#Machining PTFE

Explore tagged Tumblr posts

Text

Advancements in Medical Device Prototype Development: Exploring PTFE Machining, Plastic Overmolding, and Chinese CNC Router Technology

Introduction

The field of medical device prototype development has witnessed remarkable advancements in recent years, driven by cutting-edge technologies and innovative manufacturing processes. This article delves into three key areas revolutionizing medical device prototyping: machining PTFE, overmolding plastic on metal, and the utilization of Chinese CNC routers. These advancements are shaping the future of medical device innovation, precision, and functionality.

Machining PTFE: Unlocking Possibilities in Medical Device Design

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has become a popular material choice for medical device applications due to its exceptional biocompatibility, chemical resistance, and low friction properties. Machining PTFE allows for the creation of intricate and precise components, enabling the design and development of advanced medical devices.

CNC machines, equipped with specialized tooling, can accurately shape and machine PTFE into complex geometries. From surgical instrument handles to implantable components, machining PTFE offers the flexibility to translate design concepts into functional prototypes with high tolerances. This level of precision is crucial in the medical field, where device performance and patient safety are paramount.

Overmolding Plastic on Metal: Combining Strength and Versatility

Overmolding, a process that involves molding one material onto another, has gained significant traction in medical device manufacturing. Overmolding plastic on metal offers a unique set of benefits, combining the strength and durability of metal with the versatility and design possibilities of plastic.

In medical devices, overmolding allows for the creation of components with soft, ergonomic grips or cushioning features that enhance patient comfort. The process involves placing a pre-machined metal substrate into a mold, followed by injecting plastic material around it. This seamless integration of metal and plastic results in robust and functional prototypes, providing the necessary balance between structural integrity and user-friendly design.

Chinese CNC Routers: Affordable Precision and Manufacturing Capabilities

Chinese CNC routers have emerged as a cost-effective solution for medical device prototype development. These machines leverage advanced computer-controlled technology to precisely cut, shape, and carve a wide range of materials, including metals, plastics, and composites.

Chinese CNC routers offer competitive pricing without sacrificing precision and quality. With their versatility and scalability, these machines enable the production of complex medical device prototypes at a fraction of the cost compared to traditional machining methods. Leveraging Chinese CNC routers��empowers medical device manufacturers to accelerate the development timeline, reduce costs, and iterate designs more efficiently.

Regulatory Considerations and Quality Assurance

While embracing these advancements in medical device prototype development, it is essential to emphasize the significance of regulatory compliance and quality assurance. Medical devices must adhere to rigorous standards and regulations to ensure patient safety and efficacy. Manufacturers must engage in thorough testing, validation, and documentation processes to meet regulatory requirements.

Additionally, collaborating with reputable suppliers and manufacturers in the medical device industry is crucial. When outsourcing production or utilizing technologies such as Chinese CNC routers, it is important to partner with trusted vendors who prioritize quality control, have a proven track record, and comply with the necessary certifications and regulations.

Conclusion

The landscape of medical device prototype development continues to evolve, driven by technological advancements and innovative manufacturing processes. Machining PTFE opens the doors to intricate designs and highly precise components, while overmolding plastic on metal combines strength and versatility for enhanced functionality. Chinese CNC routers provide affordable precision and manufacturing capabilities, enabling efficient production of medical device prototypes.

#medical device prototype development#Machining PTFE#overmolding plastic on metal#Chinese cnc router

0 notes

Text

PTFE Derlin, PTFE Derlin Manufacturer, PTFE DerlinE Supplier

PTFE Derlin : Luwol Industries provide more details of PTFE Derlin, PTFE Derlin Manufacturer, PTFE Derlin in Mumbai, India.

#Peek Rods Bush and Rings#PTFE Balls#PTFE Bottle Caps#PTFE Carbon Filled Components#PTFE Derlin#PTFE Filters#PTFE Glove Ports#PTFE Machining Components#PTFE Mechanical Seal Bellow#PTFE Moulded Bushes#PTFE Moulded Rods#PTFE Naylon#PTFE O Rings#PTFE PCD Rings#PTFE Screws#PTFE T Bush#PTFE T C Gaskets#PTFE Teflon#PTFE V Packing Set#PTFE Wear Strips#Satara#Sangli#Kolhapur#Mumbai#India.

0 notes

Text

Medium & Large PTFE Film Skiving Machine

0 notes

Text

How to Choose the Right PTFE Material for Precision Machining

Polytetrafluoroethylene (PTFE) is a remarkable fluoropolymer widely used in precision machining applications due to its unique properties. However, selecting the right PTFE grade for your specific machining requirements can be challenging. This guide will help you navigate the selection process to ensure optimal performance in your precision components. Understanding PTFE Grades for…

0 notes

Text

Premium White Hard PTFE Sheets for Demanding Industrial Applications

Aohong's white hard PTFE sheet stands as a benchmark in high-performance fluoropolymer solutions, delivering exceptional mechanical strength and chemical resistance. Manufactured from 100% virgin PTFE (polytetrafluoroethylene), these rigid fluoropolymer sheets maintain superior dimensional stability across extreme temperatures (-200°C to +260°C), outperforming conventional filled PTFE variants in purity and longevity.

Unmatched Material Properties

Our pure white PTFE sheets exhibit critical advantages:

0.02% deformation under 20MPa compressive load (ASTM D695)

28MPa tensile strength – 40% higher than recycled PTFE blends

60kV/mm dielectric strength (IEC 60243 at 200°C)

Zero moisture absorption – ideal for semiconductor cleanrooms

Microscopic analysis reveals a homogeneous crystalline structure with <0.1% void content, achieved through Aohong's proprietary isostatic pressing technology.

Precision Manufacturing Process

At our ISO 9001:2015-certified Suzhou facility, each sheet undergoes:

Ultra-fine resin filtration (99.99% purity)

Cold compaction at 65MPa for density uniformity

Controlled sintering (375±5°C for 20 hours)

Precision machining to ±0.03mm tolerances

This process yields FDA-compliant white PTFE sheets meeting:

USP Class VI biological safety standards

EU 10/2011 food contact regulations

RoHS 3 Directive compliance

Industrial Applications

Medical Devices

MRI component insulators

Autoclavable surgical tool handles

Food Processing

Non-stick conveyor liners

Dairy equipment gaskets

Semiconductor

Wafer carrier components

Plasma etch chamber liners

Chemical Processing

Hydrofluoric acid tank linings

Chlor-alkali cell seals

Quality Verification

Every production batch includes:

FTIR spectroscopy for molecular integrity checks

DSC analysis confirming 327±2°C melt point

X-ray diffraction testing crystallinity (15-20% range)

100% thickness gauging with laser micrometers

Recent third-party testing demonstrated 300% longer service life versus Chinese Q/YZB standards for PTFE sheets in sulfuric acid exposure.

Customization Options

Aohong provides tailored solutions:

Thicknesses from 0.5mm to 150mm

Anti-static versions (10⁶-10⁹ Ω/sq)

High-wear grades with 15% improved abrasion resistance

FDA white color-stable formulations

Pre-cut blanks for CNC machining

Why Aohong Excels

With 18 years of PTFE specialization, we offer:

12-month performance guarantee

Teflon™-equivalent properties at competitive pricing

Technical support from materials PhDs

Case Study: A Shanghai semiconductor fab reduced particle contamination by 92% after switching to our ultra-clean white PTFE sheets for wafer handling.

Advanced White PTFE Sheet Solutions for Critical Environments Contact Aohong today to request samples or discuss your application requirements. Our engineers combine deep material science expertise with practical experience from 1,200+ successful installations worldwide.

2 notes

·

View notes

Note

hii sorry to barge into your asks but i saw your tag on the 0-tolerance machining gifset. im a machinist too!! please tell me about some of the stuff youve made i love hearing about cool jobs other people have done and doing parts for nasa is so sick... do you mostly work on manual machines? or cnc too??

right now i work on cnc, i learned manual in trade school n tell people i have a few months on that when i wanna get my foot a little farther in the door in an interview. id say i loved working with polymer, ptfe cuts like a dream and g10 looks like jade... its so pretty,,, those guys were nasa my new guys just got a bigass deal for fuckin. spacex, babes im scareeed of high tolerance and high costs. kms

2 notes

·

View notes

Text

Medical Processing Seals Market SWOT Analysis, Dynamics, Drivers, Key Indicators and Forecast to 2027

The global medical processing seals market is expected to grow significantly, reaching a valuation of USD 3.36 billion by 2033 from USD 2.01 billion in 2023. This projected growth, at a steady CAGR of 5.2% during the forecast period, is primarily driven by the increasing demand for medical devices, rising healthcare expenditure, and growing awareness about infection control and hygiene in healthcare environments.

Market Overview

Medical processing seals are critical components used in various healthcare devices and systems to ensure sterile, leak-proof operations. These seals play an essential role in preventing contamination, maintaining vacuum integrity, and ensuring chemical resistance in medical applications.

The global medical devices industry is witnessing rapid expansion due to technological advancements and a growing aging population. This, in turn, is driving the demand for reliable and durable sealing solutions across diagnostic, therapeutic, and surgical devices. Additionally, the COVID-19 pandemic has amplified the emphasis on stringent hygiene standards and sterile medical equipment, further contributing to market growth.

Read More: https://www.factmr.com/report/medical-processing-seals-market

Key Growth Drivers

Rising Demand for Medical Devices

The surge in chronic diseases, coupled with increased surgical procedures, has escalated the production and utilization of medical devices globally. As manufacturers ramp up production to meet this demand, the need for high-performance medical processing seals has become vital. Seals used in ventilators, IV pumps, dialysis machines, and other critical systems are essential for ensuring safety and performance.

Stringent Regulatory and Sterility Requirements

The healthcare industry adheres to stringent regulations concerning hygiene and contamination control. Seals must comply with FDA and ISO standards, ensuring biocompatibility and resistance to various chemicals and sterilization methods. This regulatory pressure is prompting manufacturers to invest in high-quality, compliant sealing solutions.

Advancements in Seal Materials and Manufacturing

Innovations in elastomeric materials such as silicone, EPDM, and PTFE have enabled the development of seals that withstand extreme conditions without degrading. Manufacturers are increasingly incorporating precision engineering and cleanroom manufacturing to produce seals tailored for specialized medical applications.

Regional Outlook

North America at the Forefront

North America remains the largest market for medical processing seals due to its advanced healthcare infrastructure, strong regulatory framework, and high adoption of medical technology. The U.S. leads with significant investments in healthcare R&D and a robust presence of leading medical device manufacturers.

Rapid Growth in Asia Pacific

Asia Pacific is expected to witness the highest CAGR through 2033. Rising healthcare expenditure, a growing geriatric population, and expanding medical tourism in countries like China, India, and Japan are fueling the demand for quality medical devices and components, including processing seals.

Competitive Landscape

The global market is moderately consolidated, with leading players focusing on strategic acquisitions, product innovations, and geographic expansion to maintain a competitive edge. These companies are also investing in R&D to develop seals that meet evolving regulatory and performance standards.

Key players in the medical processing seals market include:

Trelleborg AB

Freudenberg Group

IDEX Corporation

Saint-Gobain S.A.

Parker Hannifin Corporation

Minnesota Rubber and Plastics

Morgan Advanced Materials

Bal Seal Engineering, Inc.

Apple Rubber Products Inc.

Marco Rubber & Plastics

Future Outlook

As the medical device industry continues to evolve, the demand for safe, durable, and high-performance sealing solutions will grow in parallel. With increasing focus on infection prevention, patient safety, and compliance with global health standards, the medical processing seals market is expected to maintain steady growth and play a critical role in advancing healthcare technology and infrastructure globally.

Other Sources: https://www.whatech.com/og/markets-research/medical/838620-medical-processing-seals-market-driven-by-expanding-medical-devices-and-equipment-industries.html

0 notes

Text

Hex Flange Bolts Manufacturer, Supplier & Exporter

Introduction

Ananka Group is a leading global manufacturer, supplier, and exporter of industrial fasteners, known for delivering precision-engineered solutions to a wide range of sectors including oil & gas, petrochemical, aerospace, marine, construction, and heavy engineering.

With a state-of-the-art manufacturing facility based in Vasai, Maharashtra (India) and fully operational offices in the USA and UK, Ananka Group is strategically positioned to serve clients worldwide with superior quality, timely delivery, and technical support.

We specialize in standard and non-standard fasteners, made from high-performance materials such as stainless steel, duplex, and super duplex, Inconel, Monel, Hastelloy, Titanium, and other specialty alloys. Our commitment to ISO-certified quality management, innovation in design, and customization capabilities makes us a preferred partner for mission-critical applications.

Key Strengths:

In-house design, prototyping, and rapid manufacturing

Wide range of coating and plating solutions

Custom fastener solutions in both metric and imperial sizes

Global exports with full compliance to ASTM, DIN, ISO, and BS standards

A dedicated R&D division focused on aerospace and API-certified components

Hex flange bolts are among the most versatile and widely used fasteners in the industrial world, known for their built-in washer-like flange that distributes load efficiently and eliminates the need for a separate washer. As a trusted manufacturer and supplier of hex flange bolts, we deliver high-performance, corrosion-resistant, and precision-engineered fasteners tailored to suit diverse applications across global industries.

What Are Hex Flange Bolts?

Hex flange bolts are hexagonal head bolts with an integrated flange at the base of the head. This flange acts as a washer, spreading the clamping load over a larger surface area. It reduces the risk of damage to the fastening material and enhances bolt retention, especially in high-vibration environments.

These bolts are frequently used in the automotive, aerospace, oil & gas, heavy machinery, and construction sectors for their strength and reliability.

Design & Prototyping

Whether you need a bolt designed for extreme environments or specialized machinery, our engineering team can prototype the fastener to your exact specifications, including:

Flange diameter customization

Thread pitch variation (coarse/fine)

Head height and drive type

Unique surface treatments or alloy choices

Our focus is on innovative fastening solutions to meet modern engineering demands.

Rapid Manufacturing Capabilities

Thanks to our state-of-the-art CNC machines, forging units, and automated plating lines, we support rapid manufacturing of hex flange bolts, from small-batch custom orders to bulk production runs.

We maintain large inventories of standard sizes and provide just-in-time delivery across various industries and countries. Our agile manufacturing approach ensures minimal lead times and consistent quality.

Custom Coating & Plating Options

Corrosion resistance and environmental compatibility are crucial for bolt longevity.

Zinc and yellow zinc plating

PTFE (Teflon) coating

Hot-dip galvanizing

Black oxide finish

Dacromet and Geomet coatings

Nickel, chrome, and copper plating

These coatings enhance performance in aggressive conditions like marine, chemical, offshore, and automotive applications.

Product Types Offered

High-Performance Hex Flange Bolts

Designed for critical applications like aerospace, nuclear, and motorsports, where reliability and durability are essential.

Custom Fastener Solutions

Our team creates bespoke fasteners that align with your blueprints or technical requirements, including unique dimensions, threading, and materials.

Precision-Engineered Fasteners

Manufactured to tight tolerances, ensuring optimal performance in applications that demand high accuracy.

Specialty Alloy Hex Flange Bolts

Manufactured from premium materials like Inconel, Monel, Hastelloy, Titanium, Duplex, Super Duplex, and others, engineered to perform reliably in the most demanding and corrosive environments.

Corrosion-Resistant Fasteners

Manufactured using stainless steel grades like SS 304, SS 316, and SS 316L or coated with advanced finishes to withstand harsh conditions.

Non-Standard Hex Flange Bolts

Custom dimensions, threading types, and geometries that don't conform to conventional fastener norms.

Metric & Imperial Sizes

Available in a wide range of thread sizes and lengths in both metric (M6 to M80) and imperial (¼” to 3”) standards.

Applications of Hex Flange Bolts

Automotive Industry: Engine components, transmissions, and chassis

Construction: Steel frameworks, bridges, and heavy structures

Oil & Gas: Offshore rigs, refineries, and chemical plants

Aerospace: Airframe structures and engine assemblies

Heavy Equipment: Cranes, bulldozers, and mining machinery

Railways: Track assemblies and locomotive parts

Why Choose Us?

As an ISO-certified manufacturer, supplier, and exporter of hex flange bolts, we ensure:

Superior material selection & quality control

Compliance with international standards: DIN, ASTM, ISO, BS, JIS

Bulk availability and global shipping

In-house R&D for developing advanced fastening systems

Offices & supply chains in India, USA, UK, Europe, and the Middle East

Conclusion

Whether you require standard, non-standard, or custom-engineered hex flange bolts, we have the manufacturing expertise, design capability, and international reach to deliver what you need fast and reliably. With a focus on quality, innovation, and performance, we are your ideal partner for all your fastener requirements.

FAQs

What materials are hex flange bolts made from?

They are typically manufactured from stainless steel, alloy steel, titanium, and specialty alloys like Inconel and Monel.

Are hex flange bolts reusable?

Yes, if not overtightened or damaged, they can be reused. However, it depends on the application and environmental conditions.

Do I need a washer with a hex flange bolt?

No, the integrated flange serves the same purpose as a washer, distributing the load and preventing loosening.

#HexFlangeBolts#FlangeBolt#CustomFasteners#CorrosionResistantBolts#SpecialtyAlloyFasteners#NonStandardFasteners#CustomBoltSolutions#RapidManufacturing#CoatedFasteners#AnankaGroup#HexBoltsSupplier#FastenersExporter#BoltsAndNuts#FlangeBoltSupplier#Anankafasteners#Blog#Articles#tumblr#ananka#tumblr blog

0 notes

Text

Height Demonstration Industrial Bolts and Fasteners: Engineer for Reliability

In a world that sometimes developed with commercial infrastructure and machine technique, the call for accurate bolts and fasteners has never been high. Whether it is strong pressure pipelines, structural mounting or marine equipment, the general performance of these additives immediately affects safety and strengthening. India is a first-rate hub for producing international-class fasteners that meet global standards. This article explores the specialized variety of bolts synthetic in India, consisting of ASTM A193 B6, Inconel 718 bolts, and other advanced answers.

ASTM Grade Fasteners for Critical Applications

India’s main producers produce a huge range of ASTM-grade bolts that serve various commercial sectors. ASTM A193 B6 fasteners are made of ferritic chrome steel and have excellent corrosion resistance and energy, making them appropriate for usage in high-temperature situations such as warm exchangers and refinery buildings.

Similarly, ASTM A193 B8M bolts are made of molybdenum-bearing austenitic chrome steel and are often used in maritime and chemical processing applications. Known for their superior pitting resistance, these bolts make certain structural stability even below harsh environmental publicity.

Another standout character ASTM A453 Grade 660, it is a high tensile cheese and incredible creep resistance. These bolts are usually used in turbine engines, reactors and various high -pressure applications where general performance during stress is important.

High-Performance Alloy Bolts: Inconel for Extreme Conditions

For the atmosphere that requires better heat and corrosion resistance, 718 bolts are a desired priority. These nickel chromising parties are accepted for their excessive tensile force, fatigue resistance and ability to preserve mechanical properties of increased temperatures. Aerospace, nuclear, and chemical industries depend on Inconel bolts to deliver unwavering performance even below intense situations.

Specialized Bolt Types for Industrial Applications

India is likewise domestic to some of the maximum trusted Stud Bolts Manufacturers, providing precision-engineered studs for flanged connections. These bolts are commonly utilized in oil and gas, strength technology, and petrochemical industries. Their potential to provide a uniform clamping force makes them best suited for high-pressure systems.

When it involves lifting and rigging operations, Eye Bolt Manufacturers in India offer cast and heat-treated eye bolts that meet strict load-bearing requirements. These bolts make sure protection and durability in cranes, hoists, and heavy-lifting gadget.

For foundational balance, Anchor Bolt Manufacturers design high-strength bolts used to connect structural and non-structural factors to concrete. These bolts are essential for the construction of bridges, wind turbines, and commercial equipment installations.

Coated Bolts for Added Protection

In corrosive or chemically reactive environments, fasteners should be included with coatings. That’s where PTFE-coated bolts are offered. These bolts are made with polytetrafluoroethylene, which reduces friction and increases resistance to corrosion, chemical reactions, and extreme temperatures. Fasteners with PTFE coatings are often utilised in water treatment plants, chemical industries, and offshore systems.

From superior alloys to specialized coatings, India’s fastener enterprise keeps to raise the bar in terms of quality, precision, and international competitiveness. With a huge spectrum of merchandise together with ASTM A193 B6, Inconel 718 bolts, and PTFE Coated Bolts, Indian producers are assembly the stringent needs of industries internationally. For projects where sturdiness, power, and overall performance are non-negotiable, Indian fasteners are the trusted solution.

0 notes

Text

Stainless Steel PTFE Seals Built to Withstand the Toughest Industrial Challenges

Have you ever faced unexpected downtime caused by seal failure in your equipment? For industries running under corrosive, high-pressure, or high-speed conditions, the stainless steel PTFE oil seal series by DEDE could be the upgrade your system needs.

What Makes These Seals Special?

Unlike conventional rubber seals, PTFE-based seals:

Maintain integrity at temperatures up to 250°C

Resist deterioration in acidic or solvent-rich environments

Minimize friction, reducing energy loss and motor wear

Offer long-term sealing with low torque requirements

Combined with a stainless steel frame, the structure offers both durability and precision.

Typical Applications

From precision motor systems to marine gearboxes, DEDE’s seals are engineered for:

Industrial pumps

Gear reduction units

Electric drives in automation

Hydraulic systems

Agricultural harvesters and processing lines

Wind turbines and offshore installations

DEDE’s Full-Cycle Support

With 30+ years in sealing technology, DEDE provides more than products:

On-demand inventory — Over 10,000 stock items with same-day response

End-to-end custom service — Tailored sealing based on your machine’s real-world conditions

Engineering consultation — Improve overall system sealing performance

Global-Ready Manufacturer

As a trusted name in the sealing industry, DEDE features:

A self-owned smart manufacturing base

Strong presence across 80+ countries

Certifications as a provincial innovation and specialized enterprise

Ongoing collaboration with energy and automation brands worldwide

If you’re seeking a sealing solution that matches today’s industrial complexity, stainless steel PTFE oil seals by DEDE deliver exceptional value. They’re not just seals—they’re the foundation of operational continuity.

0 notes

Text

E-PRO Lined Dispensing Tip – What Makes It a Precision Essential?

Introduction to E-PRO Lined Dispensing Tip

In the world of high-precision dispensing systems, the E-PRO Lined Dispensing Tip stands out as an essential component for a variety of industries. Whether you're dealing with sensitive adhesives, solder pastes, thermal compounds, or silicone-based fluids, these lined tips offer consistent flow, minimized contamination, and exceptional control. As industries increasingly rely on accuracy in micro-dispensing, especially in electronics, safety-critical tools, and connector assemblies, the demand for these dispensing tips has surged globally.

Why Choose E-PRO Lined Dispensing Tips?

These tips are engineered for performance and reliability. They are specifically designed to prevent fluid contamination and enhance precision in applications where exact fluid delivery is essential. Unlike conventional metal or plastic tips, lined versions include a PTFE or Teflon lining that prevents fluid degradation, reduces back pressure, and ensures chemical resistance. Consequently, they become vital in industries like electronics manufacturing, PCB assembly, automotive, and even aerospace.

Features of E-PRO Lined Dispensing Tip

Designed with smooth internal linings for ultra-precise control

Compatible with high-viscosity and low-viscosity materials

Corrosion-resistant and chemical-resistant construction

Available in a variety of gauges and lengths for different applications

Flexible and kink-resistant design for better user control

Universally compatible with dispensing syringes and automation equipment

Ideal for sensitive compounds such as oils, adhesives, and thermal pastes

Key Applications Across Industries

The E-PRO Lined Dispensing Tip isn't just limited to one industry. Its widespread compatibility and reliable flow make it suitable for various tasks, including:

Electronics Manufacturing

Used in the application of solder pastes, epoxies, and thermal pads

Ensures safe dispensing in environments with capacitors, microcontrollers, and controllers

Useful in assembling devices like laptops, sensors, and microprocessors

Automotive and Aerospace

Offers durability for dispensing in tight areas near contactors and fuses

Precision application of lubricants, greases, and sealants around switches and LEDs

Medical Device Assembly

Applied in microfluidic systems for assembling and testing advanced diagnostic tools

Ensures bio-compatible handling when working with sensitive chemical fluids

Cable and Connector Industry

Ideal for sealing around cables, connectors, and grips

Helps prevent contamination during high-voltage or delicate installations

Tool Manufacturing and Repairs

Enhances control during application of thread lockers, oils, and adhesives

Assists in applying insulating compounds in critical tool repairs

Benefits That Matter

Choosing E-PRO Lined Dispensing Tips over traditional options provides significant advantages that directly impact operational efficiency and quality control:

Reduces risk of contamination and chemical breakdown

Increases flow control and repeatability in dispensing

Minimizes material waste, improving cost efficiency

Enhances safety when working with hazardous or reactive materials

Streamlines production processes, especially in high-volume environments

Integration With Other Equipment

These dispensing tips easily integrate with automated systems, hand-held tools, and robotic dispensers. Their compatibility with a wide array of machines makes them a seamless choice for industries where cables, switches, and thermal components are part of the daily workflow. Whether you're automating a process that handles capacitors or applying thermal paste near delicate microcontrollers, these tips provide the finesse and reliability required.

Considerations When Choosing the Right Tip

While all lined dispensing tips offer excellent performance, selecting the right one depends on several factors:

Material compatibility – Ensure the tip lining suits the compound (e.g., silicone, epoxy, flux)

Gauge and length – Choose based on the precision required and the depth of the application area

Viscosity of the fluid – High-viscosity fluids need wider tips; low-viscosity requires finer ones

Environment – In temperature-sensitive or chemically reactive zones, lined tips offer safety benefits

Growing Importance in Modern Manufacturing

With electronics becoming smaller and more complex, the margin for error during assembly shrinks. A misapplied adhesive or excess solder can damage a microprocessor or short-circuit a laptop motherboard. Therefore, having control at the dispensing level is essential. Similarly, in tools and safety equipment manufacturing, where adhesives or thermal greases are involved, the lined tips guarantee precise, repeatable results.

Eco-Friendly and Cost-Saving Benefits

Many manufacturers now demand eco-friendly solutions. These tips reduce waste due to their targeted application, lowering the need for excessive cleaning or material rework. Additionally, their reusability with proper cleaning reduces overall expenditure on disposable parts. This efficiency, combined with their compatibility with connectors, fuses, and cables, makes them a sustainable choice for modern industries.

Conclusion

The E-PRO Lined Dispensing Tip is more than a simple nozzle; it is a critical tool designed for precision, reliability, and safety. Whether working in electronics, thermal management, connector production, or even medical device manufacturing, these tips help deliver superior performance while maintaining cost-efficiency. Their compatibility with controllers, capacitors, tools, and other components only strengthens their position in the global manufacturing space

0 notes

Text

PTFE Carbon Filled Components, PTFE Carbon Filled Components Manufacturer

PTFE Carbon Filled Components : Luwol Industries provide more details of PTFE Carbon Filled Components Manufacturer, PTFE Carbon Filled Components in Mumbai, India.

#Peek Rods Bush and Rings#PTFE Balls#PTFE Bottle Caps#PTFE Carbon Filled Components#PTFE Derlin#PTFE Filters#PTFE Glove Ports#PTFE Machining Components#PTFE Mechanical Seal Bellow#PTFE Moulded Bushes#PTFE Moulded Rods#PTFE Naylon#PTFE O Rings#PTFE PCD Rings#PTFE Screws#PTFE T Bush#PTFE T C Gaskets#PTFE Teflon#PTFE V Packing Set#PTFE Wear Strips#Satara#Sangli#Kolhapur#Mumbai#India.

0 notes

Text

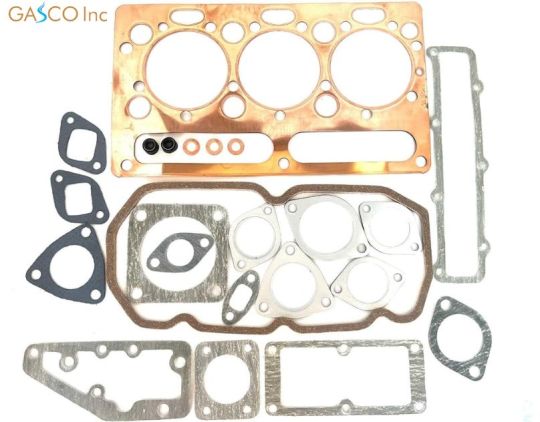

Choosing the Right Gasket Manufacturer in India – What Industry Experts Recommend

When it comes to industrial applications, even the smallest component can have a significant impact. Gaskets, though seemingly minor, play a critical role in ensuring leak-proof seals in various systems be it pipelines, engines, or machinery. Selecting the right gasket manufacturer can make all the difference in performance, durability, and safety. Among the many gasket manufacturers in India, one name that consistently stands out is Gasco INC. With decades of experience and a strong presence as gasket manufacturers in Mumbai, they have become a trusted choice for industries nationwide.

But how do industry experts recommend choosing the right gasket supplier for your needs? In this article, we’ll walk through the key considerations that can help you make an informed decision.

1. Industry Experience and Reputation

Industry experts unanimously agree that experience is non-negotiable. A manufacturer’s longevity often reflects their commitment to quality and customer satisfaction. Established gasket manufacturers like Gasco INC have a proven track record of delivering high-performance gaskets to sectors including oil & gas, pharmaceuticals, chemicals, and power generation.

Checking a company’s portfolio, client testimonials, and case studies can give you valuable insights into their reputation. A strong client base and a history of successful projects speak volumes about a manufacturer's reliability.

2. Quality Certifications and Standards Compliance

Quality is paramount when choosing a gasket. A reputable gasket manufacturer in India should adhere to international standards such as ISO, ASME, and API. Certifications serve as proof that the company meets stringent quality and safety requirements.

Gasco INC, for instance, maintains compliance with major international standards, ensuring that every gasket produced meets exacting requirements. Whether it’s spiral wound gaskets, ring joint gaskets, or custom-engineered solutions, their commitment to quality control is evident.

3. Wide Range of Products and Customization Options

No two industrial applications are the same. Experts recommend opting for gasket manufacturers that offer a wide variety of products and are capable of customizing solutions based on specific project needs. Look for a manufacturer that can supply everything from metallic and non-metallic gaskets to high-temperature and chemical-resistant variants.

Gasco INC excels in offering both standard and customized gasket solutions. Whether you need PTFE gaskets for aggressive chemical environments or graphite gaskets for high-temperature systems, they provide solutions tailored to your application.

4. Manufacturing Capabilities and Technology

Advanced manufacturing technology plays a crucial role in the production of high-precision gaskets. State-of-the-art equipment ensures better consistency, tighter tolerances, and enhanced product performance.

Top gasket suppliers like Gasco INC invest heavily in modern infrastructure and automated machinery. Their manufacturing facilities in Mumbai are equipped with CNC machines, laser cutting tools, and quality inspection systems to ensure the highest product standards.

5. Timely Delivery and Supply Chain Efficiency

Lead time is a critical factor in industrial procurement. Delays in gasket supply can halt operations and lead to costly downtime. Experts advise choosing gasket manufacturers in Mumbai or nearby regions if your facility is located in Western India, as proximity can improve logistics and reduce delivery times.

We, being strategically located in Mumbai, ensures timely delivery across India and to international markets. Their robust supply chain and extensive inventory system allow them to meet urgent demands without compromising on quality.

6. Technical Support and After-Sales Service

A good manufacturer doesn’t just sell a product they offer end-to-end support. From material selection and gasket design to installation guidance and post-sale service, technical support is vital for long-term satisfaction.

We offers comprehensive technical support, including engineering consultations and troubleshooting assistance. This ensures that customers get the right gasket for their application and optimal system performance throughout the gasket's life cycle.

Conclusion

With so many gasket manufacturers in India, selecting the right one may seem daunting. However, by focusing on experience, product range, quality standards, technological capabilities, and customer support, you can narrow your options to a few top performers. Gasco INC, with its strong industry presence and commitment to excellence, exemplifies what to look for in a gasket manufacturer.

Whether you’re seeking reliable gasket suppliers for high-pressure environments or custom sealing solutions for specialized equipment, partnering with a trusted name like Gasco INC can save time, reduce risks, and improve operational efficiency. Make your choice wisely because the right gasket manufacturer isn’t just a vendor; they’re a strategic partner in your success.

0 notes

Text

Professional Machining Techniques for PTFE Rods and Tubes

Polytetrafluoroethylene (PTFE) is an exceptional polymer material widely used in various industrial applications due to its outstanding chemical stability, high temperature resistance, and low friction coefficient. However, the unique properties of PTFE also present numerous challenges in machining processes. This article provides detailed techniques for machining PTFE rods and tubes to help…

#fluoropolymer processing#plastic machining techniques#PTFE machining#PTFE rods#PTFE tubes#Teflon processing

0 notes

Text

Why Kunsil Industry is India’s Leading PTFE Products Manufacturer

In today’s dynamic industrial sector, finding a reliable and high-quality PTFE products manufacturer in India is essential for businesses that rely on high-performance materials. Whether in the chemical, pharmaceutical, food processing, electronics, or automotive industry, Polytetrafluoroethylene (PTFE) is an irreplaceable material thanks to its non-stick properties, excellent chemical resistance, high temperature tolerance, and low friction surface.

One company that has emerged as a standout performer in this space is Kunsil Industry. With decades of experience and an unwavering commitment to quality, Kunsil has become the best PTFE product supplier in India—and for good reason.

🏭 Advanced Manufacturing Infrastructure

Kunsil Industry operates with state-of-the-art facilities, including precision CNC machining, extrusion units, and automated molding lines. These advanced technologies enable the production of consistent, high-quality PTFE components. From sheets, rods, and tubes to custom-engineered parts, the company offers a full spectrum of PTFE solutions.

As a custom PTFE parts manufacturer in India, Kunsil Industry caters to both standard and highly specialized product requirements, providing tight-tolerance machining and application-specific designs.

📦 Extensive PTFE Product Range

Kunsil’s reputation as a leading industrial PTFE manufacturer in India is backed by a diverse product catalog, including:

PTFE Sheets and Rods – Commonly used in gaskets, bearings, and insulation

PTFE Tubes and Bushes – Ideal for fluid handling, chemical lining, and mechanical support

PTFE Gaskets and Seals – Offering unmatched durability in corrosive and high-pressure environments

Precision Machined PTFE Parts – Serving OEMs and custom machine builders across sectors

As a top-rated PTFE bush and tube supplier in India, Kunsil’s products are widely used across electrical insulation, food-grade applications, and industrial sealing systems.

✅ Certified Quality and Global Compliance

Quality is the cornerstone of Kunsil Industry’s success. The company is an ISO-certified PTFE manufacturer in India, and every product goes through strict inspection and testing to meet domestic and international quality standards.

Their use of pure, virgin PTFE raw material ensures that each component delivers outstanding performance in terms of tensile strength, heat stability, and chemical resistance. This makes them a trusted supplier of high-purity PTFE in India and in global markets.

🌍 Export Capabilities & Worldwide Reach

Kunsil Industry isn’t just an Indian leader — it’s a global player. As an export-quality PTFE products manufacturer in India, Kunsil ships its products to clients in Europe, the Middle East, Southeast Asia, and beyond.

A strong logistics framework, combined with reliable customer service and timely delivery, has helped Kunsil become a PTFE manufacturer with global export capabilities in India.

🔧 Customization & Technical Support

One of Kunsil’s key strengths is its ability to provide custom-engineered PTFE components. Whether you need food-grade PTFE materials, electrical insulation PTFE parts, or chemical-resistant PTFE components, Kunsil works closely with clients to develop the right solution.

Their in-house technical team supports industries with CAD design, prototyping, and bulk production, making them a trusted partner for OEMs and industrial users alike.

🌱 Focus on Sustainability

Kunsil Industry is also committed to eco-friendly manufacturing. With practices that minimize waste and energy consumption, the company aligns with modern sustainability goals, offering long-lasting PTFE solutions that reduce environmental impact over time.

✅ Final Thoughts

When it comes to reliable and high-performance PTFE manufacturing in India, Kunsil Industry stands out as the go-to choice. Their combination of technical expertise, product quality, customization, and customer service has made them the best PTFE products manufacturer in India.

Whether you're searching for a PTFE sheet and rod manufacturer, a custom machining partner, or an exporter of PTFE parts, Kunsil delivers on all fronts.

📞 Connect with Kunsil Industry

Ready to partner with a trusted name in PTFE manufacturing? Explore the full product range at: https://kunsilindustry.com Or reach out to their team for a customized quote.

0 notes

Text

What are Cryogenic Valves: Type, Application (LNG, Medical)

1. Introduction to Cryogenic Valves

Cryogenic valves are specially designed valves used to control the flow of extremely cold liquids and gases, typically at temperatures below -40°C (-40°F). These valves are critical in industries handling liquefied natural gas (LNG), liquid nitrogen, oxygen, hydrogen, and helium, where standard valves would fail due to thermal stress, material brittleness, or seal failure.

To ensure safe and efficient operation, cryogenic valves are engineered with unique materials, extended stems, and specialized sealing mechanisms to withstand ultra-low temperatures without leakage or mechanical failure.

2. Key Structural Features of Cryogenic Valves

Unlike conventional valves, cryogenic valves incorporate specific design elements to handle extreme cold:

2.1 Extended Bonnet (Stem Extension)

- Prevents heat transfer from the environment to the valve body, reducing ice formation.

- Keeps the packing and actuator at ambient temperature to ensure smooth operation.

2.2 Specialized Sealing Materials

- Uses PTFE (Teflon), graphite, or metal seals to maintain tight closure even at cryogenic temperatures.

- Prevents leakage, which is critical for hazardous gases like LNG or liquid oxygen.

2.3 Robust Body Materials

- Made from stainless steel (SS316, SS304L), brass, or nickel alloys to resist brittleness.

- Some high-pressure cryogenic valves use forged steel for extra strength.

2.4 Vacuum Insulation (Optional for Extreme Cold)

- Some valves feature double-walled vacuum jackets to minimize heat ingress in ultra-low-temperature applications.

3. Classification of Cryogenic Valves

3.1 By Temperature Range

CategoryTemperature RangeApplicationsLow-Temperature Valves-40°C to -100°C (-40°F to -148°F)LPG (propane, butane)Cryogenic Valves-100°C to -196°C (-148°F to -320°F)Liquid nitrogen, oxygen, argonUltra-Cryogenic ValvesBelow -196°C (-320°F)Liquid hydrogen, helium

3.2 By Valve Type

- Cryogenic Ball Valves – Best for quick shut-off; common in LNG and industrial gas systems.

- Cryogenic Gate Valves – Used for full open/close control with minimal pressure drop.

- Cryogenic Globe Valves – Provide precise flow regulation in cryogenic pipelines.

- Cryogenic Check Valves – Prevent backflow in low-temperature systems.

- Cryogenic Butterfly Valves – Lightweight and compact, ideal for large-diameter pipes.

3.3 By Application

- LNG Valves – Handle liquefied natural gas at -162°C (-260°F).

- Aerospace & Defense – Used in rocket fuel systems (liquid hydrogen & oxygen).

- Medical & Scientific – Found in MRI machines and cryogenic storage.

- Industrial Gas Processing – Used in air separation plants (oxygen, nitrogen, argon).

4. Advantages of Cryogenic Valves

✔ Leak-Proof Performance – Advanced sealing prevents dangerous gas leaks.

✔ Thermal Efficiency – Extended bonnets and insulation reduce heat transfer.

✔ Durability – High-grade materials resist cracking and brittleness.

✔ Safety Compliance – Meets ASME, BS, ISO, and API standards for cryogenic use.

✔ Low Maintenance – Designed for long-term reliability in harsh conditions.

5. Key Differences Between Cryogenic and Ordinary Valves

FeatureCryogenic ValvesOrdinary ValvesTemperature RangeBelow -40°C (-40°F)Above -20°C (-4°F)MaterialsStainless steel, nickel alloys, brassCarbon steel, cast iron, plasticSeal TypePTFE, graphite, or metal sealsRubber, EPDM, or standard elastomersStem DesignExtended bonnet to prevent icingStandard stem lengthTestingCryogenic proof testing (liquid nitrogen)Ambient pressure testing

Conclusion

Cryogenic valves are essential for industries dealing with ultra-low-temperature fluids. Their specialized design—featuring extended bonnets, high-performance seals, and durable materials—ensures safe and efficient operation in extreme conditions. Understanding their classifications, advantages, and differences from standard valves helps in selecting the right valve for demanding cryogenic applications.

0 notes