#Liquid Dispenser Manufacturers India

Explore tagged Tumblr posts

Text

Top Liquid Dispenser Suppliers in India

Looking for reliable liquid dispenser manufacturers in India? Explore Urban Bath Accessories, a trusted brand offering liquid soap dispensers. Become a dealership partner in Rajkot. High-quality products and excellent service guaranteed. https://www.urbanbath.in/liquid-dispenser-manufacturers.aspx

0 notes

Text

Filling Line - End to End Packaging Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Filling Line - End to End Packaging Solution in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Filling lines are advanced, automated systems that optimize packaging efficiency for various industries, such as food and beverages, pharmaceuticals, chemicals, and cosmetics. From product filling to capping, labeling, and sealing, these systems provide a seamless, end-to-end packaging solution. Process of Filling Lines: Filling lines follow a systematic, step-by-step process to ensure efficient product packaging: Product Feeding: The raw material or liquid is fed into the system, often from bulk storage tanks. Filling: The system accurately measures and dispenses the product into containers or bottles. Capping: The system automatically places and tightens caps or lids onto the filled containers. Sealing: The system seals containers using heat or adhesives to ensure product integrity. Labeling: The system applies custom labels to containers for branding and regulatory compliance. Inspection: The system conducts quality checks to ensure that the packaging meets standards. Cartoning & Palletizing: The system groups, boxes, and prepares packaged items for shipping. Applications of Filling Lines: Food & Beverage Industry Pharmaceutical Industry Cosmetics & Personal Care Chemical Industry Agricultural Products What is a filling line? A filling line automates the process of filling containers with liquids, powders, or granules. It can include processes like capping, labeling, and packaging for a complete solution. What industries use filling lines? Industries like food and beverage, pharmaceuticals, cosmetics, and chemical manufacturing commonly use filling lines. Can a filling line handle multiple product types? Yes, our filling lines are versatile and can handle various product types, including liquids, semi-liquids, powders, and viscous materials. Shiv Shakti Machtech is a Filling Line - End to End Packaging Solution and an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad#Chile#Colombia#Congo

2 notes

·

View notes

Text

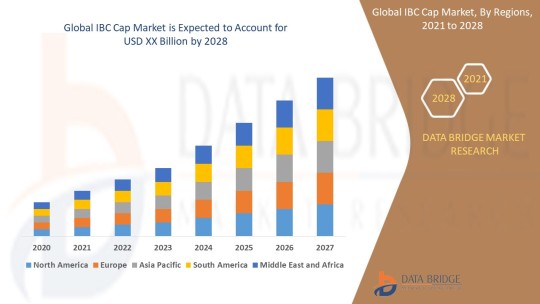

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

What is Bagging Machine? - Payper India

A bagging machine is a type of industrial equipment used to automate the process of filling and sealing bags with various products. These machines are widely used in different industries, such as food, pharmaceuticals, chemicals, and agriculture, to efficiently package goods ranging from powders and granules to liquids and solids.

Image Ref : What is Bagging Machine — Payper India

Key Functions of Bagging Machines:

Filling: The machine accurately dispenses a pre-set amount of product into each bag. This can be achieved through various mechanisms, such as volumetric fillers, auger fillers, or weigh scales, depending on the nature of the product being packaged. Click here for Ref : www.payperindia.com

Sealing: After the bag is filled, the machine seals it to ensure the product is contained and protected. Sealing methods can include heat sealing, ultrasonic sealing, or using adhesive tapes, depending on the bag material and the product requirements. Click here for Ref : www.payperindia.com

Cutting/Trimming: Some bagging machines also trim excess material from the sealed bags to ensure a neat and uniform appearance. Click here for Ref : www.payperindia.com

Types of Bagging Machines:

Valve Bagging Machines: Designed for heavy-duty products such as cement, sand, or chemicals, these machines fill bags through a valve and then seal the valve to prevent leakage. Click here for Ref : www.payperindia.com

Open-Mouth Bagging Machines: Used for bulk products like grains, animal feed, or fertilizers, these machines fill pre-made bags that are manually or automatically positioned under the filling spout. Click here for Ref : www.payperindia.com

FIBC- Jumbo Bagging Machine: A jumbo bagging machine, or bulk bag filling machine, is designed to fill large bags (500–2000 kg) with bulk materials.

Why Payper ?

Payper India develops and manufactures bagging machines for all types of bulk solids such as powders or granulates. Other important product lines are palletizers and complete lines.

Our customers come from many different sectors, e.g., Chemical Industry, Agro-food Industry, Mining Industry and Building Industry. Payper India offers a comprehensive solution for each sector.

No need or demand is too small neither too big for us. We supply bagging machines for smaller industries with low volume requirements. We also provide complete turnkey projects for customers with high demands as to capacity and speed.

What matters to us is that our customer is comfortable and satisfied with the solution we have developed for them

Visit Payper at — https://www.payperindia.com/

Business LinkedIn -http://bit.ly/45Y1xMQ

Twitter — https://twitter.com/PayperIndia

Instagram — https://www.instagram.com/payperindia/

#payper#payperindia#baggingmachines#manufacturer#industry#machinery#robotics#palletisers#jumbobaggingmachine

2 notes

·

View notes

Text

Semi-Automatic Volumetric Filling Machine in Karnataka

SATV Industries is a prominent Supplier of Semi-Automatic Volumetric Filling Machine in Karnataka, India. We have manufacturing based in very well-known industrial area of Gujarat named Ahmedabad. SATV Industries offers top-of-the-line Semi-Automatic Volumetric Filling Machines, designed to provide efficient, accurate, and reliable solutions for filling liquid products in various industries. Our semi-automatic filling machines are ideal for medium-scale production, ensuring consistency and precision in every fill. Our machines can fill a variety of liquids, ranging from thin liquids like water and juices to thicker products like creams, oils, and sauces. Features: Semi-Automatic with filling range from 5 ml to 500 ml. Accuracy ± 1 % in single doze. Three different speeds depending upon capacity of bottles. Body covered with SS sheet. All contact parts SS 316. A unit to fill variety of Liquid and can be used for various type of containers. Minimum change over time from one size to another container or fill size. Applications: Food & Beverages: Bottling juices, sauces, syrups, oils, and other liquid products. Cosmetics & Personal Care: Filling lotions, creams, shampoos, and liquid soaps. Pharmaceuticals: Bottling liquid medicines, syrups, and essential oils. Chemicals: Dispensing industrial oils, cleaning agents, and lubricants. FAQs: How accurate is the filling process? SATV’s semi-automatic volumetric filling machines offer high accuracy with a deviation of just ±1%, ensuring precise fills every time. Can the machine handle different bottle sizes? Our machines easily adjust to handle different bottle sizes, offering flexibility in your production line. How easy is it to operate the machine? We design our semi-automatic volumetric filling machines with user-friendliness in mind. The intuitive control panel allows operation with minimal training. SATV Industries is a prominent Supplier of Semi-Automatic Volumetric Filling Machine in Karnataka, India including location like Badami, Belagavi, Chamarajanagar, Bhadravati, Bidar, Hassan, Bagalkot, Bidar, Chikkamagaluru, Kalaburagi, Kolar, Ballari, Belagavi, Bangalore, Dakshina Kannada, Haveri, Kodagu, Bengaluru, Davangere, Halebid, Hassan, Hubballi-Dharwad, Kalaburagi, Kolar, Madikeri, Mandya, Mangaluru, Urban, Chitradurga, Vijayapura, Gadag, Tumakuru, Bangaluru, Mysuru, Raichur, Shivamogga, Shravanabelagola, Shrirangapattana, Ramanagara, Kittur. Contact us today to get more information, request a quote, or place an order! View Product: Click Here Read the full article

#Badami#Bagalkot#Ballari#Bangalore#Bangaluru#Belagavi#Bengaluru#Bhadravati#Bidar#Chamarajanagar#Chikkamagaluru#Chitradurga#DakshinaKannada#Davangere#ExporterofSemi-AutomaticVolumetricFillingMachine#Gadag#Halebid#Hassan#Haveri#Hubballi-Dharwad#Kalaburagi#Karnataka#Kittur#Kodagu#Kolar#Madikeri#Mandya#Mangaluru#ManufacturerofSemi-AutomaticVolumetricFillingMachine#Mysuru

0 notes

Text

Tanishka Packaging Machines: Leading Pouch Packing Machine Manufacturers in Jaipur | Packaging Machine Manufacturers in India

Why Choose Tanishka Packaging Machines?

Tanishka Packaging Machines offers a comprehensive range of packaging solutions, including pouch packing machines and box packing machines that cater to diverse industries. What sets them apart from other manufacturers in India is their focus on advanced technology, durability, and customer-centric service. Their machines are designed to ensure that the packaging process is quick, accurate, and efficient, reducing downtime and improving overall production speed.

Advanced Technology Tanishka Packaging Machines uses state-of-the-art technology to design and manufacture their machines. The incorporation of automation and smart features in their equipment ensures smoother operations, less human error, and increased efficiency.

Customization Options One of the biggest advantages of working with Tanishka Packaging Machines is the ability to customize machines according to specific requirements. Whether it’s the size, capacity, or the type of product being packed, Tanishka ensures that the machines are tailored to meet the precise needs of their clients.

Durability and Reliability The company is known for manufacturing machines that are not only efficient but also highly durable. The quality of materials used in manufacturing ensures that the machines can withstand the test of time and offer long-term service, even under the most demanding conditions.

Wide Range of Machines Tanishka Packaging Machines provides a variety of packaging equipment, including pouch packing machines for liquids, powders, and granular products, as well as box packing machines in Rajasthan. Their wide range of machines makes them a one-stop solution for businesses in need of reliable packaging solutions.

Pouch Packing Machines: The Heart of Modern Packaging

Pouch packing machines are an essential component in the packaging industry. These machines are designed to efficiently fill and seal pouches of various sizes, making them ideal for packing items like snacks, powders, liquids, and even pharmaceuticals. Tanishka Packaging Machines offers a variety of pouch packing machines that cater to different industries, ensuring that products are packaged in an airtight, tamper-proof, and visually appealing manner.

Some of the key benefits of using Tanishka’s pouch packing machines include:

High-Speed Operation: Their pouch packing machines are designed to pack a high volume of products in a short amount of time, improving productivity.

Versatility: They can handle different types of materials and packaging formats, giving businesses the flexibility they need.

Accurate Filling and Sealing: These machines ensure that the correct quantity of product is dispensed into each pouch, reducing waste and ensuring consistency.

Box Packing Machines in Rajasthan: Reliable and Efficient Solutions

In addition to pouch packing machines, Tanishka Packaging Machines also manufactures box packing machines in Rajasthan, catering to businesses that require packaging in cartons or boxes. These machines are designed to pack products into boxes with precision, speed, and minimal manual intervention.

Key features of box packing machines include:

Automation: Box packing machines are highly automated, which reduces the need for manual labor and increases the efficiency of the packaging process.

Customization: Tanishka offers customizable features to fit the unique packaging needs of various industries, including food, electronics, and more.

Compact Design: These machines are designed to occupy less space without compromising on performance, making them ideal for businesses with limited production space.

The Tanishka Advantage: Why Businesses Choose Them

Competitive Pricing: Despite offering top-tier machines, Tanishka Packaging Machines maintains a competitive edge by offering their products at affordable prices, making it easier for businesses of all sizes to invest in high-quality packaging solutions.

Nationwide Reach: Tanishka Packaging Machines serves clients not just in Jaipur, Rajasthan, but across India. With a strong distribution network and excellent after-sales service, they have become a go-to choice for businesses looking for reliable packaging solutions.

Expert Team: The company’s team consists of highly skilled professionals who are dedicated to designing and producing packaging machines that meet global standards. Their focus on research and development ensures that Tanishka Packaging Machines remains at the forefront of the industry.

Conclusion

Tanishka Packaging Machines has established itself as a prominent name in the packaging machine manufacturing industry. Whether you’re looking for a pouch packing machine or a box packing machine in Rajasthan, Tanishka offers the perfect solution for your packaging needs. With their commitment to quality, innovation, and customer satisfaction, Tanishka Packaging Machines is the ideal partner for businesses looking to enhance their packaging operations.

If you’re in need of a reliable packaging machine manufacturer in India, look no further than Tanishka Packaging Machines. Reach out to them today to learn more about their products and services, and take the first step towards improving your packaging process.

0 notes

Text

A Complete Overview of Laboratory Glassware Manufacturers in India

The use of Laboratory Glassware is an important component in scientific research, experimentation, and educational laboratories in various industries. Whether in the field of chemistry, biology, or physics, Laboratory Glassware is used for accurate measuring, analysis, and safe handling of chemicals and their compounds. With an increase in demand for high-quality equipment, many laboratory glassware manufacturers in India have cropped up on the market these days relatively to supply the ever-expanding needs of educational, research institutes, and industrial laboratories. In this blog, we mentioned the complete overview of laboratory glassware manufacturers in India.

The Importance of Laboratory Glassware

Laboratory glassware is made to withstand heat, corrosive material, and other harsh surroundings to promote accuracy and safety in the laboratory. Some of the most commonly used glassware includes beakers, flasks, test tubes, pipettes, and burettes. These are used for processes such as measurement, where a substance needs to be measured in different meters, and also mixing, heating, and storing different substances. The results of the experiments in the laboratory depend on the accuracy levels and thus the need for quality manufacturing in the glassware industry for both educational institutions and industrial laboratories.

The Expanding Laboratory Glassware Market in India

The immense rise in demand for laboratory glassware can be attributed to India’s status as a center of scientific research and education. The country has many manufacturers who provide high-quality products at affordable rates. The Indian manufacturers are widely recognized on the international stage for their quality and modern technologies used in the production of exported products.

The major Laboratory Glassware Manufacturers in India is a well-rounded company and its production is directed towards pharmaceutical, biotechnology, healthcare, and academic research. They concentrate on the innovative development of modern durable products. The constructed products are able to resist chemical interaction and have high transparency to improve observation.

Overview of Laboratory Glassware Manufacturers in India

Wide Range of Laboratory Glassware

India produces an extensive array of laboratory glassware such as beakers, flasks, test tubes, pipettes, burettes, and other products. Such products are useful to pharmaceutical, biotechnology, healthcare, and academic research sectors.

Laboratory Glassware manufacturers in India offer a wide range of laboratory glassware such as:

Beakers: A beaker is a laboratory glassware created for mixing, heating, and stirring almost any liquid. It is one of the most basic glassware used in a laboratory.

Flasks: Flasks adopted many different shapes; round bottom flasks, and conical (Erlenmeyer) flasks are designed for the purpose of measuring and mixing substances with precision.

Test Tubes: A test tube is a type of laboratory glassware used in experiments it is mainly employed for enclosing small amounts of substances.

According to Wikipedia, A typical piece of laboratory glassware, a test tube is a finger-length piece of glass or clear plastic tubing that is open at the top and closed at the bottom. It is also referred to as a culture tube or sample tube.

Pipettes: A pipette is a type of apparatus used in biochemistry, biology, or clinical laboratories specially designed to measure and transfer a small volume of liquid.

Burettes: A Burette is a standard laboratory equipment used to dispense an exact amount of liquid and is particularly useful in titration.

Prioritize Quality

The manufacturers focus on quality by selecting high-quality materials such as borosilicate glass which is durable, heat resistant, and chemically stable. This enables obtaining precise outcomes of experiments and secure usage.

International Standards Compliance

Laboratory Glassware Manufacturers in India have been able to meet a number of international safety and quality standards, making them viable products in the domestic as well as global markets.

Innovative Manufacturing Processes

Indian firms are readily embracing the change and are adopting cutting-edge technology to manufacture Laboratory Glassware that meets the current standards of science and research organizations.

Low-cost and Economical Solutions

Educational institutions, research centers, and industries that need laboratory glassware have the option of choosing Indian manufacturers who do not compromise quality at a low price.

International Export and Distribution

Several manufacturers in India export their Laboratory Glassware to international markets, ensuring that their products reach a global audience, further establishing India as a leader in laboratory glassware production.

Why Science Lab India?

Science Lab India has become one of the trusted Laboratory Glassware Manufacturers in India due to its focus on innovation and quality. Their extensive product range, standardized quality, and ability to price affordably make them the preferred option for all laboratories worldwide. The reason to choose Science Lab India is because of their quality assurance, a wide range of laboratory glassware, cost-effectiveness, excellent customer support, customization options, and after-sales service.

Conclusion

Due to the increasing need for accuracy and durability in laboratory Glassware, Laboratory Glassware Manufacturers in India are coming up with suitable and cost-effective products for the needs of modern science. It does not matter if you are a student, educator, or an industry practitioner, the choice of a laboratory glassware manufacturer is paramount to the reliability and safety of your experiments.

Science Lab India offers superior products to meet the needs of your Laboratory Glassware at very reasonable rates, making it a preferred choice for all your Laboratory Glassware requirements.

#laboratory glassware manufacturers in India#laboratory glassware manufacturers#laboratory glassware manufacturer and supplier

1 note

·

View note

Text

10 Types of Laboratory Glassware Every Scientist Should Know

When it comes to research and contributing to science through experimentation, all scientific laboratory glassware is of utmost importance. Whether it is chemistry, biology or any other scientific field, the correct glassware is essential for getting precise results and completing processes efficiently. The leading laboratory glassware manufacturers in India are equipped with different kinds of high-quality Laboratory Glassware to cater to the diverse demands of scientists. In this Blog, we will explore ten essential types of laboratory glassware that every scientist should be familiar with.

10 Essential Laboratory Glassware That Every Scientist Should Know

Flasks

Flasks can be broadly classified into 2 categories; basically, there are Erlenmeyer flasks and volumetric flasks. An Erlenmeyer flask is conical so it has a narrow glass neck so it is good for swirling liquid without spilling it out. Volumetric flasks have very distinctive shaped bodies and are for making accurate measurements of specific volumes most often for preparing dilutions.

Beakers

A beaker is a cylindrical shape with a flat bottom and is usually made from glass or plastic. The beakers are employed in mixing as well as in heating and stirring the liquids. Beakers come in a variety of shapes and sizes promoting the accurate measurement of volumes by the scientist.

Pipettes

Pipettes are very useful devices when accurate measurements of small volumes are necessary. There are various kinds of Pipettes like the volumetric ones, which help in making precision and micropipettes for small amounts. Pipettes are of help in experimental procedures where accuracy in liquid transfer is needed.

Test Tubes

Test tubes are small-sized cylindrical containers made of glass whose function is to contain, combine, or heat small amounts of certain substances. Various sized test tubes are available and they are typically used for qualitative analysis and in experiments. Test tubes are very common in every laboratory and allow for easy and quick reactions and monitoring of the outcome of the reactions.

Burettes

A burette is a long calibrated enclosed glass tube with an aperture at its lower end, which is fixed and is used in dispensing liquid chemicals in specific volumes, more commonly during the titration. They are structured in such a way that controlled amounts of fluids can be expelled which is very crucial in analytical chemistry.

According to Wikipedia, A burette is a graduated glass tube used for titrations that has a tap at one end to dispense known volumes of a liquid. It is a long, graded glass tube with a tapered capillary tube at the stopcock's output and a stopcock at the lower end. The stopcock valve regulates the liquid flow from the tube to the burette tip.

Petri Dishes

Petri dishes are shallow and flat circular dishes used for microbiological study and for the maintenance of solid samples. Constructed from glass or composite polymers they are used to maintain bacterium, fungus, or other specimens in a laboratory. The petri dish is very useful when working in the fields of microbiology and cell cultures.

Funnels

Funnels can be defined as implements used to direct liquids and powdered substances into narrow-necked vessels. They often come in handy in the process of filtering substances or pouring out liquids into containers such as beakers and flasks. Funnels may be manufactured out of glass and plastic materials and may at times incorporate filter paper inside for filtration purposes.

Crucibles

A crucible is a type of vessel made of heat-proof materials which is usually small in size and is used to heat a substance to extreme temperatures. In chemistry, crucibles are crucial in experiments that involve melting, combustion, or high-temperature reactions of materials since these activities generate high heat. Porcelain, glass, or metal containers are all examples of materials from which crucibles can be made.

Reagent Bottles

The term ‘reagent bottle’ applies to any container for the reasonable or safe storage of any chemical substances. They employ rubber closing to prevent contamination as well as the evaporation of the internal mixtures. The laboratory also makes sure that there is proper storage of the reagent bottles and that their labels are indicated.

Desiccators

Desiccators are airtight containers filled with a desiccant, which pulls moisture out from the surrounding environment. They serve to keep hygroscopic materials or sealed items that require to be dry. The use of desiccators is very important, especially in laboratories where moisture is a crucial factor to consider.

Why Choose SciLab Export for Your Laboratory Glassware Needs?

As one of the best laboratory glassware manufacturers in India, SciLab Export strives to offer quality laboratory glassware that is tailored toward scientists and researchers in general. We have the following advantages, which you should consider when sourcing for laboratory glassware from SciLab Export:

The caliber of Service: All kinds of laboratory glassware at SciLab Export are manufactured in compliance with undisputable quality control which is above the international standard. We surely manufacture products that are strong enough to ensure accuracy over a long period.

Product Range: We have a full range of laboratory glassware from simple beakers, flasks, and test tubes to special purposes glassware, for instance, desiccators and crucibles.

Personalization: Different laboratories use different kinds of glass wares, and therefore SciLab Export understands this need and offers laboratory glassware customization.

Conclusion

It is equally important to familiarize yourself with the different forms of laboratory glassware. Each piece of glassware from beakers and flasks to pipettes and desiccators has a vital purpose that helps advances in experiments and research. As one of the best Laboratory Glassware manufacturers in India, SciLab Export is equipped to provide quality, variety, and support for all your laboratory glassware requirements. With the correct Laboratory Glassware aimed at performing research work, you can be sure of getting the maximum possible results, which makes this item an important part of the laboratory setup.

#laboratory glassware manufacturers in India#laboratory glassware manufacturers#laboratory glassware

1 note

·

View note

Text

Rajkot's Leading Liquid Soap Dispenser Dealers - Urban Bath

Find top-quality liquid soap dispenser dealers in Rajkot at UrbanBath. Explore a wide range of reliable and stylish liquid dispensers for your bathroom needs.

Care must be taken to present neat and attractive appearances of appliances, walls, and floors. visit the best Liquid Soap Dispenser Dealers/traders Rajkot today.

Visit now! https://www.urbanbath.in/liquid-dispenser-manufacturers.aspx

#Liquid Soap Dispenser Dealers Rajkot#Liquid Dispenser Manufacturers India#Buy Liquid Soap Dispenser Online#Liquid Dispenser Dealership Rajkot#Liquid Soap Dispenser Dealers#Liquid Dispenser Manufacturers#Liquid Soap Dispenser Suppliers#Liquid Soap Dispenser Traders Rajkot#Liquid Dispenser Manufacturers Rajkot

0 notes

Text

Liquid Paraffin Filling Machine Servo Based

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Liquid Paraffin Filling Machine Servo Based in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Shiv Shakti Machtech manufactures and supplies high-quality servo-based Liquid Paraffin Filling Machines, providing exceptional accuracy, speed, and efficiency in the filling process. We design our advanced filling machines to meet the specific needs of industries dealing with paraffin, lubricants, oils, and similar liquids. These machines offer precision and reliability, ensuring optimal production capacity in industries like pharmaceuticals, cosmetics, and chemicals. Similar Name of the Machine: Servo-Driven Liquid Filling Machine, Mineral Oil Filling Machine with Servo Control, Liquid Paraffin Servo-Based Filling Equipment, Servo-Based Mineral Oil Packaging Machine, High-Speed Liquid Paraffin Bottling Machine, Liquid Paraffin Filling Machine Servo Based, Servo-Controlled Mineral Oil Filling Line, Automatic Liquid Paraffin Filling System, Mineral Oils Bottle Filling Machine with Servo Drive, Liquid Paraffin Packaging Machine with Advanced Servo Technology, Oil Dispensing Machine Types of Liquid Paraffin Filling Machines (Servo Based): Single Head Machine Multi-Head Machine Automatic Liquid Filling Machine Semi-Automatic Machine Features: Servo Motor: Utilizes a servo motor for accurate and consistent filling, ensuring uniformity in every container. Filling Capacity: Capable of handling different volumes based on the machine configuration. High Precision: Provides +/- 1% accuracy, minimizing wastage and optimizing product quality. Automation: Fully automatic operation for increased productivity and reduced manual labor. Customization: Can be customized to meet specific requirements for liquid paraffin packaging, including container sizes and filling speeds. FAQS: What makes the servo-based filling machine better than other types? Servo-based filling machines provide superior accuracy, faster filling speeds, and greater control over the filling process compared to pneumatic or mechanical machines. Can the filling volume be adjusted easily? Yes, the servo motor allows for easy adjustment of the filling volume via the touchscreen interface, providing flexibility for different container sizes. Shiv Shakti Machtech is a Supplier of Filling Machine Servo Based in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatnam, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, and Chhachhrauli. For more information or to request a quote, please reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#AutomaticLiquidParaffinFillingSystem#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar#Chennai

0 notes

Text

Cryogenic Equipment Market: Driving Innovations in Low-Temperature Solutions - UnivDatos

The surge in the demand for clean energy sources is one of the key factors driving the demand for the cryogenic equipment market during the forecast period.

There is a significant potential for market growth in the applications of transport, storage, and regasification as well as energy from renewable sources. The demand for cryogenic equipment is driven by the evolution of the healthcare sector from emerging economies, as well as a substantial investment in metallurgical and chemical and petrochemical industries.

There is a significant potential for market growth in the applications of transport, storage, and regasification as well as energy from renewable sources. The demand for cryogenic equipment is driven by the evolution of the healthcare sector from emerging economies, as well as a substantial investment in metallurgical and chemical and petrochemical industries.

Request To Download Sample of This Strategic Report - https://univdatos.com/get-a-free-sample-form-php/?product_id=45233&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Several factors have led to a rise in LNG trade around the world. The abundance of natural gas reserves in countries like the United States, Australia, and Qatar is a major reason for this. Countries that are looking for ways of diversifying their energy supplies and reducing their dependence on fossil fuels have benefited from the availability of LNG at competitive prices.

The development of cryogenic energy storage systems also plays a role in the growth of the LNG trade. These systems use Supercooled Liquids to Store Energy, such as in the form of gaseous liquids like Air or Natural Gas. It may be used for storing energy during periods of low demand and releasing it into the grid in times of peak demand, thereby contributing to power balance and reducing its dependence on traditional fuels.

Top Investors of the Cryogenic Equipment Products and Services

Over the last few years, cryogenic equipment has witnessed a string of institutional investors and corporations, who are looking at the growing demand for cryogenic equipment devices and are investing in the industry be it small or large investments. Big companies are acquiring/partnering with smaller companies or start-ups to increase their market share. Some of the prominent mergers and acquisitions/partnerships in the Cryogenic Equipment include:

· In Apr 2023, Air Water Inc. acquired Specialized Cryogenic Distribution Equipment Producer M1 Engineering.

· In Apr 2023, India’s largest cryogenic equipment manufacturing facility with the ability to fabricate over 20,000 metric tons per year of stainless-steel equipment INOXCVA.

· In Sep 2022, President Murmu inaugurated HAL's new facility to build cryogenic engines for ISRO rockets.

· In Mar 2021, Gujarat Co Inoxcva launched LNG dispensers. The company has also developed equipment for mobile LNG fueling stations to cater to the requirements of the mining industry and remote areas.

· In Feb 2023, Azenta launched Cryo Store Pico, a Novel Automated Cryogenic Storage System Designed for Clinical and Laboratory Applications.

Ask for Report Customization - https://univdatos.com/get-a-free-sample-form-php/?product_id=45233&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Conclusion:

The cryogenic equipment industry has witnessed rapid expansion over the last few years, with big players acquiring emerging small companies who are acting as treats for the large players in the cryogenic equipment. Further, investments in cryogenic equipment technologies have also increased over the past few years and so are the adoption rate. According to the UnivDatos Market Insights analysis, the development of advanced technologies would massively transform the global scenario of cryogenic equipment and as per their “Cryogenic Equipment Market” report, the global market was valued at USD 19.3 billion in 2022, growing at a CAGR of 6% during the forecast period from 2023 - 2030.

0 notes

Text

Automatic PFS Filling Machine and Closing Machine in Rajasthan

Radiant Industries is a Manufacturer and Supplier of Automatic PFS Filling Machine and Closing Machine in Rajasthan, India. Our registered office and manufacturing unit are located in Ahmedabad, Gujarat, India. An automatic pre-filled syringe filling machine precisely fills syringes with liquid medication, vaccines, or biologic substances. The system automates the filling, capping, and sometimes labeling processes, working seamlessly with pre-sterilized syringes. This makes it ideal for large-scale pharmaceutical production. How It Works: Syringe Loading: The machine loads pre-sterilized syringes either manually or automatically. Filling Process: The filling machine dispenses a precise volume of liquid into each syringe using a sterile filling nozzle. The system is calibrated to fill the exact dosage. Control and Quality Checks: Sensors monitor the fill level, ensuring each syringe is filled accurately. Sterility and Hygiene: The system conducts the entire filling process in a controlled, sterile environment to keep the product uncontaminated. Completion: Once filled, the machine automatically moves the syringes to the closing machine for sealing. Features: High Precision: Ensures accurate filling of syringes to avoid overfilling or underfilling, which can lead to dosing errors. Automation: Fully automated processes that minimize human intervention and increase speed and efficiency. Flexibility: Capable of handling different syringe sizes and types (e.g., standard or safety syringes). Inline Monitoring: Built-in monitoring systems for continuous inspection and quality assurance during production. Applications: Pharmaceutical Industry Biotechnology Hospitals and Clinics Research and Development What types of syringes can be used with these machines? These machines handle various types of pre-sterilized syringes, including glass and plastic syringes of different sizes and capacities. What is the production speed of these machines? The production speed can vary depending on the specific machine model, but typically, automatic filling and closing machines can process hundreds to thousands of syringes per hour. Radiant Industries is a Manufacturer and Supplier of Automatic PFS Filling Machine and Closing Machine in Rajasthan, India Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alwar#Anupgarh#AutomaticPFSFillingMachineandClosingMachine#AutomaticPFSFillingMachineandClosingMachineinIndia#AutomaticPFSFillingMachineandClosingMachineinRajasthan#Balotra#Banswara#Baran#Barmer#Beaware#Bharatpur#Bhilwara#Bikaner#Bundi#Chittorgarh#Churu#Dausa#Deeg#Dholpur#Didwalna-Kuchaman#Dudu#Dungarpur#Ganganagar#GangapurCity#Hanumangarh#Jaipur#Jaisalmer#Jalore

0 notes

Text

Six Head Ampoule Filling Machine

youtube

Specifically produced This durable machine with a slant travel mechanism is a six head ampoule filling machine. To achieve GMP compatibility, make contact with the injectable liquid’s surface areas composed of stainless steel 316L. a machine with six liquid filling nozzles that performs extremely accurate filling operations. In addition, there are six pre- and post-nitrogen nozzles for nitrogen flushing both before and after filling operations.

In a single dosage procedure, a six-head ampoule filler and sealer can dispense volumes ranging from 0.5ml to 10ml. The machine is designed to accommodate open-mouth ampoules, but we also have a type that can accommodate closed-mouth ampoules. We provide a variety of filling mechanism options, the most popular being peristaltic pump filling, servo controlled filling, and piston pump filling. The machine has an integrated sealing unit that can perform two stages of sealing operations. Preheating is done in step one to remove any droplets that may have been on the ampoule’s inside during the filling process. Stage two sealing is done using cutters and LPG and oxygen gas. There are rollers that spin the ampoules to project a 360-degree flame onto the glass of the ampoule.

Ampoule sealers and fillers are used to precisely fill various kinds of injectable liquids. The ampoule is transported by means of the rack moving at an angle. Nitrogen purging, filling, preheating, and sealing procedures were carried out during rack movement transfer. It’s interesting to note that no liquid will emerge from the filling needles if there is no ampoule present at the filling unit.

As one of the leading manufacturers of six head ampoule filling machines, we provide dependable, easily operated equipment that needs little upkeep. Adinath International is one of the leading exporters of ampoule filling machines from India.

0 notes

Text

Macleods Pharmaceuticals Walk-in Drive Macleods Pharmaceuticals, a leading name in the pharmaceutical industry, is conducting a walk-in drive for multiple roles across Production, Quality Assurance (QA), Quality Control (QC), Engineering, and Stores departments. This hiring event, taking place in Rangpo, East Sikkim, offers an excellent opportunity for candidates with relevant qualifications and experience to work with one of India's premier pharmaceutical companies. Here’s everything you need to know about the job roles, requirements, and application details. Pharma Jobs in Rangpo, East Sikkim Walk-in Drive Details Date: November 17, 2024 Time: 09:00 AM onwards Venue: Eco Paradise Resort, NH 10, Mining, Near Rangpo, East Sikkim - 737132 Contact Numbers: 7477714922, 8768996504, 9046006953 Candidates are encouraged to bring their updated CV, a detailed salary structure (CTC breakdown), and a government-issued ID for verification. Available Positions at Macleods Pharmaceuticals 1. Production Department (DPI & Tablet OSD) Roles: Sr. Officer, Officer, TA/Operator Responsibilities: Candidates will manage various stages of production, including DPI, Granulation, Compression, Coating, and Packing for Oral Solid Dosage (OSD) forms. Qualifications: B.Pharm, M.Pharm, ITI, or Diploma in Engineering Experience: 2–8 years in DPI washing, sterilization, compounding, and sealing activities 2. Production (Liquid Injection & Oral Liquid) Roles: Executive, Officer Responsibilities: Oversee production processes for injectable and oral liquid forms, ensuring compliance with IPQA, validation, and documentation standards. Qualifications: M.Pharm, B.Pharm, ITI, Diploma in Engineering Experience: 2–8 years in Liquid Injection sterile environments 3. Quality Assurance (QA) and Quality Control (QC) Roles: Officer, Executive Responsibilities: Ensure product quality, manage documentation, and maintain GLP standards. This includes handling raw materials, finished goods, and stability studies. Qualifications: M.Sc., B.Pharm, M.Pharm Experience: 2–8 years in QA/QC activities related to pharmaceutical products 4. Engineering Services Roles: Officer, Executive Responsibilities: Handle electrical, mechanical, HVAC, and utility services for optimal plant operations. Qualifications: Diploma in Engineering, ITI, or B.Tech Experience: 4–10 years in mechanical and electrical engineering processes 5. Stores Department Roles: Executive, Officer, TA Responsibilities: Manage receipt and dispersal of raw materials, inventory control, packing, and dispensing activities. Qualifications: B.Sc., B.Com, D.Pharm Experience: 2–8 years in store management and material handling Qualification & Skills Required Candidates should possess the following: Educational Background: Relevant qualifications such as B.Pharm, M.Pharm, D.Pharm, ITI, Diploma in Engineering, B.Tech, or B.Sc. Experience: 2–10 years in the respective roles with hands-on experience in pharmaceutical processes, manufacturing, engineering maintenance, or store management. Technical Skills: Familiarity with GMP, GLP, IPQA standards, and documentation practices. Interpersonal Skills: Strong teamwork, communication, and compliance with quality and safety standards. [caption id="attachment_56144" align="alignnone" width="300"] MACLEODS Walk-in Drive for Production, QA, and Stores[/caption] How to Apply for Macleods Pharmaceuticals Walk-in Drive To streamline the registration process, candidates are encouraged to register online through Macleods’ official link. This ensures quicker processing and helps the recruitment team manage applications more effectively. Please follow this link (preferably in Google Chrome) for registration: Macleods Registration. Note: Remember to bring the following documents: Updated CV Salary structure with CTC breakdown Aadhar card or any government-issued ID

0 notes

Text

Pharmaceutical Packaging Market 2030 Top Key Players, Trends, Share, Industry Size, Segmentation

The global pharmaceutical packaging market was valued at USD 139.37 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 9.7% from 2024 to 2030. This growth is largely driven by the rapid expansion of the pharmaceutical industry, which has been advancing due to scientific and technological innovations. The ongoing growth is expected to continue, especially in developing regions such as China, India, Saudi Arabia, and Brazil, where healthcare infrastructure and demand for medicines are expanding significantly.

In 2023, the United States represented the largest pharmaceutical market globally. Several factors contribute to this, including a well-established healthcare system, high per capita income, and substantial investments in research and drug development. The increasing focus on generic drugs and the improvement in healthcare services are expected to provide promising opportunities for the pharmaceutical packaging market. Notably, the 21st Century Cures Act (Cures Act), signed in 2016, is aimed at accelerating medical product development in the U.S., thus fostering innovation in the pharmaceutical industry. This legislation is anticipated to boost demand for pharmaceutical packaging by supporting the launch of new and innovative drug formulations.

Gather more insights about the market drivers, restrains and growth of the Pharmaceutical Packaging Market

Europe’s pharmaceutical sector is one of its high-performing and technologically advanced industries, significantly contributing to the regional economy. The sector is evolving with an increased focus on developing biopharmaceutical drugs, which has grown over recent years. Many biotechnology-based drug therapies are sensitive to degradation and thus require specialized packaging, such as lyophilized or dry powder forms, to maintain stability. This demand for sophisticated packaging solutions is creating new growth opportunities for packaging manufacturers.

Pharmaceutical products are primarily available in forms such as tablets, capsules, liquids, and powders. They require various packaging solutions, including rigid bottles, stand-up pouches, flat pouches, sachets, and blister packs, each designed to meet specific needs. Packaging companies are now prioritizing features like dispensing aids, administration tools, eco-friendly materials, tamper-evident seals, and anti-counterfeiting measures to enhance product safety, accessibility, and sustainability.

End-use Segmentation Insights:

The pharma manufacturing segment was the largest end-use segment in 2023, accounting for a 49.9% market share, and is anticipated to see strong growth through to 2030. This trend is primarily due to the rising demand for medicines worldwide. According to the World Health Organization (WHO), the global population aged over 60 is expected to nearly double from 12% in 2015 to 22% by 2050, increasing the need for medicines and healthcare. The aging population requires more medical assistance, which is driving pharmaceutical production and, subsequently, the demand for pharmaceutical packaging.

To manage costs and increase efficiency, pharmaceutical companies are increasingly outsourcing packaging activities. By outsourcing, companies can avoid investing directly in packaging materials and equipment, instead working with specialized contractors who provide efficient packaging solutions. This shift is expected to fuel demand for contract manufacturing and pharmaceutical packaging equipment.

Retail pharmacies, especially in developing countries like India, China, and Brazil, are using branding on packaging materials such as polybags and paper pouches to differentiate their products. As retail penetration expands in these regions, the retail pharmacy segment is likely to see significant growth.

Institutional pharmacies, which operate within healthcare facilities like hospitals, nursing homes, and assisted living communities, are expected to grow as well. The increasing number of hospitals and healthcare facilities, along with rising healthcare expenditures, is likely to drive demand for pharmaceutical packaging in this segment. With a growing focus on healthcare accessibility and quality, the institutional pharmacy end-use sector is anticipated to contribute significantly to the overall growth of the pharmaceutical packaging market.

Order a free sample PDF of the Pharmaceutical Packaging Market Intelligence Study, published by Grand View Research.

0 notes

Text

Pharmaceutical Packaging Market 2030 Driving Factors, Future Trends, Size & Key Vendors

The global pharmaceutical packaging market was valued at USD 139.37 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 9.7% from 2024 to 2030. This growth is largely driven by the rapid expansion of the pharmaceutical industry, which has been advancing due to scientific and technological innovations. The ongoing growth is expected to continue, especially in developing regions such as China, India, Saudi Arabia, and Brazil, where healthcare infrastructure and demand for medicines are expanding significantly.

In 2023, the United States represented the largest pharmaceutical market globally. Several factors contribute to this, including a well-established healthcare system, high per capita income, and substantial investments in research and drug development. The increasing focus on generic drugs and the improvement in healthcare services are expected to provide promising opportunities for the pharmaceutical packaging market. Notably, the 21st Century Cures Act (Cures Act), signed in 2016, is aimed at accelerating medical product development in the U.S., thus fostering innovation in the pharmaceutical industry. This legislation is anticipated to boost demand for pharmaceutical packaging by supporting the launch of new and innovative drug formulations.

Gather more insights about the market drivers, restrains and growth of the Pharmaceutical Packaging Market

Europe’s pharmaceutical sector is one of its high-performing and technologically advanced industries, significantly contributing to the regional economy. The sector is evolving with an increased focus on developing biopharmaceutical drugs, which has grown over recent years. Many biotechnology-based drug therapies are sensitive to degradation and thus require specialized packaging, such as lyophilized or dry powder forms, to maintain stability. This demand for sophisticated packaging solutions is creating new growth opportunities for packaging manufacturers.

Pharmaceutical products are primarily available in forms such as tablets, capsules, liquids, and powders. They require various packaging solutions, including rigid bottles, stand-up pouches, flat pouches, sachets, and blister packs, each designed to meet specific needs. Packaging companies are now prioritizing features like dispensing aids, administration tools, eco-friendly materials, tamper-evident seals, and anti-counterfeiting measures to enhance product safety, accessibility, and sustainability.

End-use Segmentation Insights:

The pharma manufacturing segment was the largest end-use segment in 2023, accounting for a 49.9% market share, and is anticipated to see strong growth through to 2030. This trend is primarily due to the rising demand for medicines worldwide. According to the World Health Organization (WHO), the global population aged over 60 is expected to nearly double from 12% in 2015 to 22% by 2050, increasing the need for medicines and healthcare. The aging population requires more medical assistance, which is driving pharmaceutical production and, subsequently, the demand for pharmaceutical packaging.

To manage costs and increase efficiency, pharmaceutical companies are increasingly outsourcing packaging activities. By outsourcing, companies can avoid investing directly in packaging materials and equipment, instead working with specialized contractors who provide efficient packaging solutions. This shift is expected to fuel demand for contract manufacturing and pharmaceutical packaging equipment.

Retail pharmacies, especially in developing countries like India, China, and Brazil, are using branding on packaging materials such as polybags and paper pouches to differentiate their products. As retail penetration expands in these regions, the retail pharmacy segment is likely to see significant growth.

Institutional pharmacies, which operate within healthcare facilities like hospitals, nursing homes, and assisted living communities, are expected to grow as well. The increasing number of hospitals and healthcare facilities, along with rising healthcare expenditures, is likely to drive demand for pharmaceutical packaging in this segment. With a growing focus on healthcare accessibility and quality, the institutional pharmacy end-use sector is anticipated to contribute significantly to the overall growth of the pharmaceutical packaging market.

Order a free sample PDF of the Pharmaceutical Packaging Market Intelligence Study, published by Grand View Research.

0 notes