#Lithium Ion Battery Manufacturing Equipment Supplier

Explore tagged Tumblr posts

Text

Understanding the Importance of Regular Testing with Hynn Battery Pack Testers

In today's fast-moving world, demand for effective and dependable battery technology is at an all-time high. Be it electric vehicles, renewable energy systems, or consumer electronics, batteries are at the very heart. Standardized testing with advanced equipment—like the Hynn Battery Pack Tester—is how one ascertains safety, ensures reliability, and realizes optimal performance.

Why Regular Testing Is Important?

A battery pack is composed of many cells, and only one weak cell may create serious problems. That is why periodic testing is so very important, to avoid huge failure costs by spotting problems in their early stage. Here are some of the key reasons why Hynn Machines have been considered vital for testing:

Ensure Safety: In terms of battery manufacturing, safety is very important. Overheating or overcharging may result in dangerous malfunctions, which means that regular testing with the Hynn Battery Pack Tester significantly decreases safety risks as it detects problems before they have time to escalate.

Performance Optimization: Performance would be left at the mercy of such factors as capacity, charge cycles, and environmental conditions. The Hynn Battery Cell Tester provides the manufacturer with the actual health of a battery to optimize performance for longevity with greater efficiency.

Improve Quality Control: Battery manufacturers are always in pursuit of keeping quality standards at their best. Testing with the Hynn Battery Pack Tester ensures that each and every lot emerges at standards set under rigorous standards, detects defective units early in production, and increases overall efficiency in the process.

Improve Long-term Reliability: Long-term reliability is a factor in applications like EVs or energy storage systems. Frequent testing helps manufacturers prove that battery packs will be consistent not only now but also for a long time. The Hynn Battery Pack Tester provides very detailed data about degradation and charge cycles that can help predict long-term performance.

Compliance with the Requirements: With regulations becoming more stringent, compliance in the battery industry is increasingly important. As frequent testing is conducted by Hynn Machines, batteries can be guaranteed to work under all levels of safety and environmental considerations. Indeed, with comprehensive reports produced by the Hynn Battery Pack Tester, there is even a guarantee for compliance with both local and international standards.

The Role of Hynn Machines in Battery Testing

Examples include the Hynn Battery Pack Tester and the Hynn Battery Cell Tester, which are designed to provide accurate and reliable data. The equipment has been very helpful for any battery manufacturer looking forward to optimizing performance and safety. Here's why they stand out:

Comprehensive Data: Hynn Machines present in-depth data on voltage, current, temperature, and internal resistance, thus helping manufacturers with the information they require to keep batteries running efficiently.

Ease of Use: The Hynn Battery Pack Testers are user-friendly, and thus the device is made available for beginners and experts alike, hence fastening the testing process.

Wide Applications: Be it for small-scale batteries for application in electronic components or high-scale ones for EVs, Hynn Machines have grown capable of handling each type of battery.

Advanced Power Solution: The Hynn Power Cabinet System assists with accommodating large-scale energy storage and distribution; scalable solutions are made available to manufacturers as per their needs.

Why Partner with a Reliable Supplier?

Working with a reliable Lithium-Ion Battery Manufacturing Equipment Supplier can ensure that you get optimum output from your testing processes. A good supplier will ensure that you have all modern tools in your workshop, like the Hynn Battery Pack Tester, Hynn Battery Cell Tester, and Hynn Power Cabinet System. Such advanced machines go a long way in helping your batteries meet the highest standards of safety, performance, and durability.

Conclusion

Manufacturers willing to stay on top in the competitive battery industry have to undertake regular testing with the Hynn Battery Pack Tester. Regular testing ensures that battery safety and performance are maintained while highlighting areas for quality improvement. These steps result in reliable battery packs that meet all regulatory standards as well as consumer expectations. Consider partnering with a trusted Lithium-Ion Battery Manufacturing Equipment Supplier offering advanced tools—Hynn Machines—that make the process efficient, compliant, and reliable.

#hynn machines#hynn battery pack tester#hynn battery cell tester#hynn power cabinet system#lithium ion battery manufacturing equipment#lithium ion battery manufacturing equipment supplier

0 notes

Text

#Battery Manufacturers in India#Best Battery Sector Stocks in India#Indian battery maker#Top EV Battery Manufacturers in India#best battery suppliers in India.#lithium-ion battery manufacturers in India#leading battery manufacturers in India.#supply high-quality automotive battery#largest Battery Manufacturer In India#India's first lithium-ion battery factory#India's largest automotive batteries manufacturer#Indian battery manufacturing ecosystem.#The largest battery producer in India#Features of Lithium Batteries#electrical equipment manufacturing#Lithium Ion Battery Manufacturers Stocks In India#best manufacturer and supplier of li ion battery#Lithium Battery Manufacturer in India#TDS Lithium-Ion Battery#Lithium-ion Battery Manufacturers In India#Lithium-ion battery manufacturers and assemblers in India#TDS lithium Battery#lithium-ion battery manufacturers in india for electric vehicles#top ev battery manufacturers in india#lithium-ion battery rechargeable#list of electric vehicle battery manufacturers in india listed#in nse#12v 150ah lithium ion battery price in india#24v lithium ion battery for solar

0 notes

Text

Empowering lithium battery production line, revealing Second Intelligent's “smart” engine

● New Energy Power Battery Core Coating Project ●

Thanks to the explosive development of the new energy automobile industry, the lithium battery also ushered in a period of rapid development. Shenzhen Second Intelligent Equipment Co., Ltd (Second Intelligent) lithium battery gluing machine equipment is based on the new energy lithium battery packaging section, through the core, side plate, end plate, insulating sheet, etc. to glue to achieve bonding, sealing, thermal conductivity and other functions, its performance requirements and stability have reached the international leading level.

In 2023, Second Intelligent provided more than 20 sets of gluing machine equipments for 3 production lines of a new energy power battery manufacturer, which helped it to further improve the production efficiency, meet the market demand for production capacity, and escort the stability of product quality, and helped the customer to rapidly expand the market share!

New energy, new opportunities!

With the new energy vehicle market penetration rate continues to increase corresponds to the global power battery manufacturing continues to expand. Currently, the demand for power batteries is “blowout” explosive growth. Industry data predicts that the global electric vehicle sales of 23.3 million units in 2025, corresponding to the demand for power batteries amounted to 1,691GWh.

2021-2025 power battery demand CAGR of nearly 48%.

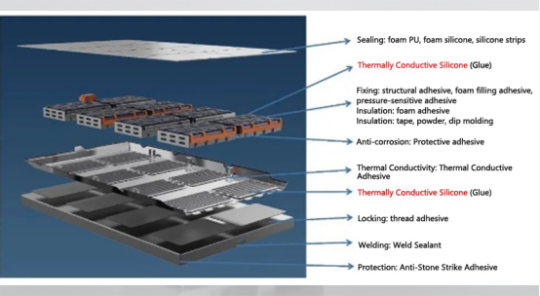

| Adhesive technology in the battery system application point

The power battery is the "heart" of new energy vehicles. It refers to the rechargeable battery system used in new energy vehicles to provide power sources. The battery cell is the smallest unit of a battery system. Multiple battery cells form a module, and multiple modules form a battery pack. This is the basic structure of automotive power batteries.

Behind the rapid development of the industry is the continuous technological refinement of the manufacturing process and supporting equipment. Among the many key processes and materials, new energy power battery cell gluing as one of the most important processes in the assembly process, how to improve the precision of gluing,

Stability and automation has become the focus of industry attention.

To solve the reliability of new energy vehicle batteries, it is necessary to deal with the “core gluing” problem. Therefore, the well-known brands of new energy power battery cell suppliers in all aspects of the screening is very strict.

New energy power battery market demand soars, and lithium-ion coating machine as an important battery core production equipment, its market demand is also increasing. At present, in the domestic new energy automobile industry chain rapid development background, lithium-ion coating machine development trend is good.

| Choosing Second Intelligent to build new energy power battery cell coating project together

After seventeen years of technological precipitation and innovation, customizable solutions, professional design, fast delivery and excellent service, Second Intelligent has gradually established a brand image of high quality, credibility and service in the industry. Against this background, the new energy power battery manufacturer finally chose Second Intelligent.

The new energy power battery manufacturer finally selected Second Intelligent as the new energy power battery core coating supplier, the two sides of the team strong combination, around the site environment and process technology needs, from the early equipment program planning to the late equipment on-line always maintain close communication and cooperation.

Since December 2022, after receiving the customer's new energy power battery cell coating project procurement needs, the team composed of R&D, engineering, after-sales, project and sales of Second Intelligent, responded to the customer's needs in a timely manner, decomposed the customer's needs, carried out product validation, and efficiently linked the functions of various sections within the company, closely communicated with the customer and finalized the program.

Communicate closely with the customer and finalize the details of the program. Second Intelligent team and customer team keep online meeting about 2 times a week to continuously optimize the solution design.

In March and April 2023, the equipment for this project was delivered in stages. Due to the imperfect supporting facilities of the manufacturer affected the commissioning time, Sechun technicians actively cooperated with the customer, overcame the difficulties with the customer, chased the progress, and compressed the commissioning time from the original plan of 1 month to 10 days. Due to the tight time,

Due to the tight time and heavy task, the technicians worked overtime and sprinted with all their strength, and finally the equipment was put into normal use according to the original date and the task was successfully completed. The debugging personnel stationed at the customer's production site, set up night shift rotation, always focusing on the customer, and the spirit of continuous fighting were fully affirmed by the customer.

It shows the team spirit of hard work and excellence of Second Intelligent people.

This is not only due to the exploration and development of Second Intelligent team, but also inseparable from the customer's high trust to Second Intelligent. In the process of project communication between the two sides, the customer always encourages Second Intelligentteam to give full play to the technical advantages in the lithium equipment overall solutions for the new energy power battery core gluing process to provide new technology,

New ideas to solve the industry automation and industrialization problems. In the end, Second Intelligent also lived up to the expectations, riding on the momentum to make progress, and completed the answer sheet with more than expected performance, and a number of innovative designs are more efficient compared with traditional solutions.

The new energy power battery manufacturer said that this is a very happy cooperation, Second Intelligent team solved the glue production line problems that had been bothering for a long time, and the project also shines because of the power of mutual creation and prosperity, and we hope that the two sides can cooperate in more fields in the future.

| Technological innovation, help lithium industry high-quality development

The main body of this equipment consists of loading system, transfer system, feeding system, metering system, distribution system, etc., with the lack of material monitoring, pressure monitoring, flow monitoring and other functions, through software control and information management (MES system) into a glue raw material processing,

Through software control and information management (MES system), it becomes a gluing machine with the functions of raw material handling, precise metering and automatic mixing, with high stability and high precision, which effectively improves the overall production efficiency of the production line.

| Second Intelligent-Battery cell glue coating machine

The feeding system adopts a pressure plate pump, which can reliably transfer glue from the raw material drum to the transit tank. It has the following technical advantages: new NXT air motor for durability, less pulsation for uniform glue pattern; lowest initial investment cost, the system has reliable feeding capability;

High-quality shared parts reduce maintenance time, normal use time > 6 months; pump contains low level alarm, to low level automatic shutdown; integrated air control method, easy to operate, according to the needs of different sizes and materials of the pump body can be selected.

Metering system for high filler, highly abrasive materials, improve service life. Stable flow rate of glue discharge, high precision and repeatability. Pressure monitoring, through the control of the system pressure, to eliminate the beginning and end of the glue start and end point of the size of the head, line consistency is high; and can monitor the system pressure, high and low pressure alarm.

Pump body structure design, reduce dead space, into the glue out of the basic push through, to prevent glue accumulation.

Mixing system using two-component dispensing mixing valve, dual cylinder control, can be individually controlled A/B, with a suction-back structure, no glue dripping, no pulling, no glue leakage after closing the valve. Universal dispensing head, can be matched with standard static mixing tube, with proportional dispensing head, easy to test the ratio.

The modular design of this gluing equipment facilitates the maintenance and repair of customers and saves the maintenance and repair cost. Repeatedly verified components and control programs to ensure the long-term stable operation of the equipment, improve the customer's production capacity. 24-hour continuous production, no downtime for glue drum change, the equipment can be unmanned, reducing the customer's labor costs. The real-time uploading of key parameters of the equipment provides strong support for the traceability of each product. Simple and clear control interface, easy-to-operate control mode, and perfect anti-dumbness and anti-error settings can be easily operated to avoid the loss caused by unfamiliar operation.

This cooperation marks the customer's high recognition of the lithium equipment created by Second Intelligent, and also highlights the strong technical strength of Second Intelligent in the automated production and manufacturing of lithium equipment and rich process areas, which is an important demonstration and driving role for the company's new energy power battery business promotion and expansion.

Second Intelligent sales elites also have confidence and ability to add bricks and mortar for more lithium industry production lines.

Second Intelligent gluing machine, used in lithium industry well-known brands, rapid breakthroughs in research and development and batch application in the market, casting Second Intelligent in the field of power battery gluing the leading position, for the subsequent expansion of more new energy power battery gluing projects and cooperation has strengthened a solid foundation. As an enabler of the new energy power battery industry chain, in line with the three major trends of the lithium equipment industry line, standardization and globalization, in the future, Second Intelligent Intelligence will pay close attention to the technological development of the new generation of batteries, and carry out product iteration in a timely manner in accordance with the requirements of the new process and new equipment, and continue to promote the innovative development of the lithium industry together with our partners and lead the industrial progress.

Cylindrical Core Module

0 notes

Text

Lithion Unveils Next-Generation BMS with Unmatched Safety Features and Up to 16 Temperature Sensors

With the release of its most recent Battery Management System (BMS), Lithion has once again demonstrated its dedication to safety and innovation in the face of the battery industry's unprecedently rapid advancement. This new BMS has innovative features, such as support for up to 16 temperature sensors, and is intended for applications that demand accurate thermal monitoring and increased safety.

The Need for Advanced Battery Management

The need for dependable and secure battery systems is greater than ever in the age of electric vehicles (EVs), portable electronics, and renewable energy storage. Despite their extreme efficiency, lithium-ion batteries have inherent dangers that can jeopardize safety, such as thermal runaway and overcharging. By keeping an eye on, balancing, and safeguarding the battery cells, a strong BMS is necessary to reduce these hazards.

Key Features of Lithion’s New BMS

1. Comprehensive Thermal Monitoring

With support for up to 16 temperature sensors, Lithion's BMS offers unmatched thermal monitoring capabilities. This characteristic makes it possible for:

Enhanced safety: Precise temperature data across multiple cells ensures early detection of anomalies.

Improved lifespan: Consistent thermal management reduces the stress on battery cells, extending their operational life.

Wide application scope: Suitable for large-scale battery packs in EVs, energy storage systems, and industrial equipment.

2. Safety-Centric Design

The foundation of Lithion's design philosophy has always been safety. Advanced protective methods are integrated into the new BMS, including:

Overcharge and over-discharge prevention.

Short-circuit protection.

Real-time fault detection and automatic shutdown capabilities.

3. Scalability and Flexibility

The system is designed to adapt to various battery configurations, making it ideal for:

Modular battery systems.

Applications ranging from consumer electronics to high-capacity energy storage units.

4. User-Friendly Interface

With an intuitive interface and advanced diagnostic tools, users can:

Monitor battery health in real-time.

Access detailed logs for performance analysis.

Customize settings to suit specific application needs.

Applications and Impact

Industries dependent on battery technology are expected to undergo significant change with the advent of this high-precision, safety-focused BMS:

Electric Vehicles: The automotive industry can benefit from enhanced safety and reliability, addressing consumer concerns around battery fires.

Renewable Energy Storage: As renewable energy adoption grows, robust battery systems are critical for grid stability and efficiency.

Industrial Applications: From robotics to heavy machinery, industries can leverage this BMS for safer and more efficient operations.

The Future of Battery Management

Battery management technology has advanced significantly with Lithion's most recent BMS. It tackles the difficulties of contemporary battery systems head-on by fusing cutting-edge heat monitoring with extensive safety features. Innovations such as these will be essential in guaranteeing efficiency, safety, and sustainability as industries continue to adopt electrification.

Lithion's new BMS is a game-changer worth investigating whether you're an EV manufacturer, a renewable energy supplier, or an enthusiast for industrial technology. It establishes a new standard for the sector with its capacity to manage intricate battery systems while putting safety and performance first.

#lithium battery#lithion#battery management system#bms#lithion power#batterymanagementsystem#electricvehicle#ev#lithionpower

0 notes

Text

Top 15 Market Players in Global Graphene Oxide Nanoplatelets Market

Top 15 Market Players in Global Graphene Oxide Nanoplatelets Market

The global graphene oxide nanoplatelets (GONPs) market has seen remarkable growth in recent years, driven by advancements in nanotechnology, expanding applications in diverse industries, and increasing investment in R&D. Here are 15 key market players contributing to the growth and innovation in this space:

XG Sciences Known for its advanced materials solutions, XG Sciences is a leader in graphene nanoplatelets production, offering customized solutions for various industries.

Angstron Materials Inc. A pioneering company in graphene oxide and graphene nanoplatelet production, Angstron Materials focuses on R&D for applications in energy storage, coatings, and composites.

Graphenea Based in Europe, Graphenea is a major supplier of high-quality graphene oxide and graphene nanoplatelets for academic and industrial use.

CVD Equipment Corporation This company specializes in chemical vapor deposition systems and offers graphene materials tailored for electronics and energy storage.

Haydale Graphene Industries Haydale integrates graphene and other nanomaterials into innovative composite solutions, enhancing product performance across industries.

Global Graphene Group (G3) G3 focuses on scalable production of graphene oxide nanoplatelets and offers advanced materials for lithium-ion batteries and thermal management applications.

ACS Material, LLC A global supplier of high-purity graphene oxide nanoplatelets, ACS Material serves clients in academic research and commercial applications.

Graphite Central Specializing in graphene oxide and nanoplatelets, Graphite Central caters to diverse industries, including energy, construction, and healthcare.

Thomas Swan & Co. Ltd. A UK-based company, Thomas Swan produces graphene nanoplatelets and works on integrating nanotechnology into coatings, plastics, and composites.

Vorbeck Materials Vorbeck focuses on commercial applications of graphene oxide nanoplatelets, particularly in conductive inks, coatings, and composites.

Applied Graphene Materials (AGM) AGM offers graphene oxide nanoplatelets tailored for industrial use, including coatings, lubricants, and energy storage systems.

Nanoinnova Technologies This Spain-based company provides advanced graphene oxide nanoplatelets for academic and industrial applications, particularly in electronics and energy.

Directa Plus Directa Plus specializes in the production of graphene-based materials and nanoplatelets for environmental and industrial applications.

CealTech Known for its innovative approach to graphene production, CealTech offers high-quality nanoplatelets for medical and industrial applications.

Elcora Advanced Materials Elcora mines and processes graphite, offering graphene oxide nanoplatelets for high-performance applications.

Request report sample at https://datavagyanik.com/reports/global-graphene-oxide-nanoplatelets-market-size-production-sales-average-product-price-market-share/

Top Winning Strategies in Graphene Oxide Nanoplatelets Market

To thrive in the competitive graphene oxide nanoplatelets market, companies are adopting innovative strategies. Here are the key approaches being used:

Investment in R&D Companies are heavily investing in research to develop high-quality, scalable, and cost-effective graphene oxide nanoplatelets.

Partnerships and Collaborations Strategic collaborations between manufacturers and end-use industries, such as automotive and electronics, are driving product adoption.

Customization of Products Tailoring graphene oxide nanoplatelets to meet specific industrial needs has become a key differentiator.

Focus on Sustainability Companies are exploring eco-friendly production processes to minimize environmental impact and meet regulatory standards.

Expansion into Emerging Markets Targeting growing economies in Asia-Pacific and the Middle East provides opportunities for new market penetration.

Technology Licensing Licensing proprietary production technologies is helping companies expand their global footprint while ensuring quality control.

Vertical Integration Integrating upstream and downstream processes ensures better control over quality, cost, and supply chain management.

Government Support and Grants Leveraging government initiatives and funding for nanotechnology innovation helps companies accelerate growth.

Product Diversification Expanding applications of graphene oxide nanoplatelets into sectors like healthcare, aerospace, and energy storage broadens revenue streams.

Digital Marketing and Online Platforms Using digital channels to market graphene products and engage directly with researchers and manufacturers enhances visibility.

Cost Optimization Companies are focusing on reducing production costs while maintaining high-quality standards to stay competitive.

Patents and Intellectual Property (IP) Protection Securing patents for proprietary technologies ensures competitive advantage and market exclusivity.

Customer Education Educating customers about the benefits of graphene oxide nanoplatelets through seminars, webinars, and workshops drives adoption.

Focus on High-Growth Applications Targeting booming sectors like electric vehicles, 5G technology, and renewable energy accelerates demand.

Global Supply Chain Optimization Enhancing distribution networks and ensuring timely delivery to global markets ensures customer satisfaction and market growth.

By adopting these strategies, companies can strengthen their market position and capitalize on the expanding opportunities in the graphene oxide nanoplatelets market.

Request a free sample copy at https://datavagyanik.com/reports/global-graphene-oxide-nanoplatelets-market-size-production-sales-average-product-price-market-share/

#Graphene Oxide Nanoplatelets Market#Graphene Oxide Nanoplatelets Production#market players#market size#market share#top trends#revenue#average price

0 notes

Text

Exploring the Forklift Market: Growth and Forecasts for 2025 and Beyond

The global forklift market is expected to reach USD 154.99 billion by 2030 and is anticipated to expand at a CAGR of 13.5% from 2024 to 2030, according to a new report by Grand View Research, Inc. The e-commerce industry has experienced significant growth due to factors such as increased disposable income, widespread internet access, and enhanced shopping convenience. This surge in online shopping, coupled with unpredictable shipping and shopping patterns, as well as direct-to-customer shipments, has led to a substantial increase in retail sales. Hence, this growth in retail sales has brought about a noticeable transformation in warehouse operations. Warehouses are tasked with fulfilling substantial orders for individual items. This shift necessitates greater efficiency among warehouse workers and forklifts in the processes of locating, selecting, and transporting goods within the warehouse space.

Manufacturers such as Toyota Material Handling and Hyster-Yale Materials Handling, Inc. are focusing on investing heavily in R&D activities to manufacture technologically advanced autonomous forklifts. Hyster-Yale Materials Handling, Inc. integrates forklifts with systems such as Enterprise Resource Planning (ERP) and Warehouse Management System (WMS), offering employees a complete real-time view of the automated forklift. In addition, manufacturers aim to reduce the dependency of autonomous forklifts on guide wires, magnets, and lasers. Autonomous forklifts provide stable and consistent performance. These machines may reduce the cost of finding as well as onboarding a new workforce. They decrease product damage and reduce the ergonomic impact of physically demanding and monotonous work tasks for warehouse workers.

Forklift suppliers are constantly upgrading the technologies used in forklifts to provide advanced features, such as operator assist, improved ergonomics, and onboard programming and diagnostics. For instance, in October 2022, Toyota Material Handling (TMH), a forklift manufacturer and warehousing solutions provider, launched an updated version of its 3-Wheel Electric Forklift featuring Toyota Assist's SEnS+ pedestrian detection technology to detect objects and pedestrians within the detection range. Other features included enhanced energy efficiency to allow for a 40% longer run time on a single charge, an auto power mode to detect slopes and automatically switch to a higher power mode to maintain speed, and a lithium-ion battery to minimize maintenance costs and reduce downtime for improved productivity. These enhancements were designed to enable operators to be more productive while incurring a lower cost of ownership over the forklift’s lifespan.

Forklift Market Segmentation

Grand View Research has segmented the global forklift market based on class, power source, load capacity, electric battery type, end-use, and region.

Forklift Class Outlook (Volume Units; Revenue, USD Million, 2018 - 2030)

Class 1

Class 2

Class 3

Class 4/5

Forklift Power Source Outlook (Volume Units; Revenue, USD Million, 2018 - 2030)

ICE

Electric

Forklift Load Capacity Outlook (Revenue, USD Million, 2018 - 2030)

Below 5 Ton

5-15 Ton

Above 16 Ton

Forklift Electric Battery Type Outlook (Revenue, USD Million, 2018 - 2030)

Li-ion

Lead Acid

Forklift End-use Outlook (Revenue, USD Million, 2018 - 2030)

Industrial

Logistics

Chemical

Food & Beverage

Retail & E-Commerce

Others

Forklift Regional Outlook (Revenue, USD Billion; 2018 - 2030)

North America

US

Canada

Europe

UK

Germany

France

Italy

Spain

Asia Pacific

China

India

Japan

Australia

South Korea

Latin America

Brazil

Mexico

Argentina

MEA

A.E.

Saudi Arabia

South Africa

Key Companies profiled:

Anhui Heli Co., Ltd.

Clark Material Handing Company, (Clark Equipment Company)

Crown Equipment Corporation

Doosan Corporation

Hangcha Forklift

Hyster-Yale Materials Handling, Inc.(Hyster-Yale Group, Inc.)

Jungheinrich AG

KION Group AG

Komatsu Ltd.

Mitsubishi Logisnext Co., Ltd.

Toyota Motor Corporation (Toyota Material Handling)

Key Forklift Company Insights

Some of the key players operating in the market include Toyota Motor Corporation (Toyota Material Handling); KION Group AG; Jungheinrich AG; Crown Equipment Corporation; and Mitsubishi Logisnext Co., Ltd.

Mitsubishi Logisnext Co., Ltd is engaged in developing, designing, and selling engine and electric-powered forklifts, local area networks, electric vehicles, automated warehouses, monorails, transportation robots, and other logistics equipment. The company has a strong market presence in North America, Europe, Asia & Oceania, and China. For the company Asia is the most potential market for future growth.

Jungheinrich AG is an intralogistics solutions provider offering a wide product portfolio comprising material handling equipment, digital solutions, automated systems, and related services, including rental services and aftermarket services. The company provides its customers with tailor-made solutions from a single source to help them expand their intralogistics services The company has developed an automated intralogistics workflow using various automated warehouse equipment, mobile robots, and software.

Combilift, BYD, Hangcha Forklift, UniCarriers Corporation, and Maximal Forklift are some of the emerging market participants in the forklift market.

Hangcha Forklift is a manufacturer and distributor of material handling equipment. The company serves industries and industry verticals, such as retail, warehousing, food, pharmaceuticals, logistics, and automotive, along with ports & terminals. The company maintains a product portfolio of pallet trucks, stackers, reach trucks, order pickers, and forklifts.

Maximal Forklift is engaged in designing and manufacturing of material handling equipment. The company owns robot welding equipment, forklifts performance test lines, assembly lines, and coating lines, among others. The company’s current product range covers four series of forklifts, including 13.5-32.0T heavy duty forklift, 1.8-5.0T rough terrain forklift, 1.5-compact12T industrial forklift, and warehouse equipment.

Recent Developments

In August 2023, Jungheinrich AG acquired Magazino, an automated solution provider. The acquisition helped the former company to strengthen position in autonomous mobile robots and related software.

In September 2023, Hangcha Forklift launched a high-voltage Lithium Battery based electric rough terrain forklift. The forklift ranges from 2.5-3.5 ton and features as reduced noise, zero-emission, and fast charging time.

In May 2023, Toyota Material Handling announced the launch of three new forklift models. The new forklifts have features such as standard power steering, industrial tow tractor, automatic parking brake, side-entry end rider, and center rider stacker. These features offer the user enhanced performance, efficiency, and a comfortable operating environment in the cabin. The models fall between the 6,000-8,000 lbs. weight classes and are ideal for order picking and cross-warehouse transportation.

In January 2023, Crown Equipment Corporation announced the launch of an electric counterbalance forklift. The C-B series features electric forklifts equipped with 80-volt motors. The forklifts have applications-oriented ergonomics such as a full suspension adjustable seat, intuitive control system, compact mast, and overhead guard. These features provide enhanced safety and productivity and reduce operator strain and fatigue.

Order a free sample PDF of the Forklift Market Intelligence Study, published by Grand View Research.

0 notes

Text

In today’s fast-paced world, uninterrupted power supply (UPS) systems have become a critical component for businesses and industries. They ensure smooth operations during power outages, safeguard critical data, and protect sensitive equipment. Among various UPS capacities, the 20 kVA online UPS stands out for its robust performance and reliability, making it a preferred choice for medium-sized businesses, data centers, and industrial applications. In this blog, we’ll explore the factors influencing the price of a 20 kVA online UPS and why Online UPS is your trusted partner in securing the best deals.

Why Choose a 20 kVA Online UPS?

Before diving into the pricing details, let’s understand why a 20 kVA online UPS priceis a popular choice:

High Power Capacity: With a 20 kVA capacity, this UPS can support a significant load, making it ideal for critical systems and operations.

Continuous Power Supply: The online topology ensures zero transfer time, providing seamless power during outages.

Voltage Regulation: It offers superior voltage regulation, protecting equipment from voltage fluctuations.

Scalability: Many models allow for scalability, accommodating future growth.

Factors Influencing the Price of a 20 kVA Online UPS

When shopping for a 20 kVA online UPS, the price can vary based on several factors. Here’s what determines the cost:

1. Brand and Model

Established brands often command higher prices due to their proven reliability and customer trust. Specific models with advanced features may also cost more.

2. Battery Backup Duration

The duration of backup provided by the UPS significantly impacts its price. Longer backup times require more batteries, increasing the overall cost.

3. Technology and Features

Advanced features such as remote monitoring, energy efficiency, and scalability add to the cost. Models with lithium-ion batteries are generally more expensive than those with lead-acid batteries.

4. Warranty and Support

A UPS with an extended warranty or comprehensive support package may cost more initially but offers long-term savings and peace of mind.

5. Installation and Maintenance Costs

Some suppliers include installation and maintenance in the price, while others charge separately. Factoring in these costs gives you a clearer picture of the total investment.

6. Location and Shipping

Shipping charges and regional pricing variations can influence the final cost, especially for businesses in remote areas.

Estimated Price Range of a 20 kVA Online UPS

At Online UPS, we strive to provide competitive pricing without compromising on quality. Based on market trends, the price of a 20 kVA online UPS typically ranges from INR 2,00,000 to INR 4,50,000, depending on the brand, features, and battery configuration. We recommend reaching out to our team for personalized quotes tailored to your specific requirements.

Why Choose Online UPS?

Here are some reasons why Online UPS is the trusted partner for all your power backup needs:

1. Wide Range of Products

We offer a comprehensive selection of UPS systems, including 20 kVA models, from leading brands to meet diverse requirements.

2. Competitive Pricing

Our direct partnerships with manufacturers allow us to provide the best prices, ensuring value for money.

3. Expert Consultation

Our team of experts helps you choose the right UPS system based on your unique needs and budget.

4. After-Sales Support

We provide excellent after-sales service, including installation, maintenance, and troubleshooting.

5. Customization Options

We offer customized solutions to meet specific power backup demands, ensuring maximum efficiency and reliability.

Conclusion

Investing in a 20 kVA online UPS price is a smart decision for businesses looking to ensure uninterrupted operations and protect their critical assets. While the price may vary based on several factors, Online UPS guarantees the best deals tailored to your needs. Contact us today for a detailed quote and expert guidance on choosing the right UPS system.

0 notes

Text

Lithium-ion Battery Market 2030 Size Outlook, Growth Insight, Share, Trends

In 2023, the global lithium-ion (Li-ion) battery market was estimated to be worth USD 54.4 billion and is projected to grow at a compound annual growth rate (CAGR) of 20.3% from 2024 to 2030. This growth is largely driven by rising demand for electric vehicles (EVs), supported by the cost-effectiveness and energy efficiency of Li-ion batteries. The automotive sector, in particular, is expected to see significant expansion due to the increasing global registration of EVs, as more consumers seek cleaner and more sustainable transport options. In the United States, the largest North American market for Li-ion batteries in 2023, federal policies and the presence of key industry players are anticipated to drive further product demand. Government policies, such as tax incentives for EV purchases under the American Recovery and Reinvestment Act of 2009, as well as fuel efficiency standards introduced by the Corporate Average Fuel Economy (CAFE) regulations, have accelerated the shift towards electric drive technologies in both passenger cars and light commercial vehicles (LCVs).

In addition to the automotive sector, the demand for Li-ion batteries in consumer electronics is also driving market growth. As consumers seek more durable and energy-efficient devices, lithium-ion batteries are becoming a preferred choice for smartphones, tablets, and other electronics due to their long lifespan and high performance. The demand for EVs is similarly bolstered by growing awareness of carbon emissions and the environmental impact of traditional gasoline-powered vehicles, which motivates consumers to adopt cleaner alternatives. This trend is supported by regulatory pressures on lead-acid batteries due to environmental concerns. Specifically, regulations set by the Environmental Protection Agency (EPA) aim to reduce lead contamination and govern the storage, disposal, and recycling of lead-acid batteries, prompting a shift towards safer Li-ion battery solutions for automotive applications.

Gather more insights about the market drivers, restrains and growth of the Lithium-ion Battery Market

Mexico has also emerged as a strategic center for the global automotive industry, attracting investments from companies worldwide due to its large automotive production capacity. As the fourth-largest exporter of vehicles globally, following Germany, Japan, and South Korea, Mexico's automotive production is expected to further stimulate demand for lithium-ion batteries in the region. However, the market faced challenges during the COVID-19 pandemic. Battery providers had to adapt by reducing operational costs due to lower demand and by managing disruptions in the supply of spare parts caused by reduced manufacturing activity and logistical issues. To maintain service quality for clients with long-term contracts, suppliers turned to digital tools and implemented strict health and safety measures, including social distancing and personal protective equipment, to ensure safe on-site maintenance and repair services where necessary.

Application Segmentation Insights:

The Li-ion battery market is categorized into several application segments: automotive, consumer electronics, industrial, medical devices, and energy storage systems. In 2023, the consumer electronics segment led the market, accounting for over 31% of total revenue. Portable lithium-ion batteries are widely used in consumer electronics due to their compact size, high energy density, and rechargeability. They are incorporated into various devices, including mobile phones, laptops, tablets, LED lighting, digital cameras, wristwatches, hearing aids, and other wearable gadgets. This high demand for portable devices has positioned the consumer electronics segment as a dominant sector in the market.

The electric and hybrid EV market is anticipated to be the fastest-growing application segment over the forecast period. Rising fossil fuel prices and increased awareness of the environmental benefits of battery-operated vehicles are expected to drive this growth, especially in emerging markets across Asia-Pacific, Europe, and North America. Moreover, Li-ion batteries are widely utilized for backup power solutions in commercial settings, such as data centers, office buildings, and institutions. In residential applications, Li-ion batteries are becoming popular for energy storage in solar photovoltaic (PV) systems, enhancing the growth potential of the energy storage segment.

Li-ion batteries are also gaining traction in various industrial applications. They are commonly used in power tools, cordless tools, marine equipment, agricultural machinery, industrial automation systems, aviation, military & defense, civil infrastructure, and the oil and gas sector. The versatility of Li-ion batteries, combined with their ability to deliver consistent power across diverse conditions, makes them ideal for these industries. Their use in such a broad range of applications is projected to further boost market demand as industries seek reliable and efficient energy solutions that can support both heavy-duty equipment and everyday electronic devices.

In summary, the lithium-ion battery market is poised for rapid growth across multiple sectors. The automotive and consumer electronics segments, in particular, are driving demand, supported by governmental policies, environmental concerns, and technological advancements. The expansion into applications like energy storage and industrial machinery further underscores the adaptability and efficiency of Li-ion batteries, positioning them as a critical component of future energy solutions across the globe.

Order a free sample PDF of the Lithium-ion Battery Market Intelligence Study, published by Grand View Research.

0 notes

Text

Environmental Benefits of Laser Welding Machines in Indian Manufacturing

In recent years, the manufacturing landscape in India has seen significant advancements. One of the most notable innovations is the adoption of laser welding machines. These machines are not only efficient but also environmentally friendly. In this blog, we will explore the environmental benefits of laser welding machines in India and why they matter for the future of manufacturing.

1. Reduced Energy Consumption

Laser welding equipment is designed to be energy efficient. They use a focused beam of light to join materials, requiring significantly less energy than traditional welding methods like MIG and TIG. This reduced energy consumption leads to lower operational costs and a smaller carbon footprint for manufacturers. In a world where energy conservation is crucial, this advantage must be noticed.

2. Minimal Material Waste

One of the standout features of laser welding machines is their precision. The focused laser beam creates accurate welds, which minimizes the amount of material wasted during the process. Traditional welding methods often require filler materials, leading to more waste and higher material consumption. By reducing waste, laser welding machines in India contribute to resource efficiency and support sustainable manufacturing practices.

3. Lower Emissions

Laser welding equipment produces far fewer emissions compared to conventional welding techniques. Traditional methods often involve the use of gases and fluxes that can release harmful pollutants into the atmosphere. In contrast, laser welding is a cleaner process, emitting significantly lower levels of harmful gases. This reduction in emissions is vital for improving air quality and protecting the environment.

4. Enhanced Safety

Safety is a critical concern in manufacturing. Laser welding machines operate with less risk of accidents compared to traditional methods that involve open flames or high electrical currents. This not only protects workers but also reduces the potential for hazardous emissions. A safer work environment is essential for promoting sustainable practices in manufacturing.

5. Versatility Across Materials

Laser welding machines in India can handle a wide range of materials, including metals and plastics. This versatility allows manufacturers to optimize processes and reduce the need for multiple machines. By streamlining operations, companies can further decrease their environmental impact while maintaining high-quality standards.

6. Contribution to Sustainability Goals

As industries strive to meet sustainability goals, adopting laser welding equipment can be a significant step forward. The combination of reduced energy consumption, minimal waste, and lower emissions aligns with the objectives of many manufacturers aiming for eco-friendly practices. By investing in laser welding, companies can enhance their reputation as environmentally responsible businesses.

Conclusion

The environmental benefits of laser welding machines are clear. They offer reduced energy consumption, minimal material waste, and lower emissions, all while providing a safer and more versatile manufacturing solution. As Indian industries continue to evolve, embracing laser welding machines in India can lead to a more sustainable future. By prioritizing eco-friendly practices, manufacturers can contribute to a healthier planet while also improving their operational efficiency.

For those interested in expanding their capabilities, partnering with a reputable battery manufacturing equipment supplier in India can help integrate advanced technologies like laser welding into their operations. This collaboration can further enhance productivity and sustainability in the manufacturing sector.

#laser welding machine#laser welding machines in India#laser welding equipment#fiber laser welding machine#battery manufacturing equipment#battery manufacturing equipment supplier#lithium ion battery manufacturing equipment#lithium ion battery manufacturing equipment supplier

0 notes

Text

Lithium-ion Battery Industry Strategies With Forecast Till 2030

In 2023, the global lithium-ion (Li-ion) battery market was estimated to be worth USD 54.4 billion and is projected to grow at a compound annual growth rate (CAGR) of 20.3% from 2024 to 2030. This growth is largely driven by rising demand for electric vehicles (EVs), supported by the cost-effectiveness and energy efficiency of Li-ion batteries. The automotive sector, in particular, is expected to see significant expansion due to the increasing global registration of EVs, as more consumers seek cleaner and more sustainable transport options. In the United States, the largest North American market for Li-ion batteries in 2023, federal policies and the presence of key industry players are anticipated to drive further product demand. Government policies, such as tax incentives for EV purchases under the American Recovery and Reinvestment Act of 2009, as well as fuel efficiency standards introduced by the Corporate Average Fuel Economy (CAFE) regulations, have accelerated the shift towards electric drive technologies in both passenger cars and light commercial vehicles (LCVs).

In addition to the automotive sector, the demand for Li-ion batteries in consumer electronics is also driving market growth. As consumers seek more durable and energy-efficient devices, lithium-ion batteries are becoming a preferred choice for smartphones, tablets, and other electronics due to their long lifespan and high performance. The demand for EVs is similarly bolstered by growing awareness of carbon emissions and the environmental impact of traditional gasoline-powered vehicles, which motivates consumers to adopt cleaner alternatives. This trend is supported by regulatory pressures on lead-acid batteries due to environmental concerns. Specifically, regulations set by the Environmental Protection Agency (EPA) aim to reduce lead contamination and govern the storage, disposal, and recycling of lead-acid batteries, prompting a shift towards safer Li-ion battery solutions for automotive applications.

Gather more insights about the market drivers, restrains and growth of the Lithium-ion Battery Market

Mexico has also emerged as a strategic center for the global automotive industry, attracting investments from companies worldwide due to its large automotive production capacity. As the fourth-largest exporter of vehicles globally, following Germany, Japan, and South Korea, Mexico's automotive production is expected to further stimulate demand for lithium-ion batteries in the region. However, the market faced challenges during the COVID-19 pandemic. Battery providers had to adapt by reducing operational costs due to lower demand and by managing disruptions in the supply of spare parts caused by reduced manufacturing activity and logistical issues. To maintain service quality for clients with long-term contracts, suppliers turned to digital tools and implemented strict health and safety measures, including social distancing and personal protective equipment, to ensure safe on-site maintenance and repair services where necessary.

Application Segmentation Insights:

The Li-ion battery market is categorized into several application segments: automotive, consumer electronics, industrial, medical devices, and energy storage systems. In 2023, the consumer electronics segment led the market, accounting for over 31% of total revenue. Portable lithium-ion batteries are widely used in consumer electronics due to their compact size, high energy density, and rechargeability. They are incorporated into various devices, including mobile phones, laptops, tablets, LED lighting, digital cameras, wristwatches, hearing aids, and other wearable gadgets. This high demand for portable devices has positioned the consumer electronics segment as a dominant sector in the market.

The electric and hybrid EV market is anticipated to be the fastest-growing application segment over the forecast period. Rising fossil fuel prices and increased awareness of the environmental benefits of battery-operated vehicles are expected to drive this growth, especially in emerging markets across Asia-Pacific, Europe, and North America. Moreover, Li-ion batteries are widely utilized for backup power solutions in commercial settings, such as data centers, office buildings, and institutions. In residential applications, Li-ion batteries are becoming popular for energy storage in solar photovoltaic (PV) systems, enhancing the growth potential of the energy storage segment.

Li-ion batteries are also gaining traction in various industrial applications. They are commonly used in power tools, cordless tools, marine equipment, agricultural machinery, industrial automation systems, aviation, military & defense, civil infrastructure, and the oil and gas sector. The versatility of Li-ion batteries, combined with their ability to deliver consistent power across diverse conditions, makes them ideal for these industries. Their use in such a broad range of applications is projected to further boost market demand as industries seek reliable and efficient energy solutions that can support both heavy-duty equipment and everyday electronic devices.

In summary, the lithium-ion battery market is poised for rapid growth across multiple sectors. The automotive and consumer electronics segments, in particular, are driving demand, supported by governmental policies, environmental concerns, and technological advancements. The expansion into applications like energy storage and industrial machinery further underscores the adaptability and efficiency of Li-ion batteries, positioning them as a critical component of future energy solutions across the globe.

Order a free sample PDF of the Lithium-ion Battery Market Intelligence Study, published by Grand View Research.

0 notes

Text

Power-Sports Batteries Market Size, Share, Trends, Opportunities, Key Drivers and Growth Prospectus

"Global Power-Sports Batteries Market – Industry Trends and Forecast to 2028

Global Power-Sports Batteries Market, By Vehicle Type (Motorcycles, Scooters and Mopeds, ATVs and Quads, Golf Carts, Water Sports, Snowmobiles, UTVs, Lawn Mowers), Battery Type (Conventional Batteries, Absorbent Glass Mat (AGM) Batteries, Lithium Batteries, Others) Voltage Range (6 Volt, 12 Volt, 24 Volt, 36 Volt, 48 Volt, Others), Distribution Channel (Original Equipment Manufacturer (OEM), Aftermarket/Replacement), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa)Industry Trends and Forecast to 2028.

Access Full 350 Pages PDF Report @

**Segments**

- **Type:** The power-sports batteries market can be segmented based on the type of batteries, including lithium-ion, lead-acid, and others. Lithium-ion batteries are gaining traction in the market due to their light weight and high energy density, making them ideal for power-sports applications. - **Vehicle Type:** Another crucial segmentation factor is the vehicle type, which includes motorcycles, scooters, ATVs, UTVs, snowmobiles, and others. Different types of power-sports vehicles have varying power requirements, leading to a diverse range of battery specifications. - **Sales Channel:** The market can also be segmented based on the sales channel, including OEMs and aftermarket. OEMs often have exclusive partnerships with battery suppliers, while the aftermarket segment offers opportunities for third-party manufacturers and distributors to enter the market.

**Market Players**

- **Exide Technologies:** A key player in the power-sports batteries market, Exide Technologies offers a wide range of batteries for motorcycles, ATVs, and other power-sports vehicles. The company's focus on technological innovation and sustainability has helped it maintain a strong market position. - **Johnson Controls:** Johnson Controls is another prominent player in the market, known for its high-performance batteries for power-sports applications. The company's strategic partnerships and global presence contribute to its success in this competitive industry. - **Yuasa Battery, Inc.:** Yuasa Battery, Inc. is a leading manufacturer of lead-acid batteries for power-sports vehicles, known for their durability and reliability. The company's extensive product portfolio and commitment to quality make it a preferred choice for many consumers. - **Chloride Exide Ltd:** Chloride Exide Ltd. is a well-established name in the power-sports batteries market, offering a range of products for motorcycles, ATVs, and other applications. The company's emphasis on customer service and product innovation sets it apart from competitors.

For more detailed insights and market trends, please visit:The power-sports batteries market is witnessing significant growth and evolution driven by technological advancements, changing consumer preferences, and expanding applications across various power-sports vehicles. One of the key trends shaping the market is the increasing demand for lithium-ion batteries due to their superior energy density, lightweight properties, and longer lifespan compared to traditional lead-acid batteries. As consumers seek more efficient and high-performance power solutions for their motorcycles, ATVs, UTVs, and other vehicles, the shift towards lithium-ion batteries is expected to continue.

In addition to battery type, the segmentation based on vehicle type is crucial in understanding the specific requirements of different power-sports applications. For instance, motorcycles may require smaller, lighter batteries for enhanced performance, while ATVs and UTVs may need more robust batteries to support their power needs in off-road environments. This segmentation approach allows manufacturers to tailor their products to meet the diverse demands of each vehicle category, driving innovation and competitiveness in the market.

Moreover, the sales channel segmentation highlights the dual dynamics of the power-sports batteries market, with OEMs focusing on exclusive partnerships and aftermarket players capitalizing on distribution networks and aftermarket servicing. OEMs play a critical role in shaping the market through long-term collaborations with battery suppliers, ensuring quality standards and product integration. On the other hand, the aftermarket segment offers opportunities for smaller manufacturers and distributors to enter the market with innovative solutions and competitive pricing strategies to cater to the growing demand for replacement batteries and custom upgrades.

Market players such as Exide Technologies, Johnson Controls, Yuasa Battery, Inc., and Chloride Exide Ltd. are pivotal in driving innovation, market expansion, and customer satisfaction within the power-sports batteries industry. These companies leverage their industry expertise, technological capabilities, and consumer insights to develop cutting-edge battery solutions that meet the evolving needs of power-sports enthusiasts worldwide. From sustainability initiatives to product diversification, these key players are at the forefront of market trends, setting benchmarks for quality, performance, and reliability in the power**Global Power-Sports Batteries Market Analysis:**

- The global power-sports batteries market is witnessing significant growth driven by technological advancements and increasing demand for high-performance batteries in motorcycles, ATVs, UTVs, and other vehicles. - The market segmentation based on battery type highlights the rising popularity of lithium-ion batteries due to their lightweight properties, high energy density, and longer lifespan compared to traditional lead-acid batteries. - Vehicle type segmentation plays a crucial role in understanding the specific power requirements of different power-sports applications, driving manufacturers to tailor their products to meet diverse demands. - The sales channel segmentation showcases the dual dynamics of the market with OEMs focusing on exclusive partnerships and aftermarket players capitalizing on distribution networks to cater to replacement battery demand and custom upgrades. - Key market players like Exide Technologies, Johnson Controls, Yuasa Battery, Inc., and Chloride Exide Ltd. are driving innovation, market expansion, and customer satisfaction through technological advancements and strategic partnerships.

**Segments:**

- **Type:** The power-sports batteries market can be segmented into lithium-ion, lead-acid, and other battery types, with lithium-ion batteries gaining traction due to their light weight and high energy density. - **Vehicle Type:** Segmentation based on vehicle type includes motorcycles, scooters, ATVs, UTVs, snowmobiles, and others, reflecting the diverse power requirements across different power-sports vehicles. - **Sales Channel:** The market segmentation by sales channel encompasses OEMs and

Key points covered in the report: -

The pivotal aspect considered in the global Power-Sports Batteries Market report consists of the major competitors functioning in the global market.

The report includes profiles of companies with prominent positions in the global market.

The sales, corporate strategies and technical capabilities of key manufacturers are also mentioned in the report.

The driving factors for the growth of the global Power-Sports Batteries Market are thoroughly explained along with in-depth descriptions of the industry end users.

The report also elucidates important application segments of the global market to readers/users.

This report performs a SWOT analysis of the market. In the final section, the report recalls the sentiments and perspectives of industry-prepared and trained experts.

The experts also evaluate the export/import policies that might propel the growth of the Global Power-Sports Batteries Market.

The Global Power-Sports Batteries Market report provides valuable information for policymakers, investors, stakeholders, service providers, producers, suppliers, and organizations operating in the industry and looking to purchase this research document.

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Power-Sports Batteries Market Landscape

Part 04: Global Power-Sports Batteries Market Sizing

Part 05: Global Power-Sports Batteries Market Segmentation by Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

The investment made in the study would provide you access to information such as:

Power-Sports Batteries Market [Global – Broken-down into regions]

Regional level split [North America, Europe, Asia Pacific, South America, Middle East & Africa]

Country-wise Market Size Split [of important countries with major market share]

Market Share and Revenue/Sales by leading players

Market Trends – Emerging Technologies/products/start-ups, PESTEL Analysis, SWOT Analysis, Porter’s Five Forces, etc.

Market Size

Market Size by application/industry verticals

Market Projections/Forecast

Browse Trending Reports:

Body Scanner Market Prenatal Genetic Counselling Market Lead Acid Ev Vehicle Market Tuck Top Box Market Hexagonal Boron Nitride Powder Market Erythropoietin Epo Drugs Market Pancreatic Cancer Treatment Market Ionic Liquid Market Oat Bran Market Liquid Sulfur Fertilizers Market Edible Packaging Market Non Gmo Food Market Antenna Market Cervical Intraepithelial Neoplasia Drugs Market Contraceptives Market Triac Market Primary Antibodies Market Breast Implants Accessories Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

How Leading International Battery Suppliers are Empowering Bahrain’s Industrial Growth

Bahrain, a vibrant economic hub in the Middle East, is experiencing a surge in industrial growth, driven by technological advancements and a strategic push towards sustainable energy solutions. At the heart of this transformation are international battery suppliers, whose innovative products and services are playing a pivotal role in powering the nation’s industrial sector. In this blog, we will explore how leading international battery suppliers are empowering Bahrain’s industrial growth and shaping its future.

The Role of Batteries in Industrial Growth

Batteries are essential for various industrial applications, from powering machinery and equipment to providing backup power solutions and supporting renewable energy systems. The demand for reliable, high-performance batteries is growing as industries in Bahrain continue to expand and modernize. This is where leading international battery suppliers come into play, offering advanced battery technologies that meet the evolving needs of the industrial sector.

Advancing Industrial Efficiency

One of the primary ways international battery suppliers are contributing to Bahrain’s industrial growth is by enhancing operational efficiency. High-quality batteries from top suppliers ensure uninterrupted power supply, reducing downtime and increasing productivity. For instance, in manufacturing plants, reliable battery systems are crucial for running automated machinery and maintaining consistent production levels. By providing durable and efficient battery solutions, international suppliers help businesses minimize operational disruptions and optimize their processes.

Supporting Renewable Energy Initiatives

Bahrain is increasingly focusing on renewable energy to diversify its energy sources and reduce its carbon footprint. Leading international battery suppliers are instrumental in this transition by offering cutting-edge energy storage solutions. Advanced battery technologies, such as lithium-ion batteries, are essential for storing energy generated from renewable sources like solar and wind. These batteries ensure a stable and reliable power supply, even when the sun isn’t shining or the wind isn’t blowing. By integrating these energy storage systems, Bahrain can maximize the utilization of its renewable energy resources and move closer to its sustainability goals.

Enhancing Energy Management

Effective energy management is crucial for industrial operations, and international battery suppliers are providing the tools needed to achieve this. Advanced battery systems come equipped with smart management features that allow businesses to monitor and control their energy usage in real-time. This capability is particularly valuable in Bahrain’s industrial sector, where energy costs can be significant. By optimizing energy consumption, businesses can reduce their operational expenses and enhance their overall efficiency. Leading battery suppliers offer solutions that integrate seamlessly with existing systems, providing comprehensive energy management capabilities.

Ensuring Reliability and Safety

Reliability and safety are paramount in industrial settings. Leading international battery suppliers adhere to stringent quality standards, ensuring their products are reliable and safe to use. These batteries undergo rigorous testing and certification processes to meet international safety and performance standards. For industries in Bahrain, this means having access to battery solutions that can withstand harsh operating conditions and deliver consistent performance. The reliability of these batteries translates to increased operational stability and reduced risks, which are critical factors for industrial growth.

Facilitating Technological Innovation

The industrial landscape is evolving rapidly, driven by technological advancements and the adoption of Industry 4.0 principles. International battery suppliers are at the forefront of this innovation, providing batteries that support new technologies such as IoT, AI, and automation. These advanced batteries power a range of smart devices and systems, enabling industries to leverage data analytics, predictive maintenance, and other cutting-edge technologies. By facilitating the adoption of these innovations, international battery suppliers are helping Bahrain’s industrial sector stay competitive and future-ready.

Case Study: AAGE International

AAGE International, a leading international battery supplier, exemplifies the impact of global players on Bahrain’s industrial growth. With a comprehensive range of batteries, including industrial and lithium-ion batteries, AAGE International provides solutions tailored to the specific needs of Bahrain’s industries. Their commitment to quality, innovation, and customer service has made them a trusted partner for businesses seeking reliable power solutions. Through their advanced battery technologies and extensive support services, AAGE International is contributing significantly to the efficiency, sustainability, and growth of Bahrain’s industrial sector.

Building a Sustainable Future

Sustainability is a key priority for Bahrain, and leading international battery suppliers are playing a crucial role in this endeavor. By offering eco-friendly battery solutions and supporting the integration of renewable energy, these suppliers are helping Bahrain reduce its environmental impact. Advanced battery technologies enable the storage and efficient use of clean energy, contributing to a greener and more sustainable industrial sector. The efforts of international battery suppliers align with Bahrain’s vision for a sustainable future, ensuring that industrial growth does not come at the expense of the environment.

Conclusion

The industrial growth of Bahrain is being significantly empowered by leading international battery suppliers. Through their advanced battery technologies, these suppliers are enhancing operational efficiency, supporting renewable energy initiatives, ensuring reliability and safety, facilitating technological innovation, and contributing to sustainability. As Bahrain continues to expand and modernize its industrial sector, the role of international battery suppliers will remain pivotal in driving progress and shaping a prosperous future. By partnering with these global leaders, Bahrain can harness the full potential of its industrial capabilities and achieve long-term growth and sustainability.

0 notes

Text

Benefits of Choosing AAGE International Batteries

In today's technologically driven world, having a reliable power source is essential. When it comes to batteries, AAGE International stands out as a leader in the industry. Here are the key benefits of choosing AAGE International, the international battery supplier, for your battery needs:

Superior Quality and Reliability

AAGE International is known for producing batteries that meet the highest standards of quality and reliability. Each battery undergoes rigorous testing to ensure optimal performance and longevity. This means you can trust their batteries to power your devices, vehicles, and industrial equipment without interruption.

Wide Range of Products

As one of the No.1 global battery distributors, AAGE International offers an extensive product range. Whether you need lithium-ion batteries, lead-acid batteries, or other advanced battery technologies, AAGE International has you covered. Their diverse portfolio ensures that you can find the perfect battery for any application.

Global Reach and Accessibility

Being among the top battery distributors, AAGE International has a robust global supply chain. This allows them to deliver products quickly and efficiently to customers worldwide. No matter where you are located, you can count on AAGE International to provide timely and reliable battery solutions.

Commitment to Sustainability

AAGE International, the best international battery supplier, is committed to environmentally friendly practices. They prioritize sustainable manufacturing processes and invest in green technologies. By choosing their batteries, you are not only getting a top-quality product but also contributing to a greener future.

Exceptional Customer Support

Customer satisfaction is at the core of AAGE International's business. As leading international battery distributors, their dedicated support team is always ready to assist with any inquiries or issues. They provide personalized solutions and expert guidance to ensure you get the most out of their products.

Innovation and Advancement

AAGE International, the leading international battery supplier, continuously invests in research and development to stay at the forefront of battery technology. Their innovative approach ensures that you are getting the latest advancements in battery performance and efficiency.

In summary, AAGE International offers superior quality, a wide range of products, global accessibility, sustainability, exceptional customer support, and innovative solutions. As the best battery traders and leading international battery supplier, they provide reliable and high-performance battery solutions. Visit their official website at aageinternational.com to learn more.

1 note

·

View note

Text