#Industrial Winder Rewinder

Text

Trim Winder Machine Manufacturers

Blueeye Machine, located in Ahmedabad, is specialised in the manufacture of trim winders, which are designed to meet the needs of the industries that require precise winding solutions for a variety of materials.

#trim winder machine#trim winder machine manufacturer#trim winder machine supplier#trim winder machine in india#trim winder machine manufacturer in Ahmedabad

0 notes

Text

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed to cut large rolls of paper into smaller, more manageable rolls of desired width and length. This machine is crucial in various sectors, including printing, packaging, and converting industries.

Unwinding: The process begins with loading a large roll of paper onto the unwinding shaft. The machine then unwinds the paper roll at a controlled speed.

Slitting: The unwound paper is then passed through sharp blades or rotary knives that slit the paper into smaller widths. The number of blades can be adjusted based on the number of rolls required.

Rewinding: The slit paper is then rewound onto separate cores to form smaller rolls. The tension and speed of rewinding can be controlled to ensure the rolls are wound tightly and evenly.

Cutting: Some machines also have an integrated cutting mechanism that cuts the rewound rolls to the desired length.

Quality Control: Many Paper Slitter Rewinders come with built-in inspection systems that check for defects or irregularities in the paper.

The Paper Slitter Rewinder is known for its high efficiency, precision, and speed. It can handle a wide range of paper types and thicknesses, making it a versatile choice for businesses. With its robust construction and advanced features, this paper core machine ensures smooth and consistent operation, enhancing productivity and reducing waste. Whether you’re a small print shop or a large paper mill, a Paper Slitter Rewinder can be a valuable addition to your production line.

Paper Slitter Rewinder: Enhancing Efficiency in Manufacturing

The Paper Slitter Rewinder is a game-changer in the manufacturing industry, significantly enhancing efficiency and productivity. This machine is designed to transform large rolls of paper into smaller ones, tailored to specific requirements. Here’s how it contributes to manufacturing efficiency:

High-Speed Operation: paper tube winder machine operate at high speeds, capable of processing large volumes of paper in a short time. This speed significantly reduces production time, enabling businesses to meet high demand quickly.

Precision Cutting: With adjustable blades, the machine ensures precise and consistent cuts every time. This precision eliminates waste from inaccurate cuts, saving materials and costs.

Automation: Many models come with automated features, reducing the need for manual intervention. This automation not only saves labor costs but also minimizes human error, ensuring consistent quality.

Quality Control: With built-in inspection systems, the machine can detect and rectify defects or irregularities in the paper. This feature ensures that only high-quality paper rolls reach the end of the production line.

Space Efficiency: Despite its robust capabilities, the Paper Slitter Rewinder has a compact design that saves valuable floor space in manufacturing facilities.

By investing in a Paper Slitter Rewinder, businesses can significantly enhance their manufacturing efficiency. This core pipe-making machine not only speeds up the production process but also ensures the consistent quality of the final product, leading to increased customer satisfaction and profitability.

Paper Slitter Rewinders for Every Industry Need

Paper slitter rewinders play a pivotal role across diverse industries, addressing unique needs with precision and efficiency:

Printing Industry: In printing, these machines facilitate the production of custom-sized paper rolls, optimizing printing processes and reducing waste.

Packaging Sector: The packaging industry benefits from the adaptability of paper slitter rewinders, ensuring the creation of tailored rolls for various packaging applications, enhancing efficiency and minimizing material costs.

Converting Industries: Paper converting relies on these machines to transform large paper rolls into smaller, usable rolls with specific dimensions, meeting the requirements of different product lines.

Flexibility in Width and Length: The versatility of paper slitter rewinders allows for the customization of roll width and length, catering to the unique specifications of each industry and product.

Enhanced Productivity: With precise cutting and rewinding capabilities, these machines contribute to increased productivity, reducing downtime and enhancing overall operational efficiency in multiple sectors.

0 notes

Text

Use the Best Watch Winders to Improve the Care of Your Timepieces

Introduction:

For watch box winders enthusiasts and collectors, maintaining the accuracy and longevity of their automatic watches is of utmost importance. A watch winder serves as an essential accessory that keeps your timepieces in optimal condition when not in use. In this blog, we will delve into the world of watch winders, exploring their benefits and guiding you towards finding the best watch winder for your prized collection.

The Power of a Watch Winder:

Automatic watches, known for their intricate mechanics, require regular movement to stay fully wound. A watch winder provides the perfect solution by simulating the natural motion of the wrist, keeping your timepieces running smoothly. By utilizing a watch winder, you not only ensure accurate timekeeping but also extend the lifespan of your watches.

Exploring Watch Box Winders:

When searching for the ideal Watch winder, consider the following factors:

a. Compatibility: Opt for a watch winder that caters to various watch sizes and brands. Look for customizable settings that can accommodate different rotation directions, turns per day, and winding programs to meet the specific needs of your timepieces.

b. Quality Craftsmanship: Invest in a watch winder made from high-quality materials such as premium wood, carbon fiber, or leather. Superior craftsmanship and attention to detail are essential, as they reflect the level of care and protection your watches deserve.

c. Silent Operation: A watch winder should operate quietly, ensuring a peaceful environment. Seek models equipped with noise-dampening technology, guaranteeing minimal disruption while your watches are being wound.

Unveiling the Best Watch Winder:

Considering the vast array of watch winders available, we recommend exploring the following top-notch options:

a. : With a reputation for precision engineering and reliability, [Brand 1] offers a range of watch winders that cater to different watch models. Their commitment to craftsmanship and attention to detail make them a popular choice among watch aficionados.

b. Renowned for their elegant and stylish designs, [Brand 2] provides watch winders that harmoniously blend functionality with aesthetics. Their versatile rotation settings and durable construction make them a trusted brand in the industry.

c. [Brand 3]: Combining advanced technology with a passion for horology, [Brand 3] offers exceptional watch winders designed to cater to various automatic watch brands. Their innovative features and superior performance have garnered a loyal following among watch collectors.

The Perfect Companion: Auto Watch Winder:

An auto watch winder ensures that your timepieces are always ready to wear, eliminating the hassle of resetting and rewinding. The convenience it offers is unmatched, making it an ideal companion for busy individuals and those with an extensive watch collection.

Conclusion:

Investing in the best watch winder is a testament to your commitment to preserving the accuracy and beauty of your automatic watches. By providing consistent and gentle motion, a watch winder keeps your timepieces running smoothly and eliminates the need for manual winding. Consider compatibility, quality craftsmanship, and silent operation when selecting a watch winder that aligns with your preferences. With the right watch winder by your side, you can enjoy the convenience and peace of mind that come with owning a meticulously cared-for watch collection.

0 notes

Text

All You Need To Know About Wire Coiling Machine

Wire coils use in a variety of industries and applications. The wire coil industry is an ever-growing, competitive market that can be challenging.

Wire Coiling Machine: A wire coiler is set off by someone who stands on a platform and feeds steel or aluminum wires through the machine as it winds them into circles or squares. The coiler has two sets of rollers, with one set rotating clockwise while the other set rotates counterclockwise so that when the steel or aluminum wires go through them.

Advantages of using Wire Coiling Machine

Wire coiling machine are a great way to save time and money for wire production. They are a cost-effective alternative to manual labor, making the winding wire process more efficient.

These automated wire coil wrapping machines offer greater flexibility than their manual counterparts. They’re also easy to install and operate, with a low chance of failure.

Unlike manual winding equipment, they can deliver reliable service.

They help reduce the quantity of personnel needed to run the business. It helps to reduce labor and production costs dramatically.

Choosing the Right Coil Machine for Your Company

The best wire shuffling machine is the one that will suit your company’s needs. For example, if you are a jewelry manufacturer, you need a device that can produce enough coils for your production needs.

If you are looking for the best automatic coil machine, then you need to look for features like precision and speed. These will help decide which type of coil machine will work best for your company. For more Details https://dailyorbitnews.com/

Step-by-Step Guide to Choosing the Right Coil Machine for You

A coil machine winds the wire around a metal tube to create coils. This process can is done manually or with the help of machines. Choosing the suitable coil machine for you can be difficult, but there are some factors that you should consider before making a purchase.

The first thing you should consider is what type of material you will often work with; if this is steel, choose an electric coil winder because it will save time and energy. If it’s copper, choose an air-powered coiler because they are more versatile and allow for smaller coils.

If you will be working with aluminum, choose an electric coil winder because they are more powerful and efficient. The next thing that you should consider is what type of job you will usually be doing with the coils. If it’s maintenance work, choose a hand-held coiler because it will only have to be used once in a while. If it’s a production line, choose a power coiler because it will be used more often.

The next thing you should consider is the type of machine that you want to coil the wire in. For production line work, choose an electric machine or a hydraulic machine. For maintenance work, choose a hand-held coiler or a gas-powered engine-driven reeler and rewind er.

You’ll also want to consider the length of wire that you need, as well as the diameter, and subsequently gauge of steel wire that it is made from. If you have a specific length requirement, you should choose a machine with a minimum and maximum capacity to accommodate your needs in terms of both size and weight.

Last but not least, don’t forget that you also have to consider the portability of your machine. A heavy, bulky model won’t be as easy to transport as a lightweight, small one.

Conclusion

With the need for high speed and precision automation in coil winding, a modern automatic coil winding machine is an ideal solution.ReelPower Industrial offers a variety of proper coiling equipment to fulfill various demands, including massive and custom coiling machines. Do not hesitate to ask any questions about the wire coiling machine. Get in touch right now.

Source URL: http://bit.ly/42mldZj

0 notes

Link

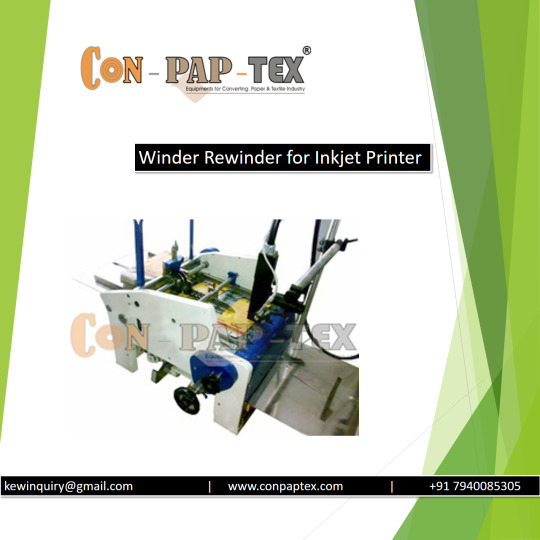

#Winder Rewinder for Inkjet Printer Manufacturer#Winder Rewinder for Inkjet Printer#Winder Rewinder for Inkjet#Winder Rewinder#Winder Rewinder Machine

0 notes

Link

We are Manufacturer of Inkjet Print Rewinding Machine Manufacturer, Industrial Inkjet Printer, Winding Rewinding, inkjet printer with winder Rewinder, Industrial Winder Rewinder, Winding Rewinder Machine manufacturer, Winder Rewinding Machine. Also, for automatic feeding with nice and quick adjustments, easy to operate with easy controls, accurate registering, uniform impressions and many more facility. Inkjet Print Rewinding Machine Manufacturer, Inkjet Printer for industrial use is a highly flexible printer designed for a range of packaging applications.

#Inkjet Print Rewinding Machine#Inkjet Print Rewinding Machines#Industrial Inkjet Printer#Winding Rewinding#Winding Rewindings#Industrial Winder Rewinder#Winding Rewinder Machine#Winding Rewinder#Winder Rewinding Machine#Winder Rewinding#Inkjet Printer#Inkjet Printers

0 notes

Link

Krishna Engineering Works Manufacturers, exports & supplies Table Top Doctoring Rewinding. Our Table Top Doctoring Rewinding Machine is used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC, etc. Our Table Top Doctoring Rewinding Machine is manufactured with us most precision which ensure zero maintenance up to 10 years. We have been manufacturing various types of Doctoring Rewinding Machine for different industries and for different applications per client’s requirement. For more information contact our sales team: [email protected]

#Doctoring Rewinding Machine#Standard Doctoring Rewinding Machine#Table Top Doctoring Rewinding#High Speed Doctoring Rewinding#Heavy Duty Doctoring Rewinding#Doctoring Rewinding With Slitting System#Doctoring Slitting Rewinding#Doctoring Rewinding Winding Unwinding#Doctoring Rewinding Winding Rewinding For Batch Printing#Doctoring Winding Rewinding With Inkjet Printer#Industrial Inkjet Printer with Winder Rewinder Machine#Inspection Doctoring Rewinding Machine

4 notes

·

View notes

Link

Krishna Engineering Works is a leading manufacturer, exporter and supplier of Rewinding Machine, Roll-to-Roll Processing Machines for a variety of processes such as Rewinding Machine, Slitting, Docking Rewinding, Winding Rewinding, Rewinding Unwinding, Jumbo Roll to Small Roll Folding, etc. Different types of Winding Rewinding Machine with high quality and heavy duty equipment. Winding rewinding machine with 25 different types per client's application and industry specific requirements. Also a manufacturer of doctoring rewinding machine, Rotogravure printing machine.

#Winding Rewinding Machine for Inkjet Printer#Winding Rewinding Machine#Film Winder Rewinder Machine#Rewinder for Inkjet Printer#Industrial Inkjet Printer with Winder Rewinder Machine#Heavy Duty Doctoring Rewinding Machine#Doctoring Rewinding Machines#Doctoring Machine#Doctoring Re-Reeling Machine#Doctoring Inspection Machine with Slitting System

6 notes

·

View notes

Link

We are leading exporter, and supplier of Industrial Inkjet Printer from last 25 years. Industrial Inkjet Printer gives you high-quality prints. Offline Batch Coding is an important part in packaging design process. Our Batch Printing Machine, Batch Coding Machine Inkjet Printers are working on sophisticated date codes and traceability codes. It can apply on pouches, rigid plastic pots, cartons, plastic inserts, leaflets, labeling and much more. An automatic system with unique 15 digital serial number, 2D barcode, batch, expiry detail and many more.

#Industrial Inkjet Printer#Inkjet Coder#Industrial Printer#Batch Printing Machine#Batch Coding Machine#Winder Rewinder for Inkjet Printer Thermal Printer#Winding Rewinding Machine#Doctoring Rewinding Machine

1 note

·

View note

Link

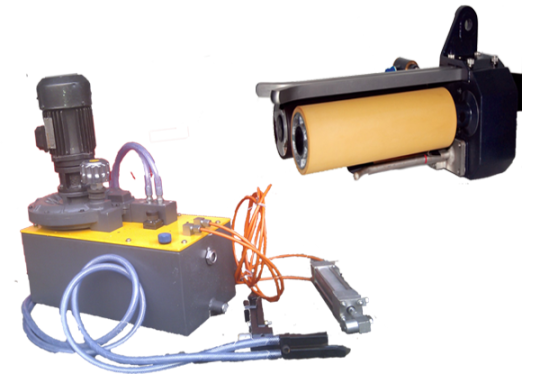

We manufacture all types of Textile Machinery Spares Parts like Stenter Machine, Jigger Machine, Rotary Screen Printing Machine, Spinning Machinery, and Textile Machinery, Stenter Machine Spare Parts like Stenter Pin Bar, Stenter Clip, Cloth Guider, Chain link Bottom Parts, etc. We are also one of the leading manufacturers of Rubber Roller, Rubber Fillet, Nip Roll, Rubber Grip, Turn Bar System, PU Roll, Paper Core Cutting Machine Manufacturers, Web Corona Treater, and Wrapping Machine. We manufacture all types of Converting & Flexible Packaging Machinery, Textile Machinery & Equipment of Rubber Roller, Industrial Rubber Rollers, Web Aligner Unit, Slat Expanding Roller, Winder Rewinder Machine, Web Converting Machinery, Textile Machinery Spare Parts, Strapping Machine, Bow Roll, Stenter Machine, Pneumatic Cloth Guider, Tension Controller, Air Shaft, and more.

#Stenter Machine#Jigger Machine#Pin Bar#Stenter Clip#Cloth Guider#Chain link Bottom Parts#Rubber Roller#Rubber Fillet#Nip Roll#Rubber Grip#Turn Bar System#PU Roll#Paper Core Cutting Machine Manufacturers#Web Corona Treater#Wrapping Machine#Industrial Rubber Rollers#Web Aligner Unit#Slat Expanding Roller#Winder Rewinder#Strapping Machine#Bow Roll#Pneumatic Cloth Guider#Tension Controller#Air Shaft#Wrinkle Removing Rolls#Web Guiding Equipment#Doctoring Rewinding Machine#Slitter Rewinder Machine#Batch Coding Equipments

0 notes

Link

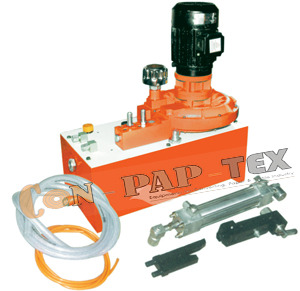

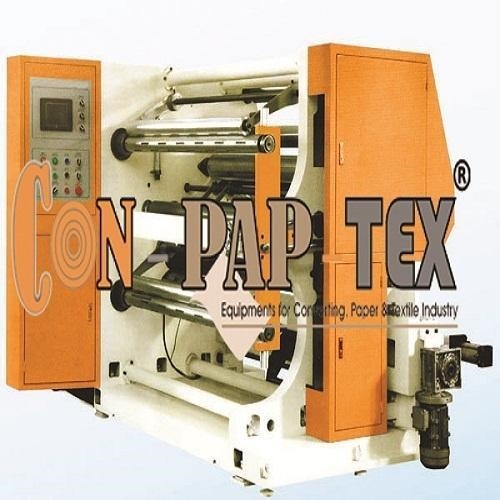

We are Winding Rewinding Machine With Slitting System, Winding Rewinding Machine on custom application and client's requirement. All type of slitter Rewinder machines is special quality machines, designed and created for special applications. We are Manufacturer of Winding Rewinding Machine, Unwinder Rewinder System, Slitter Rewinder Machine on custom application and client’s requirement. Manufacturer of widely used Winding rewinding with Slitting System with variable speed drive and salvage rewinding, corrosion resistant system in flexible packaging and converting industry. Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner). Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying.

#Slitter Rewinder Machine#Slitting System#Winding Rewinding#Winding Rewinding Machine#Winder Rewinder#Slitting Rewinding Machine#Slitting Rewinding#Slitter Machine#Slitters#Winding Rewinding Manufacturer#Slitter Rewinder Machine Manufacturer#Slitter Rewinder Machine Supplier#Inkjet Printer#Doctor Rewinder Machine#Doctoring Rewinding#Industrial Inkjet Printer#Batch Coding Machine#Winding Rewinding Machine with Slitting System

0 notes

Link

Industrial Thermal Transfer Printer Manufacturer India, Batch coding machine is ideal for printing labels on papers, thin cardboard, non-absorbent plastic film and aluminum film with solid ink or color ribbon, characterized by high definition, instant printing & instant dry, various colors selectable and strong adhesion. Industrial Thermal Transfer Printer, Thermal Transfer Overprinter, Winding Rewinding, Winder Rewinder, Rewinder Machine, Slitter Machine Manufacturer, Slitter Rewinder, Industrial Printers and Conveyor, Doctoring Slitting Rewinding Machine Manufacturer, Doctor Slitter Rewinder, Doctoring Rewinding Provision for incorporating Inkjet Printing System with Hot air ink drying. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation. It is great substitute to online coding / batching operation.

#industrial printers#Doctoring Slitting Rewinding#Conveyor#Winding Rewinding#slitter machine#Rewinder Machine#Thermal Transfer Overprinter#Industrial Thermal Transfer Printer#Inkjet Printing System#Doctor Slitter Rewinder#Batch coding machine#Unwinder Rewinder System#Printer Price#core cutter machine#Paper Slitter Machine#Rotogravure Printing#flexo printing machine#Motor Winding Machine#Winding Rewinding Machine#Winder Rewinder#Slitting Rewinding Machine

1 note

·

View note

Link

We are specialised manufacturer and supplier of Lidding High Performance Doctoring Rewinding Machines, high quality equipment Doctoring Slitter Machine. Doctoring Rewinding, Doctoring Rewinding Table Top, Table Top Doctoring Rewinding, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding With Slitter System, Doctoring Slitting Rewinding, Label Stock Doctoring Rewinding, Special Application For Doctoring Rewinding, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing. Winding Rewinding With Inkjet Printer, Winding Rewinding With Thermal Transfer Overprinted, Winding Rewinding With Multihead Inkjet Printer, Doctoring Film Strip Winding Rewinding, Winding Rewinding With Slitter System, Winding Rewinding Without Slitter System, Coil Winding, Winding Unwinding, Inspection Doctoring Slitting, Inspection Rewinding for Inkjet and Batch Printing, Doctoring Inspection, Doctoring Inspection with Slitter System, Doctor Re Reeling, Industrial Inkjet Printer, Industrial Inkjet Printer With Winder Rewinder, Industrial Thermal Transfer Printer.

#Doctoring Slitter Machine#Slitter Machine#Doctoring Rewinding Machines#Doctoring Rewinding#Rewinding Machines#Rewinder Machine#Slitting Machine#Winder Rewinder#Doctor Rewinding#Slitter System#Doctor Re Reeling#Industrial Inkjet Printer#slitter Rewinder manufacturers#foil slitting machine#aluminium foil slitting machine#aluminum slitting machine#paper slitting machine#slitting machine price#fabric slitting machine#paper roll slitting machine

0 notes

Link

KEW High Speed Manufacturer, exporter & supplier Of Winding Rewinding Machines, winding machine, winding machine price, automatic winding machine, winding equipment, winding machine manufacturer, winding machines, winder machine, winder machines, winding rewinding, winding rewinding Machine, winding rewindings. Winding Rewinding Machines Like, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing, Winding Rewinding With Inkjet Printer and with Multihead Inkjet Printer.

#Winding Rewinding Machines#Winding Rewinding Machine#winding machine#winding machine price#automatic winding machine#winding equipment#winding machine manufacturer#winding machines#winder machine#winder machines#winder machines Manufacturer#Inspection Rewinding Machine#Industrial Inkjet Machine#Doctoring Rewinding Machine#Industrial Thermal Transfer Printer Machine

0 notes

Link

Thermal Transfer Overprinted TTO with Winding Rewinding Machine, which allows printing high-density bar-codes and labels that require longevity, paper, film, and even foil substrates. Also, direct thermal printing is popular in applications such as mailing, small parcel delivery, retail and the food industries where most items are stored away from heat and sunlight. It allows heat activated labels and do not require a ribbon. Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner).Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation.It is great substitute to online coding / batching operation. Convenient height for operation. Compact Design. Variable speed drive, Double drive.

#Winding Rewinding Machine#Winding Rewinding#Winder Rewinder#Thermal Transfer Over printer#Inkjet Printing Machine#Web Aligner#Industrial Thermal Inkjet Printer#Winding Rewinder Machine#Web guiding System.

1 note

·

View note

Link

Krishna Engineering Works we have been manufacturing, exporting, and supplier of all types of Doctor Re Reeling Machine, Doctoring Rewinding Machine, Inspection Rewinding Manufacturer, Winding Rewinding Machine. We have designed and built for accuracy for doctoring use with air brake with reel diameter, Edge Guide with actuator for the Unwind reel, Air shafts for Doctoring Re Reeling Machine units. It is used to salvage badly rewound coils produced on the Slitting and Rewinding Machine.

#Doctoring Re Reeling Machine#Doctoring Slitting Machine#Winding Unwinding Machine#Unwinding & Rewinding Machine#Inspection Doctoring Rewinding Machine#Doctoring Rewinding Machine#Fabric Winding Machine#Inspection Rewinding#Automatic Reeling Machine Price#Textile Reeling Machine#Industrial Slitting#Winding Rewinding Machine#Film Winder Rewinder Machine#Doctoring Inspection Machine

5 notes

·

View notes