#Lithographic Printing Chemicals Industry

Explore tagged Tumblr posts

Text

Overwhelmed By Advertising? The Battle For Cincinnati Consumers Has Raged For More Than A Century

Depending on the source, it is estimated that each American is confronted by 6,000 to 10,000 advertising messages every single day. That immersive media onslaught swelled as we started carrying little video screens around wherever we go, but invasive and obnoxious marketing has bothered Cincinnatians for much more than a century.

For example, on 20 July 1871, a correspondent for the Cincinnati Times related an enjoyable voyage he had undertaken down the Ohio River. After praising the service of his riverboat’s staff, the remarkable scenery along the river, the picturesque little town he floated by, the writer registered one complaint, about a cliff near the town of Hanging Rock:

“High up on the face of this wall of white sandstone, hundreds of feet beyond the reach of a scaling ladder, I noticed a patent medicine advertisement. It was penciled there by a man let down with ropes from above, and the letters are large enough to be read from the deck of a steamer two miles distant. I was sorry to see this defacement. It is bad enough that all the fences throughout the land should be made to lie for patent medicines without debasing the hill-sides with such marking. I suppose that when the ‘chemical affinity necessary to be the motor of some immense flying machine’ shall be discovered, some enterprising patent medicine man will be plastering the face of the moon with some of his ‘wonderful remedies.’”

If only the poor man knew what lay ahead! Even in the 1870s, almost every vertical surface in Cincinnati was slathered with posters, placards and bills advertising shows at the local theaters, patent medicines and political candidates. Cincinnati was the center of the bill-posting world. For one thing, Cincinnati was among the top printing cities of the United States, with the mighty Strobridge Lithographing Company dominating the poster industry.

Also, Billboard magazine was headquartered here in Cincinnati. What we now think of as a music magazine, Billboard was founded in Cincinnati as a trade publication for men who posted “bills” on walls. From its first issue in 1894, Billboard covered the entertainment industry, such as circuses, fairs and burlesque shows, and also created a mail service for travelling entertainers. Initially it covered the advertising and bill-posting trade and was known as Billboard Advertising.

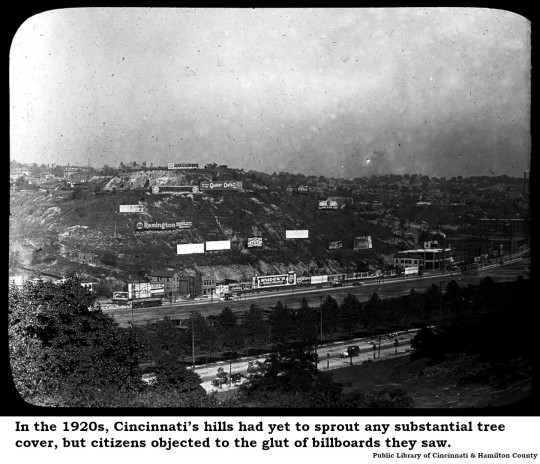

Far from inspiring civic pride, advertising rankled Cincinnati residents as they witnessed visual pollution encrusting the region’s hillsides. Leading the opposition was the Municipal Art Society – a sort of ad-hoc predecessor to today’s Urban Design Review Board. The opening shot was fired 24 August 1896 when the Enquirer reported:

“A matter that will undoubtedly be of interest to the business men is the fact that war has been declared by the Cincinnati Municipal Art Society against advertising signs on fences along the car routes and drives of the city. The art society maintains that these signs mar the beauty of the city, especially in the case of landscape scenes on the hills and in the suburbs, and that they are offensive to the public taste.”

The Society was persistent. It took five years but the Cincinnati Post reported [24 November 1901] that the Baldwin Piano Company had demolished 200 feet of billboards erected on company property along Gilbert Avenue. The Post described this as the “first result” of the Society’s campaign.

The Municipal Art Society was soon joined by some strange bedfellows. The Cincinnati Business Men’s Club, among whose members were certainly a number of advertisers who employed billboards to disseminate their messages, created its own Municipal Art Committee to lobby for restrictions on outdoor advertising. On 1 June 1907, the committee circulated a postcard illustrated with a photo of signage clogging the view from the Grand Central Depot, with the sarcastic caption, “A Nice Welcome To Cincinnati.”

As early as 1895, the city chased the Fountain saloon’s advertising off Fountain Square, but appears not to have drafted a comprehensive law about outdoor advertising until 1909 when, as part of a broader safety ordinance, the city adopted limitations on the size of billboards, their placement near thoroughfares and the materials to be used in their construction.

While the city pondered how to encourage commerce while maintaining attractive views, the entire billboard industry was gaining momentum through a Cincinnati entrepreneur named Philip Morton. Before Morton, “bill boards” were basically fences on which bill posters slapped printed advertisements glued up with a flour-water paste. Morton took outdoor advertising to a new level, according to Jay Gilbert, who has researched his influence on marketing [Cincinnati Magazine September 2016]:

“By 1898 he’d become the Steve Jobs of roadside blight. Doing business as Ph. Morton, Phil was an early pioneer of putting ads into free-standing frames called ‘bill-boards’ and plunking them down everywhere. Eventually every railroad route and motorway in America had its view ruined by a Ph. Morton billboard.”

Even the powerhouse Morton found himself in the city’s crosshairs. Parks Superintendent John W. Rodgers, according to the Enquirer [20 September 1907], exasperated by Morton’s billboards blocking the view of Inwood Park, erupted.

“Park Superintendent Rodgers yesterday tore down over 12,000 feet of big billboards that stretched along for a distance south of Hollister street, facing Vine street, in front of Inwood Park. The billboards were 12 feet high, about 1,000 feet long and contained the advertisements of leading firms of the city, and were illuminated at night with electric lights. They had been at that place for years.”

All of those billboards were leased by Philip Morton who, as coincidence would have it, dropped off a check to pay the lease while workmen were busily engaged demolishing his thousand feet of signage. This was the Boss Cox era in Cincinnati where the right hand was very often ignorant of the left hand’s activity. And so it was, while the Park Superintendent was demolishing billboards on Vine Street, the Board of Public Service pondered a lease for billboards along Gilbert Avenue. That’s right – the same Gilbert Avenue divested of billboards just six years earlier.

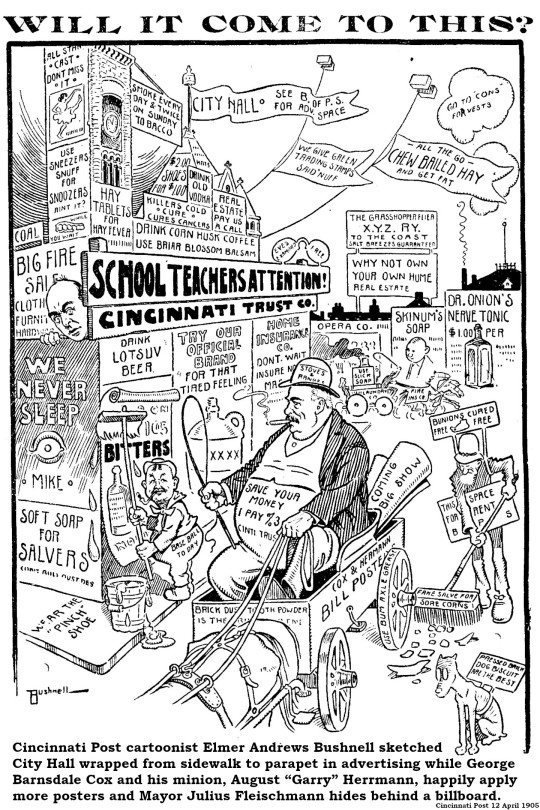

A common theme of cartoon artists at that time was the eventual coverage of all available exterior surfaces with advertising signs and slogans. In response, Cincinnati Post cartoonist Elmer Andrews Bushnell sketched City Hall wrapped from sidewalk to parapet in advertising while George Barnsdale Cox and his minion, August “Garry” Herrmann, happily apply more posters and Mayor Julius Fleischmann hides behind a billboard.

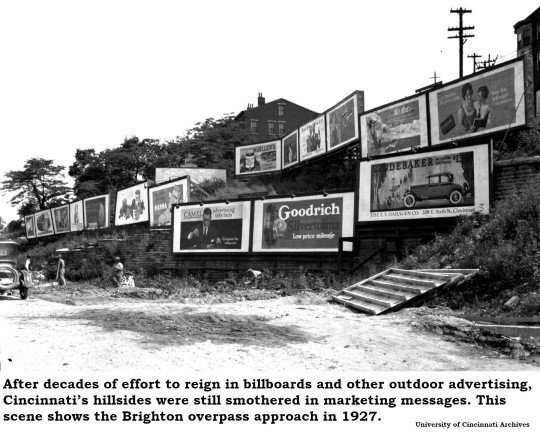

The battle raged for decades. Photographs from 1927 show dozens of billboards crowding the hillside over the Brighton overpass to Central Parkway and the Enquirer [24 March 1929] begged for relief because billboards and other unsightly structures had a negative effect on property values:

“What of the gaudy billboard that intrudes itself into a residential district, the sign which girds the tree or telephone pole, the roadside ‘shack’ which is made more ugly with bizarre advertisements? Do they affect values?”

A century later, we hardly notice billboards anymore. We’re too busy texting while we drive.

10 notes

·

View notes

Text

Printing Inks Market: Key Applications in Packaging, Commercial & Digital Printing 2021 - 2028

The global printing inks market size is expected to reach USD 23.8 billion by 2028, registering a CAGR of 2.8% over the forecast period, according to a new report by Grand View Research, Inc. Growing demand from end-use applications including flexible packaging & labels, corrugated cardboards, commercial letterpress, and folding cartons are the main factors expected to drive the market over the forecast period. Rise in consumer spending in Asia Pacific and North American regions, increasing demand for superior quality flexible packaging are some of the main parameters influencing the overall demand for printing inks globally.

Product innovations, technological progressions, new raw material sourcing models and expansion strategies are some of the major drifts the companies are focusing on to cater to the specific consumer requirements. The recent trends witnessed by this industry include rising significance of flexographic and digital toners, food-safe printing inks and a shift in consumer preference towards environment-friendly products.

Gather more insights about the market drivers, restrains and growth of the Printing Inks Market

The regulatory framework also plays a crucial role in this industry dynamics. Stringent regulations regarding toxic metals in solvents & volatile organic compound (VOC) emissions in these inks are expected to hamper the growth of the overall market. This rationale has led to increased usage of cellulose and rosin derivatives as resins for manufacturing energy-efficient inks.

Digital ink is expected to be the fastest growing product segment owing to its superior properties and specific demands from textile, ceramic and 3D printing application sectors. The digital toners have observed a lower label costs as compared to conventional inks and its potential of switching among labels instantly have resulted in this product to be the fastest growing.

Browse through Grand View Research's Paints, Coatings & Printing Inks Industry Research Reports.

The Central and South America automotive wrap films market size was valued at USD 165.7 million in 2024 and is projected to register a CAGR of 3.8% from 2025 to 2030.

The global thermal insulation coating market sizewas estimated at USD 10.45 billion in 2024 and is projected to grow at a CAGR of 6.6% from 2025 to 2030.

Printing Inks Market Segmentation

Grand View Research has segmented the global printing inks market on the basis of product, resins and application:

Printing Inks Product Outlook (USD Million, 2016 - 2028)

Gravure

Flexographic

Lithographic

Digital

Others

Printing Inks Resin Outlook (USD Million, 2016 - 2028)

Modified rosin

Modified cellulose

Acrylic

Polyurethane

Others

Printing Inks Application Outlook (USD Million, 2016 - 2028)

Packaging & labels

Corrugated cardboards

Commercial printing/Publishing

Others

Printing Inks Regional Outlook (Revenue, USD Million, 2016 - 2028)

North America

US

Canada

Mexico

Europe

Germany

Italy

UK

Asia Pacific

China

Japan

India

Central & South America (CSA)

Brazil

Middle East & Africa

Key Companies profiled:

Flint Group

DIC Corporation

Siegwerk Druckfarben AG & Co. KGaA

Sakata Inx Corporation

T&K TOKA Corporation

Dainichiseika Color & Chemicals Mfg. Co., Ltd.

DEERS I CO., Ltd.

Epple Druckfarben AG

TOYO INK SC HOLDINGS CO., LTD.

Hubergroup

TOKYO PRINTING INK MFG CO., LTD.

Order a free sample PDF of the Printing Inks Market Intelligence Study, published by Grand View Research.

0 notes

Text

What is Lithography? A Simple Explanation

Lithography, a centuries-old technique, is a planographic printing process that relies on the principle that oil and water don't mix. It involves drawing or painting an image on a flat surface, typically a stone or metal plate. The image is created using a greasy substance, such as crayon, ink, or tusche, which makes the drawn areas receptive to oily ink.

What is Lithography & its Process

Here's a breakdown of the key steps in the lithography process:

Image Creation:

Drawing: The artist directly draws the image onto the plate using a greasy medium.

Photolithography: A photographic process is used to transfer an image onto the plate. A light-sensitive emulsion is applied to the plate, and then exposed to light through a negative of the desired image. The exposed areas become receptive to ink.

Chemical Treatment:

The plate is treated with a chemical solution that desensitizes the non-image areas, making them water-receptive.

Inking and Printing:

The plate is dampened with water, which adheres to the non-image areas.

Oily ink is then applied to the plate. The ink adheres to the greasy image areas, while the water repels it.

The inked image is transferred to paper or another material using a printing press.

The Magic of Lithography

Lithography offers several advantages that have contributed to its enduring popularity:

Versatility: It can be used to create a wide range of artistic styles, from delicate line drawings to bold, expressive works.

Detail and Precision: The process allows for fine details and subtle tonal variations.

Durability: Lithographs can be printed in large quantities without significant loss of quality.

Artistic Expression: Lithography has been embraced by many renowned artists as a medium for self-expression and experimentation.

Historical Significance

Lithography was invented in 1796 by German author and actor Alois Senefelder. Initially used for printing music scores and maps, it quickly gained popularity among artists and publishers. The technique revolutionized printmaking, making it more accessible and affordable.

Modern Applications

While traditional lithography is still practiced by artists today, the principles of the process have been adapted for various modern applications:

Offset Printing: This widely used printing technique is based on lithography. It involves transferring the image from a plate to a rubber blanket, and then to the paper.

Photolithography: This process is crucial in the semiconductor industry for creating intricate circuit patterns on silicon wafers.

Digital Lithography: Digital imaging technology has enabled the creation of digital lithographs, where images are directly transferred to plates using computer-controlled laser systems.

Lithography continues to be a valuable tool for artists and industries alike, offering a unique blend of tradition and innovation. Its ability to produce high-quality prints with intricate detail and artistic expression ensures its enduring legacy in the world of printmaking. Sources and related content

0 notes

Text

Printing Inks Market Size and Share Analysis: Key Growth Trends and Projections

Printing Inks Market Strategies: Taking Advantage of Trends to Drive Growth in 2032

The Printing Inks Market Report provides essential insights for business strategists, offering a comprehensive overview of industry trends and growth projections. It includes detailed historical and future data on costs, revenues, supply, and demand, where applicable. The report features an in-depth analysis of the value chain and distributor networks.

Employing various analytical techniques such as SWOT analysis, Porter’s Five Forces analysis, and feasibility studies, the report offers a thorough understanding of competitive dynamics, the risk of substitutes and new entrants, and identifies strengths, challenges, and business opportunities. This detailed assessment covers current patterns, driving factors, limitations, emerging developments, and high-growth areas, aiding stakeholders in making informed strategic decisions based on both current and future market trends. Additionally, the report includes an examination of the Automatic Rising Arm Barriers sector and its key opportunities.

According to Straits Research, the global Printing Inks Market market size was valued at USD XX Billion in 2023. It is projected to reach from USD XX Billion in 2024 to USD XX Billion by 2032, growing at a CAGR of 2.9% during the forecast period (2024–2032).

Get Free Request Sample Report @ https://straitsresearch.com/report/printing-inks-market/request-sample

TOP Key Industry Players of the Printing Inks Market

ALTANA

Dainichiseika Color & Chemicals Mfg. Co. Ltd

Dow

Epple Druckfarben AG

Flint Group

FUJIFILM Corporation

Huber Group Deutschland GmbH

SAKATA INX CORPORATION

Sanchez SA de CV

SICPA HOLDING SA

Siegwerk Druckfarben AG & Co. KGaA

Sun Chemical

T&K TOKA Corporation

Tokyo Printing Ink Mfg Co. Ltd

Toyo Ink SC Holdings Co. Ltd

Wikoff Color Corporation

Yip's Chemical Holdings Limited

Zeller+Gmelin

Global Printing Inks Market: Segmentation

As a result of the Printing Inks market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Product

Gravure

Lithographic

Flexographic

Digital Printing

Others

By Resin

Modified rosin

Modified cellulose

Acrylic

Polyurethane

Others

By Application

Packaging & Labels

Corrugated Cardboards

Commercial Printing/Publishing

Others

Browse Full Report and TOC @ https://straitsresearch.com/report/printing-inks-market/request-sample

Reasons for Buying This Report:

Provides an analysis of the evolving competitive landscape of the Automatic Rising Arm Barriers market.

Offers analytical insights and strategic planning guidance to support informed business decisions.

Highlights key market dynamics, including drivers, restraints, emerging trends, developments, and opportunities.

Includes market estimates by region and profiles of various industry stakeholders.

Aids in understanding critical market segments.

Delivers extensive data on trends that could impact market growth.

Research Methodology:

Utilizes a robust methodology involving data triangulation with top-down and bottom-up approaches.

Validates market estimates through primary research with key stakeholders.

Estimates market size and forecasts for different segments at global, regional, and country levels using reliable published sources and stakeholder interviews.

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Printing Inks Market#Printing Inks Market Share#Printing Inks Market Size#Printing Inks Market Research#Printing Inks Industry#What is Printing Inks?

0 notes

Text

The Photoresist Ancillaries Market is projected to witness substantial growth, with the market value expected to surge from USD 4,125.63 million in 2023 to reach USD 6,455.27 million by 2032, reflecting a notable compound annual growth rate (CAGR) of 5.10% during the forecast period.The photoresist ancillaries market plays a crucial role in the semiconductor and electronics industries, providing essential materials that support the manufacturing processes of integrated circuits (ICs), printed circuit boards (PCBs), and other electronic components. These ancillaries are integral to the photolithography process, which is foundational to creating intricate patterns on semiconductor wafers and other substrates.

Browse the full report at https://www.credenceresearch.com/report/photoresist-ancillaries-market

Market Overview

The global photoresist ancillaries market has witnessed steady growth in recent years, driven by advancements in semiconductor technology and the increasing demand for smaller, more efficient electronic devices. Photoresist ancillaries encompass a range of materials and chemicals, including developers, removers, primers, and edge-bead removers, among others. These materials are designed to enhance the performance and efficiency of photoresist materials used in photolithography processes.

Key Drivers of Market Growth

Several factors contribute to the growth of the photoresist ancillaries market:

1. Technological Advancements: Continuous innovations in semiconductor manufacturing technology, such as the development of advanced photoresists and ancillary materials, drive the demand for high-performance ancillary products.

2. Increasing Demand for Electronics: The proliferation of electronic devices across various sectors, including consumer electronics, automotive, and telecommunications, fuels the demand for advanced semiconductor components, thereby boosting the market for photoresist ancillaries.

3. Miniaturization Trends: The trend towards smaller and more complex electronic devices requires finer patterning capabilities, which in turn necessitates high-quality photoresist ancillaries for precise lithographic processes.

4. Geographical Expansion: Emerging economies in Asia-Pacific, particularly China, Japan, and South Korea, are significant contributors to market growth due to their expanding semiconductor and electronics manufacturing sectors.

Challenges and Opportunities

Despite robust growth prospects, the photoresist ancillaries market faces challenges such as stringent environmental regulations and volatility in raw material prices. Manufacturers are increasingly focusing on developing eco-friendly ancillary solutions and optimizing production processes to mitigate these challenges.

Opportunities abound for market players to capitalize on:

1. Research and Development: Investment in research and development to innovate new ancillary products that meet evolving technological requirements and regulatory standards.

2. Collaborations and Partnerships: Strategic collaborations between semiconductor manufacturers, research institutions, and ancillary suppliers can foster innovation and accelerate market penetration.

3. Market Expansion: Exploring untapped markets in emerging economies and diversifying product portfolios to cater to a wide range of applications in the electronics industry.

Future Outlook

The future of the photoresist ancillaries market looks promising with anticipated advancements in semiconductor technology and the growing adoption of advanced electronic devices worldwide. Continued investments in research and development, coupled with strategic initiatives to address environmental concerns, are expected to drive sustainable growth in the market.

Key Players

Tokyo Ohka Kogyo Co., Ltd.

JSR Corporation

Merck KGaA

Shin-Etsu Chemical Co., Ltd.

Dow Inc.

Fujifilm Holdings Corporation

MicroChem Corporation

Avantor, Inc.

DuPont de Nemours, Inc.

Sumitomo Chemical Co., Ltd.

Segments:

By Types:

Anti-reflective Coatings

Photoresist Developers

Edge Bead Removers

Other Type

By Application:

Semiconductors and Integrated Circuits

Printed Circuit Boards

Other Application

By Region

North America

Europe

Japan

Latin America

The Middle East and Africa

Asia-Pacific

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

The History Of Lithography

Lithography is a printing technique that has been used for over two centuries. The process involves printing an image from a flat surface onto paper or other materials. Lithography was a significant innovation in the printing industry, as it allowed for the mass production of high-quality images and text. This article will explore the history of lithography, from its invention to its modern-day use.

The Invention of Lithography

Lithography was invented in 1796 by Alois Senefelder, a German playwright and actor. Senefelder was struggling to produce copies of his plays, which he had written by hand. He experimented with various printing techniques, including engraving and etching, but found them to be too expensive and time-consuming.

One day, while cleaning a stone slab that he had used to write a script, Senefelder noticed that the grease from his writing had created a visible image on the stone. He realized that he could use this process to create printing plates that could be used to mass-produce copies of his plays.

Senefelder's process involved drawing an image onto a smooth stone surface using a greasy substance, such as a mixture of wax, soap, and lampblack. He then treated the stone with a chemical solution that would fix the image onto the stone surface. The stone was then inked and pressed onto a sheet of paper, creating a printed image.

The Advancement of Lithography

Senefelder's invention quickly gained popularity, as it allowed for the mass production of high-quality images and text. However, the early lithography process was time-consuming and required skilled craftsmen to create the printing plates.

In the early 19th century, new advances in lithography made the process more efficient and accessible. One of the most significant innovations was the development of lithographic presses, which allowed for faster and more consistent printing. The introduction of zinc plates also made it easier to create lithographic printing plates.

Lithography became popular in the art world as well, as artists began to use the process to create prints of their artwork. Many famous artists, such as Francisco Goya and Henri de Toulouse-Lautrec, used lithography to create their prints.

Lithography also became a popular method for printing maps, books, and other materials. The process allowed for the mass-production of high-quality materials, making it an essential tool for businesses and governments.

The Rise of Color Lithography

In the mid-19th century, lithography underwent another significant advancement with the introduction of color printing. The process of color lithography involved using multiple printing plates, each with a different color ink, to create a full-color image.

Color lithography was a significant innovation in the printing industry, as it allowed for the creation of vivid, colorful images. The process was particularly popular in the advertising industry, as companies began to use color lithography to create eye-catching posters and advertisements.

The Modern Use of Lithography

Today, lithography is still a popular printing technique, although it has been largely replaced by digital printing in many applications. However, lithography is still used in many industries, including art, publishing, and packaging.

In the art world, lithography is still used to create prints of artwork. Many artists appreciate the unique qualities of lithography, such as the ability to create bold, textured images. Lithography is also used to create limited edition prints, which are highly valued by collectors.

In the publishing industry, lithography is still used to print books, particularly high-quality art books. Lithography allows for the creation of high-quality images and text, making it an essential tool for producing high-end publications.

Lithography is also used in the packaging industry, particularly for the printing of labels and packaging materials. Lithography allows for the creation of highly detailed and vibrant images, making it an ideal method for creating eye-catching packaging.

In recent years, digital printing has become increasingly popular, and many industries have shifted away from lithography. However, lithography still offers unique benefits, such as the ability to print on a wide range of materials and create textured images.

Conclusion

Lithography has a rich history that spans over two centuries. From its invention by Alois Senefelder in 1796 to its modern-day use in the art, publishing, and packaging industries, lithography has played a significant role in the printing industry.

Senefelder's invention revolutionized the printing industry, allowing for the mass production of high-quality images and text. Advances in lithography technology, such as the development of lithographic presses and color printing, further expanded the capabilities of the process.

Today, lithography is still used in many industries, although it has been largely replaced by digital printing in some applications. However, lithography continues to offer unique benefits, making it an essential tool for creating high-quality prints and packaging materials.

#lithograph#nostalgia#pacasso#fine art#artwork#historical art#collectible#collectables#collection#collectibles#history#nostolgia#art print#art collecting/sales#art collectors#art collection#antiques#antique#vintage style#vintage#vintage art#1950s vintage#1950s style#1950s art#pablo picasso#lithography#enlightenment#abstract art#art deco#art

1 note

·

View note

Text

Lithographic Printing Chemicals Market, by Product Type, by Application, by End User, and by Region, Size, Share, Outlook, and Opportunity Analysis, 2020 - 2027

Lithographic printing chemicals also referred as offset print chemicals which are used in the printing process. It is one of the world’s most commonly used printing methods. These chemicals allow huge amounts to be printed in a shorter period and at much cheaper prices compared with conventional technologies. These chemical includes casting solvents, inks, anti-reflection coatings, developers, etc.

The key operating players in the Global Lithographic Printing Chemicals Market are also profiled in detail in the report to offer readers with a complete understanding of the competitive landscape of the target market. Major competitive strategies employed by key operating players in the market are described in detail, so that readers can get an accurate image of what is working in the market & what is likely to bring them sustained success. Along with this, the report also of serves the readers with a handy guide to what to avoid in the Lithographic Printing Chemicals Market & remain free from the major concerns plaguing the key players.

Sample Copy of This Report @ https://qualiketresearch.com/request-sample/OEM-Insulation-Market/request-sample

Lithographic Printing Chemicals Market Key Competitors

Various key players are discussed in this report such as Toyo Ink Company, Wikoff Color Corporation, T&K TOKA Corporation, Yip's Chemical Holdings Limited, Flint Group, DIC Corporation, Daihan Ink Company, SICPA Holding SA, Sakata Inx Corporation, Huber Group, etc.

Lithographic Printing Chemicals Market Taxonomy

By Type

Inks

Cleaning Solutions

Foundation Solutions

Other

By Application

Publication

Packaging

Promotion

Others

By Region

North America

Latin America

Europe

Asia Pacific

Middle East & Africa

Get full Study @ https://qualiketresearch.com/reports-details/Lithographic-Printing-Chemicals-Market

About Us

QualiKet Research is a leading Market Research and Competitive Intelligence partner helping leaders across the world to develop robust strategy and stay ahead for evolution by providing actionable insights about ever changing market scenario, competition and customers. QualiKet Research is dedicated to enhancing the ability of faster decision making by providing timely and scalable intelligence. We use different intelligence tools to come up with evidence that showcases the threats and opportunities which helps our clients outperform their competition.

#Lithographic Printing Chemicals Market#Lithographic Printing Chemicals Industry#Lithographic Printing Chemicals Market Size#Lithographic Printing Chemicals Market Share#Lithographic Printing Chemicals Market Growth

0 notes

Text

specialty ink market – Size , Cost, Growth, Key Players, Regional Analysis and Opportunities Rising Demand and Changing Trends forecast till 2027

Market Segmentation:

The global specialty ink market is broadly segmented on the basis of type, resin type, application, and region. On the basis of type, the global specialty resin market is divide into thermochromic and photochromic. Thermochromic type of specialty inks are heat sensitive in nature which changes its color when exposed to heat. This segment is projected to hold major share of the market over the forecast period due to its substantial applications in safety & security of confidential documents. Both thermochromic and photochromic type of specialty inks have great potential in protection of documents form forgery, counterfeit, duplications and also from the fake validation of brand.

Based on the resin type, the market is categorized into modified resin, acrylic, cellulose, polyamide, polyurethane, hydrocarbon, and others. Among these types, the modified resin segment is the largest one owing to the flexibility of application and ease of operation offered by this type of specialty ink. Additionally, there is a rise in research activities in this resin type to develop innovative inks to meet ever increasing scope of applications in this market.

By application, the global specialty ink market is classified into printing & publication, flexible packaging, safety & security, entertainment, and others. Among these applications, printing & publication segment is dominating the market on account of greater demand of flexible packaging, surging trend of super market shopping and vast spread print media. In coming years, the safety & security segment is anticipated to grow at considerable rate on the backdrop of rising demand for the product to protect the integrity of security institutions.

Access Sample Report @ https://www.marketresearchfuture.com/reports/specialty-ink-market-5177

Competitive Analysis:

Key players in the global polyurethane catalyst market are IIMAK (U.S.), Sun Chemical (U.S.), Toyo Ink International Corp., (U.S.), TOKYO PRINTING INK MFG CO.,LTD. (Japan), DAIHANINK Co., Ltd. (South Korea), Siegwerk Druckfarben AG & Co. KGaA (Germany), Huber Group Holding SE (Germany), Bordeaux Digital PrintInk Ltd. (Israel), T&K TOKA Corporation (Japan), and Royal Dutch Printing Ink Factories Van Son (The Netherlands), among others.

Regional Analysis:

There are five major regions in which the global specialty ink market is divided into: Asia Pacific, Europe, North America, the Middle East & Africa, and Latin America. Asia Pacific is set to dominate the market. It held over 35% share of the market, as of 2016. The region is anticipated to remain dominant in both production and demand of specialty ink market size . Growing consumer awareness and favoring regulatory trends in this region are driving growth of the market during the forecast period. India, Japan, South Korea and China are the leading markets in this region. North America is holding the second largest share of the market. The U.S is anticipated to hold the maximum share in this market, which is attributed to the presence of major market players and substantial end users such as foods & beverages and packaging industry. Europe is following North America in terms of market size, with Germany, the U.K and France holding considerable share of the market. This region is witnessing a growth due to some strategic initiatives on part of regulatory agencies. The Middle East & Africa is a swiftly growing market where the growth is driven by the demand from foods & beverages and tourism industry. Latin America is anticipated to witness a rise in the regional market due to the pacifying political and reviving economic situation.

Market Overview:

Ink is a complex aqueous medium that is composed of solvents, pigments, dyes, resins, lubricants, solubilizes, surfactants, particulate matter, fluorescents, and other materials. Each of these components of inks serve many purpose such as the ink carrier, colorants, and other additives affect the flow and thickness of the ink and its dry appearance. The specialty inks are the special purpose inks that are intended to fulfil needs of the distinguished applications which can be hardly served by their counterpart. The product is majorly used to print the substrates such as paper, composites, metal foils to impart a design, or draw a high importance or confidential text on it. These types of inks are either available in the form of thick paste or liquid, in the market. Thicker inks are primarily used in letterpress and lithographic printing and the thinner form is applied on the substrate by using a pen, brush, or quill. There are various applications wherein the specialty inks have successfully penetrated so far such as security printings, cheque printing, fluorescent that catches attention, metallic shade inks, and carbon copy paper printing ink, among others. According to the leading research organizations, the global printing ink market for packaging is estimated to grow at significant growth rate of 6% due to surging global demand for the label packaging, which provides nutritive and product information. At present, with the rising cases of document breaching, forgery, counterfeit, and fake branding, the demand for the specialty inks is projected to rise manifolds. However, there are some factors that hamper growth of the market such as the fluctuations in the crude oil prices, cost intensive nature of new technologies and shift from traditional to digital market.

NOTE: Our Team of Researchers are Studying Covid19 and its Impact on Various Industry Verticals and wherever required we will be considering Covid19 Footprints for Better Analysis of Market and Industries. Cordially get in Touch for More Details.

1 note

·

View note

Photo

*META / LIVING CONDITIONS !

style wise, the overall look of the building which houses sam’s loft is very brutalist. massive slabs of concrete dominate the bilduing’s outer appearance: stairs, entrances and hallways all designed to create the impression that they were cut from one enormous piece, rather than just assembled. large glass fronts and planned space loosen up the strong stylistic unit, with the term ‘planned space’ suggesting room for green or rest areas.

green areas will follow geometric shapes and contain room for in-door gardens and plants, most of which are very large and high-growing, but, ideally, as undemanding as possible. the more succulent the foliage and rich their color the better.

rest areas will often go hand in hand with green areas with benches or chairs made from concrete ( shaped like rectangles and cubes ) set in front of a glass wall or a green spot. the theme the architects of the building had in mind was “the invasion of nature into urban life”.

the building contains forty floors with eighty apartments and lofts in total. heeded either north- or southwards, all apartments share the same basic layout: by entering through a spacious living room which connects directly to the kitchen, a bedroom and two bathrooms detour from the living space. while the building’s highest situated apartments - the lofts right underneath what would normally pose as an attic – have access to a walkable 360° balcony, sam’s apartment, which is on the 24th floor, makes do with what can only be described as an extended windowsill, which can be stepped, but not walked on.

in spirit of the late 80′s, the time during which sam moved into his apartment, the apartment’s overall look is sleek, but heavily stylized: the walls and floor are clad with large white panels made from a sort of synthetic material which in part reach straight from the floor to the walls ( think 90’s futuristic spaceship cgi interior ). there are no doors in between rooms, except for a matted glass door preserving any and all bathroom users’ modesty.

the building itself was erected in the late 1970s, but, due to financing issues remained largely a work in progress until 1985. at the time during which sam moved in, the apartment was far above his pay grade. by laying claim to one of the building’s apartments in exchange for a comparably low investment in the company charged with the planning of the building – a company, so sam happened to find out, which had planned to go bankrupt throughout the deal from the very beginning – sam was lucky enough to come across a legal loophole which would eventually lead him to lose the entire sum of his investment, but keep the unfinished apartment in turn.

sam has always, and even more so since entering thraldom as a ghoul, spent the majority of his time at work, rather than at home. because of this the interior of his apartment has largely remained the same since he moved in during the 80′s and, in a lot of ways, up to today embodies the stereotypical home of a mid -90’s yuppie. glass, leather, wood and steel combinations dominate the apartment with clear and strong designs and shapes. items, like electronics, which tends to expire or fall out of favor quickly, do get replaced occasionally, but only selectively.

sam keeps his apartment lively by keeping plants. although he did start selecting them by looks, nowadays sam has adjusted to picking low-maintenance plants to work with his irregular schedule and rhythm. while he won’t go out of his way to cater to their demands, sam will still savour the chance taking a tour through his apartment in peace, watering and tending to them. it’s an act of mindfulness he enjoys, much like watching his indoor fountain or putting the yoga mat in his bedroom to use.

sam has a taste for art. paintings by the likes of franko grignani or jackson pollock decorate the walls of his home with the rare exception being the odd warhol photo - or lithograph. they’re all prints, not originals, although sam will claim they are should you ask him. graphic design elements will follow an abstract expressionist or constructivist style and have bold, clear shapes which pop out to the onlooker. unlike me, sam can afford a 1986’s enorme phone and will likely have purchased one back when it became popular, just to exchange it for a more recent model later on – and to place it back in action one 80’s design was a la mode again. unfortunately, it’s not a cordless phone, and as sam is used to walking around his apartment or office while he’s on the phone, he will usually use his mobile, rather than a stationary one. or just videochat.

sam doesn’t keep any pets and hasn’t ever much cared for them. according to him, they’re tedious and bothersome to clean up after and take care of, much unlike the fish tanks at work, which he has no obligation to clean or feed and therefore enjoys. they don’t enjoy him staring at them too much.

kitchen area: sam’s kitchen doesn’t look like it has ever seen much use, simply because it has never been used much as sam prefers to eat out or at work. the only object to show real signs of wear is the cupboard underneath the sink which stores a selection of various industrial chemical cleaning agents. the – vastly outdated - fridge keeps nourishments fresh but most of them are not meant for his delight. the fridge gives off an eery, red glow when opened at night. since beginning to keep blood bags inside sam’s desire to store any of his food inside has diminished.

bedroom: a large, modern cupboard makes up the entirety of the bedroom’s wall. would it be filled to the brim with clothes years ago, nowadays it contains a modest collection of dress shirts, suit jackets and ties, with the odd casual outfit thrown in. a studded womans jacket is still covered in the laundry shop’s foil with a mobile number attached which doesn’t belong to the laundry shop. a safe was placed in the upper right corner of the cupboard and wall.

the room’s air conditioning isn’t working and the conditioner was utilized to safeguard objects and information which is too sensible to be stored inside a safe, including a transparent vinyl suit that’s obviously been used before.

bathroom: appearances and first impressions count and the busyness of sam’s bathroom reflects the meticulous dedication to his own. whereas personal belongings have been sparsely distributed throughout the rest of his apartment, sam’s bathroom is filled with intimate items, ranging from beauty products to jewelry ( including, for example, his signature perfume, wristwatch or golden necklace ).

multiple prescription bottles line up, unabashedly, on the glass shelf right beneath the large bathroom mirror, some of which would be better off flushed down the drain should anyone ever think of searching his apartment. some glass vials with a dense, transparent fluid inside stack next to syringes still in packaging.

living room: sam keeps an obnoxiously yellow, very heavy ashtray made from concrete on his living room table, despite being a non-smoker. he did use to smoke very early on, even before moving into his apartment, but stopped after being educated on the health risks associated with being a smoker and being on testosterone with instances of thrombosis in his family’s medical history. the ashtray is a design object and was purchased long after he stopped smoking. it’s hardly been used.

a table made from glass and steel serves as a workspace. sam doesn’t store much more than his laptop on it. right beside it is a see-through cocktail cabinet.

should he have guests over ( sam does not keep guests overnight, unless they are the type to share a bed with him ) they’d probably think the white leather couch is meant to be their place of rest for the evening. they’re wrong: sam wants the couch to remain spotless. he has begun to place a vinyl cover on it when work demands the presence of people messy and uncaring enough to not bring any old newspaper to sit on.

a signed, framed photo of a young and handsome man standing next to a piano sits on a mantelpiece that comes without a chimney.

#EDIT.#HURGL i was so sick of this i just said .. fug it and am posting now#honestly i wanted to write meta and instead of writing ABOUT sam i end up writing abt... his home#which is obvs part of ..him.. but .. like i don't think i've ever really mentioned what he does or... likes or anything lmao#it's also a bit of a note for me so i don't randomly forget what i imagine his apartment to look like..#because i tend to do that a lot#and the picture is literally an edited screenshot of sam :')#being mandhandled :')#long ass post about interior#long post ///#i took some liberty with some things...links

6 notes

·

View notes

Text

Deep UV Lithography Market - Forecast (2022 - 2027)

Deep UV Lithography Market

is forecast to reach $1.04 billion by 2025, growing at a CAGR 8.4% from 2020 to 2025. Deep UV Lithography is a lithographic method of an optical projection technique where the reticle/mask pattern is projected onto the wafer surface by means of an optical 4X or 5X device. The wavelengths used in DUV lithography are 248 nm or 193 nm. The revealing light is passed through a chrome-on-quartz photomask, the opaque areas of which serve as a stencil of the pattern they desire. The exposed polymer then undergoes a cycle of chemical production where the unwanted polymer areas are removed leaving the target areas unprotected from subsequent processing. Deep UV lithography is a viable candidate for advanced processes requiring half micron and small features. Deep ultraviolet lithography systems dive deep into the UV spectrum to print the minute features on which the microchip is based. The light sources used in the fabrication of semiconductors are usually excimer lasers and emit either 248-nm or 193-nm light. Typically the light is transmitted through the photomask and then a reduction lens that decreases the pattern size by a factor of 5 to 4 times. Geometry scaling beyond 20 nm demands that semiconductor manufacturers implement a deep ultraviolet lithography. The DUV lithography is one of the leading lithography technologies of the next generation. The technology has increased resolving power and is cost-effective. The global demand for deep ultraviolet lithography systems is therefore expected to be witnessing significant growth in the future.

Key Takeaways

Scaling geometry beyond 20 nm requires that manufacturers of semiconductors implement deep ultraviolet lithography. DUV lithography is one of next-generation leading lithography technologies.

At foundries the amount of wafer processing is usually higher than in IDMs. The foundry has a wide variety of specifications to work for various clients. The foundry has the largest number of wafer processing capabilities in the manufacturing of semiconductors than any other application and the rising use of Deep UV Lithography is expected to contribute to market growth.

The biggest share is expected to be in the APAC market. The growing number of wafer processing capacities and the rising demand for miniaturized devices are the key drivers for the rapid growth of APAC's DUV lithography market.

The DUV lithography is one of the next decade's leading developments in lithography. The global demand for DUV lithography is driven primarily by the increase of miniaturization. Lithography is used for the printing of complex patterns which characterize integrated circuits on semiconductor wafers.

By Application- Segment Analysis

During the forecast period the Foundry segment is expected to grow at a CAGR of 6.9%. The amount of wafer processing at the foundries is normally higher than in IDMs. The foundry has a wide variety of specifications for working with various clients. TSMC is a leading pure-play foundry and has the largest wafer making revenue. In addition, the growing demand for advanced miniaturized packaging is expected to be the main driver for adoption of DUV lithography in foundries. The foundry holds the highest number of wafer-processing capabilities in the semiconductor manufacturing industry than any other leading players.

Request Sample

By Geography - Segment Analysis

APAC currently dominates the global Deep UV Lithography market with a share of more than 42.3%. The rising number of wafer processing capabilities and increasing demand for miniaturized devices are the major drivers for the rapid growth of the DUV lithography market at APAC. TSMC, the world's leading foundry with more than 50% share in the semiconductor foundry sector, has begun investing in expanding its wafer-processing capability and has planned to invest in deep UV lithography. The presence of a large number of semiconductor companies in the area has led to a rise in Asia Pacific's adoption of deep ultraviolet lithography.

Drivers – Deep UV Lithography Market

Trend of Miniaturization

The DUV lithography is one of the leading lithography technologies of the next decade. Global DUV Lithography market is driven primarily by the miniaturization trend. Lithography is used for printing of complex patterns that characterize integrated circuits on semiconductor wafers. Using DUVL, lightweight electronic chips with lower power demands are easy to get. The platform features improved power resolution and is cost-effective. These structures together form an integrated circuit which is known as a chip. The semiconductor industry's unrelenting quest for even more efficient microchips means chipmakers have to cram ever more structures onto a chip, making the chip faster and more efficient while also reducing production costs. This is anticipated to boost the market growth of DUV Lithography.

Rising Investment into New Fab

One of the market driver is ramping up investment in new fabs. One of the key reasons for the growth of the global demand for EUV lithography systems is the rising investment to develop new fabs and expand older facilities. As the emergence of numerous new fabs significantly boosts the EUV lithography market, investments for fab technology and product upgrades, as well as additional capacity, will grow. The World Fab Forecast Report currently tracks 78 new fabs and lines built between 2017 and 2020 or will be initiated and this will help in the market growth of EUV Lithography.

Inquiry Before Buying

Challenges – Deep UV Lithography Market

Limited Acceptance

Limited acceptance and risk of unknown technical flaws are estimated to hamper the market growth. Complexities in taking the DUV technology from drawing boards to actual foundries are one of the major challenges on the DUV lithography market. Manufacturing uncertainties and resulting delays in adoption are also emerging as key challenges for players in the industry. Such issues are expected to hamper market growth of Deep UV Lithography.

Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in Deep UV Lithography Market. Deep UV Lithography Market is expected to be dominated by major companies such as ASML, IEEE, Intel, TSMC.

Buy Now

Acquisitions/Technology Launches

In July 2017, ASML announced innovations in lithography, metrology, and software. ASML's Holistic Lithography integrates a set of products that allows chipmakers to develop, optimize, and control the production process using the 7/5 nanometer (nm) logic and 16 nm DRAM nodes.

In Oct 2019, TSMC announced that the industry's first commercially accessible Extreme Ultraviolet (EUV) lithography technology, the seven-nanometer plus (N7 +), is shipping high-volume customer items. Building on TSMC 's popular 7 nm node, the N7 + process with EUV technology paves the way for 6 nm and more advanced technologies.

0 notes

Text

Printing Inks Market Performance from 2020 to 2029

Based on past and recent market performance, the Printing Inks market is estimated to reach USD 25.62 billion in size by 2029 at a CAGR of 4%.

Overview of the Printing Inks Market

This report provides an evaluation of the most recent developments in the global Printing Inks market. This report focuses on providing a broad perspective to the end-client and assisting them in developing market approaches and plans. The Printing Inks market report investigates and provides a forecast for the period 2020 to 2029.

The research provides an outline and foundation for the Printing Inks market, including section, arrangement, definition, item data, and the most recent turns of events and occasions associated with the market that might influence market activity.

The report addresses issues such as item order, item cost, and item developments. The information is centred on the global market's major drivers, limiting factors, obstacles, and opportunities.

Get the Report Sample Pages for Free@

Key Players Are - Wikoff Color Corporation, T&K TOKA Corporation, Flint Group, Sakata INX Corporation, Huber Group, Sun Chemical Corporation, Zeller+Gmelin GmbH & Co. KG, ALTANA AG, and TOYO Ink Group.

This report includes study Following Regions

North America (Country Analysis: the USA, Canada)

Europe (Country Analysis: Germany, France, Russia, Denmark, and Rest of Europe)

Asia-Pacific (Country Analysis: China, Japan, and Rest of Asia-Pacific)

Rest of the World (Sub-Region Analysis: Latin America, the Middle East, and Others)

Read Out the Summary of the Report Here@

The Printing Inks Market is Segmented As Follows

Printing Ink Market by Printing Process, 2020-2029, (USD Million), (Kilotons)

Lithographic Inks

Flexographic Inks

Digital Inks

Gravure Inks

Others

Printing Ink Market by Application, 2020-2029, (USD Million), (Kilotons)

Packaging

Publication and Commercial Printing

Decorative Printing

Printing Ink Market by Product Type, 2020-2029, (USD Million), (Kilotons)

Solvent Based

Water Based

Oil Based

UV-Cured Inks

Ten Reasons to Buy this Report

Gathering industry knowledge quickly

Internal research validation

Obtain a Complete Market Analysis

Use Objective Data to Make Informed Decisions

Strengthen Your Credibility and Reputation

Recognize Business Opportunities Easily

Know Where to Advertise

Raise Your Company's Objectives

Maintain a customer-centric mindset

Enhance Your Interaction with Your Audience

#Printing Inks Market Analysis#Printing Inks Market Research#Printing Inks Market Size#Printing Inks Market Share#Printing Inks Market Technology#Printing Inks Market Scope#Printing Inks Market Opportunity#Printing Inks Market Trend#Printing Inks Market Outlook#Printing Inks Market 2022#Printing Inks Market Forecast

0 notes

Photo

Studio tidy finds. Amazing technical printing manuals from 1933 "The Art And Practice Of Printing. Complete In Twenty Four Parts' and my first poster, and piece of design work, from fourteen (?) years ago. Everything was stencilled, sprayed then scanned. I barely know what.I was doing as far as computers went. Can't argue with past Jones's choices though, DIN stencil font, biohazard/japanese clan sigil logo, single colour black litho on yellow cardstock. Printed at Juma by a partially sighted printer. You had to walk across the floor of an old kickboxing gym to get into the printshop at the time. The smells of sweat and blood fading into the printshop of warm metal, paper and the curious chemicals of ink will stay with me forever, as will the noises, the musical echoing chink of punchbag chains, feet on mats, swearing and the physical noise of sparring which blended into the intricate industrial clanking of old Victorian lithographic presses Martin was still refusing to stop using at the time. This was for Sequoia's first outing as a soundsystem at the Red House, a tiny pub that was fine with you filling it halfway with speakers! Also responsible for starting and hosting Tinnitus Danger Noise sound and the legends of Offmenut records. I'd painted all the speaker grilles in a tessellating lionhead pattern too, if anyone's got any pictures of that I'd love to see it again... . . . #roots #design #printing #start #sequoia #soundsystem #music #musicposter #throwback https://www.instagram.com/p/Bsf_Y7oA6ST/?utm_source=ig_tumblr_share&igshid=tf2vj1rhyp73

1 note

·

View note

Text

system uses auto powerful ramping to provide

The Curing system is used for flexographic printing which is used to make packaging and label material. Less downtime: The Curing system involves auto troubleshooting and auto fault protection for maximizing uptime. Screen printing is a very professional and economical way of any marketing company. What is UV Curing System? UV Curing system involves the transformation of a liquid into a solid by using light energy with low temperature and chain-addition polymerization. Some of the distinct benefits of Curing system purchased from renowned UV Curing System manufacturers are as follows - High standard print quality: The methodology involves rich solid, the outstanding density of ink and fine print quality for printing services. Chemical protection: The methodology includes cross-linking by a chemical reaction which gives high-quality chemical protection for exclusive product quality and excellent product longevity.

The industries, which use the Curing technique, are varied and diverse. There is no use of volatile organic compound or emission into the atmosphere when the UV Curing system is used. This technique is also used in 3D printers to make products such as signage, posters, packaging, labels and 3D objects. Moreover, this technique is used in screen printing which is essential for direct tube and bottle decoration which eliminates the requirement of levelling. The application of UV curable ink has developed automation specifically in manufacturing sectors. In the advanced technology of Curing methodology, the material is generally dried or solidified when it escapes from the UV cure area.

The UV Curing system is an important drying method in screen printing applications. So, screen printing machine manufacturers includes UV Curing system in screen printing machines. Benefits of UV Curing System There are several benefits of Curing system Cardboard Tubes Packaging company in the coating, converting and printing. This technique is essential to develop the product quality and provide unique designs including an excellent product performance according to the customers&39; requirement. Application of UV Curing System UV Curing system provides many advantages over other finishing procedures. The reaction of polymerization is initiated by a chemical reaction of a low amount of ingredients which is named as the photoinitiator. Durability: An effective coating abrasion, ink density, and chemical resistance help to keep the superior quality of the product for a long time.

Presently, most of the inks are made based on free radical chemical compounds which offer a comprehensive solid system. It absorbs and starts reacting to the UV light. Moreover, UV curable inks are free from any kind of solvent which can evaporate at the time of curing. Less amount of energy consumption: The technology of Curing system uses auto powerful ramping to provide the right amount of power-saving the valuable energy. The required time for Curing technique is less than traditional thermal curing method. Any efficient commercial printing services need to offer high-quality printing services.. Green technology: Coating, solid inks, and adhesive are dried through exposure to the powerful UV light. A solvent like water-based inks was applied for textile printing, flexographic printing, screen printing and so on. These industries for medical products, automotive components, CDs and DVDs, electronics, pipe and tube coating, fibre optics, furniture, flooring, containers, and packaging. Usually, product lines include a coating on different types of metal, wood, plastic, and paper, inks for lithographic, letterpress, screen printing and gravure and adhesive for foil, film or paper substrates.

0 notes

Text

Research: Printing techniques in the 1920′s

Throughout the course of my research I spent time looking at various printing techniques in the 1920′s, especially for printing posters. The most common technique I found and looked into was lithography, and various subsets within it such as stone lithography and offset lithography. The early version of offset lithography was four-color lithography, used by designers such as Jules Cheret. Silk-screen printing was also developed in 1907 but not popularised until later years. I also saw a lot of developments in typography and stamp printing throughout my research but focused on poster and advertising printing.

The key sources that I found to be useful are attached below, with quotes of the most useful information and my own annotations.

This blog from a screen printing company founded in 1982 was very interesting and useful information on screen printing.

https://anatol.com/screen-printing-an/a-history-of-screen-printing-tracing-our-industrys-roots/

The early days of modern screen printing

From its earliest roots, screen printing would be revolutionized through the 20th century into what we know it as today: A way to quickly and easily produce images on a variety of items, as well as an art form that allows artists to create unique, interesting imagery on a variety of substrates. As with most modern-day technologies, the process evolved rapidly throughout the 20th century due to industrial and technological advances so that it could be used to cheaply and efficiently produce items for mass consumption.

The rest of the blog article goes on to discuss the use of screen printing in America and in the 20th century, so that was not relevant to the topics I am looking at for my essay. However, I found this interesting and the early development of silk screen printing in Europe in the 1900′s.

The images in the moodboard above are sourced from How Posters Were Made. (2018). France. https://posterfrance.com/content/4-how-posters-were-made.

This article unpacks 5 parts:

1 - Stone Lithography

2 - Offset Lithography

3 - A poster is not just a lithograph

4 - What is an "original" poster

5 - Linenbacking explained

This was one of the most helpful sources for my subject. It explained the different types of printing at the time and their relevancy, I also found imagery in this article with my original “personality��, Leonetto Cappiello. He is in the top right images, working on the lithograph we see in the very corner.

“Leonetto Cappiello at Vercasson Imprimerie working on a limestone”

...Lithography is unique among printmaking techniques in the way that it allows the artist to draw freely on the stone. Artists from a wide variety of media other than printmaking are drawn to lithography because of the directness of its process. After the artist has completed his drawing, the stone is chemically treated to fix the image securely.

The article discusses the practical process of developing and creating a lithograph, including the drawing, soaking and finally the printing stage. It’s also useful for mass production and printing.

Part 4 - What is an "Original Poster"

Posters can be made by any printing method ie: serigraph, stone lithograph, offset lithograph, woodblock, silk screen on any number of types of paper. A poster is a "publicity" for something....

The important aspect is that the "poster" no matter what artistic merit, no matter what printing technique, is the original printing for the event or product and was "either used or intended for use at the time" for that purpose. Some posters were reprinted by the advertiser when a publicity campaign was successful like "Thermogene" by Cappiello which actually had close to a 1/2 century of use with printings in many countries, by many printers, and many consecutive years...

It’s not the technique that sets the value, but the demand for the piece. What set's the demand, can be a variety of factors ie: Artist, image, place, product, rarity, condition, and other factors.

My next source is another article about the making of posters.

How Posters Were Made. (2018). France. https://posterfrance.com/content/4-how-posters-were-made

The article discusses, similarly to the previous one, the processes of making posters. This is done in a timeline format, however, and discusses beyond the era I am researching and occasionally in a different place. It was still useful to develop my understanding of the topic and the context around what I am looking at.

1907 – Using silk for screen printing

The Englishman Samuel Simon is awarded a patent for the process of using silk fabric as a printing screen. Screen printing quickly becomes popular for producing expensive wallpaper and printing on fabrics such as linen and silk. Screen printing had first appeared in China during the Shang Dynasty (960–1279 AD).

1911 – Roland presses and Intertype typesetters

The first offset press to bear the name Roland appears on the market. It is manufactured in Offenbach, Germany by Faber & Schleicher AG. The company had been founded in 1871 and started shipping its first Albatros press 4 years later. Their 1922 single-color Klein-Roland 00 offset press can print up to 5000 sheets per hour. US newspaperman Hermann Ridder founds the International Typesetting Machine Company which manufactures the Intertype. This typesetter has a simpler design than the Linotype. In late 1912 the first machine is installed at the New York Journal of Commerce. It costs $2150 which is over $53000 in today’s currency.

1912 – Offset printing takes off

There are already 560 offset presses in operation in the United States. By the 1930s it is the dominant form of lithography.

1 note

·

View note

Text

Printing Processes for Art Prints

You've finally bought that art print you've been eyeing and are looking forward to showing it off to your visitors and friends, but before you start hanging it on the wall, you might want to spend a minute or two to consider how these prints were made. That piece of art that you bought is certainly not the original. It is a reproduced print made from the original art work. Art prints are created using different printing processes, and you may have come across these different terms as you were making enquiries and shopping for your print. Before making your purchase, it would be helpful to know the printing process by which your art print was made. Below is a brief description of some of the more common printing methods for art prints: Giclee Print pronounced as zhee-klay, it is a French word which means a spray or spurt of liquid. The name is descriptive of the way in which the print is created. A giclee is basically a digital printout of the original art work, created from digital scans of the original. Once the scan is made and the image digitally archived, a sophisticated printer then makes a high resolution printout with high quality inks. The printer does this using a fine stream of ink, resulting in vivid, pure color with exceptional detail. A giclee can be printed in various sizes and onto various mediums like canvas and photo paper. An advantage of giclee printing is the high level of accuracy and richness in color. Another advantage is that it enables artists to make easy reprints of their work to be sold, as and when required, or in bulk. It also avoids the heartache of selling off the original painting. Lithograph A lithograph works on the principle that water and oil do not mix. A hand-made lithograph is a print made by drawing with an oily substance such as crayons and pencils on porous stone or metal plates. An Oil-based ink is then applied to the moistened stone that adheres only to the lines drawn. The plates are then pressed onto a sheet of paper to produce the final print. Serigraph Serigraphy, or screenprinting, is a stencil printmaking process in which high quality paper is placed beneath a screen (or stencil). Ink is then applied over the screen using a squeegee. The screen has certain portions cut out so that the ink can be transferred onto the paper below. This process is then repeated for different screens and color until the final picture is complete. Screenprinting can be used on a variety of surfaces such as textiles, ceramics, metal, wood and paper and is commonly used in industries from clothing to product labeling. If you have any queries with regards to where by and how to use dog word art, you can get hold of us at our webpage. Monoprint A monoprint or monotype is a printing process whereby the artist paints a design onto a plate using a low drying ink. The image is then printed before the ink dries. One characteristic of monoprints, as the term "mono" implies, is that only one unique impression can be made using this process. That is, no two prints will ever be alike. Canvas Transfer A canvas transfer is a process of transferring an art work from a print onto a canvas. A special chemical is applied onto the art print, which when dried, can be separated from the paper and transferred onto a canvas. The canvas is then stretched across a frame and an artist will then apply brushstrokes to create the texture found on the original art work. The end result is artwork on the canvas that looks very much like the original.

1 note

·

View note

Text

specialty ink market -Market 2021 Consumption size , share , growth of the market Market Business Outlook With COVID 19 Pandemic Scenario Analysis

Market Segmentation:

The global specialty ink market is broadly segmented on the basis of type, resin type, application, and region. On the basis of type, the global specialty resin market is divide into thermochromic and photochromic. Thermochromic type of specialty inks are heat sensitive in nature which changes its color when exposed to heat. This segment is projected to hold major share of the market over the forecast period due to its substantial applications in safety & security of confidential documents. Both thermochromic and photochromic type of specialty inks have great potential in protection of documents form forgery, counterfeit, duplications and also from the fake validation of brand.

Based on the resin type, the market is categorized into modified resin, acrylic, cellulose, polyamide, polyurethane, hydrocarbon, and others. Among these types, the modified resin segment is the largest one owing to the flexibility of application and ease of operation offered by this type of specialty ink. Additionally, there is a rise in research activities in this resin type to develop innovative inks to meet ever increasing scope of applications in this market.

By application, the global specialty ink market is classified into printing & publication, flexible packaging, safety & security, entertainment, and others. Among these applications, printing & publication segment is dominating the market on account of greater demand of flexible packaging, surging trend of super market shopping and vast spread print media. In coming years, the safety & security segment is anticipated to grow at considerable rate on the backdrop of rising demand for the product to protect the integrity of security institutions.

Access Sample Report @ https://www.marketresearchfuture.com/reports/specialty-ink-market-5177

Competitive Analysis:

Key players in the global polyurethane catalyst market are IIMAK (U.S.), Sun Chemical (U.S.), Toyo Ink International Corp., (U.S.), TOKYO PRINTING INK MFG CO.,LTD. (Japan), DAIHANINK Co., Ltd. (South Korea), Siegwerk Druckfarben AG & Co. KGaA (Germany), Huber Group Holding SE (Germany), Bordeaux Digital PrintInk Ltd. (Israel), T&K TOKA Corporation (Japan), and Royal Dutch Printing Ink Factories Van Son (The Netherlands), among others.

Regional Analysis:

There are five major regions in which the global specialty ink market is divided into: Asia Pacific, Europe, North America, the Middle East & Africa, and Latin America. Asia Pacific is set to dominate the market. It held over 35% share of the market, as of 2016. The region is anticipated to remain dominant in both production and demand of specialty ink. Growing consumer awareness and favoring regulatory trends in this region are driving growth of the market during the forecast period. India, Japan, South Korea and China are the leading markets in this region. North America is holding the second largest share of the market. The U.S is anticipated to hold the maximum share in this market, which is attributed to the presence of major market players and substantial end users such as foods & beverages and packaging industry. Europe is following North America in terms of market size, with Germany, the U.K and France holding considerable share of the market. This region is witnessing a growth due to some strategic initiatives on part of regulatory agencies. The Middle East & Africa is a swiftly growing market where the growth is driven by the demand from foods & beverages and tourism industry. Latin America is anticipated to witness a rise in the regional market due to the pacifying political and reviving economic situation.

Market Overview:

Ink is a complex aqueous medium that is composed of solvents, pigments, dyes, resins, lubricants, solubilizes, surfactants, particulate matter, fluorescents, and other materials. Each of these components of inks serve many purpose such as the ink carrier, colorants, and other additives affect the flow and thickness of the ink and its dry appearance. The specialty inks are the special purpose inks that are intended to fulfil needs of the distinguished applications which can be hardly served by their counterpart. The product is majorly used to print the substrates such as paper, composites, metal foils to impart a design, or draw a high importance or confidential text on it. These types of inks are either available in the form of thick paste or liquid, in the market. Thicker inks are primarily used in letterpress and lithographic printing and the thinner form is applied on the substrate by using a pen, brush, or quill. There are various applications wherein the specialty inks have successfully penetrated so far such as security printings, cheque printing, fluorescent that catches attention, metallic shade inks, and carbon copy paper printing ink, among others. According to the leading research organizations, the global printing ink market for packaging is estimated to grow at significant growth rate of 6% due to surging global demand for the label packaging, which provides nutritive and product information. At present, with the rising cases of document breaching, forgery, counterfeit, and fake branding, the demand for the specialty inks is projected to rise manifolds. However, there are some factors that hamper growth of the market such as the fluctuations in the crude oil prices, cost intensive nature of new technologies and shift from traditional to digital market.

NOTE: Our Team of Researchers are Studying Covid19 and its Impact on Various Industry Verticals and wherever required we will be considering Covid19 Footprints for Better Analysis of Market and Industries. Cordially get in Touch for More Details.

#Specialty Ink Market#Specialty Ink Market Sales#Specialty Ink Market Trends#Specialty Ink Market Analysis#Specialty Ink Industry

1 note

·

View note