#Lubricants For Wind Turbines Market Trend

Explore tagged Tumblr posts

Text

Lubricants For Wind Turbines Market to Hit $275.9 Million by 2032

The global Lubricants For Wind Turbines Market was valued at USD 155.9 Million in 2024 and it is estimated to garner USD 275.9 Million by 2032 with a registered CAGR of 8.5% during the forecast period 2024 to 2032.

Global Lubricants For Wind Turbines Market Research Report 2024, Growth Rate, Market Segmentation, Lubricants For Wind Turbines Market. It affords qualitative and quantitative insights in phrases of market size, destiny trends, and nearby outlook Lubricants For Wind Turbines Market. Contemporary possibilities projected to influence the destiny capability of the market are analyzed in the report. Additionally, the document affords special insights into the opposition in particular industries and diverse businesses. This document in addition examines and evaluates the contemporary outlook for the ever-evolving commercial enterprise area and the prevailing and future outcomes of the market.

Get Sample Copy of Report @ https://www.vantagemarketresearch.com/lubricants-for-wind-turbines-market-0509/request-sample

** Note: You Must Use A Corporate Email Address OR Business Details.

The Major Players Profiled in the Market Report are:-

CNPC, Exxon Mobil, BP, Total Lubricants, Quaker Chemical, Southwestern Petroleum Corporation, CNOOC, Axel Christiernsson, Klüber, Dow Corning, FUCHS, SKF, Sinopec, Indian Oil Corporation, Chevron, Petro-Canada, JX Nippon, Oil & Energy Corporation, LUKOIL, Shell.

Lubricants For Wind Turbines Market 2024 covers powerful research on global industry size, share, and growth which will allow clients to view possible requirements and forecasts. Opportunities and drivers are assembled after in-depth research by the expertise of the construction robot market. The Lubricants For Wind Turbines Market report provides an analysis of future development strategies, key players, competitive potential, and key challenges in the industry.

Global Lubricants For Wind Turbines Market Report 2024 reveals all critical factors related to diverse boom factors inclusive of contemporary trends and traits withinside the worldwide enterprise. It affords a complete review of the top manufacturers, present-day enterprise status, boom sectors, and commercial enterprise improvement plans for the destiny scope.

The Lubricants For Wind Turbines Market document objectives to offer nearby improvement to the market using elements inclusive of income revenue, destiny market boom rate. It gives special observation and analysis of key aspects with quite a few studies strategies consisting of frenzy and pestle evaluation, highlighting present-day market conditions. to be. Additionally, the document affords insightful records approximately the destiny techniques and opportunities of worldwide players.

You Can Buy This Report From Here: https://www.vantagemarketresearch.com/buy-now/lubricants-for-wind-turbines-market-0509/0

Global Lubricants For Wind Turbines Market, By Region

1) North America- (United States, Canada, Mexico, Cuba, Guatemala, Panama, Barbados, and many others)

2) Europe- (Germany, France, UK, Italy, Russia, Spain, Netherlands, Switzerland, Belgium, and many others)

3) the Asia Pacific- (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Vietnam, and many others)

4) the Middle East & Africa- (Turkey, Saudi Arabia, United Arab Emirates, South Africa, Israel, Egypt, Nigeria, and many others)

5) Latin America- (Brazil, Argentina, Colombia, Chile, Peru, and many others)

This Lubricants For Wind Turbines Market Research/analysis Report Contains Answers to your following Questions

What trends, challenges, and barriers will impact the development and sizing of the global market?

What is the Lubricants For Wind Turbines Market growth accelerator during the forecast period?

SWOT Analysis of key players along with its profile and Porter’s five forces analysis to supplement the same.

How much is the Lubricants For Wind Turbines Market industry worth in 2019? and estimated size by 2024?

How large is the Lubricants For Wind Turbines Market? How long will it keep growing and at what rate?

Which section or location will force the market and why?

What is the important thing current tendencies witnessed in the Lubricants For Wind Turbines Market?

Who are the top players in the market?

What and How many patents are filed by the leading players?

What is our Offering for a bright industry future?

The Research Objectives of this Report are to:-

Company, key regions/countries, merchandise and applications, historical records from 2018 to 2022, and global Lubricants For Wind Turbines Market till 2032. Study and analyze the market length (cost and volume).

To recognize the structure of Lubricants For Wind Turbines Market via way of means of figuring out its numerous subsegments.

Lubricants For Wind Turbines Market on the subject of the primary regions (with every essential country). Predict the cost and length of submarkets.

To examine the Lubricants For Wind Turbines Markets with appreciation to person boom trends, destiny prospects, and their contribution to the general market.

To examine aggressive trends consisting of expansions, contracts, new product launches, and acquisitions withinside the market.

Strategic profiling of key gamers and complete evaluation of growth strategies.

Read Full Research Report with [TOC] @ https://www.vantagemarketresearch.com/industry-report/lubricants-for-wind-turbines-market-0509

Reasons to Buy Market Report

The market record presents a qualitative and quantitative analysis of the market based on segmentation that includes each economic and non-economic element.

Lubricants For Wind Turbines Market through the region. The market evaluation highlights the consumption of products/services in areas and well-known shows elements influencing the market in every region.

Lubricants For Wind Turbines Market. It consists of an in-depth analysis of the market from specific views via Market Porter's Five Forces Analysis and provides insights into the market via the Value Chain.

The Lubricants For Wind Turbines Market file provides an outline of market fee (USD) information for every segment and sub-segment.

It consists of an in-depth analysis of the market from distinct views via a 5 forces analysis of the Lubricants For Wind Turbines Market and offers insights into the market through the fee chain.

Check Out More Reports

Global Herbal Beverages Market : Report Forecast by 2032

Global How Can the Automotive Industry Evade the Omicron Disruptions? Is the Automotive Supply Chain Prepared for the New Omicron Variant?: Report Forecast by 2032

Global Stone Coated Steel Roofing Market: Report Forecast by 2032

Global Automotive for Electric Vehicles Market: Report Forecast by 2032

Global Specialty Silica Market: Report Forecast by 2032

#Lubricants For Wind Turbines Market#Lubricants For Wind Turbines Market 2024#Global Lubricants For Wind Turbines Market#Lubricants For Wind Turbines Market outlook#Lubricants For Wind Turbines Market Trend#Lubricants For Wind Turbines Market Size & Share#Lubricants For Wind Turbines Market Forecast#Lubricants For Wind Turbines Market Demand#Lubricants For Wind Turbines Market sales & price

0 notes

Text

Saved the plant from a major breakdown

The Minimac team successfully completed a critical flushing project in a big fertilizer company with a capacity of 4000 tonnes in Jharkhand.

Synopsis

An installation project was ongoing at the fertilizer plant’s premises. Newly built lube pipelines and tanks were to be flushed to remove the welding debris and other components left inside while fabricating the pipelines. The entire project was delayed due to a very slow flushing process. Minimac Operations and Maintenance Service (MOMS) team evaluated the situation and came out with a solution to expedite the flushing process. The project required flushing their two main compressors, i.e., PSE processed air compressor and carbon dioxide compressor

Problems

Proper flushing had to be done as the pipeline was newly fabricated; otherwise, it would have led to a major breakdown of the compressor, as the impurities would choke the blades and erode/damage the compressor. Other issues were to ensure proper calculation for variable pipe diameters, and if the oil goes to the rundown tank and overflows, 60-65 degree oil will fall, causing a huge mishap.

Client’s Requirement

Fast completion of the job to meet the project timeline.

Solutions

Minimac Systems examined the pipeline, which consisted of a low-pressure pipeline, high-pressure pipeline, and run-down tank.

A proper calculation was done as the work was a bit critical; any negligence could become a mishap

All parameters must be considered, including segment-wise flushing, hammering, thermal showering, etc.

At the end of the flushing, a mesh was installed to check if any impurities were present

Completing the flushing project was ensured as per ISO 18/15/12

Cost Saving

This plant managed to save:

Cost of import caused due to deficit of fertilizer.

CO2 e Saving

Benefits

The reliable operation of the system and trouble-free operation of machines.

Sustainable performance of manufacturing process.

Elimination of new compressor cost.

Avoiding the risk of fire and explosion.

Reduction in the possibility of product degradation due to lack of proper flushing

Timely execution.

Feedback

As a result of Minimac's excellent work, another assignment of a similar nature was assigned to them. Minimac achieved the OEM's request for no debris in the mesh.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#hydraulic oil#oil & gas#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#hydraulic oil flushing#chemical cleaning flushing#oil filtration#oil filtration systems#oil contamination#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#gas turbine market trends#steam turbine#wind turbines#coalescer separator#transformer oil#transformation oil purification#transformer oil cleaning#transformer oil filtration#oil dehydration systems#frf condition systems#electrostatics lube cleaner

0 notes

Text

Bearing Market Overview: Key Players, Competitive Landscape, Regional Trends

The global bearing market size is expected to reach USD 226.60 billion by 2030, registering a CAGR of 9.5% during the forecast period, according to a new report by Grand View Research, Inc. Bearings are essential in almost every application that involves motion, and they help minimize friction between different mechanical components in several industrial machinery and equipment, resulting in reduced energy consumption. Hence, this machine element finds application in all industries, ranging from automobiles, household appliances, and aerospace to industrial machinery, using machinery or related motor-driven linkages.

Bearing Market Report Highlights

The development of cost-effective wind energy-generating products has resulted in their increased espousal within wind turbine applications that aid in increasing energy production, reduce lubricant consumption, and enhancing turbine performance and reliability.

In 2023, the roller bearings segment accounted for the largest revenue share of more than 45%. Roller bearings are ideal for applications requiring higher load-carrying capacity than speed. They are used in heavy-load settings across various industries, including equipment and machinery, aerospace, manufacturing, and power generation. The aggressive investments in infrastructure developments, which drive the demand for heavy-duty equipment and machinery, bode well for the growing demand for roller bearings.

Railway and Aerospace application is estimated to witness the fastest CAGR during the forecast period to their growing demand in applications such as shock absorbers, gearboxes, doors, and tilting mechanisms. Further, different types of bearings are commonly used in locomotives, traction motors, wagon wheels, freight carriers, and suspension. The development of the commercial aerospace industry, in line with the growing demand for aircraft, space vehicles, space shuttles, and satellites, is expected to drive the growth of the bearing market over the forecast period.

In 2023, the Asia Pacific market accounted for a revenue share of more than 40.0%, owing to the rapid expansion of the industrial and construction sector. Further, growing motor vehicle production coupled with the region's strong aftermarket demand for industrial equipment and motorcycle repairs augurs well for the growth in the region.

For More Details or Sample Copy please visit link @: Bearing Market Report

The market is estimated to witness considerable growth in the forthcoming years, ascribed to the aim to achieve energy efficiency. Energy-saving and bearings go hand-in-hand. The main objective of this element is saving energy by reducing friction, be it during the rotation of shafts of a transmission or the wheel of a vehicle. Additionally, the rising demand for commercial vehicles is expected to catapult the demand from the automotive sector across the world.

Technological advancements including smart bearings, the development of advanced materials and lubricants, and integrating sensor units, are anticipated to provide high growth potential to the market. With the objective of enhancing performance, vendors are incorporating sensor units of the product. Sensor units help with digital monitoring of rotation speed, axial movement, load-carrying capacity acceleration, and deceleration. These units are presently being used in conveyors forklifts, road rollers, and electric motors. Furthermore, the integration of IoT capabilities facilitates manufacturers to monitor operations constantly.

The market is mature with a dynamic demand closely related to the state of engineering industries and capital goods. Companies are offering integrated products that significantly decrease the number of bearings that go into an assembled product and reduce the overall cost of equipment. This in turn is also increasing the shelf-life and reliability of the product. Product manufacturers are increasingly investing in R&D to address the intensifying competition by providing innovative products.

List of Key Players in the Bearing Market

Rubix

Harbin Bearing Manufacturing Co., Ltd.

HKT Bearings Ltd.

JTEKT Corporation

NBI Group

NSK Ltd

NTN Corporation

RBC Bearings Incorporated.

Regal Rexnord Corporation

Schaeffler AG

SKF

The Timken Company

We have segmented the global bearing market based on product, application, and region

#BearingMarket#Bearings#IndustrialBearings#RollingBearings#PlainBearings#EngineeringComponents#SmartBearings#AutomatedManufacturing#EngineeringInnovation#AIinManufacturing#MechanicalComponents

0 notes

Text

The Future of Industrial Lubricants: Driving Efficiency and Sustainability in Modern Industries

In today’s industrial landscape, the role of industrial lubricants is more critical than ever. From towering manufacturing plants to high-precision automotive assembly lines, lubricants are the unsung heroes that keep machinery running smoothly, reduce wear and tear, and ensure operational efficiency. But as industries evolve, so do the demands placed on these essential fluids. The future of industrial lubricants is not just about reducing friction—it’s about driving sustainability, embracing innovation, and meeting the challenges of a rapidly changing world.

The Evolving Role of Industrial Lubricants

Industrial lubricants have come a long way from being simple oils and greases. Today, they are sophisticated formulations designed to meet the specific needs of modern machinery and processes. With industries increasingly adopting automation, IoT, and Industry 4.0 technologies, the demand for high-performance lubricants has surged. These advanced fluids are engineered to:

Minimize friction and heat generation in high-speed operations.

Extend equipment lifespan by reducing wear and corrosion.

Enhance energy efficiency by optimizing machinery performance.

But the story doesn’t end there. As global industries face mounting pressure to reduce their environmental footprint, lubricants are also evolving to support sustainability goals.

Key Trends Shaping the Industrial Lubricants Market

The global industrial lubricants market, valued at USD 63.9 billion in 2024, is expected to reach USD 74.3 billion by 2029, growing at a CAGR of 3.1%. This growth is driven by rising demand from industries like construction, mining, agriculture, and marine, as well as the increasing automation of manufacturing processes. Additionally, advancements in lubricant technology and the growing need for processed food are boosting market consumption, making the outlook for industrial lubricants highly promising.

1. Sustainability Takes Center Stage

The push for greener operations has led to the development of bio-based and eco-friendly lubricants. These products are derived from renewable resources and are biodegradable, making them a safer choice for the environment. For instance, industries are increasingly adopting vegetable oil-based lubricants and synthetic esters that offer superior performance while aligning with sustainability initiatives.

2. Smart Lubricants for Smart Factories

The rise of Industry 4.0 has ushered in a new era of smart manufacturing, where machinery is interconnected and data-driven. In this context, smart lubricants are emerging as a game-changer. These lubricants are embedded with sensors that monitor viscosity, temperature, and contamination levels in real-time, enabling predictive maintenance and reducing unplanned downtime.

3. High-Performance Solutions for Extreme Conditions

Industries such as energy, aerospace, and metals operate under extreme conditions, requiring lubricants that can withstand high temperatures, heavy loads, and corrosive environments. Advanced formulations like synthetic lubricants and solid-film lubricants are being developed to meet these challenges, ensuring reliability and performance even in the harshest conditions.

Real-World Applications Across Industries

Manufacturing

In manufacturing plants, lubricants play a crucial role in maintaining the efficiency of CNC machines, conveyors, and robotic arms. By reducing friction and wear, they help minimize downtime and improve productivity.

Automotive

The automotive industry relies on lubricants for everything from engine oils to transmission fluids. With the rise of electric vehicles (EVs), there’s a growing demand for specialized lubricants that can handle the unique requirements of EV components, such as batteries and electric motors.

Energy

In the energy sector, lubricants are essential for the smooth operation of wind turbines, gas compressors, and hydraulic systems. The shift toward renewable energy sources like wind and solar has further increased the need for high-performance lubricants that can operate efficiently in demanding environments.

Metals and Mining

The metals and mining industry faces some of the toughest operating conditions, with heavy machinery exposed to dust, heat, and moisture. Here, lubricants are critical for preventing equipment failure and ensuring safety.

Actionable Insights for Businesses

1. Choose the Right Lubricant

Not all lubricants are created equal. Businesses must select products that are tailored to their specific machinery and operating conditions. Consulting with lubricant experts can help identify the best solutions for your needs.

2. Embrace Predictive Maintenance

By integrating IoT-enabled lubricants and monitoring systems, businesses can move from reactive to predictive maintenance. This approach not only reduces downtime but also lowers maintenance costs.

3. Prioritize Sustainability

Switching to eco-friendly lubricants can help businesses meet regulatory requirements and enhance their brand reputation. Look for products with certifications like ISO 14001 or Ecolabel.

The Road Ahead: A Greener, Smarter Future

As industries continue to evolve, so will the role of industrial lubricants. The future will see a greater emphasis on sustainability, innovation, and digital integration. Lubricants will no longer be just a maintenance tool—they will be a strategic asset that drives efficiency, reduces environmental impact, and supports the transition to smarter, more connected factories.

Download Sample Report : For businesses, staying ahead of these trends will be key to maintaining a competitive edge. By investing in the right lubricants and adopting advanced maintenance practices, industries can unlock new levels of performance and sustainability. The future of industrial lubricants is bright, and it’s time to embrace the change. After all, in the world of modern industry, every drop counts.

#IndustrialLubricants#Sustainability#Industry40#Efficiency#Manufacturing#Automotive Energy#FutureTech#PredictiveMaintenance#GreenSolutions

0 notes

Text

The Growing Trend of Hydraulic Plate Bending Machines in Heavy Industries

Introduction

In the evolving landscape of heavy industries, precision and efficiency have become more critical than ever. Among the equipment revolutionizing these industries, hydraulic plate bending machines stand out as a game-changer. Whether you're shaping metal for wind turbines, shipbuilding, or construction, these plate bending machines bring unmatched precision to the table.

But why are these machines gaining so much traction? And how does leading manufacturer Himalaya Machinery play a role in this growing trend? Let’s explore this transformative shift and understand its significance for metal manufacturers.

1. The Importance of Plate Bending Machines in Heavy Industries

Heavy industries demand precision engineering. Whether it’s shaping steel for massive structures or fabricating components for machinery, plate bending machines form the backbone of metal fabrication. These machines ensure uniformity, reduce waste, and speed up production timelines. Without them, meeting today’s industrial demands would be nearly impossible.

2. What Are Hydraulic Plate Bending Machines?

A hydraulic plate bending machine uses hydraulic force to bend and shape metal plates. Unlike traditional mechanical machines, these leverage fluid power for higher precision and energy efficiency. Think of it like pressing clay into a mold—the hydraulic system applies consistent force to create perfect bends.

3. How Does Pre Bending Enhance Efficiency?

Pre bending is the process of preparing the edges of a metal plate for bending. It eliminates the risk of irregularities at the edges, ensuring smooth and accurate bends. By focusing on pre bending, manufacturers save material and reduce wastage, directly impacting profitability.

4. Key Features of Hydraulic Plate Bending Machines

Here are the standout features of modern hydraulic plate bending machines:

Precision Bending: Ensures consistent results every time.

Energy Efficiency: Hydraulic systems consume less power compared to mechanical counterparts.

Durability: Built to handle heavy-duty operations.

User-Friendly Controls: Easy-to-operate panels streamline operations.

5. Applications of Plate Bending Machines in Various Sectors

Plate bending machines find applications across multiple industries, including:

Shipbuilding: Shaping large metal plates for hulls.

Wind Energy: Crafting towers and turbine components.

Automotive: Bending chassis and body components.

Construction: Fabricating beams and metal frameworks.

6. Why Himalaya Machinery Leads the Market?

India’s Himalaya Machinery, a heavy engineering company has emerged as a trusted name in the manufacturing of plate rolling machines. Known for their innovation, durability, and customer support, they provide cutting-edge solutions tailored to various industries. Their hydraulic models are designed to deliver unmatched performance, making them a go-to choice for metal manufacturers.

7. Benefits of Using Hydraulic Plate Bending Machines

Why should industries switch to hydraulic machines?

Time-Saving: Faster operations lead to higher productivity.

Reduced Material Waste: Enhanced precision minimizes errors.

Versatility: Suitable for bending various metals, including steel and aluminum.

Cost-Effective Maintenance: Easier to maintain with the right machine maintenance checklist.

8. Crafting a Machine Maintenance Checklist

Maintenance is key to ensuring the longevity of your machine. Here’s a basic machine maintenance checklist:

Regularly inspect hydraulic oil levels.

Check for wear and tear on mechanical parts.

Clean and lubricate components weekly.

Test safety features like emergency stops.

Keep software and firmware updated.

9. Tips for Selecting the Right Machine for Bending Metal

Choosing the right machine for bending metal can feel overwhelming. Consider the following:

Material Thickness: Ensure the machine can handle your material's thickness.

Bend Radius Requirements: Match the machine’s capability to your project needs.

Energy Efficiency: Look for models with lower power consumption.

Brand Reputation: Opt for trusted manufacturers like Himalaya Machinery.

10. Innovations in Plate Bending Technology

The integration of smart technology has transformed plate bending. Advanced hydraulic machines now feature:

CNC Controls: For enhanced precision and repeatability.

IoT Integration: Enabling remote monitoring and diagnostics.

Eco-Friendly Systems: Designed to minimize energy consumption.

11. The Role of Automation in Plate Bending Machines

Automation is reshaping how plate bending machines operate. From programmable settings to AI-assisted decision-making, automation reduces manual effort and enhances accuracy, making it an indispensable feature for modern manufacturers.

12. Common Challenges and Solutions in Plate Bending

Challenge: Material cracking during bending. Solution: Use pre bending and apply gradual force.

Challenge: Machine downtime. Solution: Follow a strict machine maintenance checklist to avoid unexpected breakdowns.

13. Future Trends in Hydraulic Plate Bending Machines

As industries evolve, so do their tools. Expect to see:

Greater Automation: Fully autonomous bending processes.

Green Manufacturing: Machines designed with sustainability in mind.

Enhanced Customization: Machines tailored to specific industry needs.

14. Customer Testimonials and Success Stories

Many manufacturers have shared success stories about using Himalaya Machinery’s hydraulic plate bending machines. One customer stated, “The precision and efficiency of these machines have transformed our production line.” Stories like these highlight the real-world impact of choosing the right equipment.

15. Conclusion

The rise of hydraulic plate bending machines in heavy industries marks a significant leap in efficiency and innovation. By investing in advanced solutions like those offered by Himalaya Machinery, manufacturers can stay competitive, reduce costs, and meet the growing demands of their industries.

0 notes

Text

Lubricant Additives Market,Industry Forecast, 2024–2030.

Lubricant Additives Market Overview

Request Sample :

The increasing public interest in sustainable products has been a driving force behind the growing demand for Lubricant Additives. This trend aligns with the significant traction seen in bio-based lubricant additives, propelled by environmental concerns and regulatory pressures surrounding emission norms. These additives, derived from renewable resources, offer eco-friendly and sustainable solutions, reducing dependency on traditional petroleum-based additives. They exhibit improved biodegradability, lower toxicity, and enhanced lubrication performance. Manufacturers are investing in research to develop innovative bio-based additives that meet stringent performance requirements across various applications, from automotive to industrial lubricants. The increasing adoption of bio-lubricants is driven by a growing emphasis on sustainability and a push for greener alternatives across industries.

Additionally, there’s a growing demand for lubricant additives that offer multifunctional benefits beyond basic lubrication. Advanced functional additives are designed to cater to specific applications and address evolving performance requirements such as anti-wear, extreme pressure protection, friction reduction, and viscosity control. Manufacturers are focusing on developing additives with improved thermal stability, oxidation resistance, and compatibility with modern base oils. These additives are crucial for meeting the demands of high-performance engines, machinery, and equipment in diverse industries like automotive, aerospace, marine, and manufacturing. The trend is shifting towards tailored additives that offer enhanced performance under extreme operating conditions, prolonging equipment lifespan and reducing maintenance costs.

Inquiry Before Buying :

COVID-19 Impact

COVID-19 pandemic had negatively impacted the lubricant additives market on a global level, as due to restrictions and lockdown imposed by governments all across the globe, the productivity went down of various manufacturing sectors like metalworking, fabricating oil & gas, chemicals, consumer goods, etc. But the automobile sector was majorly hit, as there was shutting down of large part of the auto industry and its many suppliers around the world. Hence due to this, vehicle usage, as well as vehicle sales, took a downfall. And as lubricants additives are used mainly in heavy-duty and passenger vehicle lubricants, so with the decline in vehicle production the demand for lubricant additives especially the passenger vehicle lubricant in the automotive segment also declined. As per the International Organization of Motor Vehicle Manufacturing, in 2020 there was a 16% global decline in vehicles production i.e., less than 78 million vehicles, with all major producing regions like the U.S, Brazil, Germany having a sharp decline of 11% to 44% and Europe saw a drop of 21% on average.

Market Snapshot:-

Report Coverage

The report: “Lubricant Additive Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Lubricant Additive Industry.

By Product Type — Hydraulic Oil, Gear Oil, Engine Oil, Transmission Oil, Compressor Oil (Air Compressor Oil, Gas Compressor Oil, Refrigerator Compressor Oil)

By Additive Type — Anti-Oxidants, Anti-Wear, Viscosity Improvers, Corrosion Inhibitors, Detergents, Dispersants, Others

By Application — Heavy Duty engine, Metal Working Fluids, Industrial Machinery, Others

By End-user-industry — Construction (Draglines, Crane, Bulldozer, Dump Trucks, Others), Automotive (Passenger Vehicles, Heavy Vehicles, Light Vehicles, Others), Agriculture (Tractors, Harvester, Balers, Harrows, Others), Food & Beverages, Energy (Wind Turbine, Solar Plant, Hydropower plant) Manufacturing, Others By Geography — North America (USA, Canada, Mexico), Europe (UK, Germany, France, Italy, Netherland, Spain, Russia, Belgium, Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, Rest of South America), Rest of the World (Middle East, Africa)

Schedule a Call :

Key Takeaways

Bio-lubricants are becoming a suitable replacement for petroleum-based lubricants as they provide better lubricity, high flashpoint, high viscosity index. And as bio-based lubricants are derived from bio-based raw material, so they are environmentally friendly.

Asia-Pacific region dominates the Lubricant Additive Market, industrial and automotive sector in countries like China, India, Japan is rapidly advancing. The region has become a global manufacturing and commercial hub where several major companies are planning to invest to expand their global image

The development of new and efficient lubricating technology like Matched Molecular Chemistry, which is more efficient, requires less maintenance and water cooling for industrial application has created significant growth opportunities for the lubricant additive industry

For more details on this report — Request for Sample

Lubricant Additive Market Segment Analysis — By Product Type

Engine oil held the largest share in the Lubricant Additive Market in 2023, with a share of over 30%. As it helps to preserve engine performance, reduce wear and tear of machinery, provide prolonged life to it with consistent use, therefore it is used for all different kinds of machinery and engines. They are also used in heavy industrial equipment such as automobiles or construction equipment. For instance, In August 2023, China implemented robust measures to address its property market crisis, including the relaxation of mortgage policies and the initiation of guidelines for affordable housing construction. Hence such demand for affordable housing and an increase in infrastructure projects will drive construction in the country, due to which demand for engine oil used in heavy equipment like cranes and scrapers used in the construction sector will also increase.

Lubricant Additives Market Segment Analysis — By Additive Type

Viscosity index improvers held the largest share in the lubricant additives market in 2023, with a share of over 35%. Viscosity improver is majorly used to enhance the performance of the engine as it improves the performance of lubricant at high and low temperatures. As they are made of a polymeric molecule, so they are sensitive to changes in temperature i.e., the molecular chain contracts at low temperature and relax at high temperature. The automotive industry is the main user of this additive. In 2022, motor vehicle production in the U.S increased up to 9.8%. And, as per the European Association of Motorcycle Manufacturers, New motorcycle registrations in five of the largest European markets i.e. France, Germany, Italy, Spain and the UK) reached 873,985 units during the first nine months of 2023. This represents an increase of approximately 11.8% compared to the same period in 2022. As the production of two-wheeler and motor vehicles are increasing in the automotive sector in these regions, so demand for viscosity index improvers which is used in various automobile oils like engine oil, gear oil, hydraulic oil, transmission oil, etc. will also increase.

Lubricant Additive Market Segment Analysis — By Application

Heavy-Duty Engine held the largest share in the Lubricant Additive Market in 2023, with a share of around 40%. The lubricant for the heavy-duty engine is mainly used in heavy and off-road equipment like diesel trucks, bulldozers, Graders, etc. And it provides certain benefits like enhancing fuel economy, increase in engine life, minimizing downtime for equipment and vehicle, etc. As the equipment is used mainly in construction projects so their selection depends upon the work and economy of the project. For instance, in 2022, construction projects surged notably in the U.S., driven by policies like the IIJA and CHIPS Act, notably boosting facilities such as semiconductor factories and automobile assembly plants. Hence, with the increase in such construction projects the demand for lubricants used in heavy-duty equipment like a bulldozer, excavators will also increase.

Lubricant Additive Market Segment Analysis — By End User

The automotive segment held the largest share in the Lubricant Additive Market in 2023, with a share of over 45%. Lubricant additives are used in an automobile to clean, cool, prevent metal parts from corrosion and rust. Lubricants like engine oil are used to enhance fuel efficiency and performance of the engine in automobiles and gear oil is used in automobile gearbox to protect gear parts from high mechanical pressure. Hence with the rapid development in the automotive sector and increase in production of vehicles in major regions, the demand for gear and engine oil will also increase as it has high applicability in the automotive sector. For instance, as per the International Organization of Motor Vehicle Manufacturing, the global production volume of vehicles increased to 61 million in 2022 from 57 million, the previous year. As per European Automobile Manufacturers Association, the production of passenger cars in the EU increased by 8.3% in 2022.

Lubricant Additive Market Segment Analysis — By Geography

Asia-Pacific held the largest share in the lubricant additives market in 2023, with a share of over 35%. It is due to factors such as rising economies and an increase in investments in various industrial sectors. As per the Indian Brand and Equity Foundation, the automobile industry attracted Foreign Direct Investment equity inflow (FDI) worth US$34.74 billion between April 2000-March 2023, accounting for 5.45% of the total equity FDI during the period. As per the 2022 report of the European Automobile Manufacturers Association on global vehicle production, China produces 34.1% of 68.5 million cars manufactured worldwide followed by Europe 19.4%. And as per China Electronic Information Industry Development, the country is expected to spend US$1.4 trillion on new infrastructure projects between 2020–2025, including investments in renewable energy and residential buildings. Hence as the construction and automobile sector in China and India and the automobile sector in Japan & Korea are rapidly developing, so this has led to an increase in demand for advanced lubrication in these sectors in the Asia Pacific region.

Lubricant Additive Market Drivers

Changes in Automobile Engines Technology

Modern engines in terms of reliability and efficiency depend directly on the effectiveness of the lubricating system. lubrication is responsible for cooling internal parts of the engine which are acting relative to each other creating friction and heat which results in overheating. With the advancement in passenger car engine technology like Gasoline Direct Injection & Turbocharge Gasoline Direct Injection, there have been some advancements in lubricant standards too. For instance, in 2022, the evaluation commenced for the prospective ILSAC GF-7 standard, intended to supersede GF-6. The proposed improvements span crucial engine tests, aiming to adapt to evolving engine technologies, address component availability concerns, and align with potential EPA/CARB regulations. Hence such implementation will increase demand for lower viscosity index improvers lubricants as they are used in all vehicles and efficiently reduce engine friction.

Buy Now :

Nation’s effort for Achieving Fuel economy

For improving vehicle efficiency and transition to low carbon vehicles, various initiative has been launched in nations globally focusing on all automobile sectors like light-duty vehicles, heavy-duty vehicles, buses, motorcycles, trucks, etc. For instance, The Global Fuel Economy Initiative (GFEI) promotes fuel efficiency in cars and light duty vans, through the adoption of the cost-effective fuel efficiency technologies. These fuel efficiency gains would save 33Gt of CO2 by 2050 and $2 trillion by 2025, money which could be used to support the transition to electric vehicles. Hence such initiative will increase the demand for efficient lubricants like bio-based and nanotube-based lubricants that can be used in new vehicles to achieve low engine friction and fuel economy.

Lubricant Additive Market Challenge

Growing demand for E-Vehicles

Due to rising environmental concerns and growing technological advancements consumers have started shifting their demand from fuel combustion vehicles to electric hybrid vehicles. Various automotive plants for e-vehicles are being set up in countries. For instance, as per European Automobile Manufacturing Association, in 2022, the share of electric vehicles in new car registrations increased in almost all countries compared with the previous year. The highest shares were found in Norway (89%), Sweden (58%) and Iceland (56%). And as per the International Energy Agency, EV sales are expected to continue strongly through 2023. Over 2.3 million electric cars were sold in the first quarter, about 25% more than in the same period last year. We currently expect to see 14 million in sales by the end of 2023. Hence such an increase in demand and production of e-vehicles can ban petrol and diesel vehicles which are the main consumers of lubricant, thereby negatively impacting the lubricant additive industry.

Lubricant Additive Industry Outlook

The companies to develop a strong regional presence and strengthen their market position, continuously engage in mergers and acquisitions. Some of the major players in this market are as follows:

BASF SE

Croda International PLC

Evonik Industries AG

The Lubrizol Corporation

Afton Chemical Corporation

Infineum International Limited

BRB International

Chevron Oronite Company

LANXESS

Tianhe Chemicals Group

Recent Developments

In November 2023, IMCD China’s acquisition of Guangzhou RBD Chemical, a specialist in lubricant additives, signaled a significant stride in the Chinese industrial landscape. This strategic move fortified IMCD’s position, leveraging RBD’s extensive 20-year expertise in South China’s lubricants market. The acquisition, expected to close in Q1 2024, promises a transformative collaboration, enriching IMCD’s foothold in the lubricant additives sector.

In November 2023, Trecora LLC’s acquisition of Chemtrade’s Lubricant Additives Business expanded its specialty chemical division, enhancing its portfolio and meeting dynamic lubricant demands. This strategic move highlighted industry collaboration, emphasizing market adaptability and innovation.

For more Chemicals and Materials Market reports, please click here

0 notes

Text

Transformer Oil Market Navigating Dynamics and Opportunities in the Global Transformer Oil Market Forecast 2023-2032

Transformer Oil Market: Powering the Future of Electrical Infrastructure

Introduction

The Transformer Oil Market is poised for robust growth, driven by the increasing demand for electrical power and the global shift towards sustainable energy. Transformer oil, also known as insulating oil, plays a crucial role in maintaining the efficiency and insulation of transformers, ensuring the smooth functioning of electrical systems. In this comprehensive market analysis, we delve into the dynamics, trends, and factors influencing the Transformer Oil Market.

Market Overview

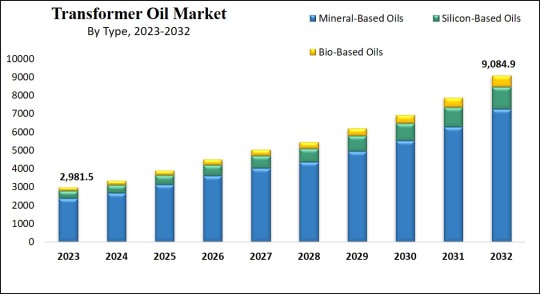

In 2023, the Global Transformer Oil Market is estimated to be valued at USD 2,981.5 Million, with a projected compound annual growth rate (CAGR) of 13.2% for the forecast period from 2023 to 2032. Transformer oil, recognized for its stability at high temperatures and superior electrical insulation properties, serves as a key component in transformers. Its dual function of suppressing arcing and dissipating heat is vital for the efficient operation of transformers.

Get a free simple request:-https://dimensionmarketresearch.com/report/transformer-oil-market/request-sample

Functions of Transformer Oil

Transformer oil performs two crucial functions in transformers:

Moreover, transformer oil acts as a protective layer against oxidation of metal surfaces and aids in better cooling and insulation by properly dipping the core and windings of transformers.

Alternatives and Environmental Concerns

To address environmental concerns and economic considerations, alternative transformer oils, including soybean oil, palm kernel oil, and coconut oil, have emerged. These alternatives are readily available in countries like India, Malaysia, and Sri Lanka. Bio-based transformer oils are gaining traction due to their superior fire resistance and non-toxic characteristics, aligning with environmental sustainability.

Market Dynamics

The Transformer Oil Market is experiencing significant growth, primarily fueled by its extensive use in the power generation sector. The global emphasis on sustainable energy sources and the rise in electricity trade across borders, particularly in Asia, contribute to market expansion. The surge in wind power projects further bolsters the demand for transformer oil, serving as a lubricant and coolant in turbines and transformers.

Challenges and Opportunities

Despite the positive outlook, challenges such as the acceptance of alternative transformer techniques and fluctuations in crude oil prices exist. Strict regulations addressing the negative impacts of minerals and crude oil price variations also impede market growth. However, the expanding distribution of energy, driven by increased electricity consumption in emerging economies like India and China, presents significant growth opportunities.

Research Scope and Analysis

By Type

Mineral-Based Oils

Mineral-based oils dominate the market, holding a maximum share in 2023. These oils find extensive use in various sectors, including circuit breakers, capacitors, and high-compatibility areas. The preference for mineral-based oils in conditioning switchgear, transformers, and boilers is attributed to their efficiency in heat transfer and preservation of transformer interiors.

On the other hand, a shift towards bio-based products is evident in recent times. Bio-based oils, derived from vegetable sources, offer superior performance and environmental friendliness. The rising trend of bio-based products is expected to create new growth avenues, although challenges related to non-biodegradability may impact certain mineral oil products.

Silicon-Based Oils

Bio-Based Oils

By Rating

The market is segmented by rating, with the 100 MVA-500 MVA segment dominating in 2023. These transformers, designed for extensive industrial environments, play a crucial role in power generation, transmission, and distribution. The <100 MVA segment follows, anticipated to exhibit the fastest CAGR by 2032 due to widespread applications in power distribution channels.

By End User

Industrial

The industrial segment commands the market with the maximum share in 2023. The global rise in industrialization has increased the demand for transformers across sectors like food processing, chemicals, steel, and automotive. Transformers are essential for various electrical machinery operating at different voltage levels, driving the demand for transformer oils to ensure smooth operations.

Residential

The residential segment is poised to grow with the maximum CAGR in the coming years. The increasing population and residential developments drive the need for transformers in houses, apartments, and villas, contributing to the demand for transformer oils.

Recent Developments in the Transformer Oil Market (as of February 5, 2024):

Market Growth:

Global Transformer Oil Market Report Segmentation

By Type:

By Rating:

By End-User:

Regional Analysis

Asia Pacific

Asia Pacific dominates the Transformer Oil Market, commanding a significant share of 55.8% in 2023. The region's rising electricity demand in economies such as India, China, Australia, and Japan is a key driver. The focus on capacity building for renewable energy in China and India contributes to the demand for transformer oil in the sub-transmission segment. Local producers in Asia Pacific pose challenges for international entrants seeking market foothold.

North America

In North America, the market is driven by the growth of the industrial and manufacturing industries in Canada and the U.S. Technological advancements and developments in established transformers, coupled with the decline in the crude oil market, are anticipated to propel the market in these nations.

Buy Now Click here:- https://dimensionmarketresearch.com/checkout/transformer-oil-market

Frequently Asked Questions (FAQs)

1. What is the expected valuation of the Global Transformer Oil Market in 2023?

2. What functions does transformer oil perform in transformers?

4. What challenges does the Transformer Oil Market face?

5. Which region dominates the Transformer Oil Market in 2023?

#Transformer Oil Market Growth#Sustainable Energy#Electrical Systems Efficiency#Arc Suppression#Heat Dissipation#Bio-based Transformer Oils#Market Dynamics#Regional Dominance: Asia Pacific#Environmental Sustainability#Industrial Growth

1 note

·

View note

Text

0 notes

Text

0 notes

Text

Do you know? Did you know that how we maintain our machines can be classified in various types and what is interesting to note is each technique has some benefits and some consequences.

In this article, we will understand different types of maintenance techniques their pros and cons along with a brief guideline on how they impact a company’s cost structure with some interesting facts. Contact Minimac to schedule maintenance: +91 7030901266 There are four types of maintenance strategies:

Reactive Maintenance: Maintenance is scheduled in response to operational failure. This type of maintenance is very useful for lowering initial cost, reducing manpower cost as you need fewer staff members and doesn’t require any planning. On the contrary, this strategy compels you to keep more inventory to brace for unexpected failure. This not only leads to a higher cost but also makes the project budgets unpredictable.

Preventive Maintenance: Maintenance is scheduled according to historic trends, experience or reliability data considerable guesswork is required. Preventive maintenance helps plan operations better and provides a better grip on the project budget as you don’t have to keep a lot of inventory on the shelf. However, sometimes we end up sending parts that do not require maintenance which leads to unnecessary expenditure and work.

Predictive Maintenance: Progression of failure is monitored. Machine repair is scheduled prior to a catastrophic breakdown. Reduction in maintenance costs, reduction in repair and Overhaul time and reduction in spare part inventory are some of the advantages of this technique, however high implementation cost, expense on manpower training and increased manpower are some of the downsides.

Proactive Maintenance: Ahead of the first initiation of failure, not in response to failure. Focused on the root cause.

This is one of the superior types as the elimination of the cause of failure saves a lot of costs and contributes to the project’s profitability. However, this can be only applied if the manpower has greater diligence and are consistent with observing and recording their feedback. Also, read https://www.linkedin.com/pulse/functions-hydraulic-oil-reasons-its-contamination-anshuman-agrawal/

We at Minimac Systems Pvt Ltd. not only design a maintenance schedule for the lubrication oil but also provide a range of OIL PURIFICATION SYSTEMS & FLUSHING SYSTEMS. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil testing#oil filteration#oil filters#oil industry#oil and gas#oil#gas turbine market trends#gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#wind#turbine oil#oil contamination#oil dehydration systems#oil purification system#oil purification machine#oil purification#oil purification machine

0 notes

Text

Lubricants Market Outlook: Demand Forecast and Competitive Landscape

The global lubricants market size is expected to reach USD 180.21 billion by 2030, registering a CAGR of 3.8% over the forecast period, according to a new report by Grand View Research, Inc. Growth in demand for biobased lubes owing to their eco-friendly characteristics is poised to pave way for higher demand over the coming years. Furthermore, the manufacturers are shifting and expanding their production units in developing nations owing to various factors, such as availability of raw materials and reduced infrastructure & labor costs. This, in turn, is anticipated to boost the market growth over the forecast period. Typical oil manufacturers use crude oil, CBM, tight oil, and other additives to formulate all types of lubricants.

Medical was the largest application for PEG, accounting for more than 40% of market share in 2022. Superior blending, hygroscopicity, and non-toxic properties of PEG have resulted in high demand for the chemical in numerous pharmaceutical products such as tablets and ointments. Increasing pharmaceutical expenditure, particularly in emerging economies of India, China, and Brazil, is expected to boost PEG market over the forecast period. Growing demand for paints & coatings coupled with the increasing use of PEG as a solvent due to its low VOC emissions is anticipated to fuel market growth over the next six years.

Economic growth in emerging markets, such as China, India, and Brazil, has led to the betterment of public transportation in these regions. This trend is expected to further strengthen commercial automotive lubricant demand. The Asia Pacific automotive industry is anticipated to witness a high growth rate over the forecast period owing to rapid economic development, mega construction projects, and the introduction of various favorable policies by the government, such as 100% FDI and “Smart Cities”. Rapid industrial development and growing demand for high-performance luxurious passenger cars have also attracted heavy investments from international automotive players.

Companies, such as ExxonMobil and Chevron, are directly involved in the production of lubricants for specific applications, these companies are further involved in supply agreements with major end-users to ensure steady sales of lubricants. Companies, such as Total, Shell, Amsoil, and Castrol, have entered into exclusive supply agreements with Tata Motors & Vestas Wind Systems to supply their lubricant brands. Global as well as regional industry players are developing direct sales channels, especially for automotive lubricant users, at their local service centers. Some companies also participate in annual events of their end-users and showcase their products at offer prices.

For More Details or Sample Copy please visit link @: Lubricants Market Report

Lubricants Market Report Highlights

The market is estimated significantly due to the increasing demand for automotive oils and greases on account of the growing trade of vehicles and their spare parts

Lubricants are majorly used as diesel engine oils, gearbox lubricants, and transmission oils in passenger cars, commercial vehicles, and motorcycle segments of the automotive sector. As per OICA, global motor vehicle production reached 85, 016,728 in 2022, which is anticipated to drive the product demand

Gas turbine oil is a high-performance oil created to help gas turbines run more efficiently and reliably while also enhancing the safety and productivity of power plant operations

Asia Pacific dominated the market with a revenue share of 44.6% in 2023. A rising number of consumers is demanding advanced technological products with superior performance characteristics. This factor is conducive to market growth.

Gain deeper insights on the market and receive your free copy with TOC now @: Lubricants Market Report

We have segmented the global lubricants market on the basis of application, base oil, and region.

#Lubricants#LubricantsMarket#MarketAnalysis#SyntheticLubricants#BioBasedLubricants#IndustrialLubricants#AutomotiveLubricants#SustainabilityInLubricants#MarketTrends#LubricationTechnology#GlobalMarketInsights#PerformanceLubricants#OilAndGas#IndustrialApplications#LubricantsIndustry

0 notes

Text

Wind Turbine Operations And Maintenance Market 2022 | Growth Strategies, Opportunity, Challenges, Rising Trends and Revenue Analysis 2030

The latest market report published by Credence Research, Inc. “Global Wind Turbine operations And maintenance market has witnessed steady growth in recent years and is expected to continue growing at a CAGR of 8.70% between 2023 and 2030. The market was valued at USD 34.2 billion in 2022 and is expected to reach USD 61.3 billion Market: Growth, Future Prospects, and Competitive Analysis, 2016 – 2028. The global wind turbine Operations and Maintenance

The Significance of Wind Turbine Operations and Maintenance

Wind turbines are intricate machines that require regular maintenance and monitoring to function at their best. Effective O&M practices ensure that wind farms operate reliably and efficiently throughout their lifespan, which typically spans two decades or more. Neglecting maintenance can lead to decreased energy output, increased downtime, and higher operational costs. Therefore, implementing a robust O&M strategy is crucial to safeguarding the long-term viability and profitability of wind energy projects.

Key Elements of Wind Turbine Operations and Maintenance

1. Preventive Maintenance

Preventive maintenance forms the cornerstone of wind turbine O&M. It involves routine inspections, lubrication, and replacement of components to prevent potential failures. Regular maintenance helps identify early signs of wear and tear, allowing technicians to address issues before they escalate into major problems. This approach not only minimizes downtime but also extends the lifespan of turbine components.

2. Condition Monitoring

Condition monitoring involves the use of advanced sensors and data analytics to continuously assess the health of wind turbines. Real-time data on vibration, temperature, and other performance indicators enable early detection of anomalies, helping operators plan maintenance activities proactively. By monitoring turbine conditions, operators can optimize maintenance schedules and reduce unplanned downtime, resulting in higher energy production.

3. Technological Advancements

As the wind energy sector progresses, so do the technologies used in wind turbine O&M. Innovations like drone inspections, artificial intelligence-driven predictive maintenance, and remote monitoring have revolutionized the way wind farms are managed. These advancements not only enhance efficiency but also reduce the need for physical human presence, making O&M processes more cost-effective and safer.

The Role of Sustainable O&M Practices

In the era of increasing environmental awareness, sustainable O&M practices have gained significant importance. By adopting eco-friendly approaches to maintenance, wind energy projects can further contribute to environmental conservation. Here are some ways sustainable O&M practices positively impact the industry:

1. Eco-Friendly Lubricants

Using biodegradable and non-toxic lubricants in wind turbine gearboxes reduces the risk of oil leakage and minimizes environmental impact in case of any spills. This eco-conscious approach ensures that wind farms operate in harmony with the surrounding ecosystem.

2. Recycling and Repurposing

Responsible disposal of decommissioned turbine components and recycling materials help minimize waste generation and reduce the carbon footprint of wind energy projects. Repurposing certain components for secondary applications also adds to the sustainability aspect of wind turbine O&M.

3. Wildlife Protection

Adopting wildlife-friendly practices, such as installing anti-collision systems and ensuring proper siting of wind farms, helps safeguard avian and bat species from collisions with turbine blades. These measures promote biodiversity and align the wind energy industry with conservation efforts.

Challenges in Wind Turbine Operations and Maintenance

1. Turbine Reliability and Downtime Reduction

Wind turbine failures and unplanned downtime can significantly impact energy generation and project profitability. Ensuring the reliability of critical components and implementing proactive maintenance strategies are essential in mitigating these challenges.

2. Remote Monitoring and Data Management

Many wind farms are located in remote areas, making it challenging to monitor turbine performance and collect real-time data. Implementing robust remote monitoring systems and efficient data management protocols are crucial in diagnosing issues promptly and optimizing maintenance schedules.

3. Skilled Workforce Shortage

The wind energy sector's rapid growth has led to an increasing demand for skilled technicians and engineers. However, there is a shortage of qualified personnel with expertise in wind turbine operations and maintenance, necessitating the development of training programs and talent acquisition strategies.

4. Environmental and Regulatory Compliance

Wind farms often operate in environmentally sensitive areas, necessitating compliance with stringent environmental regulations. Implementing eco-friendly maintenance practices and adhering to regulatory requirements are vital in ensuring the sustainability of wind energy projects.

Browse 250 pages report Wind Turbine Operations And Maintenance Market By Type (Scheduled, Unscheduled) By Location (Onshore, Offshore)- Growth, Future Prospects & Competitive Analysis, 2016 – 2030)- https://www.credenceresearch.com/report/wind-turbine-operations-and-maintenance-market

Current trends in Wind Turbine Operations And Maintenance Market

The Wind Turbine Operations And Maintenance Market is experiencing a noteworthy upsurge, with several emerging trends shaping its landscape. One of the key trends driving this market is the increasing implementation of predictive maintenance techniques. Advanced technologies such as artificial intelligence and machine learning are being employed to analyze data from various sensors installed in wind turbines, enabling operators to detect potential faults before they lead to major breakdowns. This predictive approach not only minimizes downtime but also reduces overall maintenance costs.

Another prominent trend is the adoption of drone-based inspections for turbine maintenance. Drones equipped with high-resolution cameras and thermal imaging capabilities can efficiently scan large areas and capture detailed images, providing valuable insights into any structural or component issues that need attention.

Why to Buy This Report-

•The report provides a qualitative as well as quantitative analysis of the global Wind Turbine Operations And Maintenance Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

•The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

•Major nations in each region with their import/export statistics

•The global Wind Turbine Operations And Maintenance Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major players analysis, market growth strategies, and key application areas.

Browse Complete Report- https://www.credenceresearch.com/report/wind-turbine-operations-and-maintenance-market

Visit our Website- https://www.credenceresearch.com/

Related Reports- https://www.credenceresearch.com/report/digital-substations-market

https://www.credenceresearch.com/report/medium-and-high-power-electric-motors-market

Browse Our Blog- https://www.linkedin.com/pulse/wind-turbine-operations-maintenance-market-grow-steadily-shukla

About Us -

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 10,000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives. For nearly a century, we’ve built a company well-prepared for this task.

Contact Us:

Office No 3 Second Floor, Abhilasha Bhawan, Pinto Park, Gwalior [M.P] 474005 India

0 notes

Text

wind turbine lubricants Market : Forecast by Key Products, Types, Application, Regions and Overview of History

The wind turbine lubricants market is expected to witness market growth at a rate of 8.0% in the forecast period of 2021 to 2028 and is expected to reach USD 300.0 million by 2028. Data Bridge Market Research report on wind turbine lubricants market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market’s growth. The rise in the adoption of wind turbines is escalating the growth of the wind turbine lubricants market.

Reports Web adds “Wind Turbine Lubricants Market Forecast to 2028 – COVID-19 Impact and Global Analysis” to its store providing analysis of the current and future market competition in the market.

Get Sample Copy of This Report: https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-wind-turbine-lubricants-market

Note – In order to provide more accurate market forecast, all our reports will be updated before delivery by considering the impact of COVID-19.

The global Wind Turbine Lubricants market is segmented on the basis of offering, component, building type. Based on offering, the Wind Turbine Lubricants market is segmented into solution and services. On the basis of component, the market is segmented into security & surveillance, asset management, sales & advertisement, and others. Whereas, based on end-user industry the market is divided into residential and non-residential.

Top Key Players Profiled in This Report: Exxon Mobil Corporation., Shell, Amsoil, Inc., bp p.l.c, Chevron Corporation., Castrol Limited, Klüber Lubrication, Afton Chemical, Evonik Industries AG, FUCHS, Lubrita, Quaker Chemical, Total, PetroChina Company Limited, Idemitsu Kosan Co, Ltd, LUKOIL, Phillips 66 Company., Sinopec, Petroliam Nasional Berhad (PETRONAS), and OKS Spezialschmierstoffe GmbH

Global Wind Turbine Lubricants Market by Geography:

Asia-Pacific (Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia)

Europe (Turkey, Germany, Russia UK, Italy, France, etc.)

North America (the United States, Mexico, and Canada.)

South America (Brazil etc.)

The Middle East and Africa (GCC Countries and Egypt.)

COVID-19 Impact Analysis:

The outburst of the Covid-19 pandemic crisis in the global Wind Turbine Lubricants market has expressively impacted the infrastructure in overall market in 2021. This pandemic crisis has brought the impact on various industries in different ways like disruption of the supply chain, shutdown of the manufacturing processes and manufacturing plants, all indoor events restricted, over forty countries state of emergency declared, stock market volatility and uncertainty about future. This global Wind Turbine Lubricants market research report covers the new survey on the Covid-19 impact on the Wind Turbine Lubricants market, which helps the marketers to find latest market dynamics, new development in the market and in the industry, along with this, this survey also helps to form the new business plans, product portfolio and segmentations.

Interested in purchasing this Report Click here @ https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-wind-turbine-lubricants-market

This analysis provides evaluation for altering competitive dynamics:

· This thorough Wind Turbine Lubricants analysis of this shifting contest dynamics and keeps you in front of competitions;

· Six-year prediction assessment primarily based mostly on the way the sector is anticipated to development;

· Precisely which Wind Turbine Lubricants application/end-user kind or Types can observe incremental increase prospects;

· Which trends, barriers, and challenges could impact the development and size of Wind Turbine Lubricants economy;

· It helps to know that the vital product-type sections along with their growth;

Fundamentals of Table of Content:

1 Report Overview 1.1 Study Scope 1.2 Key Market Segments 1.3 Players Covered 1.4 Market Analysis by Type 1.5 Market by Application 1.6 Study Objectives 1.7 Years Considered

2 Global Growth Trends 2.1 Wind Turbine Lubricants Market Size 2.2 Wind Turbine Lubricants Growth Trends by Regions 2.3 Industry Trends

3 Market Share by Key Players 3.1 Wind Turbine Lubricants Market Size by Manufacturers 3.2 Wind Turbine Lubricants Key Players Head office and Area Served 3.3 Key Players Wind Turbine Lubricants Product/Solution/Service 3.4 Date of Enter into Wind Turbine Lubricants Market 3.5 Mergers & Acquisitions, Expansion Plans

4 Breakdown Data by Product 4.1 Global Wind Turbine Lubricants Sales by Product 4.2 Global Wind Turbine Lubricants Revenue by Product 4.3 Wind Turbine Lubricants Price by Product

5 Breakdown Data by End User 5.1 Overview 5.2 Global Wind Turbine Lubricants Breakdown Data by End User

1 note

·

View note

Text

Poland Industrial Lubricants Market Trends: Share, Growth, Demand, Industry Analysis, Key Player profile and Regional Outlook by 2027

Market Research Future will be publishing a cooked research report on “Poland Industrial Lubricants Market” that contains the information from 2017 to 2023. Poland Industrial Lubricants Market is expected to grow with the CAGR 3.29% during forecast period of 2017 to 2023.

Market Research Future (MRFR) recognizes a few companies as the key players in the Poland Industrial Lubricants Market that includes Orlen Oil Sp.z o.o, LOTOS Oil Sp. z o.o, Lubricant Consult GmbH, Klüber Lubrication Polska Sp. z o.o., Total S.A, Nynas AB, BP Europa SE, FUCHS, ExxonMobil Corporation, and Oemeta Polska Sp. z o.o., among the others.

Access Complete Report @ https://www.marketresearchfuture.com/reports/poland-industrial-lubricants-market-4338

Market Highlights:

Commenting on this report, an analyst from Market Research Future (MRFR)’s team said “Poland Industrial Lubricants Market” is estimated to be valued at USD 156.8 million in 2016 and is expected to grow at CAGR of 3.29% during the forecast period from 2017-2023.

Segment Analysis:

Poland Industrial Lubricants Market is segmented on the basis of type and application. On the basis of type the market is divided into process oils, hydraulic fluids, gear lubricants, compressor lubricants, turbine lubricants, metalworking fluids, industrial engine oils, and others. Process oils emerged as the leading segment with demand driven by factors such as increasing usage in manufacturing of tires and rubbers. They are helpful in enhancing abrasion & rolling resistance of tires. Widening application scope in end-use industries such as polymer, personal care, and textile is further anticipated to positively influence market growth. The segment is projected to grow at a CAGR of 3.52% to reach USD 53.7 million by the end of 2023. Process oils were followed by hydraulic fluids and metalworking fluids in terms of overall market share in 2016. Increasing demand for metalworking processes such as cutting, welding, and forming across various applications, such as automotive, foundry, ships, aircraft, milling, and industrial machinery, is expected to drive the demand for metalworking fluids over the forecast period. General industrial oils such as gear lubricants, turbine lubricants, and compressor lubricants are set to witness moderate growth over the forecast period.

Based on application, the Poland Industrial Lubricants Market is segmented as automotive manufacturing, power generation, process industry, food & beverages, mining, rail, construction, and others. Construction sector accounted for the largest market share of over 20% in 2016 and is set to grow at an estimated CAGR of 3.45% from 2017 to 2023. The country is set to be the largest recipient of EU-funding and financial assistance of over EUR 80 billion from 2014 to 2020. This factor has resulted in significant development of construction and infrastructure projects across the country. Power generation is expected to witness the highest revenue CAGR of 3.55% from 2017 to 2023. Numerous energy facilities rely heavily on the performance of their equipment to remain competitive, including gas and steam turbine power plants, wind turbines, natural gas compression plants.

Get a FREE Sample Copy@ https://www.marketresearchfuture.com/sample_request/4338

Regional Analysis:

The Poland Industrial Lubricants Market is expected to reach USD 195.3 million by 2023 from USD 156.8 million in 2016, expanding at CAGR of 3.29 % from 2017-2023. Rapidly expanding industrial base coupled with escalating investments in construction sector is expected to drive demand for industrial lubricants over the forecast period. The growth drivers for manufacturing sector in the country include availability of large pool of skilled labor and technological know-how along with favorable foreign investment norms. Robust growth in niche sectors, for instance, 3D printing and medical devices, is expected to positively support the industrial growth rate. Increasing mining activities in the country has led to a significant rise in demand over the past few years. The key strategies followed by most companies in the market are, agreements and collaborations, mergers and acquisitions, joint ventures and expansion. Total started up the lubricants oil blending plant in Singapore with annual capacity of 310,000 metric tons, whereas BP signed a production sharing contract (PSC) with China National Petroleum Corporation (CNPC). This deal will result in combined operational expertise of both BP and CNPC in the field of exploration, development, and production of shale gas to jointly realize the efficient development of unconventional resources. Such developments within key industry participants is expected to result in improved product offerings at optimum price levels and benefit overall industry growth.

1 note

·

View note