#Laser Cleaning Machines for Wood

Explore tagged Tumblr posts

Text

Pulse Laser Cleaning Machine for Wood

In the realm of wood restoration and maintenance, the advent of the pulse laser cleaning machine has revolutionized the industry. This cutting-edge technology offers an efficient, precise, and eco-friendly solution for cleaning and restoring wooden surfaces. In this comprehensive guide, we will delve into the intricacies of pulse laser cleaning machines, exploring their benefits, applications, and the science behind their operation.

Pulse Laser Cleaning Machine for Wood

A pulse laser cleaning machine utilizes high-intensity laser pulses to remove contaminants, coatings, and residues from surfaces. Unlike traditional cleaning methods, this technology is non-abrasive and does not involve chemicals, making it an ideal choice for delicate materials such as wood.

The machine emits short bursts of laser energy, which are absorbed by the contaminants on the wood surface. This absorption causes the contaminants to vaporize or disintegrate, leaving the underlying wood intact and pristine. The process is highly controlled, ensuring minimal damage to the wood.

Laser-Material Interaction

The effectiveness of pulse laser cleaning lies in the interaction between the laser and the material. When the laser pulse hits the surface, it is absorbed by the contaminants, causing them to rapidly heat up and vaporize. The underlying wood, which has a different absorption rate, remains unaffected.

Parameters and Settings

The success of the cleaning process depends on various parameters, including laser wavelength, pulse duration, and energy density. These settings can be adjusted based on the type of wood and the nature of the contaminants, ensuring optimal results.

How Pulse Laser Cleaning Machines Work

Laser Pulses: The machine emits high-frequency laser pulses that target the surface layer of the material.

Absorption and Vaporization: The contaminants or unwanted layers absorb the laser energy, which causes them to vaporize or be blown away by the resulting shockwave.

Selective Cleaning: The laser can be adjusted to ensure it only affects the contaminants, preserving the underlying wood.

Applications of Pulse Laser Cleaning Machines in Wood Restoration

Antique Furniture Restoration

Antique furniture requires delicate handling to preserve its historical value. Pulse laser cleaning machines provide a non-invasive method to remove dirt and old finishes, revealing the original beauty of the wood.

Wooden Artifacts and Sculptures

Museums and galleries often use pulse laser cleaning machines to maintain and restore wooden artifacts and sculptures. The precision of the laser ensures that intricate details are preserved while removing unwanted residues.

Flooring and Paneling

For large-scale projects such as flooring and paneling, pulse laser cleaning machines offer a quick and effective solution. They can strip old finishes and stains, preparing the wood for refinishing without causing damage.

Benefits of Using Pulse Laser Cleaning Machines for Wood

Precision and Control

One of the standout features of pulse laser cleaning machines is their precision. The laser can be finely tuned to target specific areas, allowing for meticulous cleaning without affecting the surrounding material. This level of control is particularly beneficial for intricate woodwork and antique furniture.

Eco-Friendly

Traditional cleaning methods often involve harsh chemicals that can be harmful to both the environment and human health. Pulse laser cleaning, on the other hand, is a green technology. It does not produce hazardous waste or emissions, making it a sustainable choice for wood restoration.

Versatility

Pulse laser cleaning machines are versatile and can be used on a variety of wooden surfaces, from furniture and flooring to historical artifacts and sculptures. This adaptability makes them a valuable tool in both commercial and residential settings.

Efficiency

The speed and efficiency of pulse laser cleaning machines are unmatched. They can quickly remove layers of dirt, paint, or varnish, significantly reducing the time and labor required for restoration projects.

0 notes

Text

"Waaaaaaahoo!" Gemma cried as the Tiburon darted through the valley, its arms flailing at the squad of battle armor latched onto it, their lasers and claws cutting into its thin armor. "Have at 'em, lads!" Gemma herself had her armor's battle claw dug deep into the internals of the 'Mech's shoulder and was riding it like she was trying to tame a wild beast, her right arm raised and the blunt nub of the laser where a hand would be on a person firing off red beams into the sky.

The Sea Fox Tiberon came cresting a small rise and turned hard, but it still couldn't shake the quartet of Inner Sphere Standard Battle Armor that was chewing it up like piranha on a sack of meat. Gemma knew that any moment someone would hurt something very important inside the clan machine and her ride would be over, leaving her and her swuad to go hunting the rest of this star, provided any were left after The Bloody Gash's conventional 'Mech troops were done with them.

She was just about to let out another whoop and go digging herself when she saw the forest coming up fast. Oh no. The bastard was going to car wash his problems away. With a shriek of despair she leaned forward, bracing the shoulder of her battle armor before her as the 'Mech entered the trees at over 90kph. Branches slammed into her and her visor was filled with nothing but a blur of leaves and broken wood. Over and over again she was buffetted and bashed about.

The feet of her armor slipped with the repeated impacts and she found herself flopping about atop the Tiberon, only still on because her armor's battle claw was stuck in a thick bundle of myomer muscle and wire inside the 'Mech. She was not too proud to scream in terror and her visor bounced off of jagged strips of ripped open armor, the edges of which she knew were sharp enough to go straight through her face and into her skull if the visor broke.

But it didn't. The venerable IS Standard was built tougher than that.

Eventually she emerged back into the light and the open plain of the valley, and she regained her footing. A quick look told her that the rest of her squad hadn't been so lucky and were lost somewhere in the forest behind. "Not so easy to lose Captain Gemma Orlais, is it Foxy?"

She rammed the muzzle of her laser into the hole her battle claw had made in the 'Mech's armor and cut loose a long burst that she held until the safety cut in to prevent her from melting the barrel. Somethingside sparked and fumed, then the Tiburon jerked once to the side and fell skidding to the ground with Gemma surfing it to a stop as she had a dozen or more times before on 'Mechs both larger and faster than the battle scout that was her current prey.

Gemma jumped off and turned towards the cockpit, but it was buried in the ground. Dead or alive, the MechWarrior inside was not going to be getting free any time soon. So, satisfied with a job well done, she turned away from the wreckage to head back towards the forest and the rest of her squad.

Movement out of the corner of her eye caught her attention and she turned to see the Tiburon's leg moving. That wasn't good. She turned, preparing to leap back onto the 'Mech when the whole leg shifted and she saw, crushed underneath it, several suits of Elemental battle armor, the feared toads of the Clans smashed to pulp when the Tiburon fell on them. They must have been on their way to answer a distress call from the MechWarrior, looking to clean her squad off of him, but luck was not on their side and the sudden fall and skid must have taken them by surprise.

But now it is Gemma's turn to be surprised, and not by the two smashed suits of elemental armor under the leg, or the two she now sees smeared across the ground in the runnel left by the skidding 'Mech, but by the fully intact one throwing the Tiburon off of itself and stalking directly towards her.

Gemma waved, "Hello there! Rough day?" Then without waiting for a reply she fired her laser at it for a full burn and ignited the jets in her armor to propel herself away. The laser went wide as the Elemental roared up into the sky itself, chasing after her. When she hit the ground it was right on top of her, its own laser coming up towards her faceplate.

She grabbed it with her battle claw and wrenched it upwards so the beam fired up and away and instead of directly into her faceplate visor. But even as her claw crushed the clan weapon to scrap the elemental's own claw punched into the side of her armor and latched on. There was a great tearing as the bigger, stronger armor hefted her bodily into the air, visor to visor.

She could see a shadow there beyond the tint and the fog of sweat and rage inside, and it seemed to be smiling. The crunch and tear of metal near her ribs told her that her enemy was still very much trying to peel her open to get at the soft flesh inside of her battle armor. Gemma never thought she'd have to do this.

She let go of the elemental's laser with her claw, but it brought its damaged arm around to guard against any blows against it. Gemma however was not trying to do anything to it. Instead she reached for the chestplate of her own armor where she traditionally kept her last ditch weapon.

The elemental continued to lift her higher and higher, and something in the right side of her armor gave. She could feel air against her bare skin and then the hard coldness of one of the pincers of the clan battle claw. Now she was staring down into the faceplate of the elemental and seeing the reflection of her own armor's chest plate and the neon pink letters mirrored there.

LET'S BE FRIENDS! Right across the front of an antipersonnel mine. Her claw found the rigged up ripcord trigger for it and pulled.

Boom.

Warning. Catastrophic damage detected. Administering morphine. Error: Morphine supplies depleted. Seek immediate medical assistance.

"Probably shouldn't have partied that hard last night," Gemma groaned at her HUD, whose flashing warnings were superimposed on a clear blue sky above. The IS Standard had held, barely, but she was done, all controls unresponsive, laying on her back in the middle of a field. She could see smoke trailing up from her prone form.

With a groan she twisted her head and bit down on the emergency release, which set off explosive bolts at the front of her armor and sent it flying away, a twisted hunk of steel done no favors by taking explosions from both sides, and she pulled herself free and into the open air. The elemental was thirty meters away, its entire left arm and shoulder missing. Idly, she noted that arm was still stuck in her own armor, leaking blood from the severed stump at the end.

Gemma was about to go digging for her radio when she heard a hiss and pop from the elemental. "Oh come on," she grumbled and turned. A hugely muscled woman was climbing out of the clan armor, her left arm a blackened, bleeding stump. Several injectprs ripped put of her skin as she pulled herself free of the crippled machine, obviously part of that clan black box thing that kept its elementals full of an entire cocktail of drugs to keep them fighting past normal human limits.

"We could talk about this," Gemma offered the woman, but if she heard she made no indication, instead bellowing a cacophonous roar of defiance and charging right at her, one gigantic hand raised up like a claw coming for Gemma's throat.

Gemma sighed and pulled her howdah pistol, which was really just an anti-materiel rifle she'd taken an angle grinder to until it could fit comfortably strapped to her thigh and could generously be called a handgun and more accurately called a huge mistake. The elemental had the audacity to look surprised before the gun barked and her face, along with most of her upper body, turned into a moist red cloud and fluttered to the grass atop the rest of her.

The recoil sent the gun flying from Gemma's hand and off into the field behind her somewhere, but she ignored it and sat down in the grass with a sigh of pain and exhaustion. Then she pulled a fine fat Phactian cigar out of her cleavage and stuffed it between her teeth with a grin. "All's well that ends well."

15 notes

·

View notes

Text

I got this ~1950s mini sewing machine when someone was giving it away locally, so I've started restoring it. This is before...

There was live woodworm eating into the wood panels, the paint was flaking off, and there were rust spots on the exposed metal. The mechanism was actually in decent working order though.

I started with the wood. For the base I just ordered a piece of plywood cut to the right size, because I don't have a table saw to easily cut down big panels.

For the table, I laser-cut layers of 2mm plywood in slightly different sizes to create the right profile in the sides of the slot. Here it is before and after sanding the edges to nice curves.

Today I got started on the metalwork. First, dissassembling everything. It was scary but I took lots of pictures to keep track of how everything goes back together, so I can hopefully retrace my steps later.

The hardest part was removing the hand-crank wheel. It was really tightly wedged and I ended up having to hammer the metal in the centre of the wheel to release it. 😬

But it all came apart with no damage eventually.

Today I stripped off the flaking paint. Just many rounds of applying paint stripper, waiting, scrubbing, and repeating. Eventually got it all cleared off though.

Next will be cleaning all the other parts of rust, and then repainting. I won't be able to exactly match the old colour so I'm thinking I might do something totally different, but I haven't decided yet.

16 notes

·

View notes

Text

Guys this is fun and all but can someone ask for a commission or smt?

Sadly I couldn't scape capitalism and my debts are stacking and job's are not popping

So wtf do you even sell?

I am glad you asked!

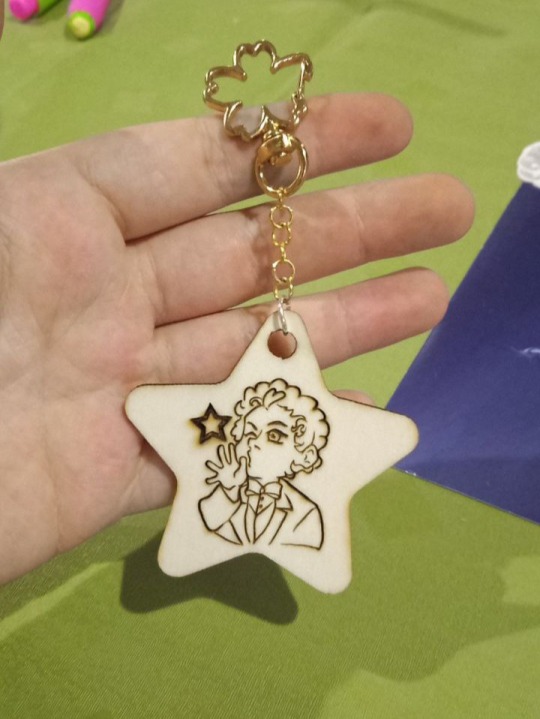

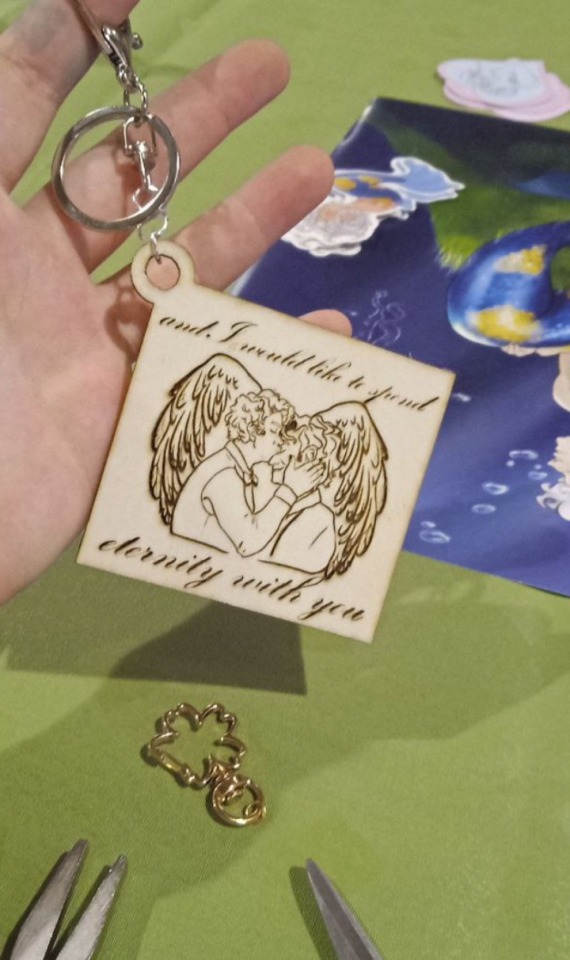

I like to draw, and I invested on a wood laser cut machine, and now that I know how It works I can do THIS

These are wood earrings (8€ a pair), I made the drawings, then laser cutted the wood and then painted them. Also varnish them for protection.

I also made them into pendants (8€ the big ones and 6€ de tiny) and keychans (8€ each one)

I am open for commissions of wood things like, "I want (put here what you want) as a keychan", but then I will charge a little bit more for the new drawing.

If the drawing it's very simple, something like this, It will be only +3€

But if it's something more complex like this, the price will be discussed on message. Idk right now how much, but a complex lineart Illustration could be around 25€.

Talking about this Illustration!!

Heheje I have It in a lgbtqia+ rgb led lamp!!

I also do like "traditional" commisions, with:

Simple chibi sketch for 3€ (+2€ for clean lineart, +1€ for colour)

Complex bust sketch for 25€ (could be more if too detailed) (+5€ clean lineart, +2€ colour) (but again depends on the commission)

Yes I know everything it's good omens, sorry (not really).

If you read till here, thank u so much.

I will be posting parts of this "ad" but I really wanted to put everything first in the same post.

And think of buying something, maybe? No? Pls?

#good omens#commission#wood pins#isadibus#led lamp#good omens 2#crowley#aziraphel#fanart#crowley x aziraphale#mermaid melody pichi pichi pitch#oc art#the shipping costs will be paid by the client btw#I am from Europe if that helps you to calculate how much It will cost#the wood thingys barely weighs#someone help me#I love doing these little thingys but it's so difficult for me to advertise them well enough#and i know the theory don't get me wrong#it's just so difficult lately for me to accomplish ANY tipe of consistency and regularity in my schedule

8 notes

·

View notes

Note

not rq, but question !!

how do yoz make the keychains? they look so clean and pretty im so amazed :''DD like wood burning is usually very difficult to get szch a consistent look with, do you use like.. smth like those irons that cartoons show being burned onto cows? (very meam scary thing but i cant think of anothet example sadly)

or is it like a manifactur thingy...? :000

hello!!! questions are welcomed :D

I use a laser engraver/cutting machine! Specfically, xTool D1 Pro Desktop Laser Engraver Cutting Machine! It's like an...exposed printer! That uses a hot laser to cut/etch/burn into wood (and many other materials).

To get a design onto the wood, I first draw them digitally, then upload the design into XTool's software, vectorize it there, adjust some settings, and connect my machine to my computer and tell it to start engraving/cutting!

Unfortunately, the machine itself is pretty expensive. I happened to get mine from a family member. It's an amazing tool tho, so worth the investment if you got cool ideas to make and sell!

hope that answers your question!! :3

1 note

·

View note

Text

Cate Dunlap x Detainer Astro Skibidi Toilet

||NO ONE ESCAPES JUSTICE||

It was a normal day on Godolkin University,Cate Dunlap was with Sam Riordan,who she just mind-Controlled to make him forgett about all his memories to turn him into a killing machine.

Cate set free all the prisoners from the woods causing chaos and ultimately a massacre on Godolkin.

She was tired of humans and wanted to see them death,she was out of control,screaming,crying and confused while Marie Moreau and Jordan Li desperately tried to stop the mind controller menace,hurting and killing supes in the process.

As the massacre continued a confrontation between Cate and Marie and Jordan Happened..

"Cate you have to stop!you are fucking crazy,innocent people is dying,this got out of control"Marie said out of breath

"We can talk about this Cate,just stop this nightmare please"Marie added

"They have used us for years,for their own benefit...,Marie im trying to save you all!"

Cate then began to cry

"Cate please,not all humans are like them...Just stop this please!"Marie Said

"But Marie you're not a person,you're a product to them,a freak Im trying to save you!"

Sam them appeared and saw a person trying to run away but he jumped at them like a beast and with a single punch exploded their head,shocking Marie and Jordan

"Sam,Fucking kill them all,make them suffer"Cate said serious...

Then she started to control other supes and peple to clean up the evidence,While sam was on a killing spree.

However the clouds started to change it's colour and a breeze started to feel over the campus

The he appeared....

And humanoid man with a toilet as a body and an metalling armor with 3 claws with lasers

He travelled at the speed of the light,a lunatic speed impossible even for A-Train himself.

The man fled towards the Supes that where wrecking the chaos on the campus and one of them tried to attack him,firing an electric blast towards him,but he just stopped the energy with his claws and sent it back to the psycho supe exploding her.

Cate shocked told Sam to attack and he did,he charged towards the Astro Toilet trying to punch him but the astro just rammed him at an incredibly lunatic speed killing Sam.

He then started to destroys the supes causing the chaos,none of them stod a chance against him.

When he was about to end Cate he just smiled and got closer to her.

"You.....you did all of this,you deserve to get punished....."The Astro said in a deep voice and an annoyed face.

"S S-Sir i-im.... sorry i was j-just confu-fused...please forgive me....."Cate said in absolute fear

"Inmoral mortals should not be forgived"Astro Toilet Said

"But you....you look rather stunning...are you alone?"Astro added

"WHAT?!....W-Well i...my boyfriend died some time ago but im n-not in the mood f-for a rela-"She replied before being stopped by Astro

"YOU have no right to choose on my stay.....You are mine now and we are gonna have an adventure together"Detainer said before grabbing Cate and fly away with her...

Cate was very scared of this guy but also somewhat amazed by him,she tought he looked cool but tried to not focus on that,a blushed cate touched his helmet as he noticed it and just smiled

"You know? Pretty girls like you deserve the whole world,what are your powers? Im genuinely interesed"detainer said

"Mind control,i can make people do whatever i want just by touching them,before the incident i used to wear gloves to prevent this from happening"Cate answered

"Interesting,i think you already noticed your cheap power is not working on me right?"Detainer said

"Yes...."Cate replied

"Don't worry,a goddess like you deserves to get everything"Detainer said

"I...I guess?,i honestly don't know what to say,thanks also"Cate replied

"We can live awesome things together,i promise you will adore them"Astro said

"Well if you say so,okay hehe"Cate said

"They flied over the city,seeing different things,at the end they came back to godolkin

"I really liked that a lot" Cate said blushed and smiling

"I liked it too"Detainer said before trying to kiss her

..however he was stopped by someone...

The one and only Homelander arrived the place in ruins as he stared deeply at detainer.

"Homelander....Vought's main product....the biggest fraud ever..."Detainer said

"And who the fuck are you supposed to be?,like are you some failed freak or something?,i"ll give you a choice....get the fuck out of my countr-"Homelander said before Detainer started to laugh

"You know the penalty for your acts,homelander....No one escapes justice"Astro said

"Patethic scum"The astro said putting Cate down

"Let's finish this now"he added

Homelander just laughed as his eyes turned red and he started to shoot his laser eyes towards Detainer

Detainer only catch them with his claws and forming a red power orb that he threw to homelander.

He avoided it and then detainer prepared to warp again but homelander just lasered him again while punching him,detainer used his magnetizer powers against him and also his retractable tentacles,it was a bloody fight that destroyed a good part of the university,Astro then did a very powerful attack that destroyed homelander and sent him directly to a pile of bricks

"Thomas Godolkin,Victoria Neuman,Stan Edgar,The seven...they already paid for their sins,you are the next John"Detainer said

The toilet pulled a large blade out of one of his claws and the destroyed homelander with it ending him once for all.

"OH MY GOD Y-YOU JUST KILLED HOMELANDER"Cate said in absolute shock

"He's nothing against me,he's just a pathetic worm"Astro said

"What the fuck,this day must be a dream,this can't be true"Cate said

"It is Reality Mrs.Cate"Astro said

Detainer then got closer to Cate and kissed her,her face was red as a tomato

"Let's get out of here"Astro said before grabbing her and flying away

#genv#catedunlap#maddiephillips#theboys#skibidi toilet#astro detainer toilet#astro toilets#dafuqboom

2 notes

·

View notes

Text

At Alsurooq Company, we offer top-quality CNC laser cutting services, delivering precision and efficiency for a variety of materials like metals, plastics, wood, and more. Our advanced CNC technology ensures smooth, clean cuts with high accuracy, making it ideal for custom designs, prototypes, and large-scale production runs. We work with industries such as automotive, aerospace, architecture, and signage to produce complex shapes, intricate details, and fine finishes. With fast turnarounds, minimal waste, and competitive pricing, Alsurooq is your trusted partner for all your laser cutting needs. Contact us today for a tailored quote! #CNCLaserCutting #PrecisionManufacturing #CustomDesigns #AlsurooqCompany

1 note

·

View note

Text

Laser Cut Ornaments: The Art of Precision and Creativity

When it comes to creating stunning, intricate designs, laser cut ornaments are in a league of their own. Whether you're crafting holiday decorations, personalized gifts, or unique home décor, laser cutting technology brings your ideas to life with unmatched precision and elegance. But what exactly makes laser-cut ornaments so special? And how can you get started with this fascinating craft? In this guide, we’ll explore the world of laser-cut ornaments, uncover their benefits, and introduce you to the xTool P2S 55W Desktop CO2 Laser Cutter, a machine that’s perfect for creating these delicate masterpieces. So, let’s dive into the magical world of laser cutting and discover how you can turn ordinary materials into extraordinary works of art!

What Are Laser Cut Ornaments?

Laser cut ornaments are decorative items created using laser cutting technology. This process involves using a focused laser beam to cut or engrave intricate designs into materials like wood, acrylic, metal, or paper. The result is a precise, clean, and detailed ornament that can be used for various purposes, from holiday decorations to personalized gifts.

How Does Laser Cutting Work?

Laser cutting works by directing a high-powered laser beam onto the surface of a material. The laser melts, burns, or vaporizes the material along a predetermined path, creating precise cuts and engravings. The process is controlled by computer software, which ensures accuracy and repeatability. This makes laser cutting ideal for creating complex designs that would be difficult or impossible to achieve with traditional cutting tools.

Why Choose Laser Cut Ornaments?

If you’re wondering why laser cut ornaments are so popular, here are some compelling reasons:

1. Precision and Detail

Laser cutting allows for incredibly detailed designs, with cuts as fine as a fraction of a millimeter. This level of precision is perfect for creating intricate patterns and delicate ornaments.

2. Versatility

Laser cutting can be used on a wide range of materials, including wood, acrylic, paper, leather, and even metal. This versatility makes it easy to create ornaments for any occasion or style.

3. Speed and Efficiency

Laser cutting is a fast process, allowing you to create multiple ornaments in a short amount of time. This is especially useful for holiday decorations or event favors.

4. Customization

With laser cutting, you can easily personalize ornaments with names, dates, or custom designs. This makes them perfect for gifts or special occasions.

5. Eco-Friendly

Laser cutting produces minimal waste, as the laser beam is precise and only removes the material needed for the design. This makes it an environmentally friendly option for crafting.

Applications of Laser Cut Ornaments

The applications of laser cut ornaments are as diverse as the materials they’re made from. Here are just a few examples:

1. Holiday Decorations

From Christmas tree ornaments to Halloween decorations, laser cutting can create festive designs that add a touch of magic to any celebration.

2. Personalized Gifts

Laser-cut ornaments make thoughtful and unique gifts. Whether it’s a nameplate, a photo frame, or a custom design, these ornaments are sure to impress.

3. Home Décor

Laser-cut ornaments can be used to create beautiful wall art, lampshades, or even furniture accents. The possibilities are endless!

4. Weddings and Events

Laser-cut ornaments are perfect for weddings and special events. Use them as table decorations, place cards, or even wedding favors.

5. Art and Craft Projects

Artists and crafters love using laser-cut ornaments to add intricate details to their projects. From paper art to mixed-media creations, the results are always stunning.

Introducing the xTool P2S 55W Desktop CO2 Laser Cutter: Your Gateway to Laser Cut Ornaments

When it comes to creating laser cut ornaments, the xTool P2S 55W Desktop CO2 Laser Cutter is a game-changer. This powerful yet compact machine is designed for precision and ease of use, making it perfect for both beginners and experienced crafters.

Key Features of the xTool P2S 55W

High Power and Speed: With a 55W laser tube, this machine can cut through materials quickly and efficiently.

Exceptional Precision: The xTool P2S delivers precise cuts and engravings, ensuring your ornaments are flawless.

Wide Material Compatibility: From wood and acrylic to leather and paper, this machine can handle it all.

User-Friendly Interface: The intuitive software makes it easy to design and cut your ornaments with just a few clicks.

Compact Design: Despite its power, the xTool P2S is compact enough to fit on a desktop, making it ideal for small workshops or home studios.

Why Choose the xTool P2S 55W?

The xTool P2S 55W is more than just a laser cutter; it’s a creative powerhouse. Whether you’re crafting holiday decorations, personalized gifts, or intricate art pieces, this machine delivers professional-quality results every time. Plus, its compact design and user-friendly features make it accessible to crafters of all skill levels.

Tips for Creating Stunning Laser Cut Ornaments

Ready to start creating your own laser cut ornaments? Here are some tips to help you get started:

Choose the Right Material: Different materials require different laser settings. Experiment with wood, acrylic, paper, and more to find what works best for your designs.

Design with Precision: Use vector-based design software like Adobe Illustrator or CorelDRAW to create detailed and scalable designs.

Test Your Settings: Before cutting your final design, test the laser settings on a scrap piece of material to ensure the best results.

Safety First: Always wear protective eyewear and follow safety guidelines when operating a laser cutter.

Get Creative: Don’t be afraid to experiment with different designs, colors, and finishes. The possibilities are endless!

Conclusion: Unleash Your Creativity with Laser Cut Ornaments

In the world of crafting and design, laser cut ornaments are a true game-changer. With their precision, versatility, and endless customization options, they offer a unique way to bring your creative visions to life. And if you’re looking for the perfect tool to get started, the xTool P2S 55W Desktop CO2 Laser Cutter is your ultimate companion. Whether you’re a seasoned crafter or a curious beginner, this machine will help you create ornaments that are as unique as you are. So why wait? Dive into the world of laser cutting and start crafting your own laser cut ornaments today!

0 notes

Text

Why Laser Machines Are Essential for Precision Cutting and Engraving

In the realm of modern manufacturing, laser machines have revolutionized precision cutting and engraving processes. Their ability to deliver unparalleled accuracy, speed, and efficiency has made them indispensable across various industries. Whether working on metal, wood, glass, or fabric, laser machines ensure top-notch results, helping businesses maintain a competitive edge.

Benefits of Using a Laser Machine

Unmatched PrecisionLaser machines can achieve intricate designs and cuts with incredible accuracy. The focused laser beam ensures clean edges and minimizes material wastage, making it an ideal choice for detailed engraving or precise cutting tasks.

Versatility Across MaterialsFrom metals to plastics and even delicate fabrics, a laser cutting machine can handle a wide range of materials. This versatility eliminates the need for multiple tools and simplifies the production process.

Speed and EfficiencyLaser machines can work at high speeds without compromising accuracy, making them suitable for large-scale production. The automation capabilities further reduce downtime and increase productivity.

Cost-Effective OperationsAlthough the laser cutting machine price might seem high initially, its efficiency, low maintenance, and minimal material wastage result in long-term cost savings.

Applications of Laser Machines

Laser machines are widely used in industries like automotive, jewelry, electronics, and signage. Their precision ensures flawless designs in engraving applications, while their cutting capabilities are vital for creating intricate components for manufacturing.

Choosing the Right Laser Cutting Machine

When selecting a laser machine, consider factors such as cutting speed, material compatibility, and budget. Opt for a reliable manufacturer that offers robust after-sales support and advanced features to ensure optimal performance.

Conclusion

Terron India stands as a trusted name in the field, offering high-quality laser machines designed for precision and durability. Whether you're looking for a versatile laser cutting machine or cost-effective solutions, Terron India delivers excellence tailored to your business needs.

0 notes

Text

Key Advantages of using Laser Cutting Machine In Industry

Industrial Laser cutting machines are unmatched in providing excellent precision and efficiency in industrial applications. Such machines yield clean, accurate cuts on metals, plastics, wood, and many other materials, minimising waste and time of production. High speed added with being of great automation capability and little or no demanding post-processing makes it more productive, safe, and so cost-effective thereby making them absolutely necessary in the current manufacturing processes.

#laser cutting machine#industrial laser cutting machine#hand laser cutting machine#fibre laser cutting machine

0 notes

Text

Model making has always been an essential aspect of design, architecture, and engineering. From conceptualizing skyscrapers to prototyping intricate mechanical systems, models serve as tangible representations of creative visions. In recent years, laser cutting technology has emerged as a game-changer in the field of model making. By combining precision with unparalleled versatility, laser cutting has redefined the way designers and artisans approach their craft.

Precision at Its Best

One of the standout features of laser cutting is its ability to deliver unmatched precision. Traditional model-making methods often relied on manual cutting tools, which could be time-consuming and prone to human error. With laser cutting, even the most intricate designs can be executed flawlessly. The laser beam’s fine focus allows for cuts as thin as fractions of a millimeter, ensuring that every detail is rendered accurately.

For architects, this means being able to create highly detailed architectural models that showcase everything from window patterns to structural frameworks. Engineers benefit from the precision of laser cutting when crafting prototypes, where even a minor error could compromise functionality. This level of accuracy not only saves time but also enhances the overall quality of the final model.

Speed and Efficiency

Time is a critical factor in model making, especially in industries where deadlines are tight. Laser cutting dramatically speeds up the process by automating intricate cuts that would otherwise take hours to complete by hand. Once a design is uploaded to the machine, the laser cutter can execute it with minimal supervision, allowing designers to focus on other aspects of their projects.

Additionally, laser cutting reduces the need for post-processing. The clean edges and smooth finishes produced by the laser eliminate the need for extensive sanding or trimming. This efficiency not only shortens production times but also reduces labor costs, making laser cutting a cost-effective solution for both small and large-scale projects.

Versatility in Materials

Another significant advantage of laser cutting is its ability to work with a wide range of materials. Whether you’re working with wood, acrylic, cardboard, metal, or fabric, laser cutting machines can handle it all. This versatility allows model makers to experiment with different textures and finishes, adding depth and dimension to their creations.

For example, architectural models often incorporate a mix of materials to differentiate between surfaces like glass, concrete, and greenery. Laser cutting enables seamless transitions between these materials, ensuring a cohesive and professional look. Similarly, in the world of product design, prototypes can be made using a combination of metals and plastics, all precisely cut to fit together perfectly.

Empowering Creativity

Beyond its technical capabilities, laser cutting also fosters creativity. The technology enables model makers to push the boundaries of what’s possible, bringing complex and imaginative designs to life. Intricate patterns, delicate engravings, and three-dimensional structures that were once difficult or impossible to achieve can now be created with ease.

Artists and designers, in particular, have embraced laser cutting as a tool for expressing their creativity. From sculptural pieces to interactive installations, the precision and flexibility of laser cutting open up new avenues for exploration. For example, model makers can incorporate intricate lattice designs or layered elements that add visual interest and complexity to their work.

Sustainability and Waste Reduction

In today’s world, sustainability is a growing concern across industries. Laser cutting contributes to eco-friendly practices by optimizing material usage. The technology’s precision minimizes waste, ensuring that every piece of material is used effectively. Additionally, many laser cutting machines are energy-efficient, further reducing their environmental impact.

For model makers, this means being able to create high-quality models while maintaining a commitment to sustainability. The ability to reuse offcuts and scraps for smaller components or experimental designs adds another layer of efficiency to the process.

The Future of Model Making

As laser cutting technology continues to advance, its role in model making is expected to grow even further. Innovations such as multi-axis laser cutting and integration with 3D printing are already expanding the possibilities for designers and engineers. These advancements allow for the creation of more complex models, combining the precision of laser cutting with the flexibility of additive manufacturing.

Moreover, the accessibility of laser cutting is improving. Smaller, more affordable machines are making their way into workshops and studios, enabling hobbyists and small businesses to leverage the technology. This democratization of laser cutting is fostering a new wave of creativity and innovation in the model-making community.

Conclusion

The role of laser cutting in modern model making is undeniable. By offering precision, efficiency, versatility, and sustainability, this technology has transformed the way models are designed and constructed. Whether you’re an architect crafting a scale model, an engineer prototyping a new product, or an artist exploring intricate designs, laser cutting provides the tools to bring your vision to life with unparalleled accuracy and creativity.

As the technology continues to evolve, it’s exciting to imagine the new possibilities it will unlock. For now, laser cutting remains a cornerstone of modern model making, bridging the gap between imagination and reality with precision and style.

0 notes

Text

CO2 Laser Machine in

Success Technologies is a Manufacturer, and Supplier of CO2 Laser Machine in Rajasthan, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. A CO2 laser machine is a powerful tool that uses carbon dioxide (CO2) gas as the lasing medium to generate a laser beam. This beam is then focused onto the material to cut, engrave, or mark it with high precision. CO2 lasers can cut through a wide range of materials, making them highly versatile and efficient for industrial applications. Specifications: Laser Type: CO2 Cutting Speed: 30m/min Voltage: 240 V Weight: 1900 Kg Frequency: 50 Hz Automation Grade: Semi-Automatic Phase: Single Phase Applications of CO2 Laser Machines: Cutting and engraving metal, wood, plastic, glass, acrylic, and fabric Custom engraving of logos and patterns on products Sign-making and promotional materials production Decorative designs on wood, leather, and textiles Precision cutting for automotive and manufacturing industries Which materials can CO2 laser machines cut? These machines can cut a wide variety of materials, including wood, acrylic, plastics, metals, leather, and more. Are CO2 laser machines easy to maintain? CO2 laser machines require relatively low maintenance compared to other industrial cutting tools. You typically need to perform regular cleaning and occasional alignment checks. Success Technologies is a Manufacturer, and Supplier of CO2 Laser Machine in Rajasthan, India Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alwar#Anupgarh#Balotra#Banswara#Baran#Barmer#Beaware#Bharatpur#Bhilwara#Bikaner#Bundi#Chittorgarh#Churu#CO2LaserMachineinAhmedabad#CO2LaserMachineinGujarat#CO2LaserMachineinIndia#CO2LaserMachineinRajasthan#Dausa#Deeg#Dholpur#Didwalna-Kuchaman#Dudu#Dungarpur#Exporter#ExporterofCo2LaserMachine#Ganganagar#GangapurCity#Gujarat

0 notes

Text

Laser Cutting Services at Samarth Sharp Edge: Precision and Versatility in Every Cut

In today's world of manufacturing, precision and efficiency are key to producing high-quality products. Samarth Sharp Edge, based in Pune, provides top-of-the-line laser cutting services powered by advanced German technology, ensuring clean and precise cuts for a wide range of materials.

Unmatched Precision and Technology

At Samarth Sharp Edge, we employ a 12KW laser cutting machine with a large cutting bed of 6 meters by 2.5 meters, enabling us to handle a wide range of projects. Whether you're working with stainless steel, aluminum, copper, or even wood and acrylic, our technology ensures exceptional accuracy, minimizing waste and improving overall product quality.

Versatility Across Materials

Our laser cutting services cater to a variety of industries by offering compatibility with multiple materials. From metals like stainless steel, aluminum, and copper to non-metallic materials such as wood and acrylic, we provide solutions that fit diverse needs. We specialize in cutting thick materials with impressive capabilities: up to 50 mm for stainless steel and Inconel, and 12.7 mm for copper and brass.

Custom Solutions and Fast Turnaround

Understanding that each project is unique, we work closely with clients to offer tailored solutions that align with their specific requirements. Our large bed size and fast turnaround times ensure efficiency, reducing the need for multiple setups, which is crucial for large-scale projects.

Why Choose Samarth Sharp Edge for Laser Cutting?

High Precision: Our advanced laser technology delivers exceptional accuracy, ensuring intricate designs with smooth finishes.

Wide Material Compatibility: We work with a range of materials, making us a versatile choice for various industries.

Efficiency: Our spacious cutting bed allows us to handle large projects, providing faster production times without sacrificing quality.

Custom Solutions: We collaborate with clients to provide custom laser cutting services that meet their exact specifications.

For your next project requiring laser cutting services, Samarth Sharp Edge is your ideal partner. Contact us today to discuss how we can bring your ideas to life with precision and efficiency.

Visit us at Samarth Sharp Edge Laser Cutting Services.

#Laser cutting fabrication Pune#Precision laser cutting Pune#Laser cutting near me Pune#Sheet metal laser cutting Pune#Laser cutting in Pune#Laser cutting in metal machine

0 notes

Text

Laser Wood Cutting Machine:Precision engraving and cutting

Welcome to a new era of woodworking precision and creativity! Our advanced laser wood cutting machine is the ultimate tool for woodworking enthusiasts and professionals alike. With its unrivaled precision, speed, and versatility, this cutting-edge machine is set to revolutionize the way you work with wood. Say goodbye to traditional cutting methods and unlock a world of possibilities with our extraordinary laser wood cutting machine.

Wood Engraving Machine CO2 laser cutting machine, the standard worktable size is 1300*2500, equip with 150w/180w/260w/300w laser tube, satified the engraving and cutting requirements of large plate such as S.S sheet, C.S sheet, wood sheet, acrylic sheet and so on.

Section 1: Unmatched Precision for Exquisite Craftsmanship When it comes to woodworking, precision is everything. Our wood laser cutting machine employs cutting-edge laser technology to deliver unparalleled precision in every cut. Whether you’re working on intricate designs or detailed engravings, our machine ensures immaculate results with crisp edges and clean lines. Experience the joy of crafting masterpieces with precision that surpasses traditional woodworking methods.

Section 2: Lightning-Fast Speed for Increased Efficiency Time is a valuable asset, and our wood laser cutting machine recognizes that. With its impressive cutting speed, it slashes through wood with lightning-fast precision, significantly reducing production time and boosting your overall efficiency. From small-scale projects to large-scale production runs, our machine helps you meet deadlines without compromising on quality. Witness a remarkable increase in productivity and take your woodworking business to new heights.

Section 3: Limitless Versatility for Endless Possibilities Woodworking is an art that thrives on creativity and versatility. Our laser wood cutting machine offers an array of possibilities, allowing you to explore various wood types, thicknesses, and designs. From intricate furniture pieces and decorative wooden panels to personalized wooden gifts and signage, our machine empowers you to bring your wildest ideas to life. Let your imagination run wild and create woodworking masterpieces like never before.

Section 4: Expanding Opportunities in Woodworking Industry The woodworking industry is evolving, and our laser wood cutting machine positions you at the forefront of this revolution. Embracing this advanced technology opens doors to new opportunities and expands your market reach. From customized woodworking products to personalized interior designs, the demand for laser-cut woodwork is skyrocketing. By investing in our machine, you position yourself for success in a growing market and gain a competitive edge over traditional woodworking methods.

Section 5: Seamless User Experience for Effortless Operation We understand the importance of a seamless user experience, especially in the woodworking industry. Our laser wood cutting machine is designed with user-friendliness in mind, offering an intuitive interface and easy-to-use controls. Even if you’re new to laser cutting technology, our comprehensive user manuals and dedicated customer support ensure a hassle-free operation. Experience the joy of effortless woodworking and focus on what matters most—bringing your creative visions to life.

Section 6: Sustainability and Cost-Efficiency for a Greener Future Our laser wood cutting machine not only revolutionizes woodworking but also promotes sustainability and cost-efficiency. By utilizing laser technology, it minimizes material waste, reduces energy consumption, and eliminates the need for additional tools. Additionally, the precision of our machine minimizes errors and enhances yield, ultimately saving you valuable resources and maximizing your profitability. Join the movement towards sustainable woodworking practices and embrace a greener future.

Conclusion: Unleash the power of precision in your woodworking journey with our state-of-the-art laser wood cutting machine. From unmatched precision and lightning-fast speed to limitless versatility and expanding market opportunities, this machine is the gateway to a new realm of woodworking excellence. Experience seamless operation, embrace sustainability, and unlock your full creative potential with our laser wood cutting machine. Contact us today and embark on a woodworking journey like no other.

0 notes

Text

On Tuesday I went back to the claywork studio and worked towards incorporating clay into my assemble project.

On Monday, Mary had suggested making clay models of the players with numbers on their back, so I tried to follow this advice.

My biggest inspiration for the design of these were little Jenga bricks I used to draw designs on when I was younger.

Although I struggled initially to figure out the best way of making minifigure models of players, I received advice from Elaine on how to do it easily and efficiently by using this device here:

It allowed me to press the clay into a long cylindrical shape which i used for the bodies of my players.

The photo above showed sample ideas from Elaine. As you can see the bodies look a lot less creepy, more smooth and they were also much quicker to make.

I made 17 little clay hurlers and stamped numbers on their backs using Stamps Elaine had. I also made two coaches with little angry expressions.

This idea of making players out of clay ties in perfectly with my assemble idea, as I was already planning on laser cutting a dressing room.

Once i had the players made, I decided to finally cut the design I made a few weeks ago.

I found and finished a training programme to learn to use the laser cutting machine a few weeks ago, so I went down to the Maker Station and started cutting out my design

Although I thought it went swimmingly at first, when I took the sheet of wood out of the machine i realised I set the laser 3mm too far from the wood piece when doing the cutting, so the shapes I was trying to cut didnt go all the way through.

The design turned out quite clean though, Ill try again later this week.

Although I messed up the laser cutting, I can see where I made a mistake and will avoid making this mistake in the future. Im also just delighted the rest of the laser cutting process went okay and I didnt blow up the machine👍.

Im delighted to see the concept design I made at the start of the semester is finally starting to come together.

All thats left to do is redo the laser cutting, assemble the dressing room, paint the clay figures and then put it all together!

Im really excited to see it all together and Ive learned so much in the past few weeks.

1 note

·

View note

Text

Laser Engraving Golf Clubs: The Ultimate Guide to Personalizing Your Gear

Golf is a sport that blends skill, strategy, and style. While mastering your swing is essential, having equipment that reflects your personality can elevate your game to a whole new level. Enter laser engraving golf clubs, the perfect way to add a personal touch to your irons, putters, or drivers. Whether you want to engrave your name, a motivational quote, or a custom design, laser engraving offers precision and permanence. And if you’re looking for the best tool to get started, the LH4 Laser Engraving Machine is a top choice for golfers and engraving enthusiasts alike.

What is Laser Engraving for Golf Clubs?

Laser engraving is a cutting-edge technology that uses a focused laser beam to etch designs, text, or patterns onto the surface of an object. When applied to golf clubs, this technique allows for highly detailed and durable customization. Unlike traditional engraving methods, laser engraving doesn’t involve physical contact, which means no risk of damaging your clubs. It’s fast, precise, and works on a variety of materials, including metal, wood, and composite.

Why Laser Engraving is a Game-Changer for Golfers:

Personalization: Add your name, initials, or even a custom logo to make your clubs uniquely yours.

Durability: Laser-engraved designs are resistant to wear and tear, ensuring your customization lasts for years.

Precision: The laser can create intricate details, making it ideal for small text or complex designs.

Versatility: Whether you’re engraving a driver, putter, or iron, laser engraving works on almost any club surface.

Why Customize Your Golf Clubs?

Customizing your golf clubs isn’t just about aesthetics—it’s about creating a connection with your equipment. Here’s why laser engraving your clubs is a hole-in-one idea:

1. Stand Out on the Course

Let’s be honest: golf is as much about style as it is about skill. Custom-engraved clubs are a great way to showcase your personality and make a statement on the green.

2. Boost Your Confidence

There’s something empowering about using equipment that’s tailored just for you. When you step up to the tee with a club that bears your name, you’ll feel like a pro.

3. Perfect for Gifts

Looking for a unique gift for the golfer in your life? A set of laser-engraved golf clubs is a thoughtful and memorable present.

4. Increase Resale Value

Customized clubs can be more appealing to buyers, especially if the engraving is tasteful and well-executed.

How to Choose the Right Laser Engraving Machine for Golf Clubs

Not all laser engraving machines are created equal. If you’re serious about customizing your golf clubs, you’ll need a reliable and high-quality machine. Here’s what to look for:

1. Power and Speed

Golf clubs are often made of tough materials like stainless steel or titanium, so you’ll need a machine with enough power to engrave them effectively. The LH4 Laser Engraving Machine is a great choice, offering high power and fast engraving speeds.

2. Precision

Look for a machine with a high-resolution laser to ensure clean, sharp lines and details.

3. Ease of Use

If you’re new to laser engraving, choose a machine with user-friendly software and intuitive controls.

4. Portability

If you plan to take your engraving business on the go, a compact and portable machine like the LH4 is ideal.

Fun Facts About Golf Club Customization

Did you know?

Tiger Woods’ putter is famously engraved with his nickname, “Tiger,” adding a personal touch to his winning streak.

Some golfers engrave their clubs with motivational phrases like “Stay Calm” or “Trust Your Swing” to keep their focus during games.

Laser engraving can also be used to mark the sweet spot on your club, helping you improve your accuracy.

The Future of Laser Engraving Golf Clubs

As technology continues to evolve, so does the world of golf club customization. Advanced laser engraving machines like the LH4 are making it easier than ever to create professional-quality designs at home or in your workshop. In the future, we can expect even more innovations, such as AI-powered engraving systems that automatically adjust settings based on the material and design.

Moreover, as golfers increasingly seek ways to express their individuality, laser engraving will become a standard feature in the industry. Imagine walking into a pro shop and designing your custom clubs on the spot—it’s not as far-fetched as it sounds!

Conclusion: Elevate Your Game with Laser Engraving Golf Clubs

Golf is more than just a sport—it’s a lifestyle. And what better way to embrace that lifestyle than by customizing your equipment to reflect your personality and passion? With laser engraving golf clubs, you can create a set of clubs that’s as unique as your swing. Whether you’re a seasoned pro or a weekend warrior, laser engraving adds a touch of class and individuality to your game.

Ready to get started? Check out the LH4 Laser Engraving Machine, the ultimate tool for creating stunning, personalized golf clubs. It’s time to tee up in style and make your mark on the course!

So, what are you waiting for? Grab your clubs, fire up the laser, and let your creativity shine. Your perfect game is just an engraving away!

0 notes