#Kaolin Mining Industry

Explore tagged Tumblr posts

Note

hello excellent dirt person. do you know anything about kaolin? i am curious if so, what the Dirt Person view on it would be

So the long and short of it is I have no view on it because kaolin is just, a thing that exists. I have no view on steel or grapes. They exist. There's a lot of commercial grade uses for rock and soil that lay people wouldn't anticipate but are entirely common within certain industries, from gravel and sand mining, to the mining of rocks and soils bearing certain clay minerals or rich in certain elements. Kaolin in particular has uses valuable to ceramics and the paper industry but I know very little about either of those. However, I do know things about the clay mineral that is actually what's extracted from kaolinite and what an excellent opportunity to talk about phyllosilicates, aka, clays and micas!

I am, more technically speaking, an environmental soil chemist, and though I lean on the last one of those titles the least, here we're going to have to take a quick detour onto chemical bond angles and crystals. This is a very brief oversimplification but deeply relevant.

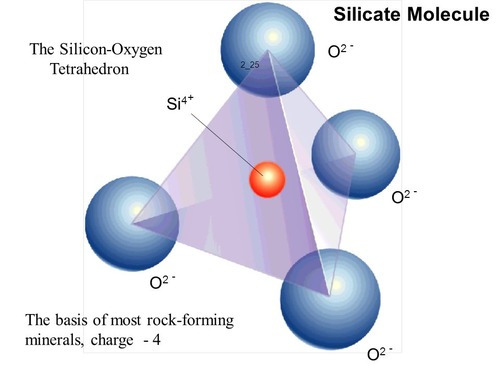

Atoms bind together in order to be more stable, but the bonds themselves are charged, and therefore repel each other. Imagine an atom as an orb with things sticking out of it:

If you have two bonds, as far apart on a circle means 360/2, so the bond angle will be 180, and they'll be on opposite ends (examples: CO2)

If you have three, 360/3 means 120, and so you get something that looks like a triangle.

If you have four, then things get fun, because the previous two have been two dimensional shapes, and what you actually get instead is a three dimensional tetrahedron with an average bond angle of ~109. And when you get into silicates, tetrahedrons are your basic building block

If you have six, then your average bond angle is 90 degrees; imagine four in a square plane and two at the 'poles'. Remember these for later!

Silicates dominate our world. If carbon forms everything living, then silicon forms everything non-living. Over 90 percent of the earth's crust is formed by silicate minerals, which are as astounding diverse and varied as big brother carbon's molecules. This diversity comes in spite of the fact that silicon is near-exclusively bound in the form of the silica tetrahedron seen above.

Where we move from bond angles to crystals is the fact that each oxygen in a silica tetrahedron has two charges, meaning oxygen can be bound to two different silicon atoms, which creates a crystal lattice structure of repeating units of silica tetrahedra. Depending on how silca tetrahedra are linked together, you get the following structures:

(Fun fact! Quartz and Zeolites are some of the most chemically and mechanically stable minerals on earth, and the Tectosilicate arrangement is the exact same crystalline pattern that makes up diamonds. Anyways!)

Focusing down on phyllosilicates, the structures that form are vast molecule thin sheets of repeated chained circles of silica, which is just one of the many ways math that may seem abstract emerges in the natural world, as what forms as a result is a tesselation. Now although silicates are dominated by silica, they are not exclusively silica tetrahedra for the simple fact that the real world conditions in which these form are messy, but secondly, the tetrahedral shape means that in a sheet crystal, silica has leftover oxygens that it could share with other ions. And so what you get in nature is that phyllosilicates are not just sheets of silica tetrahedra, but are two to three layers of repeating tetrahedra/octahedral units bound to a silica backbone.

(src paper; good resource for those who want to know more)

Now these phyllosilicates, literally "sheet-silicates", are very strong and chemically resistant molecule thin layers. But the thing about being so strongly attached to itself means that the actual attraction between layers is governed by an entirely different form of chemical bond (IMFs, which we won't get into), and ranges from no real binding to tightly bound to weakly bound.

And finally, it's time to talk about kaolinite!

Kaolinite is the clay mineral named for kaolin, the rocks/sediment that bears a lot of it. Kaolinite, pictured above, has very uniform physical properties, is very chemically stable, is quite cheap, and has abundant material use.

But, time for a shock and a swerve, I spent all this time talking about clay minerals to talk about smectite instead! You fool!

Smectitic clays differ from kaolinite substantially in ways we won't get into, but the short answer of it is that bonds form between sheet layers, but weak bonds. Strong bonds will basically not really come apart and aren't an issue. No bonds aren't an issue. Weak bonds are an issue.

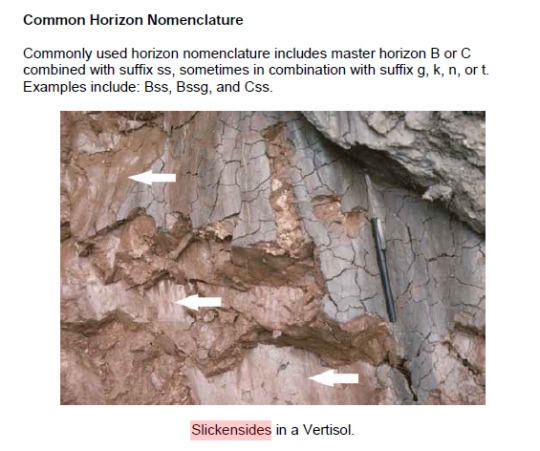

What weak bonds between layers leads to is a shrinking and swelling of clay layers over time, as water enters clay layers in the fall through spring, then leaves in the summer, causing the entire soil to shrink and swell with moisture, like thermal expansion joints on bridges but much more pronounced. This also leads to a lot of interesting soil properties, so much so there's an entire soil order named for soils with smectitic clays, the Vertisols.

What's shown here with the slickensides are literal smooth surfaces that form as large units of soil shrink-swell and rub against each other. Very strange stuff!

On the human scale, soils with vertic characteristics cause a lot of headaches in the places I grew up, meaning a lot of people in North to Central Texas spend time watering their lawns in deep summer heat to avoid foundations cracking. I've seen new homeowners in Texas who didn't know about it have their entire fence come down because of soil cracks, especially wood fences that catch the wind.

And that's how clay will ruin your foundation.

(PS: Clay mineralogy is foundational to soil chemistry but we'll get into that at a later date. To simplify: clay mineralogy is variable by geology and essentially serves as the most chemically active site in soils, but you kind of have to get real in the weeds on it and I do not have time to get into ion substitution and why every mineral's chemical formula looks like a fucking math equation just so I can talk about cation exchange capacity right now.)

17 notes

·

View notes

Text

“The war in Ukraine is also a battle for raw materials. The country has large deposits of iron, titanium and lithium, some of which are now controlled by Russia.” That’s what the federally owned German foreign trade agency Germany Trade and Invest (GTAI) reported on its website on January 16 under the title “Ukraine’s raw materials wealth at risk.”

There are trillions at stake. According to the GTAI, “raw material deposits worth $12.4 trillion” remain beyond the control of the Ukrainian army, “including 41 coal mines, 27 gas deposits, 9 oil fields and 6 iron ore deposits.” Ukraine has not only coal, gas, oil and wheat but also rare earths and metals—especially lithium, which has been called the “white gold” of the transition to new energy and transportation technologies. The country accounts for around one-third of Europe’s explored lithium deposits.

Only the ignorant could believe that this is irrelevant to NATO’s war aims. It would be the first major war in over 100 years that is not about mineral resources, markets and geostrategic interests. The World Socialist Web Site has pointed out in previous articles that deposits of critical raw materials in Russia and China, which are essential to the transition to electric mobility and renewable energy, are an important factor in the war calculus of NATO states.

Yet they go unmentioned in the media’s round-the-clock war propaganda. The media wish the public to believe that NATO is waging this war to defend “freedom” and “democracy”—and that after bombing Afghanistan, Iraq, Libya and Syria back into the Middle Ages under similar pretexts.

Relevant trade journals, industry magazines and think tanks, on the other hand, rave about Ukraine’s mineral wealth and discuss how best to capture it. It was to this end that German Economics Minister Robert Habeck (Green Party) even traveled to Ukraine at the beginning of April with a high-ranking business delegation.

According to the industry magazine Mining World, Ukraine has a total of around 20,000 raw material deposits, of which only 7,800 have been explored. Numerous other articles and strategy papers openly state that this is what the war is about.

On February 24, 2022, the day of the Russian invasion of Ukraine, the largest German business magazine, Capital, published an article stating that “Europe’s supply of raw materials” was “threatened” by the Russian occupation of eastern Ukraine. Ukraine was not only “the leading grain exporter” but also the largest EU supplier of iron ore pellets and “a linchpin for Europe’s energy security.” Among investors, the magazine said, there is “concern that the war will cut off exports of key raw materials.”

The GTAI article cited earlier reports that European steel mills were sourcing nearly one-fifth of their iron ore pellets from Ukraine in 2021. GTAI goes on to write that Ukraine is among the top ten producers of iron ore, manganese, zirconium, and graphite, and is “among the world leaders in titanium and kaolin.” In addition to “untapped oil and gas fields,” Ukraine’s lithium and titanium deposits, in particular, hold “enormous potential” for the European economy. In 2020, production volumes amounted to 1,681,000 tons of kaolin, 537,000 tons of titanium, 699,000 tons of manganese and 49,274,000 tons of iron ore.

Lithium for electromobility and energy storage

The price of lithium has increased more than eightfold in the last decade and is the subject of intense speculation. The metal is of strategic importance to the major imperialist powers because it is used in lithium-ion batteries installed in electric vehicles and off-grid renewable energy sources, and is also needed for lightweight aluminum alloys in the aerospace industry.

The largest lithium deposit in Europe is located in the Donetsk Oblast in the middle of the embattled Donbas region, only kilometers from the front lines. An article in the Tagesspiegel, published two months after the Russian invasion, points to untapped lithium reserves of 500,000 tons in Shevchenko near Potrovsk and at least two other Ukrainian deposits.

Western companies and Ukrainian oligarchs were already fighting bitterly for control of this “white gold” before the war. As the Tagesspiegel reports, “Ukrainian businessmen” (who stood close to the Ukrainian government of the time under the oligarch Petro Poroshenko) with connections to Western mining companies obtained mining licenses, without a tender process, for the lithium deposit in Shevchenko as early as 2018.

The company in question, Petro Consulting—which was renamed “European Lithium Ukraine” shortly before the war began—is expected to be bought out by the Australian-European mining company European Lithium once its access to Ukraine’s lithium reserves is secured.

In 2018, when the Ukrainian Geological Survey refused to issue a “special permit” for Ukraine’s second largest lithium deposit at Dobra, likewise bypassing the tender process, Petro Consulting went so far as to sue the agency. After the Ukrainian Procurator General’s Office eventually launched an investigation into the allegedly illegal special permits, Petro-Consulting had its Shevchenko mining license revoked by the courts in April 2020 until further notice.

However, a spokesman for European Lithium told Der Tagesspiegel that the company bears “no risk in connection with the Ukrainian deposits.” He expressed confidence that the projects would be “made production-ready” after the end of the war.

Titanium for the Western arms industry

In a September 2022 article titled “Ukraine’s Titanium Can Armor the West,” the transatlantic think tank Center for European Policy Analysis (CEPA) wrote: “Support for Ukraine has been driven by strategic concerns and moral-political values. But long-term Western help should also be based on solid material interests.”

“Ukraine’s substantial titanium deposits” are “a key resource critical to the West” because the metal is “integral to many defense systems,” such as aircraft components and missiles. Currently, the raw material for Airbus, Boeing and Co. is extracted “in an expensive and time-consuming six-step process” from titanium ore, which until then had been sourced to a considerable extent from Russia. This “dependence” on “strategic competitors and adversaries” is unacceptable from the West’s point of view and can be ended with the help of Ukrainian resources:

For example, Dnipro-based Velta, the largest private exporter of raw titanium in Europe, has developed a new production system that bypasses the intensive process of producing titanium sponge and could supply the US and European defense and aerospace industries with finished metal. Given there are only five countries in the world actively producing titanium sponge —China, Russia, Kazakhstan, Japan and Ukraine — Velta’s technology could be a game changer for the supply chain by cutting reliance on Russia and China.

CEPA is funded by US and European defense contractors and lists as members of its “scientific advisory board” Donald Trump’s National Security Advisor General H. R. McMaster, former German Defense Minister Annegret Kramp-Karrenbauer, former Swedish Prime Minister Carl Bildt and publicists Anne Applebaum, Francis Fukuyama, and Timothy Garton Ash among others.

The CEPA article continues, “Reorienting titanium contracts to Ukraine would stimulate the country’s economy, even during wartime, not to mention during postwar reconstruction, and simultaneously strike another blow at Russia’s war machine.” The goal, it states, should be “cementing Ukraine’s integration into Europe.”

A January 28, 2023 report in Newsweek reports, “there is a nascent effort underway in the U.S. and allied nations to identify, develop, and utilize Ukraine’s vast resources of a key metal crucial for the development of the West’s most advanced military technology which will form the backbone of future deterrence against Russia and China.” The report adds, “If Ukraine wins, the U.S. and its allies will be in sole position to cultivate a new conduit of titanium.”

“Strategic raw materials partnership” between EU and Ukraine

The US and EU efforts to plunder Ukraine’s lithium and titanium deposits are part of the broader goal of tying Ukraine to the West as a strategic raw materials supplier. In particular, the EU is seeking to free itself from dependence on China—currently its most important raw materials supplier—against which the imperialist powers, especially the United States, are preparing to wage war.

On July 13, 2021, Ukrainian Prime Minister Denys Shmyhal and Maroš Šefčovič, Vice President of the European Commission, signed a “Strategic Partnership on Raw Materials and Batteries” in Kiev to “integrate critical raw materials and battery value chains.” Ukraine’s inclusion in the European Raw Materials Alliance (ERMA) and the European Battery Alliance (EBA) serves to “bolster Europe’s resilience and open strategic autonomy in key technologies,” the EU Commission said.

Referring to the list of critical raw materials in the EU’s associated “action plan,” Šefčovič told the press, “21 of these critical raw materials are in Ukraine, which is also extracting 117 out of 120 globally used minerals.” He added: “We’re talking about lithium, cobalt, manganese, rare earths—all of them are in Ukraine.”

Following the signing, EU Internal Market Commissioner Thierry Breton, who is also responsible for the defense and space industries of EU countries, praised the “high potential of the critical raw material reserves in Ukraine” that could help in “addressing some of the strategic dependencies [of the EU].”

Speaking at Raw Materials Week in Brussels in November 2022, Prime Minister Shmyhal stressed that Ukraine is “among the top ten producers of titanium, iron ore, kaolin, manganese, zirconium and graphite” and renewed his pledge to make the country an “integral part of industrial supply chains in the EU.”

The EU’s “strategic dependencies” are by no means limited to Russia or China and certainly not to Ukraine. A global race for strategic sources of raw materials has long since begun, in the course of which the US and the leading EU powers are attempting to divide among themselves the mineral resources and other resources of the “weaker” states. Although they are jointly waging war against Russia in Ukraine, this inevitably exacerbates conflicts between themselves as well.

The escalation of the war in Ukraine shows that the ruling elites are willing to go to extremes to enforce their profit interests. Only the working class can put an end to permanent war and the prospect of devastating nuclear war by bringing the resources of the entire planet under its democratic control on the basis of a socialist program and holding war profiteers to account.

3 notes

·

View notes

Text

Understanding the Role of Minerals in Advanced Manufacturing

China clay, also known as kaolin, is a versatile mineral with numerous industrial applications. Derived from naturally occurring clay deposits, it is prized for its fine particle size, chemical inertness, and unique physical properties. Many industries, such as ceramics, paper, rubber, and paint, rely heavily on high-quality china clay powder. Among the key players in this industry, India stands out as a leading producer and supplier of this essential raw material. The nation boasts a wealth of resources and a well-established network of China Clay Powder Manufacturers in India, catering to both domestic and international markets.

China clay powder is extensively used in the ceramics industry as a primary ingredient in the production of porcelain, sanitary ware, and decorative pottery. Its ability to enhance the whiteness, strength, and smoothness of finished products makes it indispensable for ceramic manufacturers. Beyond ceramics, the paper industry is another major consumer of china clay powder. It serves as a filler and coating agent, improving the texture, printability, and opacity of paper products. Similarly, the rubber industry values china clay for its reinforcing properties, which contribute to the durability and flexibility of rubber goods.

In the paint and coatings sector, china clay powder is widely utilized as an extender and pigment. It not only reduces production costs but also improves the consistency, gloss, and opacity of paints. Additionally, it finds applications in the cosmetics industry, where its fine texture and absorbent qualities make it ideal for skincare and makeup products. The versatility of china clay powder has also seen its use in agriculture, pharmaceuticals, and even as a component in certain types of adhesives and sealants.

The quality of china clay powder depends on several factors, including its mineral composition, particle size, and processing techniques. Indian manufacturers have invested significantly in advanced technologies to ensure the production of high-purity china clay powder that meets global standards. Rigorous quality control measures, coupled with sustainable mining practices, have positioned India as a reliable source of this mineral. Moreover, the competitive pricing offered by Indian manufacturers has further cemented their reputation in the global market.

Environmental sustainability is a growing concern in the mining and processing of china clay. Leading manufacturers in India are adopting eco-friendly practices to minimize the environmental impact of their operations. From reforestation efforts to waste management systems, these initiatives are aimed at preserving the natural ecosystem while maintaining production efficiency. The adoption of green technologies not only enhances the environmental credentials of manufacturers but also appeals to environmentally conscious consumers worldwide.

Innovation is another driving force in the china clay powder industry. Research and development efforts are focused on improving the functionality and application scope of this mineral. For instance, surface-modified china clay powders are being developed to meet the specific requirements of advanced industries like electronics and nanotechnology. These innovations are opening up new avenues for growth and diversification, further solidifying India’s position as a hub for high-quality china clay powder.

The future of the china clay powder industry in India looks promising, with increasing demand from various sectors and a strong emphasis on sustainable development. As industries continue to evolve, the role of china clay as a critical raw material is expected to grow, creating opportunities for manufacturers and exporters alike. The emphasis on quality, sustainability, and innovation ensures that Indian manufacturers remain competitive in the global marketplace.

One of the prominent names contributing to this growth is the Sudarshan Group. Known for its commitment to quality and customer satisfaction, the Sudarshan Group has carved a niche for itself in the competitive landscape of china clay powder manufacturing. With a focus on technological advancements and sustainable practices, the company has been at the forefront of delivering exceptional products to its clients. The Sudarshan Group’s dedication to excellence and innovation makes it a trusted partner for businesses seeking premium china clay powder solutions. By continually evolving and adapting to market demands, the Sudarshan Group is not just meeting but exceeding industry standards, reinforcing its position as a leader in this field.

0 notes

Text

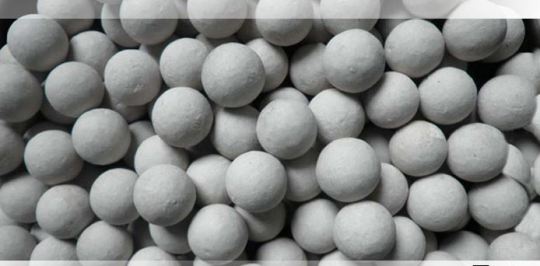

Ceramic Proppant Prices: Trend | Pricing | News | Price | Database

Ceramic Proppant are essential materials used in hydraulic fracturing, commonly known as fracking, to enhance the extraction of oil and gas from underground reservoirs. These proppants are made from high-strength ceramic materials that resist crushing under extreme pressure and are designed to keep fractures in the rock formation open, allowing oil or gas to flow freely. The ceramic proppant market has seen significant growth in recent years due to the increasing demand for oil and gas, particularly from shale plays. As a result, the prices of ceramic proppants have fluctuated in response to various factors, including raw material costs, technological advancements, and the supply and demand dynamics within the energy industry.

The price of ceramic proppants is influenced by several key factors, with raw materials being one of the primary determinants. Ceramic proppants are typically made from bauxite, kaolin, and other mineral-based materials. These raw materials have seen price fluctuations due to changes in global supply and demand, mining regulations, and geopolitical events. For instance, bauxite, the primary raw material for ceramic proppants, has been subject to price volatility due to changes in mining activity in countries like China, Australia, and Brazil. The cost of kaolin, another significant material, has also experienced fluctuations, driven by changes in demand from various industries, including ceramics and paper.

Get Real time Prices for Ceramic Proppant: https://www.chemanalyst.com/Pricing-data/ceramic-proppant-1576

In addition to raw material costs, the manufacturing process of ceramic proppants plays a crucial role in determining their price. Ceramic proppants are produced through a high-temperature sintering process, which involves heating the raw materials to a temperature where they melt and form small, spherical pellets. The energy-intensive nature of this process can impact the cost of production, particularly in regions where energy prices are high. Technological advancements in manufacturing processes have led to the development of more efficient methods for producing ceramic proppants, which could potentially reduce production costs and, in turn, impact the overall pricing of these materials.

The supply and demand dynamics of the oil and gas industry also significantly affect the price of ceramic proppants. When oil and gas prices are high, there is typically an increase in exploration and production activity, leading to a higher demand for proppants. Conversely, when oil and gas prices decline, exploration and production activities may slow down, leading to a decrease in demand for proppants. This cyclical nature of the oil and gas industry means that ceramic proppant prices are often highly sensitive to fluctuations in commodity prices. For example, during periods of high oil prices, the demand for hydraulic fracturing services increases, which in turn boosts the demand for ceramic proppants, driving up their prices. However, when oil prices drop, the demand for proppants may decrease, causing prices to soften.

Geopolitical factors can also influence ceramic proppant prices. Trade tensions, sanctions, and changes in government policies can impact the global supply chain for raw materials and finished proppants. For example, trade disputes between major ceramic proppant-producing countries like China and the United States can result in tariffs or restrictions on the import and export of these materials. Such disruptions in the supply chain can lead to shortages or price hikes for ceramic proppants in certain regions. Additionally, government regulations related to the oil and gas industry, such as stricter environmental standards or changes in hydraulic fracturing regulations, can affect the demand for ceramic proppants and, consequently, their prices.

The development of alternative proppant technologies is another factor that can influence ceramic proppant prices. While ceramic proppants are known for their high strength and durability, they are also more expensive than other types of proppants, such as sand. As a result, some oil and gas companies are exploring the use of alternative proppants that offer similar performance at a lower cost. If these alternative technologies gain traction in the market, they could put downward pressure on ceramic proppant prices. However, the high performance and reliability of ceramic proppants continue to make them a preferred choice for many operators, particularly in deep and ultra-deep wells where the risk of crushing is higher.

The competitive landscape of the ceramic proppant market also plays a role in determining pricing trends. Several large multinational companies dominate the market, and these companies typically have the resources and economies of scale to offer ceramic proppants at competitive prices. However, smaller, regional manufacturers may provide lower-cost alternatives, contributing to price fluctuations within the market. Additionally, the level of competition can affect the pricing strategies of manufacturers, as companies may adjust their prices based on market conditions and the actions of competitors.

In recent years, the global ceramic proppant market has seen increasing consolidation, with mergers and acquisitions taking place between major players in the industry. These strategic moves are aimed at expanding production capabilities, improving market reach, and achieving cost efficiencies. As a result, the consolidation trend may impact the competitive landscape and pricing dynamics in the future, as larger companies are able to leverage their resources to maintain competitive pricing.

In conclusion, the ceramic proppant market is influenced by a complex set of factors, including raw material costs, manufacturing processes, supply and demand dynamics in the oil and gas industry, geopolitical factors, and the competitive landscape. While ceramic proppants are a premium product in terms of strength and performance, their prices are subject to fluctuations based on the broader economic and energy market conditions. As the demand for hydraulic fracturing services continues to rise in response to growing global energy needs, the ceramic proppant market is expected to remain a key component of the oil and gas industry, with price trends being closely tied to the ebb and flow of global commodity prices and technological advancements.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Ceramic Proppant#Ceramic Proppant Prices#Ceramic Proppant Price Trend#Ceramic Proppant News#Ceramic Proppant Monitor#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research

0 notes

Text

White Clay Kaolin in Filtration Systems: Improving Water Purity

Water purification has always been a critical issue in the quest for sustainable living and industrial applications. One of the natural materials gaining traction in modern filtration systems is white clay kaolin. Sourced primarily through the efforts of a mineral mining company, this versatile material, also known as kaolin china clay, has demonstrated remarkable potential in enhancing water purity.

This article delves into how kaolin clay benefits filtration systems, the role of kaolin china clay manufacturers, and its impact on industries that rely on clean water.

What is White Clay Kaolin?

White clay kaolin is a naturally occurring mineral composed primarily of the hydrated aluminum silicate mineral kaolinite. Its fine particle size, chemical inertness, and high adsorption properties make it an essential component in various industries, including ceramics, paper, and, most importantly, water filtration.

Derived through sustainable mining processes by leading mineral mining companies, kaolin china clay is processed to meet the purity and performance standards required for water treatment applications. Its neutral pH and non-toxic nature further amplify its suitability for ensuring safe and clean water.

How White Clay Kaolin Enhances Filtration Systems

The integration of white clay kaolin in filtration systems is transforming water purification processes. Below are some key ways in which it improves water purity:

Adsorption of Impurities: One of the most significant kaolin clay benefits is its ability to adsorb impurities, such as heavy metals, organic compounds, and other pollutants. The fine particles create a large surface area, making it highly effective in trapping contaminants.

pH Balancing: Many filtration systems struggle with maintaining a neutral pH. Kaolin china clay, being chemically inert, ensures that the water’s pH remains balanced throughout the filtration process.

Improving Turbidity: Turbidity, or cloudiness of water, is often caused by suspended particles. White clay kaolin aids in flocculation, where smaller particles clump together and settle, resulting in clearer water.

Microbial Reduction: Kaolin’s natural antibacterial properties contribute to reducing microbial contamination in water. While not a standalone solution for pathogens, its integration with other filtration methods enhances overall microbial control.

Applications of Kaolin in Water Filtration Systems

The versatility of white clay kaolin extends across various water purification systems:

Domestic Water Filters: Home filtration units are increasingly using kaolin as a primary layer to remove impurities and improve water taste.

Industrial Wastewater Treatment: Industries dealing with heavy metals or chemical waste find kaolin clay benefits invaluable for treating effluents before discharge.

Municipal Water Treatment Plants: To meet stringent water quality regulations, municipal facilities rely on kaolin-enhanced systems to remove sediments and contaminants effectively.

The Role of Mineral Mining Companies

A significant contributor to the availability and quality of kaolin is the work of mineral mining companies. These companies focus on extracting kaolin deposits from regions rich in this mineral. Key players in this industry are dedicated to sustainable practices, ensuring minimal environmental disruption while meeting global demand.

The extracted kaolin undergoes rigorous processing, including washing, drying, and refining, to achieve the desired quality for industrial applications. This high-grade kaolin is then supplied to kaolin china clay manufacturers who tailor the material to suit specific uses, including water filtration.

Leading Kaolin China Clay Manufacturers

The role of kaolin china clay manufacturers cannot be overstated in the water filtration industry. These manufacturers refine and distribute kaolin products that meet the stringent requirements of filtration systems. They focus on enhancing the clay’s properties, such as particle size distribution and surface area, to maximize its filtration efficiency.

Collaboration between mineral mining companies and these manufacturers ensures that industries worldwide have access to reliable kaolin-based solutions. From large-scale municipal projects to compact household filters, their products are instrumental in delivering clean and safe water.

Kaolin Clay Benefits Beyond Filtration

While the focus of this article is on water filtration, it’s worth noting that kaolin clay benefits extend to other areas. These include:

Cosmetics and Skincare: Known for its gentle exfoliating and oil-absorbing properties, kaolin is a popular ingredient in beauty products.

Paper and Packaging: Kaolin enhances the brightness and printability of paper, making it a staple in the publishing industry.

Ceramics and Pottery: Its plasticity and strength contribute to the production of high-quality ceramic products.

Challenges and Future Directions

Despite its numerous advantages, integrating white clay kaolin into filtration systems comes with challenges. These include:

Processing Costs: High-quality kaolin requires extensive processing, which can increase costs.

Availability: Dependence on regions with kaolin deposits necessitates efficient logistics and distribution networks.

Looking forward, advancements in technology and increased collaboration between mineral mining companies and kaolin china clay manufacturers promise to overcome these hurdles. Innovations in nanotechnology and material science may further enhance kaolin’s adsorption and filtration capabilities.

Conclusion

White clay kaolin is proving to be a game-changer in water purification. Its natural properties, combined with the expertise of mineral mining companies and kaolin china clay manufacturers, position it as a cornerstone in modern filtration systems. The kaolin clay benefits not only improve water purity but also contribute to sustainable practices across industries.

As the demand for clean water continues to rise, the role of kaolin in filtration systems will undoubtedly expand, fostering a healthier and more sustainable future for all. Through innovation and responsible mining practices, this humble mineral will continue to play a pivotal role in solving global water challenges.

0 notes

Text

Why India is the Leading China Clay Exporter A Hub for High-Quality Kaolin

India has long been recognized as one of the world’s top suppliers of various minerals, and China clay, also known as kaolin, is no exception. As a China Clay Exporter in India, the country plays a vital role in the global supply chain, providing high-quality kaolin that meets the diverse needs of industries around the world. Kaolin’s versatility and wide range of applications have fueled its demand in sectors such as ceramics, paper, paints, rubber, pharmaceuticals, and cosmetics. This blog explores why India is the leading China Clay Exporter and how the country has become a hub for high-quality kaolin.

What is China Clay (Kaolin)?

China clay, or kaolin, is a naturally occurring white clay mineral, primarily composed of kaolinite. It forms from the weathering of rocks like feldspar and is rich in alumina and silica. Due to its high whiteness, low iron content, fine particle size, and excellent plasticity, China clay is used extensively across multiple industries. The mineral's non-toxic, absorbent, and non-abrasive nature makes it ideal for applications in ceramics, paper, rubber, paints, cosmetics, and pharmaceuticals.

China clay is an essential raw material for the manufacturing of porcelain, high-quality paper products, rubber compounds, and various beauty and personal care products. Given its wide-ranging utility, it is in high demand globally, and India’s significant reserves, along with advanced manufacturing capabilities, make the country a leading China Clay Exporter in the world.

India’s Position as a Leading China Clay Exporter

India’s dominance in the global kaolin market can be attributed to a combination of natural resources, technological advancements, cost-effective production methods, and a strong export infrastructure. Here are the key reasons why India is the leading China Clay Exporter:

1. Abundant Natural Reserves

India boasts extensive reserves of China clay, particularly in states like Rajasthan, Tamil Nadu, and Andhra Pradesh. These regions are rich in high-quality kaolin, making India a major global supplier of this mineral. The country has some of the purest and finest kaolin deposits, ensuring that the clay produced is of the highest quality, suitable for a wide range of industrial applications. India’s China clay is known for its low iron content and high whiteness, which are crucial properties for industries such as ceramics and paper production.

2. High-Quality Kaolin Production

One of the primary reasons India has become a leader in the global China clay market is its ability to produce high-quality kaolin that meets the stringent requirements of various industries. China Clay Exporters in India focus on maintaining high standards of quality, ensuring that their products are free from impurities that could affect performance.

Indian China Clay Exporters use advanced processing techniques to refine the kaolin, removing impurities such as iron, titanium, and other minerals that may impact the clay's characteristics. The refined kaolin is then tailored to meet the specific needs of different industries, whether for ceramics, paper coatings, or cosmetics. This consistency in quality has helped Indian kaolin gain global recognition.

3. Cost-Effectiveness and Competitive Pricing

India has a competitive advantage in terms of the cost of production. The relatively low cost of labor, combined with efficient mining and processing techniques, allows China Clay Exporters in India to offer kaolin at competitive prices without compromising on quality. This cost-effectiveness has made Indian kaolin a popular choice among international buyers, particularly those in the ceramics, rubber, and paper industries.

For businesses looking to source kaolin at a lower cost while maintaining high-quality standards, India provides an attractive solution. The combination of natural resources, efficient production methods, and favorable economic conditions contributes to India’s position as a cost-effective and reliable China Clay Exporter.

4. Technological Advancements in Processing

Indian China Clay Exporters have invested heavily in state-of-the-art processing technologies to meet the ever-growing global demand for kaolin. These advancements ensure that the kaolin produced is of consistent quality and meets the specific requirements of various applications. The use of modern beneficiation techniques, such as high-efficiency washing, refining, and drying processes, ensures that the clay is free from contaminants and meets international standards.

The processing plants in India are equipped to handle large volumes of kaolin while maintaining quality control, making the country one of the most efficient exporters of China clay in the world. This has enabled India to meet the needs of international markets consistently and reliably.

5. Well-Established Export Infrastructure

India’s export infrastructure plays a crucial role in facilitating the smooth and timely delivery of kaolin to global markets. Major ports like Mumbai, Chennai, and Kolkata serve as key gateways for the export of China clay, ensuring that shipments are efficiently handled and delivered to international destinations.

The country also has a strong network of logistics and transportation systems that ensure timely deliveries to global customers. As a China Clay Exporter in India, we have built strong relationships with shipping companies and freight forwarders, ensuring that our kaolin reaches our international clients on time and in excellent condition.

6. Global Demand for China Clay

The demand for China clay has been steadily rising due to its diverse applications across industries. For example, the ceramics industry uses kaolin to manufacture porcelain, tiles, and sanitary ware. The paper industry uses kaolin as a coating and filler material to improve the smoothness and brightness of paper. The paints industry relies on kaolin as a filler to enhance the texture and performance of paints.

With India’s high-quality kaolin and competitive pricing, it has become a preferred supplier for industries in Europe, the United States, Africa, and the Middle East. As a China Clay Exporter in India, we are equipped to meet the growing demand for this essential mineral and deliver it efficiently to international markets.

7. Sustainability and Environmental Responsibility

In today’s global marketplace, sustainability is a key factor for many businesses when choosing suppliers. China Clay Exporters in India are increasingly focusing on environmentally responsible mining and processing practices. The country has introduced regulations and guidelines to ensure that kaolin extraction is done sustainably, minimizing environmental impact.

Responsible mining practices, such as proper land reclamation and waste management, help mitigate the ecological footprint of kaolin production. By adopting these sustainable practices, Indian exporters contribute to environmentally-friendly business practices that align with global sustainability goals.

8. Diverse Applications Across Industries

India’s China Clay Exporters cater to a wide range of industries, ensuring that the kaolin produced can be customized to meet specific industry needs. Some of the key applications of kaolin include:

Ceramics: Kaolin is used in the production of porcelain, pottery, tiles, and sanitary ware due to its smooth texture, high whiteness, and durability.

Paper: Kaolin enhances the brightness, smoothness, and opacity of paper products, making it a crucial material in the production of high-quality printing and packaging papers.

Paints and Coatings: In the paint industry, kaolin is used as a filler and extender to improve coverage, texture, and durability.

Rubber: Kaolin is used as a reinforcing agent in rubber, improving its strength and durability, particularly in tires and footwear.

Cosmetics and Pharmaceuticals: Kaolin is utilized in personal care products such as face masks, body powders, and in pharmaceutical formulations due to its absorbent and non-toxic properties.

The versatility of kaolin has contributed to the growing demand for Indian kaolin, and China Clay Exporters in India have capitalized on this trend by offering customized products that meet the specific requirements of these industries.

Conclusion

India’s position as a China Clay Exporter is underpinned by several factors, including the country’s abundant natural reserves, competitive pricing, advanced processing technologies, and strong export infrastructure. As a hub for high-quality kaolin, India serves industries around the world with top-grade China clay that meets the exacting standards of industries such as ceramics, paper, rubber, cosmetics, and more.

By choosing a trusted China Clay Exporter in India, businesses around the world can benefit from a reliable, cost-effective, and high-quality source of kaolin. India’s commitment to sustainability, coupled with its expertise in kaolin production, ensures that the country will continue to play a pivotal role in the global supply of China clay for years to come. Whether you are in the ceramics, paper, rubber, or cosmetics industry, India remains a preferred supplier of kaolin, meeting the diverse needs of international markets with efficiency and excellence.

0 notes

Text

Who Needs To Take The MSHA Training Online?

The idea of climbing into a mine or bottomless pit is scary. There are millions of individuals doing this as a livelihood. It is helpful to know that “The Mining Health and Safety Administration” strives to keep the fatalities and, indeed, the instances of mishaps down. Their efforts have proved to be effective, and the number of deaths has been reduced significantly. People who desire to join the mining industry anew are well advised to opt for the MSHA training that can be undertaken from the privacy of home. The classes are held online, and the students are not required to go down into the mines either. It is important to know that this particular training is aimed at miners of Part 46 rather than those working to remove coal from the deep mines. On the contrary, new workers hoping to be engaged in any of the following types of mines must ensure receiving the training and obtaining the certificate:-

· Shell Dredging · Sand & Gravel · Surface Stone · Surface Clay · Colloidal Phosphate · Surface Limestone · Marble · Granite · Sandstone · Slate · Shale · Traprock · Kaolin · Cement · Feldspar · Lime

Knowing the type of mines that employ new miners well-trained in workplace safety practices can help their employers comply with local and state regulations. It is also essential to know the individuals who are expected to have the safety training apart from the new entrants in this field. Well, it suffices to know that the individuals working in the following capacities are expected to undergo the MSHA safety training as soon as possible:

· Supervisors · Contractors

Importantly, new surface miners need to undergo the New Miner Training Part 46 before starting work at a Part 46 surface mine.

Training Duration

Most employees who are beginning their jobs are usually anxious to get started. They cannot handle unsafe work areas or materials before being trained. Ordinarily, this particular training takes around 8 hours. The modules are information-based for miners who would soon be working in Part 46 mines. Simply getting the certificate is not enough. Instead, the new miners who complete the training successfully are also expected to undergo occupational health and safety training lasting 16 days. Contacting the employer with the certificate is vital to be regarded as a trained miner. Another aspect to remember is that the second training must be completed within 3 months of completing the online MSHA training course.

New miners should feel free of pressure about the training, however. While understanding English is a prerequisite, there are no other conditions to fulfill before training. The final test also needs to be passed by scoring at least 80% marks.

Taking skid steer operator training makes one an OSHA-certified skid operator capable of operating skid steer equipment and other heavy machinery in small, hard-to-reach spaces.

0 notes

Text

Kaolin Market Intelligence Report Offers Growth Prospects

Kaolin Industry Overview

The global kaolin market size was valued at USD 3.98 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 4.0% from 2024 to 2030.Increasing investment in construction and infrastructure industry is propelling demand for paints & coatings, ceramic-based products, and cement, which is driving market growth.

Global construction industry is expected to witness lucrative growth over shifting inclination towards green construction, which in turn is expected to provide a significant growth opportunity for kaolin market. For instance, according to the World Bank’s new IFC report, green construction is anticipated to make investment opportunities worth USD 1.5 trillion for emerging markets.

Gather more insights about the market drivers, restrains and growth of theKaolin Market

Investments in construction, infrastructure development, and automotive production are expected to contribute to market growth over the forecast period. Growth of construction industry in the U.S. is a key factor contributing to demand for kaolin in the country. According to U.S. Census Bureau, total construction spending (residential and non-residential) grew by 3.5% in June 2023 on a y-o-y basis. The spending on single-family housing increased by 2.1% and multi-family housing by 1.5%.

Growing demand for painting due to rising investments in construction is leading companies to engage in strategic measures such as mergers & acquisitions, which are expected to influence the market demand positively. For instance, in November 2021, GDB International, Inc., a producer of paints & coatings, acquired a paint manufacturing plant in Illinois, U.S. This plant has a production capacity of 5 million gallons per year and can produce both water and solvent-based paints.

Further investments in medical industry are another driving factor for the market. For instance, in December 2021, Pfizer announced that it would acquire Arena Pharmaceuticals for about USD 6.70 billion. This deal was completed in March 2022 and is expected to help advance its presence in treatment of several immuno-deficiency diseases. Such developments indicate healthy growth for country’s pharmaceutical and medical industries. This is anticipated to have a positive impact on demand for kaolin in pharmaceuticals and medical application segment.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The India kaolin market size was estimated at USD 349.6 million in 2023 and is expected to grow at a CAGR of 5.2% from 2024 to 2030. The increasing construction and infrastructural developments, paper manufacturing, and growing paints and coating industries are driving growth for kaolin.

The global HDPE and LLDPE geomembrane market size was estimated at USD 1.36 billion in 2023 and is expected to grow at a CAGR of 5.6% from 2024 to 2030.

Key Companies profiled:

BASF SE

EICL Ltd.

Imerys S.A.

I-Minerals Inc.

KaMin LLC

LB Minerals Ltd.

Maoming Xingli Kaolin Co. Ltd.

Quazwerke GmbH

Sibelco

Thiele Kaolin Company

Key Kaolin Company Insights

Some of the key players operating in the market include KaMin LLC, Imerys S.A. and Sibelco.

KaMin LLC acquired the kaolin business from BASF SE in September 2022. The divestiture consists of the production hub with sites Toddvile, Edgar, Deweyville, and Gordon mines, mills, and reserves in the U.S.

Imerys S.A. specializes in the production & processing of minerals. It sells its products through three business segments: Performance Minerals Americas, Performance Minerals Asia Pacific, and Performance Minerals Europe, Middle East, and Africa.

Sibelco’s product portfolio includes dry sand, wet sands, kaolin, silica flour, frac sand, ball clay, cristobalite, feldspar, filtration sand, olivine sand, spherical silica, high-purity quartz, quicklime, coated sands, red clay, prepared bodies, hydrated lime, diatomite, nepheline Semite, olivine flour, and lithium minerals. The company manufactures kaolin for producing fine ceramics. The company’s kaolin reserves are in UK, Czech Republic, France, Germany, Spain, Portugal, and Ukraine.

WA Kaolin Limited and Maoming Xingli Kaolin Co., Ltd. are some of the emerging market participants.

WA kaolin is a mineral exploration, mining, and processing company. In November 2020, the company completed its definitive feasibility study of Wickepin Kaolin Project and in 2022 the company commissioned stage 1 of the Wickepin Processing plant

Maoming Xingli Kaolin Co., Ltd. has a high-quality mine named acicular kaolin mine that spreads across 800 acres. The company offers several products such as bone china clay, clay for porcelain, kaolin clay, porcelain clay, and others. Its key focus is on washed kaolin (without acid), 90-degree ball clay, and 90- degree kaolin.

Recent Developments

In November 2023, KaMin LLC and CADAM announced a price increase of their kaolin products by up to 9% starting from January 2024. This is to offset cost increase due to inflation, increase in mining cost, stringent environmental and regulatory requirements, and increase in electricity rates in the U.S. and Brazil, and labor cost.

In January 2024, the Federal Government of Nigeria announced that it has started to explore the possibility of production of salt and kaolin in Abuja. This is expected to increase global supply, hence providing price favorability to end users at a regional level.

Order a free sample PDF of the Kaolin Market Intelligence Study, published by Grand View Research.

0 notes

Text

The Versatility of China Clay Powder: Leading Manufacturers in India

China Clay, also known as Kaolin, is an essential mineral with a multitude of uses, ranging from detergents and paints to paper and cosmetics. As one of the leading China Clay Powder Manufacturers in India, the Sudarshan Group takes pride in offering high-quality china clay powder that enhances the performance and quality of various products. This fine, white, dense, smooth, flaky, earthy aggregate mineral is processed meticulously to meet the diverse needs of our customers.

Understanding China Clay (Kaolin)

China Clay, scientifically known as Kaolin, is a naturally occurring mineral found in specific geological conditions. Its unique properties make it an indispensable component in several industrial applications. The mineral is characterized by its fine particle size, which can be processed up to 10 microns, allowing for a smooth and dense consistency. This makes China Clay an excellent additive for enhancing the texture and durability of various products.

Applications of China Clay Powder

1. Detergents and Toilet Soaps:

China Clay powder is extensively used in the production of detergents and toilet soaps. Its fine particle size and smooth texture improve the cleansing properties and consistency of these products. The Sudarshan Group supplies nearly 12,000 tons of high-quality china clay powder to detergent and soap manufacturers, ensuring superior product performance.

2. Paint Industry:

In the paint industry, China Clay powder is valued for its opacity and smooth texture. It serves as an excellent extender and pigment, enhancing the quality and durability of paints. Its fine particles help in achieving a uniform finish, making it a preferred choice for manufacturers aiming for high-quality paint products.

3. Paper Manufacturing:

China Clay plays a crucial role in the paper industry. It is used as a filler to improve the opacity, printability, and smoothness of paper. The fine particle size of Kaolin enhances the paper's surface, making it ideal for high-quality printing and packaging materials.

4. Cosmetic Industry:

In the cosmetic industry, China Clay powder is known for its absorbent and smoothening properties. It is widely used in facial masks, powders, and other skincare products. Its gentle texture makes it suitable for sensitive skin, providing a natural and effective solution for various cosmetic formulations.

Why Choose Sudarshan Group?

As leading China Clay Powder Manufacturers in India, the Sudarshan Group is committed to delivering exceptional quality and service. Here are some reasons why our china clay powder stands out:

1. Quality Assurance:

We ensure that our china clay powder meets the highest quality standards. Each batch is rigorously tested for purity, particle size, and chemical composition, ensuring that our customers receive a consistent and reliable product.

2. Advanced Processing Techniques:

Our state-of-the-art processing facilities allow us to produce china clay powder with fine particle sizes, up to 10 microns. This advanced processing ensures that our china clay powder is of the highest quality, suitable for various industrial applications.

3. Sustainable Practices:

The Sudarshan Group is committed to sustainable and eco-friendly practices. We ensure that our mining and processing activities have minimal impact on the environment, promoting responsible and sustainable mineral production.

Conclusion

China Clay powder is a versatile mineral with numerous industrial applications, from detergents and paints to paper and cosmetics. As one of the leading China Clay Powder Manufacturers in India, the Sudarshan Group offers high-quality china clay powder that enhances the performance and quality of various products. With a commitment to quality, advanced processing techniques, sustainable practices, and a customer-centric approach, we strive to be the preferred choice for all your china clay powder needs.

Whether you are in the detergent, paint, paper, or cosmetic industry, the Sudarshan Group has the expertise and resources to provide you with the best quality china clay powder. Contact us today to learn more about our products and how we can help you achieve superior product performance.

0 notes

Text

World Building | Natural Resources

Solarpunk Project - Nusa Stiglitz

Sri Lanka contains several diverse natural resources to draw from. Apart from the main ones that are used in this world (tropical climate, windy coasts, lakes and rivers), there are other smaller ones that are put to use in various other fields. They are as follows;

Mineral

Agricultural

Mineral Resources

Sri Lanka is home to several materials of the earth, such as limestone, graphite, mineral sands, gems, and phosphate.

Limestone is used in construction (in concrete) and in agriculture (to balance the pH levels in soil). It is used in a similar fashion as in Roman construction, which makes buildings and statues far more durable and in the long run, is better for the environment.

Graphite is used in writing materials, lubricants (like grease), in the electrical industry and to create graphene sheets, which are several times more durable than steel, and far more lightweight (used in the construction of certain technologies and equipment). The use of natural graphite in particular is more popular in Sri Lanka as it produces very little carbon emissions in comparison to the production of synthetic graphite.

Mineral sands are smaller ore deposits in the form of particles. Sri Lanka is well-endowed with industrial minerals including Graphite, Ilmenite, Rutile, Zircon, Quartz, Feldspar, Clay, Kaolin, Apatite, (Phosphate Rock), Silica Sand, Garnet sand, Mica, Calcite and Dolomite. Several mineral-sand deposits of Monazite, Zircon, Garnet and Ilmenite in particular are found in various parts of the island, and are now being exported. These are used in creating the wind turbine magnets that power part of the coasts of the island, and in medical, manufactured and electronic products such as fibre optics, and rechargeable batteries. Additionally, it is also used in materials such as inks, paints and sunscreen.

There exist a variety of gems that can be mined from Sri Lanka. Especially notable are blue sapphire, pink sapphire or ruby, and yellow sapphire; alexandrite and cat's-eye chrysoberyl; and almandine and hessonite garnet. These in particular resulted in a booming jewellery industry that formed in the country that often exports to other parts of the world.

Finally, phosphate is used to create phosphorous, which is itself used in fertiliser. It can also be used to create phosphorous acid, which has several applications as an agent in food, cosmetics, electronics and animal feed.

Agricultural Resources

The main agricultural export of Sri Lanka is tea, however the country also exports rubber, coconuts, rice, and spices. It was because of these resources that colonisers were drawn to this country, which also had the ideal conditions to grow them in. Ancient Sri Lankans also indulged in the practice of Chena cultivation, which was used to cultivate vegetables, greens, grains and cereals. Agriculture also heavily depended on the monsoonal seasons (Maha and Yala), and certain crops are relegated to only certain parts of the country (for example, tea is only grown in the central highlands of the country).

The nature of the Sri Lankan diet is such that most if not all compounds of a balanced meal can be locally sourced and grown in one's own garden. This led some Sri Lankans to pursue a meat-free lifestyle, although a more proper term would be to call it a minimum-meat lifestyle.

Live meat is found in the forms of cow, chicken, pig, and goat meat. Pork is slightly less common than the other two, as the demand for it is less. In addition to this, certain commodities are harvested from these animals, such as milk and eggs. Eggs in particular may come from a variety of animals, ranging from the aforementioned chicken to quail to duck. Sri Lanka also thrives on a strong fishing culture, with many fishing villages lining the coasts of the countries. However, villagers are careful not to harm crucial elements of the environment in the process (such as mangroves). Thus, more traditional means of fishing are employed. Some marine life that are often caught are crab, prawn, shark, and both large and smaller species of fish.

In addition to consumables, cotton is also grown in Sri Lanka, which is used to make a majority of the fabric seen in the country. Raw fabric is produced by "spinning" the cotton and "weaving" it once it has turned into threads.

As a result of all these boons, Sri Lanka seldom ever imports these products into the country, only ever resorting to during off-seasons for agricultural resources. This has led to a self-sustained growing economy that does not rely on international trade to benefit.

0 notes

Text

Unveiling the Excellence of Calcined Kaolin Manufacturing in India

Introduction:

India, with its rich reserves of minerals, stands as a hub for various industries, and one such mineral making waves in the manufacturing sector is calcined kaolin. This refined form of kaolin has garnered attention for its diverse applications, and its production in India has reached new heights of excellence. In this blog, we delve into the world of calcined kaolin manufacturing in India, focusing on the process, applications, and the noteworthy contributions of industry leaders like 20 Microns.

Calcined Kaolin: A Brief Overview:

Calcined kaolin is derived from the mineral kaolinite, a naturally occurring clay. The manufacturing process involves subjecting raw kaolin to high temperatures, resulting in a transformation that enhances its physical and chemical properties. The end product, calcined kaolin, exhibits improved brightness, fine particle size, and unique characteristics that make it a sought-after material in various industries.

The Manufacturing Process:

The link provided (https://www.20microns.com/products/calcined-kaolin) offers insights into the manufacturing process undertaken by 20 Microns, a prominent player in the field. The process typically involves mining high-quality kaolin deposits, followed by purification and the critical step of calcination. High temperatures during calcination remove impurities and alter the mineral structure, giving rise to the enhanced properties of calcined kaolin.

Quality Assurance:

Quality is paramount in the production of calcined kaolin, and reputable manufacturers adhere to stringent quality control measures. 20 Microns, for instance, emphasizes quality assurance at every stage of production. The link provides information on the company's commitment to quality, ensuring that the end product meets the specifications required by diverse industries.

Applications Across Industries:

Calcined kaolin finds applications across a spectrum of industries, and its versatility is a key factor driving its popularity. The blog highlights how calcined kaolin is utilized in the paper industry for coating, in ceramics for improved firing characteristics, in paint and coatings for pigment extension, and in construction materials for enhancing the strength of concrete. This showcases the wide-ranging impact of calcined kaolin on different sectors.

Innovation and Sustainability:

The blog explores how manufacturers in India, including 20 Microns, are focusing on innovation and sustainability. This includes efficient mining practices, energy optimization during calcination, and eco-friendly approaches to waste management. Such initiatives not only contribute to the industry's growth but also align with global sustainability goals.

Conclusion:

Calcined kaolin manufacturing in India has evolved into a dynamic and innovative industry, catering to the demands of diverse sectors. The link provides valuable insights into the process, quality standards, and applications of calcined kaolin, emphasizing the role of industry leaders like 20 Microns. As calcined kaolin continues to play a pivotal role in enhancing product quality across various domains, the manufacturing landscape in India is set to further elevate its global standing in this sector.

0 notes

Text

The Essential Role of China Clay Powder Manufacturers in Various Industries

China clay powder, also known as kaolin, is one of the most versatile raw materials used across a wide range of industries. From ceramics and paints to pharmaceuticals and cosmetics, this naturally occurring material plays a crucial role in enhancing product quality and performance. As a result, the demand for high-quality China clay powder has surged over the years, making China clay powder manufacturers an essential part of many industries.

What Is China Clay Powder?

China clay is a fine, white, soft powder obtained from the mineral kaolinite. It is an alumino-silicate clay mineral that is primarily composed of hydrated aluminum silicate. The powder is highly valued for its natural purity, whiteness, and low abrasive properties, making it ideal for various industrial applications. The raw clay is extracted through mining, processed to remove impurities, and then refined into the fine, powdery substance that is used in different manufacturing processes.

Applications of China Clay Powder

Ceramics Industry: One of the largest consumers of China clay powder is the ceramics industry. China clay is used as a raw material for making porcelain, tiles, pottery, and other ceramic products. Its fine texture, smoothness, and whiteness make it a preferred choice for creating high-quality ceramics that are durable and aesthetically appealing.

Paint Industry: China clay powder is widely used in the paint and coatings industry as a filler and extender. The powder enhances the smoothness, opacity, and consistency of paints. It also improves the durability and brightness of the final paint product. As a result, it is extensively used in both decorative and industrial paints.

Rubber and Plastics: The powder is also used in the rubber and plastics industry, where it acts as a reinforcing agent. It helps in improving the strength and durability of rubber and plastic products. The fine quality of China clay powder ensures the smooth finish of products like tires, gaskets, and electrical insulators.

Pharmaceutical and Cosmetic Products: China clay powder is used in pharmaceutical and cosmetic products due to its soft, absorbent, and non-toxic properties. It is found in products like face masks, talcum powders, soaps, and creams. Its absorbent nature makes it useful for controlling oil and moisture in personal care products.

Paper Industry: The paper industry relies on China clay powder as a coating pigment. It helps in improving the smoothness and brightness of paper. It also enhances the paper’s printability and opacity, making it suitable for high-quality printing jobs.

Agriculture: In agriculture, China clay powder is used in the production of fertilizers and pesticides. Its non-toxic properties make it a safe and effective option for improving soil conditions and supporting plant growth.

Why Choose High-Quality China Clay Powder Manufacturers?

The quality of China clay powder plays a critical role in the performance of products across these industries. That’s why choosing a reliable and experienced China clay powder manufacturer is of utmost importance. High-quality China clay ensures consistency, purity, and desired properties for the end product. A reputable manufacturer will offer a product that is free from impurities, properly processed, and tailored to meet specific industry standards.

Sudarshan Group: A Leading China Clay Powder Manufacturer

When it comes to sourcing high-quality China clay powder, Sudarshan Group is a name that stands out. As one of the leading manufacturers in the industry, Sudarshan Group provides premium-quality China clay that meets the diverse needs of various sectors, including ceramics, paints, pharmaceuticals, and more. With years of expertise in the field, they are known for their commitment to excellence and customer satisfaction.

Their advanced processing techniques ensure that the China clay powder retains its purity, whiteness, and smoothness, making it a preferred choice for businesses looking for top-notch raw materials. Sudarshan Group’s consistent product quality and reliable delivery make them a trusted partner for industries that require China clay powder in bulk quantities.

Conclusion

China clay powder is an essential raw material for a variety of industries, and its demand is expected to continue growing. The versatility of this natural material makes it a vital component in products ranging from ceramics and paints to cosmetics and pharmaceuticals. When selecting a China clay powder manufacturer, it’s crucial to prioritize quality and reliability. Companies like Sudarshan Group are leading the way in providing superior-quality China clay powder that meets the needs of various industries and ensures the best outcomes for their clients.

By working with the right manufacturer, businesses can ensure that they are using the highest-quality materials to produce their products, resulting in greater performance, durability, and overall customer satisfaction.

0 notes

Text

Aluminosilicate Prices: Trend | Pricing | News | Price | Database

Aluminosilicates Prices a group of minerals widely used in various industries, are experiencing dynamic shifts in pricing trends driven by market demand, supply constraints, and technological advancements. These minerals, comprising aluminum, silicon, and oxygen, play a vital role in sectors such as construction, petrochemicals, ceramics, and environmental applications. The market for aluminosilicates is influenced by their diverse applications, particularly in producing zeolites, refractories, and catalysts. Zeolites, one of the most prominent products derived from aluminosilicates, are highly sought after in water treatment, detergents, and petrochemical refining, making their demand a significant driver of aluminosilicate prices globally.

The aluminosilicate market is shaped by several key factors, including raw material availability, production costs, and regulatory policies. Natural aluminosilicates, such as feldspar and kaolin, are mined in specific geographic regions, creating regional price disparities. Additionally, synthetic aluminosilicates, which are engineered for high purity and specific applications, often carry a premium price due to their complex manufacturing processes. Rising energy costs have also contributed to fluctuating prices, as aluminosilicate production is energy-intensive, particularly in synthesizing zeolites and manufacturing ceramics. These cost pressures are exacerbated by global inflationary trends, impacting the overall pricing landscape.

Get Real time Prices for Aluminosilicates: https://www.chemanalyst.com/Pricing-data/aluminosilicate-1518

The construction industry's growing demand for lightweight and durable materials has significantly contributed to the increased consumption of aluminosilicates. As a result, prices have risen steadily, especially in markets like Asia-Pacific, where rapid urbanization and infrastructure development are driving demand. Aluminosilicates are integral to manufacturing high-strength ceramics and refractories, crucial for construction projects requiring thermal and mechanical stability. With nations prioritizing sustainable and long-lasting construction practices, the demand for these minerals is expected to remain robust, further influencing their market valuation.

Environmental regulations and sustainability concerns have also played a pivotal role in shaping aluminosilicate prices. Industries are increasingly adopting zeolite-based solutions for applications such as air purification, water treatment, and carbon capture, owing to their eco-friendly properties. As governments and organizations push for stricter emission control measures, the demand for zeolites has surged, creating upward pressure on aluminosilicate prices. Furthermore, advancements in green chemistry and circular economy practices have encouraged the development of innovative aluminosilicate applications, such as in renewable energy technologies, thereby expanding their market scope and influencing pricing dynamics.

The aluminosilicate market is also impacted by global trade dynamics and geopolitical factors. Disruptions in supply chains, trade tariffs, and export restrictions in key aluminosilicate-producing countries can lead to price volatility. For example, the availability of raw materials like feldspar and kaolin, primarily sourced from regions such as China, India, and Brazil, is subject to mining regulations and environmental policies in these countries. Any changes in these policies can significantly alter the supply-demand equilibrium, affecting prices worldwide. Similarly, geopolitical tensions can disrupt trade flows, leading to temporary shortages and price spikes in import-dependent regions.

Technological advancements and innovations in manufacturing processes have provided some relief in controlling production costs and stabilizing prices. For instance, modern methods of synthesizing zeolites and other high-performance aluminosilicates have enabled producers to achieve better efficiency and consistency. However, these advancements require substantial capital investment, which is often reflected in the product's final price. The ongoing research into optimizing aluminosilicate applications across industries, such as improving their catalytic efficiency in petrochemical processes or enhancing their durability in ceramics, also adds to the pricing considerations as manufacturers seek to recover R&D expenses.

Regional markets exhibit varying trends in aluminosilicate prices, influenced by local demand patterns, industrial growth, and resource availability. In North America and Europe, where environmental regulations are stringent, the demand for high-purity aluminosilicates, particularly zeolites, is high. This demand has supported steady price growth, especially in applications related to emission control and water purification. Conversely, in developing regions like Asia-Pacific, the market is driven more by the construction and ceramics industries, with prices reflecting the growing consumption of raw aluminosilicates. The Middle East and Africa, though smaller in market share, are witnessing increased demand for aluminosilicates in petrochemical refining, supported by regional oil and gas activities.

The future of aluminosilicate prices is expected to be influenced by global megatrends such as sustainability, digitalization, and urbanization. The transition towards renewable energy and green technologies is likely to amplify the demand for zeolites, especially in hydrogen production and carbon capture systems. Similarly, the growing emphasis on sustainable urban development will continue to drive demand for durable and eco-friendly construction materials, ensuring a steady market for aluminosilicates. However, challenges such as resource depletion, rising energy costs, and geopolitical uncertainties could pose risks to price stability in the coming years.

In conclusion, the aluminosilicate market is characterized by its complexity and responsiveness to diverse factors, ranging from industrial demand and environmental regulations to technological advancements and geopolitical dynamics. Prices are likely to remain dynamic, reflecting the interplay of these forces in a rapidly evolving global landscape. Businesses and stakeholders in the aluminosilicate industry must stay attuned to these trends, adapting their strategies to navigate challenges and capitalize on emerging opportunities in this critical market segment.

Get Real time Prices for Aluminosilicates: https://www.chemanalyst.com/Pricing-data/aluminosilicate-1518

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminosilicate#Aluminosilicate Price#Aluminosilicate Prices#Aluminosilicate Pricing#Aluminosilicate News#Aluminosilicate Price Monitor#Aluminosilicate Database

0 notes

Text

How White Clay Kaolin Enhances Plastics: A Guide for Manufacturers

White clay kaolin, also known as kaolinite, has long been recognized for its diverse industrial applications. Among these, its role in plastic manufacturing stands out as an innovation driver. This article explores how white clay kaolin contributes to the plastic industry, focusing on its unique properties, sourcing from a mineral mining company, and its availability through china clay suppliers. Additionally, we delve into the science behind its clay composition and how manufacturers can maximize its potential.

Understanding White Clay Kaolin