#Lower Housing Bearing Manufacture

Explore tagged Tumblr posts

Text

The preference for cast iron in gear box manufacturing stems from its exceptional mechanical properties that make it an ideal material for this critical component. Cast iron offers superior strength, durability, and wear resistance, ensuring longevity and reliability in demanding operational environments. Its ability to withstand heavy loads and high torque, coupled with excellent heat dissipation properties, makes cast iron the material of choice for gear boxes. Additionally, the casting process allows for intricate designs and precise shaping, optimizing the efficiency and performance of the gears within the gearbox. This insightful exploration sheds light on the compelling reasons behind the widespread utilization of cast iron, underlining its pivotal role in the functionality and durability of gear boxes across various industries.

#Housing Bearing#Housing Bearing Supplier#Housing Bearing Manufactures#Bearing Housing#Bearing Housing Supplier#Bearing Housing Suppliers#Bearing Housing Manufactures#Upper Bearing Housing#Upper Bearing housing Suppliers#Upper Bearing Housing Supplier#Lower Housing Bearing#Lower Housing Bearing Supplier#Lower Housing Bearing Manufacture#Lower Housing Bearing Suppliers

0 notes

Text

Topics: decentralization, DIY, Dual Power, health care, medicine, science

One of the central claims of capitalism is that it is the best system to bring supply and demand together; when people need a good or service, the capitalist market will provide. However, the reality of the situation can be quite the opposite. An excellent example of this—from my perspective as a lay person whose experience with the pharmaceutical industry is one of a consumer for mental health purposes—is access to important medication such as EpiPens and HIV treatment in the United States. The former averages around $700 per pack of two auto-injectors and the latter, depending on its type and whether it is brand name or generic, can reach up to over $4,000 per 30-60 tablets or capsules; and more generally, according to Andrew W. Mulcahy, medications are 2.56 times more expensive in the United States than in 32 other countries. One could arguably trace the problem to the corporate business structure or the universalization of the profit motive, but more directly the problem is one of corporate-state scheming through stringent intellectual property laws. These laws keep genuine competition—supposedly a main selling point of capitalism—from taking place in the market by granting exclusive manufacturing rights to specific entities—usually massive corporations but sometimes individual scumbags like Martin Shkreli. These entities can then drive the prices of medication to truly ridicouous levels. And in the context of insulin in particular, this price manipulation is so extreme that Lucas Kunce asserts that “[t]he cost of insulin isn’t determined by supply and demand. It’s really just 3 companies setting a price based on how many deaths and amputations the market will bear until people start rioting.”

This is a problem that has the potential to affect all human beings, but, as with many socio-economic problems, it hits the working class—and particularly its queer and BIPOC members and those with disabilities—the hardest. This is obviously in part because of how expensive the medication is, but also because people of lower class backgrounds do not have access to high-standard housing, healthy food choices, low-pollution environments, etc. All of these can both create and accentuate health problems that require the aforementioned medications. And capitalists only care enough about workers to help them be skilled enough and stay alive long enough to produce and reproduce, giving thought to their health and medical needs only at a whim or by minimal, loophole-filled legal mandates. As Karl Marx writes, wages are simply “the cost required for the maintenance of the labourer as a labourer, and for his education and training as a labourer” plus “the cost of propagation, by means of which the race of workers is enabled to multiply itself, and to replace worn-out workers with new ones.” But even putting aside (true) rhetoric about class, capitalism, and such, the simple problem of the matter is that there are people who need medication and that medication exists, but for abstract reasons invented by people in power the individuals in need cannot gain access to that medication with ease.

The obvious solution is to simply eliminate the entire institution of IP, opening the way to, as Laurance Labadie writes, “free competition, that is, free and equal access to the means of production, to the raw materials, and to an unrestricted market, [so that] the price of all articles will always tend to be measured by the effort necessary for their production. In other words, labor as a factor in measuring value will become predominant.”And—having eliminated all state-sanctioned monopolies, IP and beyond—not only would medication be massively more affordable but, according to Kevin Carson…

licensing cartels would no longer be a source of increased costs or artificial scarcity rents. [Therefore, t]here would be far more freedom and flexibility in the range of professional services and training available. Some . . . neighborhood cooperative clinics might prefer to keep a fully trained physician on joint retainer with other clinics, with primary care provided by a mid-level clinician. Or imagine an American counterpart of the Chinese “barefoot doctor,” trained to set most fractures and deal with other common traumas, perform an array of basic tests, and treat most ordinary infectious diseases. He might be able [to] listen to your symptoms and listen to your lungs, do a sputum culture, and give you a run of Zithro for your pneumonia, without having to refer you any further. And his training would also include identifying situations clearly beyond his competence that required the expertise of a nurse practitioner or physician.

But barring this effective and far-reaching but rather (at least for the meantime) improbable solution, another extrasystemic tactic is available: the open access publishing of DIY ways to produce life-saving medication by way of the Internet—essentially liberating the information from the private-corporate sphere into the digital commons.

This is not an original concept as it originates in the work of Professor Michael Lauer and his group Four Thieves Vinegar Collective, whose goal is to generate open access means for anyone with access to a computer, basic chemistry technology, and a 3D printer to synthesize medicine. These include such things as instructions for building an “Apothecary Microlab” and DIY EpiPens as well as 3D printer blueprints for homemade chemical reactors. This essential idea has been taken up by the Open Insulin Foundation, who…

are creating an open source (freely available) model for insulin production that centers sustainable, small-scale manufacturing and open source alternatives to production. [They] are developing organisms and protocols to produce rapid acting (lispro) and long acting (glargine) insulin. Additionally, [they] are working on developing open hardware equivalents to proprietary production equipment, are researching sustainable regulation pathways to bring our insulin to the public, and are developing plans for local, small-scale manufacturing pilots.

In the context of this open access availability, Sebastian A. Stern writes, “Do-It-Yourself scientists working in hackerspaces are positioned to make significant contributions with low overhead and little formal training (becoming necessary and valuable apprenticeship sites as the current higher education system deteriorates). The state has yet to heavily clamp down, but, because such freedom threatens the status quo, we can expect intervention to intensify.”

This type of strategy completely rejects the use of the state and its organs to try to correct the problem from within the system. And this makes sense! The state capitalist system is the central cause of artificial barriers to medicine, and as such solutions sought through the state follow the logic touted by Robert LeFevre that “[g]overnment is a disease masquerading as its own cure.” And the process by which state-based solutions like price ceilings are being proposed, such as for insulin under Biden’s Build Back Better plan, have proved again and again to be both convoluted and seriously drawn-out; downsides quite serious for a problem where lives are on the line. Karena Yan also points out that Colorado’s “$100 cap for a 30-day of supply” has…

revealed a few loopholes. Some health plans fell into an exemption in the legislation, leaving the people on those health plans ineligible for the insulin price cap when purchasing their monthly insulin. Additionally, instead of offering a flat $100 maximum on monthly insulin prescriptions, the current legislation allows insurers to charge $100 per prescription per month, which translates to $200 for those who take both basal and mealtime insulin or two other insulins, such as short-acting and long-acting.

And while the FDA will come cracking down on open access DIY pharmacology eventually, eluding the state apparatus for as long as possible is ideal. Milton Friedman points out that “[t]he FDA has done enormous harm to the health of the American public by greatly increasing the costs of pharmaceutical research, thereby reducing the supply of new and effective drugs, and by delaying the approval of such drugs as survive the tortuous FDA process."[1] Ryan Calhoun even accounts of the 2014 seizure of “19,618 parcels of ‘unapproved’ prescription medication. More plainly, the FDA stole people’s medication and denied them any reasonable manner of attaining it again.” And David D’Amato makes a compelling argument that “[v]oluntary membership associations, ratings and review services, and noncompulsory, competing accreditors are more than capable of furnishing the information that consumers want and need to make safe, smart decisions.”

However, there are, rather obviously, serious practical problems to this praxis. While sharing information about DIY pharmacology is not illegal and, as Grants Birmingham writes for Time, the Open Insulin “project seems to be in a regulatory safe space, but that may change as it gets closer to making actual medicine.” And, of course, “if [Open Insulin] does reach a production phase, [it] would have to conform to Good Manufacturing Practice, the FDA rules for factories that make medicine, food, cosmetics and medical devices. And because the group plans to share its insulin-production framework online, crossing state lines, there may be other legal issues on the horizon.” Then there is the immediate danger of throwing together cocktails of homemade medication. For example, pseudoscience debunker Yvette d’Entremont is firm in her opinion that “there are so many things that could go wrong in constructing [the DIY EpiPen]. It seems like such a bad idea.” And, further, “[i]t’s all fun and games until your product gets contaminated and you get a giant abscess in your muscle.” I know I would be very hesitant to try something like this at this stage of development. Furthermore, any proposal regarding the liberation of medication in the U.S. must be considered within the context of the COVID-19 Pandemic—where people are spreading vaccine misinformation en masse and making ‘independently researched’ and completely stupid decisions to take horse dewormer as treatment—as well as the long-standing opioid crisis.[2] So while with the decay and eventual collapse of state capitalism, this may certainly become the manner in which essential medications are made available through the aforementioned neighborhood cooperative clinics and North American barefoot doctors at the price of their necessarily low cost of production, for now, I–someone who, it must be made clear, is neither a scientist nor medical professional–would have to agree with the CEO of DIY genetic engineering company The Odin Josiah Zayner, who calls the work done by Four Thieves Vinegar “proof of concept stuff . . . usually the first step in innovation.”

Due to these serious problems, one might be inclined to focus on more respectable but still decentralized solutions available in the form of healthcare insurance cooperatives, fraternal benefit societies (hopefully to be raised back up to their former glory), healthcare sharing ministries, free medical clinics (in the style of the Black Panther Party), pharmaceutical purchasing cooperatives (for lay people not just pharmacies), etc. Logan Glitterbomb writes that…

[c]reating, supporting, or volunteering at [the aforementioned] free clinics, cooperative clinics, and grassroots union-run facilities are great ways to increase access to medical care for low-income individuals. Having these facilities also promote and focus on preventative care, rather than treatment, can also cut down cost and increase public health in the long term. The Ithaca Health Alliance was created by the same minds behind the labor time-based alternative currency known as, [Ithaca] Hours. It is a wonderful example of a community-based healthcare cooperative that is right in line with anarchist values and tactics. Their network of over 150 local healthcare providers offer a 5-10% discount to all IHA members. The IHA also runs the Ithaca Free Clinic, a free community clinic staffed by volunteer physicians, herbalists, acupuncturists, and more. The Ithaca Health Fund, which offers emergency medical grants to low-income patients, also provides grants to other community-based health projects in the area, all funded through donations.

Projects such as these present the possibility of creating a dual power healthcare infrastructure. But setting aside the critiques of open access DIY pharmacology presented above, a main advantage of this strategy is that it doesn’t just give people the things they need to live comfortably or live at all, it also attacks the central cause of artificially high medication costs (IP) and—as would come by any placement of medication in the information commons—decentralizes medical knowledge. The contemporary medical system—as opposed to its non-patriarchal predecessors—is oriented towards a small group of professional, highly-educated elites.[3] Though it is important to have experts and specialists (as the ignorance of large swaths of the U.S. public during the present pandemic has made clear), there is no good reason for the level of totalizing hyper-specialization and stringent regulation—public and private—that only gives a small elite within highly specific institutional frameworks access to such important knowledge.

But if the future is to be decentralized, the liberation of medication goes deeper than 3D printers and DIY chemistry. It means shifting toward antiauthoritarian community practices of health. As Simon the Simpler writes,

A society of people who are responsible for their own health and able to gather or grow their own medicines is a hard society to rule. These days we are dependent on the power structure of industrial health care and medical specialization: the secret society of the doctors, the white-male-dominated medical schools, the corporate decision makers with their toxic pharmaceuticals and heartless greed and labs full of tortured beings. That dependence is one more thing keeping us tied down to the State and unable to rebel with all our hearts or even envision a world without such oppression.[4]

And so, through a combination of decentralized medical technology and a general motion toward these kind of health practices, perhaps the liberation of medication is on the horizon.

[1] I cannot find the original source of this quote.

[2] Not much can be said that has not already been said about how the opioid crisis is not the product of some non-existent free market but of corporatism; and a properly libertarian perspective on COVID-19 can be found in Carson’s “Pandemics: The State As Cure or Cause?” and Andrew Kemle’s “Libertarianism vs Psychopathic Dumbfuckery.”

[3] See Barbara Ehrenreich’s Witches, Midwives, and Nurses: A History of Women Healers.

[4] This is not even to delve into the biopolitics of modern medicine as theorized by Michel Focuault; a topic which could fill an entire other article.

#us healthcare#us politics#healthcare#decentralization#DIY#Dual Power#health care#medicine#science#anarchism#anarchy#anarchist society#practical anarchy#practical anarchism#resistance#autonomy#revolution#communism#anti capitalist#anti capitalism#late stage capitalism#daily posts#libraries#leftism#social issues#anarchy works#anarchist library#survival#freedom#Eric Fleischmann

2 notes

·

View notes

Text

Why Premium Building Materials Are Crucial for Construction

The clear aspiration when starting any construction project is to build long-lasting structures and leave an impact, not just put things together. When constructing a large-scale infrastructure project, a commercial building, or your dream home, choosing the best construction materials is a wise choice for ensuring durability and other factors we are going to explore in this blog.

The right construction materials supply not only enhances the structural integrity of a building but also ensures compliance with industry standards, improves aesthetics and promotes sustainability. We list the factors to consider when choosing building materials suppliers for your next project in this blog as well.

1. Durability and Structural Integrity

Constructing a structure that can endure and adapt to the environmental conditions, endure for decades and make an impact on community development are the primary goals before starting any construction project. For this reason, when choosing building materials suppliers, durability is the most significant factor to keep in mind.

Strong bonding is ensured by the best cement for home construction, avoiding cracks and structural weaknesses.

Better weather resistance and load-bearing capacity are provided by high-quality bricks for construction.

Longevity is provided by superior concrete cement, which lowers the possibility of damage from heat, water, and other elements.

The reason why we discuss this in detail is because using inferior materials can save money upfront. They eventually lead to constant repairs and might lead to structural failures. For this, spending money on premium construction and building materials is a must for high-quality construction.

2. Cost-Effectiveness in the Long Run

The basic understanding of premium construction materials supply is that the cost is higher initially. The long run savings makeup for the cost and high-quality materials prolong the structure’s life, lowering maintenance costs and repairs.

Over time, Inferior bricks for construction may crack and need to be replaced.

When you discover that low-quality cement used in building construction weakens it and raises maintenance costs, it’s a logical reason to get the best construction materials as the endurance is far better.

Future restoration costs are reduced when the best bricks for home construction are used when building a home.

By choosing top-tier building materials suppliers, you’re not just investing in quality but also securing a cost-effective approach to your construction for the long run.

3. Safety and Compliance with Industry Standards

It is a given fact that construction is a heavily regulated industry and the importance of using high-quality materials is apparent. Using low-quality materials can pose significant risks. Ensuring compliance with safety regulations is vital to protect lives and property.

Certified building product manufacturers provide materials that meet strict safety guidelines.

Concrete house construction requires high-grade concrete cement to withstand structural stress.

Premium cement used in building construction ensures fire resistance, earthquake resilience, and load-bearing capabilities.

4. Aesthetics and High-Quality Finishing

The strength of the structure is internal, the materials used, indirectly or directly, have an impact on the overall appearance of a building. High-quality construction and building materials ensure superior aesthetics and finishing.

Best bricks for home construction create a uniform and visually appealing exteriors.

High-quality concrete ensures a smoother finish, reducing the need for excessive plastering.

Premium cement used in building construction enhances the quality of walls, reducing patchiness and discolouration.

Keeping these factors in mind, reliable building materials suppliers like Aparna Enterprises Limited guarantee that your project functions the best, looks polished and professional.

5. Reliable Supply and Availability

Project efficiency is often determined by the availability of premium construction materials supply in the required areas. Delays in material procurement can lead to costly downtime, missed deadlines, and budget overruns.

Trusted building materials company partnerships ensure timely delivery.

A steady supply of concrete prevents construction halts.

High-quality bricks for construction guarantees material consistency across the project.

Choosing well-established building materials suppliers helps keep your project on schedule and ensures smooth execution.

6. Strength and Efficiency in Concrete House Construction

Any and every structure starts and ends with concrete, being used most widely in construction. This concrete’s quality is the determinant factor for the strength of a structure. Concrete is the most widely used material in construction, and its quality determines the strength of a structure. Using the best construction materials for concrete-based projects guarantees superior results.

Best cement for house construction ensures strong bonding with reinforcement bars.

Premium concrete cement prevents shrinkage cracks, improving the lifespan of the building.

Reliable concrete near me ensures that construction progresses without quality concerns.

When selecting building product manufacturers, keep the enhance factor in mind. The efficiency factor of concrete house construction includes, reducing risks of damage and increasing longevity.

7. Choosing the Right Building Material Suppliers

Selecting the right building materials company is just as important as choosing high-quality products. At Aparna Enterprises Limited, we take pride in being a trusted leader in construction materials supply, ensuring every project is built on strength, durability, and excellence.

Why Choose Aparna Enterprises Limited?

Certified Quality: Our products meet the highest industry standards, ensuring superior performance and longevity. \On-Time Delivery: As one of the most reliable building materialsuppliers, we guarantee timely deliveries to keep your project on track. Proven Expertise: With decades of experience as a top building product manufacturer, we are the preferred choice for quality and trust.

When searching for building materials, look no further than Aparna Enterprises Limited where quality meets reliability.

Conclusion

Using premium construction materials is essential for ensuring durability, aesthetics, safety, and cost-effectiveness in construction. Whether it's the best bricks for home construction, high-quality concrete cement, or certified building product manufacturers, choosing the right materials is a long-term investment in your project's success.

From building materials suppliers to construction and building materials, every decision plays a vital role in creating strong, safe, and visually appealing structures. Aparna Enterprises Limited, a leading building materials company, is committed to delivering top-quality materials that meet industry standards. With a strong reputation as one of the most trusted building product manufacturers, we ensure superior solutions for your construction needs.

Reliable building materials suppliers like Aparna Enterprises Limited ensure that your construction meets all necessary safety standards, reducing the risk of legal and financial.

0 notes

Text

Why Belt-Driven Fans Are Essential for HVAC Systems in Large Facilities

Introduction

When it comes to large-scale ventilation, belt-driven fans are a key component of HVAC systems in industrial and commercial facilities. Their ability to deliver high airflow efficiency, adjustable speeds, and cost-effective operation makes them an ideal choice for factories, warehouses, and office buildings. In this post, we’ll explore why belt-driven fans are crucial for large HVAC systems and how they enhance performance, energy savings, and system longevity.

Benefits of Belt-Driven Fans in HVAC Systems

1. Adjustable Speed for Optimized Airflow

Unlike direct-drive fans, belt-driven fans allow for speed adjustments by modifying the pulley ratio. This flexibility ensures that HVAC systems maintain optimal airflow for ventilation, cooling, and air quality control in large spaces.

2. High Air Volume Handling

Large facilities require significant air movement, and belt-driven fans can handle high cubic feet per minute (CFM) capacities. This ensures even temperature distribution and improved air circulation in massive spaces.

3. Cost-Effective and Energy Efficient

While belt-driven fans require periodic maintenance, they offer better energy efficiency than many direct-drive alternatives when properly maintained. Facilities can fine-tune fan speed to match airflow needs, reducing energy waste and operational costs.

4. Extended Motor Life

The belt-drive system separates the fan motor from the impeller, reducing direct strain on the motor. This design helps prevent overheating, minimizes wear and tear, and extends the lifespan of the HVAC fan system.

5. Versatility Across Industries

From manufacturing plants to shopping malls, belt-driven fans are used in a wide range of large facilities. They offer customization options, making them adaptable for industrial, commercial, and institutional HVAC systems.

Maintenance Tips for Belt-Driven Fans in HVAC Systems

To ensure peak performance, follow these best practices:

Regularly inspect and adjust belt tension to prevent slippage.

Lubricate bearings to reduce friction and wear.

Check for belt wear and replace if frayed or cracked.

Clean the fan blades and housing to prevent dust buildup and airflow restrictions.

Frequently Asked Questions (FAQs)

1. How do belt-driven fans differ from direct-drive fans in HVAC systems?

Belt-driven fans use a belt and pulley system to connect the motor to the fan blades, allowing for adjustable speeds. Direct-drive fans have the motor directly attached to the fan, limiting speed customization but reducing maintenance.

2. How often should I inspect the belt on a belt-driven HVAC fan?

It’s recommended to inspect the belt every 3-6 months and replace it annually or as needed to prevent performance issues.

3. Can belt-driven fans help reduce energy costs in large facilities?

Yes! By adjusting the fan speed to match airflow needs, facilities can optimize energy use, reducing operational expenses.

4. Are belt-driven fans suitable for all HVAC applications?

While they are ideal for large-scale HVAC systems, smaller applications may benefit more from direct-drive fans due to lower maintenance requirements.

Upgrade Your HVAC System with Central Blower's Belt-Driven Fans

Looking for high-performance belt-driven fans for your HVAC system? Central Blower offers top-quality industrial fans designed for efficiency, durability, and optimal airflow control. Contact us today to find the right fan for your facility!

📞 Call us now or visit Central Blower to explore our range of belt-driven fans!

0 notes

Text

The floating slabs are concrete slabs that lie over the soil. This type of slab can simply laid over the water without any kind of connection between them. The floating slabs are mainly used as the base foundation for the manufacturing workshops, sheds, home additional rooms, and garages.

Advantages of floating slab in the construction process

➢ The floating slabs can be constructed in the site areas along with lower load-bearing capacity. ➢ The floating slab has the ability to spread the vertical loads over a larger area.

➢ In the case of the extension of the houses, the floating slabs are a good solution. ➢ The floating slabs also act as the barrier for the entrance of the moisture that has come from the ground. The floating slabs act as the barrier between the ground and the superstructure. In addition, the floating slab also helps to avoid seepage of water and frosting, as a result, the floating slab can be insulated from moisture and frost. ➢ There is no requirement for the usage of footer trenches in the case of floating slabs. These types of slabs can be poured with the help of digging and this process is economical. ➢ The construction of the floating slabs does not also lead to any kind of disturbance to the earth layer as well as does not interfere with the quality. ➢ In those areas where there is the possibility of shifting the earth layer because of the higher moisture content, the floating slab can be the best choice.

The construction details of the floating slabs

Read more

1 note

·

View note

Text

The Future of Construction: Why Ready Made Concrete in Karachi is Essential

In the ever-evolving world of construction, efficiency, durability, and sustainability are at the forefront of industry advancements. Ready Made Concrete Karachi has emerged as a game-changer, offering builders a reliable and cost-effective solution. Whether it’s residential, commercial, or infrastructure development, ready-mix concrete provides consistency and strength, making it an essential component of modern construction projects.

What is Ready Made Concrete?

Ready-made concrete, also known as ready-mix concrete (RMC), is a precisely batched mixture of cement, aggregates, water, and additives that is prepared in a controlled environment and delivered to construction sites in transit mixers. Unlike traditional on-site mixing, which requires manual labor and time-consuming preparation, ready-mix concrete is manufactured in specialized batching plants, ensuring consistent quality and performance.

Benefits of Ready Made Concrete in Karachi

1. Superior Quality and Consistency

One of the most significant advantages of Ready Made Concrete Karachi is its uniformity. Since it is produced in a controlled setting, each batch adheres to strict quality standards. This ensures optimal strength, durability, and workability, eliminating variations that often occur with on-site mixing.

2. Time and Labor Efficiency

In fast-paced urban environments like Karachi, time is of the essence in construction projects. Ready-mix concrete reduces the need for on-site preparation, allowing builders to complete projects faster and with fewer delays. This efficiency translates into reduced labor costs and improved productivity.

3. Cost-Effectiveness

While the initial cost of ready-made concrete may be slightly higher than traditional on-site mixing, its long-term benefits outweigh the expenses. Reduced material wastage, lower labor costs, and minimal storage requirements make it a cost-efficient choice for large and small-scale construction projects alike.

4. Environmental Benefits

Sustainability is a key concern in the construction industry. Ready-mix concrete minimizes waste, reduces dust pollution, and optimizes the use of raw materials. Additionally, many batching plants in Karachi are adopting eco-friendly practices, such as using recycled water and reducing carbon emissions, making ready-made concrete a greener choice.

5. Increased Workability and Strength

With precise control over the mix design, ready-made concrete offers enhanced workability and strength. Different formulations can be created to meet the specific requirements of a project, ensuring the best results for foundations, slabs, columns, and beams.

6. Reduced Storage Space Requirements

On-site concrete mixing requires large storage areas for raw materials like cement, sand, and gravel. With ready-made concrete, these materials are stored and mixed at the plant, freeing up valuable space at the construction site and enhancing overall project organization.

Applications of Ready Made Concrete in Karachi

1. Residential Construction

Housing developments, apartment complexes, and individual home projects benefit from ready-made concrete due to its strength and durability. It is widely used for foundations, walls, driveways, and flooring.

2. Commercial Projects

High-rise buildings, shopping malls, office complexes, and industrial facilities require robust and reliable construction materials. Ready-mix concrete ensures uniformity and strength, meeting the high demands of commercial projects.

3. Infrastructure Development

Bridges, highways, tunnels, and other public infrastructure projects require high-performance concrete with superior load-bearing capacity. Ready-mix concrete is essential in such projects, offering durability and longevity.

4. Precast Concrete Products

Many precast concrete products, such as blocks, panels, pipes, and beams, are manufactured using ready-made concrete. These prefabricated elements are then transported to the construction site, reducing overall project timelines.

Choosing the Right Ready Mix Concrete Supplier in Karachi

Selecting a reliable supplier is crucial to ensuring the quality and consistency of ready-made concrete. Here are some factors to consider:

1. Reputation and Experience

Look for a supplier with a strong track record in the industry. Established companies with years of experience are more likely to provide high-quality materials and reliable services.

2. Batching Plant Technology

Modern batching plants equipped with advanced technology produce better quality concrete. Ensure the supplier uses state-of-the-art equipment and adheres to industry standards.

3. Delivery and Logistics

Timely delivery is essential for maintaining construction schedules. Choose a supplier with an efficient fleet of transit mixers and a well-planned logistics system to ensure smooth project execution.

4. Customization Options

Different projects require different concrete formulations. A good supplier should offer customizable mix designs to meet specific construction needs.

5. Competitive Pricing

While quality should never be compromised, competitive pricing is an important factor. Compare quotes from multiple suppliers to get the best value for your investment.

Future Trends in Ready Made Concrete in Karachi

1. Use of Smart Concrete Technology

Smart concrete integrates sensors that provide real-time data on temperature, moisture, and strength development. This technology is gradually gaining traction in Karachi’s construction industry, offering enhanced monitoring and quality control.

2. Green Concrete Initiatives

With increasing environmental concerns, many suppliers are incorporating sustainable practices such as using fly ash, slag, and recycled aggregates in their concrete mixes. These eco-friendly alternatives reduce carbon footprints without compromising strength.

3. Advanced Admixtures for Improved Performance

Innovations in admixtures, such as self-healing concrete and corrosion-resistant formulations, are revolutionizing the industry. These advancements enhance durability and longevity, making concrete structures more resilient.

4. Automation and AI Integration

The future of ready-mix concrete production lies in automation and artificial intelligence. AI-driven batching plants optimize mix designs, monitor quality, and streamline logistics, ensuring higher efficiency and precision.

Conclusion

The demand for Ready Made Concrete Karachi continues to grow as builders seek faster, stronger, and more sustainable construction solutions. With its numerous advantages, including superior quality, cost-effectiveness, and environmental benefits, ready-mix concrete has become an essential component of modern construction projects. As technology and sustainability drive the industry forward, ready-made concrete will remain a crucial element in shaping Karachi’s urban landscape.

0 notes

Text

The Importance of Self-Aligning Ball Bearings in Industrial Applications

One such critical component is the Self-Aligning Ball Bearing, which offers a combination of unique features that make it particularly well-suited for handling complex load conditions and alignment challenges. These bearings are widely used across various industries, including manufacturing, automotive, and agriculture, where they help improve performance, reduce downtime, and extend equipment lifespan.

A self-aligning ball bearing is specifically designed to accommodate misalignment between the shaft and housing, a common issue in many mechanical systems. The bearing features an outer ring with a spherical raceway, allowing it to automatically adjust to angular misalignment. This self-aligning characteristic ensures that the bearing maintains smooth operation even if the shaft or housing experiences slight distortions or deformations during use. As a result, machinery that incorporates self-aligning ball bearings is less prone to damage from misalignment, which can otherwise cause excessive wear, friction, and potential system failure.

One of the primary advantages of self-aligning ball bearings is their ability to handle both radial and axial loads. Radial loads are the forces applied perpendicular to the axis of the bearing, while axial loads are forces that act along the axis. Self-aligning ball bearings are designed to support these two load types simultaneously, making them an ideal solution for machinery that experiences combined loading conditions. This versatility is crucial in industries such as food processing, textiles, and mining, where equipment is often subjected to both radial and axial stresses during operation.

Another key feature of self-aligning ball bearings is their reduced sensitivity to installation errors. Traditional bearings often require precise alignment during installation to ensure optimal performance. Even slight misalignments can lead to premature bearing failure, resulting in costly repairs and downtime. Self-aligning ball bearings, on the other hand, can adjust to minor misalignments without compromising their effectiveness. This makes them easier and quicker to install, helping to minimize the potential for operational disruptions.

Self-aligning ball bearings also contribute to improved energy efficiency in machinery. The smooth rolling motion of the bearing's balls minimizes friction, which not only reduces the amount of energy needed for operation but also generates less heat. This reduction in friction leads to lower operating temperatures, which is important in preventing overheating and extending the life of the bearing and the overall machine. In energy-intensive applications, such as motors or compressors, this can result in significant cost savings over time.

The reliability of self-aligning ball bearings is another reason they are widely used in demanding industrial applications. These bearings are known for their durability and ability to perform under heavy loads. The design of the bearing ensures that it can operate continuously, even in environments with high stress or fluctuating loads. This makes them a popular choice for heavy-duty machinery, such as conveyor systems, crushers, and pumps, where consistent performance is essential to maintaining productivity.

In terms of maintenance, self-aligning ball bearings require less attention compared to traditional bearings. While routine checks and lubrication are still necessary to ensure optimal performance, these bearings tend to have a longer service life and are less prone to damage from misalignment. This not only reduces maintenance costs but also helps prevent unexpected downtime, which can be costly for industrial operations.

In conclusion, self-aligning ball bearings provide significant benefits in terms of reliability, performance, and cost-effectiveness. Their ability to handle both radial and axial loads, along with their self-aligning capabilities, makes them an ideal choice for a wide range of industrial applications. Whether used in high-load machinery or equipment subjected to misalignment, these bearings ensure smooth operation, extend the life of components, and reduce maintenance requirements, ultimately contributing to more efficient and reliable manufacturing processes.

0 notes

Text

This exploration delves into the intriguing question: "Why is Cast Iron not Used in the Construction of Buildings?" Uncover the historical context and engineering considerations that have shaped construction material choices. Delve into the properties of cast iron and its limitations when compared to more modern alternatives. From structural challenges to advances in construction technology, this examination sheds light on the reasons behind the shift away from cast iron in contemporary building practices. Whether you're a construction professional or a curious observer, this insightful analysis aims to provide a nuanced understanding of the factors influencing material decisions in the construction industry.

#lower housing bearing manufactures#lower housing in india#lower housing bearing suppliers#bearing housing manufactures#housing bearing suppliers#housing bearing manufactures#housing bearing in india#Upper Bearing Housing#upper bearing housing in india#upper bearing housing suppliers#upper bearing housing manufactures

0 notes

Text

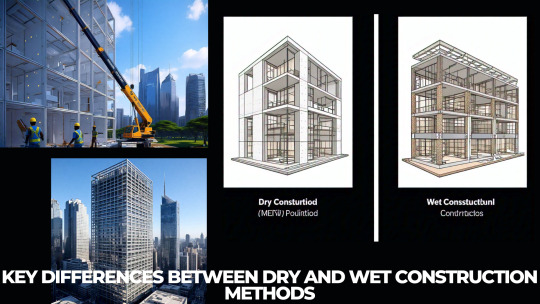

Construction methods have evolved over time, offering solutions that cater to varying project demands, climates, and timelines. The choice between dry construction and wet construction is fundamental, as each method comes with distinct processes, materials, and outcomes. Understanding these differences is essential for professionals, technicians, and aspiring engineers in Nigeria and across Africa, especially as the continent embraces modernization and sustainability in building practices.

At Jered Engineering & Designs Limited, we specialize in dry construction and its transformative potential. This article delves into the key differences between dry and wet construction methods, offering insights into their applications and advantages.

1. Definition and Processes

Dry Construction Dry construction involves assembling pre-manufactured components such as gypsum boards, aluminum panels, and steel frameworks. These materials are fixed using screws, adhesives, or fasteners without requiring water.

Wet Construction Wet construction relies on traditional materials like concrete, cement, and mortar, which are mixed with water and applied on-site. The curing process depends heavily on water availability and environmental conditions.

2. Materials Used

Dry Construction Materials:

Gypsum boards

Aluminum and steel frames

Pre-fabricated panels

Fiber cement boards

Glass panels

Wet Construction Materials:

Cement, sand, and aggregate

Bricks and blocks

Concrete mixes

Plaster and mortar

3. Construction Speed

Dry Construction:

Rapid installation since materials are prefabricated.

Reduced dependency on curing time.

Ideal for projects with tight deadlines, such as office spaces and retail fit-outs.

Wet Construction:

Time-consuming due to curing and drying processes.

Subject to delays caused by weather conditions, especially heavy rains common in parts of Nigeria and Africa.

4. Labor and Skill Requirements

Dry Construction:

Requires specialized skills for assembling prefabricated components.

Training in tools like screw guns and precision measurement devices is essential.

Jered Engineering invests in workforce training to empower local communities with these skills.

Wet Construction:

Relies on manual labor for tasks like bricklaying, plastering, and concrete mixing.

Skills required are often traditional and widely available.

5. Environmental Impact

Dry Construction:

Minimal water usage, making it suitable for areas with limited water resources.

Less on-site waste as components are prefabricated.

Recyclable materials like aluminum and steel contribute to sustainability.

Wet Construction:

High water consumption during material preparation and curing.

Significant waste generation from excess materials and construction debris.

Contributes to environmental degradation if not managed properly.

6. Structural Applications

Dry Construction:

Best suited for interiors, partitions, ceilings, and lightweight façades.

Growing use in modular buildings and prefabricated housing in Nigeria’s urban centers.

Wet Construction:

Preferred for load-bearing structures like foundations, columns, and beams.

Common in areas with traditional construction practices.

7. Cost Implications

Dry Construction:

Higher upfront costs for prefabrication and specialized materials.

Long-term savings due to faster project timelines, reduced labor costs, and lower maintenance expenses.

Wet Construction:

Generally lower initial costs, making it attractive for small-scale projects.

Higher long-term costs due to frequent maintenance and repairs.

8. Durability and Longevity

Dry Construction:

Resistant to moisture, pests, and fire when using high-quality materials like gypsum boards and fiber cement panels.

Durability depends on proper installation and material quality.

Wet Construction:

Known for its strength and ability to support heavy loads.

Susceptible to cracks, water damage, and wear over time if not maintained.

Practical Implications for Nigeria and Africa

Dry Construction Advantages:

Urbanization Demands: Rapid urbanization in cities like Lagos and Abuja calls for faster, scalable solutions that dry construction provides.

Water Scarcity: In arid regions like northern Nigeria, minimal water use in dry construction is a critical advantage.

Sustainability Goals: Governments across Africa are pushing for eco-friendly construction methods to combat climate change.

Wet Construction Suitability:

Traditional Applications: Rural areas still rely on wet construction for cost-effective housing.

Load-Bearing Needs: Essential for projects requiring heavy-duty foundations and structural support.

Why Jered Engineering Chooses Dry Construction

At Jered Engineering & Designs Limited, we believe dry construction is the future of sustainable building in Nigeria and beyond. Here’s why:

Efficiency: Faster project delivery allows us to meet the demands of a growing population.

Sustainability: By minimizing waste and water usage, we align with global environmental standards.

Quality: Our focus on precision ensures every project stands out for its durability and aesthetic appeal.

Conclusion

The choice between dry and wet construction methods depends on the project’s requirements, budget, and location. However, as the world leans towards sustainable and efficient building practices, dry construction is rapidly gaining prominence.

For professionals and aspiring technicians, understanding these methods is crucial to staying ahead in a competitive industry. With Jered Engineering & Designs Limited, you’re not just choosing a construction partner; you’re embracing a vision for the future of building in Nigeria and Africa.

#JeredEngineering

#JED

#FacadeDesign

#Dryconstruction

www.jeredengineering.com

0 notes

Text

Design Considerations for Chain Pulley Blocks: Balancing Efficiency and Durability

Chain pulley blocks are indispensable tools in industries requiring the lifting and movement of heavy loads. These mechanical devices leverage pulleys, chains, and a block housing to allow operators to lift and lower loads with minimal effort. Used extensively in demanding environments like construction, manufacturing, and warehousing, their design must strike a balance between efficiency (ease of operation) and durability (long-lasting performance).

Core Functionality and Components

A chain pulley block amplifies human strength through mechanical advantage, enabling users to lift heavy loads with significantly reduced effort. Its core components include:

Pulley system: Reduces the effort required by distributing the load across multiple sections.

Load chain: Directly engages with the load and moves it vertically.

Housing: Encases and protects the internal components while ensuring structural integrity.

Drive mechanism: Operated manually or via a handle, it activates the pulley system.

The primary design goal is to ensure these components work seamlessly to deliver optimal efficiency while withstanding the rigors of heavy-duty use.

Load Capacity and Safety

The load capacity of a chain pulley block is a critical parameter influencing its safety and functionality. Designers must ensure the block can handle expected loads while maintaining stability and durability under strain. Key considerations include:

Working Load Limit (WLL): The maximum safe load the block can handle. A sufficient safety margin is essential to prevent failures caused by overloading.

Overload protection: Advanced blocks feature mechanisms such as slip clutches or safety pawls to prevent damage when loads exceed the rated capacity.

Material strength: Components like the load chain, housing, and pulleys must withstand wear, corrosion, and fatigue. High-strength steel is often used, with additional treatments or coatings for enhanced durability.

Adherence to testing standards: Compliance with standards (e.g., ISO, ANSI) ensures the block’s ability to endure frequent heavy use while maintaining safety.

Materials and Construction

The choice of materials directly impacts both the durability and efficiency of chain pulley blocks, especially in harsh industrial environments. Key material considerations include:

High-strength steel: Steel alloys are the preferred choice for frames, gears, and pulleys due to their excellent strength and resistance to deformation under heavy loads.

Corrosion resistance: For environments prone to moisture or chemicals (e.g., offshore platforms), components may be made of stainless steel or galvanized steel to prevent corrosion and extend the block’s lifespan.

Heat treatment: Components like chains and pulleys often undergo heat treatment to increase hardness, reduce wear, and prevent metal fatigue.

Lightweight housing materials: Aluminum alloys are used in housings to reduce overall weight while maintaining structural integrity, enhancing portability and ease of use.

Enhancing Efficiency and Ease of Use

Efficiency determines how much force the operator needs to lift a load. Well-designed chain pulley blocks minimize effort while maximizing usability. Key factors include:

Pulley arrangement: The number and configuration of pulleys determine the mechanical advantage. While more pulleys reduce effort, they must be balanced against size and practicality constraints.

Smooth operation: Bearings reduce friction within the pulley and chain system, ensuring smoother and more efficient operation.

Ergonomic design: Manual blocks should feature handles or ratchets designed for operator comfort, minimizing fatigue during prolonged use. For larger operations, motorized drive systems provide enhanced convenience.

Maintenance and Longevity

Durability is intertwined with maintainability. Chain pulley blocks must be easy to service to prolong their lifespan and ensure reliable performance. Design features that enhance maintainability include:

Accessible lubrication points: Gears and moving parts need regular lubrication to prevent friction and wear. Blocks with accessible lubrication ports simplify this process.

Modular design: Modular components, such as replaceable chains, pulleys, and gears, reduce the need to replace the entire unit when individual parts wear out.

Wear indicators: Some blocks feature built-in wear indicators or limit switches that alert operators to replace or repair components, preventing unexpected failures.

Regulatory Compliance

Chain pulley blocks must meet stringent safety and performance standards set by organizations like OSHA, ISO, and CE. Compliance ensures the equipment’s reliability and safety in industrial applications. Design considerations include:

Load testing standards: Blocks must be tested under conditions that simulate real-world stresses to verify their performance.

Safety features: Anti-slip mechanisms, overload protection, and fail-safe designs ensure that blocks operate safely under varying conditions.

Striking the Right Balance

Designing an effective chain pulley block requires balancing several factors:

Efficiency: By optimizing the mechanical advantage and reducing friction, manufacturers can ensure smooth operation and reduced effort for users.

Durability: High-strength materials, corrosion resistance, and modular designs extend the block’s lifespan.

Safety: Adhering to standards and incorporating overload protection safeguards users and enhances reliability.

The ideal chain pulley block is a fusion of robust construction, efficient operation, and user-friendly design. By carefully selecting materials, incorporating safety mechanisms, and optimizing the pulley system, manufacturers can create tools that perform reliably under heavy-duty conditions.

A well-designed chain pulley block not only meets the immediate needs of lifting and material handling but also minimizes downtime, reduces maintenance costs, and ensures long-term safety and reliability in industrial applications.

#chain pulley blocks#industrial equipment#lifting solutions#material handling#chainblockpulley#industrialequipment#ManualChainPulleyHoist#chainblock#chainpulley#ropeandpulley#pulleyblocksystem#hoistingequipment

0 notes

Text

Affordable Replacements for Worn-Out Rotavator Parts: Save Big Without Compromising Quality

Rotavators play a crucial role in modern agriculture, preparing the soil for planting and ensuring high crop yields. However, frequent use can wear out their parts, leading to inefficiencies and costly downtime. Farmers often face the dilemma of choosing between high-quality replacements and budget-friendly options. With SBJ Nirmal Products, you no longer have to choose—they offer durable, high-quality, and affordable replacements that ensure your rotavator runs smoothly.

The True Cost of Ignoring Worn-Out Rotavator Parts

Overlooking wear and tear on rotavator parts can have significant consequences:

Decreased Efficiency: Blunt blades and damaged shafts make soil preparation slower and less effective.

Higher Operational Costs: Worn-out components increase fuel consumption and require frequent repairs.

Risk of Equipment Failure: A neglected rotavator is more likely to break down during critical farming periods, leading to costly delays.

Timely replacements not only prevent these issues but also ensure consistent performance during peak seasons.

The Importance of Quality in Replacement Parts

When replacing rotavator parts, quality should never be compromised. Low-quality components may seem cheaper initially, but they often lead to:

Frequent Replacements: Poorly made parts wear out faster, increasing long-term costs.

Operational Inefficiencies: Ill-fitting parts reduce the machine's overall performance.

Potential Machine Damage: Subpar materials can damage other components, leading to expensive repairs.

SBJ Nirmal Products addresses these concerns by providing replacements that combine durability, precision, and affordability.

SBJ Nirmal Products: The Affordable Solution for Farmers

SBJ Nirmal Products has established itself as a leading manufacturer of rotavator spare parts, offering solutions that cater to the diverse needs of farmers. Their products include:

Rotavator Blades and Tines: Designed for efficient soil cutting and mixing, ensuring maximum productivity.

Stub Axles and Housing: Engineered for stability, even in rugged terrains.

Gearboxes and Bearings: Built for smooth operation and long-lasting performance.

Farmers trust SBJ Nirmal for replacements that are not only affordable but also enhance the efficiency of their machinery.

How SBJ Nirmal Balances Quality and Affordability

SBJ Nirmal Products employs advanced manufacturing techniques and rigorous quality control processes to produce top-notch rotavator parts. Here's how they maintain affordability:

Efficient Manufacturing: Optimized production methods reduce costs without compromising quality.

Strategic Sourcing: High-grade materials are procured at competitive rates, ensuring durability at lower prices.

Focus on Farmer Needs: Products are designed to last longer, reducing the need for frequent replacements.

Global Reach of SBJ Nirmal Products

Although SBJ Nirmal is headquartered in Ludhiana, Punjab, their impact extends globally.

Exports to Neighboring Countries: Farmers in Bangladesh, Nepal, and Sri Lanka benefit from SBJ’s reliable products.

Expanding Presence: SBJ continues to grow its distribution network, ensuring easy access for farmers worldwide.

This global reach underscores SBJ Nirmal’s commitment to empowering farmers across borders.

Proven Benefits of SBJ Nirmal Rotavator Parts

Switching to SBJ Nirmal’s replacement parts offers several advantages:

Extended Lifespan: High-grade materials ensure durability, even under challenging conditions.

Improved Efficiency: Precision engineering guarantees seamless compatibility with various rotavator models.

Cost-Effective Solutions: Affordable pricing helps farmers save without sacrificing quality.

By choosing SBJ Nirmal, farmers make a long-term investment in reliability and performance.

Tips for Prolonging the Life of Rotavator Parts

Proper maintenance is key to getting the most out of your rotavator parts. Follow these tips:

Inspect Regularly: Check for signs of wear and tear after each use.

Clean Thoroughly: Remove dirt and debris to prevent rust and corrosion.

Lubricate Moving Parts: Use appropriate lubricants to reduce friction and extend part life.

Store Properly: Keep your rotavator in a dry, covered area when not in use.

Replace Worn Parts Promptly: Don’t delay replacements to avoid further damage.

SBJ Nirmal also provides detailed maintenance guides with their products to help farmers maximize efficiency.

Why Farmers Trust SBJ Nirmal Products

SBJ Nirmal Products has earned the trust of farmers through consistent quality and reliable performance.

Decades of Expertise: A proven track record of serving farmers with high-quality products.

Positive Testimonials: Farmers across India and neighboring countries praise SBJ for durability and affordability.

Customer-Centric Approach: SBJ prioritizes farmer satisfaction by offering robust customer support and warranties.

Conclusion: The Smart Choice for Affordable Quality

For farmers seeking reliable and affordable replacements for worn-out rotavator parts, SBJ Nirmal Products is the ultimate choice. By combining advanced manufacturing techniques, durable materials, and a customer-focused approach, SBJ delivers unmatched value.

Choose SBJ Nirmal Products today and experience the perfect balance of quality, affordability, and performance. Empower your farming operations with parts that save you money and keep your rotavator running like new!

0 notes

Text

Essential Blower Parts for Maximum Efficiency: What You Need to Know

Blowers are crucial for ventilation, cooling, and industrial applications. But to maintain peak efficiency, it's essential to understand the key components that drive their performance. Whether you’re replacing parts or optimizing your system, choosing high-quality blower components can improve efficiency, durability, and operational cost-effectiveness.

Critical Blower Components and Their Roles

1. Fan Wheels & Impellers

The heart of the blower, responsible for moving air efficiently.

Available in backward-inclined, forward-curved, and radial blade designs for different applications.

2. Bearings

Ensure smooth rotation of the blower shaft.

High-quality bearings reduce friction, noise, and premature wear.

3. Motors

Provide the power to drive the blower.

Energy-efficient motors can lower operating costs and reduce maintenance needs.

4. Belts & Pulleys (For Belt-Driven Blowers)

Transfer power from the motor to the fan wheel.

Proper alignment and tensioning prevent slippage and inefficiencies.

5. Housings & Casings

Protect internal components from dust, moisture, and external damage.

Well-designed casings improve airflow efficiency.

6. Dampers & Louvers

Control air volume and pressure, improving system efficiency.

Help maintain consistent airflow and reduce energy waste.

How Quality Parts Improve Performance & Longevity

Investing in high-quality blower parts offers several benefits: ✅ Enhanced Efficiency – Reduces energy consumption and increases airflow performance. ✅ Reduced Downtime – Fewer breakdowns mean uninterrupted operations. ✅ Extended Lifespan – Premium materials and proper maintenance prolong blower life. ✅ Cost Savings – Lower maintenance and energy costs over time.

Maintenance Tips to Extend Blower Part Life

✔ Regular Inspections – Check for wear, misalignment, and unusual noise. ✔ Lubricate Bearings – Follow manufacturer recommendations to prevent overheating. ✔ Clean Impellers & Housings – Remove dust buildup to maintain efficiency. ✔ Check Belt Tension & Alignment – Loose belts cause inefficiency; tight belts cause wear. ✔ Replace Worn-Out Components Promptly – Avoid major failures by acting early.

FAQs

🔹 How often should blower bearings be lubricated?

It depends on the operating environment, but typically every 3-6 months.

🔹 What are signs that a blower wheel needs replacement?

Excessive vibration, noise, and reduced airflow indicate wear or imbalance.

🔹 Can using aftermarket parts affect blower performance?

Yes, low-quality or incompatible parts can reduce efficiency and lead to premature failures.

🔹 How do I know if my blower motor is energy-efficient?

Look for high-efficiency ratings (such as NEMA Premium motors) and lower power consumption.

Optimize Your Blower Performance Today!

Looking for high-quality replacement parts for your blower? Central Blower offers durable, high-performance components designed to maximize efficiency.

🔹 Browse our selection of blower parts today! 📞 Call us now for expert recommendations! 📩 Get a free quote on replacement parts!

#Blower parts#Blower components#Fan wheels#Blower motors#Blower bearings#Industrial blowers#Blower maintenance#Energy-efficient blowers

0 notes

Text

Peb Structure Manufacturer | New Life Steel

New Life Steel provides high-quality PEB structures designed to meet the evolving needs of modern construction. Our pre-engineered buildings are durable, energy-efficient, and cost-effective, ideal for industrial and commercial applications. With cutting-edge technology and a dedicated team https://www.newlifesteel.com/

Pre-Engineered Buildings (PEBs) have emerged as a groundbreaking solution in the construction industry, combining efficiency, flexibility, and sustainability. Unlike traditional construction methods, PEBs involve the off-site fabrication of components that are then transported and assembled on-site, offering significant advantages in terms of cost and time.

This innovative approach has found applications across industries, from large-scale industrial warehouses to small-scale residential structures. Here, we explore the benefits, applications, and industry leaders like New Life Steel Structures, who are shaping the future of PEB manufacturing.

Benefits of PEB Structures

Reduced Construction Time: PEBs are pre-designed and fabricated, drastically cutting down on on-site construction time. This streamlined process is especially advantageous for projects with tight deadlines.

Cost Efficiency: With optimized material usage and reduced labor requirements, PEBs offer a cost-effective alternative to conventional building methods.

Design Versatility: The modular nature of PEBs allows for a wide range of designs and applications, accommodating various architectural and functional needs.

Durability: Built with high-grade steel, PEBs are designed to withstand extreme weather conditions and seismic activities, ensuring longevity.

Eco-Friendly: PEBs use recyclable materials and generate minimal waste during production, aligning with sustainable construction practices.

Ease of Maintenance: The corrosion-resistant and weatherproof properties of PEBs reduce the need for regular maintenance, lowering long-term costs.

Applications of PEB Structures

Industrial: Manufacturing plants, warehouses, and workshops benefit from the large spans and load-bearing capacities of PEBs.

Commercial: Shopping malls, office spaces, and showrooms are commonly designed using PEBs for their modern aesthetics and functional layouts.

Agricultural: Storage facilities for grains, farm equipment, and livestock housing utilize PEBs for their robust and adaptable designs.

Sports and Recreation: PEBs are ideal for sports complexes, gyms, and auditoriums due to their capacity to create expansive, column-free spaces.

Residential: Cost-effective homes and modular housing solutions are increasingly adopting PEB frameworks for their quick construction and customizable designs.

New Life Steel Structures: A Trusted PEB Manufacturer

For over three decades, New Life Steel Structures has been a trailblazer in the PEB manufacturing sector. Known for their advanced technology and customer-centric approach, they deliver tailored solutions that meet diverse construction needs.

What Sets New Life Steel Apart?

State-of-the-Art Manufacturing: New Life Steel’s facilities are equipped with cutting-edge machinery, ensuring high-quality production and fast delivery.

Comprehensive Services: From design and fabrication to installation, the company offers end-to-end PEB solutions.

Experienced Team: Their skilled engineers and technicians bring expertise to every project, ensuring innovative and cost-effective designs.

Commitment to Quality: Strict quality controls and premium-grade materials underline their reputation for reliability and excellence.

Conclusion

Pre-Engineered Buildings represent the evolution of construction, addressing the growing demand for efficient, sustainable, and versatile solutions. Companies like New Life Steel Structures are at the forefront of this transformation, offering expertise and innovation to meet the diverse needs of their clients. Whether for industrial, commercial, or residential applications, PEBs are redefining the construction landscape, ensuring a future built on strength, efficiency, and sustainability.

0 notes

Text

Friction Reduction Solutions: Using PTFE Skived Film tape to Enhance Machine Efficiency

Reducing friction is essential for maximizing the efficiency and longevity of machinery. In mechanical applications, even slight friction can hinder performance, increase energy consumption, and lead to premature wear and noise. To combat these challenges, PTFE Skived Film tape stands out as a powerful solution. This blog will delve into how using PTFE skived film tape—particularly 5 MIL skived PTFE film tape—can effectively reduce friction, noise, and wear in various mechanical applications, showcasing real-world examples to illustrate its effectiveness.

Understanding the Role of Friction in Machinery

Friction occurs when two surfaces interact, often leading to resistance, heat generation, and wear. In machinery, high friction can result in a range of issues, including:

· Increased Energy Consumption: Machines need more power to overcome friction, leading to skyrocketing operational costs.

· Wear and Tear: Components subjected to excessive friction wear out faster, increasing maintenance costs and downtime.

· Noise Production: Friction can generate unwanted noise, which may disrupt operations and negatively impact work environments.

By effectively reducing friction, businesses can enhance the performance and reliability of their equipment. This is where pure skived PTFE comes into play, offering remarkable benefits in mechanical settings.

Exceptional Properties of PTFE Film Tape

PTFE (Polytetrafluoroethylene) provides several unique properties that make it an ideal choice for reducing friction:

Low Coefficient of Friction: PTFE has one of the lowest coefficients of friction among solid materials, enabling smoother operation between surfaces.

Durability: PTFE is resistant to wear and can maintain its properties over extended periods, even under demanding conditions.

Chemical Resistance: It can withstand exposure to various chemicals and solvents without degrading, crucial for many industrial applications.

Thermal Stability: PTFE maintains its performance in a temperature range from -450°F to 500°F (-268°C to 260°C), making it versatile for many settings.

Real-World Applications of PTFE Film Tape

1. Bearing Applications

In electrical motors, bearings play a critical role in ensuring smooth operation. High friction can lead to overheating and eventual failure. By applying 5 mil skived PTFE film tape to the bearing housing, manufacturers can significantly reduce friction between the bearing surfaces and retain moisture or lubricants. For instance, a manufacturing firm that retrofitted their electric motor bearings with PTFE film tape noticed a 20% reduction in energy consumption and a marked decrease in noise levels, proving the tape's effectiveness in maintaining proper functionality.

2. Conveyor Belts

Conveyor systems are ubiquitous in manufacturing and warehousing, where loads are moved continuously. Friction between the conveyor belt and pulleys can slow down operations. Implementing PTFE skived tape on the contact surfaces of pulleys helps lower frictional resistance. A logistics company that utilized PTFE tape on its conveyor belts reported a smoother operation that resulted in a 30% increase in throughput, demonstrating how friction reduction can directly impact productivity.

3. Sliding Doors and Panels

In various industrial settings, sliding doors are essential for facilitating movement and access. Traditional sliding mechanisms can be noisy and cumbersome due to friction. Employing PTFE film tape along the track of sliding doors can significantly improve their operation. A case study involving an automotive assembly plant found that after equipping sliding doors with PTFE film tape, there was a noticeable reduction in operational noise, improving the overall working environment and allowing smoother transitions for workers and materials.

4. Sealing Applications

In many mechanical assemblies, seals are vital for preventing leaks. PTFE film tape can be effectively used to enhance the sealing capabilities of gaskets. For example, a chemical processing plant integrated pure skived PTFE as gaskets in their piping systems. This not only minimized leakage but also allowed for the safe transport of corrosive materials. The outcome was a 25% reduction in downtime related to maintenance and repairs, showcasing the economic benefits of using PTFE tape.

5. Low-Friction Surfaces for Robotics

In robotics, minimizing friction is crucial for achieving precise movements and enhancing battery life. PTFE film tape serves as a low-friction surface on joints and moving parts of robotic arms. For a robotics manufacturer, applying PTFE skived tape to the joints of robotic arms reduced frictional resistance, leading to smoother operation and increased accuracy in tasks. This adjustment improved the overall efficiency of the robotic systems, allowing for faster production cycles.

Benefits of Using PTFE Film Tape

1. Enhanced Efficiency

Reducing friction improves the energy efficiency of machines, leading to lower operational costs. Businesses that implement PTFE film tape typically notice a decrease in their energy bills and improved productivity.

2. Prolonged Equipment Lifespan

Machinery equipped with PTFE film tape experiences less wear, which translates to longer equipment lifespans and reduced maintenance costs. This longevity is a critical factor for manufacturing and industrial sectors that rely heavily on operational uptime.

3. Noise Reduction

Quiet operations are essential for maintaining a comfortable and safe workplace. Utilizing PTFE tape in various applications leads to quieter machinery, which is beneficial for employee satisfaction and regulatory compliance regarding noise levels.

4. Cost-Effectiveness

The initial investment in PTFE film tape pays off through the savings on energy, maintenance, and replacement costs. Organizations that adopt this solution can allocate their resources more efficiently.

Choosing the Right PTFE Tape Supplier

When seeking to integrate PTFE skived tape into your machinery, it’s important to source high-quality products from a reputable PTFE skived tape supplier. Look for suppliers who provide detailed specifications and certification for their tape, ensuring the right thickness and type for your application needs. Reliable suppliers will also offer support and guidance on the best practices for using their products effectively.

Final Thoughts

In the quest for increased machine efficiency, using PTFE film tape as a friction reduction solution delivers significant benefits. Its unique properties allow it to effectively minimize friction, noise, and wear across a multitude of applications—from bearings and conveyor systems to sealing and sliding mechanisms. By implementing PTFE film tape, businesses can enhance operational performance, extend the lifespan of their equipment, and foster a quieter work environment. As industries continue to evolve, the role of PTFE film tape in reducing friction and promoting efficiency will become increasingly essential.

0 notes

Text

Supporting the Circular Economy with Advanced Pumping Technologies

The circular economy model emphasizes sustainability by designing products and systems that minimize waste, reuse resources, and regenerate natural ecosystems. Pump manufacturers and suppliers are increasingly adopting circular economy principles to address global resource challenges and support environmentally responsible practices. Below are the ways in which the water pump industry is contributing to the circular economy.

1. Designing for Longevity and Durability

Extending the lifespan of pumps reduces the need for frequent replacements, lowering resource consumption and waste generation.

Robust Materials: Pumps are being designed with corrosion-resistant alloys, ceramics, and advanced composites that withstand harsh operating conditions and reduce wear.

Modular Designs: Modular pump systems allow for individual components, such as impellers or seals, to be replaced instead of discarding the entire unit, reducing material waste.

Enhanced Maintenance Protocols: Proactive maintenance solutions, such as IoT-enabled monitoring and predictive analytics, ensure pumps operate efficiently for extended periods.

2. Repair and Refurbishment Programs

Pump suppliers are increasingly offering repair and refurbishment services, giving old equipment a second life.

Remanufactured Pumps: Manufacturers refurbish used pumps to meet original performance specifications, saving energy and materials compared to producing new units.

Component Replacement Services: Damaged parts like bearings, shafts, or impellers can be replaced to restore pump functionality without the need for a full replacement.

Certified Refurbished Products: Suppliers now sell certified pre-owned pumps with warranties, providing a cost-effective and sustainable alternative to new purchases.

3. Recycling and Resource Recovery

Recycling materials from decommissioned pumps supports the circular economy by reducing raw material extraction and waste.

Metal Recycling: Key pump components made from stainless steel, bronze, or cast iron can be recycled and reused in manufacturing new products.

Plastic Recovery: High-grade plastics used in pump housings and fittings are being repurposed into new industrial applications.

Closed-Loop Manufacturing: Some manufacturers are creating closed-loop systems where old pumps are collected, disassembled, and recycled directly into new production lines.

4. Energy-Efficient Operation

Energy efficiency aligns with the circular economy by reducing the environmental footprint of pump systems throughout their lifecycle.

Low-Power Consumption Designs: Pumps with variable speed drives (VSDs), high-efficiency motors, and optimized hydraulics consume less energy, reducing greenhouse gas emissions.

Renewable Energy Integration: Solar- and wind-powered pumps eliminate reliance on fossil fuels, creating a sustainable energy loop.

IoT-Enabled Efficiency Monitoring: Smart systems optimize pump operation, ensuring minimal energy wastage and extending equipment lifespan.

5. Supporting Water Reuse and Recycling Systems

Pumps play a critical role in enabling the reuse and recycling of water in residential, commercial, and industrial settings.