#Loose Flanges Manufacturers

Explore tagged Tumblr posts

Text

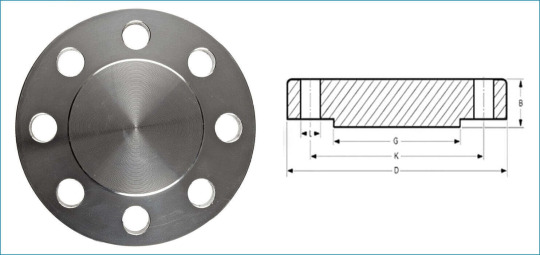

Loose Flanges

ASME B16.5 Loose flanges types to fit elbows, valves and all things considered for such a pipeline part being utilized. Carbon Steel Loose flanges is a contraption that is welded onto the complete line to make half of a flanged coupling. Containing level steel passing on with puzzle openings around the edge and an opening in the center the size of the line that should have been welded onto spread out steel Loose flanges, the part can be made of carbon steel or Stainless steel to meet the proposed application.

ASME B16.5 Loose Flanges makers in UAE. We are dispatching SS Loose Flanges, Loose Exhaust Flanges, EN 1092-2 PN16 Loose plate flanges and Loose Plate Flanges at bound costs thinking about reasonable master hours in UAE and critical wellspring of first in class ASME B16.47 Series a Loose Flanges, most extremely savvy game plan, cost open in Dubai, India.

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. We have worked with stores of Quarrel 2642 Loose flanges, PN10 Loose Flanges, EN1092-1 Loose Flanges and jis 10k Loose Flanges, a very smart arrangement, worth once-over in UAE. Stainless Steel Loose Flanges is admitted by Saudi Aramco. We keep up the beast proficiently of MSS SP-44 SS Loose Line Flange. Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a scientist and transporter of Duplex Steel Loose hubber flanges, Racket 86029 PN10 Loose hubber flanges in various sizes.

Stacking massive level of ASTM A350 Gr LF2 Loose Flanges to buy, most extremely savvy plan, cost in UAE, enquire our expense of Carbon Steel Loose Flanges including Level Face Loose Flanges, AWWA C207 Loose steel Flanges and ASME B16.5 Class 300 Loose Flanges. Loose Line Flanges to Thailand, Russia, Kuwait, France, Australia, Malaysia, USA, Iran, Italy, Sweden, Egypt, Bahrain, Turkey, UAE, Germany, Qatar, Singapore, Indonesia, UK, Israel, Oman, Canada, Sri Lanka and Saudi Arabia.

We are the clearest giving relationship of ASTM A105 Loose Flanges, most exceptionally savvy game plan, cost as we are one of the most shocking supplier and carrier of Blend steel Loose Flanges in UAE. We have our stocking wholesalers in Delhi, Bangalore, Surat (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our ASTM B381 F5 Loose Flanges cost going before buying Shaped Loose Strain Driven Flanges from India or China. Other than mail for our live deftly of Hastelloy Loose Sae Flanges to check types and sizes, with our set up stock we can give you best expense of EN 1092-1 Sort 02 Carbon Steel Loose Flanges.

We can nearly give free event of ASME B16.5 Free Flange,Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is having our Seller and Trader in Aurangabad, Kolkata, Faridabad, Ludhiana, Chennai (Madras), Chhattisgarh, Vadodara, Tamil Nadu, Pune, Ahmedabad, Maharashtra, Nagpur,Bangalore, Punjab, Rajkot, Delhi, West-Bengal, Khopoli, Raipur, Indore, Haryana, Gujarat, Uttar Pradesh, Jaipur, Rajasthan, Karnataka, Ghaziabad, Gurgaon, Kolhapur, Bhosari, Madhya Pradesh, Karnataka. So assuming you are searching for best cost of BS 4504 PN10 Split free or ASME B16.47 Series b Free Rib, Solidified Steel Free Spine close to you with briefest time improvement or free event of ANSI b16 5 Free Rib.

0 notes

Text

Hydraulic Manifold valve manufacturer in india by hydrofittings

In addition, an Air Manifold With Valves allows the set up of more than one solenoid valves in a centralized vicinity. A unmarried air deliver and port are shared by means of numerous valves. Manifold take a look at Valve acts as a primary distribution point for aircraft that have dual dry air pumps. If one pump of Manifold Pneumatic fails it’s miles designed to isolate the failed pump and provide continuous airflow from the operating pump. Water Manifold With Valves is designed to distribute water and has built-in ports in a section of pipe. They act as manage facilities of water distribution within the house. Solenoid Valve Manifold has a most preferred stress of 6000 psi at a hundred ranges F and has a mounting hollow that enables inside the self-supporting software. Hydraulic Valve Manifold Has a stainless steel pin that forestalls the bonnet from detaching itself from the frame due to vibration. Ball Valve Manifold has a burr-loose thread that reduces inner floor leaks accordingly offering accurate transmitter read. No O-ring is used bonnet to body pressure Transmitter Manifold seal. It is a steel-to-metallic seal. Hydraulic Valve Manifold Block has the choice of panel mounting. There are one of a kind sorts of Manifold Valves to be had within the market but the maximum typically used ones are the two valve, three valve, and 5 valve assemblies. Swagelok Manifold is designed mainly for liquid stage, static stress, and differential stress packages. Smc Valve Manifold has a blended isolating and venting in a single valve that eliminates the want for tubing and fitting. Festo Valve Manifold is simple to gather and set up and is dependable. They’ve dirt caps fitted on them that comprise stem lubricant and save you the ingress of contaminants. Rosemount 305 Manifold gets rid of the need for a flange because it suits immediately to the patented Rosemount. Why to choose hydrofittings ? About us – The briefcase of our company consists of numerous additions which include, – clever hydraulics, engineering, and digital answers. With the guide of 80 personnel, our company works like a well-oiled system to deliver most effective the very best fine product to our buyers. Proper from the responsibly sourced product by way of our procurement team to our nice manage team, many agencies have lauded our work. And that they admire the fact that we’re transparent in all our dealings. With a properly-mounted channel of communique, our customers can connect with us anytime. Our control and our body of workers, together form a competent and ambitious crew. The readability and high stage of performance make us one of the most modern but sought after manufacturers. And because we fee initiative behavior, we adore to have our studies and development crew collaborate with the opposite teams to recognize the current requirements of the hour. We frequently have checking out and great exams to maintain brilliant requirements.

An global provider of

TO KNOW MORE ABOUTS US VISITE OUR WEBSITE www.hydrofittings.com

3 notes

·

View notes

Text

All That You Should Know About 2 Way Lock Nuts

Introduction

In fasteners, one must ensure that there is no looseness in connection. One such minute yet significant part that can achieve this is the 2 Way Lock Nut. These specialized nuts are not designed to allow loosening when under vibration or torque. These are very important in many applications. This blog goes into what 2 Way Lock Nuts are, how they work, advantages, and their applications.

What are 2 way lock nuts?

2 Way Lock Nuts, also known as reversible lock nuts, are self-locking nuts designed to resist loosening without the aid of any extra parts such as washers or adhesives. The term "2 Way" indicates that they can be installed from either side, thus making them more versatile than conventional lock nuts. They usually have an oval or elliptical distortion at one end that creates friction when threaded onto a bolt.

How Do They Work?

The functionality of the 2 Way Lock Nut relies upon its special design. Once threaded onto a bolt, the nut exerts pressure upon the threads of the bolt. Such pressure increases the frictional resistance; the nut won't vibrate loose. This is an effective lock in both directions, thus earning it the "2 Way" designation.

Unlike regular nuts, these lock nuts do not depend on the torque provided at installation. Their self-locking feature sustains friction independently that keeps the nut tight regardless of the conditions.

Advantages of 2 Way Lock Nuts

1. Easy Installation

Can be screwed from either side. There is no specific orientation of the nut as required with regular nuts.

2. Increased Security

Offers dependable resistance against loosening caused by vibrations or dynamic loads.

3. Cost-Effective

Eliminates the requirement for extra parts like lock washers or thread-locking adhesives.

4. Reusability

Can be used multiple times without losing much of the locking force, unlike certain adhesive-based products.

5. Durability

Manufactured from strong materials such as stainless steel or high-strength alloys, so it can last longer even in the most adverse conditions.

Applications of 2 Way Lock Nuts

2 Way Lock Nuts are used in many industries because of their versatility and reliability. Some of the applications include:

1. Automotive Industry

Lock nuts are utilized to secure essential components like engine mounts, suspension systems, and exhaust assemblies.

2. Construction and Infrastructure

Lock nuts are used in structural assemblies and machinery that are exposed to vibration and dynamic forces.

3. Aerospace Industry

Lock nuts are used in applications where vibration resistance is critical, such as in aircraft engines and fuselage assemblies.

4. Industrial Machinery

The fastening should be secure in any machinery parts even during heavy-duty operations.

5. Products for Consumers

Available in house-hold appliances, furniture and sporting equipment for fastening to secure the appliance in place

Types of 2 Way Lock Nuts

1. Metal Lock Nuts

Locking occurs in this due to a deformation of a particular part. Suitable for high-temperature applications and extreme load conditions.

2. Nylon Insert Lock Nuts

Insert a nylon collar, which aids grip. Useful where the vibration level is moderate.

3. Flanged Lock Nuts

Have a built-in washer-like flange that distributes load and reduces the risk of loosening.

Installation Tips

Choose the Right Size: Ensure the nut matches the bolt diameter and thread pitch for optimal performance.

Apply Proper Torque: Follow manufacturer recommendations to avoid over-tightening or under-tightening.

Inspect Threads: Ensure threads on both the nut and bolt are clean and undamaged for a secure fit.

Reuse with Caution: While reusable, inspect the nut for wear after multiple uses to ensure continued effectiveness.

Conclusion

2 Way Lock Nuts are a testament to how small components can have a significant impact on the reliability and safety of assemblies. Their self-locking mechanism, ease of use, and versatility make them indispensable in a wide range of applications. Whether you’re working on an industrial project or a DIY task at home, understanding the benefits and proper usage of 2 Way Lock Nuts can help ensure your work stands the test of time.

FAQ

1. What makes 2 Way Lock Nuts different from standard nuts?

Unlike standard nuts, 2 Way Lock Nuts have a self-locking mechanism that prevents loosening due to vibration or dynamic loads.

2. Can 2 Way Lock Nuts be reused?

Yes, they can be reused multiple times, but it is recommended to inspect them for wear after each use to ensure effectiveness.

3. Do I need additional components like washers with 2 Way Lock Nuts?

No, they are designed to work independently, eliminating the need for additional components such as washers or adhesives.

4. Are 2 Way Lock Nuts suitable for high-temperature environments?

Yes, especially metal lock nuts, which are ideal for high-temperature and heavy-duty applications.

5. How do I select the right type of 2 Way Lock Nut for my application?

Take into account the environment, load requirements, and vibration levels. For moderate vibrations, opt for nylon insert lock nuts, while metal lock nuts are better suited for extreme conditions.

6. Can they be installed using standard tools?

Yes, standard wrenches or socket tools can be used for installation.

7. What materials are 2 Way Lock Nuts made from?

Common materials include stainless steel, high-strength alloys, and nylon for insert types.

8. Are there size limitations for 2 Way Lock Nuts?

They come in a variety of sizes to accommodate different bolt diameters and thread pitches.

#Ananka#fasteners#manufacturer#anankafasteners#2waylocknut#locknut#nut#article#linkedin#blog#locknuts#fastenersmanufacturer#supplier#mumbai#hex#bolt#usa#uk

0 notes

Text

Hastelloy C22 Flanges: Meeting the Demands of India’s Industrial Standards

In India’s swiftly evolving commercial business enterprise, the call for strong, long lasting, and corrosion-resistant substances has in no way been higher. Hastelloy C22 flanges have emerged as an important thing for various industries, imparting unrivaled performance in disturbing environments. From chemical processing plant life to energy era facilities, the ones flanges meet stringent industrial necessities in India, making them a desired choice for crucial programs. With their functionality to stand as a good deal as aggressive chemical materials, intense temperatures, and as an alternative corrosive environment, Hastelloy C22 flanges are vital for making sure reliability and performance in Indian industries.

The Importance of Industrial Standards in India

Industrial standards in India, together with the ones set by ISI (Indian Standards Institute), ASME (American Society of Mechanical Engineers), and ASTM (American Society for Testing and Materials), play a pivotal function in making sure the safety, ordinary standard overall performance, and reliability of substances utilized in vital infrastructure. These necessities outline parameters like cloth composition, tensile power, pressure ratings, and corrosion resistance to guarantee outstanding. Hastelloy C22 flanges are artificial to paste to these stringent benchmarks, providing peace of thoughts to engineers and selection-makers inside the Indian commercial region.

Why Hastelloy C22 Flanges Are Ideal for Indian Industries

Hastelloy C22 is a nickel-chromium-molybdenum alloy with wonderful resistance to pitting, crevice corrosion, and pressure corrosion cracking. This makes it a best preference for flanges utilized in India’s harsh organization environments, collectively with chemical processing plants, pharmaceutical production, and wastewater remedy facilities. Unlike known stainless-steel flanges, Hastelloy C22 flanges for Indian industries can undergo extended publicity to oxidizing and reducing dealers, ensuring durability and reduced upkeep charges.

India’s industries frequently face unique demanding conditions, which includes immoderate humidity, variable pH tiers, and publicity to harsh chemical materials. Hastelloy C22 flanges excel in such conditions due to their advanced corrosion resistance and capability to keep mechanical integrity below stress. This makes them specially precious for industries that rely upon steady, leak-loose connections in piping structures.

Compliance with Indian Industrial Standards

Hastelloy C22 flanges are artificial with strict adherence to Indian and global requirements, making sure they meet all regulatory requirements. These flanges are designed to comply with ASME B16.5, ASME B16.47, and ASTM requirements, masking dimensions, stress scores, and fabric specifications. In addition, their ordinary overall performance trends align with the desires of the Bureau of Indian Standards (BIS), making them a dependable desire for crucial applications in the Indian marketplace.

Furthermore, those flanges go through rigorous high-performance flanges India, along with hydrostatic checks, radiographic inspections, and fabric composition analyses, to ensure compliance. This focus on superb control guarantees that Hastelloy C22 flanges provide steady typical performance in India’s disturbing enterprise conditions.

Applications of Hastelloy C22 Flanges in India

Hastelloy C22 flanges are notably applied in numerous Indian industries because of their immoderate-normal usual performance skills:

Chemical Processing: Indian chemical plants depend upon substances which could face up to competitive acids and bases. Hastelloy C22 flanges offer fantastic protection towards corrosion due to sulfuric acid, hydrochloric acid, and extraordinary chemical materials.

Pharmaceutical Manufacturing: The pharmaceutical location calls for hygienic and corrosion-resistant substances. These flanges make sure clean and dependable connections, crucial for maintaining product integrity.

Oil and Gas: In offshore and onshore packages, Hastelloy C22 flanges excel in resisting saltwater corrosion and sulfide pressure cracking, making them a pass-to opportunity for Indian oil and gasoline infrastructure.

Water Treatment Plants: As India focuses on sustainable water management, Hastelloy C22 flanges are instrumental in handling corrosive wastewater and desalination methods.

Power Generation: Power plants, particularly those utilizing renewable and thermal power, enjoy the durability and heat resistance of Hastelloy C22 flanges.

Key Features of Hastelloy C22 Flanges

Exceptional Corrosion Resistance: Protects towards pitting, crevice corrosion, and strain corrosion cracking.

High Durability: Maintains structural integrity under extreme stress and temperature.

Versatile Applications: Suitable for diverse industries, from prescribed drugs to electricity technology.

Compliance with Standards: Adheres to ASME, ASTM, and BIS specs for dependable general overall performance.

Cost-Effective: Reduces protection and downtime, ensuring lengthy-time period economic financial savings.

Choosing the Right Hastelloy C22 Flanges

When selecting Hastelloy C22 flanges for your commercial responsibilities in India, it is important to take into account factors like strain magnificence, flange kind, and material certification. Partnering with a depended on provider like Sailesh Metal ensures admission to splendid raw materials that meet both assignment specifications and organization guidelines. With a strong stock and a self-control to excellence, Sailesh Metal gives customized solutions for all of your industrial agency flange requirements.

In conclusion, Hastelloy C22 flanges are an important asset for Indian industries striving to meet stringent enterprise requirements and cope with corrosive environments. Their terrific performance, durability, and compliance with policies reason them to a dependable preference for critical infrastructure across sectors. Whether it’s chemical processing, energy era, or water remedy, the ones high-normal normal performance flanges are designed to assist India’s business growth even as making sure protection and efficiency. Choose Sailesh Metal for top price-top notch Hastelloy C22 flanges tailored to meet the unique needs of Indian industries.

0 notes

Text

Carbon Steel A182 Flanges Stockists In India

Introduction:-

Carbon Steel A182 flanges are widely used in industries for connecting pipes, valves, pumps, and other equipment to form a piping system. These flanges are manufactured from carbon steel and conform to the ASTM A182 standard, which specifies forged or rolled alloy and stainless steel pipe flanges, fittings, and valves.

Carbon Steel A182 flanges are essential components in piping systems, used to connect pipes, valves, pumps, and other equipment. Manufactured from high-quality carbon steel, these flanges comply with the ASTM A182 standard, which ensures their reliability and suitability for high-pressure and high-temperature applications across a variety of industries. Their durability and cost-effectiveness make them a preferred choice in demanding environments like oil and gas, petrochemical, and power generation sectors.

Product Overview:-

A182 Carbon Steel ASTM flanges are used in high temperature applications such as: B. For stainless steel pipe flanges, valves, forged fittings and rolled alloys. Also suitable for low corrosion applications.

ASTM A182 steel is the standard specification for forged or rolled alloys, stainless steel pipe flanges, and all types of parts and valves for high temperature service.

A182 Carbon Steel ASTM flanges are manufactured with ideal chemical experiments and connections and will not wear out quickly.

Specifications:-

ASME/ANSI B 16.5A182 F92 Welding Neck Flange, A182 F92 Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, A182 F92 Lap Joint Flange, Threaded Flange, A182 F92 Ring Type Joint FlangePRESSURE CLASS150, 300, 400, 600, 900, 1500, 2500ASME/ANSI B 16.47A182 F92 Welding Neck Flange, A182 F92 Blind Flange [Series A & B]PRESSURE CLASS75, 150, 300, 400, 600, 900ASME/ANSI B 16.36A182 F92 Welding Neck Flange, A182 F92 Slip on Flange, A182 F92 Threaded FlangePRESSURE CLASS300, 400, 600, 900, 1500, 2500BS 4504 SEC 3.1A182 F92 Welding Neck Flange, A182 F92 Hubbed Slip on Flange, A182 F92 Hubbed Threaded Flange, Lapped Pipe End Flange, A182 F92 Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank FlangePRESSURE CLASSPN 2.5 TO PN 40BS 4504[PART 1]A182 F92 Welding Neck Flange, A182 F92 Hubbed Slip-On Hubbed Threaded, Plate Flange, A182 F92 Loose Plate With Weld On Plate Collar, Blank FlangePRESSURE CLASSPN 2.5 TO PN 400BS 1560 BOSSA182 F92 Welding Neck Flange, Socket Welding Flange, A182 F92 Slip-On Flange, A182 F92 Blind Flange, A182 F92 Screwed Boss Flange, A182 F92 Lapped FlangePRESSURE CLASS150, 300, 400, 600, 900, 1500, 2500BS10A182 F92 Welding Neck Flange, A182 F92 Plate Slip-On Flange, A182 F92 Screwed Boss Flange, Slip-On Boss Flange, A182 F92 Blind FlangeTABLED, E, F, HDIN FLANGESDIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673PRESSURE CLASSPN 6 TO PN 100

Benefits:-

This grade of Carbon Steel ASTM flanges is used for stainless steel pipe flanges, rolled alloys, forged pipes, valves, forged fittings, and other high temperature applications. A182 Carbon Steel ASTM flange is one of the results of the best chemical experiments and good connections. These flanges don’t wear out as quickly. Widely used in petroleum industry, chemical industry, paper industry and many other industries. Due to its properties, this type of flange is one of the most reliable products that can be used for a long time and does not require repairs immediately after installation. You can trust blindly the durability of this product if you buy it from the right place.

Conclusions:-

Carbon Steel A182 flanges are a reliable and versatile solution for various industrial piping systems, offering exceptional strength, durability, and cost-efficiency. Their compliance with ASTM A182 standards ensures superior performance in high-pressure and high-temperature environments. With a wide range of types available, these flanges are suitable for applications across industries such as oil and gas, petrochemical, power generation, and water treatment. Proper selection, installation, and maintenance of A182 flanges ensure long-lasting and efficient system performance, making them an invaluable component in modern engineering projects.

Email Id:[email protected]

Contact Number:-+918879709191

#manufacturers#industries goods and services#suppliers metals#carbon steel astm a105 flanges exporters

0 notes

Text

Undercarriage Maintenance For Equipment

Two keys to benefiting from solid undercarriages are a thorough, proactive way to deal with preventive maintenance and following accepted functional procedures. Utilize the undercarriage maintenance tips for heavy equipment below to safeguard the machines in your fleet and your primary concern.

The condition of a machine’s undercarriage effectively affects its exhibition and lifespan. An undercarriage that is all around focused on expanding power, stability, and safety while at the same time limiting the operational costs of the heavy equipment throughout its life.

Basic Preventive Undercarriage Maintenance For Equipment

Check undercarriages daily. Operators should intently analyze the undercarriage of their equipment consistently. Search for issues like damage and uneven or extreme wear (remembering for the drive sprockets and trackpads), development of soil or garbage, and missing parts or components. Additionally, search for appropriate clearance between the track chain and the idler roller. Harm and wear might demonstrate or immediately lead to more significant, more convoluted, costlier issues with the gear.

Please look at track tension every day, ideally while the gear is in its functioning conditions. Assuming that tracks are tighter than they should be, it will wear on parts and brings down power and fuel efficiency. If tracks are excessively loose, they likewise prompt component wear, add to instability and set off track derailing. Change the sag to the manufacturer’s suggested measurement for each piece of heavy equipment. Remember that sand, mud, and snow can cake undercarriage and increment tension. While working in these circumstances, check the tension more often if working circumstances change during the day.

Clean the undercarriage toward the end of each day.

Solidified soil, debris, snow, and other material can build track tension, influence component function, and negatively affect the state of the undercarriage in various ways. What’s more, these issues rapidly and effectively compound if they’re not tended to. Therefore, day-by-day cleaning is a fundamental piece of preventive maintenance and is significantly more basic in below-freezing conditions when substances can freeze up inside the track.

Guarantee appropriate track alignment. Nothing can play with undercarriage parts like track misalignment. Safeguard the equipment’s track links, track and carrier roller flanges, idler flanges, sprockets, and rock guards from unjustifiable wear and harm by watching out for track alignment.

Keep all OEM-suggested care rules and maintenance schedules. This step is essential to keeping undercarriage in the ideal shape and to getting and resolving creating issues before they become more genuine. Also, be significantly more persistent with heavy equipment that works in particularly demanding conditions or where material frequently develops undercarriage.

#constructionequipment#heavyequipment#heavydutyequipment#motor grader#heavyequipmentforsale#skid steer

0 notes

Text

Handwash and Sanitizer Mixer

youtube

Handwash and Sanitizer Mixer (liquid mixer machine) including Handwash Mixing Machine is uses for mixing handwash and sanitizers. Assembly equipped with series of paddle types blades, pitched or flat blade of appropriate shape. In Mixer two consecutive blades move in opposite direction which creates laminar thinning of the material and facilitates uniform mixing. Paddle type blades mounted on scrapping arms and welded to hollow shaft have independent drive. Bottom support to the shaft called piyot provided for firmness of shaft during rotations. Paddles mounted on internal shaft & hollow shaft rotates in anti-clockwise & clockwise direction respectively. Paddles mounted on internal shaft creates relative movement of the material. For discharge of material different types of valves can be offered as per user requirements. Flush bottom type valve can be offered for minimum residual within vessel.

Handwash Mixers (vacuum operated models) are produces to withstand perfect vacuum during the process for optimum mixing and to eliminate air trap as surfactant has tendency of forming suds. Sanitizer mixer is having shell of suitable thickness steel with a hemispherical bottom and flanged/loose lid top made out of S.S. 304 plate. There is provision of bottom entry homogenizer in the same vessel which homogenizes all ingredients & hence there is no need to go for external inline homogenizer otherwise problem of aeration will increase process time. Vacuum operated shampoo mixer is suitable for 700mm vacuum and internal pressure of 2.5 kg/cm2.

Adinath is manufacturer of handwash mixer and sanitizer making machine in India. Our range consist Standard Handwash Mixer as well as Vacuum Operated Sanitizer Mixer. We produce these vessels in capacity ranging from 10 liters Small Handwash Mixer to 20000 liters Industrial Handwash Mixer.

#liquid mixer machine#Handwash Mixing Machine#Handwash Mixers#handwash mixer and sanitizer making machine#Youtube

0 notes

Text

How to Fix a Leaking Shower: A Complete Guide

A leaking shower is not only annoying; it can also lead to water damage, mold growth, and higher water bills. Fortunately, fixing a leaking shower can often be done with a few basic tools and a little DIY know-how. This guide will walk you through identifying the cause of your shower leak and offer solutions for fixing it.

1. Identify the Source of the Leak

Before you start any repairs, it’s essential to determine where the water is coming from. Common sources of shower leaks include:

Showerhead: Drips from the showerhead after the water is turned off.

Faucet Handles: Water leaking from around the handles when the shower is on.

Tiles and Grout: Leaks through damaged tiles or cracked grout.

Drain: Water pooling around the drain or seeping through the floor below.

Pipe Connections: Leaks behind the wall from loose or damaged pipes.

2. Turn Off the Water Supply

Before performing any repairs, make sure the water supply is off. You can usually turn it off at a valve near the shower or the main water supply.

3. Repair a Leaky Showerhead

If your showerhead is dripping:

Remove the Showerhead: Unscrew it from the shower arm using a wrench or pliers (protect the finish with a cloth to avoid scratches).

Clean Mineral Buildup: Use vinegar to dissolve any mineral deposits in the showerhead, which may prevent a proper seal.

Replace the Washer or O-Ring: If the washer inside the showerhead is worn, replace it with a new one. These are available at most hardware stores.

Apply Teflon Tape: Wrap Teflon tape around the shower arm threads before screwing the showerhead back on to ensure a watertight seal.

Test for Leaks: Turn the water back on to see if the leak is resolved.

4. Fix a Leaking Shower Faucet

Water leaking from the faucet handle when the shower is on may mean a faulty valve or worn-out cartridge.

Remove the Faucet Handle: Use a screwdriver to take off the handle. Some handles may have a cap that covers the screw.

Replace the Cartridge or Washer: Inside the valve, you may find a cartridge or washer. If it looks worn, replace it. You may need a cartridge puller to remove it.

Reassemble the Faucet: Put everything back together, turn the water on, and check for leaks.

5. Repair Cracked Tiles and Grout

Leaks behind tiles or through grout can allow water to seep into walls and cause extensive damage.

Inspect for Cracks: Look for any damaged tiles or cracks in the grout.

Remove Old Grout: Use a grout removal tool to remove damaged grout around the tiles.

Reapply Grout: Mix fresh grout and apply it to the joints, ensuring all cracks and spaces are filled.

Seal the Grout: Once it dries, apply a grout sealant to prevent future water penetration.

6. Seal Around the Shower Door

If your shower door frame has a leak, it could be due to broken seals or loose caulking.

Inspect Caulking and Seals: Look for any gaps or cracks in the caulk around the door.

Remove Old Caulk: Use a caulk remover tool to scrape away old, worn-out caulk.

Apply New Caulk: Choose a waterproof silicone caulk and apply a thin bead around the frame, smoothing it with a damp finger for a clean finish.

Let It Dry: Allow the caulk to cure according to the manufacturer’s instructions before using the shower.

7. Check and Repair the Shower Drain

Drain leaks can occur if the drain assembly or seals are worn.

Inspect the Drain: Remove the drain cover and check for any signs of corrosion or loose fittings.

Tighten or Replace Drain Parts: Use a drain wrench to tighten the drain assembly, or replace it if damaged.

Apply Plumber’s Putty: Place plumber's putty around the drain flange and screw it back into place to create a watertight seal.

8. Fixing Leaks Behind the Wall

If water is leaking behind the wall, you may notice damp spots, mold, or peeling paint.

Turn Off the Water: Ensure the water is off before attempting to open the wall.

Access the Pipes: Carefully cut into the drywall to access the plumbing behind it.

Inspect the Pipes: Look for signs of corrosion or loose fittings.

Replace Damaged Pipes or Fittings: If any parts are damaged, replace them with new components.

Patch the Wall: Once the leak is fixed, repair the drywall and repaint.

9. Prevent Future Leaks

Inspect Regularly: Check shower components every few months.

Clean and Maintain: Regularly clean showerheads and remove mineral buildup.

Apply Sealants and Caulk: Reseal grout and caulk areas periodically to maintain a watertight shower.

0 notes

Text

How To Fix Cracks in Concrete

Cracks in concrete vary from minor hairline fractures to severe structural concerns. While some are merely cosmetic, others can weaken your foundation and allow groundwater, insects, and radon gas to infiltrate. Here’s a clear method to patch these cracks using concrete crack filler.

Concrete cracks arise for many reasons. Below are common types:

Hairline cracks are thin, surface-level issues, usually under 1/8 inch wide. These occur from freeze-thaw cycles or stress due to heavy loads. Though they rarely affect structural integrity, addressing them promptly prevents water infiltration that could worsen over time.

Crazing happens when concrete dries too quickly before curing, creating a spiderweb pattern. Though it doesn’t threaten stability, it can trap dirt and moisture and appears unsightly.

Settlement cracks occur when the ground beneath concrete shifts unevenly. Monitoring these is crucial, as they can indicate possible issues with your foundation.

Structural cracks are wider and deeper, signaling serious concerns, such as tree root invasion or an unstable foundation. Immediate action is recommended for these types.

Before starting concrete crack repair, preparation is key for durable results. Clean the area thoroughly, using a wire brush and vacuum to remove any loose concrete, paint, or old filler. This step promotes better adhesion for the repair material.

Measure the crack's width and depth carefully to determine the necessary amount of filler. For cracks wider than 1/4 inch or those penetrating the entire slab, seeking professional repair may be advisable.

For minor cracks, homeowners can often manage repairs with widely available products, keeping it affordable and convenient.

Concrete caulk is ideal for small hairline cracks or horizontal surfaces without substantial weight. Apply it with a caulk gun and smooth it with a putty knife, then allow it to cure as the manufacturer specifies.

For small to midsize cracks, epoxy filler provides a strong, lasting repair. Mix the epoxy per instructions, apply it carefully into the crack with a putty knife, smooth the surface, and allow full curing before use.

For larger or deeper concrete cracks, using injection ports can be highly effective. This approach combines surface sealing with deep filler injection for comprehensive repair.

Check that the crack is dry before starting. If damp, use a blow-dryer and wait 15 minutes. If moisture persists, let the crack dry naturally before proceeding.

Clean the crack again, ensuring no loose material remains, using a wire brush and vacuum. Dust-free surfaces enable optimal adhesion.

Align injection ports by tapping in 3-inch finishing nails spaced 1 foot apart along the crack. This helps position the ports accurately.

Prepare the sealer by mixing its components until the color is uniform on a scrap board. A consistent texture is essential for effective application.

Attach the injection ports by applying a bit of sealer to the base and keeping the hole clear. Slide each port over a nail, pressing firmly against the wall, repeating for each port.

Spread sealer along the entire crack, creating a layer about 1/8 inch thick and extending around 1 inch on each side. Cover each port’s flange, leaving only the neck visible, and smooth the edges.

Check the opposite side of the wall for any through-cracks, applying sealant as needed. Allow the sealant to cure for 6–10 hours before moving to the next step.

For epoxy injection, use a tube of concrete epoxy mixed with the provided plunger rod, then load it into a caulk gun. Begin injecting at the lowest port, applying steady pressure until epoxy appears at the next port.

Once a port is filled, plug it and proceed to the next, ensuring each port is plugged after use for a secure, lasting repair.

#Concrete Crack Repair#Foundation Crack Solutions#Types of Concrete Cracks#Concrete Crack Filler Guide#DIY Concrete Repair Tips#Epoxy for Concrete Cracks

0 notes

Text

Flanges in the Construction Industry: A Critical Component

Flanges are essential components in the construction industry, providing a means to connect pipes and fittings. These versatile components are used in a wide range of applications, from residential plumbing to large-scale industrial projects.

Types of Flanges Used in Construction

Several types of flanges are commonly used in the construction industry, including:

Slip-on flanges: These are the most common type of flange, featuring a loose fit over the pipe end.

Weld neck flanges: These flanges are welded directly to the pipe, providing a strong and reliable connection.

Socket weld flanges: Suitable for smaller pipe sizes, these flanges are inserted into the pipe end and welded.

Blind flanges: Used to cap off the end of a pipe, blind flanges are often used for maintenance or future connections.

Lap joint flanges: These flanges have a loose fit over the pipe end and are typically used with gaskets.

Applications of Flanges in Construction

Flanges are used in various applications within the construction industry, such as:

Plumbing systems: Connecting pipes for water supply, drainage, and sanitation.

Heating, ventilation, and air conditioning (HVAC) systems: Connecting pipes for the distribution of heating, cooling, and ventilation.

Fire protection systems: Connecting pipes for fire sprinkler systems and other fire safety equipment.

Industrial piping: Connecting pipes for various industrial processes and applications.

Benefits of Using Flanges in Construction

Flanges offer several advantages in construction:

Versatility: Flanges can be used in a wide range of applications and pipe sizes.

Reliability: They provide a reliable and secure connection between pipes and fittings.

Ease of installation: Flanges are relatively easy to install compared to other connection methods.

Maintenance: Flanges can be easily disassembled and reassembled for maintenance or repairs.

Platinex Piping Solutions

Platinex is a renowned brand offering high-quality stainless steel piping solutions, including flanges. Manufactured by Ratnamani Metals and Tubes Limited (RMTL), a leading Indian stainless steel company, Platinex flanges are ideal for the construction industry due to their:

Corrosion resistance: Stainless steel provides excellent resistance to corrosion, making Platinex flanges suitable for outdoor applications and environments prone to moisture.

Durability: Platinex flanges are designed to withstand the demands of construction projects, ensuring long-term reliability.

Customization: Platinex can provide customized flanges to meet specific project requirements, such as non-standard sizes or materials.

Conclusion

Flanges are essential components in the construction industry, providing reliable and versatile connections between pipes. By selecting high-quality flanges from reputable manufacturers like Platinex, construction professionals can ensure the durability, safety, and efficiency of their projects.

0 notes

Text

5 Common Mistakes to Avoid When Using a Benchtop Flange Marking Machine

Benchtop flange marking machines are essential tools for accurate and efficient marking of flanges in various industries. However, improper usage can lead to errors and damage to both the machine and the flanges. To avoid these issues, it's crucial to be aware of the common mistakes that users often make.

1. Incorrect Flange Placement:

Misalignment: Ensure the flange is properly aligned with the marking head to avoid inaccurate markings. Use reference points or guides to guarantee precise placement.

Loose Fit: A loose fit can cause the flange to shift during the marking process, resulting in uneven or inaccurate markings. Make sure the flange is securely clamped or held in place.

2. Overloading the Machine:

Exceeding Capacity: Attempting to mark flanges that are too large or heavy for the machine can strain its components and lead to premature wear or damage. Always consult the machine's specifications to determine its maximum capacity.

Incorrect Marking Depth: Setting the marking depth too deep can cause excessive stress on the machine and the flange material. Adjust the depth according to the specific requirements of the application.

3. Neglecting Maintenance:

Regular Cleaning: Dust, debris, and metal shavings can accumulate in the machine, affecting its performance and accuracy. Clean the machine regularly to maintain its efficiency.

Lubrication: Proper lubrication is essential for smooth operation and to prevent excessive wear. Follow the manufacturer's recommendations for lubrication intervals and types of lubricants to use.

4. Using Incorrect Marking Tools:

Incompatible Tools: Using marking tools that are not compatible with the machine can cause damage to both the machine and the tools. Always use the recommended marking tools or those specifically designed for the machine.

Dull Tools: Dull marking tools can result in poor-quality markings and increased effort. Ensure that the tools are sharp and in good condition before use.

5. Ignoring Safety Precautions:

Personal Protective Equipment: Always wear appropriate personal protective equipment, such as safety glasses and gloves, when operating the machine to protect yourself from potential injuries.

Machine Guards: Ensure that all safety guards are in place and functioning properly to prevent accidental contact with moving parts.

By avoiding these common mistakes and following proper operating procedures, you can maximize the efficiency and accuracy of your benchtop flange marking machine. Remember to consult the machine's user manual for specific guidelines and recommendations.

0 notes

Text

Carbon Steel A182 Flanges Manufacturers In India

Carbon Steel A182 Flanges Manufacturers In India,Supplier In India ,Stocklist In India ,Exporter in India

Introduction:- Carbon Steel A182 Flanges Manufacturers In India

Carbon steel A182 flanges are crucial components used to connect pipes, valves, and other equipment in high-temperature and high-pressure systems. They are known for their robustness and ability to handle extreme conditions, making them indispensable in sectors requiring reliable performance.

India is a significant player in the global manufacturing sector for carbon steel flanges, particularly those conforming to the ASTM A182 standard. The country's manufacturing industry is well-equipped with advanced technologies and practices, enabling it to produce high-quality flanges for various industrial applications. These flanges are essential in industries such as oil and gas, power generation, chemical processing, and more.

Product Overview:-

India is a significant hub for the production of carbon steel A182 flanges, offering a diverse range of high-quality products tailored to various industrial applications. Indian manufacturers leverage advanced technology and strict quality controls to deliver flanges that meet international standards.

Indian manufacturers provide a wide variety of carbon steel A182 flanges to cater to different needs and specifications

Manufacturers offer various grades of carbon steel A182 flanges to meet different performance requirements:

ASTM A182 F1: Low carbon steel suitable for moderate temperatures.

ASTM A182 F5: Alloyed with chromium and molybdenum, providing good strength and oxidation resistance at higher temperatures.

ASTM A182 F11: Medium carbon steel with chromium and molybdenum, offering better strength and heat resistance.

ASTM A182 F22: High-carbon steel with enhanced chromium and molybdenum content for superior high-temperature performance.

Specification List of Carbon Steel ASTM A 182 Flanges

ASME/ANSI B 16.5

A182 F92 Welding Neck Flange, A182 F92 Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, A182 F92 Lap Joint Flange, Threaded Flange, A182 F92 Ring Type Joint Flange

PRESSURE CLASS

150, 300, 400, 600, 900, 1500, 2500

ASME/ANSI B 16.47

A182 F92 Welding Neck Flange, A182 F92 Blind Flange [Series A & B]

PRESSURE CLASS

75, 150, 300, 400, 600, 900

ASME/ANSI B 16.36

A182 F92 Welding Neck Flange, A182 F92 Slip on Flange, A182 F92 Threaded Flange

PRESSURE CLASS

300, 400, 600, 900, 1500, 2500

BS 4504 SEC 3.1

A182 F92 Welding Neck Flange, A182 F92 Hubbed Slip on Flange, A182 F92 Hubbed Threaded Flange, Lapped Pipe End Flange, A182 F92 Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange

PRESSURE CLASS

PN 2.5 TO PN 40

BS 4504[PART 1]

A182 F92 Welding Neck Flange, A182 F92 Hubbed Slip-On Hubbed Threaded, Plate Flange, A182 F92 Loose Plate With Weld On Plate Collar, Blank Flange

PRESSURE CLASS

PN 2.5 TO PN 400

BS 1560 BOSS

A182 F92 Welding Neck Flange, Socket Welding Flange, A182 F92 Slip-On Flange, A182 F92 Blind Flange, A182 F92 Screwed Boss Flange, A182 F92 Lapped Flange

PRESSURE CLASS

150, 300, 400, 600, 900, 1500, 2500

BS10

A182 F92 Welding Neck Flange, A182 F92 Plate Slip-On Flange, A182 F92 Screwed Boss Flange, Slip-On Boss Flange, A182 F92 Blind Flange

TABLE

D, E, F, H

DIN FLANGES

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673

PRESSURE CLASS

PN 6 TO PN 100

Benefits:-

A182 Carbon Steel ASTM flanges are manufactured with ideal chemical experiments and connections and will not wear out quickly.

This grade of Carbon Steel ASTM flanges is used for stainless steel pipe flanges, rolled alloys, forged pipes, valves, forged fittings, and other high temperature applications. A182 Carbon Steel ASTM flange is one of the results of the best chemical experiments and good connections. These flanges don't wear out as quickly. Widely used in petroleum industry, chemical industry, paper industry and many other industries. Due to its properties, this type of flange is one of the most reliable products that can be used for a long time and does not require repairs immediately after installation. You can trust blindly the durability of this product if you buy it from the right place.

Conclusions:-

Carbon Steel A182 flanges are highly versatile components used in a wide range of industrial applications. They are well-suited for high-temperature and high-pressure environments, making them a reliable choice for sectors such as oil and gas, power generation, and chemical processing. Their ability to handle severe conditions underscores their importance in critical infrastructure.

Carbon Steel A182 Flanges are a critical component in many industrial systems, providing strength, durability, and reliability in challenging conditions. Their versatility, coupled with cost-effectiveness, makes them a preferred choice for a wide range of applications. However, consideration of their limitations regarding corrosion resistance and temperature constraints is essential for optimal performance.

Email Id :- [email protected] Contact No:- 88879709191

0 notes

Text

Siddhagiri Metals provides premium alloys and stainless steel to help you elevate your projects.

Siddhagiri Metals is your dependable source for great steel items, including a huge preference for alloys and stainless steel options. Our products fulfil the highest first-class and overall performance standards and are suitable for a wide range of business packages. Discover how our answers can enhance your operations with unmatched dependability and performance.

Unmatched Stainless Steel 304 Solutions

Stainless steel 304 is first rate for its first rate blend of durability, corrosion resistance, and flexibility. Our SS 304 tube fittings make sure safe and leak-loose connections are crucial for the integrity of fluid and fuel structures in sectors that include prescribed drugs, meal processing, and petrochemicals. These fittings promote operating efficiency and long-term dependability.

The 304 steel plate is well known for its suitability for a wide range of applications including manufacturing lines and automobile manufacturing. Its ductility and ease of construction make it popular with users looking for durability and durability.

High performance all performance connections for Inconel 625 and Hastelloy C276.

Inconel 625 and Hastelloy C276 are known for their complete all-around performance in extreme conditions. Our Inconel 625 round bar is opportunistically popular in industries including aerospace, marine, and medical applications due to its unique oxidation and corrosion properties. The Inconel 625 plate brings these blessings to packages like warmth exchangers and furnace additives where excessive performance is needed.

Hastelloy C276 items, which includes spherical bars and plates, can resist excessive chemical exposures. Hastelloy C276 is used in industries which include chemical processing and pollution manipulation because of its excessive power and durability. Our Hastelloy C276 flanges and tube fittings offer robust, reliable connections in vital applications, providing you with peace of mind within the maximum stressful situations.

Superior Monel four hundred and Titanium Grade 2 Products.

Monel four Hundred, a nickel-copper alloy, provides serious corrosion resistance under marine and chemical conditions. Our Monel 4 hundred round plates and plates are suitable for systems with high electrical and power requirements, such as pump shafts, seawater valves and heat exchangers. The Monel 400 tube brings these advantages to fluid transfer structures, imparting dependable and efficient operation.

Titanium Grade 2 has excessive electricity, low weight, and corrosion resistance. Our Titanium Grade 2 round bar is ideal for aerospace, clinical, and marine packages that require those characteristics. Titanium Grade 2 plate has comparable blessings, making it suitable for use in pressure vessels, heat exchangers, and desalination plant life.

Advanced and Super Duplex Stainless Steel Offerings

Duplex 2205 and Super Duplex 2507 stainless steels provide a completely unique mixture of immoderate power and corrosion resistance. Our Duplex 2205 tube fittings make reliable connections in sectors such as oil and gasoline, chemical processing, and maritime conditions. Super Duplex 2507 tube fittings are rather proof against pitting and strain corrosion cracking, making them proper for harsh environments.

The Duplex 2205 and Super Duplex 2507 pipes provide dependable answers for conveying corrosive materials. These pipelines are generally used in offshore systems, oil refineries and desalination tasks to make sure energy distribution and typical operation under extreme situations.

Our Inconel 625 flanges and tube fittings allow secure and dependable connections in applications along with fuel mills, electricity flora, and chemical reactors, keeping integrity even beneath the most extreme situations.

Hastelloy C276 flanges and tube fittings provide terrific sealing and durability, making them perfect for systems that cope with competitive chemical compounds and excessive-strain situations. These components are vital in corporations that want steady performance and dependability.

Specialised copper, nickel, and excessive-overall performance tubes

Copper-nickel tube fittings are well-known for their high resistance to saltwater corrosion and biofouling. These fittings are vital in maritime engineering, shipbuilding, and offshore oil and fuel packages, providing reliable and lengthy-lasting connections.

Our specialised tubes, including Hastelloy C276 tube, Inconel 625 tube, and Monel 400 tube, are engineered for harsh conditions. Each tube has distinct functions that help sectors inclusive of aerospace, chemical processing, and electricity technology achieve better overall performance and dependability.

Versatile Stainless Steel 304 Pipes

Our stainless steel 304 pipe moves a mixture between energy, corrosion resistance, and cost, making it best for lots of programs. From building initiatives to business plumbing systems, the Stainless Steel 304 pipe is a dependable desire for engineers and contractors that price exceptional and efficiency.

Siddhagiri Metals is dedicated to providing exceptional products that in shape the severe desires of diverse sectors. Our enormous stock and skilled knowledge can help you discover the exceptional answer in your specific requirements. Explore our services and discover the perfection that Siddhagiri Metals delivers to each venture.

1 note

·

View note

Text

Common Types of Fasteners and Their Applications

PipingProjects.in is a major Fastener Manufacturer in India. Our company's Fasteners manufacturers are made from high-quality materials, making them appropriate for various industrial applications. Our fasteners are known for their exceptional resistance against corrosion, as well as their affordability and lovely appearance. In order to satisfy the needs of various production processes, we provide a variety of Fastener grades. We are also a major Flanges Supplier in India.

1. Screws

Types:

- Wood Screws:Designed for joining wood to wood. They have a coarse thread to grip the wood fibers securely.

- Machine Screws:Used to fasten metal parts together, often with a pre-tapped hole or in conjunction with a nut.

- Sheet Metal Screws: Ideal for joining thin metal sheets. They have sharp threads to cut into the metal.

- Drywall Screws: Specifically designed for securing drywall panels to wooden or metal studs.

Applications:

- Construction (framing, drywall installation)

- Furniture assembly

- Electrical equipment

- Automotive and aerospace industries

2. Bolts

Types:

- Hex Bolts: Characterized by a hexagonal head, they are commonly used in construction and machinery.

- Carriage Bolts: Feature a rounded head and a square neck that prevents rotation when tightened. They are often used in woodworking and construction.

- Lag Bolts: Large, sturdy screws used for heavy-duty applications such as securing wood to wood or wood to masonry.

Applications:

- Heavy construction

- Machinery assembly

- Woodworking

- Securing large structural components

3. Nuts

Types:

- Hex Nuts: The most common type, paired with bolts to secure parts together.

- Lock Nuts: Designed to resist loosening under vibration or torque. Common types include nylon insert lock nuts and metal lock nuts.

- Wing Nuts: Feature two large 'wings' for easy hand tightening. Often used in applications where frequent adjustments are needed.

Applications:

- Machinery

- Automotive

- Construction

- Home repair projects

4. Washers

Types:

- Flat Washers: Distribute the load of a bolt or screw, preventing damage to the surface being fastened.

- Lock Washers: Designed to prevent nuts and bolts from coming loose due to vibration. Common types include split lock washers and tooth lock washers.

- Fender Washers: Have a larger outer diameter compared to standard washers, used to spread the load over a wider area.

Applications:

- Preventing surface damage

- Reducing the risk of loosening

- Providing a smooth bearing surface

5. Rivets

Types:

- Solid Rivets: Require access to both sides of the material. They are hammered into place and are commonly used in aerospace and structural applications.

- Blind Rivets (Pop Rivets): Can be installed from one side, making them ideal for situations where access is limited.

- Drive Rivets: Installed by driving a pin into the body of the rivet, expanding it and securing the materials together.

Applications:

- Aerospace

- Automotive

- Construction

- Metal fabrication

Choosing the right fastener for your project is crucial for ensuring strength, stability, and longevity. Each type of fastener has unique characteristics and applications, making it important to understand their specific uses and benefits. Whether you are working on a home improvement project, assembling furniture, or constructing a building, selecting the appropriate fasteners will help you achieve the best results.

#Fastener Manufacturer in India#Fastener Supplier in India#Flange Supplier in India#Fastener Manufacturer#Stainless Steel Fasteners#Stainless Steel Washer#Stainless Steel Screws#Fastener Manufacturer in Ludhiana#Fastener Manufacturer in Pune#Fastener Manufacturer in Chennai#fasteners weight chart in kg

0 notes

Text

Flange Installation Guide – Udhhyog's Expert Tips

Flanges are essential components in industrial and structural applications, ensuring secure and leak-proof connections in piping systems, machinery, and more. While choosing the right flange is crucial, proper installation is equally important for optimal performance and longevity. In this article, Udhhyog provides a comprehensive step-by-step guide to flange installation, ensuring that your systems remain secure and efficient.

Types of Flanges Commonly Installed

Before diving into the installation process, it’s important to identify the type of flange you're working with. Common types include:

Slip-On Flanges: Easy to install, ideal for low-pressure applications.

Weld Neck Flanges: Suitable for high-pressure environments, offering superior strength.

Blind Flanges: Used to seal piping systems or block flow.

Socket Weld Flanges: Often used in smaller pipe sizes for high-pressure systems.

Threaded Flanges: Convenient for systems that require quick disassembly.

Each type requires specific considerations during installation to ensure a proper seal and secure connection.

Tools and Materials Needed for Flange Installation

To ensure a smooth installation process, gather the following tools and materials:

Gaskets: For leak-proof sealing.

Bolts, Nuts, and Washers: Ensure they match the flange type and size.

Torque Wrench: For precise tightening of bolts.

Lubricant: Reduces friction during bolting and prevents galling.

Alignment Tools: Ensures precise alignment of flanges.

Protective Gear: Safety gloves, goggles, and appropriate clothing.

Step-by-Step Flange Installation Process

1. Prepare the Flanges and Components

Clean all flange surfaces, gaskets, and bolts to remove debris, dirt, or grease. Inspect for any damage, such as cracks or irregularities, that could affect the seal.

2. Align the Flanges

Ensure the flanges are properly aligned before assembly. Misalignment can lead to uneven stress distribution and potential leaks. Use alignment tools to achieve precise positioning.

3. Insert the Gasket

Place the gasket between the flanges, ensuring it is centered. The gasket material should be compatible with the fluid or gas being transported.

4. Insert Bolts and Tighten

Insert bolts through the flange holes and loosely hand-tighten the nuts. Use a star tightening pattern to evenly distribute the load and avoid uneven pressure on the gasket.

5. Torque the Bolts

Using a torque wrench, tighten the bolts to the specified torque value provided by the manufacturer. Follow the star pattern to ensure uniform sealing.

6. Inspect the Connection

Once all bolts are tightened, inspect the flange connection for any visible gaps or misalignments. Perform a pressure test if required to ensure the system is leak-free.

Common Installation Mistakes to Avoid

Skipping Cleaning: Dirt or debris on flange surfaces can compromise the seal.

Over-Tightening Bolts: Excessive torque can damage the gasket or flange.

Using Incorrect Gaskets: Always choose gaskets that match the flange material and operating conditions.

Ignoring Alignment: Misaligned flanges can lead to uneven pressure and leaks.

Why Choose Udhhyog for Flange Solutions?

At Udhhyog, we provide top-quality flanges and installation accessories to meet the demands of industrial and structural applications. Our range includes:

MS Flanges: Explore here

GI Flanges: Explore here

SS 304 Flanges: Explore here

SS 316 Flanges: Explore here

Our expert team is also available to provide guidance on installation and maintenance.

#FlangeInstallation#Udhhyog#IndustrialSolutions#PipeConnections#FlangeGuide#StructuralEngineering#SeamlessConnections

1 note

·

View note

Text

Carbon Steel A182 Flanges Manufacturers

Carbon Steel A182 Flanges ,Exporters,Stocklist,Suppliers,Manfacture

Introduction:- Carbon Steel A182 Flanges

Carbon Steel A182 flanges are a critical component in piping systems used in various industries. They are made from carbon steel and adhere to the ASTM A182 specification, which sets standards for high-temperature and high-pressure service applications. These flanges are particularly valued for their strength, durability, and resistance to high temperatures.

ASTM A182 is a standard specification for forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves. The specification is particularly relevant for high-temperature applications and includes several grades of materials. Carbon steel grades within ASTM A182 are designed to withstand high-pressure and high-temperature condition

Product Overview:-

A182 Carbon Steel ASTM flanges are used in high temperature applications such as: B. For stainless steel pipe flanges, valves, forged fittings and rolled alloys. Also suitable for low corrosion applications.

ASTM A182 steel is the standard specification for forged or rolled alloys, stainless steel pipe flanges, and all types of parts and valves for high temperature service.

A182 Carbon Steel ASTM flanges are manufactured with ideal chemical experiments and connections and will not wear out quickly.

This grade of Carbon Steel ASTM flanges is used for stainless steel pipe flanges, rolled alloys, forged pipes, valves, forged fittings, and other high temperature applications. A182 Carbon Steel ASTM flange is one of the results of the best chemical experiments and good connections. These flanges don't wear out as quickly. Widely used in petroleum industry, chemical industry, paper industry and many other industries. Due to its properties, this type of flange is one of the most reliable products that can be used for a long time and does not require repairs immediately after installation

Specifications:-

Specification List of Carbon Steel ASTM A 182 Flanges

ASME/ANSI B 16.5

A182 F92 Welding Neck Flange, A182 F92 Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, A182 F92 Lap Joint Flange, Threaded Flange, A182 F92 Ring Type Joint Flange

PRESSURE CLASS

150, 300, 400, 600, 900, 1500, 2500

ASME/ANSI B 16.47

A182 F92 Welding Neck Flange, A182 F92 Blind Flange [Series A & B]

PRESSURE CLASS

75, 150, 300, 400, 600, 900

ASME/ANSI B 16.36

A182 F92 Welding Neck Flange, A182 F92 Slip on Flange, A182 F92 Threaded Flange

PRESSURE CLASS

300, 400, 600, 900, 1500, 2500

BS 4504 SEC 3.1

A182 F92 Welding Neck Flange, A182 F92 Hubbed Slip on Flange, A182 F92 Hubbed Threaded Flange, Lapped Pipe End Flange, A182 F92 Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange

PRESSURE CLASS

PN 2.5 TO PN 40

BS 4504[PART 1]

A182 F92 Welding Neck Flange, A182 F92 Hubbed Slip-On Hubbed Threaded, Plate Flange, A182 F92 Loose Plate With Weld On Plate Collar, Blank Flange

PRESSURE CLASS

PN 2.5 TO PN 400

BS 1560 BOSS

A182 F92 Welding Neck Flange, Socket Welding Flange, A182 F92 Slip-On Flange, A182 F92 Blind Flange, A182 F92 Screwed Boss Flange, A182 F92 Lapped Flange

PRESSURE CLASS

150, 300, 400, 600, 900, 1500, 2500

BS10

A182 F92 Welding Neck Flange, A182 F92 Plate Slip-On Flange, A182 F92 Screwed Boss Flange, Slip-On Boss Flange, A182 F92 Blind Flange

TABLE

D, E, F, H

DIN FLANGES

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673

PRESSURE CLASS

PN 6 TO PN 100

Benefits:-

Carbon Steel A182 flanges offer numerous advantages that make them suitable for a wide range of industrial applications. Here’s a detailed look at the benefits:

Carbon Steel A182 flanges offer a combination of high-temperature strength, pressure resistance, and cost-effectiveness, making them a valuable component in a wide range of industrial applications. Their adherence to ASTM standards ensures quality and reliability, while their versatility in types and grades allows for customization to meet specific operational needs. These benefits make Carbon Steel A182 flanges a preferred choice for demanding environments where performance and durability are crucial.

Conclusions:-

Carbon Steel A182 flanges are essential components in high-temperature and high-pressure piping systems. Their design and material properties ensure reliability and performance in challenging environments. By adhering to ASTM A182 specifications, these flanges offer strength, durability, and versatility for various industrial applications, from oil and gas to power generation and chemical processing.

Contact:-88797–09191

Email Id:[email protected]

0 notes