#PowerDistribution

Explore tagged Tumblr posts

Text

Compact Sub-Station: Efficient Power Solutions for a Smarter Future

In today's fast-paced world, reliable and efficient power distribution is critical for industries, urban infrastructure, and commercial spaces. A Compact Sub-Station (CSS) serves as a game-changing solution, offering space-saving, high-performance energy distribution tailored to modern needs.

What is a Compact Sub-Station?

Compact Sub-Station is a complete electrical distribution system containing the vital parts such as transformers, circuit breakers, and switchgear combined into one encased system. The compact and weather-resistant structure, with excellent efficiency, is ideal for limited-space areas that can provide trouble-free power supply with less maintenance.

Why Use Compact Sub-Stations?

1. Space Optimization

Conventional power plants need plenty of space and infrastructure. CSS, on the other hand, is a compact, self-sustained system, which makes it ideal for cities, industrial sites, and off-grid areas.

2. Enhanced Safety & Reliability

Housed in a sturdy metal or polymer case, CSS systems provide greater safety from electrical failures, environmental exposure, and outside interferences. This results in safer and more reliable power distribution.

3. Cost-Effective Installation & Maintenance

In contrast to traditional substations that involve significant civil work, a Compact Sub-Station is factory-assembled, saving installation time and related expenses. Its modular construction also allows for simple maintenance and upgrades.

4. Energy Efficiency & Sustainability

CSS solutions today include energy-efficient transformers, minimizing power loss and encouraging sustainable energy consumption. Most are also compatible with renewable energy sources, paving the way for a cleaner future.

Applications of Compact Sub-Stations

Compact Sub-Stations find applications in many industries, including:

• Industrial Plants – Offering problem-free power delivery in factories.

• Commercial Complexes – Serving smooth power distribution to shopping complexes, offices, and skyscrapers.

• Renewable Energy Projects – Facilitating solar and wind farms with credible energy distribution.

• Construction Sites – Offering transient but effective power solutions.

Future of Compact Sub-Stations

As urbanization and industrialization are expanding, the requirement for smaller, efficient, and intelligent power solutions will continue to increase. Incorporation of IoT and AI-driven monitoring systems will further optimize the efficiency and predictive maintenance of CSS, allowing real-time monitoring while ensuring power supply without interruptions.

For organizations looking for economical, space-saving, and dependable power distribution, investing in a Compact Sub-Station is the best option. Not only does it guarantee efficient operation, but it also supports a green and energy-efficient tomorrow.

If you are searching for tailored Compact Sub-Station solutions, our organization provides high-quality, long-lasting, and advanced power solutions specifically designed to cater to your needs. Get in touch with Pavika Power Equipment today to find out how we can power your future!.Call or visit www.pavikapowerequipment.in today.

#CompactSubStation#EfficientPowerSolutions#PowerEfficiency#SustainableEnergy#SmartGrid#RenewableEnergy#EnergyStorage#CleanEnergy#PowerDistribution#GridReliability#EnergyInnovation#ElectricInfrastructure#RenewablePower#EnergyManagement#PowerSolutions#EcoFriendly#UtilitySolutions#Microgrid#EnergyFuture

0 notes

Text

Powering Cities & Industries: The Role of Pad-Mount Transformers

Introduction

Reliable and efficient power distribution is essential for cities and industries to function smoothly. Pad-Mount Transformers play a crucial role in delivering safe, underground, and space-saving power solutions. These transformers are designed for urban areas, industrial zones, and commercial buildings, where traditional pole-mounted transformers may not be suitable.

What Are Pad-Mount Transformers?

Pad-Mount Transformers are self-contained, tamper-proof transformers installed at ground level. They are enclosed in weather-resistant cabinets and designed for underground power distribution networks. This makes them ideal for areas where safety, space efficiency, and aesthetics are priorities.

These transformers are widely used in urban power grids, residential communities, industrial plants, and renewable energy projects. They ensure consistent voltage regulation, enhanced safety, and lower maintenance costs.

Why Are Pad-Mount Transformers Important?

✅ Safe & Secure Power Distribution

Their locked, tamper-proof enclosures prevent unauthorized access, ensuring public safety.

✅ Compact & Space-Saving Design

Since they are installed at ground level and connected to underground power lines, they save space and improve aesthetics.

✅ Reliable & Energy Efficient

Designed for high efficiency and minimal energy loss, these transformers improve overall power distribution reliability.

✅ Low Maintenance & Durable

Built with corrosion-resistant materials, Pad-Mount Transformers require minimal maintenance and have a long operational life.

✅ Suitable for Industrial & Commercial Use

These transformers are widely used in factories, business complexes, data centers, hospitals, and urban infrastructures.

Key Features of Pad-Mount Transformers

Engineered to meet international standards, these transformers offer: ✔ Fully enclosed, tamper-resistant design ✔ Optimized for underground distribution networks ✔ Highly efficient voltage regulation ✔ Oil-cooled & dry-type options available ✔ Customizable voltage and power ratings ✔ Eco-friendly design with low noise levels

The demand for high-quality transformers is increasing as cities and industries shift towards safe and efficient power solutions. With advanced insulation, cooling technology, and voltage control, these transformers provide maximum energy savings and operational safety.

The Growing Demand for Pad-Mount Transformers

As urbanization expands, underground power networks are becoming the preferred choice for modern infrastructure. The need for reliable power, reduced environmental impact, and better grid performance has led to a surge in demand for efficient and high-performance transformers.

With industries focusing on smart energy management, these transformers help achieve better load handling, improved grid stability, and long-term cost efficiency.

Conclusion

Pad-Mount Transformers are a smart, secure, and sustainable solution for modern power distribution. Their compact design, high efficiency, and low maintenance requirements make them ideal for cities and industries alike. As more regions adopt underground power infrastructure, the demand for advanced transformer solutions continues to rise, ensuring safer and more efficient energy management for the future.

🔗 Contact us today to learn more about our advanced transformers!

Company Details:

📍 Company Name: Padmavahini Transformers 🌐 Website: Padmavahini Transformers 📞 Contact No: +91 99430 49222 📧 Email: [email protected] 📍 Address: S. F. No. 353/1, Door No. 7/140, Ruby Matriculation School Road, Keeranatham, Saravanampatti, Coimbatore, Tamil Nadu - 641035, India

🔗 Follow Us on Social Media: 📘 Facebook 📸 Instagram

#PadMountTransformer#PadMountTransformerInCoimbatore#PadMountTransformerManufacturersInCoimbatoreIndia#PadMountTransformerManufacturersExportersInCoimbatoreIndia#PowerDistribution#EnergyEfficiency#IndustrialTransformers#SmartGridSolutions#UndergroundPower#ReliableEnergy#ElectricalInfrastructure#CompactPowerSolutions#SafeEnergyDistribution#SustainablePower#VoltageRegulation#UrbanEnergySolutions#HighEfficiencyTransformers#GridStability#LowMaintenanceTransformers#RenewableEnergyIntegration

0 notes

Text

How to Choose the Right Cable Gland Size for Optimal Performance

Choosing the correct cable gland size prevents issues like inadequate sealing and electrical failures. Learn about different cable glands, key selection factors, and expert-recommended steps for a secure fit. Ensure safe and efficient electrical installations with the right gland size.

#CableGlands#ElectricalSafety#IndustrialSolutions#CableManagement#EngineeringTips#PowerDistribution#AtlasMetal

1 note

·

View note

Text

Ring Main Unit Market Opportunity Analysis & Industry Forecast, 2024–2030

Ring Main Unit Market Overview:

Ring Main Unit Market size is estimated to reach $5.2 billion by 2030, growing at a CAGR of 8.0% during the forecast period 2024–2030.

Request Sample :

RMUs offer enhanced safety features like arc-flash protection which drives their adoption in hazardous environments. Moreover, the modernization of power distribution infrastructure as well as adoption of renewable energy are driving the market. In addition, the increasing investment in power infrastructure is also driving the market.

The two major trends in the Ring Main Unit Market are the adoption of eco-friendly technologies and the integration of smart systems. Increasingly, ecofriendly advancements like Siemens’ F-gas free RMUs with climate neutral Clean Air insulation are coming to the fore. These solutions eliminate SF6 gases and reduce the carbon footprint of power distribution systems by an order of magnitude, while maintaining high efficiency and safety. Moreover, smart technologies are integrated into RMUs to make them intelligent solutions. A key enabler provided by digitalization is the remote monitoring, automated control and IoT connectivity of features as seen in ABB’s SafeLink RMUS. These capabilities improve operational efficiency, support predictive maintenance, and integrate easily with the modern decentralized grids. These trends, together, guarantee that RMUs satisfy increasing requirements for sustainability, reliability, and sophisticated functionality in power distribution.

COVID-19 / Ukraine Crisis — Impact Analysis:

COVID 19 pandemic heavily impacted Ring Main Unit (RMU) market by creating delays in manufacturing, supply chain issues and project delays. Reduced availability of the workforce and the slow pace of production of RMU components in the regions with strong dependence on imports due to lockdowns and restrictions. Key sectors such as industrial and commercial projects continued to demand less due to persisting economic uncertainties.

Russia Ukraine war also added to the RMU market by aggravating the supply chain problems and intensifying the energy security issues. This conflict disrupted global trade in all critical raw materials for RMU costs, such as copper and steel, and this state of inflation. At the same time, energy supply disruptions in Europe triggered investments in reliable and decentralized power systems.

Inquiry Before Buying:

Key Takeaways:

APAC Dominates the Market

APAC is the dominant region in the Ring Main Unit market driven by industrialization, growing demand for power and infrastructure development. Countries like China, India and Japan are heavily investing in expanding their power distribution networks to support growing electricity demand. According to the Central Electricity Authority, Government of India, India generated 1,949 TWh of electricity in FY 2023–24, with 1,734 TWh coming from utilities, and achieved a per capita electricity generation of 1,395 kWh, reflecting substantial energy demands. Additionally, the region’s focus on renewable energy integration with extensive wind and solar projects increases the deployment of RMUs for efficient power distribution. There is a need for reliable electrical systems, further fueling RMU demand. Moreover, APAC’s strong manufacturing base reduces production costs for RMUs, making them more accessible to local utilities and industries.

Gas Insulated Represent the Largest Segment

The Ring Main Units (RMUs) market is dominated by Gas-insulated RMUs which are characterized by a compact design, high efficiency, and ability to support reliable electricity distribution in urban areas with limited space. This trend is further underscored by the expansion efforts of Siemens India, which were announced on May 2024. Siemens will invest $3.95 million to enhance its gas insulated switchgear (GIS) production capacity by 23% which includes 22,000 feeders for its Ring Main Unit. The expansion will be phased over three years from 2024–25 and will be funded from internal accruals. Such investments demonstrate the increasing need for gas insulated RMUs, which are essential to modern power systems for switching, transformation, measuring and distributing electrical energy in a reliable and efficient way. Thus, gas insulated RMUs are a preferred choice to address the rising energy needs globally due to their scalability and performance.

Schedule A Call:

Industrial is the Largest Segment

The industrial sector is the largest application area for RMUs owing to its high demand for reliable and uninterrupted power supply. Industries such as manufacturing, mining, oil & gas and petrochemicals operate in environments where power outages can result in significant financial losses and operational downtime. RMUs are preferred in these settings due to their compact design, durability and enhanced safety features. Additionally, industries often require medium-voltage distribution systems where RMUs provide an ideal solution for efficient load management and fault isolation. The growing trend of automation and electrification in industrial operations further boosts the demand for advanced RMUs with smart monitoring and control capabilities. According to Aktif Elektroteknik, RMUs are essential components in power distribution particularly valuable in industrial applications and humid environments. These medium-voltage switchgear systems, compact yet powerful, ensure steady electricity flow and can quickly switch between power sources during repairs or emergencies, minimizing downtime.

Their versatility, low maintenance, and adaptability for indoor and outdoor installations make them indispensable for industrial use. With advancements in smart grid technology and renewable energy integration, RMUs continue to evolve, offering enhanced capabilities to support modern industrial operations. This makes them a cornerstone for ensuring operational continuity and energy efficiency in industries worldwide.

Demand for Uninterrupted Electricity in Critical Applications to Drive the Market

The demand for uninterrupted electricity in critical applications, such as medical facilities, data centers and manufacturing, is a significant driver for RMU installations. The rapid growth in global electricity demand is projected to increase by around 4% in 2024, up from 2.5% in 2023, which compounds this need, according to the IEA’s Electricity Mid-Year Update. This is the highest annual growth rate since 2007, except for exceptional rebounds following crises. As global electricity consumption grows, with a further 4% growth expected in 2025, consistent power supply is critical to the functioning of critical sectors. They expect renewables to expand rapidly, accounting for 30% of global electricity supply in 2023 and 35 percent in 2025. Though, strong electricity demand, in economies like India with 8% growth and China with over 6% growth TO ensures stable CO₂ emissions from coal reliance. This robust demand demonstrates the need for reliable RMU systems to maintain uninterrupted power to the energy intensive infrastructure of modern economies.

Buy Now:

Lack of Skilled Professionals to Hamper the Market

There is a shortage of skilled workers required for installation, operation and maintenance. RMUs involve sophisticated technologies including advanced circuit breakers, insulation systems and digital monitoring tools which demand expertise for effective handling. In developing countries, where power infrastructure development is accelerating, the gap between workforce capabilities and technological advancements is particularly pronounced. This skill deficit leads to delays in project implementation, suboptimal system performance and increased operational risks. According to TeamLease, this problem is very significant in the renewable energy sector, where there is a skill gap of nearly 1.2 million workers. Moreover, TeamLease Services states, the industry will need 1.7 million trained workers by 2027, which is when demand for skilled professionals is expected to rise by 26%. This is a similar challenge occurring in other power sector infrastructure sectors, including RMUs, where the shortage of skilled professionals not only slows down growth, but also raises concerns about the quality and reliability of systems deployed around the world.

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Ring Main Unit Market. The top 10 companies in this industry are listed below:

Siemens AG

Schneider Electric SE

Eaton Corporation Plc

ABB Ltd.

GE Vernova

Toshiba Corporation

CG Power and Industrial Solutions

CHINT Group

LS Electric Co., Ltd

Lucy Electric

For more Automation and Instrumentation Market reports, please click here

#RingMainUnit#RMU#ElectricalEngineering#PowerDistribution#Switchgear#MediumVoltage#SmartGrid#EnergyInfrastructure

0 notes

Text

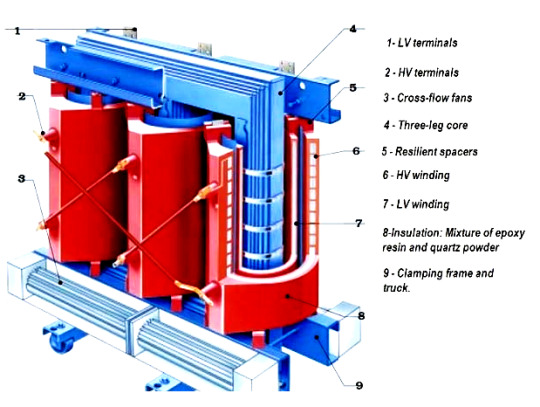

𝗣𝗼𝘄𝗲𝗿𝗶𝗻𝗴 𝘁𝗵𝗲 𝗙𝘂𝘁𝘂𝗿𝗲: 𝗧𝗵𝗲 𝗥𝗶𝘀𝗲 𝗼𝗳 𝗗𝗿𝘆 𝗧𝘆𝗽𝗲 𝗧𝗿𝗮𝗻𝘀𝗳𝗼𝗿𝗺𝗲𝗿𝘀 𝗶𝗻 𝟮𝟬𝟮𝟱 🔌

The Dry Type Transformer Market size is estimated to reach $10202.7 Million by 2030, growing at a CAGR of 6.3% during the forecast period 2024-2030.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞: 👉 https://tinyurl.com/4mu3hybr

As industries #worldwide shift towards sustainability, safety, and efficiency, the Dry Type #Transformer Market is gaining strong momentum. 🚀

#DryTypeTransformer#EnergyEfficiency#SmartGrids#SustainableEnergy#RenewableEnergy#PowerDistribution#MarketTrends

0 notes

Text

Leading Switchgear Manufacturing Companies in India & High-Quality Wires and Cables – HPL India

HPL India is a pioneer among switchgear manufacturing companies in India, offering reliable and innovative electrical solutions for homes, businesses, and industries. Our extensive product range includes top-quality wires and cables designed for safety, efficiency, and durability. As one of the most trusted switchgear manufacturing companies in India, HPL India ensures cutting-edge technology and superior performance in all its products. Whether you need advanced switchgear or premium wires and cables, we provide solutions that power the future.

Visit for more info: HPL Electric & Power Limited

Address: 1/20, Asaf Ali Road, New Delhi - 110002

Email: [email protected]

Phone: +91-11-23234411

#SwitchgearManufacturing#HPLIndia#WiresAndCables#ElectricalSolutions#PowerDistribution#SafeWiring#IndianManufacturing#ElectricalIndustry#QualitySwitchgear#EnergyEfficient

0 notes

Text

https://electronicsbuzz.in/the-future-of-power-distribution-in-indialeveraging-tech-and-innovation-to-support-rdss/

#PowerDistribution#RDSS#SmartGrid#EnergyInnovation#DigitalTransformation#RenewableEnergy#India#Sustainability#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

Victron Busbar 150A 4P & Cover 4X 1/4" Terminals http://dlvr.it/TJ45zv

0 notes

Text

Transformer Core Market — Forecast(2025–2031)

𝐏𝐨𝐰𝐞𝐫𝐢𝐧𝐠 𝐭𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞: 𝐓𝐫𝐞𝐧𝐝𝐬 & 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐓𝐫𝐚𝐧𝐬𝐟𝐨𝐫𝐦𝐞𝐫 𝐂𝐨𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 | IndustryARC™

A Transformer Core is the essential component of an electrical transformer that provides a pathway for magnetic flux. It is made of high-permeability materials like silicon steel or ferrite to efficiently transfer electrical energy between coils while minimizing energy loss.

➡️ 𝗚𝗲𝘁 𝗧𝗢𝗖 & 𝗦𝗮𝗺𝗽𝗹𝗲 𝗣𝗗𝗙 𝗥𝗲𝗽𝗼𝗿𝘁

Increase in demand for electricity production across the globe and rise in integration of renewable sources of energy to produce electricity drive the transformer core market growth. However, transformer cores are highly expensive due to the high consumption of copper wires present in the core which may act as the restraining factor for the market.

The global transformer core industry is segmented on the basis of core, product, winding, cooling, insulation, application, and region. Depending on core the market is categorized into closed, shell, and berry.

💡 𝐊𝐞𝐲 𝐅𝐮𝐧𝐜𝐭𝐢𝐨𝐧𝐬 𝐨𝐟 𝐚 𝐓𝐫𝐚𝐧𝐬𝐟𝐨𝐫𝐦𝐞𝐫 𝐂𝐨𝐫𝐞:

🔹Magnetic Flux Conduction: The core channels the magnetic flux generated by the primary coil to the secondary coil, enabling voltage transformation.

🔹Energy Efficiency: High-permeability materials reduce core losses (hysteresis and eddy currents), improving efficiency.

🔹Voltage Regulation: Helps step up or step down voltage levels in power distribution and transmission systems.

📊 𝐆𝐞𝐭 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 Click Here

✅ 𝐓𝐲𝐩𝐞𝐬 𝐨𝐟 𝐓𝐫𝐚𝐧𝐬𝐟𝐨𝐫𝐦𝐞𝐫 𝐂𝐨𝐫𝐞𝐬:

➡️Laminated Core: Made of thin steel sheets to reduce eddy current losses. Common in power and distribution transformers

➡️Toroidal Core: Circular or donut-shaped, offering minimal magnetic leakage and high efficiency

➡️C-Core & E-Core: Used in smaller transformers with lower energy losses.

➡️Ferrite Core: Used in high-frequency applications like electronic transformers and power supplies

Get this Report on discount of $1000 on purchase of Credit Card

✅ 𝗞𝗲𝘆 𝗖𝗼𝗺𝗽𝗮𝗻𝗶𝗲𝘀 𝗣𝗿𝗼𝗳𝗶𝗹𝗲𝘀 𝗶𝗻 𝗠𝗮𝗿𝗸𝗲𝘁 𝗥𝗲𝗽𝗼𝗿𝘁:RESA Power | LTC Group | Legnano Teknoelectric Co. | Manufacturer of magnetic cores for transformers & reactors | Maschinenfabrik Reinhausen | Weidmann Electrical Technology | Fortune Electric | Kyte Powertech | TOKO America, Inc | ABB | Siemens | GE | Wiltan Limited | R Baker (Electrical) Ltd | MK MAGNETICS, INC. | KTB Transformatorenbau GmbH | Core & Coil Transformers Assembling LLC | Global Transformers & Switchgears FZCO

#TransformerCore#EnergyEfficiency#PowerGrid#ElectricalEngineering#SustainableEnergy#SmartGrid#PowerDistribution#RenewableEnergy#ElectricTransformers#IndustrialPower#GridInfrastructure#HighVoltage#MagneticCore#Electrification#EnergyInnovation

0 notes

Text

High-Quality Busbar Solutions | KITO – Reliable Power Distribution Systems

Discover KITO's premium busbar solutions, designed for efficient and reliable power distribution. Engineered for durability and high performance, our busbars cater to various industrial applications, ensuring seamless electrical conductivity and safety. Explore our range of custom busbar systems today!

#kito#materialhandling#kitoindia#busbar#BusbarSolutions#PowerDistribution#ElectricalEquipment#IndustrialAutomation#EnergyEfficiency

0 notes

Text

Electric Power Distribution Automation Systems Market size by value at USD 31 billion in 2024. During the forecast period between 2025 and 2031, BlueWeave expects Global Electric Power Distribution Automation Systems Market size to boom at a significant CAGR of 5.60%, reaching a value of USD 44.3 billion by 2031. The Global Market for Electric Power Distribution Automation Systems is driven by the growing demand for reliable and efficient power distribution, increasing integration of renewable energy sources, and rising investments in smart grid technologies. Advancements in IoT, AI, and communication technologies enhance real-time monitoring and control, improving operational efficiency. Additionally, government regulations promoting energy efficiency and the need to reduce transmission losses propel market growth. The increasing adoption of distributed energy resources and rising electricity demand further support the expansion of Global Electric Power Distribution Automation Systems Market in the coming year.

Sample: https://www.blueweaveconsulting.com/report/electric-power-distribution-automation-systems-market/report-sample

Opportunity – Increasingly Aging Infrastructure

The growing prevalence of aging electrical infrastructure globally is a key driver for the adoption of electric power distribution automation systems. Outdated grids and distribution networks struggle to meet modern energy demands, leading to inefficiencies and frequent outages. Automation systems enable utilities to upgrade and retrofit existing infrastructure with advanced technologies, improving reliability, reducing operational costs, and enhancing grid resilience. Governments and utilities are increasingly investing in smart grid technologies to modernize aging infrastructure, driving market growth significantly.

#BlueWeave#Consulting#Marketforecast#Marketresearch#EnergyEfficiency#SmartGridTechnology#EnergyManagement#PowerDistribution#EnergyInnovation

0 notes

Text

Why Transformer Manufacturing Services Are Essential for Modern Industries

In strength distribution, transformers are the middle of smooth and green strength go along with the go along with the glide. Transformer manufacturing services are instrumental in making sure that those crucial additives are engineered and synthetic to maintain up with the increasing needs of present day-day industries. For electric powered powered grids, enterprise facilities, or renewable energy installations, great transformers are a need to for uninterrupted operations.

The Role of Transformer Manufacturing Services Transformers are electric equipment that convert electric energy from one circuit to some different, stepping up or down voltage to residence the requirements of diverse systems. Transformer manufacturing services consist of format, fabrication, trying out, and set up of those important gadgets. Be it in the technology of energy, distribution, or business device, transformer extraordinary has direct bearing on electric powered system overall performance, safety, and reliability.

Key Benefits of Professional Transformer Manufacturing Services

1. Tailor-Made Solutions for Varied Applications Not every transformer is the same. Every enterprise calls for definitely one in all a kind specifications relying at the type of operations, the significance of energy necessities, and geographical troubles. Expert transformer manufacturers offer tailored solutions as in step with necessities. This guarantees that the transformers could be geared up to fulfill the technical necessities, regulatory compliances, and operational dreams of the consumer.

For instance, in business programs, excessive-voltage transformers may be required to provide clean operation of heavy gadget, even as in renewable energy packages, transformers ought to be able to control fluctuating input from solar panels or wind turbines.

2. Improved Efficiency and Performance Transformer production services guarantee that each unit is built for optimum basic overall performance. Top-super transformers are made to reduce electricity loss, decorate load manipulate, and provide advanced voltage law. These traits are critical in averting strength failure and ensuring structures run with a whole lot much less downtime, thereby decreasing operational fees for industries.

Through making an funding in amazing transformer production, groups can deliver progressed ordinary overall performance and prevent vain strength outages that might bring about pricey upkeep or production delays.

3. Longevity and Durability Transformers are capital investments. They ought to, therefore, be able to face up to excessive utilization, extreme climate situations, and possible strength surges. Top transformer makers rent amazing materials and advanced generation to ensure transformers with the intention to remaining for many years, even under the most worrying conditions. Not exceptional does this assure a smooth supply of strength, however it additionally minimizes the rate and charge of replacements.

4. Adherence to International Standards Global agencies fall beneath precise rules and necessities. Professional transformer manufacturing services guarantee that each one the goods have global necessities of safety, awesome, and environmental impact. Be it the IEEE necessities in the United States or IEC requirements in Europe, the producers of transformers ensure conformity, averting regulatory issues for organizations and presenting reassurance.

How Transformer Production Services Affect Various Industries

1. Power Generation and Distribution For power stations and distribution networks, transformers are crucial in controlling voltage and ensuring that power is transmitted successfully from the element of starting to houses and groups. Transformer producers supply massive, immoderate-capability transformers that would transmit large volumes of electricity, minimizing transmission losses and ensuring the integrity of power systems.

2. Industrial Applications Industrial sectors like mining, fuel, and oil use heavy device that requires a strong and non-prevent energy deliver. Custom transformers are used to meet the load requirements, presenting a clean operation without any breaks. Additionally, transformer corporations provide compact units with region and electricity overall performance optimization, which can be very essential for business agency settings.

3. Renewable Energy Sector As the selection for for renewable power resources which incorporates solar and wind will boom, transformer manufacturing services have superior to deal with the unique wishes of such structures. They are advanced with variable input functionality, immoderate performance, and withstanding harsh environments. For every small solar farms and huge installations of wind turbines, transformers have a important characteristic in changing and transmitting energy onto the grid.

4. Commercial and Residential Projects Even past commercial-scale uses, transformers are important for residential and commercial enterprise dispositions. From powering skyscrapers to preserving the clean walking of small residential complexes, transformers assist in managing voltage goals in one-of-a-type locations, thereby presenting a uniform energy supply to any shape of building.

How to Choose the Right Transformer Manufacturing Services When deciding on a transformer manufacturing business enterprise, numerous elements want to be considered to make certain you’re getting a remarkable product that meets your wishes.

1. Experience and Reputation Seek a manufacturer with an awesome popularity and enjoy inside the industry. Businesses which have been around for decades normally recognize the ins and outs of transformer layout and might provide the technical understanding required for bespoke obligations. Customer remarks and evaluations additionally may be used to measure the reliability and exceptional in their offerings.

2. Quality and Testing Procedures A reliable transformer builder will hold stringent trying out techniques a great way to make sure each transformer meets great and overall performance ranges. Find out the attempting out finished—load take a look at, overall performance test, environmental pressure take a look at—to assure their machine will fulfill your specific goals.

3. Custom Design Capabilities If your business enterprise has specific voltage or strength desires, select out a producer that gives custom layout services. This guarantees that your transformers are optimized for your particular setup, whether or not or not you’re managing a big business facility or walking in renewable power.

4. Compliance and Certifications Verify the manufacturer complies with all applicable pointers and enterprise necessities. Certifications like ISO 9001 (top notch manipulate) and ISO 14001 (environmental manipulate) are a sign that a manufacturer complies with corporation extraordinary practices.

Transformer manufacturing services are an important issue of current power infrastructure, energizing the whole thing from business facilities to residential neighborhoods. Well-made transformers no longer terrific beautify running universal overall performance and overall performance however additionally offer lengthy-lasting, dependable electricity solutions. Whether you're within the energy technology, commercial enterprise, or renewable strength corporation, deciding on the amazing transformer producer is crucial to making sure the fulfillment of your tasks.

By deciding on a trusted transformer production enterprise, you're making an investment in the backbone of your electricity machine—ensuring a stable and inexperienced energy supply for many years to move lower back. If you're looking for transformer manufacturing services that provide great, reliability, and customization, touch our expert crew nowadays!

Contact Pavika Power Equipment on 9205442074 or visit www.pavikapowerequipment.in for professional transformer manufacturing services designed to fulfill your business company requirements!

#TransformerManufacturingServices#Transformers#Manufacturing#IndustrialServices#PowerSolutions#ElectricalEngineering#EnergyEfficiency#CustomTransformers#RenewableEnergy#PowerDistribution#ElectricalManufacturing#EngineeringExcellence#InnovationInManufacturing#ElectricalInfrastructure#PrecisionEngineering#IndustrialGrowth#SustainableEnergy#ManufacturingExcellence#B2BServices

0 notes

Text

Smart Power Solutions: Why Hybrid Transformers Are the Future

Introduction

As the world moves towards smarter and more sustainable energy solutions, the demand for Hybrid Transformers is rapidly increasing. These innovative transformers combine traditional power transmission technology with modern electronic controls, ensuring higher efficiency, better power management, and reduced energy losses.

With the rise of renewable energy sources like solar and wind power, the need for smart, adaptable, and energy-efficient transformers has never been greater. Hybrid Transformers are designed to optimize power distribution, enhance grid stability, and improve the overall lifespan of electrical systems.

What is a Hybrid Transformer?

A Hybrid Transformer is a specialized electrical device that blends conventional magnetic core technology with electronic components to provide better efficiency, lower losses, and improved voltage regulation. Unlike traditional transformers, which rely solely on electromagnetic induction, Hybrid Transformers integrate power electronics to enhance performance and adaptability.

How Do Hybrid Transformers Work?

Energy Regulation – Automatically adjusts voltage levels to match the demand.

Loss Reduction – Minimizes energy wastage by optimizing power flow.

Smart Grid Integration – Seamlessly connects with renewable energy systems and modern smart grids.

Enhanced Safety – Includes advanced cooling mechanisms and overload protection.

These intelligent power solutions are widely used in industries, commercial spaces, and renewable energy applications, ensuring greater reliability and sustainability.

Why Hybrid Transformers Are the Future?

The electric power industry is evolving rapidly, and Hybrid Transformers are at the forefront of this transformation. Here’s why they are becoming the preferred choice:

✅ Higher Energy Efficiency

Hybrid Transformers significantly reduce energy losses, improving overall power transmission efficiency. This makes them ideal for industries and power grids where energy conservation is a priority.

✅ Smart Power Management

With automated voltage regulation and digital controls, Hybrid Transformers offer real-time power optimization, ensuring consistent and stable energy flow across various applications.

✅ Eco-Friendly & Sustainable

By reducing energy wastage and optimizing power consumption, Hybrid Transformers contribute to a lower carbon footprint, making them a perfect fit for green energy initiatives.

✅ Cost-Effective & Long-Lasting

Although the initial investment may be higher, Hybrid Transformers require less maintenance and provide long-term energy savings, making them a cost-effective solution for businesses and utilities.

✅ Optimized for Renewable Energy Systems

As the demand for solar and wind energy grows, Hybrid Transformers ensure smooth power integration, enabling seamless distribution of clean energy into the grid.

Key Features of Hybrid Transformers

Hybrid Transformers come with advanced engineering and smart features designed to improve power distribution and efficiency. Some of the key features include:

✔ Advanced Voltage Regulation – Ensures stable voltage supply with minimal fluctuations. ✔ High Energy Efficiency – Reduces power loss and enhances performance. ✔ Customizable Power Ratings – Available in different voltage levels to meet specific needs. ✔ Enhanced Cooling Systems – Prevents overheating and ensures long operational life. ✔ Smart Grid Compatibility – Designed for integration with modern energy networks.

These features make Hybrid Transformers an ideal choice for industrial, commercial, and renewable energy applications, helping businesses achieve reliable and cost-effective power solutions.

Applications of Hybrid Transformers

Hybrid Transformers are widely used in various sectors and industries, including:

🏭 Industrial Power Systems – Provides stable energy supply for factories and manufacturing plants. 🔌 Smart Grids & Utilities – Enhances grid stability and efficiency in modern power networks. ☀️ Renewable Energy Integration – Optimizes the distribution of solar and wind power. 🏢 Commercial Buildings – Ensures uninterrupted power for large office spaces and malls. ⚡ High-Voltage Power Distribution – Supports efficient transmission across cities and industrial hubs.

With their versatile applications, Hybrid Transformers are rapidly replacing traditional power solutions, paving the way for more reliable and sustainable energy management.

Conclusion

The future of energy lies in smart, efficient, and sustainable solutions. Hybrid Transformers are a crucial part of this evolution, offering enhanced performance, energy efficiency, and compatibility with modern power grids. Whether for industrial applications, renewable energy systems, or urban power distribution, these intelligent transformers provide unmatched reliability and long-term benefits.

As the demand for clean and optimized energy grows, Hybrid Transformers will continue to play a vital role in shaping the future of power distribution. Investing in this technology today means better efficiency, lower costs, and a more sustainable tomorrow.

🔗 Contact us today to learn more about our advanced transformers!

Company Details:

📍 Company Name: Padmavahini Transformers 🌐 Website: Padmavahini Transformers 📞 Contact No: +91 99430 49222 📧 Email: [email protected] 📍 Address: S. F. No. 353/1, Door No. 7/140, Ruby Matriculation School Road, Keeranatham, Saravanampatti, Coimbatore, Tamil Nadu - 641035, India

🔗 Follow Us on Social Media: 📘 Facebook 📸 Instagram

#HybridTransformer#HybridTransformersInCoimbatoreIndia#HybridTransformersManufacturersInCoimbatoreIndia#HybridTransformersExportersInCoimbatoreIndia#HybridTransformersSuppliersInCoimbatoreIndia#SmartPowerSolutions#EnergyEfficiency#RenewableEnergy#SustainablePower#PowerDistribution#SmartGridTechnology#IndustrialTransformers#AdvancedPowerSystems#GreenEnergy#ElectricPowerIndustry#VoltageRegulation#FutureOfEnergy#CostEffectiveSolutions#HighEfficiencyTransformers#PowerManagemen#padmavahini transformers

0 notes

Text

Ring Main Unit Market-Industry Forecast, 2024–2030

Ring Main Unit Market Overview:

Ring Main Unit Market size is estimated to reach $5.2 billion by 2030, growing at a CAGR of 8.0% during the forecast period 2024–2030.

Request Sample Report :

The two major trends in the Ring Main Unit Market are the adoption of eco-friendly technologies and the integration of smart systems. Increasingly, ecofriendly advancements like Siemens’ F-gas free RMUs with climate neutral Clean Air insulation are coming to the fore. These solutions eliminate SF6 gases and reduce the carbon footprint of power distribution systems by an order of magnitude, while maintaining high efficiency and safety. Moreover, smart technologies are integrated into RMUs to make them intelligent solutions. A key enabler provided by digitalization is the remote monitoring, automated control and IoT connectivity of features as seen in ABB’s SafeLink RMUS. These capabilities improve operational efficiency, support predictive maintenance, and integrate easily with the modern decentralized grids. These trends, together, guarantee that RMUs satisfy increasing requirements for sustainability, reliability, and sophisticated functionality in power distribution.

Inquiry Before Buying :

COVID-19 / Ukraine Crisis — Impact Analysis:

COVID 19 pandemic heavily impacted Ring Main Unit (RMU) market by creating delays in manufacturing, supply chain issues and project delays. Reduced availability of the workforce and the slow pace of production of RMU components in the regions with strong dependence on imports due to lockdowns and restrictions. Key sectors such as industrial and commercial projects continued to demand less due to persisting economic uncertainties.

Russia Ukraine war also added to the RMU market by aggravating the supply chain problems and intensifying the energy security issues. This conflict disrupted global trade in all critical raw materials for RMU costs, such as copper and steel, and this state of inflation. At the same time, energy supply disruptions in Europe triggered investments in reliable and decentralized power systems.

Key Takeaways:

APAC Dominates the Market

APAC is the dominant region in the Ring Main Unit market driven by industrialization, growing demand for power and infrastructure development. Countries like China, India and Japan are heavily investing in expanding their power distribution networks to support growing electricity demand. According to the Central Electricity Authority, Government of India, India generated 1,949 TWh of electricity in FY 2023–24, with 1,734 TWh coming from utilities, and achieved a per capita electricity generation of 1,395 kWh, reflecting substantial energy demands. Additionally, the region’s focus on renewable energy integration with extensive wind and solar projects increases the deployment of RMUs for efficient power distribution. There is a need for reliable electrical systems, further fueling RMU demand. Moreover, APAC’s strong manufacturing base reduces production costs for RMUs, making them more accessible to local utilities and industries.

Gas Insulated Represent the Largest Segment

The Ring Main Units (RMUs) market is dominated by Gas-insulated RMUs which are characterized by a compact design, high efficiency, and ability to support reliable electricity distribution in urban areas with limited space. This trend is further underscored by the expansion efforts of Siemens India, which were announced on May 2024. Siemens will invest $3.95 million to enhance its gas insulated switchgear (GIS) production capacity by 23% which includes 22,000 feeders for its Ring Main Unit. The expansion will be phased over three years from 2024–25 and will be funded from internal accruals. Such investments demonstrate the increasing need for gas insulated RMUs, which are essential to modern power systems for switching, transformation, measuring and distributing electrical energy in a reliable and efficient way. Thus, gas insulated RMUs are a preferred choice to address the rising energy needs globally due to their scalability and performance.

Schedule A Call :

Industrial is the Largest Segment

The industrial sector is the largest application area for RMUs owing to its high demand for reliable and uninterrupted power supply. Industries such as manufacturing, mining, oil & gas and petrochemicals operate in environments where power outages can result in significant financial losses and operational downtime. RMUs are preferred in these settings due to their compact design, durability and enhanced safety features. Additionally, industries often require medium-voltage distribution systems where RMUs provide an ideal solution for efficient load management and fault isolation. The growing trend of automation and electrification in industrial operations further boosts the demand for advanced RMUs with smart monitoring and control capabilities. According to Aktif Elektroteknik, RMUs are essential components in power distribution particularly valuable in industrial applications and humid environments. These medium-voltage switchgear systems, compact yet powerful, ensure steady electricity flow and can quickly switch between power sources during repairs or emergencies, minimizing downtime. Their versatility, low maintenance, and adaptability for indoor and outdoor installations make them indispensable for industrial use. With advancements in smart grid technology and renewable energy integration, RMUs continue to evolve, offering enhanced capabilities to support modern industrial operations. This makes them a cornerstone for ensuring operational continuity and energy efficiency in industries worldwide.

Demand for Uninterrupted Electricity in Critical Applications to Drive the Market

The demand for uninterrupted electricity in critical applications, such as medical facilities, data centers and manufacturing, is a significant driver for RMU installations. The rapid growth in global electricity demand is projected to increase by around 4% in 2024, up from 2.5% in 2023, which compounds this need, according to the IEA’s Electricity Mid-Year Update. This is the highest annual growth rate since 2007, except for exceptional rebounds following crises. As global electricity consumption grows, with a further 4% growth expected in 2025, consistent power supply is critical to the functioning of critical sectors. They expect renewables to expand rapidly, accounting for 30% of global electricity supply in 2023 and 35 percent in 2025. Though, strong electricity demand, in economies like India with 8% growth and China with over 6% growth TO ensures stable CO₂ emissions from coal reliance. This robust demand demonstrates the need for reliable RMU systems to maintain uninterrupted power to the energy intensive infrastructure of modern economies.

Buy Now :

Lack of Skilled Professionals to Hamper the Market

There is a shortage of skilled workers required for installation, operation and maintenance. RMUs involve sophisticated technologies including advanced circuit breakers, insulation systems and digital monitoring tools which demand expertise for effective handling. In developing countries, where power infrastructure development is accelerating, the gap between workforce capabilities and technological advancements is particularly pronounced. This skill deficit leads to delays in project implementation, suboptimal system performance and increased operational risks. According to TeamLease, this problem is very significant in the renewable energy sector, where there is a skill gap of nearly 1.2 million workers. Moreover, TeamLease Services states, the industry will need 1.7 million trained workers by 2027, which is when demand for skilled professionals is expected to rise by 26%. This is a similar challenge occurring in other power sector infrastructure sectors, including RMUs, where the shortage of skilled professionals not only slows down growth, but also raises concerns about the quality and reliability of systems deployed around the world.

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Ring Main Unit Market. The top 10 companies in this industry are listed below:

Siemens AG

Schneider Electric SE

Eaton Corporation Plc

ABB Ltd.

GE Vernova

Toshiba Corporation

CG Power and Industrial Solutions

CHINT Group

LS Electric Co., Ltd

Lucy Electric

For more Automation and Instrumentation Market reports, please click here

#RingMainUnit#ElectricalInfrastructure#PowerDistribution#SmartGrid#ElectricalEngineering#EnergySolutions#PowerGeneration

0 notes

Text

"𝐒𝐦𝐚𝐫𝐭 𝐓𝐫𝐚𝐧𝐬𝐟𝐨𝐫𝐦𝐞𝐫𝐬": 𝐋𝐞𝐚𝐫𝐧 𝐀𝐥𝐥 𝐲𝐨𝐮 𝐍𝐞𝐞𝐝 𝐓𝐨 𝐊𝐧𝐨𝐰 𝐀𝐛𝐨𝐮𝐭 (𝐋𝐚𝐭𝐞𝐬𝐭 𝐈𝐧𝐟𝐨𝐫𝐦𝐚𝐭𝐢𝐨𝐧)

IndustryARC™ updated the market research study on “ 𝐒𝐦𝐚𝐫𝐭 𝐓𝐫𝐚𝐧𝐬𝐟𝐨𝐫𝐦𝐞𝐫𝐬 𝐌𝐚𝐫𝐤𝐞𝐭” Forecast (2024-2032)

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭

#Smarttransformers are an integral part of #smartgrids which work independently to constantly regulate voltage and maintain connection with the smart grid to allow remote administration and to provide information and feedback about #powersupply. Through a process known as voltage optimization, a smart transformer provides precise amount of power that is required, and reacts instantly to #fluctuations within the power grid, acting as a voltage regulator to ensure that the optimized voltage is uninterrupted.

#SmartTransformers#smartgrids#energyefficiency#renewableenergy#gridmodernization#iot#digitaltransformation#energymanagement#powerdistribution#electricitygrid#smartcities#energystorage#GridAutomation#sustainableenergy#electricgrid

0 notes

Text

Top Private Electrical Companies in India: Leading the Future of Power with Transmission Cable Solutions

When it comes to reliable and innovative electrical solutions, HPL India stands among the top private electrical companies in India. With a strong presence in the power sector, HPL India specializes in high-quality electrical equipment, including transmission cable solutions that ensure efficiency and safety in power distribution. As one of the top private electrical companies in India, HPL India continues to drive innovation, offering advanced transmission cable technology to meet the growing demands of the industry.

Visit for more info: HPL Electric & Power Limited

Address: 1/20, Asaf Ali Road, New Delhi - 110002

Email: [email protected]

Phone: +91-11-23234411

#HPLIndia#TopPrivateElectricalCompanies#ElectricalSolutions#TransmissionCable#PowerDistribution#EnergyEfficiency#SmartElectricity#ElectricalInnovation#IndianPowerSector#CableTechnology

0 notes