#while lever hoist is used to pull and lift in both vertically and horizontally or multi-directional positions. Lever hoist is operated usin

Explore tagged Tumblr posts

Text

Chain Pulley vs. Lever Hoist: Which One is Right for Your Job?

Chain Pulley vs. Lever Hoist: Which One is Right for Your Job?

Lifting heavy loads is a common challenge in industrial and construction settings. To make the task easier and safer, chain pulleys and lever hoists are two widely used tools. While both serve the purpose of lifting and moving materials, they work differently and are suited for different tasks. Choosing between them depends on factors like effort, load capacity, stability, and precision. This article breaks down the key differences to help you decide which tool is best for your specific needs.

What is a Chain Pulley?

A chain pulley, also called a chain block or manual chain hoist, is a lifting tool that operates using a system of gears, a lifting chain, and a hook. The gear system provides mechanical advantage, allowing users to lift heavy loads with minimal effort. By pulling a hand chain, the load is raised in a smooth and controlled motion, making it an efficient choice for certain lifting applications.

Key Benefits of Chain Pulleys:

Requires less manual effort due to gear-assisted lifting.

Smooth and controlled movement reduces sudden shifts.

Can handle a range of load capacities (typically from 0.5 tons to over 20 tons).

Best for vertical lifting in warehouses, factories, and construction sites.

What is a Lever Hoist?

A lever hoist, also known as a come-along, is a hand-operated tool that lifts and pulls heavy objects using a ratcheting mechanism. Instead of a hand chain, a lever hoist requires the operator to repeatedly push and pull a handle to lift or move a load. These hoists are often used for positioning, pulling, and securing loads in addition to lifting.

Key Benefits of Lever Hoists:

Compact and portable, making them suitable for tight spaces.

Useful for pulling, securing, and adjusting loads in addition to lifting.

Typically designed for lighter loads (up to 5 tons).

Allows for precise load positioning, making it useful in assembly and rigging tasks.

Chain Pulley vs. Lever Hoist: A Side-by-Side Comparison

1. Effort and Efficiency

A chain pulley requires less effort since it uses gears to multiply force. This means a single operator can lift heavier loads without excessive strain. In contrast, a lever hoist requires more manual effort, but this can provide greater control in situations where precise load movement is necessary.

2. Best Applications

Chain Pulley: Best suited for vertical lifting in warehouses, construction sites, and factories.

Lever Hoist: Ideal for pulling, positioning, and securing loads, especially in horizontal applications.

For lifting heavy machinery, steel beams, or industrial equipment, a chain pulley may be more effective, while lever hoists are advantageous when repositioning or securing loads in place.

3. Load Capacity and Stability

Chain pulleys can handle heavier loads, with some models capable of lifting over 20 tons.

Lever hoists generally handle up to 5 tons, but offer greater flexibility in multi-directional movement.

Chain pulleys provide steady, controlled lifting, reducing the risk of sudden shifts, while lever hoists allow more control for incremental adjustments.

4. Safety and Operator Fatigue

Chain pulleys require less continuous physical effort, making them easier on the operator for prolonged use.

Their smooth lifting motion minimizes jerky movements, reducing the risk of injury.

Lever hoists require repeated manual operation, which can lead to fatigue but offers precise handling.

Both tools include built-in safety mechanisms to prevent unexpected load drops when used properly.

5. Maintenance and Durability

Chain pulleys have fewer moving parts, leading to lower maintenance needs in long-term use.

Lever hoists rely on a ratcheting mechanism, which may require more frequent maintenance due to wear over time.

Both tools should be inspected regularly to ensure safe operation.

6. Precision and Control

Chain pulleys provide smooth, stable lifting, making them ideal for:

Construction work (lifting beams into position).

Manufacturing plants (accurate positioning of heavy machinery).

Warehouses (lifting goods onto high racks).

Lever hoists excel in fine-tuned positioning, especially for pulling, securing, and incremental lifting adjustments.

When Might a Lever Hoist Be the Better Choice?

While chain pulleys are excellent for vertical lifting, a lever hoist may be the better tool for:

Working in tight spaces, where a chain pulley system is impractical.

Tasks involving pulling or securing loads rather than just lifting.

Lighter-duty applications (typically under 5 tons).

Situations where precise load positioning is needed, such as aligning machinery parts.

Both tools have their specific roles, and the best choice depends on the task at hand and the work environment.

Which One Should You Choose?

Both chain pulleys and lever hoists are valuable tools in material handling. Chain pulleys are efficient for lifting heavy loads vertically, while lever hoists provide more versatility for pulling, securing, and precise positioning.

When selecting between the two, consider load capacity, ease of use, safety, and precision. The right tool will increase productivity, reduce fatigue, and improve workplace safety, ensuring the job gets done efficiently and securely.

#chain pulley blocks#industrial equipment#lifting solutions#chainblockpulley#chainblock#material handling#pulleyblocksystem#chainpulley#manualchainpulleyhoist#indolift#construction#equipment#lever

0 notes

Text

#indiasbestchainpulleydealers #bestoffersindia #Qualitychainpulley #trustedsellerchainpulley #chainpulleybestoffersindia #chainpulleyontimeservice #RoadSafetyFirst #chainpulleyspecialoffers #savewater #planttreessavelife #DrugFreeIndia #SaveEnergy #chainpulleydealers #chainpulleymanufacturer #Industrialchainpulleydealers #Industrialchainpulleymanufacturer #Industrialchainpulleydistributer

Also known as chain blocks or chain pulley blocks, chain hoists are used extensively to move heavy loads through chain pulling. While most chain hoists are operated by hand, lever blocks (or ratchet lever hoists) are operated by pulling a manual lever either forward or backward.

So when this gear is not engaged. This gear is a pretty tricky way to get around that a low force and a high travel input goes too low travel high force output

The most significant benefit of having chain pulley blocks is that it offers a mechanical advantage to a user. This means that employees would have to use less effort to lift heavy loads, increasing the overall efficiency of the lifting process.

main advantage in the use of pulleys is that the effort becomes less as compared to the normal lifting of the weights. In other words, it reduces the amount of actual force required to lift heavy objects. It also changes the direction of the force applied.

two types of the Morris chain pulley block. NX model and EX-model chain pulley block. the RS model chain pulley block in capacities ranging from 1 ton to 50 ton. However, these Blocks can be completely customized as per the client's requirement and can also be made in a short-headroom model.

Chain block is used to lift and lower heavy loads vertically, while lever hoist is used to pull and lift in both vertically and horizontally or multi-directional positions. Lever hoist is operated using one hand by cranking the handle/ lever forward or backward

Chain Block, commonly known as a Hand Chain Hoist or Block and Tackle, usually features top and bottom hooks; a static top hook to suspend the hoist from a beam clamp or trolley, and the bottom hook is the lad hook, raised and lowered by simply pulling down on the hand chain, turning the gears inside the hoisting

#indiasbestchainpulleydealers#bestoffersindia#Qualitychainpulley#trustedsellerchainpulley#chainpulleybestoffersindia#chainpulleyontimeservice#RoadSafetyFirst#chainpulleyspecialoffers#savewater#planttreessavelife#DrugFreeIndia#SaveEnergy#chainpulleydealers#chainpulleymanufacturer#Industrialchainpulleydealers#Industrialchainpulleymanufacturer#Industrialchainpulleydistributer#Also known as chain blocks or chain pulley blocks#chain hoists are used extensively to move heavy loads through chain pulling. While most chain hoists are operated by hand#lever blocks (or ratchet lever hoists) are operated by pulling a manual lever either forward or backward.#So when this gear is not engaged. This gear is a pretty tricky way to get around that a low force and a high travel input goes too low trav#The most significant benefit of having chain pulley blocks is that it offers a mechanical advantage to a user. This means that employees wo#increasing the overall efficiency of the lifting process.#main advantage in the use of pulleys is that the effort becomes less as compared to the normal lifting of the weights. In other words#it reduces the amount of actual force required to lift heavy objects. It also changes the direction of the force applied.#two types of the Morris chain pulley block. NX model and EX-model chain pulley block. the RS model chain pulley block in capacities ranging#these Blocks can be completely customized as per the client's requirement and can also be made in a short-headroom model.#Chain block is used to lift and lower heavy loads vertically#while lever hoist is used to pull and lift in both vertically and horizontally or multi-directional positions. Lever hoist is operated usin#Chain Block

0 notes

Text

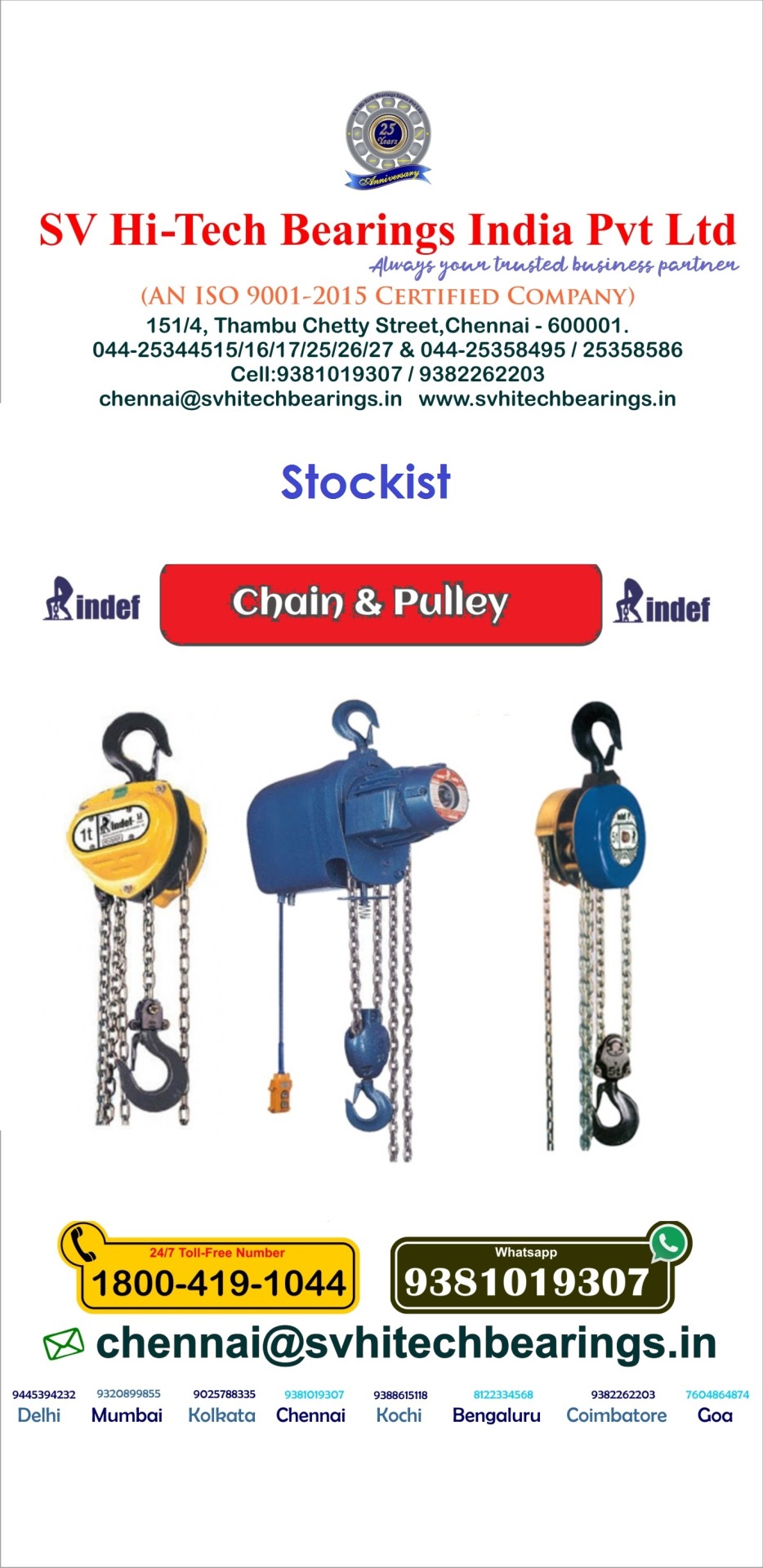

chain pulley block dealers in Chennai

Chain Pulley Block, Advantages and Lifting Loads

The chain pulley block is a tool that uses chains to raise and lower heavy objects. Two wheels with chains wrapped around them move. When the chain is pulled, it wraps around the wheel and begins to lift the object attached to the rope or chain with the hook.

Chain blocks are a very versatile method of lifting loads and are primarily operated by pulling chains by hand. We recommend lifting the item slightly off the ground first to make sure the load is balanced and everything is working properly. Always pull gently on the chain to prevent it from pulling or tangling during the lift. Are searching for reliable and efficient chain pulley block dealers in Chennai?

Chain Hoist Vs Chain Block

Both chain blocks and chain hoists are widespread usein different industries, from factories and retail stores to agriculture and construction. The difference between the two devices is in how they are used.

Chain blocks are powered by pulling hand chains and are commonly used to lift heavy loads vertically off the floor, while chain hoists use the rotational motion of a lever to manipulate heavy loads horizontally. Chain blocks also have the advantage of requiring no electricity in most cases, making them an indispensable tool for work in remote areas or where there is little or no electricity.

Advantages of Chain Pulley Block

· Lightweight and sturdy

· Easy installation because of its compact size

· Exact matching of chain and chain sprocket Pockets

· Suitable for Indoor and Outdoor Applications

· Easy to maintain

· low Headroom

· Pocket friendly

· Available in varied capacities as per IS standard

· Highly accurate hardened Gears

Other Important Details of Pulley Block

· Light, strong and easy to handle

· Long lubrication life and low maintenance requirements

· Hard faced gears and long life

· Uses needle bearings to improve work efficiency

· Smooth load chain passage and machined guide rollers

· Smooth hand chain operation and unique cover design

· Anti-rust coating finish and great aesthetics

𝐓𝐢𝐫𝐮𝐬𝐮𝐥𝐖𝐢𝐫𝐞𝐑𝐨𝐩𝐞&𝐋𝐢𝐟𝐭𝐢𝐧𝐠𝐆𝐞𝐚𝐫𝐬𝐏𝐯𝐭𝐋𝐭𝐝 is one of the best chain pulley block dealers in Chennai providing a range of Industrial Lifts. The products we supply and distribute are made from the highest quality raw materials using the latest tools and techniques. The chain roller block supplied by our company features top quality, durability, long service life, and strong and competitive price, and is in high demand in the market, creating a niche in the market. We source our products from top suppliers that meet the various requirements of our customers.

0 notes