#LightningProtection

Explore tagged Tumblr posts

Text

Earth Cable Size for Lightning Protection

Lightning strikes pose a serious threat to buildings, equipment, and human life. To reduce this risk, an effective lightning protection system is essential. One critical component of this system is the earth cable, which safely channels lightning current into the ground. Choosing the correct earth cable size for lightning protection is vital. This article dives deep into how to select the proper cable size, the factors that influence this decision, and the relevant standards and calculations involved.

Importance of Correct Earth Cable Size for Lightning Protection

When lightning hits a structure, it discharges a high amount of electrical energy in a very short time. If the earth cable size for lightning protection is too small, it can overheat or even melt, causing fire or structural damage. An undersized cable can also result in high resistance, reducing the efficiency of the entire system. On the other hand, a properly sized earth cable ensures that the energy from the strike is safely dissipated into the ground. It reduces step voltage, protects electronic systems, and maintains the integrity of the installation.

Factors Affecting Earth Cable Size for Lightning Protection

There is no one-size-fits-all answer when it comes to selecting an earth cable size for lightning protection. Several factors must be considered to determine the optimal size: - Peak lightning current (typically 100 kA for direct strikes) - Duration of current flow - Soil resistivity - Length of the cable - Type of conductor (copper or aluminum) - Installation method (buried or exposed) These variables are all essential in defining the Earthing Cable Size Standard for a given application.

Common Earth Cable Materials and Their Impact on Sizing

Copper is the most commonly used material due to its high conductivity. Aluminum is also used, though it requires a larger cross-section for the same performance. A general guideline is that a copper conductor should have a minimum cross-sectional area of 16 mm² for lightning protection. However, higher-risk areas may require 35 mm² or more. Here’s a quick comparison table: MaterialMinimum Size (IEC Std.)Common ApplicationCopper16 mm²Residential, low riskCopper35 mm²Industrial, high riskAluminum25 mm²Residential backupAluminum50 mm²Industrial systems

Earth Cable Size as Per IEC Standards

According to instrument earthing IEC standard and IEC 62305 (Protection Against Lightning), the minimum earth cable size for lightning protection should meet both mechanical and thermal requirements. The cable must be able to withstand a lightning current of 100 kA peak without damage. The Earthing Cable Size as Per IEC considers both mechanical strength and current-carrying capacity. The conductor should also be corrosion-resistant and compatible with the soil. For example, IEC recommends: - A minimum of 16 mm² copper or 25 mm² aluminum for air-termination and down conductors - A minimum of 35 mm² copper or 50 mm² aluminum for earth conductors where mechanical protection is not ensured These values may be increased depending on soil resistivity or regional codes.

Earth Cable Size Calculation Formula

To calculate the earth cable size for lightning protection, the following simplified formula is often used: S = √(I² × t) / k Where: - S = minimum cross-sectional area (mm²) - I = peak lightning current (A) - t = duration of lightning strike (s) - k = material constant (Copper: 143, Aluminum: 94) Assuming a lightning strike of 100 kA lasting 0.0005s: For copper: S = √(100,000² × 0.0005) / 143 ≈ 29.5 mm² Rounding up, a 35 mm² copper conductor is advisable in high-risk zones. This aligns with values used in most Earth Cable Size Calculators and conforms to Earthing Cable Size Calculation Formula used by engineers.

Importance of Installation Method

The way the cable is installed influences the actual performance. If it is buried directly, it is more likely to corrode, especially if dissimilar metals are in contact. Protective coating or PVC sheath may be necessary. When installed above ground, the cable must be protected from mechanical damage and UV degradation. Instrument earthing standards also recommend that the path to ground should be as straight as possible to avoid impedance from bends.

Earthing Cable Size in Special Applications

In environments like oil refineries, data centers, and substations, earthing systems must also comply with instrument earthing IEC standards. In such sensitive installations, both lightning protection and functional earthing are required. The sizing of these cables might be larger to account for induced voltages, electromagnetic interference, and surge protection. Moreover, tools like Wire Gauge Conversion Calculator are used to compare cable sizes across American Wire Gauge (AWG) and IEC metric standards. This helps in selecting the correct cable when equipment is sourced globally. Read More.....#LightningProtection, #EarthingSystem, #EarthCableSize, #ElectricalSafety, #SurgeProtection, #LightningArrestor, #EarthingCable, #GroundingSystem, #ElectricalDesign, #CableSizing, #LightningGrounding, #ElectricalEngineering, #EarthRod, #EarthingCalculation, #BuildingSafety Read the full article

#CableCalculation#CableSizing#EarthCable#EarthingStandards#Electricaldesign#ElectricalSafety#GroundingSystem#LightningArrestor#LightningProtection#SurgeProtection

0 notes

Text

Remote Fault-time Earth Resistance Monitoring: An Introductory Guide

Accurate Ground Fault detection in complex networks requires overcoming several technical hurdles. Improper grounding can lead to unfortunate failures and serious risks to equipment. Understanding the root causes of earth faults is essential for effective prevention. The Connection typically arises due to insulation breakdown, equipment malfunction or external factors such as environmental changes or lightning strikes. Earth Resistance Monitoring devices are available in the market, but our primary expertise lies in fault time measurement and performance checking of the earth pit during a fault and send alert notification to the register user. Manav has its own patented system called Remote Fault Time Earth Resistance Monitor (R-FERM). This IIoT-enabled, world-first solution provides real-time measurement of earthing system resistance during normal and fault time. It allows for the prevention of accidents caused by unhealthy /faulty earthing systems by monitoring individual earth pits.

Improper earth resistance can lead to hazards like electrical fires because it can cause fault currents to flow through unintended paths, leading to overheating of potential flammable materials. By monitoring earth resistance, you can identify issues like corrosion of ground rods, increased soil resistance or poor connections that can lead to power quality problems. Early detection of these issues allows for timely Maintenance the repairs for scheduled downtime and cost- cutting.

Manav R-FERM is a Centralized remote monitoring of the earthing system (Including Measure Step and Touch Voltage of Individual Earth Pits) where it detects the fault and pit resistance measurement during Fault-time. A 3-level Hierarchy-based alert system for inconsistencies in the earthing system, leading to in-time action like Level 1 Warning, Level 2 Alert, and Level 3 Emergency and a user-friendly software designed for easy reviewing of data and report generation.

R-FERM solution enables the user to

Monitor daily variation of earthing system resistance.

The number of faults occurred in each pit.

Resistance at the time of fault in each pit.

Worst-case step potential and touch potential at the time of earth fault

Worst-case step potential and touch potential at the time of lightning

It enables to work on the safety system pre-emptively and prepare before eventuality strikes

Conclusion

Remote Monitoring systems are like having a security guard for your electrical systems. The systems continuously track the performance of electrical equipment and wiring, checking for issues like faults, overheating or any power supply blackouts. Remote Monitoring allows you to monitor your electrical systems from anywhere using a tool or app, instead of physically checking every wire and device. It sends alerts or overload, if something goes wrong, like if a circuit is about to overload or any potential earth fault happen, you can address the problem before it becomes a major issue.

Ensure Electrical Safety Today! – Monitor earth resistance in real-time with R-FERM.

Contact us now!

#groundfaultdetection#electricalsafety#remotemonitoring#iiot#earthresistance#powerquality#manavrferm#smartgrid#preventelectricalhazards#faulttimemeasurement#industrialsafety#lightningprotection#stepvoltage#touchvoltage#electricalmaintenance#iotforsafety#energymanagement#smartmonitoring#predictivemaintenance

1 note

·

View note

Text

"Renown Power: Leading Provider of Earthing, Lightning Protection, and Solar Solutions"

Renown Power specializes in delivering advanced earthing systems, lightning arresters, surge protection devices, and solar panel solutions. Our products are designed to ensure safety and reliability across various sectors, including military, healthcare, data centers, construction, railways, mining, petrochemical, oil and gas, telecommunications, and power generation. Explore our comprehensive range of services tailored to meet your specific needs.

For more info : www.renownpower.com

0 notes

Text

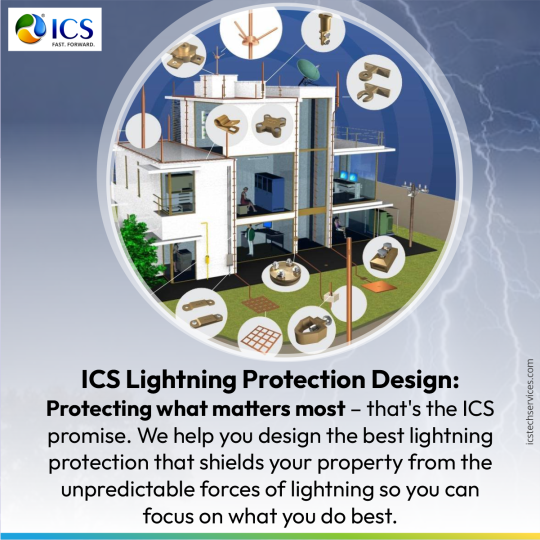

Protect Your Building and People with ICS Lightning Protection Design Services

Lightning strikes pose serious risks, including fires, structural damage, and even loss of life. At ICS, our ISO-certified experts design lightning protection systems tailored to your building's unique needs, ensuring maximum safety and compliance with NFPA 780, UL 96A, and LPI-175 standards.

Our services include:

Strike Termination Devices: Safely capture lightning strikes.

Conductors and Connectors: Efficiently transfer current to the ground.

Grounding Electrodes: Ensure effective lightning dissipation.

Surge Protection Systems: Protect sensitive equipment.

Earthing and Exo-Thermic Welds Solutions: Minimize risks with advanced grounding.

With ICS, enjoy personalized solutions, unmatched efficiency, and complete compliance. Let us help you safeguard lives, facilities, and investments.

📞 Contact ICS today to plan your lightning protection system!

0 notes

Text

An Integrated Approach For Complete Lightning Rod Protection

A lightning rod is a metal rod mounted on a structure and intended to protect the structure from a lightning strike. If lightning hits the structure, it will preferentially strike the rod and be conducted to ground through a wire instead of passing through the structure, where it could start a fire or cause��electrocution. Lightning rods are also called finials, air terminals, or strike termination devices. This technology goes back about 250 years to when Benjamin Franklin developed it.

It was designed primarily for structural protection.

Today, society has evolved to include sophisticated communications, computers, networks, power, power generation, GPS, space travel, air travel, and many more, but many companies are still using a lightning protection unit that goes back to the 1700s. Today’s standards are still rooted in the Ben Franklin system, including the National Fire Protection Agency NFPA 780 and Underwriters Laboratory (UL). Their primary mission is founded on structural protection and personal safety, but they are not geared toward electronic integrity and lightning elimination.

That is why LEC recommends an integrated approach for complete Lightning rod protection.

LEC's Charge Transfer System (patented as the Dissipation Array System or DAS) uses a naturally occurring, scientific phenomenon called point discharge to retard the collection of lightning within a finite protection zone. LEC does not attract the lightning. LEC's system lowers the static field in the protected area long enough for the lightning strike to terminate outside the protected area. The DAS is engineered for the specific application or site.

With LEC’s unique combination of experienced consultants, engineers, and integrated services, you can rely on expert advice backed by over 50 years of experience. LEC's services have provided lightning protection, grounding, and surge protection solutions throughout multiple industries, providing greater lightning safety, savings, and efficiency using a proprietary approach to risk reduction. The necessary services are dependent on your company’s lightning safety requirements. They can be as simple as a technical review or as extensive as a site survey. An LEC sales associate will be able to help you determine what your needs are.

The LEC Advantage is the heart and soul of our products and services. LEC technical development superiority, consulting services, and lightning prevention solutions are customized for each client.

Read more...

youtube

#LightningDamage#LightningProtection#LightningProtectionDesign#LightningProtectionProducts#LightningProtectionSystems#LightningRodProtection#LightningSurgeProtectionDevices#FuelTankLightningProtection#GroundingRod#TankBatteryLightningProtection#Youtube

0 notes

Text

Lightning surge protection devices are applied extensively on various industries, especially for those critical-mission industries. If you are interested in any of the applications get connected with our Lightning Eliminator team. Visit us at: https://www.lightningprotection.com/

#LightningDamage#LightningProtection#LightningProtectionDesign#LightningProtectionProducts#LightningProtectionSystems#LightningRodProtection#LightningSurgeProtectionDevices#GroundingRod

0 notes

Text

Lightning Surge Protection Devices For Every Mission-Critical Industry

Lightning surge protection devices are an indispensable part of lightning protection for electronic equipment. Its function is to limit the instantaneous overvoltage of the power line and signal transmission line to the voltage range that the equipment or system can withstand, or to discharge powerful excess lightning current into the ground.

The most reoccurring cause of surge is lightning. During a lightning storm, it may strike somewhere near a power source and affect the voltage running through it. When a lightning surge hits an electrical system, it damages the devices connected to it, resulting in a loss of efficiency.

The term surge protection device (SPD) describes electrical devices typically installed in power distribution panels, process control systems, communications systems, and other heavy-duty industrial systems, for protection against electrical surges and spikes, including those caused by lightning.

LEC provides an entire product line of lightning surge protection devices, like:

Facility guard for industrial service entrance and subpanel applications

The DC surge protector for protection of all DC applications to ensure maximum lightning safety

Data line protectors for low voltage telecom and control lines

Coaxial line protectors for protection of all types of coaxial line applications including antennas, microwaves, broadband, cellular systems, and GPS equipment

SPDs are classified according to their standards into three different types:

Type1 – this can discharge partial lightning currents and commonly employs spark gap technology. They are generally installed in the service entrance switchboard to protect low-voltage equipment from direct lightning strike overvoltage.

Type2 – this version can help prevent the spread of over-voltages in electrical installations and help protect connected equipment. They are fitted to all distribution panels that serve electrical equipment. They offer protection against the residual effects of lightning strikes and switching overvoltages.

Type3 – This are only required to be installed as a supplement to type2 and has a low discharge capacity. It's best suited for a location close to the protected equipment to further protect against switching transients generated within a facility.

Lightning surge protection devices are applied extensively on various industries, especially for those critical-mission industries. If you are interested in any of the applications get connected with our Lightning Eliminator team.

Read more…

#LightningDamage#LightningProtection#LightningProtectionDesign#LightningProtectionProducts#LightningProtectionSystems#LightningRodProtection#LightningSurgeProtectionDevices#FuelTankLightningProtection#GroundingRod#TankBatteryLightningProtection

0 notes

Text

Searching for reliable suppliers of high-quality earth rods in UAE? Tradersfind connects you with the leading earth rod suppliers for your project needs - Whether you need screw-in or drive-in earth rods in standard or heavy-duty models, our listed companies have the right product and expertise to meet your needs.

Reach us on WhatsApp at +971 56 977 3623 to discuss your requirements.

For more, Visit - https://lnkd.in/gpmkJn6e

#EarthRods#grounding#earthingsolutions#earthing#copperrods#galvanizedrods#stainlesssteel#groundingaccessories#earthingpits#lightningarrestors#GroundingRods#EarthingRods#LightningProtection#ElectricalSafety#PowerProjects#ConstructionSupplies#ElectricalAccessories#UAE#Dubai#AbuDhabi#Sharjah#Ajman#RasAlKhaimah#B2B#Manufacturers#Suppliers#TradersFind

1 note

·

View note

Text

BI METALLIC LUGS | Pioneer Power International

In the dynamic realm of electrical connections, staying ahead of the curve is essential to ensure optimal performance and safety. At Pioneer Power International, we recognize the pivotal role that bi-metallic lugs play in enhancing the efficiency and reliability of electrical systems. In this blog post, we delve into the world of bi-metallic lugs and explore how they are revolutionizing the way we connect power.

Understanding the Essence of Bi-Metallic Lugs

Bi-metallic lugs serve as crucial components in electrical connections, bridging the gap between different metals to create a seamless, conductive link. The term "bi-metallic" itself implies the combination of two distinct metals – a design that brings forth unique advantages in diverse applications.

Unparalleled Conductivity and Corrosion Resistance

One of the standout features of bi-metallic lugs is their exceptional conductivity. By combining metals with different conductive properties, these lugs ensure a smooth flow of electrical currents, minimizing resistance and maximizing efficiency. This results in reduced energy loss and enhanced overall system performance.

Corrosion can be a significant concern in electrical connections, especially in environments prone to moisture and harsh conditions. Bi-metallic lugs, however, excel in this aspect due to their corrosion-resistant nature. This feature ensures a prolonged lifespan for the connections, reducing maintenance requirements and downtime.

Versatility Across Industries

Pioneer Power International's bi-metallic lugs are engineered to cater to a wide range of industries and applications. Whether in power distribution, renewable energy projects, or industrial setups, these lugs offer a reliable solution for creating robust electrical connections.

Quality Assurance at Pioneer Power International

At Pioneer Power International, we pride ourselves on delivering products that meet and exceed industry standards. Our bi-metallic lugs undergo rigorous quality checks to ensure durability, reliability, and compliance with safety regulations. This commitment to excellence has established us as a trusted provider in the electrical connectivity landscape.

Optimizing Connectivity for a Sustainable Future

As the world embraces renewable energy and sustainable practices, the demand for reliable electrical connections has never been higher. Bi-metallic lugs from Pioneer Power International play a pivotal role in optimizing connectivity, contributing to the efficiency and longevity of renewable energy systems.

Empowering Connections for a Connected World

In the ever-evolving landscape of electrical engineering, Pioneer Power International stands as a beacon of innovation. Our bi-metallic lugs epitomize the commitment to excellence and sustainability, offering a reliable solution for diverse industries. As we continue to pave the way for a connected future, trust Pioneer Power International to be your partner in unlocking the true power of connectivity.

Discover more about our cutting-edge bi-metallic lugs and explore the possibilities they hold for your electrical systems. Pioneer Power International – Empowering Connections, Powering the Future.

0 notes

Text

Lightning Protection

For those planning to install a Surge Protection Device, look at your grounding electrode system first or have a professional electrician check it out. To improve lightning protection for your home, you must have a good earth-ground connection.

The photos depict corroded water pipe ground clamps that need to be replaced. One photo shows the new clamp and grounding electrode conductor next to the corroded original.

My article explains all of the details with photos for a good grounding electrode system, which includes the bonding of the hot and cold metal water pipes, telephone and TV grounding, and supplemental ground rod installation.

https://mrelectrician.tv/grounding-electrode-system/

#surgeprotector#lightningprotection#homeownership#electrician#electrical contractor#electrical work#electrical repairs#electricians#electrical services

1 note

·

View note

Text

BLIIoT Ethernet IO Module Passed the 3.12KA Lightning Surge Destructive Test

0 notes

Text

The Essential Guide to Earth Rods and Earthing Systems

Earthing rods known as ground rods are essential parts of the earthing system. Currently referred to as ‘autrod’, these are long conductive metal stakes like copper or galvanized steel that are hammered into the ground to provide fault currents.

What are Earth Rods?

Ground rods otherwise called earth rods are conductive metal rods that are implanted on the Earth to channel electrical fault currents safely. These are canopied and specially made from copper or galvanized steel, and offer a low resistance path to earth ensuring protection of people, equipment as well as structures from electrical accidents.

Types of Earth Rods:

Galvanized Steel Rods: Inexpensive and widely applied to general purposes.

Copper Earth Rods: Very hard wiring, does not get rust, favored in lean industries.

Chemical Earthing Rods: Having incorporated into them various conducting elements, providing improved performance in different soils.

Key Benefits of Using Earth Rods

Ensures Safety: Protects against electrical fault currents to eliminate risks of electric shocks and fire outbreaks.

2. Protects Equipment: Protect precious electrical appliances from surge and prevent frequent calls to repair or replace damaged appliances.

3. Enhances System Stability: Offers low voltage of resistance so as to afford a good and safe path to the current thereby enhancing its effectiveness in providing power to the various related electrical systems and devices.

4. Improves Lightning Protection: Discharges electric current and prevents such a catastrophe as lightning to harm people or destroy properties.

5. Reduces Electrical Noise: Reduces electromagnetic interference thereby improving on performance in complex circuits and networking systems.

Earthing Electrodes and Earth Rods

Earthing electrodes should be used together with earth rods to provide a good path of return current to the ground. They have been designed to work cooperatively in optimizing the achievement of the mentioned goals of system effectiveness.

Choosing the Right Earthing Electrode:

Opt for the soils with maximum and minimum resistivity for material selection.

Accurate certified and durable earthing electrode manufacturers are consulted with major earthing electrode manufacturers.

Use in conjunction with chemical earthing rods where severe ground conditions exist.

How to Install an Earth Rod

A well-installed earth rod ensures minimal resistance and system longevity. Follow these steps for effective copper earth rod installation:

Site Selection: Select a site with relatively low soil resistivity.

Driving the Rod: The rest is accomplished by driving either a hammer or driver with the rod burrowed deep in the ground.

Connecting to the System: Secure the rod earthing in place to the grounding system using clamps, and conductors.

Regular maintenance and testing are essential, including understanding how to test earth rod resistance for optimal performance.

Testing and Maintaining an Earthing System

An effective earthing system requires regular monitoring to maintain safety and efficiency.

Resistance Testing: Use the Fall-of-Potential or Clamp-on Resistance Test.

Visual Inspections: Check for corrosion or loose connections.

Component Upgrades: Replace outdated rods with advanced options like chemical earthing rods.

Why Choose Chemical Earthing Rods?

Chemical earthing rods contain compounds that have a capability of increasing their conductivity as opposed to the soil quality and this makes chemical earthing rods useful where there is high soil resistivity. First, they are easy to manage, and second, they provide stability as far as operational efficiency is concerned.

Conclusion

Earthing is central to electrical safety and therefore having a proper earthing system is essential. It is therefore important to use high quality components from genuine earthing electrode manufacturers; ensure proper installation of copper earth rod and conduct proper tests on copper bonded earth rod manufacturers to create a system that protects lives and property.

For More Info : https://renownpower.com/

#Renownpower#earthing#earthingsystem#electricalsafety#earthingsolution#Manufactures#CopperEarthRods#LightningProtection#ChemicalEarthing#EarthingElectrodes

0 notes

Text

The Importance of Lightning Protection System Adequacy Audit

Lightning is a natural phenomenon that can cause catastrophic damage to structures, electrical systems, and even human lives. To mitigate the risks associated with lightning strikes, many buildings and facilities are equipped with lightning protection systems. However, merely having a lightning protection system in place is not enough; ensuring its adequacy and functionality is equally critical. This is where a Lightning Protection System Adequacy Audit comes into play.

What Is a Lightning Protection System Adequacy Audit?

A Lightning Protection System Adequacy Audit is a comprehensive assessment of an existing lightning protection system to determine its effectiveness and compliance with safety standards. This audit involves a thorough evaluation of all components, including lightning rods, down conductors, grounding systems, and surge protection devices. The goal is to identify any weaknesses or deficiencies in the system that could leave a structure vulnerable to lightning-related damage.

Why Is It Necessary?

Safety: The primary purpose of a lightning protection system is to safeguard lives and property. An adequacy audit ensures that the system is fully operational and capable of directing a lightning strike safely into the ground, thereby preventing fires and other potential hazards.

Compliance: Lightning protection standards and regulations are in place to guarantee the efficacy of these systems. An audit helps confirm that a building is in compliance with these standards, reducing the risk of legal issues and insurance complications.

Preventing Damage: Lightning can cause extensive damage to electrical systems, appliances, and electronic devices. An adequate lightning protection system reduces the risk of costly damage by diverting lightning's energy harmlessly into the ground.

Peace of Mind: Knowing that your lightning protection system has been audited and is in good working order provides peace of mind for property owners and facility managers, especially in areas prone to lightning storms.

The Audit Process:

The Lightning Protection System Adequacy Audit typically involves the following steps:

Visual Inspection: The audit begins with a visual inspection of all system components, including lightning rods, conductors, bonding connections, and ground electrodes.

Testing and Measurements: Specialized equipment is used to measure the resistance of grounding electrodes and to check the continuity of the system's components.

Documentation Review: The auditor reviews the installation records and maintenance history of the lightning protection system.

Recommendations: Based on the findings, the audit report provides recommendations for necessary repairs or upgrades to ensure the system's adequacy.

Conclusion:

A Lightning Protection System Adequacy Audit is a vital step in maintaining the safety and reliability of structures and facilities. In regions prone to lightning strikes, such an audit should be conducted regularly to ensure that the lightning protection system continues to provide the necessary protection. With the assurance that the system is in optimal condition, property owners can rest easy, knowing they are well-prepared to face the unpredictable force of nature.

0 notes

Text

How Can LEC Help In Lightning Protection?

In recent years, changes in the global environment, such as global warming, extreme weather conditions, heat islands, and other phenomenon has led to increased heavy rain and lightning. On the other hand, advanced precision electronic equipment has become the need of the hour for every facility. Thus, preventing equipment damage and breakdowns caused by direct lightning strikes through lightning protection system has become the need of the hour.

Lightning strike can cause a fire, explosion, chemical release or mechanical disruptions within or around your facility.

At LEC, we are fully aware of these risks and the need for a more proactive lightning protection system. With over 5 decades of experience, research and development, support and expertise, we have assisted thousands of businesses, both large and small, to achieve effective lightning protection.

Our LPS are engineered with advanced technology and consist of the four key components – air terminals, conductor/bonding, grounding, and transient/surge protection, while our patented LPS works on CTS (Charge Transfer System) technology.

The CTS collects the induced charge developed by thunderstorm clouds from a designated protected area of the earth and transfers this charge through the ionizer into the surrounding air. The resulting difference in electrical potential between the protected site and the storm clouds is reduced thereby delaying the formation of an upward streamer from the protected site and preventing direct strikes.

The charge collector is an interconnected system of grounding electrodes and conductor designed to collect and funnel electrical charge to the ionizers. One of our patented CTS is called Dissipation Array System (DAS).

How can LEC help?

We have a very efficient technical workforce. Our personnel are responsible for installing all types of lightning protection and surge protection systems. We have all resources, materials, and the latest plant, machinery, and vehicle to work on any size project – large scale to a remote mountaintop. Our work progress and quality of workmanship are monitored regularly through various control and testing systems.

We will complete a full site survey and then use the results to design a lightning protection system that would also include recommendations for surge protection.

Contact us to find out more.

youtube

#LightningDamage#LightningProtection#LightningProtectionDesign#LightningProtectionProducts#LightningProtectionSystems#LightningRodProtection#LightningSurgeProtectionDevices#FuelTankLightningProtection#GroundingRod#TankBatteryLightningProtection#Youtube

0 notes

Text

At LEC, we are fully aware of these risks and the need for a more proactive lightning protection system. With over 5 decades of experience, research and development, support and expertise, we have assisted thousands of businesses, both large and small, to achieve effective lightning protection. Visit us at: https://www.lightningprotection.com/

#LightningDamage#LightningProtection#LightningProtectionDesign#LightningProtectionProducts#LightningProtectionSystems#LightningRodProtection#LightningSurgeProtectionDevices#GroundingRod

0 notes

Text

How Can LEC Help In Lightning Protection?

In recent years, changes in the global environment, such as global warming, extreme weather conditions, heat islands, and other phenomenon has led to increased heavy rain and lightning. On the other hand, advanced precision electronic equipment has become the need of the hour for every facility. Thus, preventing equipment damage and breakdowns caused by direct lightning strikes through lightning protection system has become the need of the hour.

Lightning strike can cause a fire, explosion, chemical release or mechanical disruptions within or around your facility.

At LEC, we are fully aware of these risks and the need for a more proactive lightning protection system. With over 5 decades of experience, research and development, support and expertise, we have assisted thousands of businesses, both large and small, to achieve effective lightning protection.

Our LPS are engineered with advanced technology and consist of the four key components – air terminals, conductor/bonding, grounding, and transient/surge protection, while our patented LPS works on CTS (Charge Transfer System) technology.

The CTS collects the induced charge developed by thunderstorm clouds from a designated protected area of the earth and transfers this charge through the ionizer into the surrounding air. The resulting difference in electrical potential between the protected site and the storm clouds is reduced thereby delaying the formation of an upward streamer from the protected site and preventing direct strikes.

The charge collector is an interconnected system of grounding electrodes and conductor designed to collect and funnel electrical charge to the ionizers. One of our patented CTS is called Dissipation Array System (DAS).

How can LEC help?

We have a very efficient technical workforce. Our personnel are responsible for installing all types of lightning protection and surge protection systems. We have all resources, materials, and the latest plant, machinery, and vehicle to work on any size project – large scale to a remote mountaintop. Our work progress and quality of workmanship are monitored regularly through various control and testing systems.

We will complete a full site survey and then use the results to design a lightning protection system that would also include recommendations for surge protection.

Contact us to find out more.

#LightningDamage#LightningProtection#LightningProtectionDesign#LightningProtectionProducts#LightningProtectionSystems#LightningRodProtection#LightningSurgeProtectionDevices#FuelTankLightningProtection#GroundingRod#TankBatteryLightningProtection

0 notes