#Injection molded plastic auto parts

Explore tagged Tumblr posts

Text

Material for the component is put into a heated barrel

Injection molded plastic auto parts is a manufacturing technology that enables for the production of huge quantities of items. The plastic injection molds operates by pouring molten materials into a mould (or'mold' in the US). It is frequently used in mass manufacturing to produce thousands of similar goods. Metals, glasses, elastomers, and confections are all injection moulding materials, however it is most typically employed with thermoplastic and thermosetting polymers. The material for the component is put into a heated barrel and combined using a helical curved screw after the mould has been made by the blow mold design.

0 notes

Text

What Industries Is Injection Molding(Moulding) Applicable To?

Injection moulding is a common manufacturing process by injecting molten plastic material into a mould so that it can be formed into the desired product shape upon cooling.

Injection moulding process has the advantages of low cost, high production efficiency and stable product quality to make it widely used in various industries. In this vast injection moulding market, there are three industries are particularly eye-catching, which are extensively used for production and manufacturing due to their specific needs and product characteristics.

1.Household Appliance Manufacturing Industry

As an indispensable part of people's daily life, the market demand for household appliances is stable and continuously growing. The injection moulding process plays a pivotal role in the manufacturing of household appliances, from the outer shell to the internal components, injection moulding technology provides key support. Most of the exterior and structural components of home appliances, such as TV remote controls, refrigerators, TV sets, air-conditioning panels, and washing machine shells, are manufactured by injection molding process.

2.Automotive Components Industry & Transportation Sector

With the booming development of the automotive industry, the auto components and parts market has ushered in unprecedented development opportunities. Components and parts such as automotive dashboards, door interior panels, bumpers, and lamp housings as well as a wide range of pipework and connections are made through the injection moulding process. These parts require not only high precision and good mechanical properties, but also need to meet the strict appearance requirements, which injection moulding process is precisely by virtue of its unique advantages, in this field to occupy a place. In addition, with the rise of new energy vehicles, injection moulded parts play an important role in the manufacturing of key components such as battery packs and motor housings.

3.Medical Device Industry

With the increasing emphasis on health, the market demand for medical devices continues to grow. In medical device manufacturing, the injection moulding process is used to produce disposable medical devices such as syringes, infusion tubes and surgical instruments. These products require strict quality control and hygiene standards, and injection moulding process ensures product safety and effectiveness.

In addition, the injection moulding process is also widely used in the electrical and electronic industry, consumer electronics, packaging industry, toy manufacturing, construction materials, industrial parts, furniture and household furnishings and agriculture, among many others.

4.Electrical & Electronic Industry

In the manufacturing process of electronic products, many components such as housings, cases, sockets, connectors, cables, switches and holders for electronic circuit boards need to be manufactured by injection moulding process. Injection moulding process can achieve precise control of product appearance, size and structure, to meet the requirements of electronic products for appearance quality, functionality and reliability.

5.Consumer Electronics Industry

In the electronics industry, injection moulded parts are equally widely used. From mobile phone housings, computer components including keyboards and mice to remote controls and battery cases, the injection moulding process offers a wide variety of appearance and structure options for electronic products. These components not only need to have good mechanical properties and appearance, but also need to have excellent electrical insulation properties to ensure the stable operation of electronic products. Injection moulding technology occupies an important position in the manufacture of electronic products due to its advantages of high precision and low cost.

6.Construction Sector

In the construction field, injection moulded parts also have a wide range of applications, the drainage systems, door and window frames, pvc pipes, valves, wire troughs, insulation materials and other construction materials and accessories are mostly manufactured by injection moulding process. These components are not only high-strength and corrosion-resistant, but also weather-resistant and easy to install, meeting the construction industry's requirements for material performance and ease of use and improve construction efficiency and aesthetics. The application of injection moulding technology in the construction field not only improves the performance and quality of construction materials, but also promotes the sustainable development of the construction industry.

7.Packaging Industry

The packaging and container industry is also one of the key application areas for injection moulding processes. Plastic bottles, food boxes, cosmetic bottles, plastic bags and other packaging containers are mostly manufactured by injection moulding process to meet food safety and aesthetic requirements. These containers need to be well-sealed, drop-resistant, retain freshness and recyclable to ensure that the products are safe and environmentally friendly. Injection moulding processes can offer flexible design and manufacturing options to adapt to different packaging needs and provide strong support for the development of the packaging industry.

These areas above are just a few examples of the application areas of the injection moulding process. In the toy industry, injection moulded parts are used to manufacture a variety of plastic toys; In the textile and clothing industry, injection moulded parts are used to manufacture accessories such as zips and buttons; In the agricultural sector, injection moulded parts are used to manufacture agricultural tools and equipment such as sprayers and watering cans; Even in the aerospace sector, injection moulded parts are also used to manufacture parts for aircraft and spacecraft. It can be said that injection moulded parts have penetrated into almost every corner of our life.

In summary, injection moulded parts play an important role in several industries by virtue of their high precision, low cost and wide applicability. The application of injection moulding process in these areas not only improves production efficiency, but also meets the needs of product diversification and individualisation. With the continuous progress of science and technology and the continuous improvement of people's requirements on product quality, injection moulding technology will continue to be widely used and developed in various fields.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#injection molding#plastic injection molding#injection moulding machine#injection moulding#plastic injection#injection molded#injection molding parts#injection molded parts

2 notes

·

View notes

Photo

New approach for rapid process stabilization of plastics

Plastic materials are prone to degradation by atmospheric oxygen. These auto-oxidation reactions occur at ambient temperature but become especially relevant during melt processing. Adding antioxidants to the polymers results in a pronounced slowing-down of the oxidation processes. Only in this way, the production of plastic parts by injection molding, for example, is possible.

Developing new plastic grades is accompanied by lengthy experimental procedures to optimize the antioxidant content. For Fraunhofer Institute for Structural Durability and System Reliability, these online rheological investigations are a promising method for accelerating the development process.

Antioxidants

Organic matter, and therefore also plastics, degrade by auto-oxidation when in contact with air. This degradation is initiated by elevated temperature or light and propagates as a radical chain reaction that causes cleavage of the polymer chains. The latter are primarily attacked by the OH radical resulting in the formation of hydroperoxide moieties. These triggers follow-up reactions leading to regeneration of the OH-radical.

Read more.

19 notes

·

View notes

Text

automation almost never looks like a person getting replaced by a machine. I'm going to call that "the android fallacy". what it does look like is process changing to something completely different that may or may not be enabled by new technology. coders getting automated away doesn't look like copilot it looks like squarespace and shopify. train drivers getting automated away doesn't look like self-driving trains it looks like longer trains that have the same number of drivers. textile workers making shoes getting automated away doesn't look like robotic sewing machines it looks like making shoes out if injection molded plastic foam instead of fabric or leather. call center workers getting automated away doesn't look like AI chatbots it looks like people filling out web forms instead of calling on the phone. auto assembly workers getting automated away doesn't look like fancier robot arms it looks like moving to large castings instead of welding and riveting together large numbers of smaller stamped parts.

8 notes

·

View notes

Text

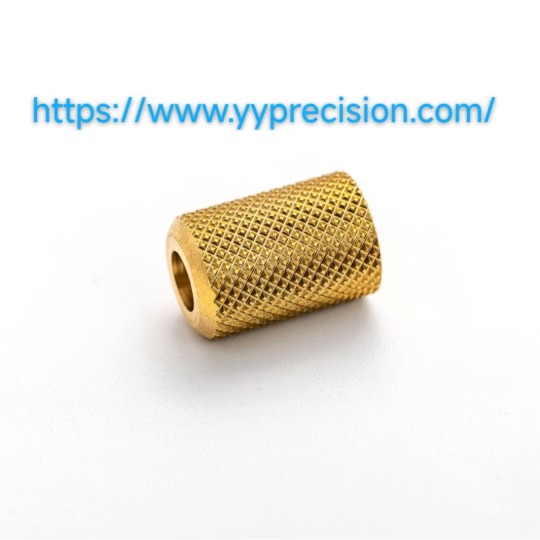

Fastening connection function:

In mechanical equipment: used to connect two or more mechanical parts to ensure the stable operation of the equipment. For example, in some small transmission devices, instruments and other equipment, circular knurled nuts can firmly connect different parts together, withstand a certain vibration and tension, and prevent parts from loosening or separation.

In the field of construction: It can be used to connect various components in the building structure, such as in steel structure buildings, round knurled nuts can be connected to steel beams, steel columns and other components to ensure the stability and safety of the building structure.

Easy to manually operate and adjust: The pattern on the surface of the knurled nut can increase the friction, and it is convenient for people to directly twist the nut by hand without the help of other tools, which is very practical in some occasions that need to be adjusted or disassembled frequently. For example, on some equipment that requires frequent adjustment of height or Angle, the use of circular knurled nuts can be easily adjusted manually.

For injection molding and embedding process: In the injection molding process of plastic products or other materials, the round knurled nut is pre-buried in the mold, and then the injection molding is carried out to make the nut and the plastic part tightly. This can form a strong threaded connection structure on the plastic products, which is convenient for subsequent assembly and use. For example, in the shell of electronic equipment, auto parts, toys and other plastic products, this kind of embedded round knurled nut is often used.

As a connector for thin plate connection: in the connection of some metal sheets, such as in the manufacture of chassis, cabinets, metal furniture, etc., round knurled nuts can be used with the pull riveting process. The nut is fixed on the thin plate by the rivet gun to realize the connection between the thin plate, which is both firm and beautiful, and can avoid welding or tapping operations on the thin plate, and reduce the damage to the thin plate.

In furniture manufacturing: used for the assembly and connection of furniture, such as the frame connecting tables and chairs, the panel fixing furniture, etc. The appearance of the knurled nut can be selected according to the design requirements of the furniture, which meets the functional requirements of the connection without affecting the aesthetics of the furniture.

0 notes

Text

The Future of Production: How Advanced Manufacturing is Shaping the World

Tailoring Parts to Specific Needs

Custom component manufacturing on the other hand takes its roots in manufacturing parts to order as per demand in different fields. Thus it is possible to obtain parts with specific unique and accurate characteristics required for a specific area of application. Custom component manufacturing refers to processes such as CNC machining, injection moulding and 3D printing since the components are engineered specifically to the required parameters.

The Role of Injection Molding in Producing Synchronous Components

It is a very efficient technique of manufacturing products whereby a material in a molten state is forced into a mold to produce parts. The injection molding process is a necessary technology in manufacturing in which a solid material such as the plastic or metal is initially heated to a liquid state and then injected into a mold. This process consists of several stages.

Because of the capability to deliver parts with high dimensional accuracy and consistency, injection molding is a dependable process for large volume production.

It is particularly suitable for creating vast numbers of synchronous components with high accuracy.

Eliminating Fine Tuning with High-Tolerance CNC Machining

CNC machining is a modern technique of manufacturing parts using machines that are controlled by computers with high accuracy of the size of the parts to be produced. This process is very important for high accuracy application such as aerospace, auto mobile and medical devices. High accuracy achieved by the precision CNC helps in achieving a high quality in the performances of individual parts and in their reliability. Using precision CNC machining allows the manufacturers to produce products with high tolerances eliminating the need for subsequent fine tuning, hence improving production rates for lower cost.

High Tolerances and Small Runs with Custom CNC Machining

The use of Computer Numerical Control technology in the manufacturing of these parts is advantageous because it allows manufacture of small and specialized parts which may be required in specific uses. Custom CNC machining is particularly suitable for first piece machining applications and for small runs, and when high tolerances are called for. When choosing custom CNC machining, new products are evolved which may serve as a niche in areas of increased competition and the specific need of clients is met, starting from the type of material and finishing to the actual requirement for the part.

Reducing Costs and Time with Online CNC Services

Online CNC machining convenience includes ability of customers to order their custom parts through the internet where they provide their designs and specifications. online CNC machining makes accessing accurately manufactured bespoke parts possible for companies without initial face-to-face meetings. As a result of the options made available by online CNC machining, companies get to cut production time and costs while also being guaranteed of quality and reliability in their parts.

Saving Materials and Costs with Custom Sheet Metal Parts

Fabrication is convenient in that sheet metals can be cut, shaped and formed on-demand and this eliminates storage of large stocks of metal parts. This service will suit industries that produce small quantity or need quick turnaround on their products. In On demand sheet metal fabrication, the manufacturers are in a position to fabricate high-value, accurate and precise components that address all manufacturing specifications. On-demand fabrication of sheet metal is advantageous in saving materials, costs, and time to market for products.

Flexibility and Precision: Custom sheet metal parts have been developed planed for attractive on-demand that focuses on exact part needs for industries that require high turnaround time and small volume.

Cost Efficiency and Responsiveness: Through the on-demand sheet metal fabrication, enterprises can minimize waste and costs, and retain the ability to adjust the product offering to the customers’ demand without holding a ton of inventories.

Rapid Design-to-Market with Metal 3D Printing Services

The 3D metal direct part production services provide solutions to manufacturing through the fabrication of geometries of metal parts from STL files. There are benefits to using metal 3D printing services and these include the ability to design and get the products to the market much faster, minimal wastage of materials and parts that are stronger and more durable than those made from conventional methods.

Creating Complex Designs with Metal 3D Printing

Conventional metal 3D printing offers an opportunity to create required articles from metal with certain characteristics. This technology makes it possible to produce designs which are at least difficult to fashion through normally used techniques of production. The use of customized metal 3D printing is critical in case where accuracy and tailored solutions must be obtained. What the use of custom metal 3D printing has made it possible for manufacturers is the ability to create prototypes, limited-run parts and components with enhanced mechanical properties which are tailored to what is needed in the specific project.

Meeting Specific Needs with Custom Metal Parts Manufacturing

Custom metal parts manufacturing is a process of manufacturing metal parts particular to the requirement of a given project. Some of the activities involved in this process may comprise of; Computer Numerically Controlled Machining, Metal Casting, and 3D Printing. Custom metal parts manufacturing are crucial for sectors where firms require high quality and specific metal part that are difficult to obtain from regular sellers. Thus, when a company decides to go for a custom manufacturing of metal parts, it is guaranteed of quality and efficiency of the manufactured parts.

Reducing Lead Times and Costs with On-Demand CNC Machining

On-demand CNC machining enables organizations to get the manufacturing services that they desire, at the time that they want them, without having to purchase a lot of parts from the manufacturers that specialize in CNC machining. On demand CNC machining is an effective way of cutting on lead times and the costs of production while at the same time keeping high standards of quality necessary for a business.

High-Quality Enclosures and Brackets

Hardware manufacturing industries rely on sheet metal fabrication work so as to produce sturdy and high quality parts that may be incorporated in a number of products. This process entails machining of metal sheets to produce forms including enclosures brackets and fasteners through processes like cutting, bending and assembling.

Sheet metal fabrication for hardware manufacturing industry enables the creation of different parts such as enclosures, brackets, and fasteners, which are accurate needed.

Through using sheet metal fabrication in hardware manufacturing industries, industries can create quality parts to the increased performance details in the hardware industry.

Building Reliable Hardware with Component Manufacturing

Component manufacturing for hardware manufacturing industry means making small but compact parts used in the manufacturing of hardware product like screws, nuts bolts, holders, wrenches, etc. Component manufacturing for hardware manufacturing industry enables firms to develop and build efficient hardware products that conform to the industry standards.

High-Quality Hardware Manufacturing with Urethane Casting

Urethane casting in the manufacturing of hardware using urethane makes it possible for the manufacturing of high quality and hard wearing part especially in small to medium quantity. This process entails the construction of molds, and utilizing urethane to fabricate parts including, gasket and seals, housing among others. Urethane casting for hardware manufacturing industry allow for an additional degree of freedom in the design and material choice –the process is appropriate for prototyping and short series production.

Reliable and Sturdy Defense Equipment through Urethane Casting

Urethane casting for defense industry is crucial in manufacture of sturdy and long-lasting products to be used in defense. Urethane casting for defense industry provides an opportunity to shape components from aerospace materials with the necessary degree of hardness and elasticity. The use of urethane casting for defense industry brings the assurance to the producers that the end products can perform to the toughest requirements expected in the defense units, durability and efficiency in emergency use.

Versatile Urethane Casting in Energy Industry Manufacturing

Optimizing Robotic Systems with Urethane-Cast Grips and Enclosures

Urethane casting in robotics industry is vital in coming up with components with flexibility, durability, and accuracy in performing their functions. This process is well suited when it comes to manufacture of mainly parts like grips, bumpers and enclosures which are used in robotic systems. Urethane casting for robotics industry facilitates complex parts for the industry to be cast in a way that will directly address need of using robotics while at the same time guarantee efficiency and durability of the parts in use.

Meeting Consumer Product Standards and Specifications

Parts employed in household articles and gadgets, ranging from electronic products to home use appliances. This process ensures that part have been manufactured to high accuracy so that they can meet the quality and performance of consumer products. In consumer products industry, the benefits of CNC machining include the ability to produce component parts for products that can be made to specific requirement of the design. When CNC machining for consumer products industry is emphasized, the manufacturers are able to produce the required products that are durable and create higher customer satisfaction.

CNC machining for consumer products industry facilitates part manufacturing for various consumer products, with high level of accuracy, for consumer products such as electronics and home appliances.

Adopting the CNC machining for consumer products industry allows the developers of products to use computer numerical control in order to develop high-value components and assemblies that meet the required standards and specifications in order to deliver efficient and innovate products that will meet consumer demand.

Durable and Flexible Parts for Electronics with Urethane Casting

Urethane casting to electronics manufacturing industry is crucial because many of the parts made need to be insulated, flexible, and extremely durable. This process is perfect for making parts such as connectors, enclosures and protective covers of electronic gadgets. Urethane casting for electronics manufacturing industry has one major advantage in the sense that it creates parts that are suitable for use in electronics in that they can easily be tailored to fit the particular demand of the application in use.

Streamlining Robotics Innovation Through Rapid Prototyping

Tailored Solutions for Consumer Products

Urethane casting for the consumer products industry is a suitable way of manufacturing a number of strong and high end parts that can be applied on different consumer products. This makes it possible to have elements such as grips, handles, and enclosures which must be rather flexible and capable of withstanding a certain pressure. Urethane casting for consumer products industry allows making custom parts in relatively small to average amounts; thus, it is most suitable for creating highly specific or short-run items.

Medical Components via Urethane Casting

Medical grade urethane casting is important because the medical industry demands high performances of the components that will be used. This process is useful when one needs to make part such as prosthetic limbs, medical device casings, or customized orthopedic appliances that must be flexible, hard-wearing, and biocompatible. Urethane casting for medical industry provides for the production of components which are bespoke to the medical application requirements and ensure durability.

Meeting Demands of Industrial Equipment

Urethane casting for industrial equipment Industry is particularly relevant for making parts that end users expect to work under heavy loads and in harsh conditions. Industrial equipment industry urethane casting provides the advantage to create individual part with properties that industrial purposes require, to provide durability and functionality. Specialization on urethane casting for industrial equipment industry allow creating the high-quality equipment needed for a variety of industries.

Sheet Metal in Energy Manufacturing

Energy manufacturing is a vital process as it involves fabrication of sheet metals which are used in making of energy products that in one way or the other are involved in energy production and distribution. It includes Sheet Metal Working, in which metal sheets are shaped into components such as enclosures, frames, and panels applied in energy systems. Sheet metal fabrication for energy industry involves the production of each individual part in its precise measure, the strength and quality needed is guaranteed.

Energy industries require various components and structures such as enclosures, frames and panels for energy equipment and systems and fabrication of sheet metal is vital in preparing these parts and guaranteeing they are of right characteristics of strength to endure certain conditions.

On using sheet metal fabrication for energy industry, manufacturers are able to have precise designs of energy systems that are durable and efficient for use in sustainable energy practices.

Micro Urethane Casting

Specialized Aerospace Components through Urethane Casting

Urethane casting for aerospace industry is very important since many parts required for the construction of planes and other flying equipment is subjected to high pressures and temperatures as well as being required to meet high safety requirements. This process is suitable for production of such parts as seals, gaskets and protective covers used in aircraft or spacecraft. Urethane casting for aerospace industry has the advantage of the ability to create components for aerospace that are specialized for the particular application and will perform with accuracy.

Key to Electronics Precision and Speed

CNC Machining plays a key role in the Electronics Manufacturing Industry. It uses machines controlled by computers to make exact parts that electronic devices need. This method ensures high precision and uniformity, which makes it perfect to create complex pieces like connectors, housings, and enclosures. In the world of electronics, cnc machining for electronics manufacturing industry allows quick production of intricate designs with strict tolerances.

The Power of Composite Materials

Composite material manufacturing for consumer products industry is essential for producing components that require a combination of strength, durability, and lightweight properties. This process involves the use of advanced materials like carbon fiber, fiberglass, and kevlar to create parts used in various consumer goods. Composite material manufacturing for consumer products industry offers the ability to produce custom components that meet the specific needs of consumer applications, ensuring reliable performance.

Quick Fixes for Energy Innovations

Rapid prototyping in the context of energy industry is a key in the build up of the energy systems. This process that enables designers and engineers to make and test designs and models in a short time permits the production of a product that meets certain standards. Rapid prototyping for energy industry favors fixes on this aspect to allow for changes on the designs before proceeding to mass production.

Conclusion

In conclusion, the current manufacturing has greatly evolved with the advancement of the new technologies including injection molding, precision CNC machining, and the custom metal 3D printing. They have therefore evolved as crucial processes in manufacture of high quality and durable parts and components in different sectors. This means that as manufacturers go for new innovations the capability to provide On-Demand Sheet Metal Fabrication and other specialized services offers them the opportunity to address all the request of the market. The advanced manufacturing does not only improve the production quality but also provides the custom and reliable solutions to improve the manufacturing possibilities.

FAQS

What industries benefit from on-demand sheet metal fabrication?

This service is popular in such spheres as automotive, aerospace, electronics, industrial equipment manufacturing, as well as other industries necessitating production of stably and accurately shaped metal parts.

What is the role of urethane casting in manufacturing?

Urethane casting is suitable for the making of superior prototype and closely limited production runs. It is versatile in its design and can produce near net shape and close tolerance parts with the appearance of injection molded parts with out having to invest in expensive tooling.

How does composite material manufacturing benefit the defense industry?

Manufacture of composite materials give lightweight but higher strength structures to the defense fraternity in areas like armors, aircrafts and UAVs.

0 notes

Text

How to Ensure the Accuracy of Injection Molding Products?

In today’s modern industrial production, plastic injection molding technology has become extremely important. Injection molding plays an irreplaceable role in the fields of home appliance shell, auto parts, medical equipment, and household necessities. However, many companies often face a problem in the production process: how to ensure the accuracy of injection molding products? Today, we will discuss the factors that affect the accuracy of injection molding products, and share the secrets of improving accuracy for you.

1. Design molds and make molds

Mold is one of the key components of injection molding, and its design and manufacturing quality directly affect the accuracy of the final product. Scientific and reasonable mold design can ensure the uniform flow of plastics in the mold, reducing the possibility of defects and deformation. The key to ensure the service life of the mold and the accuracy of the product is the high-precision mold processing and heat treatment process.

2. Choose the right plastic raw materials

The characteristics of plastics have a great impact on the quality of injection molded products. The fluidity, shrinkage and thermal stability of various plastic materials are different. The selection of plastic materials that meet the needs of the product can effectively reduce the deformation and shrinkage during the molding process, thereby improving the quality requirements of the product.

3. Control the molding process

Molding parameters are the key link of plastic injection molding. Controlling the appropriate process parameters, such as temperature, pressure and time, directly affects the molding quality and appearance accuracy of the product. Scientific and reasonable parameter setting can ensure that the plastic is fully filled in the mold, reduce bubbles, shrinkage and other defects, and improve the quality of the product.

4. Improve the post-processing technology

The treatment of the late process of the product is also one of the factors that affect the quality of the product, such as heat treatment, cooling and removal of burrs after the product is moulded. It is necessary to eliminate the internal stress in the molding process by appropriate treatment methods, reduce deformation, and thus improve the quality of the product.

5. Establish a quality control system

Ensuring the accuracy of injection molding products is a key aspect of establishing a sound quality control system. From the entry of raw materials into the warehouse to the shipment of products, every step needs to implement strict quality inspection management. Through regular inspection and evaluation, timely detection and resolution of problems to ensure that product quality remains stable and accurate.

Only by continuously improving and perfecting these steps can we ensure the high quality requirements of injection molding products. If you have any questions related to injection molding technology or need more help, please feel free to contact us and we will do our best to answer your questions.

0 notes

Text

ERP for Plastic Manufacturing Industry

safal erp for plastic manufacturing industry is the best .SAFAL have worked a lot with client into plastics industry like FIBC, Woven Sack, Non Woven, as well as manufacturers which are into technical textiles like geosynthetics material, technical fabric, fiberglass fabric, PTFE membrane, etc. Our customer consists of manufacturers of auto plastic components like plastic mold components like auto parts, pharma containers, consumer items, packaging parts, computer peripherals, electric parts. Using our Plastic ERP software for molding industry, we have mapped major processes that involve injection molding, extrusion and vacuum forming.

#erpforplasticmanufacturingindustry#erpforplasticmanufacturingindustryfree#besterpforplasticmanufacturingindustry

0 notes

Text

The role of injection molded plastic components in the automotive component revolution

In the ever-evolving landscape of auto part manufacturing, the utilization of injection-molded plastic components has emerged as a game-changer, redefining industry standards and pushing the boundaries of innovation. Among the trailblazers in this field is Taizhou Toolsong Mould Co., Ltd., a company dedicated to transforming the automotive sector through cutting-edge injection molding technology.

The Significance of Injection Moulded Plastic Components:

Injection molding has become a cornerstone in the production of auto parts due to its unparalleled efficiency, precision, and versatility. Plastic components manufactured through this process offer a myriad of advantages, such as lightweight design, intricate detailing, and cost-effectiveness. This has led to a surge in demand from auto part manufacturing companies aiming to enhance both the performance and aesthetics of their products.

Taizhou Toolsong Mould Co., Ltd.'s Expertise:

At the forefront of this revolution is Taizhou Toolsong Mould Co., Ltd., a company renowned for its expertise in producing high-quality injection-molded plastic components for the automotive industry. With state-of-the-art facilities and a team of seasoned professionals, the company has positioned itself as a leader in delivering customized solutions tailored to meet the specific needs of auto part manufacturers.

Precision Engineering and Quality Assurance:

One of the key strengths of Taizhou Toolsong lies in its commitment to precision engineering. The injection molding process is meticulously controlled to ensure that each component meets the strictest quality standards. This dedication to excellence not only enhances the overall performance of auto parts but also contributes to the longevity and reliability of the final products.

Material Innovation and Sustainability:

Taizhou Toolsong Mould Co., Ltd. places a strong emphasis on material innovation, exploring advanced polymers and composites to create components that are not only durable but also environmentally sustainable. As the automotive industry pivots towards eco-friendly practices, the company's dedication to sustainable manufacturing aligns with the growing global demand for greener alternatives.

Collaboration and Customization:

Recognizing the diverse needs of auto part manufacturing companies, Taizhou Toolsong Mould Co., Ltd. fosters collaboration by offering customized solutions. Whether it's designing intricate interior components or crafting robust exterior elements, the company's skilled engineers work closely with clients to bring their vision to life, contributing to the unique identity of each automotive product.

Global Impact and Future Prospects:

The impact of Taizhou Toolsong Mould Co., Ltd. extends beyond its home base, reaching auto part manufacturers globally. The company's commitment to innovation and quality has positioned it as a trusted partner for those seeking to stay ahead in an ever-competitive market. As the automotive industry continues to evolve, Taizhou Toolsong remains poised to play a pivotal role in shaping its future.

In conclusion, the integration of injection-molded plastic components in auto part manufacturing is reshaping the industry, and companies like Taizhou Toolsong Mould Co., Ltd. are at the forefront of this transformation. Their dedication to precision, quality, innovation, and sustainability underscores the crucial role that injection molding plays in advancing the automotive sector. As the demand for superior auto parts continues to rise, Taizhou Toolsong's commitment to excellence ensures a bright and innovative future for the industry as a whole.

0 notes

Text

Driving design: The fascinating world of auto bumper moulds for automotive aesthetics

Automotive design is a complex and fascinating process that involves numerous components, and one crucial aspect that significantly influences a vehicle's aesthetics and safety is the auto bumper. In this article, we delve into the world of auto bumper moulds, exploring their importance, design considerations, and their impact on automotive aesthetics.

Importance of auto bumper moulds: Auto bumpers serve as the first line of defense in protecting vehicles and their occupants in the event of a collision. They absorb and distribute impact forces, reducing damage to critical components and enhancing passenger safety. Beyond functionality, bumpers also play a significant role in defining a car's exterior appearance, contributing to its overall design language and aesthetic appeal.

Material selection: The choice of materials for auto bumper moulds is critical. Traditionally, bumpers were made from metal, but modern vehicles predominantly use plastic materials like polypropylene or polyurethane. Plastic offers several advantages, such as being lightweight, cost-effective, and providing design flexibility for creating intricate shapes and curves.

Auto bumper mould injection moulding process: Most auto bumpers are manufactured using injection moulding, a highly efficient and cost-effective production method. Injection moulding involves injecting molten plastic into a mould cavity under high pressure. The mould, designed with the desired bumper shape, allows for the creation of consistent, high-quality parts at a rapid rate.

Design considerations: When designing auto bumper moulds, several factors are taken into account. These include crashworthiness, aerodynamics, pedestrian safety, and aesthetics. Engineers and designers work together to create bumper designs that not only comply with safety regulations but also enhance the vehicle's overall visual appeal.

Aesthetics and brand identity: Bumpers contribute significantly to a vehicle's exterior design and can play a crucial role in establishing a brand's identity. Automotive manufacturers carefully craft bumper designs to align with their brand's signature look and style, helping consumers identify and connect with their products.

Innovative designs: With advancements in manufacturing technologies, auto bumper moulds have become more sophisticated. Innovative designs now incorporate features like integrated sensors, cameras, and aerodynamic elements to improve vehicle performance and driver assistance systems.

Customization and personalization: Auto bumper moulds allow for a high level of customization and personalization. Manufacturers can create distinct bumper designs for different vehicle models or offer optional styling packages to cater to diverse customer preferences.

Sustainability: In recent years, sustainability has become a significant concern in the automotive industry. Auto bumper moulds are now being designed with eco-friendly materials and processes to reduce their environmental impact and support efforts towards greener manufacturing.

Future trends: As the automotive industry continues to evolve, bumper designs will likely adapt to accommodate new technologies and safety features. Moreover, with the rise of electric vehicles and autonomous driving, auto bumper moulds may need to incorporate specific design elements to address the unique requirements of these vehicles.

In conclusion, auto bumper moulds play a pivotal role in shaping the aesthetics and safety of modern vehicles. Through careful design considerations, auto bumper mould manufacturers can create innovative and visually appealing bumpers that not only enhance a vehicle's exterior appearance but also contribute to its overall performance and passenger protection. As technology advances, we can expect further exciting developments in the world of auto bumper moulds, reflecting the dynamic nature of the automotive industry.

0 notes

Text

Auto Parts Car Bumper Plastic Injection Mold Factory Price Oem Injection Mold Customized Plastic Auto Car Parts Bumper Mould Wechat/Whatsapp:008613389007166 Email: [email protected]

#carbumper#mold#mould#injectionmolding#plasticmold#plasticmoulding#plasticinjectionmolding#plasticinjection#carparts#autoparts#sikaida

1 note

·

View note

Text

Resembles the act of injecting fluids using a syringe

Molds are used in plastic injection mold process. Materials such as synthetic resins (plastics) are heated and melted before being poured into a mould and chilled to make the desired shape. This procedure of plastic injection molding companies near me is known as injection moulding because it resembles the act of injecting fluids using a syringe. The following is the process plastic auto parts manufacturers flow: Materials are melted and put into the mould, where they solidify before being removed and completed.

#plastic injection molding companies near me#plastic injection mold#plastic auto parts manufacturers

0 notes

Text

LIQUID SILICONE RUBBER INJECTION MOLDING

LIQUID SILICONE RUBBER INJECTION MOLDING

Following our vision for constant inovation, and to satisfy the needs of our customers, we have invested in a new 160T injection machine featuring a Liquid Silicone Rubber (LSR) injection unit. This new Arburg machine, along with 5 others, is part of the investment made in our new factory.Get more news about Silicone Injection Molding,you can vist our website!

Liquid Silicone Rubber LSR is an elastomer which has become the choice material for the manufacturig of many products due to its durability and high resistance to temperature and chemicals. Liquid silicone rubber’s mechanical and electrical properties make it ideal for insulation and conductivity protection.

Liquid silicone rubber results from adding two components – a catalyst and a cross linking agent. A dosage system mixes both, as well as dyes and additives if desired. This new mixture is then injected and vulcanizes rapidily at very high temperatures. Often, liquid silicone is overmolded onto other parts made of different plastics.

Click here to know more about liquid silicone rubber.

Aplications This material has thousands of aplications in several industries, such as electronics, auto, aerospacial, garden tools, etc. Because of its biocompatibility it has great usage potential in the medical field, especially in the manufacturing of organs, membranes and prosthetics.

Typical applications for liquid silicone rubber are products that require high precision such as seals, sealing membranes, electric connectors, baby and children’s products where smooth surfaces are desired, ( eg. bottle nipples), medical applications as well as kitchen goods such as baking pans, spatulas, etc.

More than an Injection Moulding service With liquid silicone rubber injection we broaden our service portfolio when supplying finished and semi-finished products. These include design and development, thermoplastics injection moulding, hot stamping and ultrasonic welding, assembling and supply chain management.

Our main objective is to present solutions to support the improvement of processes and the satisfaction of our clients’ expectations. Simplastic’s team of Engineers will work with you to develop all the tools needed for industrialization and maximum process efficiency. The Quality Department will make sure that the final product fully matches your brief and technical specifications. We work with well established transportation networks and our team is fluent in portuguese, spanish, french, english and german.

0 notes

Text

Some Major Benefits of Plastic Injection Molding

Plastic injection molding is a very adaptable manufacturing process. The reason for this is that this form of injection molding has many advantages over the more conventional procedures. This approach is easy to implement, trustworthy, and more productive. Because of this, it is widely used in the production of many components.

Intricate Detail and Complicated Shapes

Plastic Parts Mass Production or molding, as we all know, requires a great deal of pressure. Because of this intense strain, the components might have many intricate design features. However, the high pressure also aids in the creation of intricate designs. It is possible to do the same thing by other means, but they will be prohibitively expensive and difficult to implement.

Extremely Effective

When compared to other Overmolding Process and techniques, the molding procedure becomes rather quick after the molds have been designed. The time required for plastic injection molding is quite short. More parts may be produced in less time with this method.

So, this approach is so much more productive. The quality of these pieces tends to be more stable over time. However, adjusting the hues will be a cumbersome process.

Increased Power

Fillers can be incorporated into the plastic Injection Mold Inserts process. They can reduce the plastic's density while molding it. Furthermore, they might contribute to the reinforcement of the parts. The strength requirements of a given application can be met with the aid of plastic molding.

In fact, greater durability is one of the primary reasons why most manufacturers favor this method.

Wide variety of plastics are used

The ability to use multiple plastic types at once is a significant benefit of this method. Co-injection molding is one method that can be used to achieve this goal. Therefore, manufacturers are no longer restricted to using only one type of plastic.

Automating processes to cut costs

Because it is automated, significant cost savings are attainable. Most of it is done by machines and robots. There is only room for one person to operate these machines. This leads to a dramatic reduction in production costs.

In addition to this, overall production costs decrease. As a result, the cost tag is more reasonable, allowing even budget-conscious shoppers to place an order. Insert Injection Mold may now be made with pinpoint accuracy thanks to automation. Close tolerance during mold production is possible because to the use of CAM and CAD.

Rapid Injection Molding is useful for producing components that do not call for extensive finishing. When an item is removed from its mold, it is finished in every way.

The plastic parts found in toys & medical equipment are manufactured via injection molding all over the world. There are millions of parts produced in the same way for the auto and aircraft industries. You can find countless examples of plastic molding all around you.

This method is widely used today because of its low environmental impact. We recycle the plastic that we gather. Thus, very no residue is left behind. So, there you have it; that was a rundown of some of the more widespread benefits of plastic injection molding.a

0 notes

Text

Exploring the Vital Role of Automotive Fasteners and Their Production Materials.

Auto part manufacturers rely on various joining mechanisms! They often need to join and connect other components to panels. From dowels and clevis pins; to screws, bolts, and nuts Many fasteners can be used in this scenario! Automotive fasteners are essential components that keep parts together. A range of panel fasteners are engineered to meet manufacturing requirements in automotive industries and other industries such as electronics, construction, aerospace, HVAC, and more.

The Importance of Automotive Fasteners

The images of diverse engine parts, hefty doors, or wheels come to mind when we think of automotive parts. The truth is that the typical vehicle consists of over 30,000 tiny pieces! The majority of them are classified under the automotive fastener category. The term "fasteners" is a collective noun that refers to all small parts like bolts, nuts, screws, spacers, or springs. Most of them are used in almost all car components. You must choose the right one and the right material before its application.

Automotive panel fasteners are available in a variety of sizes and designs, are adaptable, and may be replaced. They firmly arrange car parts by mechanically holding them together. Except for rivets, all automotive fasteners are typically temporary. It suggests that it should be possible to separate the parts from one another without causing any damage after removing the fastener. Additionally, the purpose of automotive fasteners need not be confused with that of glues and adhesives. Because they use tensional force to affix automotive parts, they are distinct from one another. As a result, a vehicle is unharmed under adverse circumstances (such as an accident) or after speed bumps.

The Materials Used in Automotive Fasteners?

Two fastener types are mainly employed in automobile projects. These are:

1. Metal Fasteners: The most frequent materials used in automotive projects are iron or aluminum alloy. The majority of bolts are covered in zinc to prevent rust and increase longevity because it is typically the most resilient and reusable material. Produced from wire and bar stock, bolts, screws, nuts, and spring fasteners are used to secure large objects, engine parts, and suspension components.

2. Plastic Fasteners: Plastic fasteners are frequently used to make connections, pins, washers, and spacers. Plastic fasteners are produced by injection molding and are made of vinyl. The materials are less expensive and don't conduct heat or electricity or rust.

The most important factors to consider while shopping for car panel fasteners are dependability, security, and time efficiency.

Trusted automotive panel fastener solution providers like Car Clip Supplier ensure you have a reliable product irrespective of your need. You can use their products for better fastening and reduce your cost of repairing & maintenance! If you have questions about automotive panel fastening solutions, reach out to Car Clip Supplier at 0499001004 today.

0 notes

Text

What are the uses of EDM wire cut machine?

EDM wire cut machine is a high-precision metal cutting equipment, which uses the principle of electric spark discharge to cut metal materials through the discharge between the electrode and the workpiece. The working principle of the EDM wire cut machine is very complicated, but its application range is very wide, and it can be used to make various metal parts and molds.

The working principle of EDM wire cut machine:

The working principle of the EDM wire cut machine is to use the electric discharge between the electrode and the workpiece to cut the metal material. The electrode of EDM wire cut machine is a thin wire, usually copper wire or tungsten wire, it is called cutting wire. The workpiece, which is the metal material to be cut, is placed in a tank filled with a working fluid, usually a release agent or mineral oil.

When the distance between the electrode and the workpiece is very close, the charge on the electrode will start to jump, forming a spark discharge. These sparks jump back and forth between the electrode and the workpiece, forming an electric arc. This arc generates high temperature and pressure between the electrode and the workpiece, which melts and vaporizes the metallic material. At the same time, the operating fluid in the tank cools the electrodes and workpieces, preventing them from overheating.

Application of EDM wire cut machine:

The application of EDM wire cut machine is very extensive, it can be used to make various metal parts and molds. Here are some common applications:

Manufacturing mold

EDM wire cut machine can be used to make various molds, such as plastic molds, die-casting molds, injection molds, etc. It can be cut to very precise shapes and sizes, resulting in high-quality molds.

manufacturing parts

EDM wire cut machines can be used to manufacture various metal parts, such as auto parts, aviation parts, mechanical parts, etc. It can be cut to very precise shapes and sizes, resulting in high-quality parts.

manufacturing model

EDM wire cut machine can be used to make various models. Models are indispensable tools for various industries, and their precision and quality have an important impact on product quality and cost. Through high-precision cutting, models of various complex shapes can be manufactured to meet the needs of different industries.

making jewelry

EDM wire cut machine can be used to make all kinds of jewelry, such as rings, necklaces, earrings, etc. It can be cut to very precise shapes and sizes, resulting in high-quality jewelry.

manufacture electronic components

EDM wire cut machines can be used to manufacture various electronic components, such as circuit boards, chips, etc. It can be cut to very precise shapes and sizes, resulting in high-quality electronic components.

manufacturing medical devices

EDM wire cut machines can be used to manufacture various medical devices, such as scalpels, needles, etc. It can be cut into very precise shapes and sizes, resulting in high-quality medical devices.

EDM wire cut machine is a very important cutting tool with a wide range of applications. The future will continue to develop, providing more efficient, accurate, and reliable cutting services for various industries. https://www.bofengmachinery.com/What-are-the-uses-of-EDM-wire-cut-machine.html

1 note

·

View note