#Injection Molded Magnets

Explore tagged Tumblr posts

Text

Injection Molded Neodymium Magnet

Injection Molded Neodymium Magnet Injection molded magnets offer designers and engineers a material with virtually unlimited size and magnetic possibilities. Made by blending a magnetic material (NdFeB) with a polymer binder (PA6, PA12 or PPS), the magnets can then be injection molded like any other plastic. In addition to providing maximum shape complexity, these magnets can be overmolded…

#Anisotropic NdFeB#Injection Molded Magnets#injection molded NdFeB#Injection molded Neodymium magnets#magnetic material#magnetic powder#Magnetic Properties#Neodymium magnets

0 notes

Text

Design of Injection Mold for NdFeB Magnetic Inductor Based on PA Loading

1 NdFeB magnetic sensor element As shown in Figure 1, NdFeB magnetic sensor is an E-shaped piece with a total width of 59 mm. Among the three branch forks, length of a single branch fork is 26 mm and thickness is 7 mm. Branch fork has two layers and a single layer thickness is 2 mm. After parts are magnetized, connecting beam is S pole of magnetic pole, three branch forks are N pole of magnetic…

View On WordPress

#Design of Injection Mold#holding pressure#Injection material#injection mold#injection mold design#Injection Mold for NdFeB Magnetic Inductor#injection molding#injection molding machine#injection molding process#intermediate molding#Mold assembly#mold design#mold structure#Mold temperature#molded parts#molding#molding part#plastic parts#Powder metallurgy molding process#two-plate mold structure#two-plate molds

0 notes

Text

youtube

Some cool things about the techniques used on Memoir of a Snail: There was a bookshelf full of pots of pre-mixed colours to make sure the strict limited palette was used. Despite that, this film has more colour than any Adam Elliot film before it... Even if that colour happens to be brown. No green or blue were allowed in the building! And everything was dry-brushed.

They used clay yes, but also silicone, wire, plastic, cardboard, foil and paper among other things. Everything you see was physically sculpted by an artist in the studio. The pupils were magnetic and could be moved around the eyeballs which must have had metal inside.

Another cool thing I saw on the tour was artists injecting molten plasticine (from a slow-cooker) into like hundreds of silicone molds to make mouths ready for the animators to use. It was really cool getting to see the artists work and ask them questions. Unbelievably cool that that was even allowed. (3/5)

🐌

#stop motion#animation#memoir of a snail#adam elliot#snail#claymation#3d animation#technically#Youtube#snail posting

30 notes

·

View notes

Photo

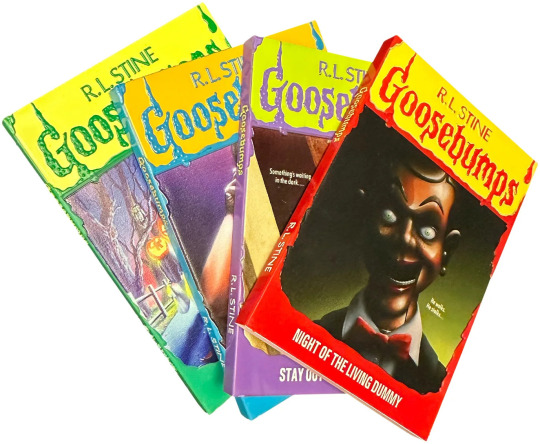

Trick or Treat Studios has turned four classic Goosebumps books - Stay Out of the Basement, Night of the Living Dummy, The Haunted Mask, and Attack of the Jack-O’-Lanterns - into magnets.

Priced at $15, each one measures 4" high and 2.5" wide. They’re made of injection molded plastic with painted details and printed artwork by Tim Jacobus. They're expected to ship in September.

#goosebumps#the haunted mask#slappy the dummy#rl stine#r.l. stine#r l stine#r. l. stine#trick or treat studios#toy#gift#book#haunted mask#night of the living dummy#tim jacobus#fear street

42 notes

·

View notes

Text

Techni3 Microwave Absorption Materials | Microwave Absorbing Foams UK

Absorbers

RF/Microwave Absorbers & Dielectric Materials

See our leading line for free space, cavity resonance, and near-field applications.

Why Laird? We are equipped with the technical know-how, software, and modeling capabilities to solve complex project issues.

As a leader in the design, development, and manufacturing of RF absorber materials, we understand that while material quality and design are important, being able to adequately solve and perfect challenges that arise during the design phase is key to a successful consumer experience. Our engineers thrive on innovation and welcome any request that comes our way. This is what separates us from our competitors – expert knowledge and high-quality products developed over decades.

We have a full line of microwave absorber stockists and mm wave absorber products for free space to cavity resonance through near field applications as well as low loss dielectric materials, such as filled polymers. Custom molded elastomeric and thermoplastic, reticulated foam, along with textile, liquids and custom composite products are on the shelf. Other key benefits include:

Testing, measurement and verification capabilities

Electromagnetic modeling and product design

Pre-loaded parameters in leading modeling software

Full custom formulation

Frequency band from MHz to > 100 Ghz

Integrated Multifunctional absorption solutions

Complete your project with the materials necessary for endurance and the expertise for long-term success. Take a look at our product sectors for more details and specifications. Or for a quick scan of some of our microwave absorber solutions, see this summary.

Explore Solutions

Low Loss Dielectrics

See our full line of high-quality, high performance, low loss dielectric materials ranging from 1.05-30 dielectric constant available in various formats from rigid to flexible, compact to foam.

Microwave Absorbing Foams

Low end cut-off RF absorbers of impregnated polyurethane foam. The standard solution to solve reflectivity issues.

Microwave Absorbing Gap Fillers

Lowering EMI noise and opening a thermal path, hybrid absorbers in interface configurations resolve compliance issues at minimum deflection force.

Elastomers and Films

Net good shielding from low to high frequencies and solve issues like internal cavity resonances up to the mm wave range. Suppress noise in the near field range.

Military Specialty Microwave and Custom Magnetic Absorbers

Our high-performance laird microwave absorbers are excellent for rugged military use.

Injection Molded, Casted and Machined

Pre-cut materials won’t work? Use our epoxy, silicone-based and thermoplastic for casting and customized molding/machining in 3D complex parts.

Sample Kits / Accessories

Order samples of our durable bonding solutions such as absorber tapes, adhesives and patching kit accessories.

0 notes

Text

Bonded magnets are made using compression or injection molding. Injection-molded magnets are flexible, but compression-bonded magnets have a higher magnetic output. Bonded magnets have many benefits, including Higher electrical resistivity than sintered magnets, Excellent geometric tolerances, Multipole magnetization, the ability to attract objects up to 640 times their own weight, and High dimensional accuracy.

0 notes

Text

Medical Plastics Market Key Companies and Emerging Trends 2024 - 2030

The global medical plastics market size was estimated at USD 52.9 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 7.4% from 2024 to 2030.

This growth can be attributed to the development of advanced plastics and plastic composites used in medical components such as catheters, surgical instrument handles, and syringes. The demand for medical device packaging is likely to be driven by a rise in demand for in-house and advanced medical devices. Plastics including polyethylene, polypropylene, and polycarbonate are increasingly being utilized for the manufacturing of medical devices. The growth of home healthcare due to its low costs compared to hospital care and intensive care has resulted in a rise in demand for medical devices.

According to the latest U.S. census, 16.8% of the U.S. population is over the age of 65 years and this number is anticipated to reach 74 million by 2030. People aged over 85 need the most care and their population is growing rapidly. In March 2021, the U.S. President, Joe Biden, proposed spending USD 400 billion on Medicaid over eight years to fund at-home care for elderly and disabled people as well as increase the wages of caregivers.

Gather more insights about the market drivers, restrains and growth of the Medical Plastics Market

Detailed Segmentation:

Market Concentration & Characteristics

Market growth stage is high, and pace of market growth is accelerating owing to overly consolidated market. Medical plastic manufacturers are actively implementing challenging strategic initiatives such as mergers & acquisitions, new product launches, production expansion, among others.

For instance, In November 2023, TekniPlex Healthcare announced the acquisition of Seisa Medical, a medical device manufacturer based in El Paso, Texas, offering various services throughout the product development cycle. This acquisition will enhance the company's materials science and process technologies worldwide for interventional therapy devices and minimally invasive. From development and design to component manufacturing, final assembly, and packaging, Seisa provides global contract manufacturing services for Class II and III medical devices and specialty components.

Process Technology Insights

Injection molding is a widely used process in the medical plastics industry. It has many advantages, including compliance with medical industry standards and regulations. The use of engineering-grade plastics ensures that parts are created to enhance patient safety and comply with FDA (Food and Drug Administration) guidelines. Injection molding is highly flexible, allowing parts to be fully customizable to fit the consumer.

Application Insights

The medical components segment dominated with a revenue share above 40.0% in 2023. The COVID-19 pandemic increased the demand for medical components such as personal protective equipment (PPE), face masks, gloves & gowns, and magnetic resonance imaging (MRI) scanners. The emerging countries manufactured PPE, face masks, and gloves, whereas, developed countries manufactured technology-intensive equipment such as MRI scanners and mechanical ventilators. Hence, the demand for the aforementioned equipment was rising during the pandemic, which in turn is expected to drive the segment’s growth.

Regional Insights

In 2023, North America dominated global medical plastics market with a market share of above 33.0%. This is expected to augment the demand for generic drugs as well as medical devices in the coming years, thereby driving North America medical plastics market over the forecast period. The key applications catered to by this industry include pharmaceutical packaging and medical components manufacturing.

Rising demand for medical plastics in pharmaceutical packaging applications and the rapid growth of the pharmaceutical industry in Mexico and Canada are expected to drive the medical plastics market in the region. For instance, the elimination of stringent regulations by the Mexican government, which had earlier restricted the establishment of new manufacturing units, has resulted in the establishment of new pharmaceutical manufacturing facilities for major companies such as Takeda and Astellas in Mexico.

Product Insights

The Poyphenylsulfone (PPSU) resin segment dominated the medical plastics market with a revenue share of above 51.0% in 2023. The heat and chemical resistance of PPSU can be attributed to this dominance. These plastics possess high strength and durability, making essential surgical tools. These are preferred in surgical robots and biopharmaceutical processing. Polyphenylsulfone exhibits good heat and chemical resistance, making it ideal for metal replacement in medical applications. These plastics possess high flexural strength, impact resistance, and durability and are ideal for producing single- and multi-use surgical instruments. Its high-temperature resistance makes it suitable for multi-use medical devices that are repeatedly steam-sterilized.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global polybutadiene market size was valued at USD 1.88 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030.

• The global polycarbonate sheet market size was valued at USD 4.64 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.7% from 2024 to 2030.

Key Companies & Market Share Insights

Some key market players include BASF SE; Celanese Corporation; Evonik Industries AG; SABIC; Dow, Inc.; Solvay S.A.; Trinseo S.A.; and Eastman Chemical Company.

• In November 2022, Celanese Corporation announced the acquisition of DuPont's Mobility & Material (M&M) business for USD 11 billion. This strategic move enables Celanese to expand its global reach and enhance its offerings in the environmental sector, particularly in sustainable transportation.

Key Medical Plastics Companies:

The following are the leading companies in the medical plastics market. These companies collectively hold the largest market share and dictate industry trends. Financials, strategy maps & products of these medical plastics companies are analyzed to map the supply network.

• Röchling SE & Co. KG

• Nolato AB

• Saint-Gobain

• SABIC

• Orthoplastics Ltd

• Eastman Chemical Company

• Celanese Corporation

• Dow, Inc.

• Tekni-Plex, Inc.

• Solvay S.A.

• HMC Polymers Company Limited

• ARAN BIOMEDICAL TEORANTA

• Trelleborg Group

• Avantor, Inc.

• Trinseo

• Evonik Industries AG

Medical Plastic Market Segmentation

Grand View Research has segmented the global medical plastic market based on product, application, and region:

Medical Plastics Product Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

• Polyethylene (PE)

• Polypropylene (PP)

• Polycarbonate (PC)

• Liquid Crystal Polymer (LCP)

• Polyphenylsulfone (PPSU)

• Polyethersulfone (PES)

• Polyethylenimine (PEI)

• Polymethyl Methacrylate (PMMA)

• Others

Medical Plastics Process Technology Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Extrusion

• Injection Molding

• Blow Molding

• Other

Medical Plastics Application Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

• Medical Device Packaging

• Medical Components

• Orthopedic Implant Packaging

• Orthopedic Soft Goods

• Wound Care

• Cleanroom Supplies

• BioPharm Devices

• Mobility Aids

• Sterilization and Infection Prevention

• Tooth Implants

• Denture Base Material

• Other Implants

• Others

Medical Plastics Region Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o U.K.

o France

o Italy

o Netherland

• Asia Pacific

o China

o India

o Japan

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o Saudi Arabia

o UAE

Order a free sample PDF of the Medical Plastics Market Intelligence Study, published by Grand View Research.

Recent Developments

Some key players operating in market include BASF SE; Celanese Corporation; Evonik Industries AG; SABIC; Dow, Inc.; Solvay S.A.; Trinseo S.A.; Eastman Chemical Company among others.

• In February 2023, Cleanse Corporation announced the acquisition of DUPONT's mobility and mobility business for USD 11.00 billion. This strategic move enables Cleanse to expand its global reach and enhance its offerings in the environmental sector, particularly in sustainable transportation.

• In June 2023, SABIC acquired Clariant's 50% stake in Scientific Design, a renowned catalysis leader. This acquisition bolstered the non-cyclical, technology-driven business and brought it closer to becoming a leading global specialist.

#Medical Plastics Market#Medical Plastics Market size#Medical Plastics Market share#Medical Plastics Market analysis#Medical Plastics Industry

0 notes

Text

Two-in-one Drop-resistant Protective Phone Cover

Product information: Color: red/Rose Red, sapphire blue/sapphire blue, white/pink, pink/Rose red, gray green/gray green, black/black, red/black, gray green/pink, purple/black Applicable model: Google Function: bracket, magnetic suction, anti-wear, anti-fall Material: TPU PC Color classification: pink, red, green, blue, black Style: Back cover type Process: Injection Molding/injection…

0 notes

Text

17 key points to pay attention to when designing injection molds

Mold industry is a basic industry in manufacturing industry, basis for transformation of technological achievements, and an important field of high-tech industries. It is called “magnetic industry” that “turns iron into gold” in industrialized countries such as Europe and United States.American industrial community believes that “mold industry is cornerstone of American industry”; Germany…

View On WordPress

#BOSS design#core pulling#core pulling slider mechanism#core-pulling mechanism#demolding slope#injection mold#injection molded parts#injection molded products#injection molding#Injection molding product#injection molds#Mold industry#plastic parts

0 notes

Text

Ceramic Packages Market 2024: Emerging Trends, Major Driving Factors, Business Growth Opportunities

Ceramic Packages Market provides in-depth analysis of the market state of Ceramic Packages manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Ceramic Packages in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Ceramic Packages Market Report:

The report offers a comprehensive and broad perspective on the global Ceramic Packages Market.

The market statistics represented in different Ceramic Packages segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Ceramic Packages are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Ceramic Packages.

Major stakeholders, key companies Ceramic Packages, investment feasibility and new market entrants study is offered.

Development scope of Ceramic Packages in each market segment is covered in this report. The macro and micro-economic factors affecting the Ceramic Packages Market

Advancement is elaborated in this report. The upstream and downstream components of Ceramic Packages and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/ceramic-packages-market-100566

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Global Magnetic Nanoparticles MarketMarket Share

Global Portable Power Station MarketMarket Growth

Phased Array Antenna MarketMarket

Car Electronics & Communication Accessories MarketMarket Share

Water Filter Jugs MarketMarket Growth Rate

Outdoor Playground Equipment MarketMarket Forecast

Global Sepsis Treatment MarketMarket Size

Battery Electric Car MarketMarket Growth

Gantry or Cartesian Robots MarketMarket Analysis

Digital Pathology MarketMarket Size

Global Microbiome Sequencing Services MarketMarket Share

Global Medical Marijuana MarketMarket Growth

High Speed Steel (HSS) Metal Cutting Tools MarketMarket

Mobile Telemedicine MarketMarket Share

Invisible Orthodontics MarketMarket Growth Rate

Wireless Charging Ic MarketMarket Forecast

Global Thermostat MarketMarket Size

UAV Drones MarketMarket Growth

Cell Phone Charging Station MarketMarket Analysis

Terahertz Spectroscopy MarketMarket Size

Global Small Household Appliances MarketMarket Share

Global Network Slicing MarketMarket Growth

Dicyandiamide (CAS 461-58-5) MarketMarket

Electric Heater MarketMarket Share

Somatosensory Game MarketMarket Growth Rate

Consumer Electronics and Home Appliances MarketMarket Forecast

Global Portable Engine Driven Pumps MarketMarket Size

2 shot Injection Molding MarketMarket Growth

Water and Wastewater Treatment Equipment MarketMarket Analysis

Wool Felt MarketMarket Size

Global Music Production Software MarketMarket Share

Global Rice Milling MarketMarket Growth

Advanced Analytics MarketMarket

Pharmacovigilance and Drug Safety Software MarketMarket Share

Noise Suppression Sheet MarketMarket Growth Rate

Arm Microprocessor MarketMarket Forecast

Global Faced Fire Resisting Panels MarketMarket Size

Memory Foam Side Sleeper Market Market Growth

All-Iron Redox Flow Battery MarketMarket Analysis

5-Sulfoisophthalic Acid Monosodium Salt MarketMarket Size

0 notes

Text

What are water chillers used for?

Commonly used to cool products and machinery, water chillers are used in a variety of applications including injection molding, tool and die cutting, food and beverage, chemical, laser, machine tools, semi-conductors and more.

Water chillers are used primarily for cooling purposes in various industrial, commercial, and residential applications. Here are some common uses:

1. **Air Conditioning Systems**: Water chillers are often used in large buildings and facilities to provide chilled water for air conditioning through HVAC systems. They help cool the air circulated through the building.

2. **Industrial Processes**: Many manufacturing processes generate heat that needs to be dissipated to maintain optimal operating conditions. Water chillers are used to cool down equipment, machinery, and products in industries such as plastics, food and beverage, pharmaceuticals, and more.

3. **Data Centers**: Data centers generate significant heat due to the operation of servers and IT equipment. Water chillers are employed to cool down the servers and maintain optimal operating temperatures to prevent overheating and equipment failure.

4. **Medical Imaging**: Equipment like MRI machines generate a lot of heat during operation. Water chillers are used to cool the magnets and maintain stable operating temperatures for accurate imaging.

5. **Beverage Production**: In breweries, wineries, and soft drink production facilities, water chillers are used to cool beverages quickly during manufacturing and to maintain consistent temperatures during storage.

6. **Injection Molding**: The process of injection molding involves heating plastic resin to high temperatures. Water chillers are used to cool the molds quickly after injection, speeding up production cycles.

7. **Aquariums**: Large aquariums and aquatic exhibits often use water chillers to maintain stable water temperatures suitable for aquatic life.

In essence, water chillers play a crucial role in maintaining temperature control across various applications, ensuring efficiency, product quality, and operational reliability.

0 notes

Text

Guangdong Qeehua Industry Equipment Co., Ltd. is a high-tech enterprise based on the research and development of corrosion resistant chemical pumps. According to modern enterprise management standards, the company has established a scientific management system, with excellent manufacturing, quality management team.

In addition, QEEHUA PUMP also has a professional R & D team and sales engineer team, from project evaluation, scheme design, motor matching, mold development, injection molding, processing, assembly, testing, product inspection, packaging, logistics and transportation, truly realize the whole process of quality control.

QEEHUA PUMP core products include acid and alkali resistant magnetic pump, centrifugal pump, vertical pump, precision filter, etc., widely used in electroplating, hardware, PCB, medical, solar energy, semiconductor, coating and other industries of chemical liquid circulation, filtration, transportation, can also be used for waste gas & wastewater treatment.

QEEHUA PUMP will adhere to the mission of “Make the world love Chinese pumps”, and will continue to develop a series of safer, more energy efficient and more efficient chemical pump products. With the experience and strength of QEEHUA PUMP, we can ensure the success of every chemical pump project for our customers. We look forward to your cooperation.

0 notes

Text

Multi-function Solutions (MFS) / ISE (Integrated Solutions Engineered) - Techni3

The signature of today’s advanced technology – whether it’s autonomous vehicles, 5G-enabled devices, sensors creating an internet of things, or home routers – is high-speed, high-volume data transfer in increasingly dense packages. It poses new and unprecedented signal interference and heat dissipation challenges for design engineers worldwide.

New products operate at higher frequencies and use more powerful ICs/SOCs to facilitate enhanced data transfer and capabilities. Therefore, these electronics generate an even higher potential for a significant amount of electromagnetic signal interference. But EMI is only one part of the problem. More components make electronics more powerful, but also hotter, thus increasing the need for fast, reliable heat dissipation. Don’t forget about increasing needs for mechanical and environmental durability, space constraints, and lightweight designs. Enclosures are not just simple, aesthetic housing. They are functional, essential parts helping to address EMI and thermal challenges while protecting devices and systems from potentially harsh environments.

Design engineers face a quandary: How do I effectively solve both signal interference and heat dissipation challenges in tight (and shrinking) spaces?

Laird´s new Integrated Solutions portfolio addresses these multifaceted challenges with a unique range of multifunctional products and solutions – from electrically conductive fabrics to board level shield covers with thermal transfer capabilities. Combining our decades-long wealth of expertise in EMI products, precision metals, RF absorber and thermal solutions – with the latest material and manufacturing innovations – sparked a new way of thinking and has resulted in a plethora of value-add solutions. Significantly reducing your total cost of ownership and maintaining premium performance while lowering design iteration efforts is Laird´s driver for ISE (your Integrated Solutions Engineered).

Laird ISE is your one-stop-shop: from simulations/modeling to co-engineering, co-designing and high-quality manufacturing. Challenge us to trust us.

Explore Solutions:

Metal-ISE:

Thermally and electro-magnetically enhanced die-cast, stamped, deep-drawn precision metal parts at board level (e.g. board level shields and RF absorbers) or subassembly level (e.g. automotive heatsinks).

Structur-ISE:

Highly durable mechanically stable solutions at enclosure and I/O interface level (e.g. radomes, using state-of-the-art injection molding or forming capabilities).

Hybrid-ISE:

Homogeneous single layer or heterogeneous multi-layer polymeric solutions offering multi-functional signal interference mitigation and heat dissipation (e.g. a thermally conductive RF absorber).

Textil-ISE:

Electrically conductive fabrics enabling sensor, switch, and heating functionality (e.g. selectively plated stretch fabric).

Multi-function Solutions (MFS) / ISE (Integrated Solutions Engineered) Groups

Hybrid - ISE

Merge Device Functionality. Laird Hybrid-ISE solutions merge thermal, EMI shielding, and microwave absorbers into a single engineered package. You have more heat, higher frequencies and ever-smaller packages. Hybrid-ISE delivers answers.

Structur - ISE

Improve performance with smart components. Device enclosures can offer more than just physical and environmental protection. Sensors and antennas need smart structural materials to keep out unwanted signal interference. Discover Structur-ISE.

Metal - ISE

Enable enhanced functionality. Metal-ISE solutions utilize Laird’s automation capabilities to enhance precision metal components with our portfolio of thermal and EMI materials. Get complete thermal and EMI solutions from one global manufacturer.

Textil - ISE

Finding solutions in smart fabrics. Textil-ISE uses selectively-plated flexible conductive fabric (stretchable and non-stretchable) to create assemblies providing more than just a conductive path. Textil-ISE provides a host of compelling solutions.

0 notes

Text

Quality Carpet Cleaning Solutions in Penrith

Carpets are a staple in many homes, providing warmth and comfort underfoot. But they can also be magnets for dirt, allergens, and stains. In Penrith, a region known for its dynamic weather, keeping carpets clean is essential. This article explores quality carpet cleaning solutions in Penrith, emphasizing why professional cleaning is crucial and offering tips for maintaining pristine carpets.

The Importance of Quality Carpet Cleaning

Health Benefits

Reducing Allergens

Carpets can trap allergens like dust, pollen, and pet dander. Regular cleaning reduces these irritants, helping those with allergies or asthma breathe easier. A clean carpet means a healthier home environment.

Preventing Mold Growth

Penrith’s climate can be humid, creating a breeding ground for mold in dirty carpets. Quality cleaning removes moisture and dirt, preventing mold and mildew from taking hold and spreading.

Aesthetic Benefits

Prolonging Carpet Life

Regular cleaning removes dirt and debris that can wear down carpet fibers, extending the life of your carpets. Think of it like routine maintenance for your car – essential for longevity.

Enhancing Home Appearance

Clean carpets make your home look and feel fresh. Stains and grime are unsightly, and a professional clean can revive your carpet’s original beauty, making your home more inviting.

Environmental Benefits

Eco-friendly Cleaning Products

Many professional carpet cleaners in Penrith use eco-friendly products that are safe for the environment and your family. These products are effective yet gentle, avoiding harsh chemicals that can harm the planet.

Sustainable Cleaning Practices

Quality carpet cleaning services often employ sustainable practices, such as using energy-efficient machines and water-saving techniques, reducing the overall environmental impact.

Common Carpet Cleaning Methods

Hot Water Extraction

How It Works

Hot water extraction, or steam cleaning, uses hot water mixed with cleaning agents. This solution is injected into the carpet and then extracted along with dirt and debris.

Pros and Cons

Pros: Deep cleans, removes tough stains, and kills bacteria. Cons: Longer drying time and higher cost.

Dry Cleaning

How It Works

Dry cleaning involves using cleaning solvents and minimal moisture. The solvents break down dirt, which is then vacuumed away.

Pros and Cons

Pros: Quick drying time and effective for surface cleaning. Cons: May not remove deep-seated dirt.

Steam Cleaning

How It Works

Steam cleaning uses steam to loosen dirt from carpet fibers. It’s often confused with hot water extraction but uses less water.

Pros and Cons

Pros: Effective at killing germs and allergens. Cons: May not be suitable for all carpet types and can be more expensive.

Bonnet Cleaning

How It Works

Bonnet cleaning involves a rotating brush immersed in cleaning solution that scrubs the carpet surface, ideal for maintenance cleaning.

Pros and Cons

Pros: Quick and less expensive. Cons: Doesn’t clean deeply and can push dirt deeper into the fibers.

Choosing the Right Carpet Cleaning Service in Penrith

Reputation and Reviews

Look for companies with strong reputations and positive customer reviews. Word of mouth and online testimonials can provide insights into the quality of service.

Services Offered

Ensure the company offers the specific services you need, whether it’s stain removal, pet odor elimination, or eco-friendly cleaning options.

Pricing and Packages

Compare pricing and packages. Look for transparency in pricing and what each package includes. Sometimes, the cheapest option isn’t the best value.

Customer Service

Good customer service is crucial. Choose a company that is responsive, professional, and willing to answer your questions and address concerns.

Benefits of Professional Carpet Cleaning

Deep Cleaning

Professionals have the tools and expertise to deep clean carpets, removing dirt, allergens, and stains that regular vacuuming can’t handle.

Time-saving

Hiring professionals saves you time and effort. Carpet cleaning can be labor-intensive, and professionals can do it more efficiently.

Expertise and Experience

Experienced cleaners know how to handle different types of carpets and stains, ensuring effective cleaning without damaging your carpet.

DIY Carpet Cleaning Tips

Regular Vacuuming

Vacuuming regularly prevents dirt from embedding into the carpet fibers, making professional cleanings more effective and less frequent.

Spot Cleaning

Address spills and stains immediately with spot cleaning to prevent them from setting. Use appropriate cleaners for different types of stains.

Using the Right Cleaning Products

Choose cleaning products that are safe for your carpet type and the environment. Avoid harsh chemicals that can damage fibers and affect indoor air quality.

Eco-friendly Carpet Cleaning Solutions

Green Cleaning Products

Opt for green cleaning products that are biodegradable and non-toxic. These products clean effectively without harming the environment.

Energy-efficient Machines

Professional services often use energy-efficient machines that consume less power, contributing to environmental conservation.

Waste Reduction Practices

Look for services that prioritize waste reduction, such as recycling water and minimizing the use of disposable cleaning materials.

Understanding Carpet Cleaning Costs

Factors Affecting Cost

Several factors affect carpet cleaning costs, including the size of the area, the type of carpet, the cleaning method used, and the level of dirtiness.

Average Price Range in Penrith

In Penrith, professional carpet cleaning typically ranges from $25 to $75 per room, depending on the factors mentioned above.

Value for Money

While cost is important, consider the value of the service. A higher upfront cost might save money in the long run by extending the life of your carpets.

Carpet Maintenance Tips for Longevity

Regular Cleaning Schedule

Stick to a regular cleaning schedule to keep carpets looking their best. Professional cleaning once a year is a good rule of thumb for most households.

Protecting High-Traffic Areas

Use rugs or runners in high-traffic areas to protect carpets from wear and tear. These can be easily cleaned or replaced.

Dealing with Stains Immediately

Tackle stains as soon as they happen to prevent them from setting. Blot, don’t rub, to avoid spreading the stain.

Conclusion

Quality carpet cleaning is essential for maintaining a healthy, attractive, and sustainable home in Penrith. By understanding the benefits of professional cleaning, the different methods available, and how to choose the right service, you can keep your carpets in top condition. Regular maintenance and eco-friendly practices further enhance the longevity and appearance of your carpets, ensuring a comfortable living space for years to come.

0 notes

Text

Our Advanced 3000W Horizontal Wind Turbine Generator

Horizontal Wind Turbine Generator

Harness the relentless power of the wind with our cutting-edge 3000W Horizontal Wind Turbine Generator. This windmill is engineered for peak efficiency and robust durability, making it an excellent solution for anyone looking to bolster their energy independence or integrate a renewable power source. Whether you’re situated off-grid or looking to supplement your existing energy setup, this turbine is perfectly suited for remote locations or any site committed to eco-friendly practices.

Key Features of Our Wind Turbine Generator

High Output: Generates 3000W of power, available in versatile outputs of 24V, 48V, and 96V to accommodate different needs and setups.

Efficient Blades: Equipped with three precision-molded blades that maximize wind energy utilization for optimal performance.

Durable Construction: Built with a robust aluminum alloy body and a sturdy iron shaft, designed to withstand extreme environmental conditions.

Advanced Technology: Features an MPPT (Maximum Power Point Tracking) Charger Controller, enhancing the efficiency of power conversion.

Off-Grid Capability: Includes an optional off-grid inverter system, making it ideal for locations without traditional power access.

Benefits of Choosing Our Wind Turbine

Eco-Friendly Energy Source: Significantly reduces your carbon footprint and lessens your dependence on conventional power sources.

Cost-Effective: Offers substantial savings on electricity costs and eliminates the need for expensive power line extensions in remote areas.

Energy Independence: Ensures a consistent and reliable power supply, even during grid failures.

Easy Installation: Designed for straightforward setup with options for tube or flange connections.

Low Maintenance: Requires minimal upkeep, thanks to its user-friendly design and superior build quality.

When and Where to Use This Wind Turbine

Ideal for use in any location that is more than 100 yards from the power grid—particularly in rural or remote areas where wind flow is consistent. This turbine is also perfect for those aspiring to achieve energy self-sufficiency:

Rural Homes

Remote Cabins and Workshops

Off-grid Living Spaces

Agricultural Settings

Eco-tourism Resorts

Why Our Wind Turbine Stands Out

Our wind turbine generator sets itself apart through a blend of sophisticated design and state-of-the-art technology. The precision injection molding of the blades and the patented design of our permanent magnet AC generator facilitate efficient energy conversion with minimal torque required. This combination of advanced features ensures that our turbine not only meets but exceeds performance expectations, providing a reliable and sustainable energy solution that is both powerful and easy to install.

Take the Next Step Towards Sustainable Living

Are you ready to embrace the benefits of wind energy? Discover how our 3000W Wind Turbine Generator can revolutionize your approach to energy consumption. With prompt delivery available in Poland and a steadfast commitment to quality and environmental sustainability, now is the perfect time to advance towards a greener, more energy-independent future. Order now and join the renewable energy movement with confidence!

HOVIRA

0 notes

Text

Insert Moulding vs Overmoulding: When To Use?

When it comes to manufacturing plastic parts with added functionalities, insert molding and overmolding are two popular techniques. Both processes offer unique advantages and are suitable for different applications. In this article, we'll explore the differences between insert molding and overmolding, their respective benefits, and when to use each method.

Gain an in-depth understanding of insert moulding and overmoulding.

What is insert moulding?

Insert molding is a process where metal or plastic inserts are placed into the mold cavity before plastic injection. The molten plastic material then surrounds the inserts, creating a single integrated part. This method is commonly used when a part requires added strength, precise positioning of inserts, or when different materials need to be combined.

What is overmoulding?

Overmolding is a process where a substrate, typically made of metal or plastic, is molded over with a second material, often a softer or more flexible material. This creates a single, multi-material part with improved functionality and aesthetics. Overmolding is commonly used to enhance grip, provide cushioning, or incorporate multiple colors or textures into a part.

Use the checklist below when deciding whether to use insert moulding or overmoulding. Or read the full article to gain an in-depth understanding of when to use insert moulding and overmoulding.

When to use overmoulding:

Consider insert moulding when making products that have the following attributes or applications:

Your finished piece can be made of thermoplastics and/or rubber.

Your goal is to enhance the grip and texture of a component.

Your product needs to be multi-colored

You aim to boost cushioning, shock absorption, or vibration damping properties.

You need to embed soft seals into your part.

When to use insert moulding:

Consider overmoulding when making products that have the following attributes or applications:

Your part includes a metal component.

You need to seamlessly integrate electronic components such as sensors, wires, or circuit boards.

You aim to incorporate other pre-fabricated substrates like magnets.

You wish to avoid the expense associated with a complex two-shot mold.

You must include threaded inserts within your part.

0 notes