#Inspection Rewinding Machine

Explore tagged Tumblr posts

Text

The rewinding inspection machine is applied in inspecting materials such as paper, film, textiles, and foil for defects.

#machinery#industrial#manufacturer#exporter#textiles#supplier#krishnaengineeringworks#machinemanufacture#machine#industry#inspection rewinding machine

1 note

·

View note

Text

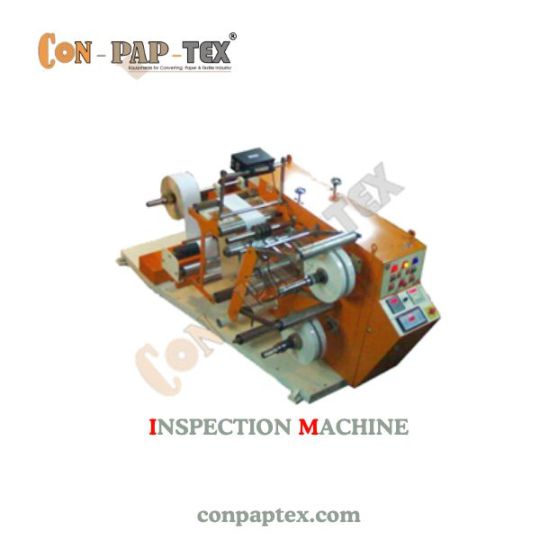

inspection machine

#conpaptex#machine#manufacture#industry#inspection machine#export#supplier#service#rewinder machine#inspection machine manufacture

1 note

·

View note

Text

Odds and Additions...

Pt 4

There was something different in the lab that morning. Not in the air, not quite. The hum of machines still droned like an endless conversation neither of you were willing to have. The windows were still fogged at the edges, smeared slightly from where your sleeve had wiped a circle days ago. The mugs were mismatched. The tension still unspoken.

But something had shifted. Slightly. Quietly. Barely.

Viktor entered first. Earlier than usual. You noticed only because the tools you typically organized were already set out, arranged with meticulous, almost surgical care. You didn’t thank him. He didn’t say anything. He just sat at his desk and began working, his movements slow, deliberate. Calculated. It was simple. An uneasy simple..

The silence settled in again. Familiar. Comfortless.

You tried to keep your eyes on your own schematics. You tried not to look when he pressed his fingertips hard into his ribs during a particularly long stretch of work, like something was grinding under the surface. You told yourself not to ask. It wasn’t your business. You weren’t here to care. You were here to win. You weren’t here to be soft.

But the question clung to your throat anyway.

Was he okay?

You didn’t ask it. Instead, you cleared your throat, let the noise puncture the silence like a crack in glass. “We need to finalize the framework if we’re going to meet the inspection deadline,” you said, voice crisp, professional. No emotion. No implication.

Viktor didn’t look up. “Then let’s work.”

And so you did. You always did. ═══ ⋆★⋆ ═══

Until the door opened.

Both your heads turned, almost in sync, as Dean Heimerdinger stepped into the lab—alone this time. No councilors trailing behind him in thick coats and pointed glances. Just him, in his worn professor’s robes, looking more tired than usual. More… disappointed, maybe.

“Good morning,” he said, scanning the room like it might reveal something it hadn’t already told him. You both nodded. Viktor stood slower than he used to, but straighter. More formal. The silence wrapped around the three of you like a second presence. The dean let it linger for a moment before speaking.

“I’ve looked over the council’s most recent notes. They seem… intrigued,” he said, and though the word was neutral, the twist of his mouth wasn’t.

Viktor’s chin lifted slightly. “I believe we’re making progress.”

The dean gave a small nod, but his gaze shifted—to you. And when he spoke again, his voice was quieter. Measured.

“But progress is only useful if it leads somewhere. I’m not here for spectacle. I’m here for substance.” He paused. “What I want… is something that helps people. That changes the way they live, not just how they look at it.”

You felt Viktor go still beside you.

“I understand the council has their interests,” the dean continued. “But I need someone who remembers why we started building things in the first place. Someone who doesn’t forget the difference between a prototype and a purpose.”

The words weren’t sharp, but they landed like a blade on the table. And though the dean didn’t say it, the implication hung between you and Viktor like a crackling wire: One of you still remembers. The other might’ve forgotten.

He gave a final look at the workbench—at the wires, the gears, the split blueprints—then turned toward the door.

“I’ll be back in a week,” he said. “I hope I’ll see something worth remembering.”

And then he left. The silence returned. But it wasn’t the same anymore. ═══ ⋆★⋆ ═══

Viktor didn’t move. Not right away. He stared at the door for a few seconds too long, as if he could will the dean back inside, or maybe just rewind the conversation.

You shifted in your seat, the creak of your chair loud in the new quiet.

“He’s not wrong,” you said, not looking at him.

Viktor’s eyes flicked toward you, sharp and unreadable.

“I mean,” you added quickly, “about helping people.”

His fingers twitched against the edge of the table. “Is that what you think I’ve forgotten?”

You hesitated. The question wasn’t loud, but it wasn’t soft either. It was a scalpel—precise, pointed.

“I think,” you said carefully, “you’re trying to win a game that doesn’t care if you lose yourself in the process.”

He scoffed under his breath. “And you think doing nothing is nobler?”

“I think doing the right thing is harder,” you snapped before you could stop yourself. “But it’s what matters.”

The words landed heavy. A breath passed. Then another.

Viktor turned away again, his voice low. “Hard doesn’t always mean possible.”

You didn’t answer. You didn’t want to answer, because deep down, you knew that was the part that scared you most. The silence returned once more—this time with weight, with heat, with something shifting beneath the surface. Neither of you looked at each other. Neither of you moved to bridge the distance.

But for the first time in days, it felt like the rift had a shape.

And it was growing. ═══ ⋆★⋆ ═══

pt 5 Slow burn so slow they dont even have firewood yet 😞😞

#i need him#arcane#viktor x reader#rivals to lovers#need that#viktor arcane#viktor x you#slow burn#slow as hell bruh#need this to burn already#it doesn't matter that im the writer#burn baby burn#NEOWWWWWWWWW

23 notes

·

View notes

Text

I hate Hamilton

Okay, buckle up, buttercups, because it’s time for a little history lesson, or rather, a history dissertation, as told by yours truly, Thomas Jefferson. And before you start with the powdered wigs and the “founding father” fanfare, let me be clear: I’m not here to wax poetic about the glories of the American experiment. Oh no. I’m here to talk about him. You know, the guy with the incessant rapping and the ridiculous hair, the man who’s somehow become the darling of the musical theater set. Yes, I’m talking about Alexander Hamilton, or as I like to call him, the “Hurricane of Hype.”

Now, let’s rewind a bit, shall we? Picture this: I, Thomas Jefferson, fresh from the intellectual salons of Paris, arrive back in this fledgling nation, ready to bring a dash of continental sophistication to the rustic proceedings. And what do I find? A frenzy of activity orchestrated by…you guessed it, the infamous Hamilton. Seriously, this man was like a caffeinated squirrel trapped in a printing press. He was everywhere, pushing his papers, scribbling his plans, and frankly, making everyone else look like they were moving in slow motion.

My introduction to the man was, shall we say, memorable. He greeted me with all the warmth of a tax collector inspecting a shipment of contraband tea. He was all sharp angles, rapid-fire questions, and that infernal, slightly-too-knowing grin that suggested he’d already calculated ten steps ahead of everyone else in the room. He looked like a particularly energetic ferret, and I, a lover of fine wine and repose, found him deeply unsettling.

The early days were…well, they were a chaotic mess. Hamilton, fueled by some kind of internal combustion engine, was determined to build his financial empire. He wanted a national bank, a federal debt, and seemingly, the personal adoration of every citizen. I, meanwhile, was trying to explain to him, in my most patient and eloquent manner, that a nation should not be run like a particularly aggressive game of Monopoly. I argued that states' rights were paramount, that the people should have a say in their own destiny, and that maybe, just maybe, we didn't need a central authority to dictate every last detail of our lives.

Of course, Hamilton brushed aside my reasonable, nuanced arguments like a toddler swatting at a butterfly. He’d talk over me, interrupting with his rapid-fire pronouncements, and always, always, with that smug little smirk. It was maddening. Truly, the man could turn a simple disagreement about the optimal placement of a comma into a full-blown constitutional crisis. He had the energy of a hummingbird after a triple espresso, and his capacity for self-promotion was truly breathtaking. It's as if he had a personal public relations firm dedicated to singing his praises 24/7.

And don't even get me started on the whole "assumption of debts" debacle. I mean, who did he think he was, some kind of financial magician, waving his wand and making debts disappear? My fellow Virginians and I were not exactly thrilled about bailing out the northern states for their… ahem…fiscal indiscretions. It felt like we were being strong-armed into a bad deal by a very persistent, very ambitious, and frankly, very annoying little man.

The constant battles over policy were exhausting. He insisted on these elaborate financial structures, while I envisioned a nation of independent farmers and intellectuals, pursuing their own path with minimal interference from the government. It felt like we were living in parallel universes, where I was trying to build a serene and contemplative garden, and he was constantly trying to build a skyscraper in the middle of it, complete with a brass band and a smoke machine.

And while I was busy crafting the Declaration of Independence, and dabbling in advanced agricultural techniques, and oh, managing my plantation, thank you very much, Hamilton was out there consolidating power and writing endless memos. He was the ultimate bureaucrat, the king of paperwork, the sultan of spreadsheets. I sometimes suspected he had a secret stash of ink and quills under his pillow. I, however, preferred to spend my evenings reading, not calculating the optimal rate of return on treasury bonds.

Later, when I became President (a position, I might add, that I earned through the sheer brilliance of my ideas and not through relentless personal promotion), I was constantly cleaning up his messes. His financial system was this elaborate contraption that, frankly, resembled a Rube Goldberg machine more than a well-oiled economic engine. I had to make sure that the whole thing didn't collapse because of his overzealous meddling. It was like trying to dismantle a bomb while simultaneously explaining the finer points of Monticello's architecture to an audience of toddlers.

Let’s be honest, the musical has painted him as some kind of tragic hero, a misunderstood genius cut down in his prime. I can hear the violins swelling already. Don’t fall for the melodrama, folks! The truth is, Hamilton was a relentless, ambitious, and ultimately, incredibly irritating man. He was brilliant, yes, but his brilliance was often wrapped up in a package of self-importance and a tendency to dominate every room he entered.

And his constant need to be in the spotlight? Please. The man was a walking, talking headline. He couldn't just have an idea; he had to have a spectacular idea, one that would be lauded by the masses and etched into the history books (preferably in large, bold font). I, on the other hand, preferred to let my actions speak for themselves, to let the quality of my work shine without the need for constant fanfare and dramatic musical numbers.

So, yes, I hate Alexander Hamilton - not in a “villainous mustache-twirling” sort of way, but in the deeply exasperated, intellectually superior kind of way. He was a constant source of frustration, a perpetual thorn in my side, a human-sized exclamation point in my carefully crafted sentence of a life. And while the world may sing his praises, I, Thomas Jefferson, will continue to stand here, shaking my powdered wig in utter disbelief at the sheer audacity of the man. Now, if you'll excuse me, I have a glass of wine and a good book to attend to. Unlike some people, I actually know how to relax. And, maybe, just maybe, I will take some time to rewrite my letters to exclude his incessant name. After all, that’s the true way to ensure he’s remembered as he really was: an irritating footnote in history.

6 notes

·

View notes

Text

Automatic Thread Recutting Machine

Automatic Thread Recutting Machine

Automatic Thread Rewinding Machine

Automatic Tapping and Retracting Machine

Automatic Reverse Tapping Machine

Automatic Thread Repair Machine

https://www.paycnc.com/servo-thread-inspection-machine-sf001_p21565.html

#thread #automatic

1 note

·

View note

Text

Rotogravure Printing Machine - Kosbridge

Buy Directly from SELLER -

Independent Rotary type Unwinder and Rewinder

Doctor Blade Pneumatic Type Design

Shaft-less Printing Cylinder loading Design

With 7 Motor Drive Tensional Control System

Auto Ink Recycle System

Computer Auto Color Register System

Web Video Inspection System

Water Chilling System

Optional: Reverse Printing Turn Bar

#print #PrintingMachine #machinedalal

0 notes

Text

Why Is Electric Motor Rewinding Important for Industrial Applications?

Electric motors are essential components in almost every industrial operation. From powering conveyor belts to running pumps and fans, these motors play a critical role in keeping operations running smoothly. However, like any machine, electric motors are subject to wear and tear over time, which can lead to decreased performance or even complete failure. One way to extend the life of an electric motor and ensure it continues to work efficiently is through a process known as motor rewinding. This blog will explore why electric motor rewinding is so important for industrial applications.

What Is Electric Motor Rewinding?

Electric motor rewinding is the process of removing the old windings (the coils of wire inside the motor that carry electrical current) and replacing them with new ones. This helps restore the motor’s performance to like-new condition. It is commonly done when a motor’s windings become damaged, worn, or overheated. The rewinding process can involve cleaning, inspecting, and repairing the motor’s components, ensuring everything is in proper working order.

Reasons for Electric Motor Rewinding

Rewinding an electric motor can bring many benefits, and it is an important part of maintaining industrial machinery. Here are the primary reasons why rewinding is essential:

1. Restores Motor Efficiency

Over time, electric motor windings can become damaged due to factors such as overheating, mechanical stress, or exposure to contaminants like dust and moisture. When the windings are compromised, the motor can lose its efficiency, leading to higher energy consumption and increased operating costs. Rewinding helps restore the motor to its original condition, improving its efficiency and reducing energy waste.

2. Extends Motor Life

Electric motors are a significant investment for industrial facilities. Instead of replacing a worn-out motor, rewinding can extend its life and delay the need for costly replacements. Proper rewinding and maintenance can keep the motor running for many additional years, making it a cost-effective solution.

3. Prevents Further Damage

When an electric motor experiences issues with its windings, it can cause other components to fail as well. For instance, a short-circuited winding can lead to overheating, which could damage the motor’s bearings or insulation. Rewinding addresses these problems before they escalate, helping prevent more expensive repairs or a complete motor failure.

4. Improves Motor Performance

Electric motor rewinding is an effective way to restore motor performance. Worn or damaged windings can lead to irregular operation, such as a decrease in speed or torque. Rewinding can bring the motor back to its optimal performance, ensuring it operates at the required speed and power output for its specific application.

5. Reduces Downtime

In industrial settings, downtime can be costly. If a motor fails, it can stop an entire production line or process. Rewinding helps ensure the motor continues to function efficiently, reducing the risk of unexpected breakdowns and the downtime that follows. A well-maintained motor is less likely to break down, leading to more reliable operations.

Key Benefits of Electric Motor Rewinding for Industrial Applications

The advantages of electric motor rewinding are significant for industrial applications. Here are some key benefits:

1. Cost-Effectiveness

Replacing an electric motor can be a significant expense. However, motor rewinding offers a more affordable alternative, especially when the motor is still in good physical condition. By investing in rewinding, businesses can save on the cost of buying a new motor while still getting the performance they need.

2. Energy Savings

Rewinding a motor can improve its efficiency, reducing the amount of energy it consumes. An inefficient motor can consume much more electricity than necessary, driving up operating costs. After rewinding, the motor’s energy usage will be reduced, resulting in long-term savings on electricity bills.

3. Environmental Benefits

By extending the life of an electric motor through rewinding, businesses can reduce waste and minimize the environmental impact associated with manufacturing and disposing of motors. Rewinding helps ensure that fewer motors need to be discarded and replaced, making it a more sustainable solution.

4. Better Performance and Reliability

Rewinding restores the motor to its full capacity, ensuring that it runs smoothly and consistently. Industrial operations rely on machinery that works without interruption, and rewinding helps keep motors in peak condition. This leads to greater reliability in production processes and improved overall productivity.

How Is Electric Motor Rewinding Done?

The rewinding process involves several steps, which are carried out by skilled technicians to ensure the motor is properly restored:

1. Disassembly and Inspection

The first step in rewinding is to disassemble the motor. This involves removing the motor’s outer casing, bearings, and other components. The windings are then inspected for damage. Any parts that are worn or damaged beyond repair are replaced.

2. Cleaning the Motor

Once the motor is disassembled, it is thoroughly cleaned to remove any dirt, debris, or dust that has accumulated over time. This helps ensure that there is no contamination that could interfere with the rewinding process.

3. Rewinding the Motor

The old windings are carefully removed, and new copper wire is wound into the motor’s stator and rotor. The technician ensures the new windings are properly insulated and positioned for optimal performance.

4. Testing the Motor

After the rewinding is complete, the motor is tested to ensure that it is functioning correctly. The technician will check for proper voltage, current, and resistance, as well as the motor’s ability to handle the required load.

5. Reassembly and Installation

Once the motor has passed all tests, it is reassembled and ready to be installed back into its industrial application.

When Should You Consider Electric Motor Rewinding?

It’s important to monitor your motors for signs of damage and wear to determine when rewinding may be necessary. Some common indicators that a motor might need rewinding include:

Decreased motor efficiency or performance

Excessive overheating

Unusual noises or vibrations

Frequent motor breakdowns or failures

If you notice any of these issues, it’s a good idea to consult a professional to assess whether rewinding could be a solution.

Conclusion

Electric motor rewinding is a vital process for ensuring the efficiency, performance, and longevity of motors used in industrial applications. By restoring damaged windings, this process can help prevent expensive replacements, reduce downtime, and improve overall motor performance. For industrial businesses, motor rewinding offers an affordable, sustainable, and effective solution to maintaining crucial equipment and keeping operations running smoothly.

0 notes

Text

Optimized Wire Management with Traverse Spool Rewind Machines

The Traverse Wire Spool Rewind Machine is an essential tool for industries that demand precision and efficiency in wire management. Its innovative design and user-friendly features make it an invaluable asset for businesses dealing with wire spooling and rewinding. Whether you're in manufacturing, electrical, or telecommunications, this machine ensures smooth operations and top-notch performance.

Why Precision Matters in Wire Management

Managing wire spools manually can lead to inaccuracies, wasted resources, and even safety risks. The Traverse Wire Spool Rewind Machine eliminates these challenges by providing automated solutions. Its advanced features allow businesses to handle spooling tasks with ease, reducing labor costs and enhancing productivity. By improving precision, this tool also minimizes material waste, translating into significant cost savings for businesses over time.

Key Features That Stand Out

Compact Design: The machine’s sleek and compact structure ensures it can fit into any workspace, no matter how small.

Versatility: Suitable for a wide range of wire types and sizes, making it adaptable for various industrial needs.

Precision Engineering: Its high-precision controls ensure accurate wire winding, preventing errors and material wastage.

Durability: Constructed with robust materials to withstand the demands of daily industrial use.

Ease of Operation: Intuitive controls make it accessible for operators of all skill levels.

Applications Across Industries

This Machine is widely used in industries such as:

Manufacturing: For assembling electronic components or preparing wire harnesses.

Telecommunications: To manage and organize wires for installations.

Electrical Engineering: For efficient cable spooling and handling.

Automotive: In wire preparation for vehicle assembly and maintenance.

Tips for Optimal Use

Regularly inspect the machine for wear and tear to ensure consistent performance.

Use appropriate settings based on wire type and size to maximize efficiency.

Clean the machine periodically to maintain its longevity.

Ensure operators are trained to utilize its features effectively for optimal results.

Why This Machine Is a Game-Changer

Investing in the Traverse Wire Spool Rewind Machine gives businesses a competitive edge. Its ability to handle tasks with precision and speed allows companies to take on more projects without compromising on quality. Moreover, its user-friendly design means minimal training time for employees, ensuring a quick return on investment.

Conclusion

For businesses looking to optimize their wire management processes, the Traverse Wire Spool Rewind Machine is a game-changer. Its efficiency, reliability, and user-friendly operation make it an indispensable tool for industries requiring precision and organization. This machine is an excellent addition to your range of industrial tool and supplies.

0 notes

Text

What to Expect from a Magnetic Chuck Repair Service: A Step-by-Step Process

Magnetic chucks are essential tools in machining and manufacturing environments, offering reliable workholding solutions for precision operations. However, like any industrial equipment, they are subject to wear and tear, requiring professional repairs to maintain performance and accuracy. Understanding the repair process can help you make informed decisions and ensure your equipment gets the care it deserves. Here’s a step-by-step look at what to expect from a magnetic chuck repair service:

Initial Assessment and Inspection

The repair process begins with a thorough inspection of the magnetic chuck. Technicians examine the chuck for visible damage, such as cracks, wear, or misalignments, and test its functionality. For electromagnetic chucks, this includes checking the electrical components, such as coils, connections, and control units. A detailed diagnostic report is prepared, outlining the issues and potential solutions.

Customer Consultation and Quotation

After the initial assessment, the repair service provider will discuss the findings with you. They’ll explain the nature of the problems, the necessary repairs, and the expected outcomes. At this stage, you’ll receive a detailed quotation that includes the cost of labor, replacement parts, and any additional services required. This step ensures transparency and allows you to make an informed decision.

Disassembly and Cleaning

Once approved, the technicians will disassemble the magnetic chuck to access internal components. This step is critical for identifying hidden issues that may not have been apparent during the initial inspection. The chuck is thoroughly cleaned to remove any dirt, debris, or old lubricant that could affect its performance. Clean components are easier to repair and ensure optimal reassembly.

Component Repair and Replacement

Damaged components are repaired or replaced as needed. For permanent magnetic chucks, technicians may re-magnetize the unit if its magnetic strength has weakened. For electromagnetic chucks, repairs may involve rewinding coils, replacing damaged wiring, or fixing control units. High-quality replacement parts are used to ensure durability and reliability.

Reassembly and Calibration

After repairs are completed, the chuck is carefully reassembled. Precision is crucial during this step to ensure that all components align correctly. The technicians then calibrate the chuck to restore its original performance standards. This includes verifying magnetic strength, flatness, and holding force to ensure the chuck functions as intended.

Testing and Quality Assurance

Before the chuck is returned to the customer, it undergoes rigorous testing to confirm that all repairs were successful. Technicians simulate real-world operating conditions to ensure the chuck performs reliably under load. Any adjustments needed are made at this stage to guarantee optimal functionality.

Final Inspection and Documentation

A final inspection is conducted to check for any remaining issues. The service provider documents the entire repair process, including the repairs performed, parts replaced, and testing results. This documentation is provided to you as a record for future reference.

Customer Support and Maintenance Advice

Reputable repair services often include post-repair support. Technicians may offer guidance on routine maintenance to prevent future issues, such as cleaning techniques and proper usage practices. This step ensures you get the most out of your repaired magnetic chuck.

Conclusion

Investing in professional magnetic chuck repair services not only restores your equipment’s performance but also extends its lifespan, saving you time and money in the long run. By understanding the step-by-step repair process, you can approach the service with confidence and ensure your magnetic chuck is in capable hands.

0 notes

Text

0 notes

Text

CONPAPTEX EQUIPMENTS delights in high-performance solutions at par with the world of modern manufacturing pace.

#conpaptex#machine#manufacturing#exporter#supplier#industrial#slitterrewinder#rewindermachine#machinery#highperformance

1 note

·

View note

Text

Professional Fabric Inspection machine Presentation :

Fabric inspection machines are used to inspect fabric materials in order to find manufacturing defects(weave), mechanical defects (holes) and dirty spots. For convenience of operator inspection machines have an illuminated panel, under the material. This machines rewinds and measures fabric in order to verify declared by the manufacturer length of roll oraz precisely mark distances between defects on the inspected roll of fabric. Yet another very important feature of the inspection machine is to ensure even tension of rewinded fabric. This is a very important condition for spreading and cutting operations in future. Fabric inspection machines are used by manufacturers, where high quality of manufactured products forces additional quality check before materials are sent for spreading and cutting.

0 notes

Text

8 common machine embroidery problems

Taming the Thread: Conquering 8 Common Machine Embroidery Problems

Machine embroidery allows you to create stunning designs on fabric, but even the most seasoned stitchers encounter occasional roadblocks. Don't let these problems prevent you from achieving beautiful embroidered finishes! This guide explores eight frequent machine embroidery issues and provides solutions to get your projects stitching smoothly again. 1. Thread Terror: Breakage Blues Upper Thread Snapping: This can be caused by several factors. Ensure proper threading, checking for snags on the thread path or a rough needle eye. Adjust the upper thread tension – too tight can cause snapping. Consider using a higher quality thread designed for embroidery. Bobbin Thread Breaking: An improperly wound bobbin or a bobbin case with rough edges can snag the thread. Rewind the bobbin with even tension and inspect the bobbin case for damage. Ensure the bobbin is inserted correctly and the tension is balanced with the upper thread. 2. The Not-So-Smooth Stitch: Uneven or skipped stitches are frustrating. Check the needle for burrs or bends and replace it if necessary. Ensure the correct needle size and type for your fabric and thread weight. Verify proper threading and tension settings. Sometimes, cleaning the machine's feed dogs and tension discs can resolve stitching issues. Consult your machine's manual for specific cleaning instructions. 3. The Dreaded Bird's Nest: This tangled mess of thread beneath the fabric occurs when the upper and bobbin threads don't catch cleanly. Re-thread both threads, ensuring they lay flat in the tension discs. Check for loose bobbin casing components or a worn-out tension spring. Using a water-soluble stabilizer can help prevent birds' nests in some fabrics. 4. Puckering Up: Puckered fabric around the embroidery is unsightly. The culprit is often improper hooping. Use a stabilizer that matches the weight of your fabric, and hoop it taut but not drum-tight. For knits or lightweight fabrics, use a floating technique where the fabric lays on top of a layer of stabilizer within the hoop. 5. Thread Shredding: A blunt or incorrect needle size can shred delicate threads. Choose a sharp needle appropriate for your fabric and thread weight. For thicker threads or dense stitch patterns, consider a larger needle. Using a higher quality thread designed for embroidery can also improve durability. 6. The Wandering Design: Stitches that veer off course can be caused by loose fabric in the hoop. Re-hoop your project with proper tension. Additionally, a stabilizer that's too weak or the wrong type for your fabric might not provide enough support, leading to shifting. 7. The Unruly Machine: Unusual noises or slow stitching can indicate an underlying issue. Consult your machine's manual for routine maintenance procedures like cleaning and oiling. Ensure the bobbin is properly seated and the needle is securely tightened. If these steps don't resolve the problem, consider seeking professional servicing for your machine. 8. Design Dilemmas: Improperly digitized embroidery files can lead to stitching problems. If you suspect the design is the culprit, try contacting the digitizer for assistance. There are also software programs available that can help you edit and troubleshoot embroidery files. Bonus Tips: Invest in quality supplies: Using good quality needles, thread, and stabilizer will significantly reduce embroidery problems. Practice on scrap fabric: Before starting your final project, experiment with different settings and stabilizer combinations on a scrap of fabric that matches your project materials. Consult your machine's manual: It's a valuable resource for troubleshooting and proper maintenance procedures. Join online communities: Online forums and embroidery groups are a wealth of information and support. Conclusion: Machine embroidery can be a rewarding hobby, and with a little troubleshooting know-how, you can overcome common challenges and achieve beautiful results. Don't be discouraged by occasional glitches – consider them opportunities to learn and refine your skills. With practice and the knowledge to address these eight frequent problems, you'll be stitching stunning embroidery designs in no time! Read the full article

0 notes

Text

Narrow Web Slitting Rewinding Machine – Precision & Efficiency by KEW ENGG. & MFG. PVT. LTD.

KEW ENGG. & MFG. PVT. LTD. has designed and developed a cutting-edge Narrow Web Slitting Rewinding Machine, engineered for slitting, salvage winding, and de-lamination of rolls. With precision engineering and superior technology, this machine guarantees accurate inspection and high-performance web slitting.

#kewengg#machinemanufacture#exporter#supply#services#industry#narrowwebslittingrewindingmahcine#slittingrewindingmachine#windingrewindingmachine#printingindustry#flexiblepackaging

1 note

·

View note

Text

An Overview of Stretch Film Manufacturing Machines: Types and Functions

Stretch Film Manufacturing Machines are specialized pieces of equipment used to produce stretch film, which is commonly used for packaging and securing products during transportation and storage. These machines play a crucial role in ensuring the durability, elasticity, and quality of the stretch film. Here's an overview of the types of stretch film manufacturing machines and their functions:

1. Blown Film Extrusion Machines:

Description: These machines use the blown film extrusion process to produce stretch film. The process involves melting polymer granules and extruding them through an annular slit die, followed by blowing to expand the film into a tube and cooling it to form the film.

Function: Blown film extrusion machines provide films with higher puncture resistance and more strength compared to other types. They allow for better control over film thickness and quality.

2. Cast Film Extrusion Machines:

Description: In contrast to blown film machines, cast film extrusion machines use a flat die to extrude the molten polymer. The extruded film is then cooled on chilled rollers.

Function: These machines produce films that are clearer and have better cling properties than blown films. Cast film machines generally have higher production rates and produce films with more consistent thickness.

3. Co-extrusion Film Machines:

Description: Co-extrusion machines combine multiple layers of material into a single stretch film product. These machines can have two or more extruders to process different types of polymers or the same polymer with different properties.

Function: The primary function is to produce multilayer stretch films, where each layer can impart different characteristics such as strength, cling, puncture resistance, or barrier properties.

4. Pre-stretch Film Machines:

Description: These machines are designed to stretch the film mechanically before it is wound onto rolls. The pre-stretching process improves the film's yield and can significantly reduce material costs.

Function: They elongate the film by using rollers rotating at different speeds. The resulting film is thinner but has increased strength and is more economical due to reduced material usage.

5. Rewinding Machines:

Description: After the film is extruded and wound onto large rolls, rewinding machines are used to convert these large rolls into smaller, more manageable rolls for commercial distribution.

Function: These machines rewind the film from the larger rolls to smaller ones, often adding a secondary layer of packaging. They can also be used to inspect the film for defects and ensure quality control.

6. Recycling Machines:

Description: In an effort to promote sustainability, some stretch film manufacturing setups include recycling machines that process production waste or used stretch film.

Function: These machines clean, melt, and pelletize the waste film, turning it back into a usable form for manufacturing, thus reducing waste and promoting circular economy practices.

Choosing the Right Machine:

The choice of machine depends on the desired film properties, production volume, and specific application requirements. For example, high-clarity film requirements might favor cast film machines, while high-strength films might be better produced with blown film machines.

By understanding the different types of Stretch Film Manufacturing Machines and their functions, manufacturers can select the most appropriate equipment to meet their production needs and produce high-quality stretch film for various packaging applications.

0 notes

Video

youtube

Rewinding and inspection platform for extrusion laminating machine

0 notes