#chain pulley blocks

Explore tagged Tumblr posts

Text

Understanding Load Stress Calculations and Techniques to Prevent Overloading in Chain Pulley Blocks

Chain pulley blocks, also known as chain hoists, are essential tools for lifting heavy loads in industries like construction, warehousing, and manufacturing. However, improper use or overloading can lead to serious accidents, mechanical failures, and unnecessary wear and tear. Calculating load stress and adhering to load limits is vital to ensure safe and efficient operation. This article provides a detailed step-by-step guide to calculating load stress and preventing overloading on chain pulley blocks, while also exploring related safety practices.

Understanding Load Stress in Chain Pulley Blocks

Load stress refers to the force exerted on a chain pulley block when it is lifting or suspending a load. If the force exceeds the equipment's rated capacity, it can result in:

Chain deformation or breakage

Pulley malfunction

Workplace accidents or injuries

Load stress is influenced by factors such as the weight of the load, the angle of lift, the condition of the chain, and environmental factors like vibration or wind.

Step-by-Step Guide to Calculating Load Stress

Step 1: Determine the Weight of the Load

The first step in calculating load stress is knowing the total weight of the object being lifted. This information can often be found in product specifications, packaging, or through direct weighing.

Example: If you're lifting a pallet of steel rods weighing 500 kg, the load weight is 500 kg.

Step 2: Account for Additional Forces

If the load is being moved at an angle (e.g., not lifted vertically), additional forces come into play due to gravity and tension.

Use the formula for calculating the effective load based on the angle of lift:

Effective Load=Load Weightcos(θ)\text{Effective Load} = \frac{\text{Load Weight}}{\cos(\theta)}

Where:

θ\theta is the angle of the load from the vertical.

Example: If the load is lifted at a 30° angle, the effective load is:

Effective Load=500cos(30)=5000.866≈577.4 kg\text{Effective Load} = \frac{500}{\cos(30)} = \frac{500}{0.866} \approx 577.4 \, \text{kg}

Step 3: Include Dynamic Forces

Dynamic forces occur due to movement, such as accelerating or decelerating the lift. To account for this, add an extra 10–20% to the calculated load to ensure safety.

Dynamic Load:

Dynamic Load=Effective Load×1.2\text{Dynamic Load} = \text{Effective Load} \times 1.2

Example:

Dynamic Load=577.4×1.2=692.88 kg\text{Dynamic Load} = 577.4 \times 1.2 = 692.88 \, \text{kg}

Step 4: Compare with the Chain Pulley Block's Rated Capacity

The rated capacity, also called the Safe Working Load (SWL), is the maximum load a chain pulley block can safely handle. Ensure the dynamic load is within the SWL of the equipment.

Example: If your chain pulley block has an SWL of 1,000 kg, the calculated dynamic load of 692.88 kg is well within safe limits.

Preventing Overloading on Chain Pulley Blocks

Preventing overloading is not just about calculating load stress but also implementing proactive measures. Follow these best practices to ensure safety:

1. Always Know the Rated Capacity

Each chain pulley block has a rated capacity, typically marked on the equipment. Never exceed this capacity, even for short lifts or small loads.

Tip: Use a chain pulley block with a slightly higher capacity than your calculated load to allow for unexpected dynamic forces.

2. Perform Pre-Use Inspections

Regular inspections help identify potential issues that could compromise the equipment's load capacity.

Check for worn-out chains, frayed wires, and deformed hooks.

Look for signs of rust, corrosion, or misaligned components.

Ensure the load chain is properly lubricated to minimize friction.

3. Avoid Shock Loading

Shock loading occurs when a load is suddenly applied or dropped onto the chain pulley block, resulting in stress that exceeds the SWL.

Lift loads smoothly and steadily to avoid abrupt movements.

Never use the chain pulley block to catch falling loads.

4. Distribute Loads Evenly

When lifting irregularly shaped or unbalanced loads, ensure the weight is evenly distributed across the chains and hooks. Uneven weight distribution increases stress on specific components and can cause premature failure.

5. Use Safety Accessories

Enhance safety by using appropriate accessories, such as:

Load limiters: These devices automatically prevent the pulley from lifting loads beyond its rated capacity.

Overload indicators: Visual indicators that alert operators when the load exceeds safe limits.

6. Train Operators

Inadequate training is a leading cause of equipment misuse and overloading. Ensure that operators understand:

How to calculate load stress

The equipment’s SWL

Proper lifting techniques and safety protocols

7. Monitor the Environment

External factors like wind, vibration, or temperature can affect the performance of a chain pulley block. Always account for these when planning a lift.

Avoid using chain pulleys in high winds or extreme weather.

Ensure the ground is stable and free from vibrations.

Consequences of Overloading

Overloading chain pulley blocks can lead to severe consequences, including:

Equipment Failure: Overloading stresses the chain and gears, causing wear and breakage.

Workplace Accidents: Dropped loads can injure workers, damage property, or block operations.

Reduced Lifespan: Frequent overloading shortens the lifespan of the chain pulley, leading to costly replacements.

Legal Penalties: Operating overloaded equipment violates safety regulations, potentially resulting in fines or shutdowns.

Proactive Maintenance for Load Stress Prevention

In addition to calculating load stress, regular maintenance ensures the chain pulley operates at peak performance. Key maintenance practices include:

Chain Inspection: Look for elongation, kinks, or damage in the load chain.

Gear Lubrication: Regularly lubricate moving parts to reduce friction and wear.

Hook Checks: Inspect hooks for deformation or cracks.

Load Testing: Conduct periodic load tests to verify that the equipment can handle its rated capacity.

Proper calculation of load stress and adherence to load limits are critical for the safe and efficient use of chain pulley blocks. By following the steps outlined in this guide—such as calculating effective and dynamic loads, inspecting equipment, and implementing safety practices—you can significantly reduce the risk of overloading and mechanical failure. Incorporating proactive maintenance, operator training, and safety accessories further ensures that your equipment performs optimally and remains compliant with safety standards. Remember, safety in material handling isn’t just about protecting equipment—it’s about safeguarding lives and creating a more efficient work environment.

#chain pulley blocks#industrial equipment#lifting solutions#chainblockpulley#material handling#chainblock#manualchainpulleyhoist#chainpulley#pulleyblocksystem#construction#hoist

0 notes

Text

https://www.indolift.in/chain-pulley-blocks.html

1 note

·

View note

Text

Reasons Why Chain Pulley Blocks Continue to be Popular

In a world dominated by technical advancement and automation, some equipment and gadgets have an amazing knack for resisting the passage of time. One of these enduring workhorses is the modest but essential chain pulley block, sometimes known as a "chain hoist."

The chain pulley block keeps up with its situation as an enduring number one in different areas regardless of the unwavering walk of headway in assembling and modern innovation. Online marketplaces featuring an extensive variety of chain pulley blocks will help you locate plenty of Chain pulley block suppliers.

A few significant reasons clarify why chain pulley blocks go on to be famous across a scope of industries:

Steadfastness

The perpetual steadfastness and life span of chain pulley blocks is one of the principal factors in their progress with the request. These plans are solid, fit for conveying significant burdens, and have a long life. In several alliances, chain pulley block dependability is essential and is used for tasks like disposal.

Convenience

The construction and use of chain pulley blocks are stunningly straightforward. For effective use, clients don't require refined specialized ability. These instruments are generally utilized due to how basic and receptive they are to various laborers.

Capacity to Change as per Various Applications

The uses for chain pulley blocks are many. They have different capabilities, including lifting and positioning enormous articles on building locales, helping with load raising in agribusiness, and putting away merchandise proficiently in distribution centers. Their adaptability stays mindful of their dependable importance in different undertakings.

Affordable

Bind pulley blocks keep on being a financially savvy choice for some lifting and material dealing with tasks notwithstanding mechanical turns of events. They are a reasonable choice for associations, especially small and medium-sized firms searching for powerful arrangements without burning through every last dollar, in light of their modest starting buy cost and little upkeep needs.

Security

In every industrial situation, safety is the number one concern. The danger of accidents is decreased by the exact control that chain pulley blocks provide for lifting and lowering activities. Their slow, steady functioning enables the cautious placing of big loads, assuring the security of staff as well as supplies.

Dependable in Troublesome Conditions

Chain pulley blocks are ideally suited for usage in difficult situations, such as dusty, dirty building sites and areas with variable weather. In tough environments where electronic alternatives would be more prone, their sturdy design enables them to operate dependably.

All in all, the prevalence of chain pulley blocks is confirmation of their steadily persevering through worth in a period depicted by particular headways and robotization. In a few areas, their trustworthiness, effortlessness, flexibility, cost-viability, and security qualities make them irreplaceable gear.

Chain pulley blocks will stay vital for the improvement of various ventures for however long there is an interest in compelling material transportation and lifting. These mechanical miracles act as a stunning illustration of how once in a while the simple arrangements are the perfect ones.

Consider factors like product quality, warranty, price, and after-sales assistance while looking for a Chain pulley block supplier. Check whether they have customization choices to match your particular demands as well. Before making a purchase, always check the reputation and qualifications of the source.

0 notes

Text

When it comes to heavy machinery and construction equipment, few names resonate as strongly as JCB. Renowned for their innovation and reliability, #JCB LiftTech have revolutionized the construction industry, enabling efficient lifting and manoeuvring of heavy loads across various job sites. At the heart of these impressive machines lies a crucial component: the Chain Pulley Block. In this blog, we delve into the intricacies of this technology, exploring its design, functionality, and the pivotal role it plays in powering #JCBLiftTech . Read More Info: https://jcblifttech.com/chain-pulley-block-effortless-power-seamless-control/

#JCBLiftTech#CHAIN PULLEY BLOCK#RATCHET LEVER HOIST#ELECTRIC CHAIN HOIST#ELECTRIC TROLLEY#MANUAL TROLLEY#BEAM CLAMP#PULLING & LIFTING MACHINE#RATCHET LASHING#TOW STRAP#FORKLIFT PROTECTOR

2 notes

·

View notes

Text

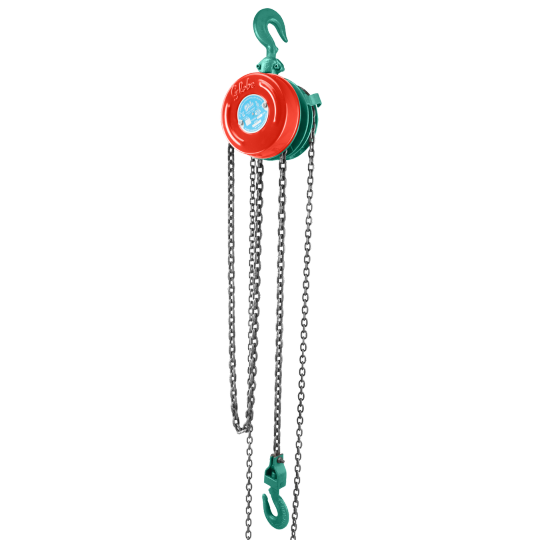

Globe Overseas Pvt. Ltd. Established in 1995, Globe Overseas Pvt Ltd has been a pioneer in the Material Handling Equipment industry, delivering reliable and efficient lifting solutions for over two decades. With a steadfast commitment to quality and innovation, we cater to industries such as manufacturing, construction, logistics, and warehousing.

#chain pulley#chain pulley block 2 ton#handling material equipment#chain kuppi#chain pulley block#lifting machine#construction materials#loader equipment#over head crane

0 notes

Text

Choosing the Right Chain Sling for Your Industrial Needs in India

When it comes to heavy lifting and material handling, chain slings are indispensable tools in various industries. Choosing the right chain sling for your industrial needs is essential for ensuring safety, efficiency, and durability in operations. With numerous chain sling manufacturers and suppliers in India, it’s crucial to make an informed choice that aligns with your specific requirements.

Understanding Chain Slings and Their Applications

Chain slings are lifting devices made of durable alloy steel chains, designed to handle heavy loads in demanding environments. They are commonly used in construction, manufacturing, shipping, and warehousing. Chain slings come in different configurations such as single-leg, double-leg, and multi-leg slings, each suited for particular applications.

For businesses relying on lifting equipment, finding the right chain sling manufacturers and suppliers in India ensures access to high-quality products that meet industry standards.

Key Factors to Consider When Choosing a Chain Sling

Load Capacity: Ensure the chain sling’s working load limit (WLL) matches the weight of your loads.

Type of Sling: Select the appropriate type—single-leg, double-leg, or multi-leg—based on the load’s size, weight, and shape.

Material and Quality: Opt for slings made of high-grade alloy steel for enhanced durability.

Inspection and Certification: Always verify that the slings are inspected and certified by the manufacturer.

Compatibility with Other Equipment: Ensure the chain sling works seamlessly with your lifting devices like electric chain hoists or chain pulley blocks. For quality products, seek reputed electric chain hoist manufacturers and suppliers in India and chain pulley block suppliers in India.

Safety Tips for Using Chain Slings

Inspect the sling before every use to check for signs of wear, corrosion, or damage.

Avoid overloading the sling beyond its WLL.

Store chain slings in a dry place to prevent rust and maintain longevity.

Train personnel on proper handling and safety protocols.

Why SVIBO Industries is the Right Choice

When it comes to reliable and high-quality lifting solutions, SVIBO Industries stands out as a trusted name. With a commitment to delivering top-notch products, they are among the leading chain sling manufacturers and suppliers in India. Their range of chain slings is built to withstand rigorous industrial applications, ensuring safety and efficiency in your operations. Additionally, SVIBO Industries offers excellent customer support and tailored solutions, making them a go-to choice for businesses seeking dependable lifting equipment. Whether you need chain slings, electric chain hoists, or chain pulley blocks, SVIBO Industries is equipped to meet all your industrial needs with precision and expertise.

By choosing SVIBO Industries, you’re not just investing in high-quality products but also in the assurance of unmatched service and reliability.

If you’re ready to enhance your material handling operations, explore the premium range of lifting equipment offered by SVIBO Industries today! To know more about SVIBO Industries, Contact us - Website - https://sviboindustries.in/

Address - 111,112,113 Mahatma Phule Peth, Block No 101, Sevadham Building, 1st Floor, Pune, Maharashtra 411042

Email - [email protected] Get directions -

#chain sling manufacturers suppliers in india#electric chain hoist manufacturer suppliers in india#chain pulley block supplier in india

0 notes

Text

Chain Pulley Block At Best Price In India

Chain Pulley Block At Best Price In India Tecon Crane System LLP offers wide a range of services, including Chain Pulley Block products.

0 notes

Text

Trolley Mounted Chain Pulley Block - Bemco

Trolley Mounted Chain Pulley Block lifts up to 50 tons, with customizable width for various I-beam flanges and anti-corrosion parts for dependable performance in tough conditions. BEMCO's dedication to ensuring safety and quality makes this product perfect for use in industrial settings.

0 notes

Text

5 Benefits of Using Chain Pulley Blocks in Heavy Lifting Operations

Chain pulley blocks, also known as chain hoists, offer an effective and safe solution for lifting heavy loads. These indispensable tools are essential in various industrial settings, providing a reliable means to handle and maneuver heavy materials with ease. If you are in the market for trustworthy lifting equipment, look no further than Thermodynamic Services, a trusted Chain Pulley Block dealer in Uttar Pradesh. With a reputation for delivering high-quality products and exceptional customer service, Thermodynamic Services is your go-to source for all your lifting equipment needs.

Chain pulley blocks operate on a simple yet highly effective mechanism that uses a chain looped around a pulley to lift and lower heavy loads. This design provides a mechanical advantage, allowing a single operator to lift loads that would otherwise require multiple workers or more complex machinery. The ease of use and efficiency offered by chain pulley blocks make them an ideal choice for a wide range of applications, from manufacturing and construction to warehousing and shipping.

0 notes

Text

The Evolution of Chain Pulley Blocks: From Traditional to Modern Designs

Introduction: In the realm of lifting and hoisting equipment, chain pulley blocks have long been a cornerstone. From humble beginnings as simple mechanical devices to the sophisticated modern designs of today, these tools have undergone a remarkable evolution. Let us embark on a journey through time, exploring the transformation of chain pulley blocks from traditional to modern designs.

Industrial Revolution and Advancements: The advent of the Industrial Revolution ushered in a new era of innovation in lifting equipment. With the rise of mechanization, chain pulley blocks underwent significant advancements. The incorporation of metal components, such as steel chains and gears, improved durability and efficiency. These developments enabled the handling of heavier loads with greater ease, revolutionizing various industries such as manufacturing, construction, and logistics.

Introduction of Safety Features: As workplace safety became a growing concern, particularly during the 20th century, manufacturers began integrating safety features into chain pulley block designs. Braking systems, overload protection mechanisms, and ergonomic enhancements were introduced to mitigate risks and ensure operator welfare. These additions not only enhanced safety but also contributed to increased productivity and longevity of the equipment.

Technological Innovations: The dawn of the digital age brought forth a wave of technological innovations that transformed chain pulley blocks into highly sophisticated machines. The integration of electronic controls, sensors, and automation revolutionized the way these devices operated. Modern chain pulley blocks feature advanced monitoring systems, remote control capabilities, and precision positioning, enabling precise and efficient lifting operations in diverse environments.

Materials and Construction: Advancements in materials science have also played a crucial role in the evolution of chain pulley block design. The use of high-strength alloys and lightweight composites has led to the development of more compact and portable units without compromising on strength or performance. Furthermore, innovations in manufacturing processes have streamlined production and reduced costs, making modern chain pulley blocks more accessible to a wider range of industries and applications.

Conclusion: The evolution of chain pulley blocks from traditional to modern designs is a testament to human ingenuity and technological progress. What once started as simple mechanical devices has evolved into sophisticated lifting solutions that empower industries around the world. As we continue to push the boundaries of innovation, it’s exciting to envision the future advancements that will further enhance the performance, safety, and sustainability of chain pulley blocks.

SVIBO industries offers high quality and modern chain pulley blocks. For more information contact: 111,112,113 Mahatma Phule Peth, Block No 101, Sevadham Building, 1st Floor, Pune, Maharashtra 411042

+91 8208803755

0 notes

Text

Design Considerations for Chain Pulley Blocks: Balancing Efficiency and Durability

Chain pulley blocks are indispensable tools in industries requiring the lifting and movement of heavy loads. These mechanical devices leverage pulleys, chains, and a block housing to allow operators to lift and lower loads with minimal effort. Used extensively in demanding environments like construction, manufacturing, and warehousing, their design must strike a balance between efficiency (ease of operation) and durability (long-lasting performance).

Core Functionality and Components

A chain pulley block amplifies human strength through mechanical advantage, enabling users to lift heavy loads with significantly reduced effort. Its core components include:

Pulley system: Reduces the effort required by distributing the load across multiple sections.

Load chain: Directly engages with the load and moves it vertically.

Housing: Encases and protects the internal components while ensuring structural integrity.

Drive mechanism: Operated manually or via a handle, it activates the pulley system.

The primary design goal is to ensure these components work seamlessly to deliver optimal efficiency while withstanding the rigors of heavy-duty use.

Load Capacity and Safety

The load capacity of a chain pulley block is a critical parameter influencing its safety and functionality. Designers must ensure the block can handle expected loads while maintaining stability and durability under strain. Key considerations include:

Working Load Limit (WLL): The maximum safe load the block can handle. A sufficient safety margin is essential to prevent failures caused by overloading.

Overload protection: Advanced blocks feature mechanisms such as slip clutches or safety pawls to prevent damage when loads exceed the rated capacity.

Material strength: Components like the load chain, housing, and pulleys must withstand wear, corrosion, and fatigue. High-strength steel is often used, with additional treatments or coatings for enhanced durability.

Adherence to testing standards: Compliance with standards (e.g., ISO, ANSI) ensures the block’s ability to endure frequent heavy use while maintaining safety.

Materials and Construction

The choice of materials directly impacts both the durability and efficiency of chain pulley blocks, especially in harsh industrial environments. Key material considerations include:

High-strength steel: Steel alloys are the preferred choice for frames, gears, and pulleys due to their excellent strength and resistance to deformation under heavy loads.

Corrosion resistance: For environments prone to moisture or chemicals (e.g., offshore platforms), components may be made of stainless steel or galvanized steel to prevent corrosion and extend the block’s lifespan.

Heat treatment: Components like chains and pulleys often undergo heat treatment to increase hardness, reduce wear, and prevent metal fatigue.

Lightweight housing materials: Aluminum alloys are used in housings to reduce overall weight while maintaining structural integrity, enhancing portability and ease of use.

Enhancing Efficiency and Ease of Use

Efficiency determines how much force the operator needs to lift a load. Well-designed chain pulley blocks minimize effort while maximizing usability. Key factors include:

Pulley arrangement: The number and configuration of pulleys determine the mechanical advantage. While more pulleys reduce effort, they must be balanced against size and practicality constraints.

Smooth operation: Bearings reduce friction within the pulley and chain system, ensuring smoother and more efficient operation.

Ergonomic design: Manual blocks should feature handles or ratchets designed for operator comfort, minimizing fatigue during prolonged use. For larger operations, motorized drive systems provide enhanced convenience.

Maintenance and Longevity

Durability is intertwined with maintainability. Chain pulley blocks must be easy to service to prolong their lifespan and ensure reliable performance. Design features that enhance maintainability include:

Accessible lubrication points: Gears and moving parts need regular lubrication to prevent friction and wear. Blocks with accessible lubrication ports simplify this process.

Modular design: Modular components, such as replaceable chains, pulleys, and gears, reduce the need to replace the entire unit when individual parts wear out.

Wear indicators: Some blocks feature built-in wear indicators or limit switches that alert operators to replace or repair components, preventing unexpected failures.

Regulatory Compliance

Chain pulley blocks must meet stringent safety and performance standards set by organizations like OSHA, ISO, and CE. Compliance ensures the equipment’s reliability and safety in industrial applications. Design considerations include:

Load testing standards: Blocks must be tested under conditions that simulate real-world stresses to verify their performance.

Safety features: Anti-slip mechanisms, overload protection, and fail-safe designs ensure that blocks operate safely under varying conditions.

Striking the Right Balance

Designing an effective chain pulley block requires balancing several factors:

Efficiency: By optimizing the mechanical advantage and reducing friction, manufacturers can ensure smooth operation and reduced effort for users.

Durability: High-strength materials, corrosion resistance, and modular designs extend the block’s lifespan.

Safety: Adhering to standards and incorporating overload protection safeguards users and enhances reliability.

The ideal chain pulley block is a fusion of robust construction, efficient operation, and user-friendly design. By carefully selecting materials, incorporating safety mechanisms, and optimizing the pulley system, manufacturers can create tools that perform reliably under heavy-duty conditions.

A well-designed chain pulley block not only meets the immediate needs of lifting and material handling but also minimizes downtime, reduces maintenance costs, and ensures long-term safety and reliability in industrial applications.

#chain pulley blocks#industrial equipment#lifting solutions#material handling#chainblockpulley#industrialequipment#ManualChainPulleyHoist#chainblock#chainpulley#ropeandpulley#pulleyblocksystem#hoistingequipment

0 notes

Text

The brand INDOLIFT was founded in 2010 by M/S. PDS Trading & Warehousing Co Pvt Ltd to enter the material handling equipment market. After extensive development and modifications, INDOLIFT successfully launched its Chain Pulley Blocks. This launch was made possible through a collaboration with Hangzhou Jentan Machinery Co Ltd, one of China's largest manufacturers of Chain Pulley Blocks.

#alloy steel chain#d shackles#forged clamps#webbing slings#wire rope company in india#manfacturer#wholesale#chain pulley#pulley blocks#hoist#material handling equipment#lifting solutions

0 notes

Text

Forged Clamps: Elevating Industrial Operations from Construction to Manufacturing

Forged clamps, robust and versatile components in the industrial toolkit, find extensive applications across diverse sectors, contributing to the efficiency, safety, and reliability of various operations. From construction sites to manufacturing facilities, the adaptability and strength of forged clamps make them indispensable for a wide range of industrial applications. In this exploration, we delve into the multifaceted roles of forged clamps in industrial settings, examining their significance in construction, manufacturing, and other key sectors.

1. Construction Industry: Lifting and Securing Heavy Loads

One of the primary applications of forged clamps lies in the construction industry, where the need to lift and secure heavy loads is paramount. Forged clamps, designed to withstand significant loads, play a crucial role in lifting materials such as steel beams, concrete panels, and other construction components. The robust construction and secure gripping mechanisms ensure that these clamps provide a reliable and safe solution for handling substantial weights, contributing to the efficiency of construction projects.

2. Manufacturing Facilities: Rigging and Material Handling

In manufacturing facilities, forged clamps are instrumental in rigging and material handling processes. Whether it's moving raw materials, positioning components on the production line, or securing heavy machinery, forged clamps offer a versatile solution. Their adaptability allows for efficient maneuvering of materials through different stages of the manufacturing process. The precision and strength of forged clamps contribute to streamlined operations, enhancing productivity in manufacturing settings.

3. Shipbuilding and Maritime Operations: Ensuring Stability and Safety

Forged clamps find crucial applications in shipbuilding and maritime operations, where the harsh marine environment demands reliable and durable solutions. These clamps are utilized for securing materials during construction, ensuring stability on ships and offshore structures. The corrosion-resistant properties of forged clamps make them well-suited for withstanding the challenges posed by saltwater exposure, contributing to the safety and longevity of marine structures.

4. Aerospace Industry: Precision in Component Handling

In the aerospace industry, where precision is paramount, forged clamps play a vital role in the handling of intricate components. From securing delicate parts during assembly to providing stability during maintenance procedures, forged clamps contribute to the precision and safety required in aerospace applications. Their strength and reliability make them an integral part of ensuring the quality and integrity of aerospace components.

5. Energy Sector: Rigging Solutions for Power Generation

Forged clamps are extensively used in the energy sector, especially in power generation facilities. Whether lifting heavy machinery in a power plant or securing components in renewable energy installations, forged clamps offer robust rigging solutions. Their ability to handle substantial loads ensures the safe and efficient operation of power generation equipment, contributing to the reliability of energy production.

6. Automotive Manufacturing: Precision in Vehicle Assembly

In the automotive industry, where precision and efficiency are paramount, forged clamps find applications in vehicle assembly. From lifting and positioning vehicle components to securing parts during the manufacturing process, these clamps contribute to the seamless production of automobiles. The adaptability of forged clamps to different shapes and sizes enhances their utility in the dynamic and varied tasks within automotive manufacturing.

The applications of forged clamps in industrial settings are diverse and far-reaching, contributing to the success of projects across construction, manufacturing, shipbuilding, aerospace, energy, and automotive industries. Their strength, adaptability, and reliability make them essential components for lifting, rigging, and securing operations. As industries continue to evolve, forged clamps remain at the forefront, providing versatile solutions that enhance safety, efficiency, and precision in a wide range of industrial applications.

Indolift stands out as a premier manufacturer of Forged Clamps, offering a diverse range of sizes suitable for various industrial applications.

0 notes

Text

#indiasbestchainpulleydealers #bestoffersindia #Qualitychainpulley #trustedsellerchainpulley #chainpulleybestoffersindia #chainpulleyontimeservice #RoadSafetyFirst #chainpulleyspecialoffers #savewater #planttreessavelife #DrugFreeIndia #SaveEnergy #chainpulleydealers #chainpulleymanufacturer #Industrialchainpulleydealers #Industrialchainpulleymanufacturer #Industrialchainpulleydistributer

Also known as chain blocks or chain pulley blocks, chain hoists are used extensively to move heavy loads through chain pulling. While most chain hoists are operated by hand, lever blocks (or ratchet lever hoists) are operated by pulling a manual lever either forward or backward.

So when this gear is not engaged. This gear is a pretty tricky way to get around that a low force and a high travel input goes too low travel high force output

The most significant benefit of having chain pulley blocks is that it offers a mechanical advantage to a user. This means that employees would have to use less effort to lift heavy loads, increasing the overall efficiency of the lifting process.

main advantage in the use of pulleys is that the effort becomes less as compared to the normal lifting of the weights. In other words, it reduces the amount of actual force required to lift heavy objects. It also changes the direction of the force applied.

two types of the Morris chain pulley block. NX model and EX-model chain pulley block. the RS model chain pulley block in capacities ranging from 1 ton to 50 ton. However, these Blocks can be completely customized as per the client's requirement and can also be made in a short-headroom model.

Chain block is used to lift and lower heavy loads vertically, while lever hoist is used to pull and lift in both vertically and horizontally or multi-directional positions. Lever hoist is operated using one hand by cranking the handle/ lever forward or backward

Chain Block, commonly known as a Hand Chain Hoist or Block and Tackle, usually features top and bottom hooks; a static top hook to suspend the hoist from a beam clamp or trolley, and the bottom hook is the lad hook, raised and lowered by simply pulling down on the hand chain, turning the gears inside the hoisting

#indiasbestchainpulleydealers#bestoffersindia#Qualitychainpulley#trustedsellerchainpulley#chainpulleybestoffersindia#chainpulleyontimeservice#RoadSafetyFirst#chainpulleyspecialoffers#savewater#planttreessavelife#DrugFreeIndia#SaveEnergy#chainpulleydealers#chainpulleymanufacturer#Industrialchainpulleydealers#Industrialchainpulleymanufacturer#Industrialchainpulleydistributer#Also known as chain blocks or chain pulley blocks#chain hoists are used extensively to move heavy loads through chain pulling. While most chain hoists are operated by hand#lever blocks (or ratchet lever hoists) are operated by pulling a manual lever either forward or backward.#So when this gear is not engaged. This gear is a pretty tricky way to get around that a low force and a high travel input goes too low trav#The most significant benefit of having chain pulley blocks is that it offers a mechanical advantage to a user. This means that employees wo#increasing the overall efficiency of the lifting process.#main advantage in the use of pulleys is that the effort becomes less as compared to the normal lifting of the weights. In other words#it reduces the amount of actual force required to lift heavy objects. It also changes the direction of the force applied.#two types of the Morris chain pulley block. NX model and EX-model chain pulley block. the RS model chain pulley block in capacities ranging#these Blocks can be completely customized as per the client's requirement and can also be made in a short-headroom model.#Chain block is used to lift and lower heavy loads vertically#while lever hoist is used to pull and lift in both vertically and horizontally or multi-directional positions. Lever hoist is operated usin#Chain Block

0 notes

Text

"SHAKE ME" "IF YOU CAN !" #JCBLiftTech #JCB #jcblovers #JCBIndia #JCBProducts #chainpulleyblock #ratchetleverhoist #electricchainhoist #towstrap #ratchetlashing https://jcblifttech.com/ratchet-lashing/

0 notes