#Intermodal Tank Container

Explore tagged Tumblr posts

Text

Efficiency and Safety: Oil Tanker Trailer Insights

Oil tanker trailers are essential for the long-distance transportation of liquid cargo, primarily petroleum products. To protect the environment, public safety, and the industry's bottom line, it is essential to ensure both efficiency and safety in this crucial sector.

The design and operation of oil tanker trailers should be optimized for efficiency. Aerodynamics and advanced materials can lower emissions and fuel use, promoting environmental sustainability. By minimizing empty trips and lowering total transportation costs, simplified logistics and route design further improve efficiency.

Safety is still the top priority in the Oil Tanker Trailer sector. Safety procedures and laws must be followed in the letter. Modern safety features like anti-lock braking systems and rollover prevention technologies are essential, as are routine maintenance inspections, rigorous driver training, and strict regulations.

Operators of oil tanker trailers should put cargo security first to avoid leaks or spills while in transit. Among the safeguards used to prevent environmental disasters are double-walled tanks and pressure release valves.

Winding Up

Efficiency and safety must be carefully balanced in the oil tanker trailer sector. We can maintain the safe and effective delivery of liquid cargo by utilizing cutting-edge technologies and abiding by severe safety regulations, protecting the environment and the future of the industry.

#Portable Led Light Towers For Sale#Intermodal Tank Container#Diesel Fuel Tank Trailer#Tanker Trucks And Trailers

0 notes

Text

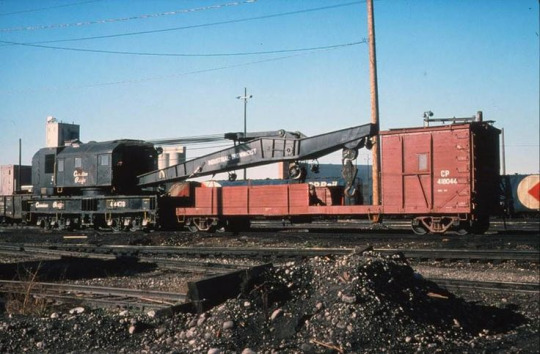

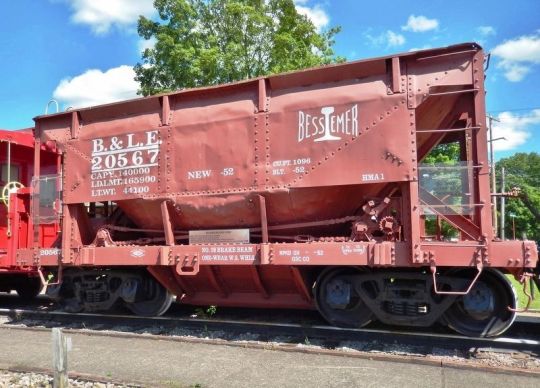

types of freight cars

made a whole post to help ppl design stex ocs as the resident freight enthusiast :) while this isn't every freight car in existence, it's definitely a good chunk of them!

FLATCARS

The most basic type of freight car. They’re…well…flat! Designed for carrying bulky loads.

Autorack: Transport automobiles. Can have single, double, or triple levels.

Boom/Idler: Placed in front of a breakdown crane to protect the boom or in front of/behind oversized loads to protect the overhang.

Bulkhead: Have walls (bulkheads) on the end. Used to transport pipe, poles, slabs, and lumber. Prone to derailing when traveling empty and put speed restrictions on the freight train.

Centerbeam: Carry lumber. Another type is the opera (round) window style. Have to be loaded/unloaded evenly to avoid the car tipping over.

Depressed Center: Used to carry extremely heavy loads such as generators. Have a lowered (depressed) middle section.

Intermodal/Well: Carry semi-truck trailers and containers. Have a lowered bottom (well).

Skeleton/Spine: Very narrow car used to transport lumber. Has stakes on the sides. Spine cars do not have stakes and are often used for intermodal transport.

GONDOLAS

Open-topped cars that generally transport loose goods. Can also be covered. Differ from hoppers in that they have flat bottoms and have to be manually unloaded or put through a rotary dumper.

Bathtub: Transport coal. Have rounded bottoms for extra space.

Coil: Carry coils of metal. Can be open or have specialized covers to protect the cargo. Typically considered a subtype of gondola, but can also be a subtype of flatcar as well.

Side-dump: Cars tip sideways to dump loads. Often carry ballast or rocks for railbeds.

HOPPERS

Evolved from gondolas but differ in that they have sloped bottoms and discharge doors. Can be covered or uncovered, and have between two to five chutes. Open cars transport bulk goods such as coal, while covered ones carry food items.

Ore Jenny: A small, specialized hopper designed to carry large loads of iron ore from mines.

BOXCAR

Enclosed cars with side or end doors. Used for bulk commodities and for goods that need to be protected from the weather.

Stock: Used to transport livestock such as cattle, horses, sheep, and poultry. Have ventilated sides for airflow. A variant used to carry fish was attached to passenger trains and was more luxurious.

Refrigerator: Insulated and cooled cars used to transport frozen goods.

TANKERS

Used to transport liquids or gases. Can be specialized to carry hazardous materials.

Milk: Specialized tank car variant (as opposed to the boxcar variant) that carries milk. Attached to passenger trains to prevent spoilage.

Pickle: There's pickles in there! The vats were filled with vinegar.

Torpedo: Carry molten iron. Designed to withstand very high temperatures.

Whale Belly: Large tank car with a lowered midsection for additional carrying capacity.

SCHNABEL

These cars are a type all of their own. Used to transport extremely large loads by pinching it between the arms of the car.

113 notes

·

View notes

Text

containers

as I sit on the rim of this bathtub, thawing (isn't it funny how thaw and dethaw mean the same thing?) my toes in foot-deep hot water (maybe, I don't know how tall a foot is anyway, and who's to say whether this water is sexy), I listen to the voice inside my head (which just happens, most of the time, to be my inner perception of my own voice). it tells me:

containers are fun, aren't they? no, not your common red-topped, tomato-sauce-stained Rubbermaids. I mean real containers, real big ones. cargo containers, grain silos, water tanks, that sort of thing. now, I don't care if they're cylindrical or rectilinear, ceramic or wooden or made of corrugated fiberboard, if they're IBCs or ULDs or FIBCs, nor whether they abide by the industry standard intermodal container size (which is, of course, the twenty-foot equivalent unit) or anything else of the sort. in fact, the only size standard I care about is big. come to think of it, maybe 'container' is too limiting a term for what I'm referring to, maybe what I'm really looking for is only properly contained within the well-defined borders of a stalwart pair of double quotes: "vessel that can hold large volumes of stuff." (the broadening of the definition of the ostensible topic of this post, as I've just done, does not work to subvert unconsciously built-up expectations because the bathtub context at the start prevents the building up of the unconscious expectations necessary for this to be considered a subversion.)

shut up, inner voice. (though, with the incorrect and incessant use of parentheses remaining largely constant between my apparent voice and my so-called inner voice, I begin to wonder who I'm really talking to.)

no no, but just think about it. do bathtubs not inspire within you the most pleasant form of joy?

given that that which is "within" me is you, and given your jolly tone, I suppose they do.

pools... are they not so rapturous to take in with your eyes? and the sea, the sea! is it not simply the largest container on earth? 71% of the planet's surface is a difficult number to beat. (since it is a majority, unless containers are in the business of sharing the earth's surface area with each other, it is actually an impossible number to beat. but then again, who knows? the containers may be commies.)

I'll concede that pools are in possession of a special something. (what, now you've gone mad too? -wait a minute, if you're you, then who was that? and who am I? this never would have happened if I'd just used the first-person singular pronoun in that first question (it even makes sense: first-person in the first question... you're grasping at straws, it is utterly nonsensical.), but, no! it's too late now and I've gone down a different branch of "me".) and as for the sea, what you meant was the ocean.

sea, ocean... what does it matter? it would take me but this bathtub to ruin your laptop. what- no- don't leave it, don't leave the bathtub, don't leave me!

fret not, dear me, I've concluded it makes no sense for the sphere of existence of my inner voice to be delimited by the immediate vicinity of the bathtub. since this is the conclusion I have drawn, you shall stay with me for the foreseeable future. rather tragically I must add.

your laptop is now out of reach of the water (which is itself disappearing down the drain), and yet you cry tragedy. the bright side is lost on you pessimists. you really cannot be helped. now please, focus, think of the sea. the... why are we thinking of the sea again?-

there it is!-

see what you've done to us, distracting us from our goals, rendering discursive (definitely the "rambling desultory digressive" definition of this word and not the "conscious reasoning" one. if you're looking on Collins dictionary, that is. why would I be? stop asking questions.) what was supposed to be a pleasant chat about containers. oh there it is, that's why we're thinking of the sea!

no, i meant there it is! the pronoun to resolve our issues of identity! first-person plural! "we"! that was a pretty long run of italics for me, I hope it doesn't confuse them on who's speaking. (hold on, where did they come from all of a sudden? can we keep these words that one may substitute for a noun or noun phrase to a strict minimum, please?) did you just quote fucking Wikipedia and in doing so introduce the indefinite pronoun into the mix? so much for wanting to keep things simple. and now you've ruined the little communist-flavoured celebration we were having at the top of this paragraph!

listen, can we go back to the sea? is it not, quite plainly, the most pretty?

I do love the sea, and I guess I do love containers. you were right all along, dear me.

#what the shit#i'm schizophrenic#just kidding i'm obviously not it's just funny to say that#what i am is sleep deprived#good night

3 notes

·

View notes

Text

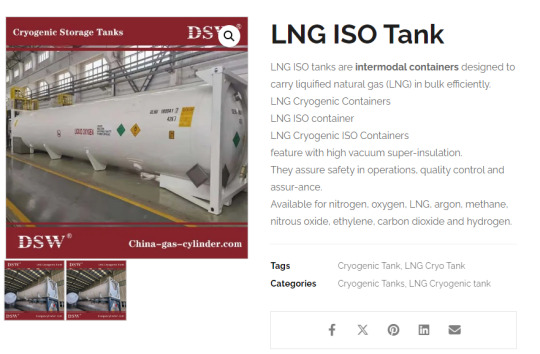

10ft Cryogenic Offshore Tank

10ft Cryogenic Offshore Tank is a container-style tank used for storing liquefied gases (such as liquid nitrogen, liquid oxygen, etc.) and is typically utilized in offshore oil and gas platforms or vessels.

These tanks are engineered with thermal insulation capabilities to facilitate the storage of cryogenic fluids at ultra-low temperatures, thereby guaranteeing their maintenance in a liquid phase.

The tanks are usually built in a standard 10-foot size, making them convenient for various transportation and storage applications. Cryogenic Offshore Tank is suitable for use on offshore oil and gas platforms or vessels where space is limited, offering a compact and reliable solution for storing cryogenic substances.

DSW offers solutions for nitrogen, oxygen, LNG, argon, methane, nitrous oxide, ethylenecarbon dioxide, and hydrogen. The 10', 20', and 40' intermodal containers are typically built according to EN, ASME/DOT, or Chinesedesign standards. Available maximum allowable working pressure (MAWP) options include 10, 18, and 24bars for European designs and 100, 150, 180, and 230 psi for ASME/DOT designs.

1 note

·

View note

Text

All you need to know about the ISO Tank containers | INOXCVA

In the realm of global logistics, the efficient and safe transportation of bulk liquids, gases, and powders is paramount. ISO tank containers have emerged as a pivotal solution, offering a standardised, reliable, and versatile method for transporting a wide array of substances across various modes of transport.

Understanding ISO Tank Containers

An ISO tank container, commonly referred to as an ISO tank, is a stainless steel vessel encased within a protective frame built to the specifications of the International Organisation for Standardisation (ISO). This standardisation ensures uniformity in dimensions and design, facilitating seamless integration across different transportation systems, including road, rail, and sea. Typically, these containers measure about 6 meters in length, 2.4 meters in width, and between 2.4 to 2.5 meters in height, with capacities ranging from 21,000 to 40,000 litres.

Advantages of ISO Tank Containers

Safety and Durability: Constructed from high-grade stainless steel and equipped with insulation and protective layers, ISO tanks are designed to withstand the rigours of transportation. Their robust construction ensures a long lifespan, typically between 20 to 35 years, making them a cost-effective investment.

Versatility: ISO tanks are suitable for transporting both hazardous and non-hazardous materials, including chemicals, food-grade liquids, gases, and powders. This versatility makes them indispensable across various industries, from chemical manufacturing to food and beverage processing.

Efficiency: Designed for intermodal transport, ISO tanks can be easily transferred between different modes of transportation without the need to unload and reload the contents. This intermodal capability reduces handling times and minimises the risk of contamination or spillage.

Types of ISO Tank Containers

ISO tanks are categorised based on the type of cargo they are designed to carry:

Standard Tanks: Used for non-hazardous liquids such as food-grade oils and juices.

Specialised Tanks: Designed for specific cargoes, including:

Refrigerated (Reefer) Tanks: Equipped with cooling systems to transport temperature-sensitive liquids.

Gas Tanks: Built to carry gases under pressure, such as liquefied petroleum gas (LPG) and ammonia.

Silo Tanks: Intended for the transport of dry bulk materials like powders and granules.

Lined Tanks: Feature specialised linings, such as rubber, for transporting corrosive acids and chemicals.

Applications Across Industries

The adaptability of ISO tank containers allows them to serve a broad spectrum of industries:

Chemical Industry: Transporting both hazardous and non-hazardous chemicals safely and efficiently.

Food and Beverage: Ensuring the hygienic transport of edible oils, juices, and other consumable liquids.

Pharmaceuticals: Maintaining the integrity of sensitive pharmaceutical ingredients during transit.

Energy Sector: Facilitating the movement of liquefied natural gas (LNG) and other energy-related substances.

INOXCVA's Commitment to Excellence

As a leader in cryogenic engineering, INOXCVA offers a comprehensive range of ISO tank containers tailored to meet the diverse needs of various industries. Our tanks are engineered with precision, adhering to stringent quality standards to ensure safety, reliability, and longevity.

Key Features of INOXCVA's ISO Tanks

High-Quality Materials: Using premium stainless steel and advanced insulation materials to maintain product integrity.

Customisation: Ability to design tanks for specific applications, including refrigeration options, specialised linings, and pressure ratings.

Global Compliance: Manufactured in accordance with international standards, ensuring compatibility and acceptance across global markets.

Conclusion

ISO tank containers represent a cornerstone in the modern logistics landscape, offering a safe, efficient, and versatile solution for transporting a wide range of bulk materials. INOXCVA's dedication to quality and innovation ensures that our ISO tanks meet the highest standards, providing our clients with reliable solutions tailored to their needs.All you need to know about the ISO Tank containers

0 notes

Text

Virtual Pipeline Systems Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Global Virtual Pipeline Systems Market – Industry Trends and Forecast to 2028

Global Virtual Pipeline Systems Market, By Type (Ordinary Type, Special Type), Product (Liquefied Petroleum Gas (LPG), Liquid Natural Gas (LNG), Compressed Natural Gas (CNG), Propane, Diesel and Oils), Container Size (Type I, Type II, Type III, Type IV), Mode of Transportation (Intermodal ISO Tank Containers, Tanker Rail Cars, Pipeline Transport, Reticulated Gas System or Piped Gas System, Road Tankers, Local Bobtail Tankers), Application (Industrial, Transportation, Commercial and Residential), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- **By Component:** The virtual pipeline systems market can be segmented based on components into compressors, trailers, cylinders, valves, fittings, and others. Compressors play a crucial role in the transportation of natural gas, enabling it to be moved efficiently through pipelines. Trailers are used for the physical transportation of compressed natural gas (CNG) or liquefied natural gas (LNG) to areas without access to pipelines. Cylinders are another essential component, providing storage for the transported gas. Valves and fittings ensure smooth operations and safe handling of the gas in the virtual pipeline system.

- **By Application:** In terms of applications, the virtual pipeline systems market can be categorized into industrial, transportation, commercial, and residential sectors. The industrial sector utilizes virtual pipelines for various operations such as heat generation, power generation, and manufacturing processes. The transportation sector relies on virtual pipelines to fuel vehicles, especially in regions where traditional pipelines are not feasible. The commercial and residential sectors use virtual pipeline systems for heating, cooking, and other energy needs.

- **By Mode of Supply:** Virtual pipeline systems can also be segmented by the mode of supply, which includes truck-based transportation, rail-based transportation, and ship-based transportation. Truck-based transportation is the most common mode, offering flexibility and scalability in delivering natural gas to remote locations. Rail-based transportation provides a cost-effective solution for long-distance gas transportation. Ship-based transportation involves the use of tankers for transporting LNG to areas inaccessible by land.

**Market Players**

- **GE Oil & Gas:** GE Oil & Gas is a key player in the virtual pipeline systems market, offering a range of solutions for the compression, transportation, and storage of natural gas. The company's expertise in industrial equipment and services makes it a reliable partner for virtual pipeline projects.

- **Hexagon Composites ASA:** Hexagon Composites ASA specializes in high-pressure composite cylinders for gas storage, making them a significant player in the virtual pipeline systems market. TheirGE Oil & Gas and Hexagon Composites ASA are two key players in the virtual pipeline systems market, each bringing unique strengths and capabilities to the industry. GE Oil & Gas stands out for its comprehensive solutions for compression, transportation, and storage of natural gas. With its expertise in industrial equipment and services, the company offers a broad range of offerings that cater to the diverse needs of virtual pipeline projects. GE's reputation for reliability and innovation positions it as a trusted partner for implementing virtual pipeline systems across various sectors.

On the other hand, Hexagon Composites ASA specializes in high-pressure composite cylinders for gas storage, a critical component in virtual pipeline systems. The use of advanced composite materials in their cylinders enables Hexagon to provide lightweight and durable storage solutions for transporting natural gas efficiently and safely. The company's focus on innovation and sustainability in gas storage technologies has solidified its position as a significant player in the virtual pipeline systems market. Hexagon's expertise in high-pressure cylinders aligns with the increasing demand for reliable and high-performance storage solutions in virtual pipeline applications.

As the virtual pipeline systems market continues to grow, players like GE Oil & Gas and Hexagon Composites ASA are poised to capitalize on the increasing demand for efficient and flexible gas transportation solutions. The market trends indicate a rising adoption of virtual pipelines across various sectors, driven by the need for reliable energy supply in remote locations and areas without access to traditional pipelines. The versatility of virtual pipeline systems in industrial, transportation, commercial, and residential applications further expands the market potential for key players like GE and Hexagon.

In terms of competition within the virtual pipeline systems market, companies like GE Oil & Gas and Hexagon Composites ASA differentiate themselves through technological advancements, product innovation, and strategic partnerships. Establishing strong relationships with customers and industry stakeholders is essential for driving growth and expanding market presence. Furthermore, addressing evolving regulatory requirements and sustainability concerns will be crucial for staying competitive in the dynamic virtual pipeline systems market.

Overall, the market outlook for virtual pipeline systems remains**Global Virtual Pipeline Systems Market Analysis:**

- **Segments:** - **By Component:** Virtual pipeline systems market components include compressors, trailers, cylinders, valves, fittings, and others. Compressors are essential for efficient gas transportation, while trailers are used for physical gas transportation to areas without traditional pipelines. Cylinders provide storage for the transported gas, with valves and fittings ensuring smooth operations and safe handling within the system.

- **By Application:** Market applications cover industrial, transportation, commercial, and residential sectors. Industrial operations utilize virtual pipelines for heat and power generation, transportation for vehicle fueling, and commercial/residential sectors for heating and cooking purposes.

- **By Mode of Supply:** Segmentation by the mode of supply includes truck-based, rail-based, and ship-based transportation. Truck-based transportation offers flexibility and scalability, rail-based is cost-effective for long-distance transportation, and ship-based involves tankers for LNG transportation to remote areas.

**Market Players:** - **GE Oil & Gas:** GE Oil & Gas offers compression, transportation, and storage solutions for natural gas with a focus on industrial expertise, making them a reliable partner for virtual pipeline projects.

- **Hexagon Composites ASA:** Specializing in high-pressure composite cylinders for gas storage, Hexagon Composites ASA provides lightweight and durable storage solutions for efficient and safe gas transportation, aligning with the increasing demand for reliable storage solutions in virtual pipeline applications.

Key players like GE Oil & Gas

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Virtual Pipeline Systems Market

Chapter 3: Regional analysis of the Global Virtual Pipeline Systems Market industry

Chapter 4: Virtual Pipeline Systems Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Key takeaways from the Virtual Pipeline Systems Market report:

Detailed considerate of Virtual Pipeline Systems Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the Virtual Pipeline Systems Market-leading players.

Virtual Pipeline Systems Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of Virtual Pipeline Systems Market for forthcoming years.

Browse Trending Reports:

Air Sports Equipment Market Secondary Macronutrients Market Blood Gas Analyzer Market Methotrexate Injection Market Smart Room Heater Market Battery Market Infrastructure As a Service Iaas Health Cloud Market Peritonitis Treatment Market Yacht Charter Market Next Generation Printing Ink Market Functional Confectionery Market Herbal Ready To Brink Beverages Market Wirewound Resistor Market Gelatin Substitutes Market Soy Based Surfactants Market Trimethlyaminuria Market Secondary Agricultural Nutrients Market Tomatoes Market Electric Kick Scooters Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Indian Freight Cars: The Backbone of the Nation's Economy

Indian freight cars, the workhorses of the Indian Railways, play a crucial role in transporting goods across the vast expanse of the country. These sturdy and versatile vehicles are essential for sustaining the nation's economy, connecting various industries and regions.

Types of Indian Freight Cars

Indian Railways operates a diverse fleet of freight cars, each designed to meet specific transportation needs. Some of the common types include:

Covered Wagons: These are enclosed cars used for transporting a wide range of goods, including food grains, textiles, and machinery.

Open Wagons: These open-top cars are ideal for transporting bulk commodities like coal, iron ore, and construction materials.

Tank Wagons: These specialized cars are used to transport liquids, such as petroleum products, chemicals, and edible oils.

Refrigerated Wagons: These temperature-controlled cars are essential for transporting perishable goods like fruits, vegetables, and dairy products.

Container Wagons: These flatbed cars are designed to carry ISO standard containers, facilitating efficient intermodal transportation.

Challenges and Innovations

Despite their significance, Indian freight cars face several challenges, including:

Aging Infrastructure: Many freight cars are outdated and require modernization to improve efficiency and safety.

Congestion: Rail networks often experience congestion, leading to delays and inefficiencies in freight transportation.

Competition: Road transport poses a significant challenge to rail freight due to factors such as flexibility and speed.

To address these challenges, Indian Railways has been implementing various innovations, such as:

Modernization: Investments are being made to upgrade freight cars with advanced technologies and improve their carrying capacity.

Infrastructure Development: The government is focusing on expanding and modernizing rail infrastructure to enhance freight transport efficiency.

Intermodal Transportation: Efforts are being made to promote intermodal transportation, combining rail and road transport for seamless movement of goods.

Future Outlook

Indian freight cars are poised to play an even more critical role in the country's economic growth. As the nation's industrialization accelerates and e-commerce expands, the demand for efficient freight transportation will continue to rise. By addressing the existing challenges and embracing technological advancements, Indian Railways can ensure that its freight cars remain the backbone of the nation's economy for years to come.

0 notes

Text

Shipping Container Market Landscape: Trends, Drivers, and Forecast (2023-2032)

The Shipping Container market is projected to grow from USD 10,408.79 million in 2024 to USD 13,780.72 million by 2032, at a compound annual growth rate (CAGR) of 3.57%.

Shipping containers are large, standardized steel boxes designed for intermodal freight transport, meaning they can be used across different modes of transport – from ship to rail to truck – without unloading and reloading their cargo. Developed in the mid-20th century, these containers revolutionized global trade by significantly reducing the cost and time of cargo transport, enhancing efficiency, and improving the security of goods. Typically, shipping containers are 20 or 40 feet long, though variations exist to accommodate different types of cargo. Their standardized design allows them to be easily stacked and handled by various types of equipment, such as cranes and forklifts, facilitating the seamless transfer of goods across the world. The durability and robustness of shipping containers, made from weathering steel, protect their contents from the harsh conditions at sea and in transit.

Additionally, they come in various types, such as dry containers, refrigerated containers (reefers) for perishable goods, open-top containers for oversized cargo, and tank containers for liquids. Beyond their primary use in transportation, shipping containers have found secondary applications in architecture and construction, being repurposed into homes, offices, and storage units due to their modular and sturdy nature. This adaptability, combined with their role in the global supply chain, underscores the shipping container's significance in modern logistics and trade.

Shipping Container Market Trends:

The shipping container market is experiencing several significant trends driven by various global economic, technological, and environmental factors. Firstly, the rising demand for efficient and cost-effective transportation solutions is propelling the growth of the shipping container market. The increasing globalization of trade and the expansion of e-commerce have heightened the need for reliable and scalable freight transport options, making shipping containers an essential component of the logistics infrastructure.

Another notable trend is the shift towards more sustainable and eco-friendly container solutions. With growing environmental concerns and stringent regulations aimed at reducing carbon emissions, there is a surge in the adoption of green containers. These include containers made from recycled materials and those designed for energy efficiency, such as refrigerated containers with advanced insulation and energy-saving refrigeration units.

Technological advancements are also playing a pivotal role in shaping the shipping container market. The integration of Internet of Things (IoT) technology and smart sensors in containers is enhancing the tracking, monitoring, and management of cargo. These innovations provide real-time data on container location, condition, and security, thus improving supply chain transparency and efficiency.

The trend towards containerization in non-traditional sectors is another factor driving market growth. Industries such as agriculture, pharmaceuticals, and retail are increasingly utilizing containers for their supply chain needs due to the advantages of standardized transport and enhanced protection of goods. For instance, the use of refrigerated containers is expanding in the food and pharmaceutical industries to maintain the quality and safety of perishable and temperature-sensitive products during transit.

Moreover, the market is witnessing a growing interest in container modification and repurposing. The versatility of shipping containers makes them suitable for various secondary applications, including portable storage units, pop-up retail shops, and even residential and commercial buildings. This trend is particularly prominent in urban areas where space constraints and sustainability goals drive the adoption of innovative container-based solutions.

Geopolitical factors and trade dynamics are also influencing the shipping container market. Trade tensions, tariff regulations, and shifts in manufacturing hubs are impacting container flows and demand patterns. For example, the relocation of manufacturing activities from China to other regions, such as Southeast Asia and India, is altering traditional shipping routes and container usage.

Key Player Analysis

P. Moller–Maersk Group

CARU containers

COSCO SHIPPING Development Co. Ltd

China International Marine Containers

CXIC Group

Singamas Container Holdings Limited

OEG Offshore limited

TLS Offshore Containers International

W&K Containers Inc.

YMC Container Solutions

More About Report- https://www.credenceresearch.com/report/shipping-containers-market

Here are the key challenges facing the shipping container market:

Supply Chain Disruptions: Unpredictable events such as natural disasters, pandemics, and geopolitical conflicts can cause significant disruptions in the global supply chain, leading to container shortages or surpluses and affecting the overall market dynamics.

Port Congestion: Increasing trade volumes and inadequate port infrastructure can result in severe congestion at major ports, causing delays in container handling and movement, which impacts the efficiency of global shipping operations.

Environmental Regulations: Stricter environmental regulations aimed at reducing carbon emissions and improving sustainability require significant investments in eco-friendly containers and alternative fuels, posing a financial challenge for industry players.

Fluctuating Freight Rates: Volatility in freight rates, influenced by factors such as fuel prices, demand-supply imbalances, and economic conditions, can create financial uncertainty and impact the profitability of shipping companies.

Technological Integration: While technological advancements offer benefits, integrating new technologies like IoT and smart sensors into existing container fleets can be costly and complex, requiring substantial investment and expertise.

Trade Policies and Tariffs: Changing trade policies, tariffs, and international trade agreements can impact container flows and demand, creating uncertainty and potential disruptions in the market.

Container Maintenance and Management: Ensuring the timely maintenance and repair of containers to meet safety and operational standards is a significant logistical and financial challenge for shipping companies.

Security Concerns: The risk of cargo theft, piracy, and smuggling presents ongoing security challenges that require robust measures and technologies to protect containers and their contents.

Capacity Constraints: Limited container manufacturing capacity and the time required to build new containers can lead to supply constraints, especially during periods of high demand, affecting market availability and pricing.

Adaptation to New Standards: The introduction of new industry standards and practices, such as those related to container tracking and data sharing, necessitates ongoing adaptation and compliance efforts from market participants.

Segments:

Based on Container Size

Large Containers (40 Feet)

Small Containers (20 Feet)

High Cube Containers (40 Feet)

Based on Product Type

Dry Storage Containers

Flat Rack Containers

Refrigerated Containers

Special-purpose Containers

Others

Based on End-User

Food and Beverages

Consumer Goods

Healthcare

Industrial Products

Vehicle Transport

Browse the full report – https://www.credenceresearch.com/report/shipping-containers-market

Browse Our Blog: https://www.linkedin.com/pulse/shipping-container-market-landscape-chulf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Guide to Shipping Containers

Guide to Shipping Containers

Shipping containers serve as the backbone of intermodal transport systems, enabling goods to traverse vast distances via trucks, trains, and ships. Whether it's heavy machinery or delicately palletized goods, these containers provide a secure enclosure, shielding cargo from the perils of shock and inclement weather.

youtube

Also known as ISO containers, conex boxes, or railroad containers, these ubiquitous units adhere to the rigorous standards set by the International Standards Organization (ISO). This global body meticulously crafted dimension specifications, fostering uniformity in container design and enhancing compatibility across transportation networks.

10053 Whittwood Dr, Suite 11284 Whittier,

CA 90603 USA

657-667-6227

What sets shipping containers apart is their innate versatility, epitomized by their ability to seamlessly transition between different modes of transport. Thanks to standardized dimensions, these containers can seamlessly hop from ship to rail to truck, eliminating the need for laborious loading and unloading processes.

The evolution of shipping containers mirrors the dynamic nature of global trade itself. Initially conceived for commercial shipping, these containers have undergone continual refinement to accommodate a diverse array of products. From perishable goods to oversized machinery, containers come in myriad shapes, sizes, and materials to suit every cargo need.

Standardization has been pivotal in streamlining the transport process, allowing for smoother transitions and quicker delivery times. By adhering to established norms, logistics operators can optimize their operations, ensuring that goods reach their destination with maximum efficiency and minimal delay.

In essence, shipping containers represent more than just metal boxes; they symbolize the interconnectedness of the modern world. As trade barriers dissolve and supply chains grow more complex, these unassuming vessels play a crucial role in sustaining the global economy's heartbeat.

Looking ahead, the future of shipping containers holds promise for further innovation and refinement. With advances in technology and sustainability, tomorrow's containers may boast enhanced durability, eco-friendly materials, and even autonomous tracking capabilities.

In a world where distance is no longer a barrier to trade, shipping containers remain the silent enablers of global commerce, bridging continents and connecting markets with unparalleled efficiency. As we navigate the complexities of a rapidly evolving world, one thing remains certain: the humble shipping container will continue to shape the future of trade for generations to come.

There are different types of Shipping Containers for different types of transportation:

Common Types of Shipping Containers

Shipping Containers are another name for the conex boxes most used on the market. Shipping Containers are typically suitable for any type of dry cargo: pallets, boxes, bags, machines, furniture, etc.

Common types include:

Dry Storage Container

Refrigerated Container

Open top container

Flat rack container

Open Side Container

Tanks Container

Ventilated containers

Dry Storage Shipping Container

Dry Storage Shipping Containers are your typical standard shipping containers. Basic construction is made of steel, and hermetically sealed, without cooling or ventilation. Sizes typically come in 20 ‘, 40’ or 40 ‘High Cube. The High Cube category facilitates an increase of 13% of the internal cubic capacity and can handle the heaviest loads (coal, tobacco, etc.)

Refrigerated Shipping Container

Reefer Shipping Containers provide a temperature controlled environment. They have a power supply that connects to energy sources during transport. This allows the products to be transported at a constant temperature throughout the journey. They have the possibility to lower temperature from -18 ° to 30 °. There are 20 and 40 foot models, in addition to the High Cube.

This type of Shipping Container is especially recommended for transporting food or products that need a low storage temperature.

Open Top Shipping Container

Open Top Shipping Container have the same measurements as the standard containers, but are open at the top because they have a removable canvas roof. These containers facilitate the transport of bulky loads.

Flat Rack Shipping Container

Flat Rack Shipping Containers are like the Open Top, but also lack side walls and even, in some cases, front and rear walls. They are used for atypical loads and pay supplements in the same way as Open Top.

Open Side Shipping Container

Open Side Shipping Containers have the same measurements as standard containers; 20 or 40 feet, with the difference that they have a side opening. This allows for transporting very long merchandise, whose dimensions prevent it from being loaded by the back door.

Tank Shipping Container

Tank Shipping Containers are used for the liquid transport and made to carry dangerous as toxic, corrosive, highly combustible chemicals, as well as oil, milk, beers, wine, mineral water, etc. They have the same dimensions as a Dry Shipping Containers, but their structure is different, as they include a polyethylene tank inside.

Ventilated Shipping Containers

Ventilated Shipping Containers are made for transporting products such as coffee or cocoa beans, which must be ventilated in transit; sometimes these units are called “coffee containers”.

Shipping Container Door Diagram and Troubleshooting

Now we are going to run through the essential parts of a shipping container.

For a door to work, you need hinges. Pins hold the shipping container's hinges together through a barrel. In certain cases when doors are difficult to open, hinge pins and blades may be seized due to corrosion. Each door is fitted with 2 to 4 vertical lock rods to enable opening, closing and locking of the doors.

The door handle rotates the lockbar to initiate the door opening process by forcing the cams out of their keepers. Each door handle has a door locking handle retainer that slides over the door handle when in locked position.

At the end of each lock rod is a cam welded in place which engages with knuckles, also known as cam keepers. The action of engaging the cams to the keepers forms an anti-racking function. In certain cases, often unfortunately too many, contents of the shipping container may have shifted causing shipping container doors and lockrods to warp.

When opening a shipping container, start with the right hand door first. Swivel the handles, engage the cams and keepers, and twist both door handles. Closing the doors is just a reverse of this process.

The lock box is a steel box welded to the right hand door which overlaps a staple welded to the left hand door. A padlock, normally CISA type 285 66 can then be attached inside the lock box through the staple and is then protected from direct attack, hindering attempts to gain entry to the container.

ISO markings and a consolidated data plate allow worldwide intermodal transport and are updated as necessary. Take note that customs authorities in some countries may also have their own container seal regulations as part of their national security.

Rubber gaskets are fitted to the container doors during the manufacturing process and prevent water ingress. Door gaskets are designed to present two or more fins against the structure or adjacent door. These are generally flexible but when the gasket is damaged, they may become stiff thus jamming the door closed, or preventing it from being closed.

Doors

Two door leaves are fabricated from two vertical rolled hollow sections and 2 horizontal c section members. The frame is infilled with corrugated steel paneling.

These are normally attached to the rear corner posts each with four drop forged steel hinge blades. The blades allow 270 degree opening which allow the doors to swing back against the container side wall.

(Cargo may shift during transit. Look at the container to make sure that the doors are aligned and level, both top and bottom. In cases where the container frame is racked and the door gear will not operate correctly.)

Lockbox

The lock box is a steel box welded to the right hand door which overlaps a staple welded to the left hand door. A padlock, normally type CISA type 285 66 can then be attached inside the lock box through the staple and is then protected from direct attack, hindering attempts to gain entry to the container.

Lockrods, cam keepers, handles

Each door is fitted with 2-4 vertical lock rods to enable opening, closing and locking of the doors.

At the end of each lock rod (top and bottom) is a cam welded in place which engages with knuckles, also known as cam keepers.

The action of engaging the cams to the keepers forms an anti-racking function.

(In certain cases, often unfortunately too many, contents of the shipping container may have shifted, or containers even dropped, causing shipping container doors and lockrods to warp)

The door handle rotates the lockbar to initiates the door opening process by forcing the cams out of their keepers. Each door handle has a door locking handle retainer that slides over the door handle when in locked position.

Rubber gaskets

Rubber gaskets are fitted to the container doors during the manufacturing process and prevent water ingress.

(Door gaskets are designed to present two or more fins against the structure or adjacent door. These are generally flexible but when the gasket is damaged, they may become hard or blocked thus jamming the door closed, or preventing it being closed.)

ISO markings and CSC plate

ISO markings and a consolidated data plate allow worldwide intermodal transport when left in place and updated as necessary.

Hinge pins

Of course for a door to work, you need hinges.

(In certain cases when doors are difficult to open, hinge pins and blade are seized due to corrosion.)

Choosing the Right Company for Buying a Shipping Container

When doing research in finding the right Shipping Container, follow some of these tips:

Research Online

Choose which companies have a good track record of excellence and reputation. Read reviews and what other customers have to say.

Check for Availability

If you are shipping from various locations, check for availability if containers can be delivered to your required areas.

Check for Best Pricing

If money matters, you can find used container resellers online that might be able to offer half the price on used containers.

Check for Good Customer Service

If you plan to order often, you might want to check for good customer service. Ask potential container companies a question through email or their online customer service. See how fast they respond.

Check for Warranty

Check with companies to see if they offer any warranties or buy back or trade in plans.

There are millions of Shipping Containers in use around the world, and a lucky few get a second life as repurposed shipping container structures. While they look a bit plain and boxy to the untrained eye, shipping containers play a critical role in our lives, whether embarking on ocean crossings to deliver the goods we use every day or venturing into a second life as a container structure.

Here are Some Fascinating Facts about Shipping Containers

Shipping Containers can be safely stacked nine-high.

Well-maintained Shipping Containers hold 759, of their original value for 25+ years.

There are over 37 million Shipping Containers in use around the world.

A Shipping Container floor can hold up 55,000 lb. of goods without warping.

Shipping Container flooring is made of 1-1/8” marine grade plywood.

Most Shipping Containers are 20 feet or 40-feet long.

Shipping Containers are made of 16-gauge corten steel.

Common container modifications include: personnel doors, windows flooring, shelving, work stations, insulation, climate control & even restrooms.

Fun Ways to Use Shipping Containers

Shipping Containers are not just used for cargo these days. There are many innovative and imaginative uses you may like to consider.

Here are few ideas of how shipping containers have been used for modern, cost effective buildings.

Homes

The trend to build cost-effective homes from recycled shipping containers started in USA and has reached Australia.

Art Galleries

Architect, Tomokaza Hayakawa designed an art gallery in Japan using two shipping containers stacked on each other.

Drive-Thru Coffee

Starbucks in Washington have used four old shipping containers to create an architect designed drive-thru store.

Cafes

A cafe in Footscray (Melbourne) called Rudimentary has been built using three 40-foot shipping containers.

Polar Stations

India has built a Polar Station in Antarctica using 134 shipping containers. They cover three floors and are well insulated for the weather conditions.

A well-maintained Shipping Container can hold 75% of their original value for 25+ years. Every day, container ships transport goods all over the world on the international seas.

Shipping Container Opening and Closing Tool

Shipping containers often take a beating, traveling around the world, being exposed to freezing conditions and rust due to seawater or when the frost has melted.

During the cold season, and in freezing parts of the world, our shipping container tool can benefit the opening and closing of frozen shipping container doors and hard to open or rusted containers.

Injuries often occur as a result of personnel trying to open and close difficult container doors, and often are the result of inappropriate techniques being used to open them.

To aid in opening and closing shipping container doors, we introduce OPNBar.

A Shipping Container (also known as Intermodal Container, ISO Container,Railroad Container, and certain Truck Trailers) is a large standardized shipping container, designed and built for intermodal freight transport. Shipping Containers can be used across different modes of transport. They can go from ship to rail to truck, without unloading and reloading their cargo.

The metal doors on the shipping containers on these containers are standardized. Shipping Containers use the same type and style of doors and locking bars, which our tool can be used.

Lengths are as follows: 20′, 40′, 45′, 48′, 50′, 53′. All these containers are globally used to transport cargo. The 53′ length is now, the new the standard length.

Here are some likely reasons a Shipping Container door will not open or close. Visit https://www.shippingcontainertool.com/what-is-a-shipping-container/ to find out how to overcome some of these issues.

Doors and lockrods may warp or container frame is racked so that the door gear will not operate correctly. This may be caused by cargo shifting during transit. Look at the container to make sure that the doors are aligned and level, both top and bottom.

The hinge pins and blade are seized due to corrosion.

The door gasket has been damaged and is preventing opening. Door gaskets are designed to present two or more fins against the structure or adjacent door. These are generally flexible but when the gasket is damaged, they may become hard or blocked thus jamming the door closed, or preventing it being closed.

Water has become trapped between frozen shipping container doors, particularly relevant to refrigerated cargoes, or containers with moisture releasing cargoes in cold weather.

1 note

·

View note

Text

ISO LNG Containers Enabling Efficient and Secure Liquefied Natural Gas Transport

ISO LNG containers, also known as ISO LNG tanks, are specialized containers designed for the transportation of liquefied natural gas (LNG). These containers adhere to the International Organization for Standardization (ISO) standards and play a crucial role in the global LNG supply chain. In this article, we will explore the significance of ISO LNG containers, delve into their key features, and discuss how they enable efficient and secure LNG transport.

ISO LNG Containers: A Foundation for LNG Transport:

ISO LNG containers are standardized containers designed to transport LNG in a safe and efficient manner. These containers ensure compliance with international regulations and standards, allowing for seamless intermodal transportation of LNG via road, rail, and sea. ISO LNG containers provide a reliable and standardized platform for LNG transport, promoting the growth of LNG trade and supporting the global energy industry.

Key Features and Design:

ISO LNG containers incorporate essential features to ensure the secure transport of LNG. They are constructed using high-quality materials, such as stainless steel, which offer excellent strength, durability, and resistance to extreme temperatures. The containers are insulated to minimize heat transfer and maintain the LNG at its cryogenic temperature. ISO LNG containers also feature advanced safety systems, including pressure relief devices, emergency shutdown valves, and leak detection systems, to prevent accidents and ensure the integrity of the container and its contents.

Advantages of ISO LNG Containers:

The use of ISO LNG containers offers several advantages for LNG transport. Firstly, these containers provide a high level of safety and security during transit, minimizing the risk of LNG leaks or spills. Their robust construction and stringent safety features ensure the containment of LNG, protecting personnel, the environment, and infrastructure. Secondly, ISO LNG containers enable efficient logistics planning and flexibility in transportation modes. They can be easily loaded and unloaded, and their standardized dimensions allow for seamless integration into existing transportation networks. Furthermore, ISO LNG containers promote cost savings by eliminating the need for specialized storage facilities at each point along the supply chain.

Regulatory Compliance and Certification:

ISO LNG containers must comply with international regulations and standards to ensure the safe transport of LNG. These standards encompass design, material selection, construction, and testing requirements. Manufacturers of ISO LNG containers undergo rigorous certification processes to validate compliance with industry standards, such as the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) and the International Organization for Standardization (ISO) standards. Compliance with these regulations is critical to maintaining the safety and integrity of LNG transport.

Expert Handling and Maintenance:

Proper handling and regular maintenance are essential for the safe and efficient operation of ISO LNG containers. Trained professionals with expertise in handling LNG oversee the loading, unloading, and securing of containers during transportation. Regular inspections, testing, and maintenance procedures are conducted to ensure the containers remain in optimal condition and comply with safety regulations. Entrusting ISO LNG container operations to experienced logistics providers or specialized LNG transport companies ensures adherence to best practices and minimizes risks associated with LNG transport.

Conclusion:

ISO LNG containers serve as a vital component in enabling efficient and secure LNG transport worldwide. Their standardized design, compliance with international regulations, and advanced safety features ensure the safe handling and transportation of LNG. ISO LNG containers offer advantages such as enhanced safety, logistical flexibility, and cost savings. By adhering to regulatory compliance and investing in expert handling and maintenance, industries can leverage ISO LNG containers to facilitate the reliable and efficient transport of LNG, supporting the growth of the global energy market and promoting sustainable energy practices.

0 notes

Text

Containerized Commerce: Unveiling the Market Share Dynamics in the ISO Tank Container Industry

The ISO tank container market is experiencing robust growth, driven by the expansion of global trade and the increasing need for efficient and secure transportation of liquids and gases. This press release provides insights into the market size, key trends, applications, and a brief competitive analysis of the ISO tank container industry.

Free Sample Copy of This Report at: https://www.econmarketresearch.com/request-sample/EMR0013/&Mode=econA

Market Size and Trends:

The ISO tank container market has witnessed substantial growth in recent years, with a notable rise in demand for the transportation of bulk liquids, chemicals, and gases. According to market research, the global ISO tank container market is anticipated to reach [insert market size] by [insert year], demonstrating a significant CAGR.

Key trends shaping the market include the growing demand for intermodal transportation solutions, the emphasis on sustainability and environmental responsibility, and advancements in tank container technology. As industries increasingly prioritize efficiency and safety in their supply chains, ISO tank containers have emerged as a preferred choice for the transportation of hazardous and non-hazardous liquids.

Ask For Discount: https://www.econmarketresearch.com/request-discount/EMR0013/?Mode=econA

Applications and Product Insights:

ISO tank containers are versatile and find applications across various industries. Key applications include:

Chemical Industry: ISO tank containers play a crucial role in the safe and secure transportation of chemicals. The containers are designed to meet stringent safety standards, ensuring the integrity of the cargo during transit.

Food and Beverage Industry: The food-grade ISO tank containers are utilized for transporting liquids such as edible oils, juices, and other food products. These containers adhere to strict hygiene standards to maintain the quality of the transported goods.

Oil and Gas Industry: ISO tank containers are widely employed for the transportation of petroleum products, liquefied natural gas (LNG), and other energy-related liquids. The containers provide a cost-effective and reliable solution for global energy logistics.

Competitive Landscape:

Some of the main manufacturers of ISO Tank Container Market are:

Bertschi AG

BNH Gas Tanks

Bulkhaul Ltd.

CARU Containers B.V.

China International Marine Containers Co., Ltd.

CIMC

CMA CGM Group

CXIC GROUP

Danteco Industries B.V.

Den Hartogh Logistics

Evergreen Marine Corporation.

Hapag-Lloyd

Hoover Ferguson Group, Inc.

HOYER GmbH

Get Full Report: https://www.econmarketresearch.com/industry-report/iso-tank-container-market/

Segmentations:

By Transport Mode

Road

Rail

Marine

By Container Type

Multi-Compartment Tank

Lined Tank

Reefer Tank

Cryogenic & Gas Tanks

Swap Body Tank

By End-use Industry

Chemicals

Petrochemicals

Food & Beverage

Pharmaceuticals

Industrial Gas

Others (Paints)

Competitive Landscape and Regional Analysis:

The ISO tank container market is characterized by the presence of key players focused on innovation and meeting the evolving needs of the industry. Major companies in the market include [insert major companies], which continue to invest in research and development to enhance container design and functionality.

Regionally, Asia-Pacific is a prominent market for ISO tank containers, driven by the expanding chemical and manufacturing industries. Europe and North America also play significant roles, owing to the mature logistics infrastructure and stringent safety regulations. The Middle East and Latin America are emerging as key growth regions, with increasing investments in oil and gas exploration and production.

In conclusion, the ISO tank container market is witnessing remarkable growth, propelled by global trade dynamics and the need for secure and efficient liquid transportation. As industries continue to prioritize safety, environmental responsibility, and cost-effectiveness, the demand for ISO tank containers is poised to remain strong.

About Us: Econ Market Research is an all-inclusive resource for providing useful insight gleaned through industry research. Through our syndicated and consulting research services, we assist our clients in finding solutions to their research needs. Industries including semiconductor and electronics, aerospace and defence, automobiles and transportation, healthcare, manufacturing and construction, media and technology, chemicals, and materials are among our areas of expertise. Contact Us: Econ Market Research Private Limited. E-mail: [email protected] Phone: +1 812 506 4440 Website: - Https://Www.Econmarketresearch.Com Connect with us at LinkedIn | Facebook | Twitter | YouTube

0 notes

Text

Discover Efficient Portable LED Light Tower

The introduction of Portable LED Light Towers has triggered a revolution in efficiency and adaptability in the field of outdoor illumination. These cutting-edge lighting options have established themselves as essential in a variety of industries, from outdoor festivals and remote labor locations to construction sites and emergency response scenarios. With improved features that address contemporary lighting requirements, their advent denotes a paradigm shift away from conventional lighting solutions.

The benefits of energy-efficient LED technology and the portability of portable LED light towers are combined in their design. These towers emit a strong and focused light, in contrast to traditional light sources, ensuring maximum visibility in even the darkest conditions. In addition to ensuring outstanding brightness, they also use a lot less energy, which lowers operating expenses and lowers the carbon imprint.

The words "Portable LED Light Towers for Sale" emphasize how affordable these innovative solutions are. They are easily accessible for purchase, making it simpler for individuals and organizations to get a dependable lighting source that can be moved around to different locations. Through amazing flexibility and adaptability, this mobility enables users to quickly illuminate sizable regions without the need for complicated setups.

Winding Up

The expectations for outdoor illumination have changed as a result of the rise of Portable LED Light Towers. For sectors needing dependable lighting solutions, their effectiveness, portability, and accessibility are game-changers. These transportable towers serve as markers of advancement, illuminating the path ahead as companies and organizations strive to maximize their operations while reducing their negative effects on the environment. With "Portable LED Light Towers for sale," everyone may look forward to a future that is both brighter and more productive.

0 notes

Text

Cargo Handling Equipment Market Outlook, Trends, Report 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the global cargo handling equipment market size at USD 24.63 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects the global cargo handling equipment market size to grow at a steady CAGR of 3.5% reaching a value of USD 30.28 billion by 2029. Major growth drivers for the global cargo handling equipment market include globalization, rapid industrialization, and increasing cargo activities. Cargo handling equipment has garnered significant attention due to its multifaceted benefits, which encompass the mitigation of revenue losses stemming from protracted cargo loading and unloading procedures. Moreover, this equipment augments the efficiency of cargo handling operations, reinforces safety protocols, and diminishes the probability of accidents. Significantly, it expedites cargo processing by streamlining cargo movement within docks and warehouses, thereby enhancing precision and reducing handling durations. Also, the equipment curtails the risk of worker injuries and the occurrence of accidents, thereby elevating safety benchmarks within the industry. However, high initial cost is anticipated to restrain the growth of the overall market during the period in analysis.

Global Cargo Handling Equipment Market – Overview

Cargo handling equipment encompasses specialized off-road, self-propelled vehicles and machinery used in intermodal rail yards and ports to handle containers, bulk goods, and liquid cargo transported by sea, air, or rail routes, with additional functions including scheduled maintenance and repairs. This equipment includes a range of machines such as mobile cranes, yard trucks, rubber-tired gantry cranes, side handlers, reach stackers, top handlers, loaders, forklifts, sweepers, dozers, excavators, and aerial lifts. The choice of equipment depends on the specific cargo type. Tankers are equipped with pumping systems, hose-handling cranes, and tank cleaning machinery. Dry-bulk carriers often rely on shoreside facilities, but some feature self-unloading mechanisms like conveyors or deck-mounted cranes. Reefer vessels are designed with refrigerated cargo holds and extensive refrigeration systems. Given the global dominance of containerized cargo transportation across land, air, and sea, precise handling of containers is vital, particularly at sea, where challenging weather conditions and strong winds prevail.

Sample Request @ https://www.blueweaveconsulting.com/report/cargo-handling-equipment-market/report-sample

Impact of COVID-19 on Global Cargo Handling Equipment Market

COVID-19 pandemic adversely affected the global cargo handling equipment market. Lockdown restrictions during the outbreak led to the closure of manufacturing units in this market. Despite the initial challenges caused by a lack of skilled professionals, there is a projected resurgence in the supply sector post-lockdown, as restrictions are gradually lifted. Also, the heightened demand for cargo handling and transportation services has created growth opportunities for the market in the aftermath of the pandemic, underscoring the profound impact of COVID-19 on the global cargo handling equipment market.

Global Cargo Handling Equipment Market – By Equipment

Based on equipment, the global cargo handling equipment market is divided into Industrial Trucks Tow Tractors, Conveying Equipment, Stackers, and Port Cranes segments. The industrial trucks tow tractors segment holds the highest share in the global cargo handling equipment market by equipment. The segment's prominence is attributed to the vital role tow tractors play in the efficient movement of materials and cargo within industrial settings, such as warehouses, factories, and distribution centers. Tow tractors are prized for their versatility and ability to tow heavy loads, making them indispensable for various logistics and materials handling operations. Their reliability, ease of use, and adaptability to diverse applications have contributed to their widespread adoption, solidifying their position as a key driver of the cargo handling equipment market.

Competitive Landscape

Major players operating in the global cargo handling equipment market include Hangcha Forklift, Siemens Logistics GmbH, TOYOTA INDUSTRIES CORPORATION, Terex Corporation, Anhui Heli, Textron Ground Support Equipment Inc., Liebherr-International Deutschland GmbH, TLD, KION GROUP AG, ABB, Hoist Material Handling, Inc., Hyster-Yale Group, Inc., and Konecranes. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

If are you looking for Bitumen tank container in Dubai

Bitumen plays a vital role in road construction projects, and ensuring its secure and efficient transportation from the factory to the building site is crucial. Tank containers offer numerous advantages for transporting bitumen. This article explores the benefits of using tank containers for the transportation of bitumen in road construction projects.

Efficient Transport of Bitumen Tank container are specifically designed to transport large quantities of bitumen effectively. Equipped with heating systems, insulation, and temperature control mechanisms, these containers maintain the proper temperature and keep the bitumen in liquid form throughout the transportation process. Moreover, tank containers can easily connect to traditional intermodal transport systems such as rail, trucks, and ships, enabling the seamless transportation of bitumen over long distances.

Flexible Storage Options Tank containers offer flexibility in storing bitumen. They can serve as temporary storage units for road construction projects, reducing the need for on-site storage facilities. This is particularly advantageous in areas with limited access to storage facilities. Additionally, these containers are suitable for storing and transporting different grades of bitumen, facilitating the seamless transition between various grades during road construction projects.

Cost-Effectiveness Transporting bitumen using tank containers is cost-effective. These containers are reusable and require minimal maintenance, reducing the need for frequent replacements. Furthermore, tank containers can also transport other items, providing added value for the money. Additionally, their stackable design eliminates the need for extra storage space, resulting in reduced storage costs.

Environmentally Friendly Bitumen tank containers offer greener transportation options compared to traditional methods. Equipped with energy-efficient heating systems, they require less energy and consequently reduce carbon emissions. Moreover, these containers minimize the risk of spills and leaks that can cause environmental damage.

In conclusion, tank containers offer several advantages for transporting bitumen in roadway construction projects. They ensure efficient transportation, reduce the risk of contamination, provide flexible storage options, offer cost-effectiveness, and contribute to environmental sustainability. Gulf Bitumen, a leading bitumen manufacturer in UAE, recognizes the importance of utilizing high-quality tank containers to transport bitumen efficiently and safely. With their state-of-the-art technology and equipment, Gulf Bitumen provides cost-effective and reliable transport solutions to construction companies, thereby supporting the growth and development of the infrastructure sector. By choosing a reputable company like Gulf Bitumen, construction companies can be confident in the success of their projects.

0 notes

Text

liquid argon suppliers

Liquid argon, a cryogenic liquid, is characterized by its low boiling point, which is below -130°F (-90°C). This extreme coldness, with a shallow boiling point of -303°F (-186.6°C), sets it apart from other liquefied gases. The stark temperature difference between liquid argon and its surroundings, even in the coldest winter conditions, necessitates the use of specialized equipment designed specifically for handling and storing cryogenic liquids like liquid argon.

DSW offers a range of high-quality tanks and cylinders designed for cryogenic applications. These tanks are suitable for storing various liquid gases such as argon, carbon dioxide, nitrogen, oxygen, and helium. Available in sizes ranging from 3,000 to over 100,000 liters, these tanks are built to withstand the extreme temperatures and pressures associated with cryogenic storage. They typically operate at standard working pressures of 18, 22, or 36 bar, ensuring safe and efficient storage of liquid argon.

For transportation purposes, the 20-foot ISO framework-type tank container is ideal for intermodal transport, including marine, highway, and railroad transportation. Built to meet ISO standards, this tank container is designed to handle as many as nine high stacking loads, making it a versatile and reliable option for transporting liquid argon and other cryogenic liquids across different modes of transportation.

0 notes

Text

Tank Container Shipping Market Growing Popularity and Emerging Trends in the Industry

Latest study released by AMA Research on Global Tank Container Shipping Market research focuses on latest market trend, opportunities and various future aspects so you can get a variety of ways to maximize your profits. Tank Container Shipping Market predicted until 2027*. Effective shipping is the key to improving supply chain performance. Tank containers are attractive from the perspectives of safety, cost, and environment, and are widely used for transporting fluid chemicals. Minimizing the logistics costs arising from the container flow imbalances across the world and container cleaning is a major issue that chemical companies and affiliated third-party logistics organizations face normally. Furthermore, tank containers deliver sustainable transport and it is re-usable. Highly sophisticated logistics methods are used to transport the tank container from points of loading to discharge.

Some of Key Players included in Tank Container Shipping Market are Bulkhaul Limited (United Kingdom),HOYER Group (Germany),NewPort Tank Containers (United States),Stolt-Nielsen Limited (SNL) (United Kingdom),Den Hartogh Logistics (Netherlands),Bertschi Group (Switzerland),Suttons Group (United Kingdom),Gruber Liquid Logistics (Germany),Eagletainer Logistics (Singapore),Intermodal Tank Transport (United States)

Market Trends: Growth of Intermodal Shipping Transportation

Drivers: Increasing Demand From Oil and Gas Industry

Growing Use of Fleet Management Systems

Challenges: Difficult To Transport Under Slack (Partially Full) Conditions

Opportunities: Low Cost and Suitable Mode of Transportation The titled segments and Market Data are Break Down by Type (Wines & Spirits, Fruit Juices, Sweet Oils, Chemicals, Fuels, Toxic Substances, Gases, Others), End User (Oil & Gas, Chemicals, Petroleum, Others)

Presented By

AMA Research & Media LLP

0 notes