#LLDPE

Explore tagged Tumblr posts

Text

Dee Five Shrink Insulations Pvt. Ltd.: Trusted Experts in Kapton Tape and LLDPE Stretch Wrap Film

High-quality materials are crucial for smooth operations and product integrity in today's quickly changing industries. By offering creative solutions that raise the bar for quality, longevity, and effectiveness, Dee Five Shrink Insulations Pvt. Ltd. has proudly established itself as the Best Kapton Tape Manufacturer and the Best LLDPE Stretch Wrap Film Supplier.

Your Reliable Source for Kapton Tape: Dee Five Shrink Insulations Pvt. Ltd.

Kapton tape is renowned for its exceptional qualities, including its ability to withstand hostile environments, electrical insulation, and strong resistance to extreme temperatures. High-quality Kapton tape is essential for sectors like electronics and aerospace, and Dee Five Shrink Insulations Pvt. Ltd. consistently and precisely delivers it.

What Sets Our Kapton Tape Apart?

1. Thermal Stability: Our Kapton tape maintains its effectiveness and stability under harsh thermal circumstances thanks to its remarkable tolerance to hot and low temperatures. 2. Electrical Insulation: Our tape is perfect for electrical and electronic applications that call for dependable, safe materials because of its superior insulating qualities. 3. Sturdy Durability: Dee Five's Kapton tape is made to withstand and shield against wear, chemicals, and solvents. 4. Custom Sizing and Specifications: Understanding our clients' different needs, we offer customizable tape alternatives to fit the precise requirements of each application.

We use cutting-edge production methods and stringent quality controls as the Best Kapton Tape Manufacturer to create tape that not only satisfies but beyond industry requirements.

Dee Five Shrink Insulations Pvt. Ltd. provides the Kapton tape that guarantees optimal performance and dependability, regardless of your application's complexity, including electrical insulation, high-temperature soldering, or intricate mechanical procedures.

High-Performance Packaging Solutions with LLDPE Stretch Wrap Film

A crucial component of retail, warehousing, and logistics is packaging. Offering high-quality stretch wrap films that offer safe, economical, and effective packaging solutions, Dee Five Shrink Insulations Pvt. Ltd. takes satisfaction in being named the Best LLDPE Stretch Wrap Film Supplier.

Why Choose Dee Five’s LLDPE Stretch Wrap Film?

Outstanding Stretchability: Our LLDPE stretch wrap film is designed to stretch effortlessly while maintaining its strength, which aids in keeping goods safe during storage and transit.

Durability and Tear Resistance: Our film's excellent resistance to tearing and punctures allows it to endure hard handling while shielding objects from harm.

Cost-Effective Packaging: Our stretch film provides an economical packaging option without sacrificing quality by optimizing yield and reducing waste.

Sustainable Options Available: We provide eco-friendly LLDPE stretch wrap film alternatives to assist businesses in lowering their carbon footprint because we are dedicated to environmental sustainability.

As the Best LLDPE Stretch Wrap Film Supplier, Dee Five Shrink Insulations Pvt. Ltd. understands the needs of modern businesses. You may benefit from Dee Five Shrink Insulations Pvt. Ltd.'s years of experience, cutting-edge manufacturing tools, and commitment to customer satisfaction by working with them. We are a trustworthy brand for Kapton tape and LLDPE stretch wrap film because of the following:

The Dee Five Shrink Insulations Pvt. Ltd. Advantage

By working with Dee Five Shrink Insulations Pvt. Ltd., you can take advantage of their years of experience, state-of-the-art manufacturing equipment, and dedication to client satisfaction. Here's what makes us a reputable brand for LLDPE stretch wrap film and Kapton tape:

• Dedication to Quality: To guarantee that you obtain materials that precisely match your specifications, each roll of tape and film is subjected to rigorous quality control. • Tailored Solutions: We give solutions that are specially made for your applications because we recognize that every client has different demands. • On-time Delivery: We can deliver orders on time because of our effective production methods, which guarantee the continuity of your supply chain. • Committed Support Staff: Our team of professionals is on hand at all times to help you with order fulfillment, customization, and product selection.

Why Businesses Choose Dee Five Shrink Insulations Pvt. Ltd.?

Trust, dependability, and an unwavering dedication to quality are the cornerstones of our reputation as the Best Kapton Tape Manufacturer and the Best LLDPE Stretch Wrap Film Supplier. We put your requirements first by offering resources that complement and advance your operating objectives. Dee Five Shrink Insulations Pvt. Ltd. has the know-how and goods to satisfy your needs, whether you're looking for durable packaging or trustworthy insulation materials.

Contact Us for Superior Kapton Tape and LLDPE Stretch Wrap Film

Dee Five Shrink Insulations Pvt. Ltd. is the best partner for companies trying to get premium Kapton tape or LLDPE stretch wrap film. Get in touch with us right now to find out more about our offerings and how we can precisely and superbly meet your industry's needs.

0 notes

Text

Shri Maninath Plastics Pvt Ltd is the leading manufacturer and supplier of Rotomoulding Powder in Maharashtra. Our commitment to excellence is reflected in the trust we’ve earned from our clients over many years, and we take pride in delivering impeccable services. Whether it’s simple or intricately designed forms, our dedication to precision and quality is evident in every product. At SMPPL, we’re more than just manufacturers; we’re partners in delivering exceptional solutions through the art of rotational moulding.

0 notes

Text

0 notes

Text

LLDPE granules in Delhi

LLDPE (Linear Low-Density Polyethylene) granules are versatile, durable, and highly flexible polymer resins ideal for film extrusion, molding, and packaging applications. Known for excellent tensile strength and puncture resistance, LLDPE granules offer superior performance in producing strong, lightweight plastic products while maintaining clarity and adaptability across various industrial uses.

0 notes

Text

Linear Low Density Polyethylene Prices Trend | Pricing | Database | Index | News | Chart

Linear Low-Density Polyethylene (LLDPE) Prices is a versatile and widely used material in the plastic industry. Its popularity can be attributed to its unique properties such as flexibility, toughness, and chemical resistance. LLDPE is commonly used in various applications, including packaging films, agricultural films, and rotomolding.

When it comes to LLDPE prices, there are several factors that influence its fluctuations in the market. One of the key factors is the cost of raw materials. LLDPE is derived from ethylene, which is obtained from crude oil or natural gas. Any changes in the prices of these raw materials can directly impact the cost of LLDPE production, thus affecting its overall price.

Another factor that affects LLDPE prices is the supply and demand dynamics in the market. If the demand for LLDPE is high and the supply is limited, the prices are likely to increase. Conversely, if the demand is low and the supply is abundant, the prices may decrease. Factors such as economic conditions, industry trends, and consumer preferences can all influence the demand for LLDPE.

Get Real Time Prices of Linear Low-Density Polyethylene (LLDPE): https://www.chemanalyst.com/Pricing-data/lldpe-6

Furthermore, LLDPE prices can also be influenced by geopolitical factors and trade policies. Tariffs, import/export regulations, and political tensions between countries can disrupt the global supply chain and impact prices. For instance, if there are restrictions on LLDPE imports, it can lead to a shortage in the market, driving up prices.

Market competition is another important factor in determining LLDPE prices. The presence of multiple suppliers can create a competitive environment, leading to price fluctuations. Suppliers may adjust their prices to attract customers and gain a competitive edge in the market.

In addition to these factors, the cost of production, transportation, and energy can also contribute to LLDPE price variations. Energy costs, such as electricity and gas, play a crucial role in the production process. Any changes in energy prices can impact the overall cost of LLDPE production, thus influencing its prices.

It is important for businesses and consumers to stay updated on LLDPE price trends to make informed decisions. Monitoring industry news, market reports, and working closely with suppliers can help in understanding the current market scenario and anticipating any potential price changes.

In conclusion, LLDPE prices are influenced by various factors such as raw material costs, supply and demand dynamics, geopolitical factors, market competition, and production costs. Understanding these factors and staying informed about market trends is crucial for businesses and consumers alike. By keeping a close eye on these factors, stakeholders can navigate the market and make informed decisions regarding LLDPE purchases.

Get Real Time Prices of Linear Low-Density Polyethylene (LLDPE): https://www.chemanalyst.com/Pricing-data/lldpe-6

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#LLDPE#LLDPE Price#LLDPE Price Monitor#Linear Low Density Polyethylene#Linear Low Density Polyethylene Price

0 notes

Text

Diving into Linear Low Density Polyethylene (LLDPE): Understanding Its Properties and Manufacturing (2023-2034)

In the world of plastics, LLDPE stands tall for its remarkable toughness, enabling the creation of thinner yet robust films. Not to be confused with its cousin LDPE, or Low Density Polyethylene, LLDPE boasts a unique structure with numerous short branches. This structural advantage allows its chains to glide smoothly during stretching, preventing entanglement—a common issue with LDPE due to its long branching chains. The result? LLDPE offers superior tensile strength, along with heightened impact and puncture resistance compared to LDPE. So, when it comes to durability and performance, LLDPE takes the lead, making it a top choice for various applications where strength and resilience are paramount.

Introduction

LLDPE or Low-Density Polyethylene is a lightweight, flexible plastic. LLDPE stands out among polyethylene variants due to its semi-crystalline nature, featuring linear molecular chains with short branches. Unlike LDPE and HDPE, these linear molecules exhibit slower tangling. LLDPE is synthesized using one of three alpha-olefin co-monomers, namely octene, hexene, or butene, each influencing its properties differently. Octene contributes long branch chains, offering superior performance. Hexene strikes a balance between octene and butene, providing a cost-effective way. Butene, the most commonly utilized co-monomer for commodity plastics due to its affordability, features the shortest branch chains. Moreover, LLDPE properties can be further tailored by blending it with other co-monomers, with combinations of butene and hexene being particularly prevalent in practice.

LLDPE’s properties include:

Puncture-resistant: making it highly resilient against sharp objects or external forces that could cause punctures or tears.

Good flexibility: its ability to adapt to different shapes or movements without losing its structural integrity.

Resistant to oxidation: LLDPE has the capability to withstand oxidation, which is a chemical reaction involving oxygen that can degrade or weaken materials over time. Resistance to oxidation ensures the material's durability and longevity.

Excellent barrier properties: LLDPE has the ability to prevent the passage of gases, liquids, or other substances through it. Materials with excellent barrier properties are effective in containing or isolating substances, protecting them from external factors.

High impact strength: LLDPE can withstand sudden or intense impacts without breaking or shattering, indicating its resilience to mechanical forces or collisions.

Good environmental stress cracking resistance: LLDPE is resistant to cracking or fracturing when subjected to stress from environmental factors such as temperature variations, chemical exposure, or mechanical loading. Low Water Absorption: With its low water absorption rate, LDPE remains unaffected by moisture, making it suitable for applications where exposure to water or humidity is common.

Low Cost: Perhaps one of its most appealing attributes is its affordability. LDPE offers a cost-effective solution without compromising on performance, making it a preferred choice for a wide range of applications across industries.

LLDPE exhibits distinctive melt flow characteristics, making it suitable for processes like blow molding, film extrusion, and injection molding. Film extrusion, particularly, dominates LLDPE processing. It's worth noting that LLDPE's semi-crystalline nature contributes to its high shrinkage rate, whereby the material occupies more volume in its molten state than when solid. Overall, LLDPE's versatile production methods and unique properties make it a go-to material for various applications in industries ranging from packaging to automotive and beyond.

Manufacturing Process

The manufacturing process consists of four primary phases:

(1) Polymerization

(2) Devolatilization

(3) Distillation

(4) Finishing

Polymerization:

Ethylene and 1-octene initially undergo treatment in fixed-bed adsorption systems to remove water, oxygen, and other polar impurities that could potentially hinder the catalyst. After purification, the monomers are mixed with a polymerization solvent comprising a blend of C8-C9 paraffins. This mixture then enters the first of two consecutive continuous stirred tank reactors (CSTR), where polymerization occurs.

The polymerization process happens adiabatically in the liquid phase, with hydrogen acting as a molecular weight regulator. These steps ensure impurity removal and create ideal conditions for controlled and efficient polymer production in the liquid-phase reactors.

Devolatilization & Pelletizing:

The polymer solution exiting the second reactor enters an adiabatic flash vessel, where pressure reduction causes volatile elements, mainly unreacted ethylene, to vaporize. The concentrated polymer solution then undergoes devolatilization to remove residual monomers. The separated volatile components are cooled and sent for distillation, while the polymer proceeds to finishing. The devolatilized polymer is fed into an extruder to incorporate additives and pelletize the polymer, resulting in the final product being transferred to blending and storage.

Raw Materials Recovery:

The volatile effluents from devolatilization, containing unreacted monomers and solvents, undergo purification through distillation columns to recover these components and eliminate impurities, refining the final product.

The manufacturing process of LLDPE (linear low-density polyethylene) by Dow Chemicals involves a combination of polymerization techniques. Here is the brief overview of the LLDPE production process:

Monomer Preparation:

The first step in LLDPE production is getting the building blocks ready, called monomers. Unlike LDPE which uses only ethylene, LLDPE is made by combining ethylene with another molecule called a comonomer. Common comonomers include 1-butene, 1-hexene, or 1-octene. Adding this comonomer creates branches in the LLDPE structure, which give it special properties different from LDPE.

Polymerization:

Dow uses various polymerization techniques to produce LLDPE.

Solution Polymerization

Monomers and a catalyst system dissolved in a solvent, it's all stirred together in a reactor under carefully controlled temperature, pressure, and mixing. This controlled environment triggers a chemical reaction called polymerization, with catalysts, which often are Ziegler-Natta or metallocene catalysts.

Gas-Phase Polymerization

For gas-phase production, the reaction happens in a special reactor with a constantly moving bed of particles. These particles may hold the catalyst system (like a supported catalyst or a metallocene one). The mixture of monomers and catalyst is fed into the reactor, along with precise controls on temperature, pressure, and how long the ingredients stay inside (residence time). The heat from the reaction itself helps keep the process going.

Product Finishing:

After the LLDPE is polymerized completely, it's time to collect it from the reactor. This raw material, called resin, might go through some finishing touches to get the exact properties needed. This involves removing any trapped gas (degassing), shaping it into pellets (pelletization), and additive incorporation.

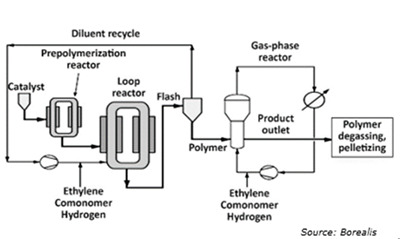

Borstar, a pioneering multi-modal patented technology employed by Borealis for PE and PP production, represents a significant advancement in process technology. Borealis is actively commercializing the latest iteration of Borstar, including Borstar PE 3G, and continues to innovate within the Borstar framework. These advancements enable flexible polymer design, ranging from bi-modal to multi-modal PE/PP resins, and contribute to the development of a diverse range of new plastics.

The Borstar polyethylene (PE) method enables the production of a wide range of bimodal and unimodal LLDPE, MDPE, and HDPE products. This method combines a loop reactor and a gas phase reactor to form Borstar PE. PE with densities ranging from 918 to 970 kg/m3 and melt flows from 0.1 to 100 can be manufactured using this process. While single-site catalysts will be utilized for PE processing in the future, Ziegler-Natta catalysts are currently employed.

A mixture of propane diluent and catalyst is injected into a small pre-polymerization reactor, where pre-polymerization takes place. The resulting slurry is then fed into the loop reactor, operating under supercritical conditions at temperatures of 75–100 °C and pressures of 55–65 bar, to produce higher density and lower molecular weight components of bimodal polymers. Afterward, diluent and unreacted materials are removed from the polymer in a flash tank.

The loop reactor and gas phase reactor operate independently, allowing for easy regulation of reactor conditions and flexibility in processing various products. In the fluidized bed gas phase reactor, polymerization continues, producing a homogeneous polymer on the same catalyst particles. Operating at temperatures between 75 and 100 °C and pressures of 20 bar, this reactor introduces fresh hydrogen, ethylene, and comonomer to form high molecular weight components and broaden the molecular weight distribution (MWD), enhancing the polymer's strength.

The production rate ratio between the reactors can be adjusted to achieve desired product qualities. Finally, hydrocarbon residues are removed, and the polymer powder is extruded to obtain the final product.

NOVA Chemicals use the SCLAIRTECH method on the other hand. The SCLAIRTECH technology method produces a wide spectrum of linear polyethylene (PE) products, including linear low, medium, and high-density grades with narrow to broad molecular weight distribution. The most effective PE swing method enables cost-effective production throughout the whole range of PE grades from a single train.

The process utilizes a reactor fed with a solution containing ethylene and a co-monomer, such as butene-1, octene-1, or even a combination of both. The short residence time (under 2 minutes) allows for a highly flexible system in the solution phase. This translates to quick transitions between producing different grades of the final product, making it adaptable to diverse market needs.

High conversion rates within the reactor maximize output and prevent uncontrolled reactions. A hydrocarbon solvent keeps the reaction mixture in solution while facilitating heat removal. This solvent is then efficiently recycled back into the reactor. Finally, the molten polymer exits the system and is shaped into pellets using a conventional extruder and pelletizer.

The Spherilene method, developed by LyondellBasell, employs a gas-phase reactor in its proprietary technology. The LyondellBasell Spherilene process encompasses a fluidized-bed, gas-phase approach for manufacturing polyethylene (PE) products across all densities, spanning from linear low density (LLDPE) to medium density (MDPE) and high density (HDPE). This technology's versatility, demonstrated by its extensive range of grades, empowers licensees to effectively navigate the continually evolving polyethylene markets well into the future.

The core of the Spherilene technology lies in its simple design with just one reactor and a recirculation system. This setup is surprisingly versatile, capable of producing a wide range of polyethylene (PE) products with melt indices between 0.01 and 100 g/10 min and densities spanning 0.918 to 0.965 g/cm3. This technology, using Avant Z Ziegler and Avant C Chromium catalysts, can create various single-modal (monomodal) products like LLDPE film, HDPE for injection molding, and MDPE for rotomolding and textiles.

Spherilene stands out for its operational stability, leading to high reliability when paired with the consistent performance of Avant catalysts. A unique reactor outlet mechanism efficiently extracts product with minimal gas contamination. Unlike competing technologies, Spherilene allows for start-up with Avant Z catalysts without needing a pre-existing polymer seed bed.

Applications of Linear Low Density Polyethylene (LLDPE)

Packaging

When storing multi-pack beverages for future use, the shrink wraps typically used to encase plastic bottles is often composed of LLDPE. Similarly, the durable plastic can rings utilized to hold together multi-pack canned beverages are also crafted from LLDPE material due to its robustness. It can be used in the form of stretch wraps.

Tubing

Beyond packaging, LLDPE finds use in tubes. LLDPE pipes for safe and reliable delivery of water to livestock.

Consumer Goods

Rigid LLDPE's affordability and ease of shaping make it a go-to material for everyday items like lids, buckets, bottles, and containers.

Market Outlook:

The global Linear Low Density Polyethylene (LLDPE) market stood at roughly 38 million tonnes in 2023 and is likely to grow at a CAGR of 4.80% by the year 2034. The rising need for low-density polyethylene (LLDPE) in packaging, fueled by its exceptional toughness and diverse applications in film production, especially in both food and non-food packaging sectors, is a significant factor driving market growth. The shift from rigid containers to flexible packaging further boosts this growth trend. Moreover, the growing demand for high-performance linear low-density polyethylene (LLDPE) with remarkable attributes such as superior strength and resistance to organic solvents significantly contributes to various applications. Importantly, the increasing utilization of LLDPE in injection molding, a crucial aspect of manufacturing technology, presents promising opportunities for market expansion.

Linear Low Density Polyethylene (LLDPE) Major Manufacturers

Significant companies in the Global Linear Low Density Polyethylene (LLDPE) market are ExxonMobil, ExxonMobil and SABIC JV, Nova Chemicals, Shell, DowDuPont, Chevron Phillips Chemical, Formosa Plastics, Lyondell Basell (Louisiana Integrated Polyethylene JV LLC), Sasol, Borealis GmbH, and Others.

Linear Low Density Polyethylene (LLDPE) Market Challenges

Linear Low Density Polyethylene (LLDPE) market has a few restraints as well that hinder its market growth trajectory. The emergence of cost-effective alternatives like linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), acrylonitrile butadiene styrene (ABS), and high-density polyethylene (HDPE) is hindering market growth. Additionally, the environmental impact of waste plastic bags, which pollute land and water, poses a significant threat to wildlife. As a result, many countries have implemented plastic bans, prohibiting the use of single-use plastic in various sectors, which could potentially impact the growth of the Low-Density Polyethylene Market.

Conclusion:

The rising need for Linear Low Density Polyethylene (LLDPE) to produce thin films for flexible packaging across diverse industries is projected to fuel the growth of the global LLDPE market. The unique properties of LLDPE like puncture resistance, resistance to corrosion, low water absorption, and tough nature makes it useful for packaging applications. Rising technological developments and product development is likely to aid the LLDPE market expansion. With increasing emphasis on cleanliness and long-lasting products, LLDPE is poised to become even more popular. Its reliability makes it a go-to material for a wide range of consumer products like buckets and bottles.

1 note

·

View note

Text

LLDPE Rotomoulding Opal T3804

Unleash Your Rotational Molding Potential with LLDPE Rotomoulding Opal T3804 from Viztaar!

Embark on your next rotational molding project with confidence using LLDPE Rotomoulding Opal T3804, available now at Viztaar Polymer Marketplace! This exceptional grade of linear low-density polyethylene (LLDPE) offers a winning combination of properties ideal for creating robust and versatile molded products.

Key Advantages of LLDPE Rotomoulding Opal T3804:

Superior Strength and Impact Resistance: Experience a significant improvement over traditional LDPE with enhanced tensile strength and impact resistance, allowing you to create highly durable molded parts.

Excellent Processability: The optimized formulation of Opal T3804 ensures smooth and efficient rotational molding, minimizing waste and maximizing production output.

Chemical Resistance: Benefit from reliable performance in applications where exposure to mild chemicals is a concern.

Food-Grade Compliance: This grade can potentially be suitable for food contact applications, subject to further verification and regulatory compliance (refer to Viztaar for details).

Unlock a World of Rotational Molding Possibilities:

LLDPE Rotomoulding Opal T3804's versatility makes it perfect for a wide range of rotational molding applications, including:

Large Tanks and Containers: Manufacture robust and reliable tanks and containers for various industrial and agricultural uses.

Material Handling Pallets and Bins: Create strong and durable pallets and bins for efficient material handling solutions.

Furniture and Outdoor Products: Design and build long-lasting furniture and outdoor products that can withstand harsh weather conditions.

Toys and Recreational Equipment: Develop safe and sturdy toys and recreational equipment with excellent impact resistance.

Experience the Viztaar Advantage:

Viztaar Polymer Marketplace provides a seamless platform to access high-quality LLDPE Rotomoulding Opal T3804. Their commitment to customer satisfaction ensures reliable supply and expert support for your rotational molding needs.

Get Started with LLDPE Rotomoulding Opal T3804 Today!

Elevate your rotational molding projects and explore the vast potential of LLDPE Rotomoulding Opal T3804. Visit Viztaar Polymer Marketplace and transform your vision into reality!

Hashtags: #LLDPE #RotationalMolding #OpalT3804 #Viztaar #DurablePlastics

for more and other polymer products please visit Viztaar Polymer Marketplace

0 notes

Text

Supplier of Monolayer Blown Film Machine in Telangana

Adroit Extrusion is a Manufacturer, Exporter, and Supplier of Monolayer Blown Film Machine in Telangana. Our ISO 9001:2015 certified manufacturing unit demonstrates our dedication to offering personalized solutions globally, assuring high-quality in all aspects of our operations. We are well-known for our commitment to quality and specialize in co-extruded blown film lines with diverse configurations such as Monolayer, ABA, two-layer, three-layer, five-layer, and seven-layer setups. We design and produce the high quality Monolayer Blown Films with constant perfection and assurance. Our Monolayer Blown films have best configured as well as professionalized outcomes according to our client’s need and satisfaction. Features: Compact size results in a minimum operational space requirement. Increased production with lower power usage Cold Start Preventer with Alarm for Machine Failure Lower product costs while maintaining great film quality Universal gusseting system. Bubble calibrating basket and iris ring, along with an embossing roller attachment from Rimzim. Specially constructed spiral die for uniform flow and improved thickness control. Rotary die head, vacuum loaders, and hopper air driers Technical Specification: Model Name: Monolayer Blown Film Plant Material Used: LDPE, LLDPE, HDPE, CACO3, Virgin Raw Materials etc. Output Range: 30-200 kg/hr Screw Diameter: 35/45/55/65/75 (Customized) Layflat Film Width: 500-3000 mm Thickness Range: 20 micron to 150 micron Applications: General purpose film, HDPE pick-up bag, Shade-net film, Lamination grade film, HD twist wrap film, Stretch and cling film, Shrink film, Anti-rust film and Paper-like film Adroit Extrusion is the trusted Supplier of Monolayer Blown Film Machine in Telangana, serving locations such as Hyderabad, Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, Wanaparthy, Jangaon. For further details and inquiries, please feel free to contact us. Read the full article

#ABA#AdroitExtrusion#andseven-layersetups#Bhongir#CACO3#ColdStartPreventerwithAlarm#Exporter#five-layer#HDPE#highqualityMonolayerBlownFilms#hopperairdriers#Hyderabad#Jagtial#Jangaon#Kamareddy#Karimnagar#Khammam#LDPE#LLDPE#Lowerproductcosts#Mahbubnagar#Mancherial#Manufacturer#minimumoperationalspacerequirement#Miryalaguda#monolayer#MonolayerBlownFilmMachineinTelangana#Nalgonda#Nizamabad#Ramagundam

0 notes

Link

1. InnoPlus' LLDPE LL7410A plastic granules

LL7410A is a linear low-density polyethylene with butene comonomers, without slip and anti-block additives. Plastic film made from InnoPlus LL7410A has high tensile strength, elongation, good toughness and outstanding puncture strength. LL7410A can also be used to blend with HDPE to increase ductility. InnoPlus LL7410A is recommended for the production of bags, general purpose films and bags, liners, heavy-duty packaging, food packaging and agricultural films.

The density is 0.918 g/cm3, and the recommended setting temperature is between 160 - 180 °C for extruders and 170 - 190 °C for die zone.

This product complies with US FDA regulations for polyethylene used in food contact products.

1 note

·

View note

Text

Enhance Outdoor Fun with Multiplay Systems from Nes Playground Equipment

Playgrounds are more than just a fun escape for kids; they are spaces where creativity, collaboration, and physical development converge. Among the various playground setups, Multiplay Systems have become a popular choice for schools, parks, and residential complexes. These versatile installations offer a combination of activities, ensuring kids have endless hours of entertainment. When it comes to durable and innovative multiplay systems, nesplaygroundequipment stands out as a reliable manufacturer and supplier.

What Makes Multiplay Systems Special?

A Multiplay System is designed to engage children of different age groups by offering a variety of activities in a single setup. These systems often include slides, swings, climbing walls, tunnels, and bridges, creating a mini adventure park for kids. They promote physical exercise, improve coordination, and encourage social interaction, making them an essential addition to any outdoor space.

Why Choose LLDPE Multiplay Systems?

One of the most sought-after variants is the LLDPE Multiplay System. LLDPE (Linear Low-Density Polyethylene) is a high-quality plastic material known for its durability, safety, and eco-friendliness. Here are some reasons why LLDPE is the preferred choice:

Durability: Resistant to harsh weather conditions, LLDPE ensures that the multiplay system remains intact and functional for years.

Safety: The smooth surface and non-toxic nature of LLDPE make it safe for children to play on.

Low Maintenance: LLDPE multiplay systems require minimal upkeep, saving time and resources.

Aesthetic Appeal: Available in vibrant colors and creative designs, these systems add charm to any outdoor space.

Nes Playground Equipment: Your Trusted Partner

nesplaygroundequipment is a leading name in the playground equipment industry, offering a wide range of multiplay systems tailored to different needs. With a commitment to quality and innovation, they design systems that are not only engaging but also meet global safety standards.

Whether you’re looking for an interactive play area for a school or a residential society, nesplaygroundequipment provides solutions that cater to all requirements. Their LLDPE Multiplay Systems are especially popular for their combination of safety, durability, and vibrant designs.

Final Thoughts

Investing in a Multiplay System is more than just creating a fun area; it’s about contributing to the overall development of children. With high-quality options like LLDPE Multiplay Systems from nesplaygroundequipment, you can ensure a safe, exciting, and long-lasting play environment.

Transform your playground today with the best multiplay solutions and watch as children enjoy the ultimate outdoor play experience!

#Multiplay System#LLDPE Multiplay System#FRP Multiplay System#Spiral Slide Multiplay System#Wave Slide Multiplay System#Outdoor gym Equipment#School Playground Equipment#Playground Equipment

0 notes

Text

Sincro, we understand the importance of durable and efficient storage solutions in various industries. Our LLDPE rotomouldings powder is at the forefront of manufacturing water storage tanks, chemical storage tanks, and waste management solutions. This versatile material provides the ideal balance of strength, flexibility, and cost-effectiveness, making it the preferred choice for creating high-quality storage products.

0 notes

Text

Enhance Play Areas with High-Quality Multiplay Systems

Playgrounds are an essential part of childhood, offering a space where kids can play, learn, and grow. Among the most exciting and versatile additions to modern play areas are multiplay systems. These systems are designed to provide a comprehensive play experience, combining various activities like climbing, sliding, and swinging in a single setup.

Why Choose a Multiplay System for Your Playground?

A multiplay system is not just a play structure; it's an all-in-one entertainment hub for children. It encourages physical activity, improves motor skills, and fosters social interaction among kids. These systems are highly customizable, making them suitable for schools, parks, and residential complexes.

Advantages of FRP Multiplay Systems

The FRP Multiplay System is a popular choice for its durability and safety features. Made from Fiber Reinforced Plastic, these systems are:

Weather-Resistant: Ideal for outdoor use in any climate.

Safe for Kids: Free from sharp edges and toxic materials.

Low Maintenance: Easy to clean and resistant to wear and tear.

Parents and facility managers often prefer FRP systems for their long-lasting performance and aesthetic appeal.

Add Thrill with a Spiral Slide Multiplay System

If you're looking to add a touch of excitement, a Spiral Slide Multiplay System is the perfect solution. These systems feature thrilling spiral slides that kids love. The unique design not only provides endless fun but also ensures safety with sturdy handrails and non-slip surfaces.

Why Partner with a Trusted Multiplay System Manufacturer?

Choosing the NAGPAL ENGINEERING AND SPORTS multiplay system manufacturer is crucial to ensure the quality and safety of your playground equipment. A reliable multiplay system manufacturer offers:

Custom designs tailored to your space and needs.

High-quality materials for enhanced durability.

Expert installation and after-sales support.

Transform your playground into a hub of joy and activity with our premium multiplay systems. Whether you need an FRP Multiplay System or a Spiral Slide Multiplay System, we have the perfect solution for your space.

Contact us today to explore our range of innovative playground equipment!

#Multiplay System#LLDPE Multiplay System#FRP Multiplay System#Spiral Slide Multiplay System#Wave Slide Multiplay System#Outdoor gym Equipment#School Playground Equipment#Playground Equipment

0 notes

Text

Best Practices for Utilizing Lite-R LLDPE Flat Bags in Your Business

In today’s fast-paced commercial environment, companies are continually seeking efficient, cost-effective, and environmentally friendly packaging solutions. Lite-R LLDPE (Linear Low-Density Polyethylene) flat bags have emerged as a popular choice, providing businesses with versatile options for storage, shipping, and retail display. This blog will explore best practices for utilizing Lite-R LLDPE flat bags effectively within your business, showcasing their benefits and practical applications.

Understanding Lite-R LLDPE Flat Bags

Before diving into best practices, it’s essential to grasp what Lite-R LLDPE flat bags are. Made from linear low-density polyethylene, these bags offer excellent strength and flexibility. They are lightweight, resistant to tears and punctures, and are available in various sizes. The clarity and versatility of these bags make them suitable for a wide range of applications, from food packaging to industrial supplies.

Key Benefits of Lite-R LLDPE Flat Bags

Durability: These bags are designed to withstand wear and tear, making them ideal for transporting and storing products.

Cost-Effectiveness: Lite-R LLDPE bags are often more affordable than alternative packaging solutions, helping businesses reduce overhead costs.

Environmental Considerations: Many manufacturers offer recyclable options, aligning with the growing demand for sustainable packaging solutions.

Customizability: Available in various sizes and thicknesses, Lite-R flat bags can be tailored to meet specific business needs.

Best Practices for Using Lite-R LLDPE Flat Bags

Choose the Right Size and Thickness

Selecting the correct size and thickness of Lite-R LLDPE flat bags is crucial for efficient packaging. Assess the dimensions and weight of your products to determine the appropriate bag size. A bag that is too small may rip or compromise the integrity of the item, while an oversized bag can increase shipping costs and create waste.

Additionally, consider the thickness of the bag. Thicker bags offer more durability and strength, making them suitable for heavier or bulkier items. In contrast, thinner bags may be appropriate for lightweight products. Always evaluate your specific product requirements to make an informed decision.

Implement Proper Sealing Techniques

Sealing your Lite-R LLDPE flat bags correctly is essential for maintaining product integrity and security. There are several sealing methods available:

Heat Sealing: This technique provides a strong, permanent seal. Ensure your heat sealer settings are correctly calibrated for the thickness of your bags to avoid damaging them.

Tape Sealing: For lighter items, using packing tape can be a quick and efficient sealing method. However, ensure the tape adheres well to the bag to prevent openings.

Twist Ties or Ties: For products that need easy access, consider using twist ties or ties. They offer a secure closure while allowing for easy opening when needed.

Regardless of the method you choose, ensure that your sealing process is consistent to maintain quality across all packages.

Optimize Storage Practices

Efficiently storing your Lite-R LLDPE flat bags can help streamline your packing and shipping operations. Here are some practical tips:

Organize by Size and Use: Store bags in a designated area, categorized by size and intended use. This organization allows employees to quickly locate the correct bags, saving time and increasing efficiency.

Use Shelving Units: Consider investing in shelving units or storage containers to maximize vertical space. This practice not only keeps your workspace tidy but also makes inventory management easier.

Implement a First-In, First-Out (FIFO) System: Adopt a FIFO system to ensure that older stock is used before newer shipments. This practice reduces waste and keeps your supplies fresh, especially if using recyclable bags.

Train Employees on Proper Handling

Training your employees on the proper handling, packing, and sealing techniques for Lite-R LLDPE flat bags can greatly enhance efficiency and reduce waste. Provide clear guidelines and training sessions that cover:

The importance of using the correct bag size and thickness

Sealing methods and testing for security

Proper packing techniques to avoid damaging products

Encourage employees to ask questions and provide feedback about the packaging process, as this can lead to adjustments that enhance overall operations.

Utilize Customization Options

Many manufacturers offer customization options for Lite-R LLDPE flat bags, such as printing logos or branding on the bags. Customization can enhance product presentation and establish brand identity. Here are some points to consider:

Design Elements: Incorporate your logo, colors, and branding elements that resonate with your target audience. A well-designed bag can serve as a marketing tool in itself.

Information and Instructions: Consider adding essential information, such as product details or handling instructions, on the bags. This practice ensures consumers understand your products better and can enhance user experience.

Evaluate Environmental Impact

In today’s eco-conscious world, it’s essential to evaluate the environmental impact of your packaging. Opt for Lite-R LLDPE flat bags made from recycled materials or those that can be easily recycled themselves. Promote your commitment to sustainability in your marketing efforts, as consumers increasingly prefer businesses with eco-friendly practices.

Conduct Quality Control Checks

Regular quality control checks on your Lite-R LLDPE flat bags are essential to maintain product quality. Inspect the bags for any signs of wear, tears, or defects before use. If you notice issues, alert your supplier or manufacturer to ensure reliable inventory.

Lite-R LLDPE flat bags can be a game-changer for businesses looking to streamline their packaging processes while maintaining product integrity and reducing costs. By adhering to best practices like choosing the right size, implementing effective sealing techniques, optimizing storage, training employees, utilizing customization, evaluating environmental impact, and conducting quality control checks, you can maximize efficiency and enhance the customer experience.

0 notes

Text

Linear Low Density Polyethylene (LLDPE) Prices Trend | Pricing | News | Database | Chart

Linear Low-Density Polyethylene (LLDPE) a significant role in the global plastics industry, primarily due to its versatile applications ranging from packaging films and containers to various molded products. The price of LLDPE is influenced by a wide range of factors, including raw material costs, supply-demand dynamics, energy prices, geopolitical events, and macroeconomic conditions. Understanding the pricing trends of LLDPE is essential for manufacturers, buyers, and traders, as these shifts can impact decision-making processes across industries reliant on this critical polymer.

The primary driver of LLDPE prices is the cost of feedstock, typically derived from crude oil or natural gas. Fluctuations in the prices of these feedstocks can directly influence LLDPE production costs. When oil or natural gas prices increase, it often leads to higher costs of ethylene, a key precursor to LLDPE. This, in turn, raises LLDPE prices, as manufacturers need to pass these additional costs down the supply chain. Conversely, falling feedstock prices may lower LLDPE costs, depending on other market conditions. Therefore, monitoring crude oil and natural gas price trends is vital for predicting LLDPE price movements.

Get Real Time Prices for Linear Low Density Polyethylene (LLDPE): https://www.chemanalyst.com/Pricing-data/lldpe-6

Demand patterns significantly shape the LLDPE market. As one of the most used polyethylene variants due to its exceptional flexibility, toughness, and compatibility with various processing techniques, demand for LLDPE can fluctuate based on consumption trends in key industries. Packaging, a dominant sector, drives much of this demand, especially for food packaging, agricultural films, and industrial wraps. Increased demand for flexible packaging due to evolving consumer lifestyles and a focus on sustainable packaging options often boosts LLDPE demand. Similarly, growth in the construction, automotive, and electronics sectors also stimulates demand for LLDPE applications. When demand is robust, prices are likely to rise due to increased competition for available supply. Conversely, a downturn in economic conditions or a drop in demand from key end-user markets can exert downward pressure on LLDPE prices.

The global supply situation is another critical determinant of LLDPE prices. Periods of oversupply can lead to significant price reductions, while supply constraints, often due to planned or unplanned plant shutdowns, disruptions from natural disasters, trade policies, or sanctions, can lead to price spikes. The location of LLDPE production facilities and supply chain logistics also plays a pivotal role. Key production hubs such as North America, China, and the Middle East influence the global market, and any changes in their production or trade practices can have global ramifications.

Trade dynamics, particularly tariffs and international trade agreements, also shape LLDPE prices. The global plastics industry often faces changes in import-export regulations, which can impact pricing by altering trade flows. For instance, any tariff barriers between major LLDPE-producing regions and key import markets can influence price trends. Similarly, favorable trade agreements may boost LLDPE exports and increase demand, thereby supporting higher prices. Additionally, global economic conditions, currency exchange rates, and inflationary pressures play a role in determining how LLDPE prices behave across different regions.

Technological advancements in LLDPE production have also impacted pricing. Modern catalysts and production techniques enable higher efficiencies and lower costs, allowing producers to compete more effectively in the market. As production technology advances, some cost reductions can be achieved, which may translate into more competitive LLDPE prices. However, the capital investment required for technological upgrades may also temporarily affect costs and market behavior.

Sustainability and environmental regulations are becoming increasingly important in shaping LLDPE market dynamics. There is growing pressure on producers and users of polyethylene products, including LLDPE, to adopt more environmentally friendly practices. This shift can affect pricing, as producers may invest in more sustainable production processes, recyclable LLDPE grades, or biodegradable alternatives. Regulatory mandates can lead to changes in product formulation, altering production costs and impacting market prices. Furthermore, shifts in consumer preferences toward recyclable and environmentally friendly packaging are creating new demand patterns, affecting price stability in the market.

Seasonal factors also play a role in determining LLDPE prices. For instance, demand for agricultural films tends to surge during planting seasons, driving temporary price increases. In contrast, reduced activity during certain periods may soften demand and lead to price corrections. Cyclical market trends and industry-specific seasonality can lead to fluctuations that market participants must monitor to manage risks effectively.

Geopolitical factors and trade tensions among leading economies can have immediate and long-term effects on LLDPE pricing. Political instability, sanctions, or tensions in major LLDPE-producing regions can disrupt supply, leading to price volatility. Additionally, energy policies in key regions impact production costs, as energy-intensive petrochemical processes depend heavily on power and resource availability.

In summary, LLDPE prices are determined by a complex interplay of factors that include feedstock prices, supply-demand dynamics, production and technological advancements, trade regulations, and geopolitical conditions. Keeping an eye on these influences is critical for understanding and anticipating market trends. For businesses involved in the LLDPE value chain, proactively adapting to these market forces can provide a competitive edge, ensuring sustainable growth in an increasingly competitive global market. While short-term volatility is common, strategic planning and market insight can help mitigate price risks and seize new opportunities in the LLDPE space.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#LLDPE Price#LLDPE Price Monitor#Linear Low Density Polyethylene#Linear Low Density Polyethylene Price

0 notes

Text

LLDPE foam material for multi layer plastic water tank — LLDPE Foam

Shree Umiya Group LLDPE (Linear Low-Density Polyethylene) are leading manufacturer of LLDPE Raw Material including Plastic Raw Material and Water Tank Raw Material. Plastic is everywhere and it is an easy material to work with. It has many applications and is available in countless variations.

Plastic Raw Material Manufacturer

Plastics today are mostly made from natural materials such as cellulose, coal, natural gas, salt and crude oil. Plastic pollution can alter habitats and natural processes, reducing ecosystems’ ability to adapt to climate change, directly affecting millions of people’s livelihoods, food production capabilities and social well-being.

Plastics manufacturing also involves a variety of manufacturing processes, including injection molding, blow molding, extrusion, rotational molding, and thermoforming.

Our Products

LLDPE FOAM MATERIAL

STONE EFFECT MARBLE COLOUR

LLDPE AGGLOMERATES

LLDPE POWDER

ROTOMOLDING POWDER

LLDPE PLASTIC RAW MATERIAL

For More Details Click here : https://www.lldpefoam.com/

0 notes

Text

LLDPE Market is Expected to Grow at CAGR of 4.79% during the forecast period until 2032

The Linear Low-Density Polyethylene (LLDPE) market has experienced substantial growth and transformation in recent years, propelled by a multitude of factors shaping the global landscape. LLDPE, a type of polyethylene characterized by its linear molecular structure and low density, finds extensive applications across various industries, including packaging, agriculture, construction, automotive, and healthcare. Its unique combination of properties, such as high tensile strength, flexibility, toughness, chemical resistance, and puncture resistance, has made LLDPE a preferred choice for a wide range of applications.

One of the primary drivers of the LLDPE market is the increasing demand for flexible packaging solutions. LLDPE films, sheets, and bags are widely used in the packaging industry for applications such as food packaging, industrial packaging, consumer goods packaging, and agricultural packaging. With the rapid expansion of the retail sector, e-commerce platforms, and convenience stores, the demand for lightweight, durable, and cost-effective packaging materials has surged, thereby driving the growth of the LLDPE market.

Read Full Report: https://www.chemanalyst.com/industry-report/lldpe-market-497

Moreover, the agriculture sector represents another significant market for LLDPE, particularly in the manufacturing of agricultural films, greenhouse films, mulch films, and silage bags. LLDPE films offer excellent properties for crop protection, soil moisture retention, weed suppression, and temperature regulation, thereby enhancing crop yields and agricultural productivity. As farmers increasingly adopt modern farming practices, precision agriculture techniques, and greenhouse cultivation methods, the demand for LLDPE films is expected to grow substantially.

Furthermore, the construction industry presents lucrative opportunities for the LLDPE market, particularly in the manufacturing of geomembranes, waterproofing membranes, construction films, and insulation materials. LLDPE's excellent mechanical properties, durability, and resistance to environmental factors make it an ideal choice for construction applications such as roofing, flooring, insulation, and vapor barriers. With urbanization, infrastructure development, and construction activities on the rise, the demand for LLDPE-based construction materials is projected to increase significantly.

Additionally, the automotive sector represents a growing market for LLDPE, driven by the increasing demand for lightweight, fuel-efficient vehicles and automotive components. LLDPE-based materials are used in automotive applications such as interior trim, door panels, seat covers, dashboard components, and underbody coatings. As automotive manufacturers focus on reducing vehicle weight, improving fuel efficiency, and enhancing passenger safety and comfort, the demand for LLDPE-based automotive materials is expected to rise.

Despite the promising outlook, the LLDPE market faces challenges and constraints, including volatile raw material prices, environmental concerns, and regulatory compliance issues. However, industry stakeholders are actively addressing these challenges through initiatives focused on product innovation, sustainability, and circular economy principles. Moreover, strategic partnerships, mergers, and acquisitions are driving consolidation and market expansion in the LLDPE industry.

In conclusion, the LLDPE market is poised for continued growth and innovation, driven by its versatile applications, inherent properties, and compatibility with evolving market trends. By leveraging its strengths in packaging, agriculture, construction, automotive, and other sectors, the LLDPE market can navigate towards a more sustainable and prosperous future, ensuring its relevance and competitiveness in the global marketplace.

About Us:

ChemAnalyst is an online platform offering a comprehensive range of market analysis and pricing services, as well as up-to-date news and deals from the chemical and petrochemical industry, globally.

Being awarded ‘The Product Innovator of the Year, 2023’, ChemAnalyst is an indispensable tool for navigating the risks of today's ever-changing chemicals market.

The platform helps companies strategize and formulate their chemical procurement by tracking real time prices of more than 400 chemicals in more than 25 countries.

ChemAnalyst also provides market analysis for more than 1000 chemical commodities covering multifaceted parameters including Production, Demand, Supply, Plant Operating Rate, Imports, Exports, and much more. The users will not only be able to analyse historical data but will also get to inspect detailed forecasts for upto 10 years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

Contact US:

420 Lexington Avenue, Suite 300

New York, NY

United States, 10170

Emai-id: [email protected]

Mobile no: +1- 3322586602

#LLDPE#LLDPEmarket#LLDPEnews#LLDPEdemand#LLDPEmarketsize#LLDPEmarketshare#LLDPEmarketforecast#LLDPEmarketanalysis

1 note

·

View note