratories

Factory audit support Assistance to foreign producers (AIR)

Support for remaining compliant and renewing.

We offer special assistance for BIS ISI Certification, BIS CRS Certification, and BIS FMCS Certification. This will save you from delays, reduce costs, and get certified at ease.

Conclusion

The Bureau of Indian Standards plays a crucial role in regulating product quality in India. Whether you are a domestic craftsman or a foreign brand, obtaining the appropriate BIS certification—ISI, CRS, or FMCS—is necessary to ensure you sell in the market lawfully and win the confidence of customers. We at Diligence Certification simplify your process of compliance. With technical expertise and years of experience, we assist you through every step of the process of certification process, so you can focus on new ideas and growth. Call Diligence Certification today and begin your BIS certification process with confidence and clarity.

2 notes

·

View notes

Text

Protecting Your Electrical Systems: A Look into Al Taqwa’s Complete Range

In today’s fast-paced world, electrical systems power everything from homes and offices to factories and infrastructure. With increasing energy demands and the growing importance of uninterrupted power supply, having the right switchgear and protection systems is more important than ever. That’s where Al Taqwa United Enterprises LLC, one of Oman’s leading electrical suppliers, plays a crucial role.

In this blog, we’ll explore how Al Taqwa offers a complete range of electrical switchgear products that protect and power systems across the country — safely and efficiently.

Why Electrical Protection Is Critical

An electrical system without proper protection is like a car without brakes. From power surges to short circuits, the risks of equipment damage, data loss, and fire hazards are significant. High-quality electrical protection devices ensure:

· Safe power distribution

· Equipment longevity

· Compliance with safety standards

· Reduced downtime in case of faults

Al Taqwa addresses all of these needs with a comprehensive and reliable product portfolio.

Al Taqwa: A Trusted Name in Electrical Switchgear in Oman

Established in 20011, Al Taqwa United Enterprises LLC has grown into a respected electrical trading and switchgear assembly company in Oman, Qatar, the UAE, and India. Their focus on quality, innovation, and customer satisfaction makes them a preferred partner for engineers, contractors, and facility managers across sectors.

Complete Electrical Switchgear Range from Al Taqwa

Al Taqwa’s product line is designed to meet the needs of low-voltage electrical systems in residential, commercial, and industrial environments.

1. Electrical Panels and Distribution Boards

These serve as the central hub for electrical power distribution. Al Taqwa supplies and assembles:

· Main Distribution Boards (MDBs)

· Sub Main Distribution Boards (SMDBs)

· Final Distribution Boards (FDBs)

· Control Panels and Feeder Pillars

All panels are tailored to meet Omani electrical standards and international safety norms.

2. Circuit Protection Devices

The key to preventing electrical fires and damage is reliable overcurrent and earth fault protection. Al Taqwa offers:

· Miniature Circuit Breakers (MCBs)

· Molded Case Circuit Breakers (MCCBs)

· Residual Current Devices (RCDs)

· Earth Leakage Relays

These components ensure quick fault detection and automatic power cut-off during hazards.

3. Metering and Monitoring Devices

To optimize energy use and improve system performance, monitoring is essential. Al Taqwa provides:

· Analog and Digital Panel Meters

· Current Transformers (CTs)

· Voltage and Frequency Meters

· Energy Monitoring Units

These products give real-time data for smarter electrical management.

4. Electrical Accessories and Control Components

To support the full installation lifecycle, Al Taqwa stocks:

· Terminal blocks

· Cable ties and lugs

· Contactors and timers

· Rotary switches and power supplies

These ensure smooth installation, operation, and maintenance of electrical systems.

Top Electrical Brands Represented by Al Taqwa

Al Taqwa partners with internationally recognized electrical brands, including:

· Enza Electric — Quality switchgear products known across Europe and the Middle East

· Civaux Electric — Comprehensive panel systems and circuit protection components

· Stefan Electric — Trusted for metering solutions and industrial electrical accessories

· Salzer Electric — Renowned for rotary switches and control products

These collaborations ensure Al Taqwa can offer reliable, durable, and cost-effective solutions to its clients.

Beyond Products: Al Taqwa’s Expert Services

Al Taqwa goes beyond just supplying electrical components. Their team of experts offers:

Custom switchgear assembly tailored to project requirements

Site inspections and installation support

Annual maintenance contracts

Technical consultation and troubleshooting

This makes Al Taqwa a one-stop solution for all electrical needs in Oman.

Conclusion: Trust Al Taqwa for Complete Electrical Protection

When it comes to protecting your electrical systems, choosing a trusted provider like Al Taqwa ensures both peace of mind and long-term performance. From high-quality panels and circuit breakers to metering systems and expert service, Al Taqwa covers the full spectrum of electrical protection.

For engineers, project managers, or business owners looking to safeguard their infrastructure, Al Taqwa United Enterprises LLC stands out as the best source of electrical switchgear in Oman.

Explore More:

Visit https://altaqwaoman.com to view the full product catalog or request a quote tailored to your project needs.

#electrical#electrical equipment#electrical supplies#switchgear#oman#ElectricalSystems#ElectricalSafety#ElectricalSolutions#ElectricalProtection#SwitchgearSolutions#PowerDistribution#LowVoltageSystems#CircuitProtection#ElectricalPanels#ControlPanels

3 notes

·

View notes

Text

Automotive Power Electronics Market Growing Business Factors, Industry Trends, Share, Size, Growth, Opportunity And Forecast 2033

According to a new industry report by Fact.MR, a market research and competitive intelligence provider, the global automotive power electronics market is projected to reach $6 billion by 2033, growing at a CAGR of 4.1% from 2023 to 2033.

Power electronics encompass a wide range of solid-state devices used for power regulation and conversion, including silicon-controlled rectifiers (SCRs), diodes, thyristors, power MOSFETs, gate turn-off thyristors, and more. These devices are crucial in controlling vehicle electronics. The term "automotive electronics" covers the application of power electronic devices in modern systems such as electric power steering, seat control, braking systems, central body management, and HEV main inverters.

Download Free Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=8423

The rising popularity of electric vehicles (EVs) is the primary driver of the global automotive power electronics market. EVs are seen as a crucial step toward modern mobility solutions, offering cleaner and more efficient transportation compared to traditional automobiles. The depletion of fuel resources and public concern over increasing pollution levels have fueled global demand for electric vehicles.

Compliance with safety and vehicle emission standards, along with the growing demand for vehicle connectivity, infotainment, and powertrain electrification, is expected to propel the global automotive power electronics market during the forecast period. The use of electronics in powertrain systems is projected to increase at a faster rate due to intensified efforts by regional governments and environmental agencies to reduce emissions by promoting environmentally friendly vehicles, such as hybrids and EVs.

Key Takeaways from Market Study

In 2023, the global automotive power electronics market was valued at $4 billion.

The market is projected to grow at a CAGR of 4.1% from 2023 to 2033, reaching $6 billion by 2033.

In 2022, the Asia Pacific region held 38.7% of the global market share.

The passenger car segment is anticipated to grow at a CAGR of 3.7% during the forecast period.

“Global automotive power electronics market projected to witness considerable growth due to increasing modernization of vehicles, expanding demand for vehicle electrification, and rising need for connected car devices,” says a Fact.MR analyst.

Key Companies Profiled in Automotive Power Electronics Market Report

Infineon Technologies AG

Texas Instruments, Inc

Mitsubishi Electric Corporation

NXP Semiconductors NV

Toshiba Corporation

Robert Bosch GmbH

Get Customization on this Report for Specific Research Solutions: https://www.factmr.com/connectus/sample?flag=RC&rep_id=8423

Competitive Landscape

Big manufacturers control the market, which is only moderately concentrated. The leading companies in the automotive power electronics sector are focusing on broadening their product lines and investing in research and development to generate high-end products. In addition, several entrepreneurs are focused on new technologies to boost their market share.

In September 2021, Panasonic Corporation and Infineon Technologies AG signed a collaboration agreement to research and manufacture the second generation (Gen2) of their renowned gallium nitride (GaN) technology. This will enhance efficiency and power density levels.

In June 2021, STMicroelectronics announced STi2GaN solutions for automotive applications. The STi2GaN series includes GaN-based drivers and safeguards, a monolithic power stage, and System-in-Package (SiP) solutions for application-specific integrated circuits with additional processing and control circuitry.

Infineon Technologies AG purchased Cypress Semiconductor Company in April 2020. Cypress provides a diverse set of software ecosystems, microcontrollers, connection components, and high-performance storage.

Infineon Technologies launched the CoolMOS CFD7A family in April 2020. These high-performance silicon-based components can be used in both the PFC and DC-DC stages of onboard charger systems, as well as HV-LV DC-DC converters designed specifically for EV use.

Key Segments of Automotive Power Electronics Industry Research

By Device Type :

Power ICs

Power Modules/Discretes

By Drive Type :

IC Engine Vehicles

Electric Vehicles

By Vehicle Type :

Passenger Cars

Commercial Vehicles

By Electric Vehicle Type :

Battery Electric Vehicles

Hybrid Electric Vehicles

Plug-in Hybrid Electric Vehicles

By Application :

Body Electronics

Chassis & Powertrain

Infotainment & Telematics

Safety & Security Systems

𝐑𝐞𝐚𝐝 𝐌𝐨𝐫𝐞: https://www.factmr.com/report/automotive-power-electronics-market

Regional Analysis

Asia Pacific dominates the worldwide automobile power electronics industry. Japan and South Korea are helping to drive market development in Asia Pacific as automotive production increases.

The North American market is increasing rapidly. The United States dominates the North American market thanks to the existence of major electric vehicle manufacturers such as Tesla. Furthermore, Germany is making a significant contribution to European market growth as electric vehicle usage increases.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Thoughts on old Electra (circa the present day)

This specific photo is always kind of my starting point, it’s kind of hard to describe but the vibe is just right. The Bochum footage of Mykal is my main inspiration for how I write older Electra in general, he’s a lot more restrained than other Electras of the time and really shows his age on a stage that big, but it’s also kind of a fascinating extension on the character. I’ve always loved that Gordon in the Railway Series had a decades-long arc weirdly tied to actual developments in rail and I’ve always loved applying that approach to Electra

-Electra lives and works in a mildly to wildly fantasy version of The Northeast Megalopolis, usually based on NYC and Philadelphia. Basically imagine The Wiz (1978) in terms of being gritty and stuck in the 70s-80s aesthetically yet whimsical and surreal and weirdly optimistic. Because that’s probably the best summary of how electric trains and their fans in the US actually are.

-We’ll start with the simpler stuff. Electra looks jarringly young face-wise because *gestures at half the actors decades later* but gets misty-eyed (foggy windows are a thing) and harder of hearing (happens to drivers due to horns/other noise) and generally just kind of worn out and tired. Doesn’t move more than needed or overexert himself because it hurts, but very efficient and practiced vs “lazy��. Slower to speed up and react but a lot more gentle and stable vs erratic. -old man yaoi with Poppa makes me laugh because I just imagine them at a pro-nuclear protest after Electra convinces him this is a better way to convert everyone to steam

-Stress related health issues no matter how human or train. Tummy hurty, high blood pressure, sore/painful components that have run too hard and hot for years. Trouble regulating temperature and overheats more easily. Heat is bad for electronics in general and damage related to it due to overwork in trains is a big cause of early aging. It’s a major part of why he makes active efforts to calm down. VERY cuddly as an emotional regulation and physical comfort thing. Electra is almost never not cuddly in my mind and endlessly craves physical touch.

-Will casually peer pressure you taking care of yourself by calling for random stretch breaks or communal apple snacktime. This sounds absurd but is a running theme with older railroaders I’ve encountered

-Thicker and stronger from moving into freight service years post-canon, puts on a fair amount of weight in general because making freight engines physically heavier with concrete/extra metal is a thing irl. Stocky and cute with a barrel tummy and big butt. Can feel conflicted about it but generally comes to accept the physical change and being a bit soft and saggy (which happens to trains too, see the DB Class 150).

-Same color scheme, just maybe with more grey/silver. Even new electric trains in the US tend to look like 70s-80s timewarps (or even 50s with the gallery car EMUs made a decadeish ago). Bright obnoxious colors are still the norm for trains, seriously, the public actively likes them being loud and color coded, they don’t follow car aesthetics with all the grey.

-No seriously, a lot of the really dated 70s-early 80s pop culture stuff in the show is still popular with urbanites in the electrified areas of the northeast US. Philadelphia still claims the Rocky series and disco and funk are notably popular. The music in Stex is not far off what you’d hear at a roller rink (which often embrace the roller disco era lol). Electra being a dated old train is VERY locally endearing and would be seen as a cool uncle figure

-hangs around with a wide variety of electric trains (and some diesels running under wire) somewhere on a commuter line. There are an indefinite number of subway cars that are just the Rockies (they’re EXTREMELY NYC or SEPTA subway coded in canon imo). They wouldn’t interact much irl since they’re usually on different stations and platforms but we’ll swing things for versatility because electric train solidarity is thematically important to me. The subways trains are even weirder age-wise because they perpetually act like everyone’s annoying but loving younger sibling while often being 50+ years old, because dear god subways last a long time. 2018 Electra is a standin for the newer ACS-64 engines and Toothpaste Electra’s sort of protegé (largely looks like Lashane, hyperactive memer who is somewhere between an ascended Rocky and stereotypical modern elevator/transit fan). Based on vibes along, I feel like Deenah is his niece somehow and they ARE physically related, she comes over to visit sometimes and he keeps telling her to deal with her engine problems by just becoming an EMU. And other similarly weird advice.

-weirdly connects well across generations due to fondness for perennially popular things like surreal memes and foreign folk music you’ve never heard of. Doesn’t always get present day trends but weirdly good at connecting them to older things

-Electra is an absolutely fascinating character in the context of actual train politics and history in the US and is by far the one I ground most in reality. So 80s Toothpaste Electra absolutely ages (and eventually dies). 40 is old by train standards, intended lifespan is usually given as 20 but lasting 40 years is pretty common and electric trains last 50+ even more often because there’s fewer moving parts to wear out and they’re so efficient to begin with that it’s often more expensive to replace old ones with somewhat more efficient newer models. They just get bumped down to freight or commuter services, sometimes even maintenance trains. I want to give him some wacky maintenance train Components but the only one I’ve decided on is “leaf-obliterating laser train” because it just feels right. Maintenance trains kind of have Zamboni Guy appeal to a surprisingly wide audience because they’re weird, rare seen machinery (very Component-coded)

-Much, much calmer than canon. Over time Electra becomes more passive aggressive and snarky in middle age, and finally just really chill and bafflingly weird at 60+. Years of directly confronting a world that’s hostile and dismissive towards him made him… become more of an Oogway figure than anything, taking “resistance is pointless” in a very different direction and becoming far more jokey vs confrontational. “When will you troglodytes stop gobbling up this stupid contextless propaganda about early 20th century rail and worshipping cars and join civilized society by electrifying your damn rail lines” vs “hehehe wouldn’t it be funny if we just electrified everything. rugged mountain passes. heavy freight. siberia. isn’t that silly and absurd? don’t you want to be an extra edgy nerd and one up the “bring back steam engines” crowd with something even more implausible?” (All of these things exist and the US government has blown hundreds of billions on far stupider things)

-Direct confrontation vs working with the system is probably one of the overarching themes of Electra’s life post-canon. It’s such a Prince vs MJ conflict and present in transit advocates’ messaging. It’s hard for Electra not to want to lash out and be the squeaky wheel when electric trains and transit have been screwed for decades and are taken for granted and nearly invisible to much of the public. But it’s also not the most effective direction to sway many vs being weird and whimsical and less confrontational.

-Talks extensively in electrical metaphors (especially the water ones) in very animist ways because the broader electrical system is such an important thing for electric trains. I have extensive Electric Train Religion lore as a long-term project that is way too detailed and unfinished to fully explain. It vaguely parallels Buddhism (tons of regional variants, cycle of rebirth, avoidance of suffering (heat and inefficiency), and very elaborate levels and systems of divine beings and hell dimensions) and Taoism (balance, SO many water metaphors) more than anything and is very culturally alien to combustion trains, especially in the West. He looks like a nutjob to most outsiders but is very observant and often has surprisingly accurate insight on things because he’s been around so long and done/seen so much.

-Never grows out of his perceived “arrogance” because those traits have a VERY different meaning in the context of transit and electrification politics. The aggressive optimism is just kind of a thing because political will towards transit spending fluctuates so badly you have to be persistent to keep that rolling progress (ala France) or things will stagnate and die like in the US. The fixation on expansion and pushing for more is pretty sad because it’s done due to projects getting cut back so much and politicians undervaluing transit and electrification. The overly assertive “I am electric” identity politics are kind of akin to LGBT Pride in the US (and to a lesswr degree UK) because electric trains are SO misunderstood and unrecognized in terms of their merits and real problems. Electric trains are genuinely OP in general and it’s hard to oversell their advantages vs the combustion ones the media overromanticizes at every turn (while just ignoring electric ones).

-I’m inconsistent on how exactly Electra dies (depends on how sci fi vs tragically realistic things are) but gravitate towarda glam rock swan songs like Blackstar and The Show Must Go On thematically. There’s definitely notable physical decline at the very end as motors get derated. Not sure on mental decline, I think it’s genuinely hard to tell since Electra is so weird (yet present and rational) to begin with. I keep imagining them going out with a dramatic transformer/other electrical failure mid-run like the last GG1. His ghost definitely lingers and haunts things (cue Ouija board and pendulum scenes and “can still feel his presence” memes)

#stex#starlight express#my US electric train lore is incredibly weird and deep and based on stuff a lot of people don’t know much about#it’ll be a different post… eventually. It’s just a VERY context-heavy topic largely detached from canon besides some visual conventions

26 notes

·

View notes

Text

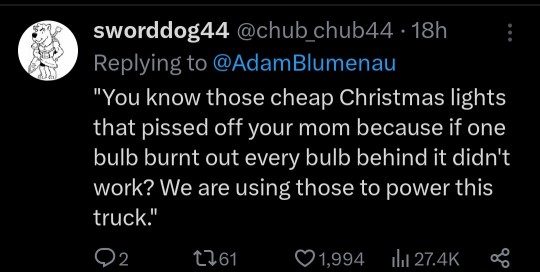

Electrical engineer with experience in designing wiring systems for trucks (and similar applications) here.

Look, I loathe Elon Musk as much as the rest of y’all, and I think the Cybertruck is an ugly-ass shitshow with an assortment of other problems, but the information here is isn’t really accurate to how this system works. Which isn’t surprising, considering that cybrtrkguy seems to be completely misunderstanding the way this whole thing gets wired up.

A typical motor vehicle has a central controller. Everything else gets fed back to it through wires that are usually bundled into harnesses depending on what part of the vehicle it’s coming from. For example, your brake lights, backup camera, rear blinkers, and everything else on the back of your car will have its wiring sent back through a harness all the way to the front of the car, where the aforementioned controller is. (It’s actually a bit more complicated than that, but that’s the basic idea.)

For the Cybertruck, Tesla replaced the main controller with a network of smaller, localized controllers; with a main harness to facilitate communication between the controllers (and, of course, send power to the local controllers/distribution boxes to distribute as needed).

As someone who’s had to design, work on, and troubleshoot electrical systems for vehicles and larger diesel engine-based power systems…this isn’t a terrible idea; in fact, I can see the appeal of it. In addition to the cost savings that comes from reducing the amount of wiring needed to make the truck work, they’ve also made it so that any problems that arise are localized - that is, if something goes wrong with the components in your passenger-side door, all of the reworking and rewiring will take place inside the door itself. There’s no need to have to trace wires all the way to the front of the truck, get under the hood, pull panels off the dashboard, etc.; all the work you’re doing is in one place. I would think that, for similar reasons, manufacturing would be simpler. (Ironically, the criticism of this system having a single point of failure is backwards - by spreading control of individual systems across multiple networked controllers, they’ve spread out the possible points of failure.)

Granted, I still think the Cybertruck is a dumpster fire, but not because of the wiring.

#also the whole thing about crumple zones is wrong#the thing about the crash test videos is that you don’t see the driver or passengers getting crushed#the problem with the ultra rigid body structure is that it’s terrifyingly dangerous to pedestrians not the people in the truck#but that’s also par for the course for American pickups anyway#which is not a defense of any of this#but an indictment of our cultural love of large trucks#Elon musk#Tesla#Cybertruck#twitter

42K notes

·

View notes

Text

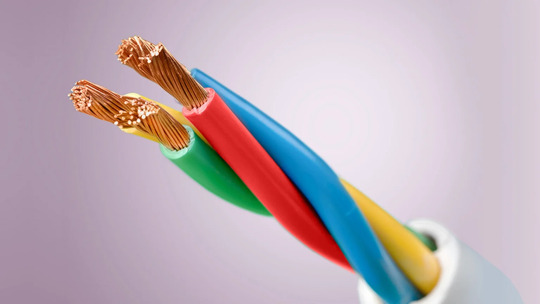

Understanding Primary Wires: What They Are and How They Are Used in Electrical Systems

When you think about electrical systems, the first thing that comes to mind might be a flick of the light switch or the hum of a well-connected device. But, behind every smooth-running electrical system, there is one key component that makes everything come alive:- primary wires. Without them, our modern-day conveniences would come to a halt. These wires carry power from their source to the systems and devices that keep us connected, powered, and safe.

But what are primary wires? And why are they such a crucial part of electrical systems? In this blog, we will explore the essentials of primary wires, their types, and their applications across various industries. By the end, you will know what makes them tick and how to choose the right cable solutions for your needs. Let us get started!

What Are Primary Wires?

At its core, primary wires are the unsung heroes of any electrical setup. These wires carry electrical current from the power source—whether a power plant, battery, or generator—to the components that need it. Think of them as the highways through which electricity travels. They are built to carry the electrical load safely and efficiently.

These wires come in different forms, depending on the intended use, but their primary role is always the same: to provide a reliable pathway for electricity to reach its destination. When you flick the switch to turn on your lights or start your car, the primary wires do all the heavy lifting.

Key Features of Primary Wires

The functionality of primary wires largely depends on three main features: material, size, and insulation.

Material:- Copper and aluminium are the most common materials used. Copper is preferred in many cases due to its excellent conductivity. However, aluminium is often used where weight is a concern, such as in power transmission lines.

Size and Gauge:- The wire’s thickness (or gauge) determines how much current it can safely carry. A thicker wire can handle more power without overheating, making choosing the right size based on your system’s needs crucial.

Insulation:- This is the protective coating around the wire that prevents it from short-circuiting and protects you from potential electrical shocks. It also ensures the wire can withstand environmental factors like moisture, heat, or physical damage.

Applications of Primary Wires in Various Systems

There is no place where primary wires are not working behind the scenes. Whether in your home, car, or massive infrastructure projects, these wires keep things running smoothly.

Automotive Industry:- In cars, primary wires connect the battery to essential systems like ignition, lights, and sensors. Without them, your car would not start, and systems would fail to communicate.

Electric Vehicles:- The need for specialized primary wires has increased as electric vehicles have become more popular. The cables ensure seamless operation by transferring energy from the battery to the electric motor.

Building and Construction:- Primary cables are used in building construction to supply electricity from the grid to a variety of systems, including air conditioning, lighting, elevators, and more. The quality of these wires directly impacts the overall performance and safety of the building’s electrical system.

Choosing the Right Primary Wire for Your Needs.

Picking the right primary wire is not always as simple as choosing any wire off the shelf. It depends on several factors—what the wire is being used for, the load it needs to carry, and the conditions it will operate under.

To ensure safety, bigger cables with the right insulation are required if you are working on a high-power industrial project. Installing wires in an electric car may need the use of stronger, lighter materials that can tolerate vibrations and high temperatures.

It is essential to get the specifications right. An underpowered wire can lead to overheating and system failures, while an oversized wire could mean unnecessary costs.

The Role of Primary Wires in Safety and Efficiency.

Safety and efficiency are top priorities for electrical systems. That is where primary wires come into play. Properly insulated and correctly sized wires ensure electricity travels safely and efficiently from point A to point B without mishaps.

Safety:- Poorly chosen or damaged wires can lead to short circuits, fires, or electric shocks. A strong, insulated primary wire helps minimize these risks.